Page 1

IQ RADAR 160

Instruction Manual PL-550

January 2001

33455500

Rev. 3.1

Page 2

Safety Guideline s

Warning notices must be obser v ed to ensure personal safety as w ell as that of others, and to

protect the product and the connected equipment. These warning notices are accompanied

by a clarification of the level of caution to be observed .

Qualified Personnel

This device/system may only be set up and operated in conjunction with this manual.

Qualified personn el ar e only authorized to install and operate this equipment in accordance

with established safety practices and standards.

Warning: This product can only function properly and safely if it is correctly transported,

stored, installed, set up , operated, and maintained.

Note: Always use p r od uct in accordance with specifications.

Copyright Siemens Milltronics Process

Disclaimer of Liability

Instruments Inc. 2000. All Rights Reserved

This document is available in bound version and in

electronic version. We encourage users to

purchase authorized bound manuals, or to view

electronic versions as designed and authored by

Siemens Milltronics Process Instruments Inc.

Siemens Milltronics Process Instruments Inc. will

not be responsible for t he contents of partial or

whole reproductions of eit her bound or electronic

versions.

MILLTRONICS®is a registered trademark of Siemens Milltronics Process Instrume nt s Inc.

Contact SMPI Technical Publications at the following address:

Technical Publicat ions

Siemens Milltronics Process Instruments Inc.

1954 Technology Drive, P.O. Box 4225

Peterborough, Ontari o, Canada, K9J 7B1

Email: techpubs@millt ronics.com

While we have verified the contents of

this manual for agreement w it h t h e

instrumentation described, variations

remain possible. Thus we cannot

guarantee full agreement. The

contents of this manual are regularly

reviewed and corrections are included

in subsequent editions. We w elcome

all suggestions for improvement.

Technical data subject to change.

For the library of SMPI instr uction manuals, visit our Web site: www.milltronics.com

© Siemens Milltronics Process Instruments Inc. 2001

Page 3

Table of Contents

General Information .........................................................................................5

About this Manual......................................................................................5

About IQ Radar 160/160 Ex......................................................................6

Specifications ................................................................................................... 7

IQ Radar 160/160 Ex................................................................................7

Installation.......................................................................................................11

Location ...................................................................................................11

Dimensions: Standard Unit with Rod Antenna.......................................12

Dimensions: Ex Unit with Rod Antenna.................................................13

Dimensions: Threaded Rod....................................................................14

Dimensions: Horn....................................................................................15

Dimensions: W aveguide Extension........................................................16

Dimensions: Sanitary Horn.....................................................................17

Dimensions: Sanitary Rod ......................................................................18

Dimensions: W aveguide.........................................................................19

Dimensions: Flanges ..............................................................................20

Mounting..................................................................................................21

Rod Asse m bly.........................................................................................23

Mounting: Rod Assembl y........................................................................24

Mounting: M anhole Covers.....................................................................25

Mounting: Horn Antennas.......................................................................25

Mounting: W aveguide Antenna..............................................................26

Mounting: Still pipe or Side pipe.............................................................27

Mounting: Horn with Waveguide Extensions.........................................28

Mounting: Sanitary Mounting..................................................................28

Mounting: Location/Beam Angle............................................................29

Interconnection ........................................................................................30

Start Up ............................................................................................................33

Overview..................................................................................................33

Display.....................................................................................................35

Aiming the Hand Programmer ................................................................35

Local Operation.......................................................................................36

Operation ........................................................................................................41

Overview..................................................................................................41

Transceiver..............................................................................................41

Los s of Echo............................................................................................42

Blanking...................................................................................................42

Analog Ou tput..........................................................................................43

Run / Pro gram .........................................................................................45

Application Example: Asphalt in Storage Tank......................................46

Application Exam p le: Horizo ntal Tan k with V olume..............................4 7

PL-550 IQ Radar 160/160 Ex Page 3

Page 4

Application Example: Juice Batch Tank with Sanitary Horn Antenna ..48

Application Example: Sliding Waveguide on Anaerobic Digesters.......49

Application Example: Stand Pipe .........................................................50

Parameter Descriptions..............................................................................53

Troubleshooting ......................................................................................... 63

Maintenance ...............................................................................................64

Appendix I....................................................................................................65

Alphabetical Parameter List .................................................................65

Appendix II...................................................................................................67

Appendix III..................................................................................................69

Temperature Derating ..........................................................................69

Rod Antenna ANSI Hole Pattern, 150# ................................................70

Rod Antenna DN Hole Pattern, PN16 ..................................................70

Rod Antenna Threaded Connection.....................................................71

Rod Antenna Sanitary Connection....................................................... 71

Horn Antenna or Wave Guide Still Pipe – ANSI Hole Pattern, 150#....72

Horn Antenna or Wave Guide Still Pipe DN Hole Pattern, PN16 .........72

Horn Antenna Sanitary Connection......................................................73

Appendix IV .................................................................................................75

BZT Approval – English........................................................................75

BZT Approval – German Original Text................................................. 76

Index.............................................................................................................77

Page 4 IQ Radar 160/160 Ex PL-550

Page 5

General Information

About this Manual

Refer to this manual for proper installation and operation of your IQ Radar

160/160 Ex.

General Information

Installation

Start-up

Operation

Applications

Parameters

Troubleshooting

gives you step-by-step direction for the installation and

interconnection of your IQ Radar 160/160 Ex.

instructs you in how to operate the keypad, program the

unit and read the display.

describes the operation of the IQ Radar 160/160 Ex.

looks at the IQ Radar 160/160 Ex from a practical point of

view, using a typical application example.

lists the parameters available to you, with a description of

their function and use. You are urged to read this section

to familiarize yourself with the parameters available to you

and get your IQ Radar 160/160 Ex working to its fullest.

tabulates symptoms, causes and actions to common

installation and application problems that you might

encounter. Hopefully you will never have to read this

section, but know it’s there to help you.

Appendices

An alphabetical cross-reference of the parameters and

their numbers, a record sheet for jotting down parameter

values, a Temperature Derating Chart, as well as a list of

approvals and certificates.

PL-550 IQ Radar 160/160 Ex Page 5

Page 6

About IQ Radar 160/160 Ex

The IQ Radar 160/160 Ex is to be used only in the manner outlined in this

manual.

IQ Radar 160/160 Ex is a versatile process material level monitoring

instrument. Material level measurement is achieved using advanced pulse

General Information

radar techniques. The unit consists of an electronic component coupled to the

antenna and process connection.

IQ Radar 160/160 Ex Features:

{

ANSI, DIN flange or sanitary tri-clamp mounting

{

corrosion-resistant construction, epoxy coated aluminium enclosure with

stainless steel flange and Teflon

{

local display

{

infrared keypad

{

Dolphin-compatible

IQ Radar 160/160 Ex Applications:

1

®

antenna and process seal.

{

liquids, slurries

process temperatures up to 200°C

{

vacuum and pressurized vessels

{

IQ Radar 160/160 Ex Approvals and Certificates

safety and radio

{

hazardous area

{

Note:

See Specifications on page 7 for an approvals listing and Appendix IV on

page 75 for approvals documentation.

1

Teflon is a registered trademark of Du Pont

Page 6 IQ Radar 160/160 Ex PL-550

Page 7

Specifications

Every attempt has been made to ensure the accuracy of these specifications,

however Milltronics reserves the right to change them at any time. Contact

your Milltronics representative for the most recent specifications.

IQ Radar 160/160 Ex

Power:

AC version:

{

DC version:

{

Fuse:

AC version:

{

DC version:

{

Interface:

analog output:

{

Dolphin/RS-485 link:

{

programmer link:

{

display (local):

{

Performance:

frequency:

{

accuracy at 20° C:

{

temperature drift:

{

measuring range:

{

repeatability:

{

fail-safe:

{

100/115/200/230 ±15% V ac2, 50/60 Hz, 15 VA

{

18 – 36 V dc, 15W

{

FU1, 2AG type, slow blow, .25 Amp, 250V

{

F1, 2AG type, slow blow, 0.375A, 250V

{

optically-isolated 0/4-20 mA into 750 Ω max, 0.02

{

mA resolution

refer to Dolphin Plus product specification

{

infrared receiver (refer to Programmer

{

specification on page 9)

backlit, alphanumeric and multi-graphic liquid

{

crystal for readout and entry

5.8 GHz (U.S.A. 6.3 GHz)

{

better than ±0.3% of range from 1 to 15 m

{

<±0.5% of range from –40 to 60° C (-40 to 392°F)

{

0.4 to 15 m

{

± 10 mm

{

mA programmable high, low or hold upon LOE

{

condition

Specifications

Mechanical:

Process Connections: Refer to Appendix III for pressure / temperature

flat faced flanges:

{

threaded connection:{316 stainless steel, 1-1/2” or 2”, NPT, BSP,G

{

sanitary connection:

{

2

Factory set – see device nameplate

PL-550 IQ Radar 160/160 Ex Page 7

limitations.

316 stainless steel, 2”, 3”, 4”, 50mm, 80mm,

{

100mm. Bolt hole pattern to ANSI & DIN types.

316 stainless steel, 2”, 3”, or 4” tri-clamp

{

Page 8

Antennas:

dielectric rod:

{

Teflon®3 (PTFE)

{

Ultra high molecular weight Polyethylene

{

(UHMW-PE

Length 41cm (16.3”) including integral gasket

{

4

)

horn:

{

waveguide:

{

Sanitary Antennas (FDA approved materials):

dielectric rod:

{

Specifications

horn:

{

Enclosure (electronic):

construction:

{

conduit:

{

ingress protection:

{

316 stainless steel

{

nominal diameters 100mm (4”), 150mm (6”),

{

200mm (8”)

emitter cone PTFE or UHMW-PE

{

waveguide extensions optional

{

316 stainless steel

{

emitter cone PTFE or UHMW-PE

{

one piece UHMW-PE4, optional PTFE

{

2”, 3”, 4” tri-clamp connection

{

304 stainless steel (316 special order)

{

horn with integral 4” tri-clamp connection

{

PTFE emitter

{

aluminium, epoxy coated

{

2 x 1/2" NPT or PG 16 entry

{

Type 6 / NEMA 6, IP-67

{

4

4

Weight:

6.5 kg (14.3 lb) with 2"/150 psi flange

{

weight will vary with flange size and rating

Environmental:

location:

{

altitude:

{

ambient temperature:{-40 to 60° C (-40 to 140° F)

{

relative humidity:

{

indoor/outdoor

{

2000 m max

{

suitable for outdoor

{

5

(Type 6/NEMA 6/IP 67 enclosure)

installation category:

{

pollution degree:

{

3

Teflon is a registered trademark of Du Pont

4

Not available for CENELEC EEx approval

5

See Temperature Derating on page 69 and Approvals on page 9.

II for ac version; I for dc version

{

4

{

Page 8 IQ Radar 160/160 Ex PL-550

Page 9

Process:

material dielectric:

{

εr > 1.8

{

(For εr < 3, you should use a wave guide antenna or

still pipe. See Mounting: Waveguide Antenna on page

26 or Mounting: Still pipe or Side pipe on page 27.)

temperature:

{

pressure (vessel):

{

UHMW-PE -40 to 80°C (-40 to 176°F)

{

PTFE -40 to 200°C (-40 to 392°F)

{

dependant on process connection type and

{

temperature. Refer to Appendix III on page 69 for

charts.

Approvals (refer to device nameplate):

safety:

{

radio:

{

hazardous areas:

{

IQ Radar 160:

{

(standard) and G, Class III.

IQ Radar 160Ex6:

{

CSA

{

BAPT, Industry Canada, FCC

{

CSA Class I/II, Div.2, Group A, B, C, D, F

{

CE, CSA

{

Cenelec/Sira7, EEx de IIB+H2 T6 (Note: antenna

{

NRTL/C

, CE, FM

NRTL/C

may be used in Zone 0 environments).

FM (USA) Class I, Div 1, Group A, B, C, D. Class

{

II/III, Div. 1, Group E, F, G (Class I, Zone 1 IIC

T6)

CSA Class I/II, Div. 1, Group B, C, D, E, F, G.

{

CE, CSA

{

NRTL/C

5

Specifications

FM (non-hazardous)

FM (non-hazardous)

Canadian Registration Number (CRN) for pressure fittings8:

{

Ontario, British Columbia, Alberta: OF6494.512

others pending

3A Sanitary

{

Contact Milltronics for complete and up to date list of approvals.

Programmer (remote keypad):

enclosure:

{

ambient temperature:{-20 to 50° C (-5 to 122° F)

{

interface:

{

power:

{

weight:

{

6

Cenelec: -20 to 40°C (-4 to 104°F), CSA and FM: -20 to 60°C (-4 to 140°F) ambient

7

Approved for PTFE material only

8

All process connections except for the sliding waveguide

general purpose

{

67 mm w x 100 mm h x 25 mm d

(2.6" w x 4" h x 1" d)

proprietary infrared pulse signal

{

9V battery (ANSI/NEDA 1604, PP3 or equivalent)

{

150g (0.3 lb)

{

PL-550 IQ Radar 160/160 Ex Page 9

Page 10

Specifications

Page 10 IQ Radar 160/160 Ex PL-550

Page 11

Installation

Location

Notes:

• Installation shall only be performed by qualified personnel and in

accordance with local governing regulations.

• This product is susceptible to electrostatic shock. Follow proper

grounding procedures.

• Do not mount in direct sunlight without the use of a sun shield.

Warning:

For vessels with conical or parabolic tops, it is not advisable to

mount the unit at the centre. Otherwise, the concavity of the top can

focus echoes into the centre, giving false readings.

