Document History

______________________________________________________________________________

Document History

Author Reviewer

Initials Date Initials Date

PG 04 Jan 06 - - UK0157.04 Original.

PG 16 Feb 06 - - UK0157.05 Update

PG 05 Apr 06 - - UK0157.07 Removal of Walkie Functionality

PG 24 Apr 06 - - UK0157.08 Added proportional direction braking

Version Reason for Modification

MillipaK PMAC Controller Manual Page 2 26/04/06

Contents

______________________________________________________________________________

CONTENTS

Introduction.......................................................................................................................................5

Safety ................................................................................................................................................6

Installation.........................................................................................................................................7

MOUNTING......................................................................................................................................................................7

MILLIPAK PMAC POWER WIRING.......................................................................... ............................ ...........................8

MILLIPAK LIGHT WIRING EXAMPLE.............................................................................................................................. .9

Calibrator ........................................................................................................................................11

DRIVE HOURS COUNTER...............................................................................................................................................12

CALIBRATOR SECURITY LEVELS ..................................................................................................................................13

NAVIGATION .................................................................................................................................................................14

ADJUSTMENTS............................................................................................................ ...................................................15

STATUS AND TEST INFORMATION.................................... .................................................................................. ...........16

Configuration..................................................................................................................................17

SYSTEM CONFIGURATION......................................... .................................................................................. ..................17

System Voltage....................................................... ...................................................... ............................................18

System I/O Configuration........................................................................................................................................19

Contactor chopping............................ ............................................................................................................ .........22

Accelerator Full /Zero Setting ............................ .. ... .. .. ..... .. ... .. ..... .. .. ... .. ..... .. .. ... ..... .. .. ... .... ... .. ................................23

Motor Poles ........................................ ... .. .. ..... .. ... .... ... .. ... .... ... .. .. ..... .. ... .. ..... .. .. ..... .. ... .. ............................................24

Maximum Motor RPM.................................... ..... .. ........................................................... .......................................25

Phase Adjustment ........................................................................................ ............................................................26

PERFORMANCE............................................................................... ............................ ...................................................27

Control Mode............................... ... .... ... .. .. ..... ... .. .. ..... .. ... .. ..... .. .. ... .... ... .. .. ..... .. ... .. ..... .. .. ... .......................................27

Speed Control PI Gains................................ .. ... .. ..... .. .. ... .... ... .. .. ... .... ... .. .. ..... ... .. .. ..... .. .. ... .. .....................................28

Acceleration Delay..................................................................................................................................................30

Deceleration Delay....................................................... ...........................................................................................30

Direction Change Deceleration Delay................................................................................... ................................30

Neutral Deceleration Delay..................................................... ...............................................................................30

Regen Braking.................................. .. ... .... ... .. .. ..... ... .. .. ..... .. ... .. ..... .. .. ... .... ... .. .. ..... .. ... .. ..... ............................ ...........31

Braking Levels.............................................. .. ..... .. ... .. ..... .. .. ... .... ... .. .. ..... .. ... .... ... .. .. ..... ... .........................................31

Footbraking.................................................... ................................................................................ .........................32

Creep Speed........................................................... ............................ ............................. .........................................34

Maximum Speed.............................. .... ... .. .. ..... .. ... .. ..... .. ... .. ..... .. .. ..... .. ... .. ..... .. .. ... .... ... .. .. ..... .....................................35

Accelerator Characteristics ..................................... .... ..... ..... .... ....... ..... ..... .... ..... ....... ..... ..... ..................................36

Features...........................................................................................................................................37

STANDARD CONTROLLER FEATURES................................................................................ ............................................37

Power Steer.............................. .. .. ..... .. ... .. ..... .. .. ... ..... .. .. ..... .. ... .. ..... .. .. ... .... ... .. .. ..... .. ... ..............................................38

Seat Switch.................................................................... ...........................................................................................39

Handbrake Switch ............................................ ... .. ..... .. ... .. ..... .. .. ... .... ... .. .. ... .... ... .. .. ..... ... .. .. .....................................40

Cutback speeds..................................................................................................... ............................ .......................41

Reverse Speed............................................................. .................................................................................. ...........42

Pump Contactor.......................................................................................................................................................43

External LED Drive................................................................................ .................................................................44

Traction Motor Over-Temperature Input....................................................... ... .. ..... .. ... .... ... .. .. ..... .. .......................45

Drive Hours Meter .............................................. .... ... .. ... .... ... .. .. ..... .. ... .. ..... .. .. ... .... ... .. .. ..... ... ..................................46

Personality Checksum........................................... ..... .. ... .. ..... .. .. ... .. ..... .. .. ... .... ... .. .. ..... ... .. .. .....................................47

Line Contactor Drop out.........................................................................................................................................48

MillipaK PMAC Controller Manual Page 3 26/04/06

Contents

______________________________________________________________________________

Alarm Buzzer ...................................... ... .. .. ..... ... .. ..... .. .. ... .... ... .. .. ..... .. ... .. ..... .. .. ..... .. ... .. ............................................49

Electric Outboard Drive and Low Battery Warning ..............................................................................................50

Temporary Current Boost................................ .......................................................................................................51

SAFETY FEATURES ........................................................................................................................................................52

Start Up Sequence...................................................................................................................................................52

FS1 Recycle .............................................................................................. ...............................................................53

SRO (Static return to off) ..................................................................... ...................................................................54

Anti-Rollback................................................................ ................................................................................ ...........55

Anti-Rolloff ............................................ ...................................................... ................................................... .........56

Idle Fault ...................................................................... ......................................................... ..................................57

Motor Stall Protection...................................... ... .. ..... .. ... .. ..... .. .. ... .. ..... .. .. ... .. ..... .. .. ... .. ..... .. .....................................58

Fail-safe..................................................... ..............................................................................................................59

Controller Protection Features........................................................................................................60

TEMPERATURE MONITORING............................................. ............................ ...............................................................60

Maximum Temperature Logging....................................................................................................................... ......60

SAFE OPERATING AREA (SOA) ................................................................... ............................ .....................................62

UNDER-VOLTAGE AND OVER-VOLTAGE PROTECTION........................... ...................................................... ..................63

Commissioning Checklist...............................................................................................................66

PERSONALITY RECORD .................................................................................................................................... .............67

Fault Finding...................................................................................................................................69

FAULT CLEARANCE................................................................................................................ .......................................70

FAULT REPORTING FORM ..................................................................................... ........................................................71

SOFTWARE VERSION AND SERIAL NUMBER INDICATION .................................................................. ...........................72

Specifications..................................................................................................................................73

POWER CONFIGURATIONS.............................................................................................................................................73

EMC STANDARDS .................................................. .......................................................................................................73

SOCKET B PROTECTION................................. .................................................................................. ..............................73

CONTACTOR DRIVE RATINGS.............................................................................. ............................ ..............................73

ANALOGUE INPUT IMPEDANCE.................................................... ............................ .....................................................73

DIGITAL INPUT IMPEDANCE................................................................................ ............................ ..............................73

EMC Guidelines..............................................................................................................................74

MillipaK PMAC Controller Manual Page 4 26/04/06

Introduction

______________________________________________________________________________

Introduction

The MillipaK PMAC (Permanent Magnet AC) range of controllers provides a new range of power

frames for 24V-36V, 250A and 48V, 200A in small highly efficient packages. This is achieved

using a Sevcon patented power switching scheme and radical new construction techniques, which

enable large powers to be incorporated into very small packages.

The MillipaK provides a completely sealed (IP66) unit containing both power and logic circuitry,

as well as all suppression components.

MillipaK supports Sevcon’s existing MOS90 calibrator for adjustment of vehicle performance

characteristics.

Controllers are FLASH microprocessor based enabling field re-programming for new features and

have numerous user set-up options. The MillipaK uses high frequency (silent) MOSFET power

switching technology, to control a 3-phase power frame bridge. Armature current is monitored.

Motor feedback is necessary in the form of position sensors. Controllers have been designed to

satisfy the requirements of the relevant UL and EC standards.

MillipaK PMAC Controller Manual Page 5 26/04/06

Safety

______________________________________________________________________________

Safety

The MillipaK controller contains a triple fail-safe system to give a high level of safety. If the

diagnostic LED is not illuminated or flashes, the safety circuit may have tripped and the motor

may not drive.

The controller must be used with a line contactor as indicated in the wiring diagrams.

As blow-out magnets are fitted to contactors (except 24V) ensure that no magnetic particles can

accumulate in the contact gaps and cause malfunction. Ensure that contactors are wired with the

correct polarity to their power terminals as indicated by the + sign on the top moulding.

The MillipaK controller may be used with suitable onboard chargers, as supplied by Sevcon.

There are several software features which are intended to prevent inadvertent or unexpected motor

movement – Accelerator power up fault and sequence checking. Some of these features cannot be

disabled and the appropriate signals must be supplied to the controller before drive will be

allowed.

MillipaK PMAC Controller Manual Page 6 26/04/06

Installation Mounting

______________________________________________________________________________

Installation

The small footprint of the MillipaK controller gives maximum flexibility to the user for mounting

options. The following section gives details of certain criteria that should be considered when

situating the controller on a vehicle.

