Miller Electric Three-Phase Running Gear, Weld Cable Holder, Cylinder Rack/Lift, Stationary Cylinder Rack, 042 886 Owner's Manual

...

OWNER’S MANUAL FORM: OM-687 164 063D

December 1998

Three-Phase Running Gear (042 886), Weld Cable Holder (043 055),

Cylinder Rack/Lift (043 005), And Stationary Cylinder Rack (042 887)

WARNING

ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Turn Off welding power source and input disconnect

device.

• Disconnect input power conductors from

deenergized supply BEFORE moving welding

power source.

CYLINDERS can explode if damaged.

• Keep cylinders away from welding and other

electrical circuits.

• Never touch cylinder with welding electrode.

• Always secure cylinder to running gear, wall, or

other stationary support.

1

2

3

4

5

7

7

6

For more weld cable

wraps around handle,

install handle in this

position.

FALLING EQUIPMENT can cause injury

and damage.

• Use proper equipment to lift unit.

• Use lifting forks long enough to extend out opposite

side of base.

• Do not put any body part under unit while lifting.

Tools Needed:

3/8, 7/16, 9/16, 5/8 in

Part

Item

No.

No.

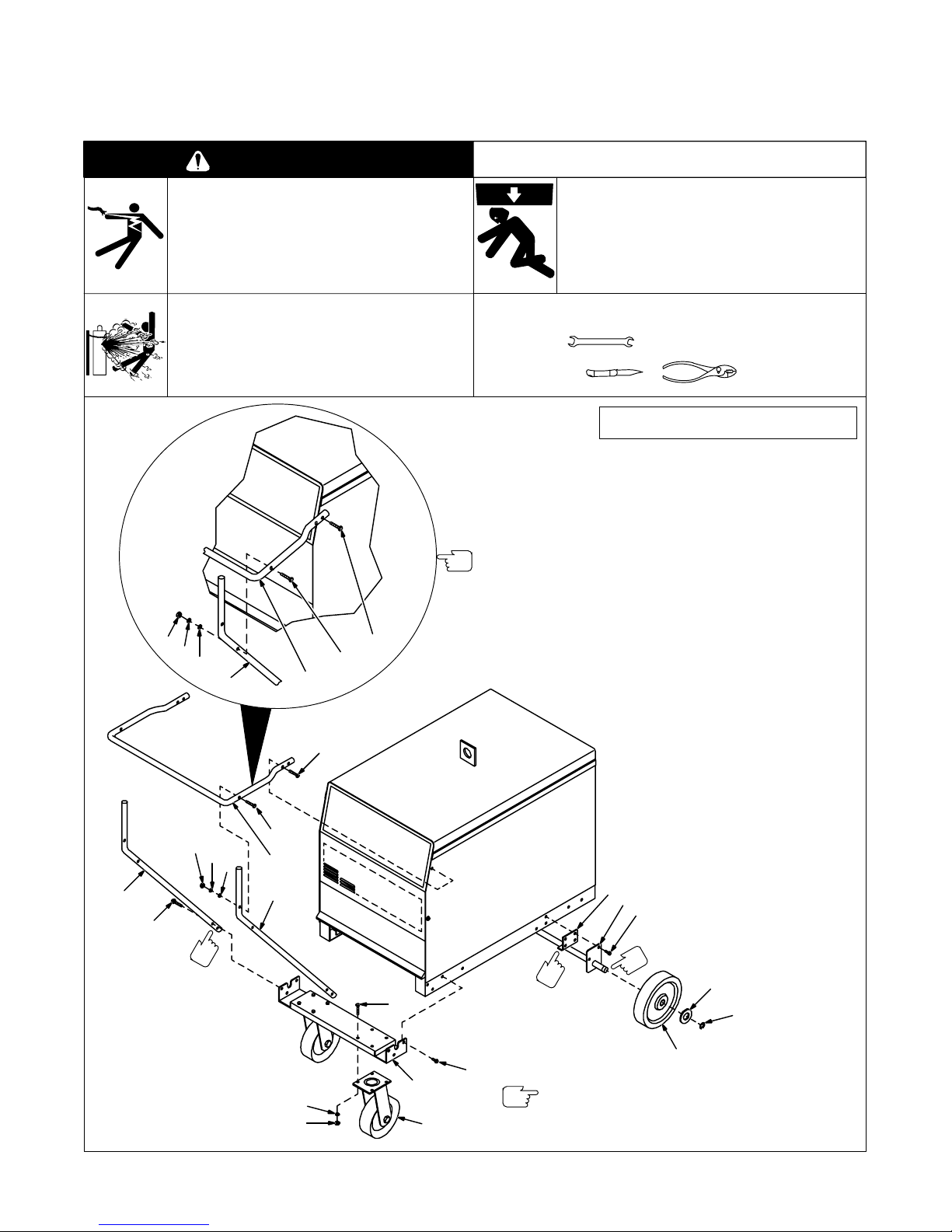

1 +601 865 Nut, 1/4-20 (2)

2 +602 207 Washer, 1/4 lock (2)

3 +602 241 Washer, 1/4 flat (2)

4 +168 342 Upright Handle (2)

5 +168 341 Front Handle (1)

6 +098 877 Screw, 1/4-20 x 2-1/4 (2)

7 +049 966 Screw, 1/4-20 x 1-1/2 (6)

8 163 444 Shim (2)

9 163 446 Axle (1)

10 604 224 Screw, 1/4-20 x 3/4 (6)

11 602 250 Washer, 13/16 flat (2)

12 121 614 Retaining Ring (2)

13 163 463 Wheel, 10 in (2)

14 601 965 Screw, 3/8-16 x 1 (8)

15 163 442 Caster Mounting Bracket (1)

16 168 247 Caster (2)

17 601 872 Nut, 3/8-16 (8)

18 602 213 Washer , 3/8 lock (8)

+These it e m s a r e c o m m o n t o K i t N os. 042 886

and 043 055.

Be sure to provide Model when ordering

replacement parts.

Description (Qty)

miscwarn1.1 5/93

1

2

4

7

When installing Weld Cable

Holder Kit 043 055, use

same holes in welding power source that a r e used to install Three-Phase Running