Conical

Parabolic

Installation

Flat

PL-550 IQ Radar 160/160 Ex Page 11

Page 12

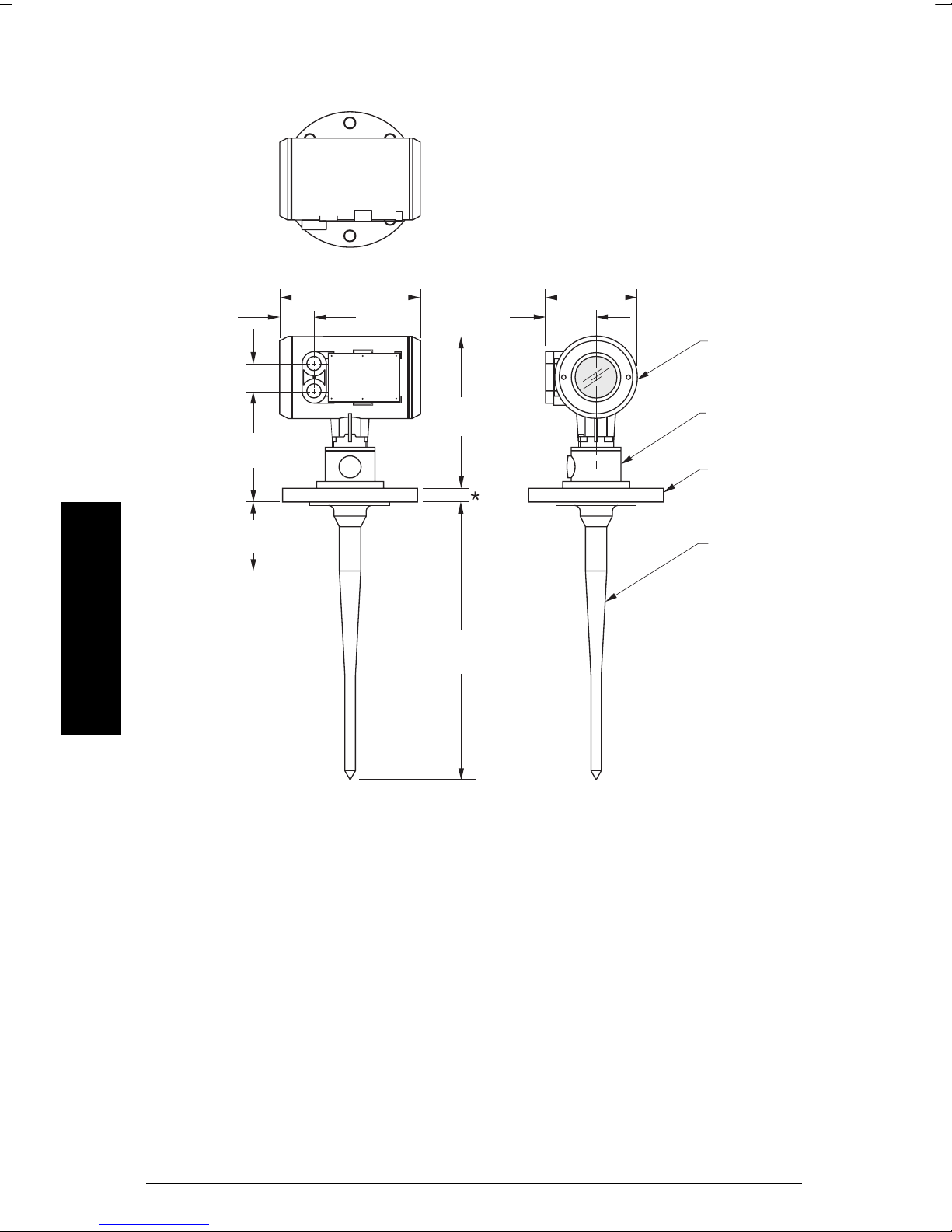

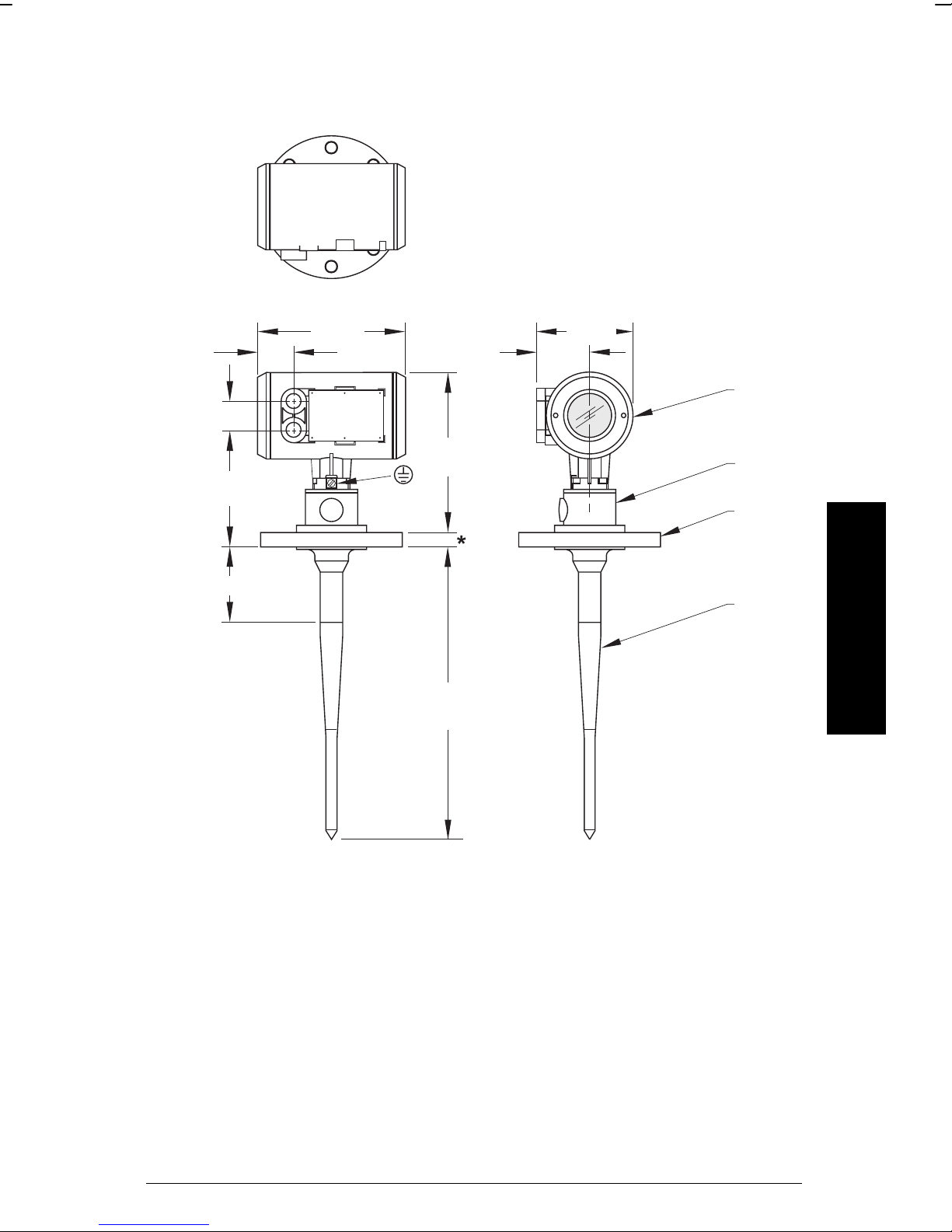

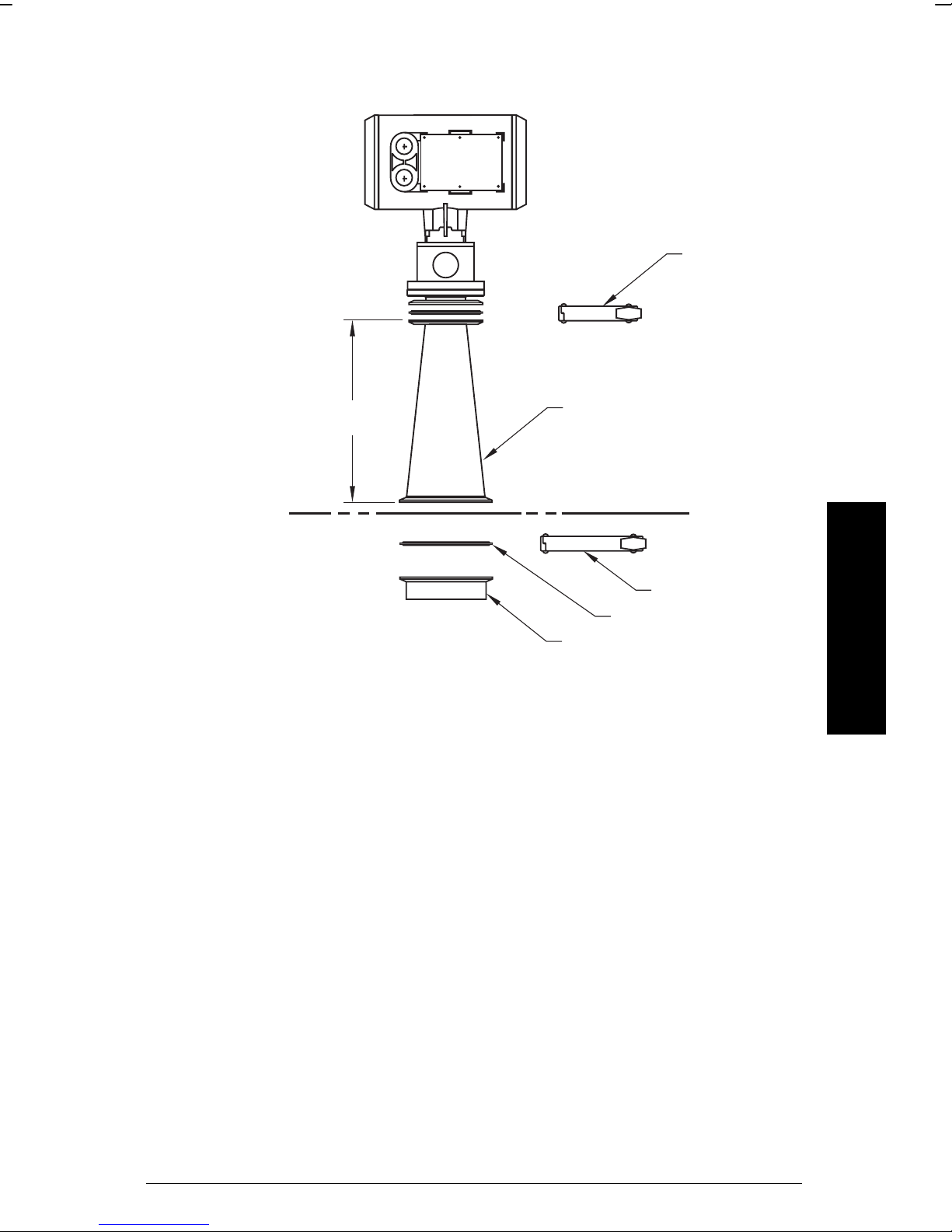

Dimensions: Standard Unit with Rod Antenna

(

)

(

)

(

)

*

Installation

50 mm

2.0"

41 mm(1.6")

183 mm

(7.2")

100 mm

(4.0")

211 mm

8.3"

245 mm

(9.6")

412 mm

(16.3")

136 mm

5.4"

75 mm

(3.0")

enclosure/

electronics

antenna

(resonator)

flange

antenna

(rod)

*

* Flange thickness 25 mm (1") nominal.

** Standard length, 50 and 100 mm (2” and 4") extensions available.

For information on temperature and pressure ratings, see Appendix III on

page 69.

Page 12 IQ Radar 160/160 Ex PL-550

Page 13

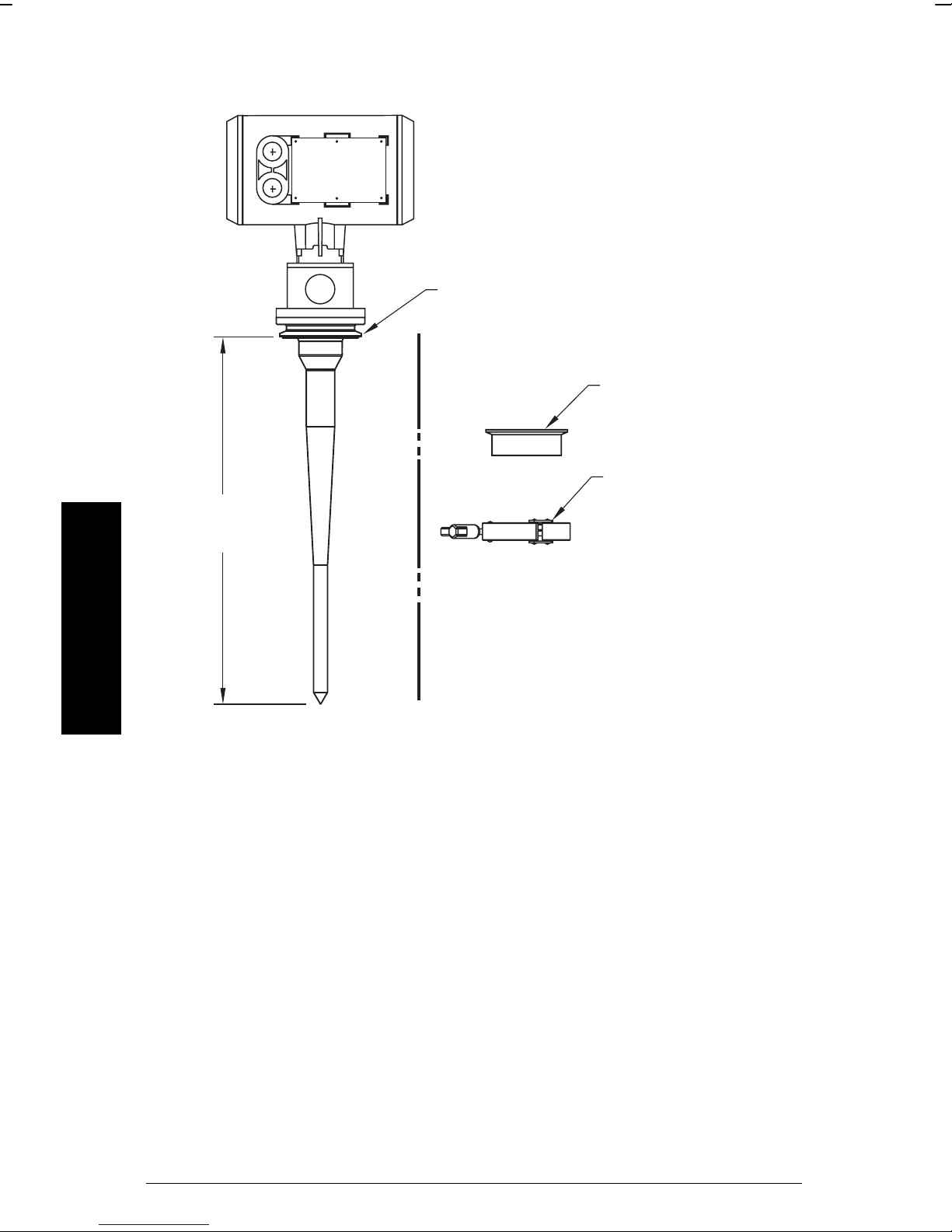

Dimensions: Ex Unit with Rod Antenna

(

)

(

)

(

)

(

)

*

64 mm

2.5"

41 mm (1.6")

183 mm

100 mm (4.0")

(7.2")

239 mm

9.4"

earth

connection

245 mm

(9.6")

412 mm

(16.3")

136 mm

5.4"

75 mm

(3.0")

enclosure/

electronics

antenna

(resonator)

flange

Installation

antenna

rod

*

* Flange thickness 25 mm (1") nominal.