Mounting

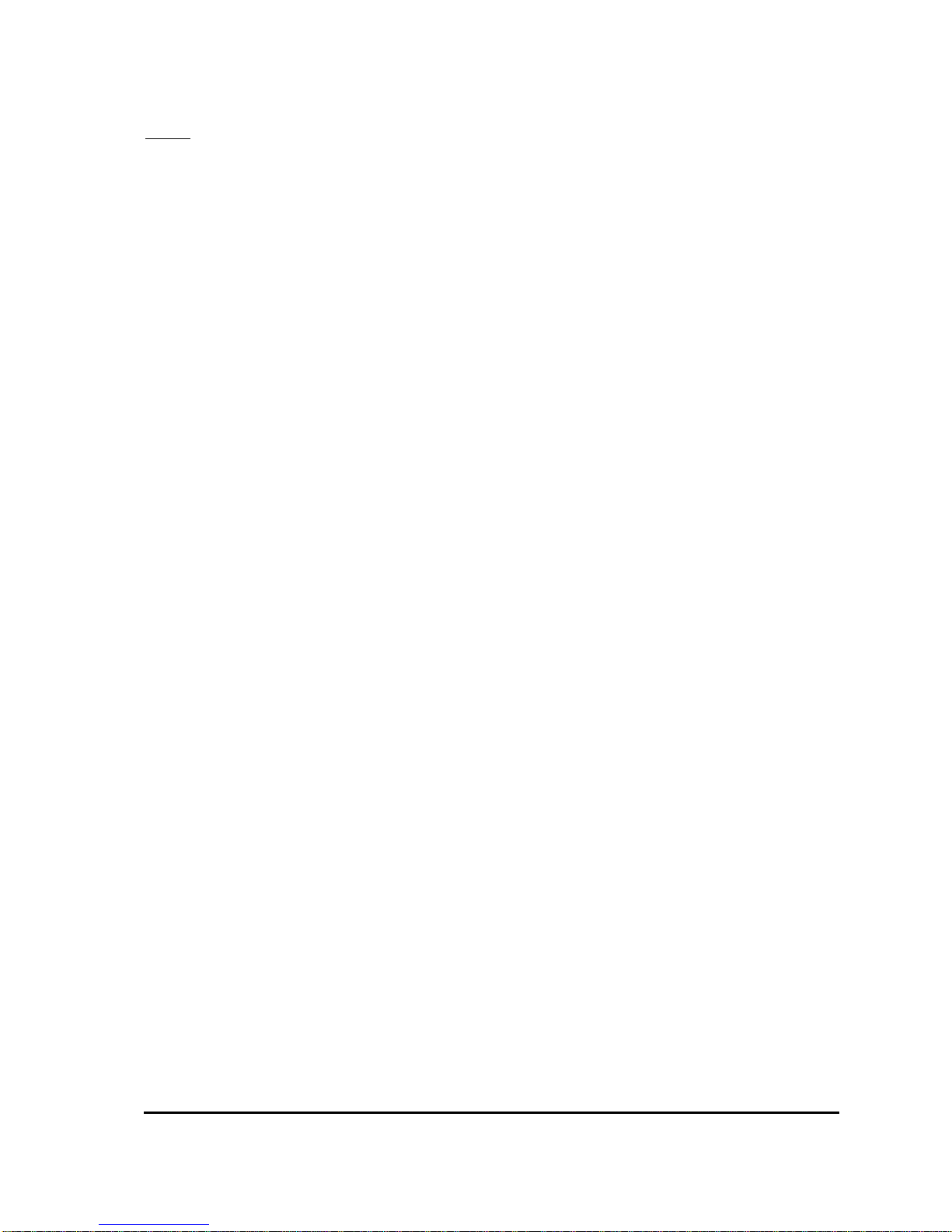

The MillipaK PMAC unit provides 4 x M6 clearance holes for mounting. The controller should be

mounted onto a metal base plate, as large as possible to provide heat-sinking. The surface finish

should be flat, clean and burr free and thermal compound should be applied to the controller base

before fitting.

Figure 1: MillipaK PMAC Dimensions

Maximum terminal torque: M8 terminals – 10NM

M6 terminals – 7NM

MillipaK PMAC Controller Manual Page 7 26/04/06

Installation Wiring/Power

______________________________________________________________________________

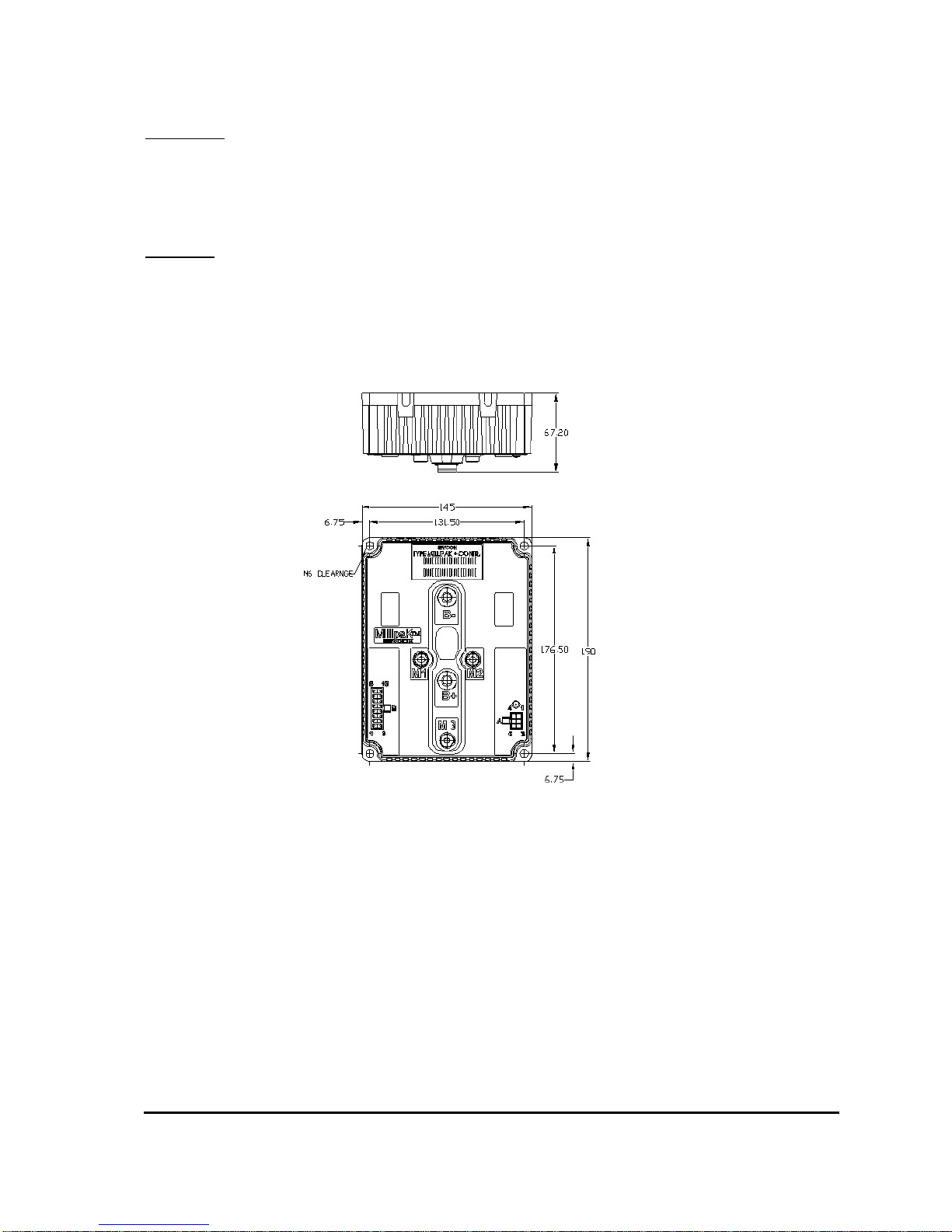

MillipaK PMAC Power Wiring

Fuse

Batte ry

Supply

Line

Contactor

B+

B-

Figure 2: MillipaK PMAC Power Wiring

BPM Motor

M1

M2

M3

MillipaK PMAC Controller Manual Page 8 26/04/06

Installation Wiring/Light

______________________________________________________________________________

MillipaK Light Wiring example

SEL

CALIBRATOR

Sevcontrol

Batte ry +ve

Fuse

Battery -ve

NOTES:

*Conta ctor Coil Suppression fitted internal ly.

* *Extra Suppr ession and Hor n Suppression inputs to be used as shown below:

Key-sw itch

Accel.

Pot.

Analog

0V

Calibrator Detect

+ 10.5V

Clock

Data

Forward (Dig 1)

Reverse (Dig 2)

Dig I/P 3

Dig I/P 4

Dig I/P 5

Dig I/P 6

Line Contactor*

Auxiliary Contactor*

Analogue Input 1

Analogue Input 2

12V Output

Extra Suppression 1**

Extra Suppression 2**

Horn Suppression**

Encoder - RPS1

Encoder - RPS2

Encoder - RPS3

Encoder - 0V

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Connec tor A

Conne ct or B

Battery +ve

Battery -ve

Figure 3: MillipaK Light Wiring

MillipaK PMAC Controller Manual Page 9 26/04/06

Extra Suppression 1 or 2

or Horn S uppression

External Contactor /

Horn

Installation Wiring/Light

______________________________________________________________________________

NOTES:

The line and auxiliary contactors are wired to B+, on the switched side of the key-switch.

Pin 12 is available for 100mA supply, typically used for (but not limited to) accelerator modules.

Pins 13,14 & 15 are general-purpose suppression connections and may be used to suppress spikes

generated by contactors opening / closing. The internal configuration is shown below:

Pin 16 is used to select FLASH memory program update mode and should normally be left

unconnected.

MillipaK PMAC Controller Manual Page 10 26/04/06

Calibrator Calibrator/General

______________________________________________________________________________

Calibrator

The Calibrator is a hand-held adjustment unit which can be used to configure and test the system.

The MillipaK is designed to work with the Calibrator currently in use with SEVCON's MOS90

system. See diagram below. The menu structure is shown in the Calibrator Map located near the

end of this manual.

i.8.8.8

+

-

SELECT

CALIBRATOR

Sevcontrol

Figure 4: MillipaK Calibrator

MillipaK PMAC Controller Manual Page 11 26/04/06

Calibrator Calibrator/ Drive Hours Counter

______________________________________________________________________________

Drive Hours Counter

When the Calibrator is first plugged into the unit after power up, the Calibrator shows the Drive

Hours Counter. Refer to the Drive Hours Counter section for more information on this function.

With no buttons pressed, the number displayed shows the number of minutes (accurate to 0.5

minutes). Pressing the '-' button displays the number of hours under 1000 and pressing the '-'

button displays the number of 1000 x hours.

For example, if the hours counter was 12, 345 hours, 13 minutes and 40 seconds, with no buttons

pressed, the display would show 13.5. Minutes are only shown to the nearest 0.5 minutes. If the '-'

button was pressed, the display would show 345 (number of hours under 1000) and if the '+'

button was pressed, the display would show 12 (number of 1000 x hours).

This is the only time that the hours counter can be viewed. Once the Select button has been

pressed to enter the normal calibrator menu structure, it is not possible to return to this point. To

view the hours counter again, you must recycle the Keyswitch.

This is also the point at which you can enter a password to enable different levels of access to

personalities. Refer to the section below on Calibrator Security Levels for more details.