Gear handle.

6

5

3

4

18

17

Figure 1. Installing Three-Phase Running Gear

14

15

16

Shim (8) is installed as a

spacer when cylinder

rack is not used.

10

When installing running gear and cylinder rack at the

same time, install axle according to Figure 2 or Figure 4.

8

9

10

Remove paint from axle grooves (9)

before installing retaining rings (12).

11

12

13

ST-800 213-B

Connect primary power cord

to welding power source before installing cylinder rack.

Installing mounting brackets and axle.

1

4

Installing cylinder rack and wheels

12

11

1 Welding Power Source

2 Mounting Bracket

Use matching holes on welding

power source base to install mounting brackets.

3 Axle (Supplied With Running

Gear)

Install axle to mounting brackets

(2).

2

3

5

6

7

8

4 Support Bracket

5 Cylinder Rack Assembly

Install support bracket to cylinder

rack assembly.

Remove the three screws from the

top rear of the welding power

source cover.

Secure cylinder rack assembly to

mounting brackets (2).

Secure support bracket to welding

power source (1) with screws removed from top rear of cover.

6 Wheel (Supplied With

Running Gear)

7 Washer (Supplied With

Running Gear)

8 Retaining Ring

Install wheels to axle, and secure

with washers and retaining rings.

9 Weld Cable Guide

Install weld cable guides.

10 Spring Hook

Install spring hooks into hole that

will allow chains to be tightened as

tight as possible around gas cylinders. Secure cylinder with chains

as shown.

11 Safety Lock

12 Lift Lever

Push safety lock while turning lift le-

ver to raise or lower cylinder rack.

Keep a tight grip on lever when raising and lowering rack loaded with a

cylinder as lever is under tension.

Keep body parts out from under

rack while raising and lowering

rack.

See Parts List for hardware sizes

used in this installation.

Installing weld cable guides and spring hooks,

Figure 2. Installing And Operating The Cylinder Rack/Lift

OM-687 Page 2

and operating the lift rack.

10

9

ST-800 656-A / Ref. S-170 364

Loading...

Loading...