** Standard length, 50 and 100 mm (2” and 4") extensions available.

For information on temperature and pressure ratings, see Appendix III on

page 69.

PL-550 IQ Radar 160/160 Ex Page 13

Page 14

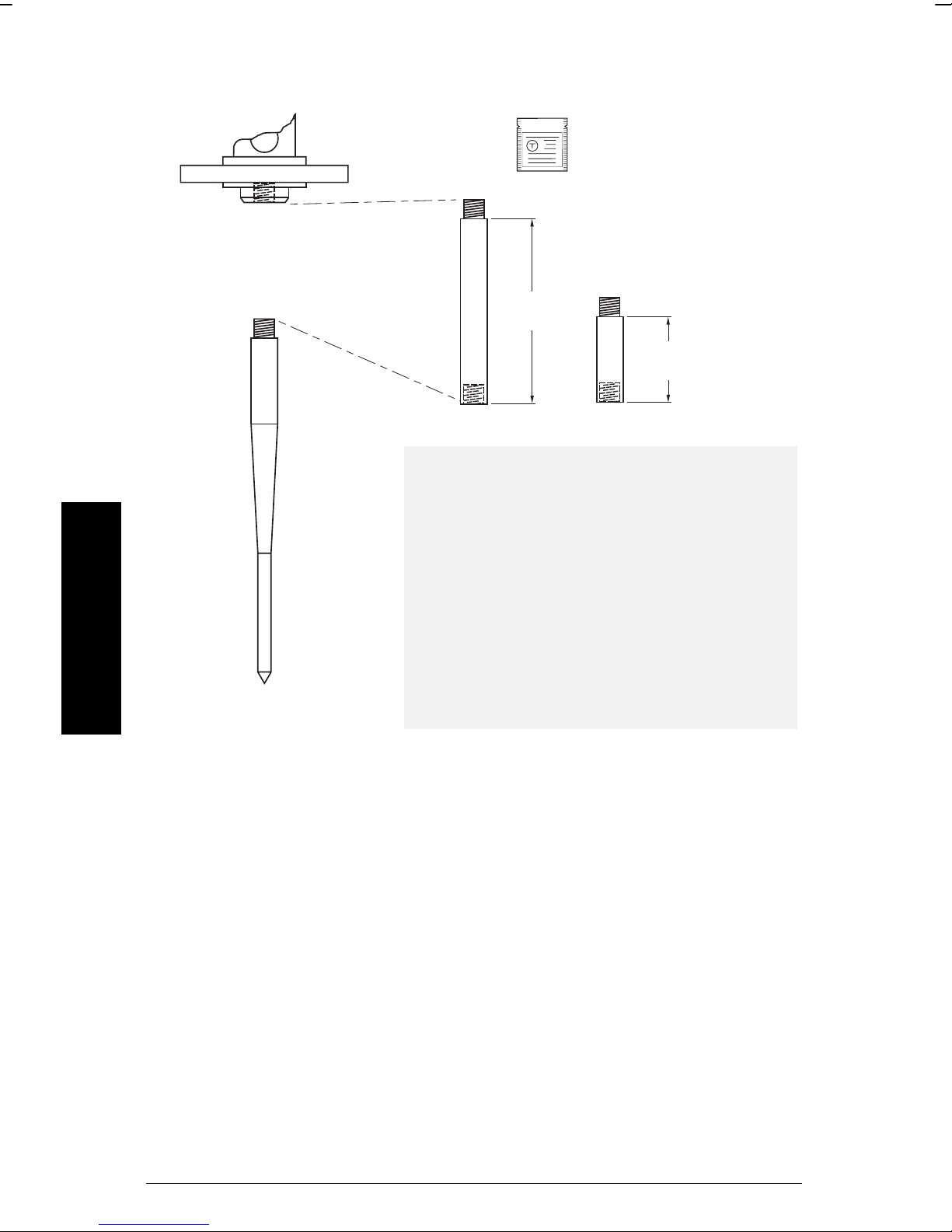

Dimensions: Threaded Rod

(4”)

optional

extension

Note:

Ingress of water or process fluids into the connecting

threads can cause reflections at the connection,

appearing as false echoes.

Teflon paste

(supplied)

100 mm

50 mm

(2”)

Installation

standard antenna

Apply Teflon paste to threads and tighten slowly.

Ensure that the rod sections mate securely with no

gaps. Do not apply too much Teflon paste or parts

will not mate securely.

Do not use wrenches or pliers. Hand tight only.

Sealant must have

εr < 3

. We recommend a sealant

such as Teflon paste or silicone compound.

Page 14 IQ Radar 160/160 Ex PL-550

Page 15

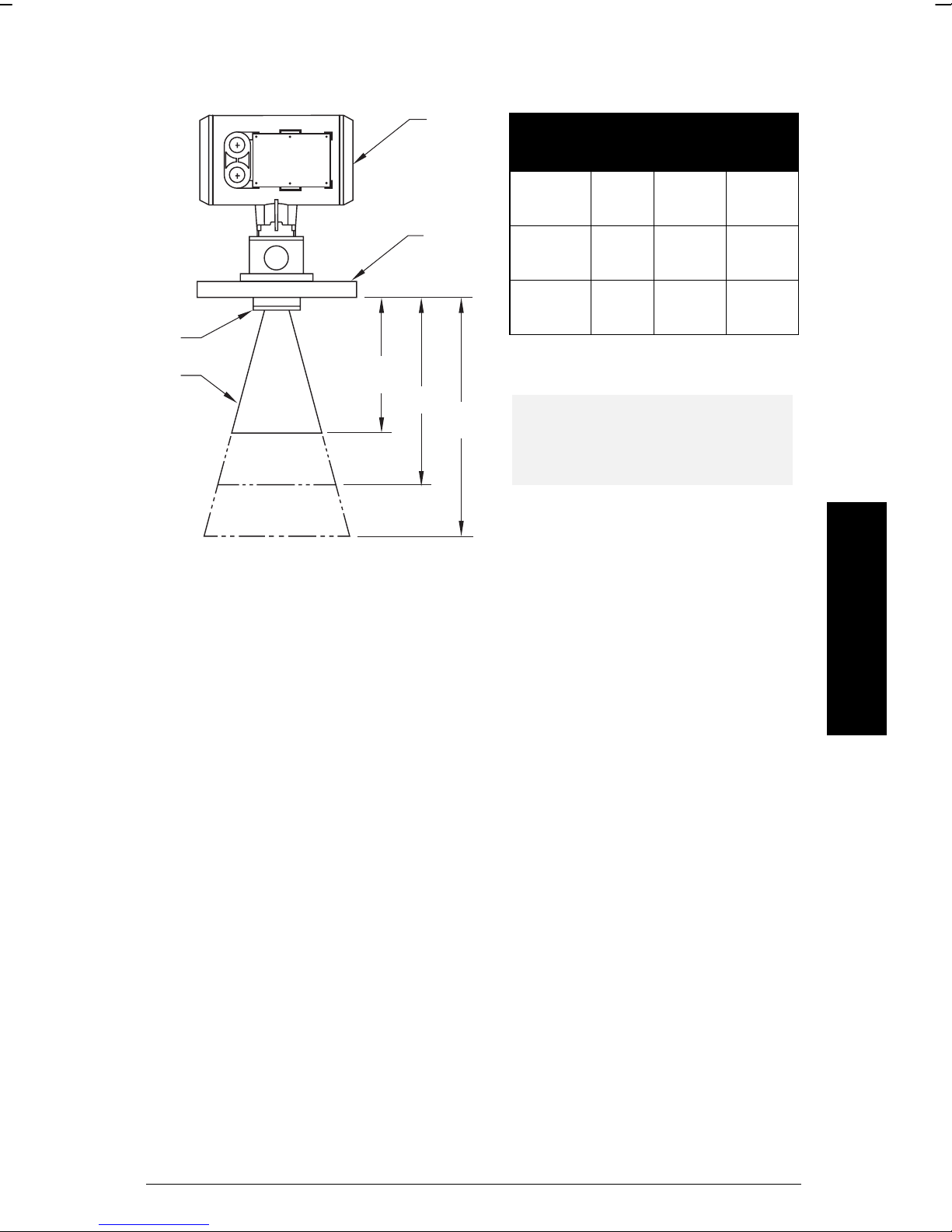

Dimensions: Horn

∅ 80 mm

(3”)

horn 131 mm

100 mm

(4”)

150 mm

(6”)

200 mm

(8”)

(5.16”)

enclosure /

electronics

flange

225.8 mm

325.1 mm

(12.8”)

Nominal

Horn

Size

100 mm

(4”)

150 mm

(6”)

200 mm

(8”)

Horn

O.D.

95.3

mm

(3.75”)

146.0

mm

(5.75”)

199.4

mm

(7.85”)

Horn

Height

131.0

mm

(5.16”)

225.8

mm

(8.89”)

325.1

mm

(12.8”)

Beam

Angle

28

degrees

20

degrees

12

degrees

Note:

Signal amplitude increases with horn

diameter, so use the largest size

practical.

Installation

PL-550 IQ Radar 160/160 Ex Page 15

Page 16

Dimensions: Waveguide Extension

optional sliding flange

(see flange table)

Note:

Always clamp the instrument in the

same position for operation.

(see P006 on page 53).

1000 mm

(40.8”)

Installation

131 mm

(5.16”)

225 mm

(8.89”)

325 mm

(12.8”)

Note:

1. Maximum pressure 0.5 bar at 60 deg. C (140 deg. F) for sliding flange

option.

Page 16 IQ Radar 160/160 Ex PL-550

Page 17

Dimensions: Sanitary Horn

Materials: standard optional

horn SS 304 SS 316

ferrule SS 304 SS 316

clamp SS 304 SS 316

gasket PTFE

50 mm (2”) clamp

(supplied)

232 mm

(9.13”)

horn

Installation

100 mm (4”) clamp (optional)

gasket (optional)

ferrule (optional)

PL-550 IQ Radar 160/160 Ex Page 17

Page 18

Dimensions: Sanitary Rod

50 mm (2”), 80 mm (3”) or 100 mm (4”)

with integral gasket

ferrule (optional)

clamp (optional)

406 mm (16”)

Installation

nominal

Materials: SS304 standard

SS316 optional.

Page 18 IQ Radar 160/160 Ex PL-550

Page 19

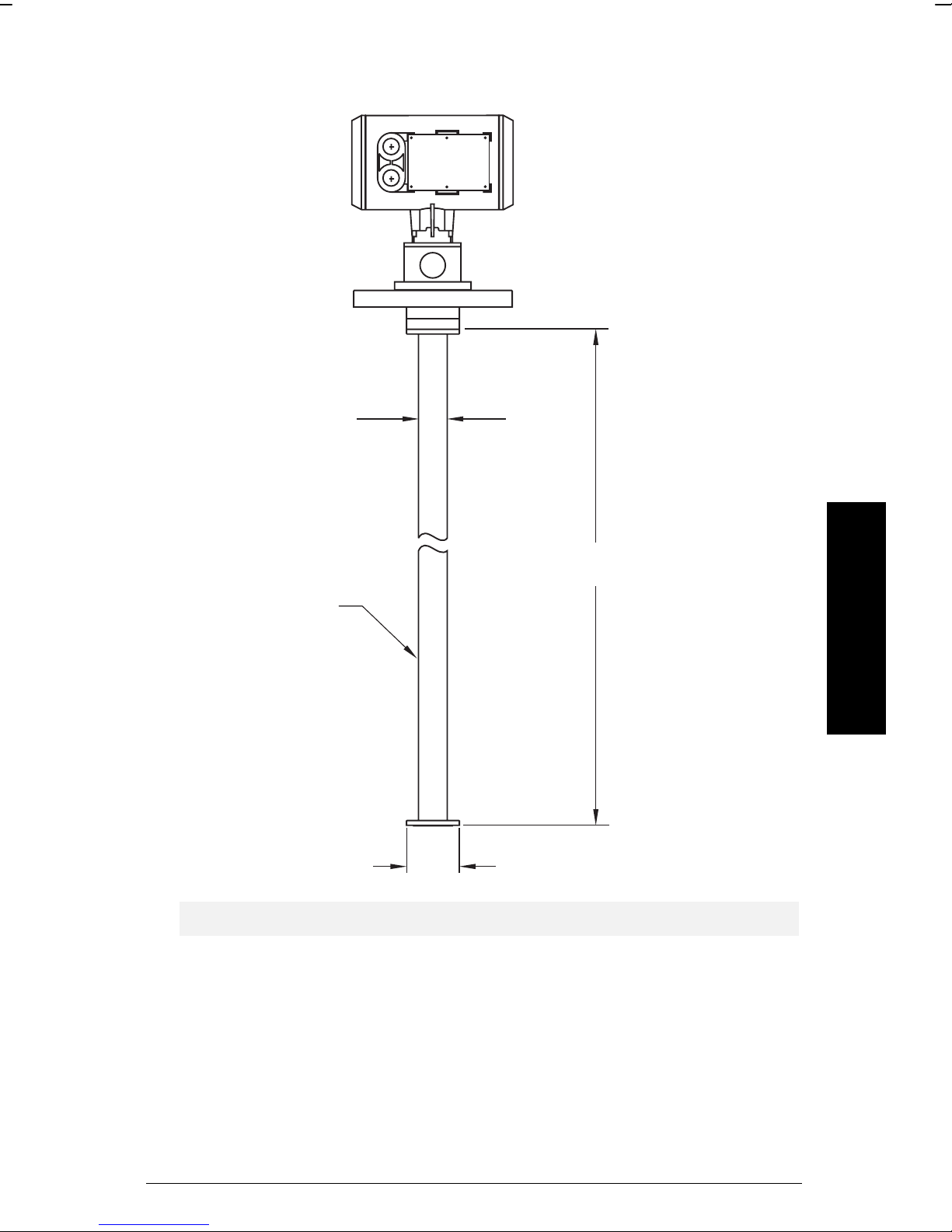

Dimensions: Waveguide

41.4 mm

(1.69”)

variable

waveguide

76.2 mm

(3.0”)

min: 100 mm (4.08”)

max: 6000 mm (244.90”)

Note: you can connect multiple waveguides together (maximum 2).