MillipaK PMAC Controller Manual Page 12 26/04/06

Calibrator Calibrator/Security Levels

______________________________________________________________________________

Calibrator Security Levels

Which personalities and status items which can be viewed on the Calibrator is restricted using

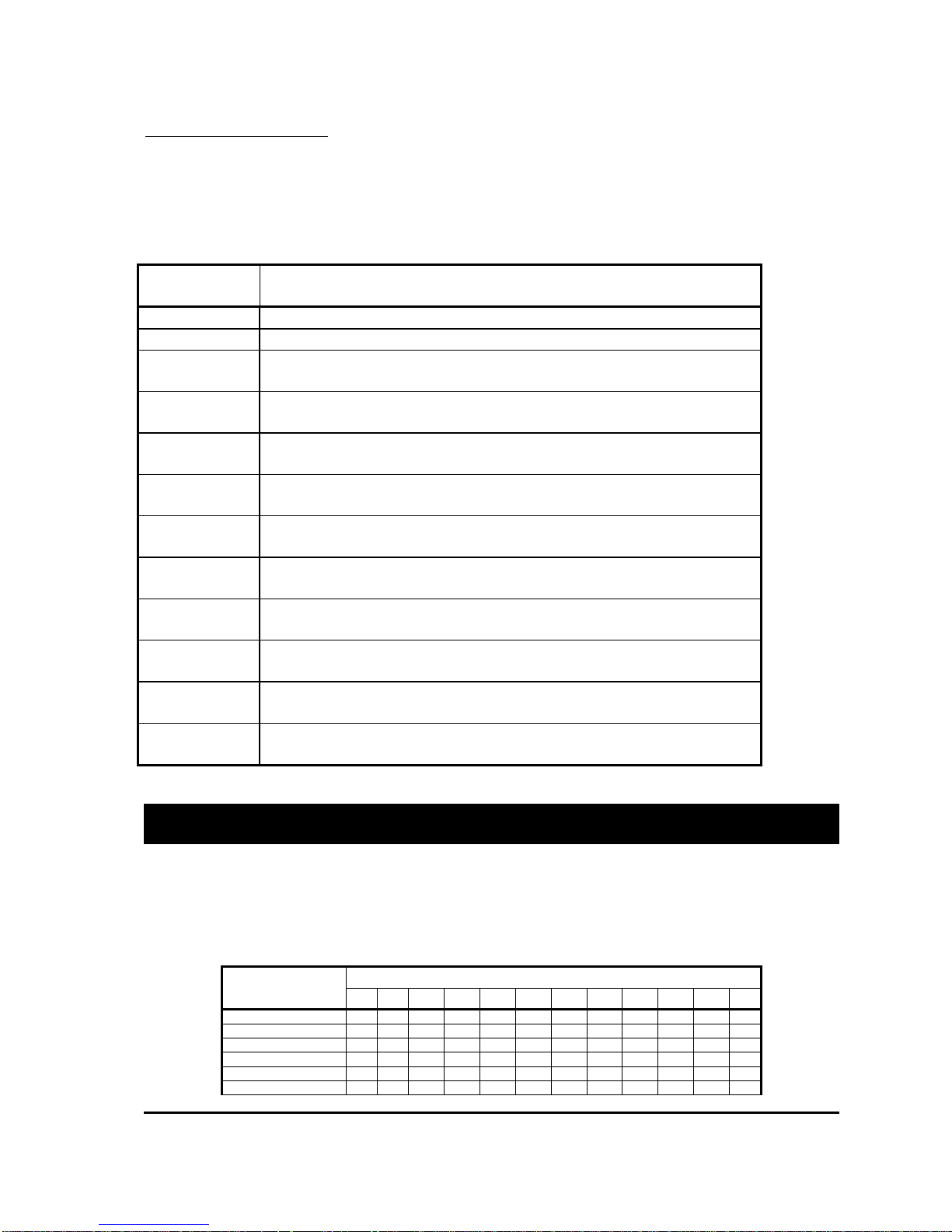

passwords. There are three levels of Calibrator access. These are shown in Table 1.

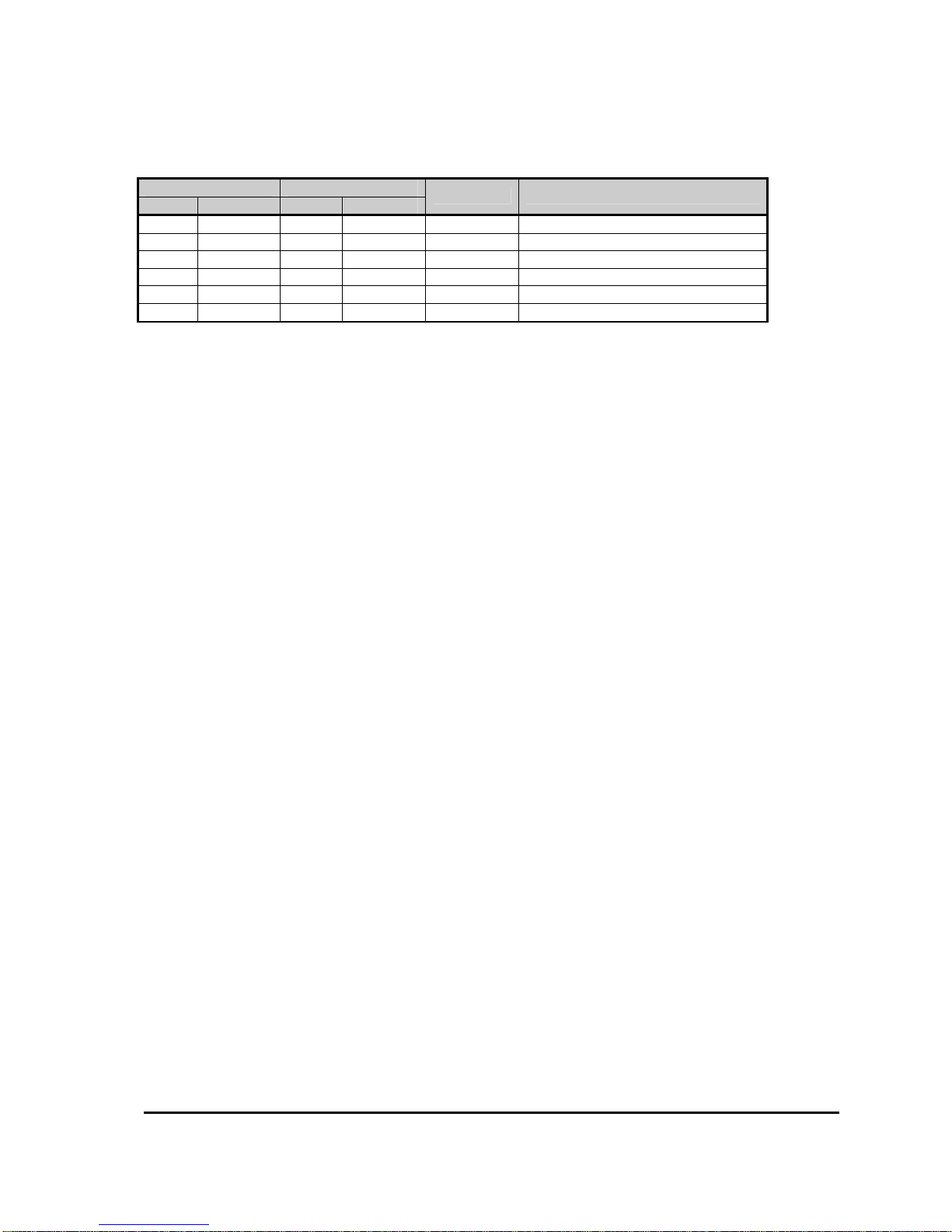

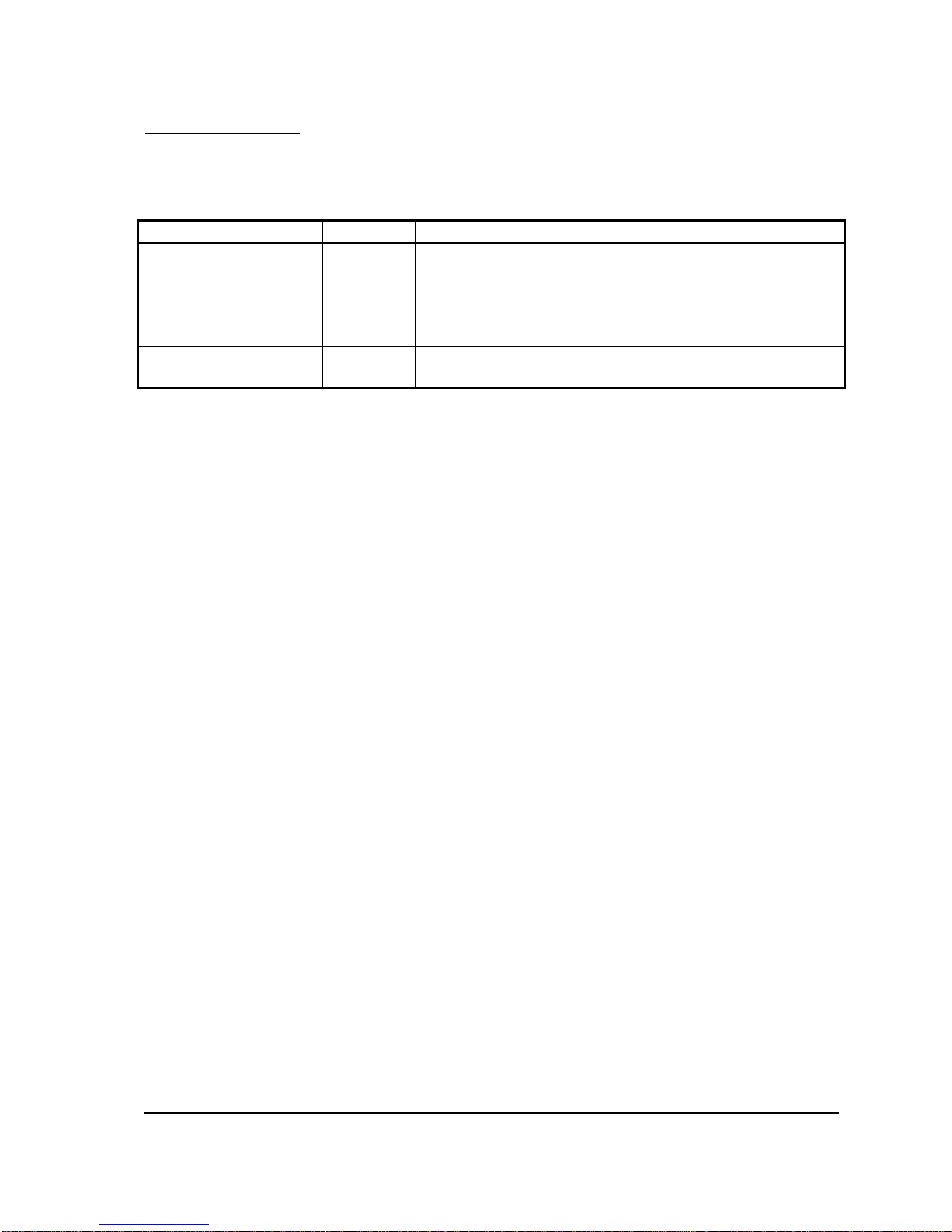

Access Level Text Password Description

Default. This level is selected when no password or an

Service Ser -

invalid password is entered. Only items shown in the

Calibrator Map with a thick solid border are displayed.

Engineering Eng 1645

All Adjust All

Contact

SEVCON

All items, except those in the Setup menu, can be

displayed.

All items are be displayed, regardless of configuration.

Table 1: Calibrator Security Levels

Note, for Service and Engineering security levels only items appropriate to the current system

configuration are displayed. For example, if the line contactor dropout feature is disabled then the

line contactor dropout delay personality will not be displayed.

The All Adjust security level allows access to all personalities, including those not required by the

current configuration. The items in the Setup menu can only be accessed at this security level.

The password can only be entered just after power up when the Traction Drive Hours Counter is

displayed. The '+' and '-' buttons are used to enter the password. The first digit is entered by

pressing the '+' button the appropriate number of times (i.e. once to enter 1). The second digit is

entered by pressing the '-' button the appropriate number of times (i.e. 6 times to enter 6). The

third digit is entered using the '+' button again and the final digit is entered using the '-' button

again. Note that when the '+' or '-' buttons are pressed, the display still changes to show hours or

1000 x hours.