Installation

PL-550 IQ Radar 160/160 Ex Page 19

Page 20

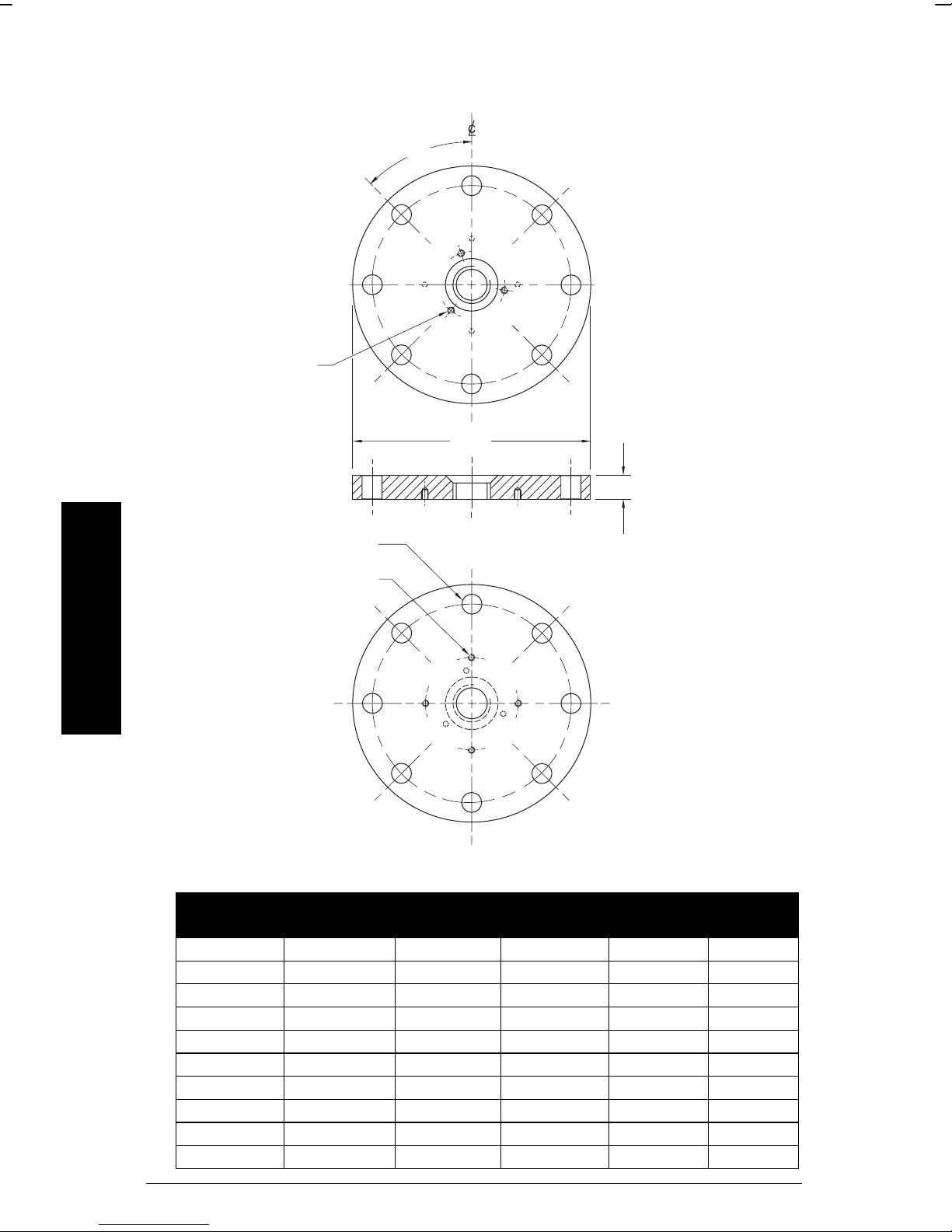

Dimensions: Flanges

45°

bolt hole

Installation

horn / waveguide

mounting holes

(threaded)

enclosure mounting

holes (threaded)

bolt hole

O.D.

bolt hole

circle

bolt hole

circle

process side

20 mm (0.8”), nominal

Pipe Size Flange

Size

2” ANSI 150# 6.0” 4.75” .7” 4

3” ANSI 150# 7.5” 6.0” .75” 4

4” ANSI 150# 9.0” 7.50” .75” 8

6” ANSI 150# 11.0” 9.50” .88” 8

8” ANSI 150# 13.5” 11.75” .88” 8

50 mm DN PN 16 165 mm 125 mm 18 mm 4

80 mm DN PN 16 200 mm 160 mm 18 mm 8

100 mm DN PN 16 220 mm 180 mm 18 mm 8

150 mm DN PN 16 285 mm 240 mm 22 mm 8

200 mm DN PN 16 340 mm 295 mm 22 mm 12

Page 20 IQ Radar 160/160 Ex PL-550

Flange

O.D.

Bolt Hole

Circle Ø

Bolt

Hole Ø

Number

of Bolts

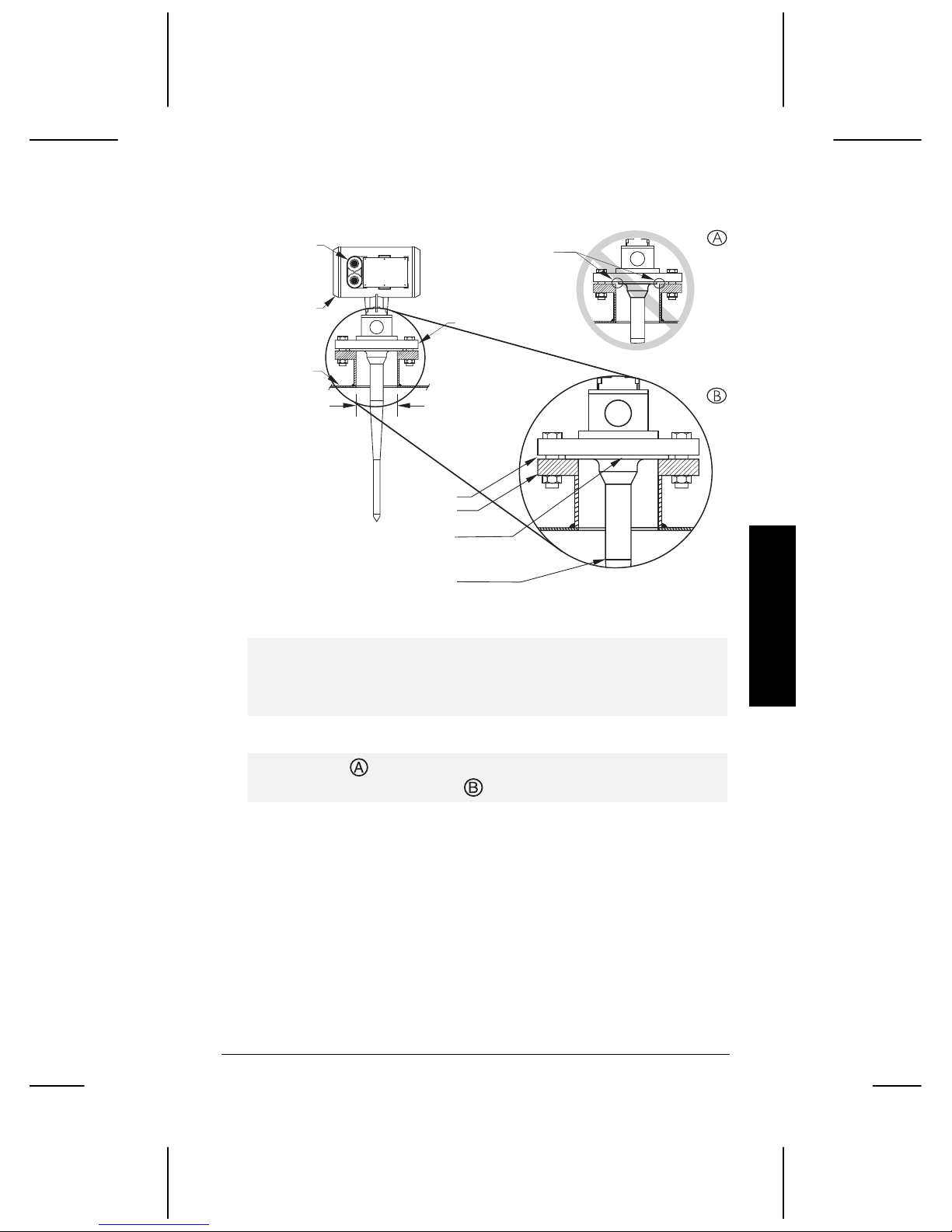

Page 21

Mounting

1/2" NPT or PG

16 conduit entry

wiring access

cover

tank

minimum diameter

2" / DIN 50

standpipe/vessel jun cture

customer flange

integral process seal

*

see below

customer flanged

standpipe to suit

straight/taper transition

Notes:

• The straight/taper transition of the rod should extend past the

standpipe/vessel opening. Add extensions as required.

• Refer to the Rod Extension Requirements table.

• The unit in

is improperly mounted. The Integral process seal MUST

rest on customer flange as in .

Installation

PL-550 IQ Radar 160/160 Ex Page 21

Page 22

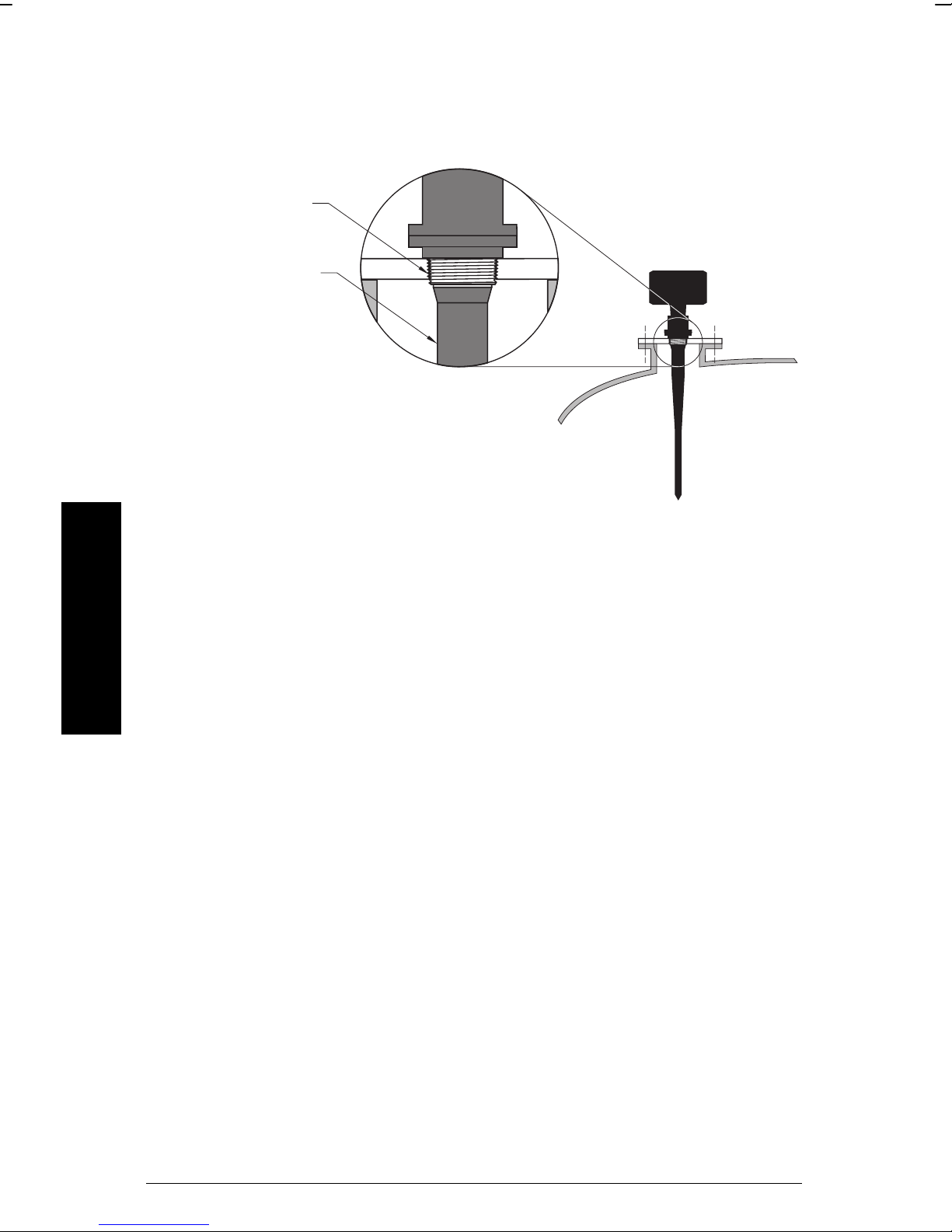

Threaded Rod Antenna

You can use 1.5” or 2” threaded process connections. There are three thread

types: NPT, BSP and G.

316 S.S.

PTFE or UHMW-PE

Wetted Parts:

Metal: 316SS

Polymeric: PTFE or UHMW-PE

Internal O-ring: Viton

Installation

Page 22 IQ Radar 160/160 Ex PL-550

Page 23

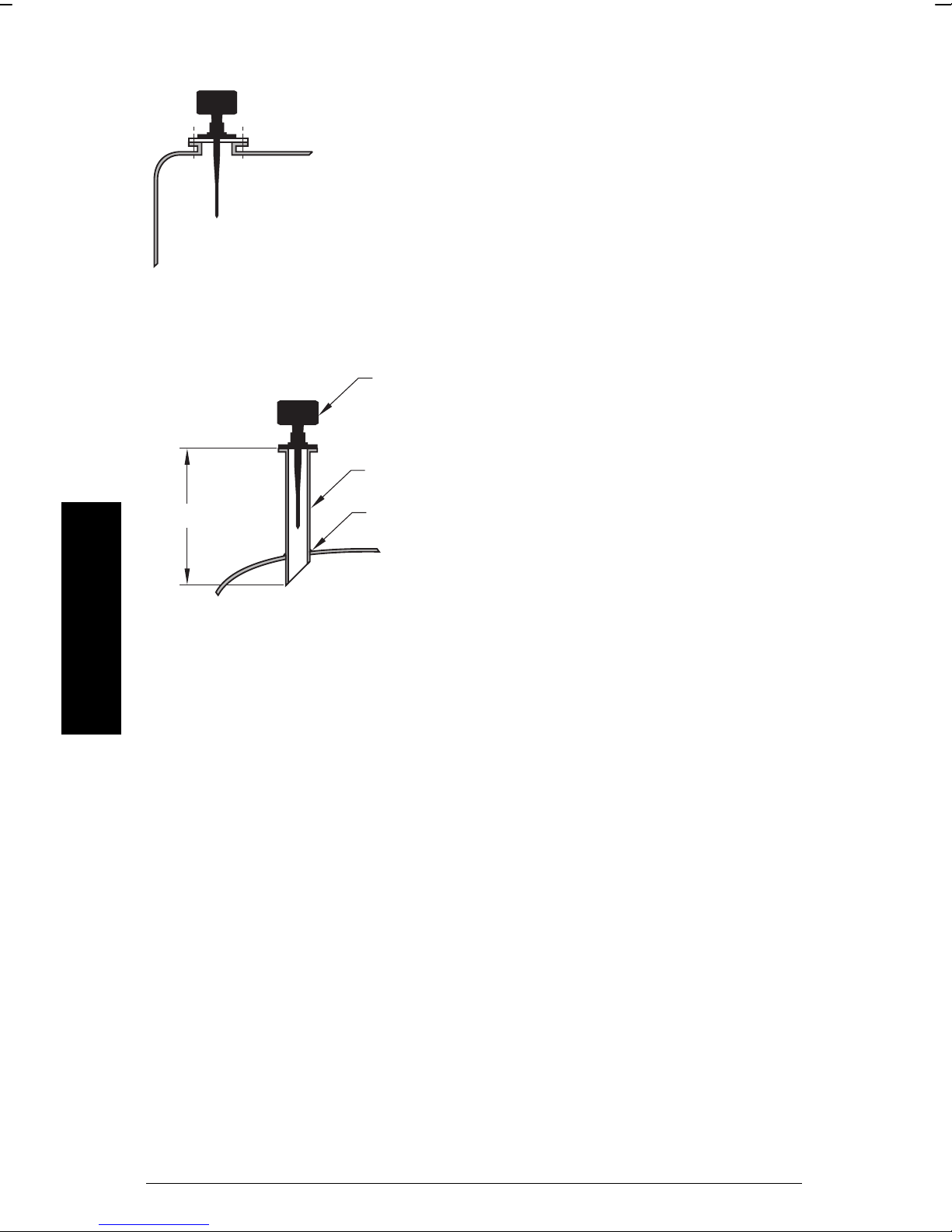

Rod Assembly

(4”)

optional

extension

Teflon paste

(supplied)

100 mm

50 mm

(2”)

Note:

Ingress of water or process fluids into the connecting

threads can cause reflections at the connection,

appearing as false echoes.

Apply Teflon paste to threads and tighten slowly. Ensure

that the rod sections mate securely with no gaps. Do not

apply too much Teflon paste or parts will not mate

securely.

Do not use wrenches or pliers. Hand tight only.

Sealant must have

as Teflon paste or silicone compound.

Rod Extension Requirements

standpipe i.d.

<100 (4) 100 to 150 (4 to 6) 150 to 200 (6 to 8)

50 mm (2”)n/r

80 mm (3”) n/r 50 mm 100 mm

100 mm (4”) n/r 50 mm 100 mm

150 mm (6”) n/r 50 mm 100 mm

>150 mm (6”) n/r n/r n/r

n/r extension not required

Consult Milltronics for assistance with standpipe sizes not listed.

*

application not recommended for 50 mm (2”) i.d. standpipes greater than 100 mm (4”)

**

long

standpipe height mm (inches)

εr < 3

. We recommend a sealant such

*

** **

Installation

PL-550 IQ Radar 160/160 Ex Page 23

Page 24

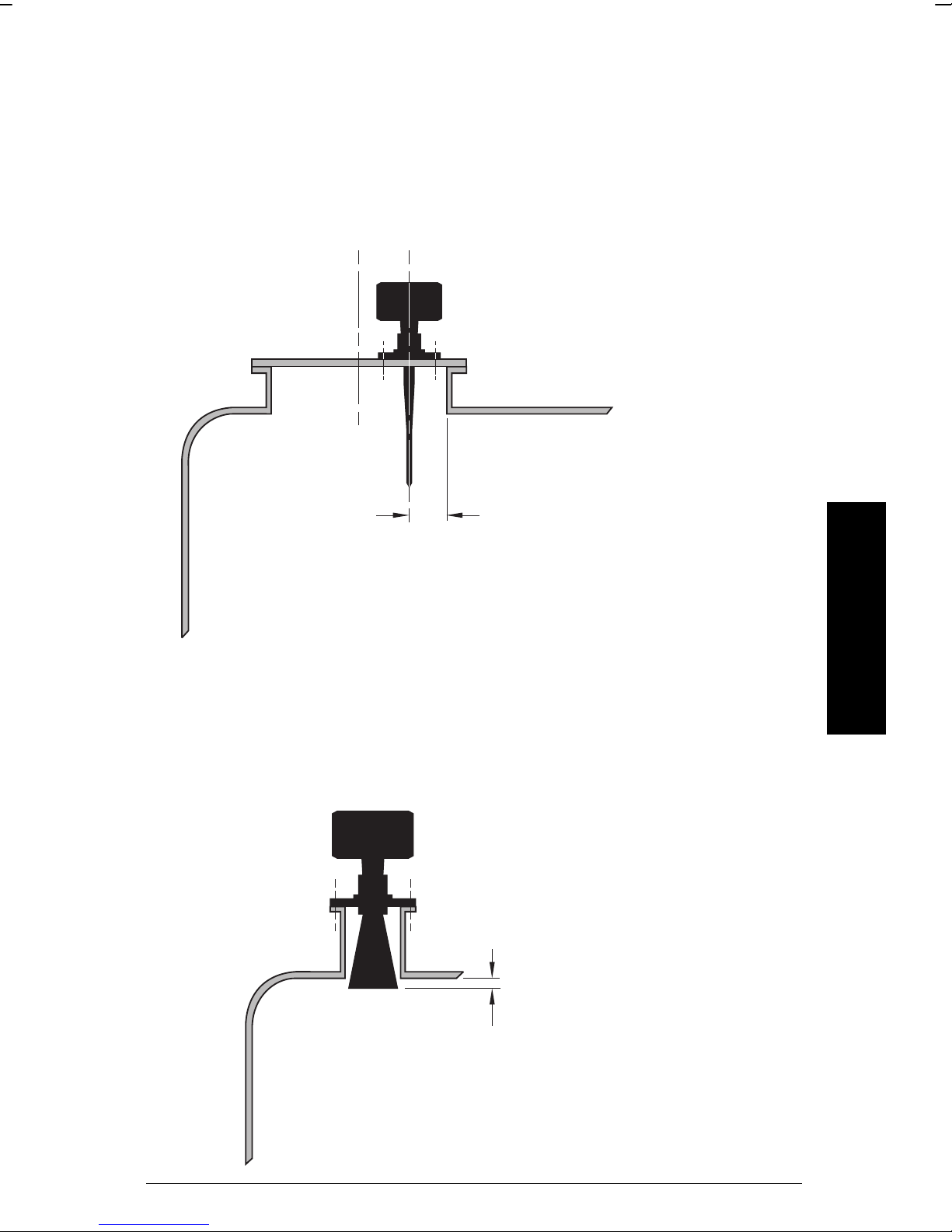

Mounting: Rod Assembly

Ideally, the stand pipe should be as short as possible. If

your application requires a stand pipe that exceeds our

recommended maximum lengths, consider using a

waveguide and horn combination. If you create a new

stand pipe for the radar unit, ensure the weld seams are

on the outside of the stand pipe, not the inside.

Ensure that there are no seams or lips on the inside of

the stand pipe or you may get erratic readings.

If the mounting illustrated above is not suitable due to the minimum blanking

requirements, consider the following option:

enclosure

minimum diameter 100mm (4”)

A

Installation

Stand pipes that are 8” or larger in diameter provide excellent signal

conditions. These conditions allow for stand pipe lengths of up to 24” using

the standard rod without any extensions.

45

weld on outside

°

Maximum length 610 mm (24”)

No antenna extensions required

Page 24 IQ Radar 160/160 Ex PL-550

Page 25

Mounting: Manhole Covers

A manhole cover is typically a stand pipe that is 24” in diameter or greater and

that have a cover.

To provide the optimum signal conditions, locate the antenna off-centre with

respect to the cover, typically 100 mm (4”) from the side of the manhole.

100 mm (4”)

Mounting: Horn Antennas

Usually, horns are mounted on short stand pipes.

Installation

The end of the horn should

protrude a minimum of 10 mm

(0.5”) to avoid interference with

the stand pipe.

PL-550 IQ Radar 160/160 Ex Page 25

Page 26

Mounting: Waveguide Antenna

This option is recommended for products with εr lower than 3. The maximum

range of this application is reduced to 10 m (33 feet). See P655 on page 58.

vent hole

minimum 80 mm (3”)

Installation

Page 26 IQ Radar 160/160 Ex PL-550

Page 27

Mounting: Still pipe or Side pipe

An alternate to the waveguide antenna, this option is also used for products

with an ε

mounting arrangement can also be used to provide optimum signal conditions

on foaming materials.

Suitable pipe diameters are 2” (50 mm) to 10” (250 mm). A rod antenna or a

horn antenna may be used.

Note: The measurement range is reduced to 13 m (43’) for a 50 mm (2”)

still pipe or 14.5 m (47’) for a 80 mm (3”) still pipe.

Smoothness

One continuous length of metallic pipe is preferred (no joints). If joints are

required due to long length, then you must machine the joints to close

tolerances ± 0.25mm (± 0.010”) and weld a connecting sleeve on the outside.

less than 3 or for extremely turbulent or vortex conditions. This

r

vent hole

See P655 on page 58.

Installation

Suitable pipe diameters

are 2” (50mm) to 10”

(250mm).

You can use either a

Rod or Horn antenna.

Ensure there is a vent at the upper end of the surge pipe to equalize pressure

and keep the liquid level in the pipe constant with level in the vessel.

PL-550 IQ Radar 160/160 Ex Page 27

Page 28

Mounting: Horn with Waveguide Extensions

In applications where the stand pipe is too

long and the diameter is too small (such as a

stand pipe that is 100 mm (4”) in diameter

and 460 mm (18”) in length), the rod antenna

is not suitable due to stand pipe interference.

In this case, use the waveguide / horn

combination. Waveguide extensions are

available in custom lengths.

If the horn diameter is too large for the stand

pipe opening, you need to insert it from inside

the vessel. The horn must be connected to

the IQ160 process flange.

Note: The IQ160 maximum range of 15m is reduced by [0.64 x waveguide

length]. Blanking and offset parameters will be set by Milltronics, see the

device tag for values.

Mounting: Sanitary Mounting

There are two common sanitary mounting options; the 2”, 3” and 4” tri-clamp

Installation

with rod antenna and the sanitary 4” horn antenna.

Wetted Parts:

PTFE or UHMW-PE only.

Page 28 IQ Radar 160/160 Ex PL-550

Page 29

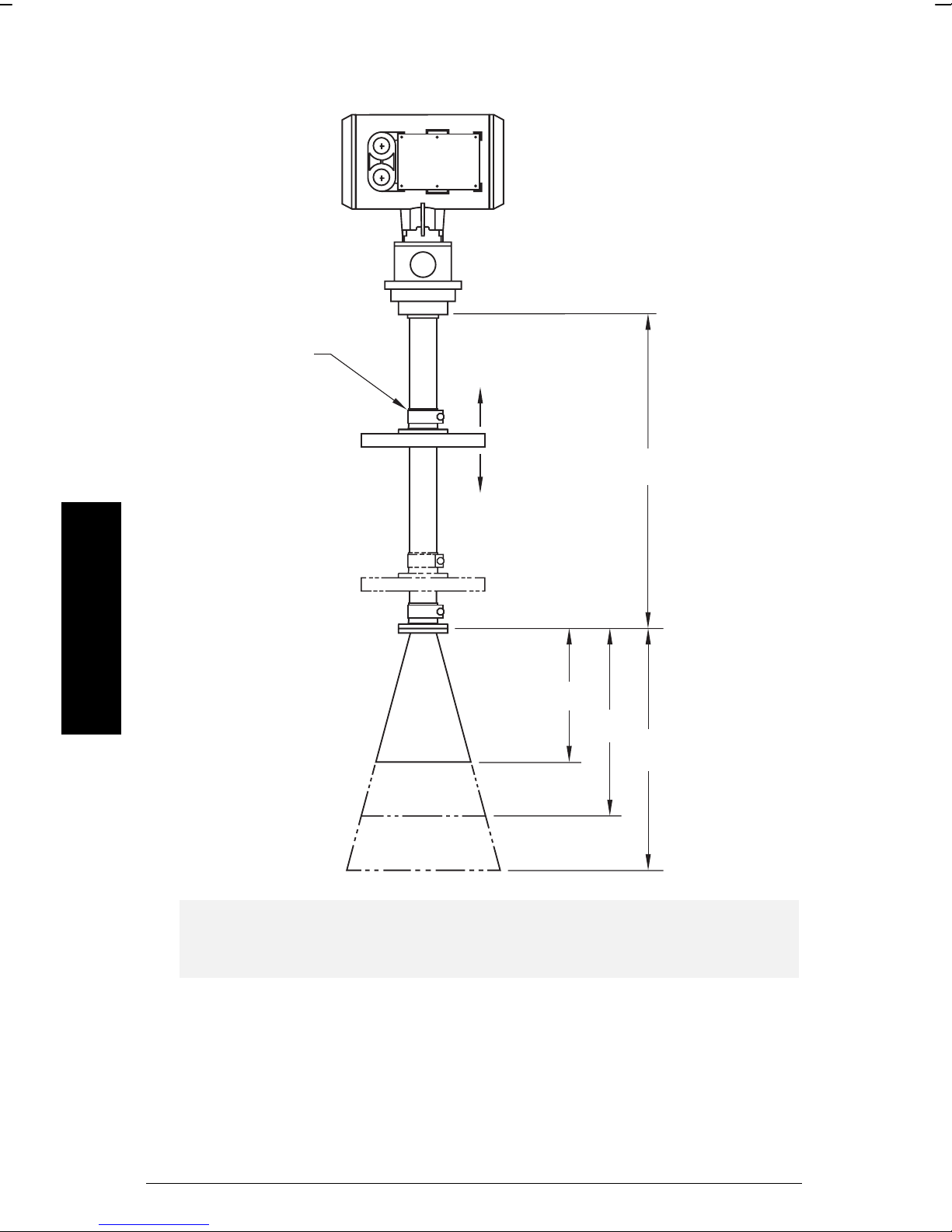

Mounting: Location/Beam Angle

Angle

Due to the polarization effect of

the microwave signal related to

the wall of the vessel, we

recommend locating the IQ160

a minimum of 30 cm (1’) away

from the side wall for every 3 m

Keep the emission cone

free of obstructions.