When the password has been completely entered press either the '+' button or the SELECT button

to initiate verification. If the password has been entered correctly, the text shown in Table 1

appropriate to the required level will be displayed for 1s indicating the password was accepted. If

the password was incorrect or no password was entered, the system always defaults to Service

mode.

After the Security Level has been displayed, the system enters the normal menu structure shown

in the Calibrator Map. To change the password level, you need to recycle the Keyswitch.

MillipaK PMAC Controller Manual Page 13 26/04/06

Calibrator Calibrator/Navigation

______________________________________________________________________________

Navigation

The Calibrator uses all three buttons for navigating through the menu structure.

Use the SELECT button to move through the menu structure. When the SELECT button is

pressed the next menu item is displayed. The default direction is from left to right, top to bottom.

If the '+' and '-' buttons are held down together, the ID of the currently displayed menu item is

shown. For example, if the Armature Current Limit personality was selected, then the ID would

be 0.01 (menu 0, item 1). This allows the operator to locate where they are in the map.

If the '+' and '-' buttons are held down together for more than 1 second, the direction through the

menu structure is reversed. Now when the SELECT button is pressed the direction is from right to

left, bottom to top. In this mode, the LED on the Calibrator will flash. If the '+' and '-' buttons are

held down together for more than 1 second again, the direction reverts back to the first direction

and the Calibrator LED stops flashing.

The SELECT button is used to navigate through most of the menu structure, however, the Test

menu (menu 19) is slightly different. Pressing the SELECT button will take you to the first item

in the Test menu, (item 19.01 - Accelerator Demand). To navigate the Test menu, you need to use

the '+' and '-' buttons. The '+' button moves up the Test menu and the '-' button moves back down.

Pressing the SELECT button at any time exits the Test menu and moves to the first item in the

menu structure (menu item 0.01 - Armature Current Limit).

The items which are displayed depends on the current system configuration and the Security

Level.

MillipaK PMAC Controller Manual Page 14 26/04/06

Calibrator Calibrator/Adjustments

______________________________________________________________________________

Adjustments

Menus 0 to 12 are primarily used for configuring the system. All the personalities that the system

uses to configure each function are in one of these menus. A brief description of the purpose of

each menu is listed below. For more complete descriptions of each personality refer to the

appropriate section in this manual.

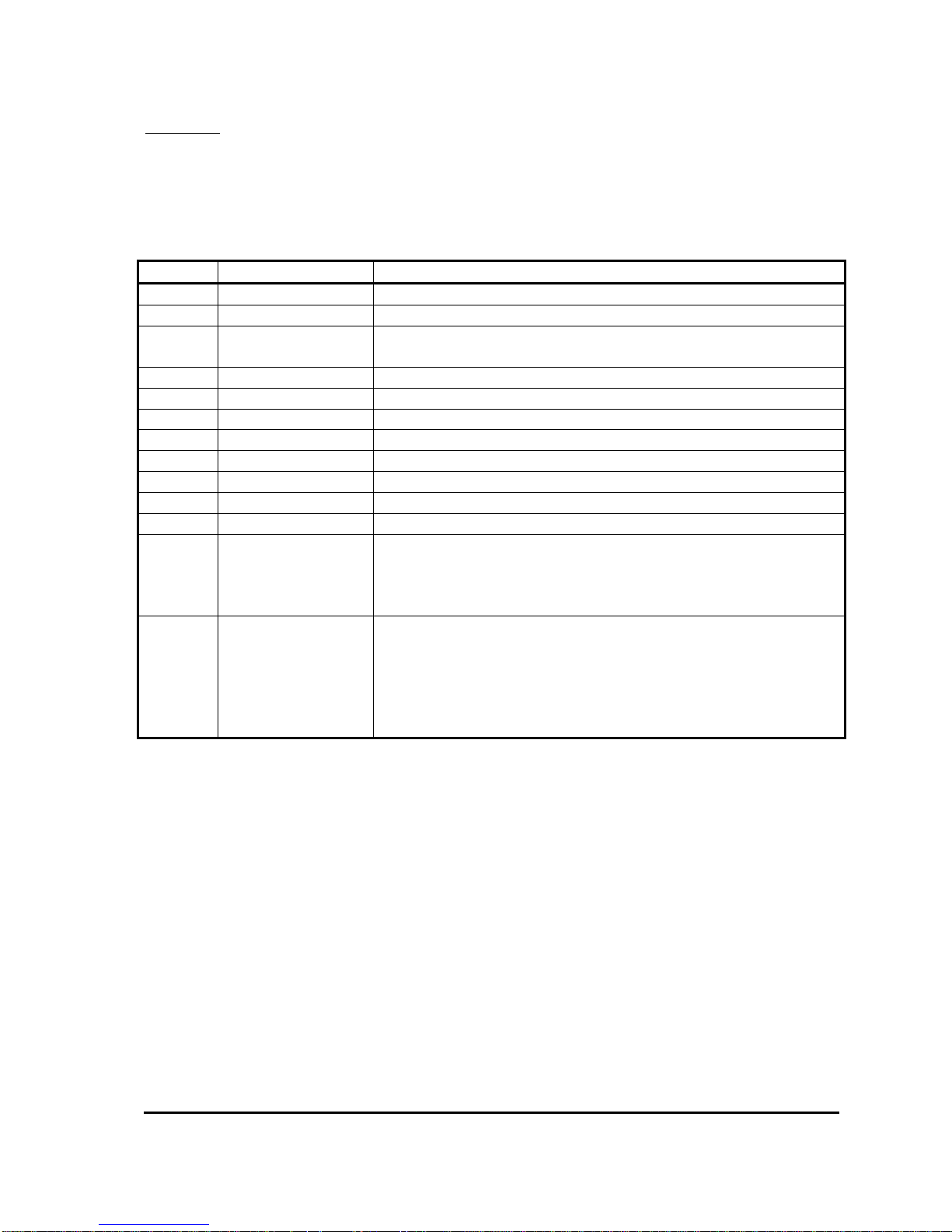

Menu Name Purpose

0 Current Limits Used to setup maximum currents for motor.

1 Braking Levels Used to setup braking strength and performance.

2 Accelerator

Used to setup acceleration and deceleration performance and to

configure the accelerator input voltage range.

3 Creep Speed Used to setup creep speed.

4 Bypass Not Used

5 Maximum Speed Used to setup maximum speeds.

6 Cutback 1 Speed Used to setup the speed for Cutback Speed 1.

7 Cutback 2 Speed Used to setup the speed for Cutback Speed 2.

8 Motor Setup Used to setup motor control parameters.

9 Power Steer Timer Used to setup the Power Steer timer.

10 Seat Delay Used to setup the Seat Switch debounce delay.

Used to setup additional personalities. These are personalities

11

Additional

Personalities

which do not belong in any of the menus shown above, or they

are deemed to be unsuitable for modification by service

engineers or end users.

Used to configure the system at a high level. Items to configure

the system I/O and performance are located in here. It is

12 System Setup

recommended that items in this menu are configured first before

any of the other personalities. Unlike the personalities in the

other menus, changes to items in this menu do not take affect

until the Keyswitch is recycled.

Table 2: Adjustment Menus

MillipaK PMAC Controller Manual Page 15 26/04/06

Calibrator Calibrator/Status and Test Information

______________________________________________________________________________

Status and Test Information

Menus 13 to 19 are primarily used for providing information about the system. Every parameter

which the system measures in located in one of these menus. A brief description of the purpose of

each menu is listed below.

Menu Name Purpose

If there is a fault active in the system, this menu provides

13 System Status

information about what the fault is. Refer to the Diagnostics

section for more information.

Used to show the Motor Speed measurements. Shown as a

14 Motor Speed

percentage of the maximum RPM specified, in RPM (20rpm per

step) and electrical frequency of the motor.

Used to display Battery and Capacitor Voltage measurements.

The Battery Voltage measurement shows the voltage measured

15 System Voltages

at the Keyswitch pin (pin 1 on connector B). The Capacitor

Voltage measurement shows the voltage measured at the B+

terminal.

16 Motor Voltages Used to show the voltage measured at the Point A terminals.

17 Motor Currents Used to show the Armature and Battery Current Measurements.

18

Heatsink

Temperature

Used to access the Heatsink Temperature measurement. Refer to

the Temperature Monitoring section.

Used to access items which allow for testing of all the Analogue

and Digital inputs available on connector B. Also displays unit

19 Test Menu

information such as the Software Version, Controller Serial

Number and the Personality Checksum. Refer to the appropriate

sections for more information on each of these items.

Table 3: Status and Test Information Menus

MillipaK PMAC Controller Manual Page 16 26/04/06

Configuration System

______________________________________________________________________________

Configuration

Configuration of the MillipaK controller is split into two categories – system and performance,

which will be discussed in turn.

System Configuration

The MillipaK system configuration items relate to how the MillipaK will interface with connected

hardware such as the system battery, vehicle control switches, accelerator and the traction motor.

MillipaK PMAC Controller Manual Page 17 26/04/06

Configuration System/Voltage

______________________________________________________________________________

System Voltage

The system voltage usually refers to the main system supply battery voltage. The controller uses

this information to ensure low and high voltage settings are within an appropriate range.

Power Up System Voltage

Calibrator Menu Reference:

12.16

Minimum Maximum Step Size Default

24V 48V 2V 48V

MillipaK PMAC Controller Manual Page 18 26/04/06

Configuration System/IO Configuration

______________________________________________________________________________

System I/O Configuration

The digital inputs, analogue inputs and contactor drive outputs available on socket B can be

configured in a number of ways to suit various applications. Table 4 shows a range of predetermined settings which are available to the user and should cover the majority of applications,

see below:

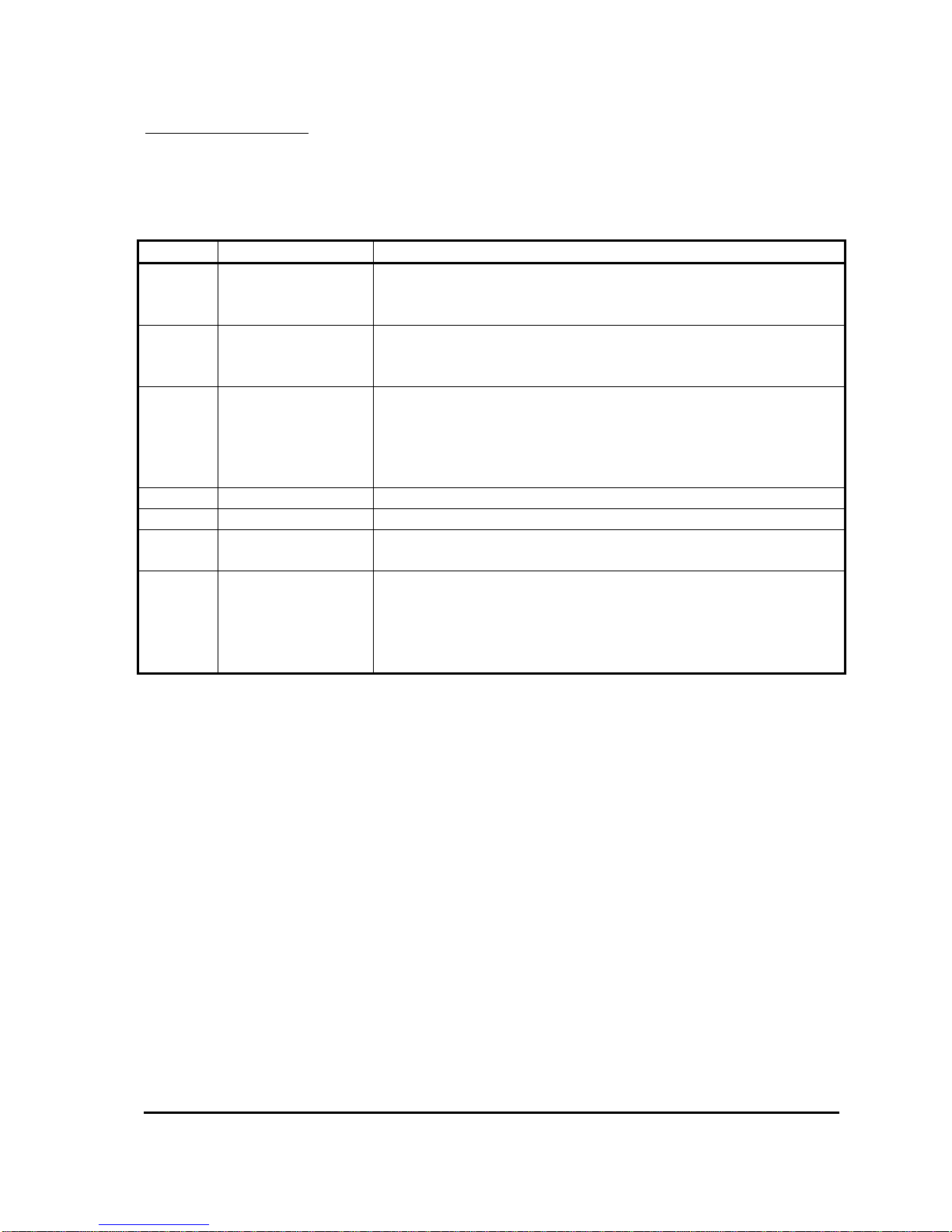

Digital I/O

Description

Value

1 Forward and Reverse switches only with Line Contactor.

2 Forward and Reverse switches only with Electric Outboard Drive.

3 Ride On vehicle with Speed Cutback 1 and 2 switches and external

LED drive.

4 Ride On vehicle with Speed Cutback 1 switch, Handbrake switch

and external LED drive.

5 Ride On vehicle with Traction Motor Overtemperature switch,

Handbrake switch and external LED drive.

6 Ride On vehicle with Handbrake switch, Power Steer Trigger switch

and Power Steer Contactor.

7 Ride On vehicle with Speed Cutback 1 switch, Power Steer Trigger

switch and Power Steer Contactor.

8 Ride On vehicle with Power Steer Trigger switch, Traction Motor

Overtemperature switch and Power Steer Contactor.

9 Ride On vehicle with Power Steer Trigger switch, Footbrake switch

and Power Steer Contactor.

10 Ride On vehicle with Handbrake switch, Pump Trigger switch and

Pump Contactor.

11 Ride On vehicle with Speed Cutback 1 switch, Pump Trigger switch

and Pump Contactor.

12 Ride On vehicle with Speed Cutback 1 and 2 switches and Alarm

Buzzer drive.

Table 4: Description of each Digital I/O configuration.

WARNING: Incorrect configuration could cause a vehicle to move unexpectedly,

for example if FS1 was inadvertently configured as a belly switch.

If your application doesn’t fit any of the above, please contact Sevcon with details of your

requirements.

Each of the above configurations allocates the controller i/o as shown below:

Digital

Function

Forward B2 B2 B2 B2 B2 B2 B2 B2 B2 B2 B2 B2

Reverse B3 B3 B3 B3 B3 B3 B3 B3 B3 B3 B3 B3

FS1 B4 B4 B4 B4 B4 B4 B4 B4 B4 B4

Seat B5 B5 B5 B5 B5 B5 B5 B5 B5 B5

Speed Cutback 1 B6 B6 B6 B6 B6

Speed Cutback 2 B7 B7

MillipaK PMAC Controller Manual Page 19 26/04/06

Value of Digital I/O Configuration Item

1 2 3 4 5 6 7 8 9 10 11 12

Configuration System/IO Configuration

______________________________________________________________________________

Handbrake B7 B7 B7 B7

P. Steer Trigger B6 B7 B7 B7

Pump Trigger B6 B7

Motor Over Temp B6 B6

Footbrake B6

Line Contactor B8 B8 B8 B8 B8 B8 B8 B8 B8 B8 B8 B8

P. Steer Contactor B9 B9 B9 B9

Pump Contactor B9 B9

External LED B9 B9 B9

Buzzer B9

Electric Outboard B9

Table 5: Digital Functions

Notes:

1. Bx refers to Socket B pin numbers.

2. All setups have Forward and Reverse Switches and a Line Contactor.

3. All Ride On vehicles have FS1 and Seat Switches.

Analogue

Function

Value of Analogue Input Configuration Item

1

2 3

4

Accelerator B10 B11 B10

Footbrake B11

Table 6: Analogue Functions

Notes:

1. Bx refers to Socket B pin numbers.

2. Configuration 1 does not have an analogue input configured.

Table 6 details which analogue functions are configured for each value of the Analogue Input

Configuration Item.

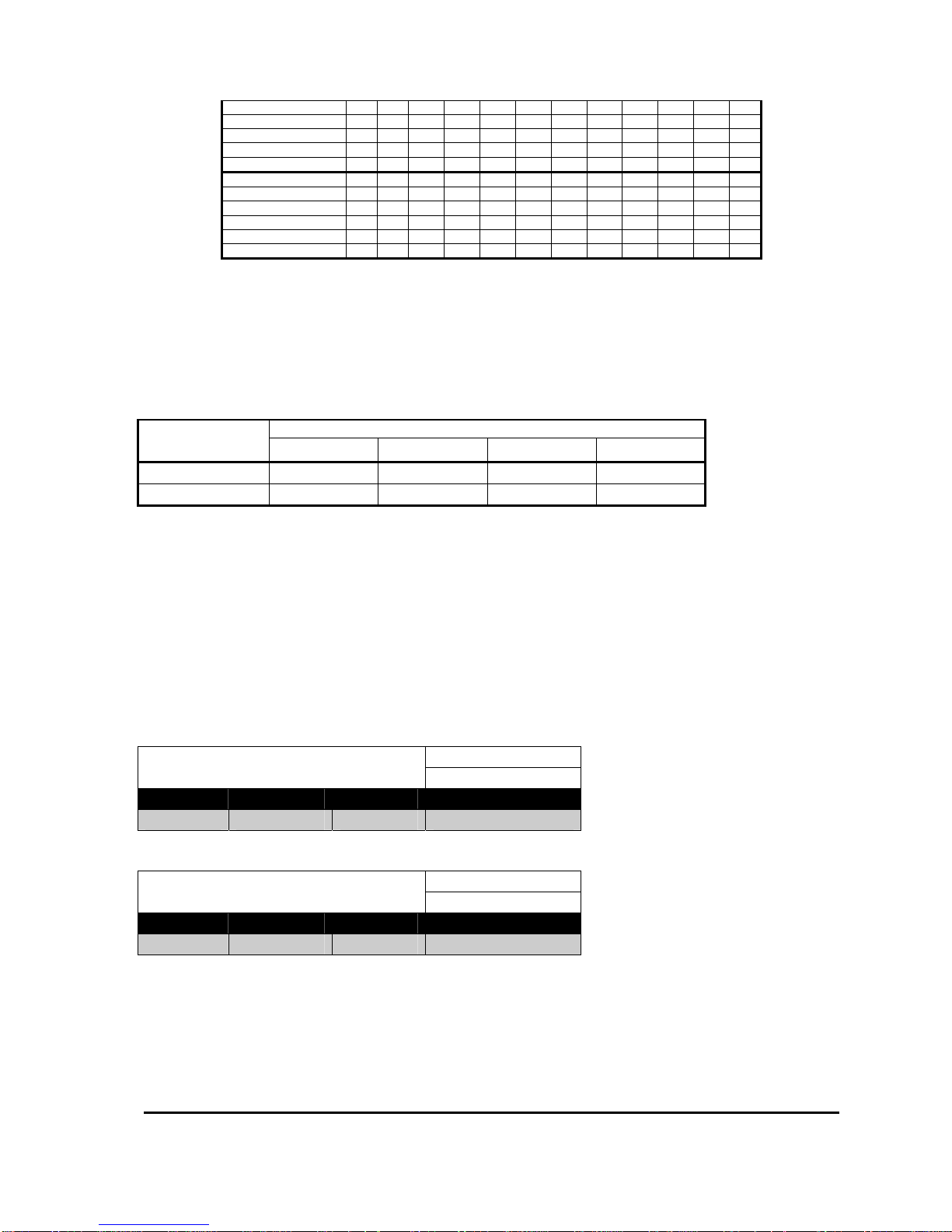

Power Up Digital Configuration

Calibrator Menu Reference:

12.14

Minimum Maximum Step Size Default

1 12 1 As Required

Power Up Analogue Configuration

Calibrator Menu Reference:

12.15

Minimum Maximum Step Size Default

1 4 1 As Required

MillipaK PMAC Controller Manual Page 20 26/04/06

Configuration System/Armature Current Limit

______________________________________________________________________________

Armature Current Limit

The armature current limit personality is provided to allow the user to limit the maximum current

supplied to the motor to a value lower than the peak rating of the controller.

Immediate Armature Current Limit

Calibrator Menu Reference:

0.01

Minimum Maximum Step Size Typical Value

50A ABR 10A ABR

ABR – Armature Block Rating refers to the controller maximum peak current.

The above personality allows the armature current limit to be set. The actual armature current

limit control is performed using a control loop. The following two personalities can be used to

setup this control loop.

Immediate Current Limit Prop Gain

Calibrator Menu Reference:

0.02

Minimum Maximum Step Size Typical Value

0 255 1 As set

Immediate Current Limit Int Gain

Calibrator Menu Reference:

0.03

Minimum Maximum Step Size Typical Value

0 255 1 As set

WARNING: Seek advice from SEVCON before changing these two personality

values. Changing these can affect the capability of the current limit

function which could damage the unit due to over-current. The

factory set values should be suitable for most applications

MillipaK PMAC Controller Manual Page 21 26/04/06

Configuration System/Contactor Chopping

______________________________________________________________________________

Contactor chopping

This feature allows 24 V contactors to be used at all battery voltages 24V – 48V, by continuously

monitoring the battery voltage and chopping the contactor output pins accordingly, to present an

average voltage suitable for 24V coils. Chopping is selectable by the calibrator. Care must be

taken to ensure that chopping is always selected if 24V contactors are being used on battery

voltages higher than 24V. In applications > 24 volts contactors must be fitted with blow out

magnets. Chopping can reduce the overall dissipation in the coils and allows only one set of

contactors to be stocked for all battery voltages.