(10’) of vessel height.

Antenna Beam Angle

Rod 20

4” Horn 28

6” Horn 20

8” Horn 12

Beam

Polarization Effect

Mounting the unit too close to a wall may cause echoes to d isappear at

specific levels due to wave cancellation. A strong false reflection from an

internal tank obstruction can be reduced or eliminated by rotating the unit to

reduce the polarization effect.

False Reflections

Flat obstructions, and struts that are perpendicular to the emission cone,

cause large false reflections. They reflect the radar signal with high amplitude.

Round profile interfering surfaces diffuse reflections of the radar signals and

cause false reflections with low amplitude.

o

o

o

o

Installation

PL-550 IQ Radar 160/160 Ex Page 29

Page 30

Interconnection

IQ Radar 160 Terminal Block

IQ Radar 160 Ex Terminal Block

AC version DC version

1

mA

mA

2

SHLD

3

4A

5B

6

7

8

9

R

S

4

8

5

L2/N

L1

Installation

AC version DC version

Notes for both AC and DC versions:

• mA, RS-485, wiring, 14 – 20 AWG, shielded copper wire.

• Recommended torque on terminal clamping screws, 0.5 – 0.6 Nm

• Ground shields at one end only.

Page 30 IQ Radar 160/160 Ex PL-550

Page 31

IQ Radar 160 Wiring

AC version DC version

IQ Radar 160 Ex Wiring

AC version DC version

4-20 mA,

to instrumentation

RS-485,

to host device

to reliable

earth ground

V supply,

see nameplate

4-20 mA,

to instrumentation

RS-485,

to host device

V supply,

see nameplate

enclosure

Notes for AC version only:

• Line, 12 – 14 AWG, copper wire

• The equipment must be protected by a 15 A fuse or circuit breaker in

the building installation.

• A circuit breaker or switch in the building installation, marked as the

disconnect switch, shall be in close proximity to the equipment and

within easy reach of the operator.

Installation

All field wiring must have insulation suitable for at least 250 V.

Note for DC version only:

DC terminals shall be supplied from an SELV source in

accordance with IEC 1010.1 Annex H.

PL-550 IQ Radar 160/160 Ex Page 31

Page 32

Installation

Page 32 IQ Radar 160/160 Ex PL-550

Page 33

Start Up

Overview

The IQ Radar 160/160 Ex has two modes of operation:

When the unit is powered, after installation procedures have been completed,

run

it is programmed to start up in the

antenna flange to the target in meters.

Typical display

The unit can be placed into the

of program parameters in order to better suit the application or user’s

preferences. Programming can be carried out locally via the hand

programmer or remotely via the optional Dolphin/RS-485 interface.

program

mode, to detect the distance from the

mode at any time; to alter a number

run

and

program

.

PL-550 IQ Radar 160/160 Ex Page 33

Start Up

RS-485

hand programmer

Page 34

The first step in programming is to ensure that all parameters are at their

factory setting. The quickest way is to perform a master reset, P999 (see

page 61).

For a Quick Start, P001 to P007 are the key parameters requiring entry.

They set:

• mode of measurement

• process material

• antenna configuration

• measurement response

• units

• empty distance

• span

There are a number of other program parameters that can be changed

subsequently or during another programming session. Refer to the Parameter

Description that starts on page 53, for a list of the parameters available.

When programming has been completed, the IQ Radar 160/160 Ex can be

put into

run

by pressing, or exiting Dolphin.

Hand Programmer

Start Up

Page 34 IQ Radar 160/160 Ex PL-550

Page 35

Display

Aiming the Hand Programmer

Start Up

PL-550 IQ Radar 160/160 Ex Page 35

Page 36

Local Operation

Run Display

bar graph

representation of

material level, 0 to

100% of span

reading

units

reading questionable,

appears during fail-safe

operation

auxiliary reading

Program Display

Start Up

parameter type

(measurement of mA output)

= normal reading

= fail-safe operation

parameter value

units

Page 36 IQ Radar 160/160 Ex PL-550

parameter number

Page 37

Hand Programmer

Function

Keys

Numeric and

Auxiliary Keys

Key Programming Mode Run Mode

to

End program session and

Parameter scroll-up

Parameter scroll-down

Enter the displayed value

Values

Decimal point

Negative value

Clear value

run

enable

mode

“mA output value”

Toggle between units

and % on reading display

Initiate and complete

program mode access

“Distance”

Start Up

PL-550 IQ Radar 160/160 Ex Page 37

Page 38

Local Programming

To Access Program Mode

run

mode

Press

To Access a Parameter

Scroll Access

Press

Direct Access

Press

Initial program starts

at P000

Scroll up or down

e.g. P000 accessed

Press

Start Up

Page 38 IQ Radar 160/160 Ex PL-550

index parameter field

e.g. P005 accessed

Page 39

To Modify a Parameter Value:

Note:

Security must be disabled!

Changing Parameter Values

Select parameter

e.g. P001 = 3

Press

Clearing a Parameter Value

Press

Press

Resetting a Parameter Value

e.g. P001 = 1

e.g. field entry = 2

e.g. P001 = 1

e.g. P001 = 1

Press

To Access Run Mode:

Press

PL-550 IQ Radar 160/160 Ex Page 39

Reset to factory value

P001 = 3

from

program

exit and return to

run

Start Up

Page 40

Start Up

Page 40 IQ Radar 160/160 Ex PL-550

Page 41

Operation

Overview

The IQ Radar 160/160 Ex is a level measuring device for use with liquids and

slurries. Using advanced pulse radar technology, the device calculates

material level by first emitting a series of radar pulses and then analyzing their

reflections.

The device consists of an enclosed electronic component, mounted to a

flanged antenna component. The electronic component generates a 5.8 GHz

(U.S.A. 6.3 GHz) radar signal, which is directed to the antenna, waveguide, or

horn.

The radar signal is emitted axially from the antenna and propagates along this

axis in a defined conical beam decreasing in strength at a rate inversely

proportional to the distance.

The radar pulse detects the interface between the dielectric constant of the

atmosphere, and that of the material being measured. Electro-magnetic wave

propagation is not sensitive to the temperature and atmospheric conditions or

variations in the vessel.

The series of echoes from the pulses transmitted are sensed by the antenna

during the receive period of the electronics. The echoes are stored as a

profile of the activity in the vessel. The profile is analysed and the distance of

the material surface to the radar antenna is determined. This distance is used

as a basis for display of material level and mA output.

Transceiver

The IQ Radar 160/160 Ex transceiver operates under 1 of 5 sets of preset

conditions (P003), summarized as follows:

parameter

value

1 0.1 m/min slow on on 100

2 1 m/min • on on 10

3 10 m/min • on on 1

4 100 m/min • off on 0.1

5 1000 m/min fast off off 0

measurement

response

echo

verification filter

fail-safe

timer

Operation

When the echoes are received, the relevant echo extraction technique (P820

and P830) is applied to determine the true material echo.

PL-550 IQ Radar 160/160 Ex Page 41

Page 42

The measurement response limits the maximum rate at which the display and

analog output respond to changes in measurement. It is of concern especially

where liquid surfaces are in agitation or fall into the radar path during filling.

Loss of Echo

A loss of echo occurs when the IQ Radar 160/160 Ex deems that the

calculated measurement is unreliable, i.e. the confidence (P805) is less than

the threshold (P804). Refer to Troubleshooting on page 63.

If the condition persists for a time beyond the limit as set by the fail-safe timer

(P070), the confidence icon changes from full to partial (see page 36) and the

reading and mA output are immediately forced to the fail-safe default (P071).

Upon receiving a reliable echo, the loss of echo condition is aborted (icon

returns to full) and the reading and mA output return to the present level

immediately.

Blanking

Near blanking (P800) is used to ignore the zone in front of the antenna where

false echoes (e.g. ladder rung) appear as an echo during the receive cycle.

This is usually indicated by an incorrect high level reading and can be

overcome by increasing the near blanking from its factory set value.

Far end blanking is a feature that ignores the zone below the zero or empty

level where false echoes can appear at levels that interfere with the

processing of the true echo.

Typical Receiver Signal

end of

transmit

P800

near blanking

0

level

far end blanking

empty distance to antenna

Operation

Page 42 IQ Radar 160/160 Ex PL-550

P006

range extension

(P801) as % P006

range

Page 43

In applications where the zero level is above the bottom of the vessel and it is

desired to monitor the zone below the normal zero, range extension (P801)

can be used to extend the range into the far end blanking. Range extension is

entered as a percentage of P006. As range extension reduces the protection

afforded by the far end blanking, it should be used judiciously. Avoid

excessive range extension as this can reduce the measurement’s reliability

and accuracy. Range extension is factory set for 5% of P006. If it is found that

false echoes are appearing, after the blanking zone, P801 should be

increased accordingly.

Analog Output

The IQ Radar 160/160 Ex can be programmed to provide an analog output

(P200) of 0 to 20 or 4 to 20 mA, and for proportional or inverse span.

Programming

Upon entering the Program mode, the analog output level holds its prior

value.

PL-550 IQ Radar 160/160 Ex Page 43

Operation

Page 44

Run

The analog output responds in the following manner:

Level

(P001=1)

Space

(P001=2)

0/4 – 20 mA

(P200 = 1 or 2)

20 – 0/4 mA

(P200 = 3 or 4)

Distance

(P001=3)

*reference value only. mA level limited by near blanking.

0 and 100% are percentage of full scale reading (m, cm, mm, ft, in)

Volume

To program the unit for volume, set:

• operation (P001) to level “1” (see page 53),

• tank shape (P050) to a value other than 0 (see page 55),

• other volume parameters (P051 to P053) as required.

Operation

Page 44 IQ Radar 160/160 Ex PL-550

Page 45

Fail-Safe

When the fail-safe timer (P070) expires, the mA output responds as follows:

Fail-safe Mode (071) Status (0/4 – 20) Status (20 - 0/4)

high 22 0/2

low 0/2 22

hold hold hold

Run / Program

When the IQ Radar 160/160 Ex changes from

longer responds to the process. The last measurement is stored and the

associated reading and mA output are held.

As a courtesy, the unit reverts to the parameter last addressed during the

previous program session.

run

Upon return to

output default to the last measurement taken. The reading and associated

outputs migrate to the current process level at a rate controlled by the

measurement response (P003).

If the IQ 160/160 Ex is left in

reverts to

Run

, the transceiver resumes operation. The reading and mA

Program

mode.

mode for 10 minutes, it automatically

run

to

program

, the unit no

PL-550 IQ Radar 160/160 Ex Page 45

Operation

Page 46

Application Example: Asphalt in Storage Tank

Note:

The minimum distance from the antenna face to the target is limited by the

near blanking, P800.

The application is to obtain a level

measurement and corresponding 4-20

mA output proportional to asphalt levels

in a storage tank. The bottom of the

antenna flange is 5 m from the tank

Empty

(P006)

Span

(P007)

bottom. The empty level is 0 m (bottom)

and the full level (span) is 4.5 m from

the bottom. The maximum rate of filling

or emptying is about 0.1 m/min. In the

event of a loss of echo, the IQ Radar

160/160 Ex is to go into fail-safe Hi after

2 minutes.

Asphalt build-up on the rod antenna

does not effect performance.

Reset:

P999 master reset

Program:

P001 enter ‘1’ mode of measurement = level

P002 enter ‘1’ material = liquid

P003 enter ‘2’ measurement response = 1m/min.

P004 enter ‘240’ antenna

= dielectric rod,

standard length

P005 enter ‘1’ units = metres

P006 enter ‘5’ empty distance = 5 m

P007 enter ‘4.5’ span = 4.5 m

P070 enter ‘2’ fail-safe timer = 2 min.

P071 enter ‘1’ fail-safe = Hi

P820 enter ‘1’ algorithm = factory

P830 enter ‘4’ TVT type = factory

Run:

Press run to start normal operation. Press

.

Operation

Page 46 IQ Radar 160/160 Ex PL-550

Page 47

Application Example: Horizontal Tank with

Volume

Note:

The minimum distance from the antenna face to the target is limited by the

near blanking, P800.

The application is to obtain a level measurement and corresponding 4-20 mA

output proportional to material levels in a chemical tank. The bottom of the

antenna flange is 3.5 m from the tank bottom. The empty level is 0 m (bottom)

and the full level (span) is 3.0 m from the bottom. The maximum rate of filling

or emptying is about 0.1 m/min. In the event of a loss of echo, the IQ Radar

160/160 Ex is to go into fail-safe Hi after 2 minutes.

500 mm

(20.4”)

3000 mm

(122.4”)

Reset:

P999 master reset

Program:

P001 enter ‘1’ mode of measurement = level

P002 enter ‘1’ material = liquid

P003 enter ‘2’ measurement response = 1m/min.

P004 enter ‘240’ antenna

= dielectric rod,

standard length

P005 enter ‘1’ units = metres

P006 enter ‘5’ empty distance = 3.5 m

P007 enter ‘4.5’ span = 3 m

P050 enter ‘7’ tank shape = parabolic ends

P051 enter ‘8000’ maximum volume = litres

P052 enter ‘.8’ tank dimension A = metres

P053 enter ‘6’ tank dimension L = metres

P070 enter ‘2’ fail-safe timer = 2 min.

P071 enter ‘1’ fail-safe = Hi

P820 enter ‘6’ algorithm = first echo

P830 enter ‘4’ TVT type = factory

Operation

Run:

Press run to start normal operation. Press

PL-550 IQ Radar 160/160 Ex Page 47

.

Page 48

Application Example: Juice Batch Tank with

Sanitary Horn Antenna

Note:

The minimum distance from the antenna face to the target is limited by the

near blanking, P800.

Sanitary Antenna Options:

• One-piece antenna/process seal

• This provides an excellent mounting method, even on non-sanitary

installations.

P006

mixer

4” sanitary horn

existing 4” tri-clamp connection

P007

mixer

Operation

Page 48 IQ Radar 160/160 Ex PL-550

Page 49

Reset:

P999 master reset

Program:

P001 enter ‘1’ mode of measurement = level

P002 enter ‘1’ material = liquid

P003 enter ‘2’ measurement response = 1m/min.

P004 enter ‘240’ antenna

= dielectric rod,

standard length

P005 enter ‘1’ units = metres

P006 enter ‘5’ empty distance = 5 m

P007 enter ‘4.5’ span = 4.5 m

P070 enter ‘2’ fail-safe timer = 2 min.

P071 enter ‘1’ fail-safe = Hi

P652 enter tag value offset correction = factory

P820 enter ‘1’ algorithm = factory

P830 enter ‘4’ TVT type = factory

Run:

Press run to start normal operation. Press

.

Application Example: Sliding Waveguide on

Anaerobic Digesters

Blanking, P800 and offset P652 are set at the factory. Check the device tag

for specific values.

Maximum level should be maintained at

least .46 m (18”) from the end of the horn.

The raised position is for installation and

maintenance. The lowered position is for

horn

operation. Program the unit for operation

in the lowered position.

P006

P007

PL-550 IQ Radar 160/160 Ex Page 49

Operation

Page 50

Reset:

P999 master reset

Program:

P001 enter ‘1’ mode of measurement = level

P002 enter ‘1’ material = liquid

P003 enter ‘2’ measurement response = 1m/min.

P004 enter ‘240’ antenna

P005 enter ‘1’ units = metres

P006 enter ‘5’ empty distance = 9.6 m

P007 enter ‘4.5’ span = 8.5 m

P652 enter tag value offset correction = factory

P800 enter tag value blanking = factory

P820 enter ‘1’ algorithm = factory

P830 enter ‘4’ TVT type = factory

Run:

Press run to start normal operation. Press

= dielectric rod,

standard length

.

Application Example: Still Pipe

An alternate to the waveguide antenna, this option is also used for products

with an ε

100 mm (4”) diameter

or less than 3 or if extremely turbulent or vortex conditions exist.

r

vent hole

Note: For ε

< 3, the lower 40 cm of vessel level may not be measurable.

r

Operation

Page 50 IQ Radar 160/160 Ex PL-550

Page 51

This mounting arrangement can also be used to provide optimum signal

conditions on foaming materials.

Suitable pipe diameters are 50 mm (2”) to 250 mm (10”).

Note: The measurement range is reduced to 13 m (43’) for a 50 mm (2”)

still pipe or 14.5 m (47’) for an 80 mm (3”) still pipe.

Reset:

P999 master reset

Program:

P001 enter ‘1’ mode of measurement = level

P002 enter ‘1’ material = liquid

P003 enter ‘2’ measurement response = 1m/min.

P004 enter ‘240’ antenna

= dielectric rod,

standard length

P005 enter ‘1’ units = metres

P006 enter ‘5’ empty distance = 9.6 m

P007 enter ‘4.5’ span = 8.5 m

P655 enter ‘0.955 propagation factor = 100 mm (4”) pipe

P820 enter ‘6’ algorithm = first echo

P830 enter ‘4’ TVT type = factory

Run:

Press run to start normal operation. Press

.

Pipe P655 Value

50 mm (2”) 0.827

80 mm (3”) 0.915

100 mm (4”) 0.955

150 mm (6”) 0.980

200 mm (8”) 0.990

Note: See the P655 table on page 58 for other pipe diameters.

Operation

PL-550 IQ Radar 160/160 Ex Page 51

Page 52

Operation

Page 52 IQ Radar 160/160 Ex PL-550

Page 53

Parameter Descriptions

P000 Lock

Locks out the ability to change parameter values P001 through P999. The

program mode is still active, but restricted to viewing only. The lock is enabled

if P000 value is other than 1954.

Entry:

1954 = unlocked

= locked

1954

P001 Operation

Determines the mode of measurement.

Entry:

1 = level; material level referenced to empty distance (P006)

2 = space; space to material level referenced from (P007) span

3 = distance; distance to target referenced from the flange face

Parameter Descriptions

Level

(P001 = 1)

Space

(P001 = 2)

Distance

(P001 = 3)

P002 Material

Optimizes measurement reliability for target type.

Entry:

1 = liquids, slurries

P003 Measurement Response

Collectively sets a number of operating parameters that determine the

maximum rate of change in target range that the reading and mA output can

keep up to.

If IQ Radar 160/160 Ex cannot keep up with the rate of level change, select a

faster rate. If the reading bounces around an average value, select a slower

rate. In general, reliability is traded for speed. Noisy applications or those with

PL-550 IQ Radar 160/160 Ex Page 53

Page 54

agitators tend to be more manageable at slower response rates, as these

make use of filtering, echo verification and longer fail-safe delay.

Note:

Select P003 for a measurement response just faster than the greater of the

maximum filling or emptying rate.

echo verification:

Parameter Descriptions

filter:

fail-safe timer:

Entry:

measurement response echo

1 = 0.1 m/min slow on on 100

2 = 1 m/min • on on 10

3 = 10 m/min • on on 1

4 = 102 m/min • off on 0.1

5 = 1020 m/min fast off off 0

discriminates between agitator blades in motion or

spurious noise, and the target surface (true echo).

averages successive measurements to filter out false

echoes.

establishes the period from the time a loss of echo starts

until the fail-safe default (P071) is effected. The P003

preset timer value can be overridden by P070.

filter f-s timer

verification

(P070)

P004 Antenna

Identifies antenna configuration.

Entry:

240 = factory

241 = rod + 50 mm extension

242 = rod + 100 mm extension

243 = rod + 150 mm extension (50 + 100 mm)

Notes:

• Setting this parameter automatically configures the offset correction,

P652.

• Horn antennas and waveguide/horn combinations will come from the

factory with P652 pre-set and P004 set to 240.

Page 54 IQ Radar 160/160 Ex PL-550

Page 55

P005 Units

Determines the units for programming and measurement.

Entry:

1 = metres

2 = centimetres

3 = millimetres

4 = feet

5 = inches

P006 Empty

Distance from flange face to empty level or

maximum target range.

P007 Span

Distance from empty (P006) to full/100% level

or minimum target range.

Parameter Descriptions

P050 Tank Shape

This parameter, in conjunction with parameters P051, P052 and P053, enable

the IQ 160/160 Ex to show readings based on reservoir volume (rather than

level).

Enter the Tank Shape value that matches the monitored vessel or reservoir.

When Operation is "level" (P001 = 1), liquid (material) volume is calculated.

run

In the

(P051) on page 56. When percent is selected the displayed Reading is the

calculated volume as a percentage of Max Volume.

Entry:

0 = disabled (Factory)

mode, Readings are displayed in volumetric units, see Max Volume

1 = flat bottom

2 = conical or pyramidal

bottom

PL-550 IQ Radar 160/160 Ex Page 55

Page 56

3 = parabolic bottom

Parameter Descriptions

4 = spherical bottom

5 = angled bottom

6 = flat ends

7 = parabolic ends

8 = sphere

Note:

Tank dimensions ‘A’ and ‘L’ are entered via parameters P052 and P053

respectively.

P051 Max Volume

For Readings in volumetric units (rather than percent), enter the vessel

volume between Empty (P006) and Span (P007).

The units of measurement for this reading are non-dimensional. The volume

is calculated from the empty position to the maximum position and is scaled

according to the Tank Shape (P050) value. This enables the use of any

volume units required.

Example

1. If max. volume = 3650 m

2. If max. volume = 267500 gallons, enter 267.5 (1000's of gallons).

Enter the volume of the tank at full (Factory = 1)

3

, enter 3650.

Page 56 IQ Radar 160/160 Ex PL-550

Page 57

P052 Tank Dimension ‘A’

This is dimension ‘A’ as used in the tank shape parameter (P050) on page 55.

Enter the height of the tank bottom if P050 = 2,3,4, or 5, or the length of one

end section of the tank if P050 = 7.

Enter the dimension in units (P005)

P053 Tank Dimension ‘L’

This is dimension ‘L’ as used in the tank shape parameter (P050) on page 55.

Enter the tank length (excluding both end sections) if P050 = 7.

Enter the dimension in units (P005)

P070 Fail-Safe Timer

The amount of time delay, in minutes, before going into fail-safe mode.

Parameter Descriptions

P071 Fail-Safe Material Level

Selects the default measurement in the event that the fail-safe timer expires.

Entry:

1 = high; maximum span value

2 = low; minimum span value

3 = hold; hold current value

P200 mA Range

Enables the mA output function by selecting the range and relationship to

span.

Entry:

1 = 0 to 20 mA

2 = 4 to 20 mA

3 = 20 to 0 mA

4 = 20 to 4 mA

P341 Run Time

View the accumulated number of days the IQ Radar 160/160 Ex has been

operating.

PL-550 IQ Radar 160/160 Ex Page 57

Page 58

P652 Offset Correction

An offset value can be applied to the reading as a correction to the

measurement.

Note:

This parameter is automatically set when you enter parameter P004. In

addition, this parameter may have been factory set to a specific value to

accommodate options such as horn and waveguide antenna systems. A

Parameter Descriptions

tag on the instrument will specify the P652 value when these options have

been supplied.

Values:

-999 to 9999

Factory = 0

P655 Propagation Factor

The propagation factor (p.f.) is used to compensate for the change in the

microwave velocity, as compared with propagation in free space, when

propagation is within a still pipe (metal).

pipe size (i.d.) Propagation Factor

50 mm (2”) 0.827

80 mm (3”) 0.915

100 mm (4”) 0.955

150 mm (6”) 0.980

200 mm (8”) 0.990

Consult the factory for other sizes and propagation factor numbers.

Note: For waveguide antennas used as still pipes, this value is provided

on the product tag.

The propagation factor is constant for a

given pipe diameter, or can be determined

by comparing the radar distance reading

to the actual process material distance

(measured from the face of the IQ 160

flange).

p.f. =

actual distance

IQ 160 distance

e.g. p.f. =

10.42 m

= 0.827

12.6 m

Enter the propagation factor Factory = 1

Page 58 IQ Radar 160/160 Ex PL-550

Page 59

P800 Near Blanking

Sets the amount of blanking as measured from the flange face and extending

into the measurement range. See Blanking on page 42.

Enter value in units of P005.

Factory = 0.4m

Note: This parameter may be set at the factory, if so the appropriate

values appears on the product tag.

P801 Range Extension

Sets the amount of range extension as measured from the empty distance

(P006) and extending into the far end blanking. See Blanking on page 42.

Enter as a % of P006, the distance below empty not blanked.

Factory = 5%

On tanks with conical or parabolic bottoms, it may be helpful to increase this

parameter to ensure that an empty tank reads empty.

Parameter Descriptions

P804 Confidence Threshold

The minimum echo confidence in dB that the echo must meet in order to

prevent a loss of echo condition and the expiration of the fail-safe timer

(P070).

Enter value in the range of 0 to 99.

Factory = 5

P805 Echo Confidence

A measure of echo reliability.

P806 Echo Strength

The absolute strength of the selected echo, in dB above 1 µV rms.

P820 Algorithm

Selects the algorithm to be applied to the echo profile in order to extract the

true echo.

Select 1 for most applications and all mounting locations except the centre of

the vessel. Select 6 for the centre of the vessel mounting location and for still

pipes and waveguide antennas used as still pipes.

PL-550 IQ Radar 160/160 Ex Page 59

Page 60

Entry:

1 = best of first and largest (factory

2 = reserved

3 = largest echo

4 = reserved

5 = reserved

6 = first echo

P825 Echo Marker Trigger

Parameter Descriptions

Authorized factory personnel only.

P830 TVT Type

Selects the TVT profile applied to the echo profile.

Entry:

1 = reserved

2 = reserved

3 = reserved

4 = Smooth 2 (factory – contact Milltronics for assistance with other selections)

5 = reserved

6 = reserved

P900 Software Revision

Displays the EPROM software revision level.

P901 Memory

Tests the memory. Test is initiated by scrolling to the parameter or repeated

by pressing

Display:

PASS = normal

FAIL = consult Milltronics

.

P911 mA Output Value

Displays the value from the previous measurement. A test value can be

entered and the displayed value is transmitted to the output. Upon returning to

the run mode, the parameter assumes the actual mA output level.

P920 Reading Measurement

Displays the reading measurement that the unit is programmed for in run

mode (P001, operation).

Page 60 IQ Radar 160/160 Ex PL-550

Page 61

P921 Material Measurement

Displays the reading measurement as though the unit were programmed to

read level (P001 = 1).

P922 Space Measurement

Displays the reading measurement as though the unit were programmed to

read space (P001 = 2).