Chopping Frequency approx. = 800Hz (Slightly audible).

Typical contactor coil voltage during chopping = 16 volts.

Typical contactor coil voltage during energisation = 24 volts for 1 second.

There are 3 contactor chopping options available via the setup menu: Off, On and 24V. The off

setting is used for nominal battery voltage coils, and the On setting is for 24V coils on higher

voltage vehicles. Setting to 24V provides chopping for 24V coils and lamps without the drop to

16V after 1s.

When the electric outboard solenoid is configured, both the line contactor and electric outboard

solenoid coil voltage will be battery voltage for 100ms during energisation and then reduced to 16

volts.

Power Up Chop Select

Calibrator Menu Reference:

12.01

Options Default

OFF ON 24V OFF

MillipaK PMAC Controller Manual Page 22 26/04/06

Configuration System/Accelerator

______________________________________________________________________________

Accelerator Full /Zero Setting

The accelerator/analogue inputs are flexible in the range of signal sources they can accommodate

and can be adjusted to minimise dead-bands and mechanical tolerances. Each analogue input has

2 adjustments associated with it to allow the input voltage range to be determined.

For the Traction Accelerator, for example, the 2 adjustments are called the “Accelerator Zero

Level” and the “Accelerator Full Level”. If these were set to 0.20V and 4.80V then 0% pulsing

would start at 0.20V at the input, increasing to 100% pulsing at 4.80V. For accelerators with

decreasing voltage outputs, the Zero adjustment might be set to 3.5V and the Full adjustment to

0.0V. The Calibrator test menu shows the instantaneous voltage reading, and the equivalent %

“push” for each input.

Immediate Accelerator Zero Volts

Calibrator Menu Reference:

2.05

Minimum Maximum Step Size Typical Value

0.00V 4.50V 0.02V

0.10V

Immediate Accelerator Full Volts

Calibrator Menu Reference:

2.06

Minimum Maximum Step Size Typical Value

0.00V 4.50V 0.02V 3.50V

Note that a 6 flash fault will occur if the full and zero levels are set within 0.50V of each other.

The PWM demand will vary between the Creep level and Maximum Speed level as the

accelerator voltage varies between “Accelerator Zero” and “Accelerator Full”.

MillipaK PMAC Controller Manual Page 23 26/04/06

Configuration System/Motor Poles

______________________________________________________________________________

Motor Poles

The motor poles refer to the number of poles in the motor. The motor poles are used to calculate

the mechanical speed of the motor.

Power Up Motor Poles

Calibrator Menu Reference:

8.01

Minimum Maximum Step Size Typical Value

2 20 2 8

MillipaK PMAC Controller Manual Page 24 26/04/06

Configuration System/Maximum Motor RPM

______________________________________________________________________________

Maximum Moto r RPM

The maximum motor RPM is the maximum RPM when the motor is unloaded and maximum

voltage is applied to the motor. The value is in 100rpm per step size.

Power Up Maximum Moto r RPM

Calibrator Menu Reference:

8.02

Minimum Maximum Step Size Typical Value

10 40 1 20

MillipaK PMAC Controller Manual Page 25 26/04/06

Configuration System/Phase Adjustment

______________________________________________________________________________

Phase Adjustment

The phase offset personalities can be adjusted if the sensors are not aligned perfectly in the motor.

A value of 128 represents a perfectly aligned motor.

Immediate Phase Offset - Forward

Calibrator Menu Reference:

8.03

Minimum Maximum Step Size Typical Value

1 255 1 128

Immediate Phase Offset - Reverse

Calibrator Menu Reference:

8.04

Minimum Maximum Step Size Typical Value

1 255 1 128

The system corrects the phase angle of the applied voltage to achieve a unity power factor. The

feature can disabled if required.

NOTE: If this feature is disabled, the phase current could be higher than that measured by

the system. Only disable this feature if it is known high phase currents can not occur.

Power Up Power Factor Phase Correction

Calibrator Menu Reference:

12.13

Options Default

OFF ON ON

MillipaK PMAC Controller Manual Page 26 26/04/06

Configuration Performance/Control Mode

______________________________________________________________________________

Performance

Various parameters may be adjusted to tailor the performance of the vehicle to customer

requirements.

Control Mode

The method of motor control may be switched between Torque and Speed control.

Power Up Control Mode

Calibrator Menu Reference:

12.03

Options Default

Torque Speed Torque

Torque Control

In Torque Control mode, the voltage applied across the motor armature is proportional to the

accelerator demand. When climbing an incline, the operator will need to increase the accelerator

demand to maintain the speed. When descending an incline, there will be no maximum speed

limit applied.

Closed Loop Speed Control

In Closed Loop Speed Control mode, the speed of the vehicle is controlled to the speed demand

from the operator. The controller will increase or decrease power to the motor or will initiate

braking to maintain the target speed.

MillipaK PMAC Controller Manual Page 27 26/04/06

Configuration Performance/Speed Control PI Gains

______________________________________________________________________________

Speed Control PI Gains

The system uses a PI algorithm for Speed Control. As with all PI algorithms, there are

proportional and integral gains which need to be setup correctly. The following diagram illustrates

the affect of proportional and integral gains on a standard PI control loop.

PI Control Algorithm

180%

160%

140%

120%

100%

80%

Output

60%

40%

20%

0%

024681012

Time

Proportional and Integral OK Proportional too high Integral too high Target

As can be seen, too much proportional gain can cause large over-shoot and poor control to occur

from the PI Control Loop and too much integral gain can cause the speed to over-shoot and take a

long time to get back to the required output.

To set up the speed control proportional and integral gains use the following guidelines.

1. Set the speed target to approximately 50%.

2. Set the speed control proportional and integral terms to 0. Increase the proportional term

slightly. The motor will drive very slowly but the control will be smooth. Increase the speed

control proportional until the motor control is no longer smooth. Once this happens reduce the

speed control proportional value to the point at which the control became unstable. Set the

speed control proportional to half this value. The motor control will now be smooth, but it will

not reach the required speed. This is where the speed control integral gain comes into use.

3. Increase the speed control integral gain to a point where the motor can easily reach the

required speed in a time equal to the Acceleration Delay. Ensure that the integr al term is not

set too high, otherwise the motor speed will over-shoot.

4. Reduce the speed target to approximately 5%.

5. Check that the motor control is still smooth. If the control is unstable, decrease the

proportional gain until the control is stable.

MillipaK PMAC Controller Manual Page 28 26/04/06

Configuration Performance/Speed Control PI Gains

______________________________________________________________________________

The following two personalities can be used to setup the control loop.

Immediate Speed Proportional Gain

Calibrator Menu Reference:

2.07

Minimum Maximum Step Size Typical Value

0 255 1 64

Immediate Speed Integral Gain

Calibrator Menu Reference:

2.08

Minimum Maximum Step Size Typical Value

0 255 1 4

MillipaK PMAC Controller Manual Page 29 26/04/06

Configuration Performance/Acceleration

______________________________________________________________________________

Acceleration Delay

This is an adjustable delay to ramp up the armature voltage from 0% on to 100% in Torque mode

or to ramp up the speed demand from 0% to 100% in Speed mode, and can be used to ensure

smooth acceleration.

Immediate Acceleration Delay

Calibrator Menu Reference:

2.01

Minimum Maximum Step Size Typical Value

0.1S 5.0S 0.1S 2.0S

Deceleration Delay

This is an adjustable delay to ramp down the armature voltage from 100% on to 0% in Torque

mode or to ramp down the speed demand from 100% to 0% in Speed mode, and can be used to

provide a smooth reduction of power to the motor.

Immediate Deceleration Delay

Calibrator Menu Reference:

2.02

Minimum Maximum Step Size Typical Value

0.1S 5.0S 0.1S 2.0S

Direction Change Deceleration Delay

This is an adjustable delay to ramp down the pulsing from 100% on to 0% on when a new Drive

direction is selected, and can be used to provide a smooth reduction of power to the motor.

Direction Change Deceleration Delay

Calibrator Menu Reference:

Immediate

2.03

Minimum Maximum Step Size Typical Value

0.1S 10.0S 0.1S 0.1S

Neutral Deceleration Delay

This is an adjustable delay to ramp down the pulsing from 100% on to 0% on when Neutral is

selected, and can be used to provide a smooth reduction of power to the motor.

Neutral Deceleration Delay

Calibrator Menu Reference:

Immediate

2.04

Minimum Maximum Step Size Typical Value

0.1S 10.0S 0.1S 0.1S

MillipaK PMAC Controller Manual Page 30 26/04/06

Configuration Performance/Regen Braking

______________________________________________________________________________

Regen Braking

All braking types are implemented using regenerative braking in the 4QPM MillipaK.

Braking can be initiated in one of 4 ways:

(i) Direction Braking. Initiated when the direction switch inputs are reversed during drive.

i.e., Reverse is selected when driving in Forward or Forward is selected when driving in

Reverse.

(ii) Footbrake Braking. Initiated when the operator depresses the Footbrake pedal and a

footbrake input is configured. See section below for more information about setting up and

configuring the system for Footbraking.

(iii) Neutral braking. Initiated when the vehicle is put into neutral during drive and neutral

braking level is greater than 0%.

(iv) Reduction braking. Initiated when the operator reduces accelerator demand, but does not

select neutral. See the Error! Reference source not found. section for more information.

Braking Levels

Each Braking Type has its own personality for setting the required braking level. These are shown

below:

Immediate Direction braking level

Calibrator Menu Reference:

1.01

Minimum Maximum Step Size Typical Value

5% 100% 1% 75%

Immediate Neutral braking level

Calibrator Menu Reference:

1.02

Minimum Maximum Step Size Typical Value

1% 100% 1% 10%

Immediate Reduction braking level

Calibrator Menu Reference:

1.03

Minimum Maximum Step Size Typical Value

0% 100% 1% 10%

Immediate Footbrake braking level

Calibrator Menu Reference:

1.04

Minimum Maximum Step Size Typical Value

0% 100% 1% 0%

MillipaK PMAC Controller Manual Page 31 26/04/06

Configuration Performance/Regen Braking

______________________________________________________________________________

The four braking levels for direction, neutral, reduction and footbraking are used to determine the

strength of the braking. Setting the level to 0% disables braking (Note: Direction Braking cannot

be disabled), 1% sets the braking strength to minimum (weakest braking) and 100% sets the

braking strength to maximum (strongest braking).

Direction Braking

Braking effort is proportional to the accelerator position, with a minimum accelerator pedal

position giving 50% of the set brake level increasing to 100% for a fully depressed pedal. The

proportionality range allows the driver to modify the braking effort without allowing

freewheeling. The proportionality feature is optional and can be configured in the setup menu to

give fixed braking at the set personality level.