P923 Distance Measurement

Displays the reading measurement as though the unit were programmed to

read distance (P001 = 3)

P999 Master Reset

Resets parameters to their factory setting.

Parameter Descriptions

Press

initiate reset

reset complete

PL-550 IQ Radar 160/160 Ex Page 61

Page 62

Parameter Descriptions

Page 62 IQ Radar 160/160 Ex PL-550

Page 63

Troubleshooting

The following is a list of operating symptoms, their probable causes, and the

actions needed to resolve them.

Symptom

display reads

Reading does

not change, but

the level does

Measurement is

consistently off

by a constant

amount

Screen blank

Reading erratic

Cause

level or target is out of

range

material build-up on

antenna

location or aiming:

• poor installation

• flange not level

• standpipe not vertical

antenna malfunction:

• temperature too high

• physical damage

• excessive foam

IQ Radar 160/160 Ex

processing wrong echo,

i.e. vessel wall, or

structural member

P006 not correct

P652 not correct

power error

echo confidence weak

liquid surface vortexed

material filling

Action

• check specifications

• check parameters

• clean

• re-locate IQ Radar

160/160 Ex

• check to ensure stand

pipe is vertical

• inspect

• use foam deflector or

stilling well

• relocate

• use a defoamer

• re-locate IQ Radar

160/160 Ex

• check standpipe for

internal burrs or welds

• increase blanking, P800

• Check distance from

Flange face to zero level

(P006)

• Check offset value (P652)

or device tag

• check nameplate rating

against voltage supply

• check power wiring or

source

• refer to P805

• use foam deflector or

stilling well

• decrease measurement

response P003

• increase confidence

threshold P804

• re-locate IQ Radar

160/160 Ex

Troubleshooting

Reading

response slow

PL-550 IQ Radar 160/160 Ex Page 63

P003 setting

• increase response if

possible

Page 64

Symptom

Reads correctly

but occasionally

reads high when

vessel is not full

Level reading

lower than

material level

Troubleshooting

Cause

• detecting close range

echo

• build up near top of tank

or nozzle

• water or other high ε

r

material in antenna

threads

• wrong antenna choice

for application

• stand pipe problem

• material is within near

blanking zone

• tank near empty and low

ε

material

r

• multiple echoes

processed

• Standpipe too narrow

for length

• Internal seam in

standpipe

Action

• increase blanking

• increase confidence

threshold P804

• rod extensions may be

required

• See Application Example:

Still Pipe on page 50

• decrease blanking P800

(min. 0.4 m)

• raise IQ160/160 Ex

• decrease range extension

• install still pipe deflector

(contact Milltronics)

• set P820 to ‘6’

• See Rod Extension

Requirements on page 23

• Inspect and remove seam

Maintenance

The IQ Radar 160/160 Ex requires no maintenance or cleaning; however, a

program of periodic checks is advised.

Page 64 IQ Radar 160/160 Ex PL-550

Page 65

Appendix I

Alphabetical Parameter List

Parameter Name Parameter Number Page Number

Algorithm 820 59

Antenna 004 54

Confidence Threshold 804 59

Distance Measurement 923 61

Echo Confidence 805 59

Echo Marker Trigger 825 60

Echo Strength 806 59

Empty 006 55

Fail-Safe Timer 070 57

Lock 000 53

Long Shot Number* 841 --

mA Output Value 911 60

mA Range 200 57

Master Reset 999 61

Material 002 53

Material Measurement 921 61

Max Volume 051 56

Measurement Response 003 53

Memory 901 60

Near Blanking 800 59

Offset Correction 652 58

Operation 001 53

Propagation Factor 655 58

Range Extension 801 59

Reading Measurement 920 60

Run Time 341 57

Software Revision 900 60

Space Measurement 922 61

Span 007 55

Tank Dimension ‘A’ 052 57

Tank Dimension ‘L’ 053 57

Tank Shape 050 55

TVT Type 830 60

Units 005 55

Appendix I

*

accessible only by service personnel.

PL-550 IQ Radar 160/160 Ex Page 65

Page 66

Appendix I

Page 66 IQ Radar 160/160 Ex PL-550

Page 67

Appendix II

Programming Chart

Number Parameter Name Value

001 Operation

002 Material

003 Measurement Response

004 Antenna

005 Units

006 Empty

007 Span

050 Tank Shape

051 Max Volume

052 Tank Dimension ‘A’

053 Tank Dimension ‘L’

070 Fail-Safe Timer

200 mA Range

341 Run Time

652 Offset Correction

655 Propagation Factor

800 Near Blanking

801 Range Extension

804 Confidence Threshold

805 Echo Confidence

806 Echo Strength

820 Algorithm

825 Echo Marker Trigger

830 TVT Type

841 Long Shot Number*

900 Software Revision

901 Memory

Appendix II

911 mA Output Value

920 Reading Measurement

921 Material Measurement

922 Space Measurement

923 Distance Measurement

PL-550 IQ Radar 160/160 Ex Page 67

Page 68

Appendix II

Page 68 IQ Radar 160/160 Ex PL-550

Page 69

Appendix III

Temperature Derating

e.g. if the IQ 160/160 Ex is operating in an

ambient temperature of 60 °C, then

the maximum process temperature

allowable at the flange is 100 °C

ambient temperature in degrees Celsius at enclosure

process temperature in degrees Celsius at IQ 160/160 Ex flange

Note: UHMW-PE is limited to a maximum continuous service temperature

of 80°C / 176°F

Appendix III

PL-550 IQ Radar 160/160 Ex Page 69

Page 70

Rod Antenna ANSI Hole Pattern, 150#

pressure (bar, gauge)

temperature (•C)

9, 10

2”

4”

3”

6”

Rod Antenna DN Hole Pattern, PN16

pressure (bar, gauge)

temperature (•C)

50mm

100mm

80mm

150mm

9, 10

9

Appendix III

UHMW-PE antennas are rated to a maximum of 80°C (176°F) of continuous duty.

10

Customer to provide adequate bolting to retain vessel pressure and provide sufficient

sealing.

Page 70 IQ Radar 160/160 Ex PL-550

Page 71

Rod Antenna Threaded Connection

pressure (bar, gauge)

temperature (•C)

1½” and 2”

Rod Antenna Sanitary Connection

pressure (bar, gauge)

temperature (•C)

2”

4”

3”

11

11

UHMW-PE antennas are rated to a maximum of 80°C (176°F) of continuous duty,

however, they can be used for periods up to 3 hours at temperatures up to 120°C

(248°F) at 1 bar pressure.

PL-550 IQ Radar 160/160 Ex Page 71

Appendix III

Page 72

Horn Antenna or Wave Guide – ANSI Hole

Pattern, 150#

12

pressure (bar, gauge)

temperature (•C)

3”

6”

4”

8”

Horn Antenna or Wave Guide DN Hole Pattern,

PN16

12

pressure (bar, gauge)

temperature (•C)

80mm

150mm

100mm

200mm

Appendix III

12

Customer to provide adequate bolting and flat-faced gasket to retain vessel pressure

and provide sufficient sealing.

Page 72 IQ Radar 160/160 Ex PL-550

Page 73

Horn Antenna Sanitary Connection

45.0

40.0

35.0

30.0

25.0

20.0

pressure (bar, gauge)

-50 100 150 200

15.0

10.0

5.0

0

50

temperature (•C)

4” PTFE

PL-550 IQ Radar 160/160 Ex Page 73

Appendix III

Page 74

Appendix III

Page 74 IQ Radar 160/160 Ex PL-550

Page 75

Appendix IV

BZT Approval – English

Regulierungsbehörde für Telekommunikation und Post

Telecommunications

Decree 39/1998

General Licence No. 826 Intended for common use when employing transmission and

reception plants of MILLTRONICS LIMITED company, Worcester, England.

1. Based on § 47 par. 1 and 5 of the Telecommunications Law (TKG) from July 25

1120, the frequency 5.8 GHz is assigned as General Assignment for common use when employing

transmission and reception radio plants distributed by MILLTRONICS LIMITED company,

Worcester, England, and characterized by the designation “IQ Radar”. These radio plants are used

for level measurement in chemical Industry plants with maximum radiating capacity of 30uW and a

bandwidth of up to 1.3GHz. This General Assignment does not exclude further assignments of the

same frequency for similar or equal purposes when using other devices.

2. The radio plants must be identified as follows: “Bundesadler”(Federal Eagle Symbol), assignment

number “BZT G750826K”, company name “MILLTRONICS LIMITED, Worcester, England” and

identification “IQ Radar”.

3. The use of this frequency must not Interfere with other telecommunication or radio plants.

4. This General Assignment does not provide any protection for users of such radio plants against

frequency interferences by users operating in the same frequency range.

th

, 1996 (BGBI. I.S.

Appendix IV

Additional Information for the distributor and users of radio plants sold under this General

Assignment

1. There is no need for particular frequency assignment or for conformity rating as ruled by §61 of the

Telecomunications Law. If the radio plants sold for this frequency use and for this purpose comply

electrically and mechanically with a design technically proofed by an accredited testing lab and if

they are identified as described under #2 of the above mentioned regulations.

2. The identification label must be applied to the radio devices’ enclosure, either on a nameplate or in

an appropriate location on the enclosure. When stamped or engraved, it must be visible. The

identification must be time and wear resistant and must be fixed in such a way to the enclosure, in

order that any attempted removal of the latter will cause it to tear. It must always be visible from the

outside.

3. The distributing company has to add a complete reprint of this General Assignment to each device

for sale under the above mentioned approval.

4. The General Assignment allows for interconnection of the radio plants with other

telecommunication plants, provided there is a need to do so. In this case, the corresponding

technical requirements and legal requirements for telecommunication must be respected. If the

telecommunication plants to be interconnected with the radio plants are linked to public

telecommunication networks, the interconnection is subject to a preceding written authorization by

the Telecommunications and Mail Regulation Service. For further information, please contact the

responsible offices of this Service.

5. The above mentioned transmission and reception radio plants must comply with the EMVG

directives, and consequently include CE identification.

6. The General Assignment does not deal with the security of persons in electromagnetic fields, nor

with the electrical or mechanical security of radio plants, including antenna plants. Those are

subject to special regulations and directives.

7. The General Assignment only applies to frequency use in its legal aspect for telecommunication. It

does not involve any other directives, even if they concern legal aspects for telecommunication,

and third-party rights, particularly additional permissions and approvals, if required, with regards to

construction and private jurisdiction, for example.

PL-550 IQ Radar 160/160 Ex Page 75

Gazette 7/98

Page 76

BZT Approval – German Original Text

Regulierungsbehörde für Telekommunikation und Post

Fernmeldewesen

Appendix IV

Vfg 39/1998

Allgemeinzuteilung Nr. 826 für die Benutzung durch die Allgemeinheit unter Verwendung von

Sende- und Empfangsfunkanlange der Firma MILLTRONICS LIMITED, Worcester, England.

1. Hiermit wird auf Grund § 47 Abs. 1 und 5 des Telekommunikationsgesetzes (TKG) vom 25. Juli 1996

(BGBI. I S. 1120) die Frequenz 5,8 GHz als Allgemeinzuteilung für die Benutzung durch die

Allgemeinheit unter Verwendung von Sende- und Empfangsfunkanlagen der Vertriebsfirma

MILLTRONICS LIMITED, Worcester, England, mit der Typenbezeichnung “IQ Radar” zugeteilt,

Diese Funkanlagen dienen der Füllstandsmessung in Anlagen der chemischen Industrie mit

einer Strahlungsleistung von maximal 30 uW und einer belegten Bandbreite von bis zu 1,3 GHz.

Diese Allgemeinzuteilung schließt weitere Zuteilungen der gleichen Frequenz zu ähnlichen oder

gleichen Zwecken unter Verwendung anderer Geräte nicht aus.

2. Die Funkanlagen sind wie folgt zu kennzeichnen: Bundesadler, Zulassungsnummer “BZT

G750826K”, sowie der Name der Vertriebsfirma MILLTRONICS LIMITED, Worcester, England und

der Typenbezeichnung “

3. Im Rahmen dieser Frequenznutzung dürfen andere Telekommunikationsanlagen sowie andere

Funkanlagen nicht gestört werden.

4. Im Rahmen dieser Allgemeinzuteilung besteht für die Benutzer solcher Funkanlagen keinerlei

Schutz vor frequenzmäßigen Beeinträchtigungen durch andere Frequenznutzer im gleichen

Frequenzbereich.

Zusatzhinweise für die Vertriebsfirma und die Benutzer einer unter dieser Allgemeinzeteilung

in den Verkehr gebrachten Funkanlage

1. Es bedarf keiner weiteren Frequenzzuteilung und keiner Konformitätsbewertung im Sinne des § 61

TKG im einzelnen, wenn die für diese Frequenznutzung und diesen Verwendungszweck in Verkehr

gebrachten Funkanlagen mit dem bei einem akkreditierten Prüflabor technisch geprüften

Baumuster elektrisch und mechanisch übereinstimmen und wie unter Ziffer 2 der o. a.

Bestimmungen beschrieben, gekennzeichnet sind.

2. Die Kennzeichnung ist am Gehäuse der Funkanlagen, entweder auf einem Typenschild oder an

örtllich zusammenhängender Stelle, wenn die Form einer Prägung oder Gravur gewählt wird, an

gut sichtbarer Stelle anzubringen. Die Kennzeichnung muß dauerhaft und abnutzungssicher

ausgeführt und so mit dem Gehäuse verbunden sein, daß sie beim Entfernen zerstört wird.

Sie muß von außen jederzeit sichtbar sein.

3. Die Vertriebsfirma dieser Funkanlagen ist verpflichtet, jedem unter dem o. g. Zulassungszeichen in

den Verkehr zu bringenden Funkgerät einen vollständigen Nachdruck dieser Allgemeinzuteilung

beizufügen.

4. Auf Grund dieser allgemeinen Frequenzzuteilung düfen diese Funkanlagen mit anderen

Telekommunikationsanlagen zusammengeschaltet werden, soweit dafür ein Bedarf besteht und die

jeweiligen technischen und telekommunikationsrechtlichen Anforderungen erfüllt werden.

Sofern die Telekommunikationsanlangen, mit denen diese Funkanlagen zusammenschaltet werden