Power Up Proportional Dir Braking

Calibrator Menu Reference:

12.17

Options Default

OFF ON OFF

Footbraking

Footbraking can be initiated in one of two ways:

Via an analogue input configured as a Footbrake Pot. Using a potentiometer allows the

operator to vary the amount of braking they want. See below.

Via a digital input configured as a Footbrake switch. When the switch is active, the system

will brake at the footbrake level.

Footbrake Pot

If the system is configured to use a Footbrake Pot, then the system will allow the operator to vary

the amount of footbraking depending on the position of the footbrake pedal. Similar to the

Accelerator input there are 2 personalities which can be used to setup the input voltage range of

the Footbrake Pot.

Immediate Footbrake Zero Volts

Calibrator Menu Reference:

11.11

Minimum Maximum Step Size Typical Value

0.00V 4.50V 0.02V 0.10V

Immediate Footbrake Full Volts

Calibrator Menu Reference:

11.13

Minimum Maximum Step Size Typical Value

0.00V 4.50V 0.02V 3.50V

As the input voltage varies from the Zero level to the Full level, the footbrake demand varies from

0% to 100%. When the footbrake demand is at 0%, there is no footbraking. As the footbrake

MillipaK PMAC Controller Manual Page 32 26/04/06

Configuration Performance/Regen Braking

=

=

______________________________________________________________________________

demand increases from 1% to 100%, the braking level applied by the system increases from 50%

of the Footbrake Level personality to 100% of the Footbrake Level personality.

For example, assume the system is configured to have a footbrake pot and the Footbrake Level

personality is set to 60%. If the operator has not depressed the footbrake pedal, then the voltage

into the controller will be outside of the Footbrake Zero Level personality and the footbrake

demand will be 0%. There will be no Footbraking.

If the operator starts to press the footbrake pedal, then the footbrake demand will increase. When

the demand increases above 0% the system will start braking and will set the braking effort

according to the following formula:

⎛

⎛

⎜

⎜

⎝

⎜

=

effort braking ×

⎜

demand footbrake

2

100

⎜

⎝

⎞

⎞

+

50

⎟

⎟

⎠

⎟

⎟

ypersonalit level footbrake

⎟

⎠

So, for this example, at 1% demand the braking effort would be

⎛

1

⎛

⎜

⎜

2

⎝

effort braking

⎜

=

⎜

100

⎜

⎝

⎞

⎞

50

+

⎟

⎟

⎠

⎟

06

×

⎟

⎟

⎠

%30

and at 75% demand the braking effort would be

⎛

75

⎛

⎜

⎜

2

⎝

effort braking

⎜

=

⎜

100

⎜

⎝

⎞

⎞

50

+

⎟

⎟

⎠

⎟

06

×

⎟

⎟

⎠

%5.52

Footbrake Priority

Footbrake priority can be set to drive or brake and this determines the controller action in the case

of the accelerator and footbrake pedal both being active at the same time.

Calibrator Menu Reference:

Options Default

Drive Brake Drive

MillipaK PMAC Controller Manual Page 33 26/04/06

Power Up Footbrake Priority

12.11

Configuration Performance/Creep Speed

______________________________________________________________________________

Creep Speed

The Creep speed is adjustable and is used to select a minimum pulsing level as soon as drive is

requested, to minimise delays and dead-bands. The motor voltage is rapidly ramped to the creep

level (equivalent to a 100mS acceleration delay).

Immediate Creep Speed

Calibrator Menu Reference:

3.01

Minimum Maximum Step Size Typical Value

0% 25% 1% 0%

MillipaK PMAC Controller Manual Page 34 26/04/06

Configuration Performance/Maximum Speed

______________________________________________________________________________

Maximum Speed

Adjustment limits the maximum applied voltage to the armature in Torque mode or the maximum

speed as a percentage of the maximum speed (rpm) in Speed mode.

Immediate Maximum Speed

Calibrator Menu Reference:

5.01

Minimum Maximum Step Size Typical Value

0% 100% 1% 100%

MillipaK PMAC Controller Manual Page 35 26/04/06

Configuration Performance/Accelerator Characteristics

______________________________________________________________________________

Accelerator Characteristics

Accelerator Characteristics

100

90

80

70

60

50

40

30

Accelerator Demand

20

10

0

0 102030405060708090100

Accelerator Push

Linear Curved Dual Slope Crawl

Figure 5: Accelerator Characteristics

Power Up Accelerator Characteristics

Calibrator Menu Reference:

12.09

Options Default

Linear Curved 2*Slope Crawl Linear

This function is used to vary how much speed is demanded depending on the accelerator position.

Setting either Curved, Dual Slope or Crawl gives a smaller change in speed for large changes in

accelerator position and is useful for low speed maneuvering.

The accelerator push refers to how much the operator has the accelerator depressed. This is the

value which is displayed on item 19.01 in the Test menu on the Calibrator. The Accelerator

Demand refers to how much accelerator demand is requested after the Characteristic function is

applied. This accelerator demand is then used along with the Creep Speed and Maximum Speed

personalities to determine the speed demand for the vehicle.

If a valid direction is selected and the accelerator demand is at 0%, the speed demand will be set

to the Creep Speed personality. As the accelerator demand is increased to 100%, the speed

demand increases linearly to the Maximum Speed personality.

MillipaK PMAC Controller Manual Page 36 26/04/06

Features Features

______________________________________________________________________________

Features

The MillipaK controller has several features designed to offer the user maximum flexibility,

safety and performance whilst ensuring the controller is protected against adverse or harsh driving

conditions. These features can be split into three categories – standard controller features, safety

features and controller protection features.

Standard Controller Features

The following section details the standard features found on a MillipaK controller.

MillipaK PMAC Controller Manual Page 37 26/04/06

Features Standard Features/Power Steer

______________________________________________________________________________

Power Steer

A contactor drive is available to control a separate Power Steer motor. An adjustable delay allows

the motor to operate for a set time, after the power steer trigger or power steer demand has been

removed.

The following triggers are available and configurable for power steer:

Triggers Power Steer Trigger

Configuration Item

FS1 switch Fwd or Rev switch Seat switch

0 No No No

1 Yes No No

2 No Yes No

3 Yes Yes No

4 No No Yes

5 Yes No Yes

6 No Yes Yes

7 Yes Yes Yes

Table 7: Internal Power Steer Triggers

The software also monitors the motor for movement (if the Anti-Roll-Off feature is enabled) and

activates the power steer driver accordingly.

Power Steer Personalities:

Immediate Power Steer Timer

Calibrator Menu Reference:

9.01

Minimum Maximum Step Size Typical Value

0S 60S 1S 2S

Power On Power Steer Trigger

Calibrator Menu Reference:

12.10

Minimum Maximum Step Size Default

0 7 1 0

See also contactor drive output configuration (System/Digital IO).

MillipaK PMAC Controller Manual Page 38 26/04/06

Features Standard Features/Seat Switch

______________________________________________________________________________

Seat Switch

If the seat switch is opened and the seat switch timer has timed out during drive the controller will

stop pulsing and a seat fault will be indicated. Before drive can be restarted the seat switch must

be closed, and FS1 and the direction switch must be recycled through neutral. Note the start

sequence for drive requires that the seat switch is closed and both the direction and FS1 switches

are in the neutral position simultaneously before drive can be initiated. The time period is

programmed by means of the Calibrator (Seat Switch Delay). As a setup menu option the seat

switch can also inhibit pump operation if required.

Immediate Seat Delay

Calibrator Menu Reference:

10.01

Minimum Maximum Step Size Typical Value

0.1S 5.0S 0.1S 5.0S

Power On Seat Cuts Pump

Calibrator Menu Reference:

12.04

Options Typical Value

OFF ON OFF

MillipaK PMAC Controller Manual Page 39 26/04/06

Features Standard Features/Handbrake Switch

______________________________________________________________________________

Handbrake Switch

An input is provided for the connection of a handbrake switch, which if operated will disable

armature pulsing.

MillipaK PMAC Controller Manual Page 40 26/04/06

Features Standard Features/Cutback Speeds

______________________________________________________________________________

Cutback speeds

There are 2 cutback switch inputs as standard. Each one has an associated personality to adjust the

maximum % on when the switch is active. When both switches are active together, the lower

speed is selected. The cutback speed inputs are usually normally closed so that a wire off type

fault or bad connection initiates a lower speed.

Immediate Cutback Speed 1

Calibrator Menu Reference:

6.01

Minimum Maximum Step Size Typical Value

0% 100% 1% 100%

Immediate Cutback Speed 2

Calibrator Menu Reference:

7.01

Minimum Maximum Step Size Typical Value

0% 100% 1% 100%

MillipaK PMAC Controller Manual Page 41 26/04/06

Features Standard Features/Reverse Speed

______________________________________________________________________________

Reverse Speed

In some instances the maximum reverse speed of the vehicle is required to be slower than the

forward speed. This can be achieved by enabling the reverse speed limit and setting the Maximum

Reverse Speed personality accordingly.

Immediate Maximum Rev e rse Sp e ed

Calibrator Menu Reference:

5.02

Minimum Maximum Step Size Typical Value

0% 100% 1% 100%

Power Up Reverse Speed Limit Enable

Calibrator Menu Reference:

12.05

Options Default

OFF ON OFF

MillipaK PMAC Controller Manual Page 42 26/04/06

Features Standard Features/Pump Contactor

______________________________________________________________________________

Pump Contactor

A contactor drive is available to control a separate Pump motor. To use this feature, both the

Pump Trigger switch and Pump Contactor drive must be configured.

The Pump Contactor drive will activate when the Pump Trigger switch is active and will

deactivate 0.5s after the Pump Trigger switch is deactivated. The 0.5s delay is used to de-bounce

the Pump Trigger switch.

MillipaK PMAC Controller Manual Page 43 26/04/06

Features Standard Feat u r es /External LE D D ri v e

______________________________________________________________________________

External LED Drive

To use this feature, the External LED Drive output must be configured.

This output is pulsed at the same rate as the Controller LED. It can be used to control a fault lamp

on the vehicle dash board. Any flash faults shown on the LED can also be shown via this output.

If Contactor Chopping is set to On or 24V, the output will only pulse at 24V to prevent the lamp

brightness from varying when other contactor outputs are activated.

MillipaK PMAC Controller Manual Page 44 26/04/06

Features Standard Features/T raction Motor Over-Temperature Input

______________________________________________________________________________

Traction Motor Over-Temperature Input.

To use this feature, the Traction Motor Over-Temperature Input must be configured. This feature

can be used to reduce the power output from the controller if the Traction Motor is over heating.

If the Traction Motor Over-Temperature Input is active, the armature current limit is reduced to

rd

of the Armature Current Limit personality.

1/3

MillipaK PMAC Controller Manual Page 45 26/04/06

Features Standard Features/Dri ve Hours Met er

______________________________________________________________________________

Drive Hours Meter

The MillipaK maintains a log of the number of hours during which the controller is providing

Drive functionality. The Drive Hours Meter runs whenever the vehicle is driving or braking. The

current number of logged Drive hours can be viewed using the Calibrator. Refer to the Calibrator

section for more information.

MillipaK PMAC Controller Manual Page 46 26/04/06

Features Standard Features/Personality Checksum

______________________________________________________________________________

Personality Checksum

As you can see from this Manual and the Calibrator Map, the MillipaK employs quite a few

personalities to give the user as much flexibility as possible in setting up their system. After the

personalities have been setup to give the desired functionality and performance, most customers

will request the same setup for each subsequent controller they purchase.

If you wanted to check that a controller had the correct personalities, it is very tedious and time

consuming to check each individual personality in turn. To remove the need for this, the system

calculates a checksum value based on the value of each of the personalities in its memory. The

checksum value is simply a number between 0 and 255 which is calculated by passing all the

personality values through an algorithm.

The Personality Checksum will be same on every unit (with the same number of personalities) for

the same set of personality values. This can be used to instantly confirm that all the personalities

are correct. The Personality Checksum is located in the Test menu.

MillipaK PMAC Controller Manual Page 47 26/04/06

Features Optional Features/Line Contactor Drop out

______________________________________________________________________________

Line Contactor Drop out

The controller will close the line contactor once a successful power up sequence has been carried

out, after which drive operation can be achieved. The line contactor will remain closed unless it is

opened following a serious fault or power being disconnected.

A further configurable option is available where the line contactor is opened (dropped out) if no

drive activity has occurred for a period exceeding the line contactor dropout delay personality. If

drive operation is selected once the line has been opened then it will be closed again so that drive

operation can occur. Line contactor dropout operation can be selected in the PERS set up:

Power Up Line Contactor Drop out

Calibrator Menu Reference:

12.09

Options Default

OFF ON OFF

Immediate Line Contactor Drop out Delay

Calibrator Menu Reference:

11.01

Minimum Maximum Step Size Typical Value

0s 60s 1s 5s

MillipaK PMAC Controller Manual Page 48 26/04/06

Features Optional Features/Alarm Buzzer

______________________________________________________________________________

Alarm Buzzer

The Buzzer function is used to drive a warning buzzer when the vehicle is moving or in a fault

condition. When a Buzzer output is configured, the following options can be selected in the Setup

Menu:

Off

Reverse / Roll Off

Motion

Off is selected, the buzzer output will remain off.

If

Reverse / Roll Off is selected, the buzzer output will do one of the following:

If

If the reverse switch is closed or the vehicle is moving in reverse, the buzzer output will

activate continuously.

If the controller is applying Anti-Roll Off braking, the buzzer output will be pulsed with an on

time of 0.5s and an off time of 1.0s.

If the controller is in a fault condition which would prevent drive, the buzzer output will be

pulsed with an on time of 1.0s and an off time of 1.0s.

Motion is selected, the buzzer output will do all of the actions described for Reverse / Roll Off,

If

and, in addition, the buzzer output will also activate continuously when the forward switch is

closed or the vehicle is moving in forward. Basically, the Buzzer Output is active whenever the

vehicle is moving.

Power Up Alarm Buzzer

Calibrator Menu Reference:

12.12

Options Default

Off Rol All Rol

MillipaK PMAC Controller Manual Page 49 26/04/06

Features Optional Fe atures/Electric Outboard Drive

______________________________________________________________________________

Electric Outboard Drive and Low Battery Warning

The Electric Outboard Drive is used to drive a solenoid, which, in turn, activates a hook that holds

the propeller in place when the REVERSE direction is selected. It is also used to drive an alarm

buzzer when the FORWARD direction is selected in conjunction with the Low Battery Warning

feature.

When the REVERSE direction is selected the solenoid engages the hook which holds the

propeller in place by outputting battery voltage for 100ms, after which the output is chopped at

16V.

When the FORWARD direction is selected, the buzzer alarm will sound if the following is true:

The average battery voltage drops below the Battery Warning Level personality setting

continuously for a period of time longer than that specified by the Battery Warning

Timer personality setting.

If the above is true, the buzzer will sound intermittently, and will be ON for 5s and OFF for 20s.

Immediate Low Battery Warning Level

Calibrator Menu Reference:

11.09

Minimum Maximum Step Size Typical Value

0.0V 70.0V 0.5V 16.0V

Immediate Low Battery Warning Timer

Calibrator Menu Reference:

11.10

Minimum Maximum Step Size Typical Value

0.0s 20.0s 0.1s 0.0s

MillipaK PMAC Controller Manual Page 50 26/04/06

Features Optional Features/Temporary Current Boost

______________________________________________________________________________

Temporary Current Boost

This is a feature intended to allow the user to temporarily boost the armature current limit in an

attempt to improve acceleration.

Immediately after drive demand is requested, the system will set the armature current limit to the

Temporary Armature Current Limit personality (not to exceed the controller’s block rating) for

the time period specified by the Temporary Armature Current Limit personality setting. After the

expiration of the Temporary Armature Current Limit Timer, the system will reset the armature

current limit according to the Armature Current Limit personality.

Temporary Armature I Limit

Calibrator Menu Reference:

Immediate

0.04

Minimum Maximum Step Size Typical Value

5A ABR 10A 100A

Temporary Armature I Limit Timer

Calibrator Menu Reference:

Immediate

0.05

Minimum Maximum Step Size Typical Value

0S 10S 1S 4S

MillipaK PMAC Controller Manual Page 51 26/04/06

Safety Features Safety Features/Start Up Sequence

______________________________________________________________________________

Safety Features

The features listed in this section are designed with the safety of the operator in mind.

Start Up Sequence

At keyswitch on, the Direction switches must be in the neutral condition simultaneously at least

once before drive can be selected. This is a safety feature to help prevent unexpected movement

immediately after power up.

Alternatively, the system may be programmed not to check the Direction switches at power on.

This option is programmable:

Power Up Direction Switch Checking

Calibrator Menu Reference:

12.07

Options Default

OFF ON OFF

MillipaK PMAC Controller Manual Page 52 26/04/06

Safety Features Safety Features/FS1 Recycle

______________________________________________________________________________

FS1 Recycle

On some vehicles, such as Golf Cars, it is desirable to force the operator to remove accelerator

demand before allowing the vehicle to drive in the opposite direction from that it has been

traveling in. This feature is implemented as an option.

Power Up FS1 Recycle

Calibrator Menu Reference:

12.06

Options Default

OFF ON OFF

MillipaK PMAC Controller Manual Page 53 26/04/06

Safety Features Safety Features/SRO

______________________________________________________________________________

SRO (Static return to off)

This feature is optional in the setup menu and, when specified, forces the following sequences of

switch inputs to be followed before drive is allowed: Keyswitch-Direction-FS1 or KeyswitchFS1-Direction (within the SRO delay). Any other sequence will not allow drive. Drive will be

inhibited if FS1 is active for more than the SRO delay with no direction selected. In this case the

FS1 will need to be recycled.

Power Up Static Return to Off

Calibrator Menu Reference:

12.02

Options Default

OFF ON OFF

Immediate SRO Delay

Calibrator Menu Reference:

11.03

Minimum Maximum Step Size Typical Value

0s 5s 1s 2s

MillipaK PMAC Controller Manual Page 54 26/04/06

Safety Features Safety Features/Anti-Rollback

______________________________________________________________________________

Anti-Rollback

This is a standard SEVCON feature and is used to help prevent roll back conditions on ramps. If

the driver reselects the previous direction after a neutral condition, braking is not attempted, and

full drive power is available to restart on a hill.

MillipaK PMAC Controller Manual Page 55 26/04/06

Safety Features Safety Features/Anti-Rolloff

______________________________________________________________________________

Anti-Rolloff

This feature is designed so that if a vehicle is powered up, without its handbrake applied, any nondrive condition on a gradient results in the vehicle braking slowly, in a controlled way, down a

ramp without running away. The vehicle has to be stationary at least once after power up before

the feature is applied.

The Roll-Off strength is not adjustable but can be enabled and disabled using the Roll-Off Enable

option.

Immediate Roll-Off Enable

Calibrator Menu Reference:

11.01

Options Default

OFF ON ON

MillipaK PMAC Controller Manual Page 56 26/04/06

Safety Features Safety Features/Idle Fault

______________________________________________________________________________

Idle Fault

This feature is intended to prevent accidents caused by unintentional movement.

The system will exhibit a severe fault (cannot be cleared without a key recycle) and a 2 flash fault

will be displayed by the Diagnostic LED mounted on the controller, if the following is true:

system is powered up

-

forward or reverse is closed

-

accelerator push is zero

-

The above conditions are both true continuously for the time specified by the Idle

Timer personality.

Setting the Idle Timer personality at zero disables the feature.

Immediate Idle Timer

Calibrator Menu Reference:

11.04

Minimum Maximum Step Size Typical Value

0s 255s 1s 240s

MillipaK PMAC Controller Manual Page 57 26/04/06

Safety Features Safety Features/Motor Stall Protection

______________________________________________________________________________

Motor Stall Protection

By monitoring the motor current and voltage over a period of time, the controller is able to detect

if a motor stall condition has occurred.

If the armature current rises above the level specified by the Stall Motor Current personality,

while the motor voltage drops below the level specified by the Stall Motor Voltage personality,

for a continuous period of time longer than that specified by the Stall Timer personality setting,

then a motor stall condition will be identified. As a result, the controller will exhibit a severe fault

(cannot be cleared without a key recycle), accompanied by a 9 flash fault being displayed by the

Diagnostic LED mounted on it.

Setting the Stall Timer personality to zero disables the feature.

Immediate Stall Timer

Calibrator Menu Reference:

8.05

Minimum Maximum Step Size Typical Value

0s 60s 1s 2s

Immediate Stall Motor Voltage

Calibrator Menu Reference:

8.06

Minimum Maximum Step Size Typical Value

1V 24V 1V 8V

Immediate Stall Motor Current

Calibrator Menu Reference:

8.07

Minimum Maximum Step Size Typical Value

10A ABR 10A 50A

MillipaK PMAC Controller Manual Page 58 26/04/06

Safety Features Fail-safe

______________________________________________________________________________

Fail-safe

The controller’s safety system includes a microprocessor watchdog which can detect software

failure, and a hardware fail-safe system which can prevent dangerous runaway conditions in the

event of certain hardware failures.

Every time the controller is powered-up, the software checks that the fail-safe circuit is able to

switch off the MOSFETs and open the contactors.

MillipaK PMAC Controller Manual Page 59 26/04/06

Controller Protection Temperature Monitoring

______________________________________________________________________________

Controller Protection Features

There are several in built features which are designed to protect the MillipaK controller from

damage due to excessive load currents, voltages and prolonged periods of high demand.

Temperature Monitoring

If the temperature of the power frame exceeds 75oC its maximum available curr e nt will be

reduced. Note, however, that if the set current limit is less than the maximum available current

limit actual cutback will occur at progressively higher temperatures than 75oC. The thermal

cutback ensures that the maximum heatsink temperature is limited to 90oC (See Figure 6). When

actual cutback occurs the diagnostic LED will flash 8 times. Inspection of the calibrator fault