Page 1

OM-215 092 210 177A

August 2005

Processes

MIG (GMAW) Welding

Flux Cored (FCAW) W elding

Description

Wire Feeder

UWF-SC12RC

Page 2

Page 3

TABLE OF CONTENTS

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. Symbol Usage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. Arc Welding Hazards 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3. Additional Symbols For Installation, Operation, And Maintenance 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4. California Proposition 65 Warnings 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5. Principal Safety Standards 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6. EMF Information 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 − DEFINITIONS 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. Warning Label Definitions 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2. Manufacturer’s Rating Label For CE Products 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3. Symbols And Definitions 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 − INSTALLATION 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. Specifications 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. 14-Pin Plug Information 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. Equipment Connection Diagram 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4. Gun Recommendation Table 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5. Consumable Parts and Spares for the T-400 MP Torch 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6. Installing And Aligning Wire Guide And Drive Rolls 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7. Connecting Welding Gun 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8. Connecting Shielding Gas 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9. Connecting Weld Cable 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10. Installing And Threading Welding Wire 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 − OPERATION 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. Controls 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2. Setting Digital Meter Board PC4 DIP Switches 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 − MAINTENANCE & TROUBLESHOOTING 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1. Routine Maintenance 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2. Overload Protection And Thermostat Protection 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3. Troubleshooting 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 − ELECTRICAL DIAGRAMS 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7− PARTS LIST 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY

Page 4

Declaration of Conformity for

European Community (CE) Products

NOTE

Manufacturer: European Contact:

Miller Electric Mg. Co. Mr. Danilo Fedolfi,

1635 W. Spencer St. Managing Director

Appleton, WI 54914 USA ITW Welding Products Italy S.r.l.

Phone: (920) 734-9821 Via Privata Iseo 6/E

European Contact Signature:

Declares that the product: UWF-SC12RC

This information is provided for units with CE certification (see rating label on unit).

20098 San Giuliano

Milanese, Italy

Phone: 39(02)98290-1

Fax: 39(02)98290203

conforms to the following Directives and Standards:

Directives

Low Voltage Directive: 73/23/EEC

Electromagnetic Compatibility (EMC) Directive: 89/336/EEC

Machinery Directives: 98/37/EEC, 91/368/EEC, 92/31/EEC, 133/04, 93/68/EEC

Standards

Arc Welding Equipment − Part 5: Wire Feeders. IEC 60974-5 Ed. 1

Arc Welding Equipment − Part 10: Electromagnetic Compatibility (EMC) Requirements. IEC 60974-10 August 2002

Arc Welding Equipment − Part 1: Welding Power Sources. IEC 60974-1 Ed. 2.1

Degrees Of Protection Provided By Enclosure (IP Code) IEC 60529 Ed. 2.1

Insulation Coordination For Equipment Within Low-Voltage Systems −

Part 1: Principles, Requirements and Tests: IEC 60664-1 Ed. 1.1

The product technical file is maintained by the responsible Business Unit(s) located at the manufacturing facility.

dec_wire_6/05

Page 5

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING

Y Warning: Protect yourself and others from injury — read and follow these precautions.

1-1. Symbol Usage

Means Warning! Watch Out! There are possible hazards

with this procedure! The possible hazards are shown in

the adjoining symbols.

som _3/05

Y Marks a special safety message.

. Means “Note”; not safety related.

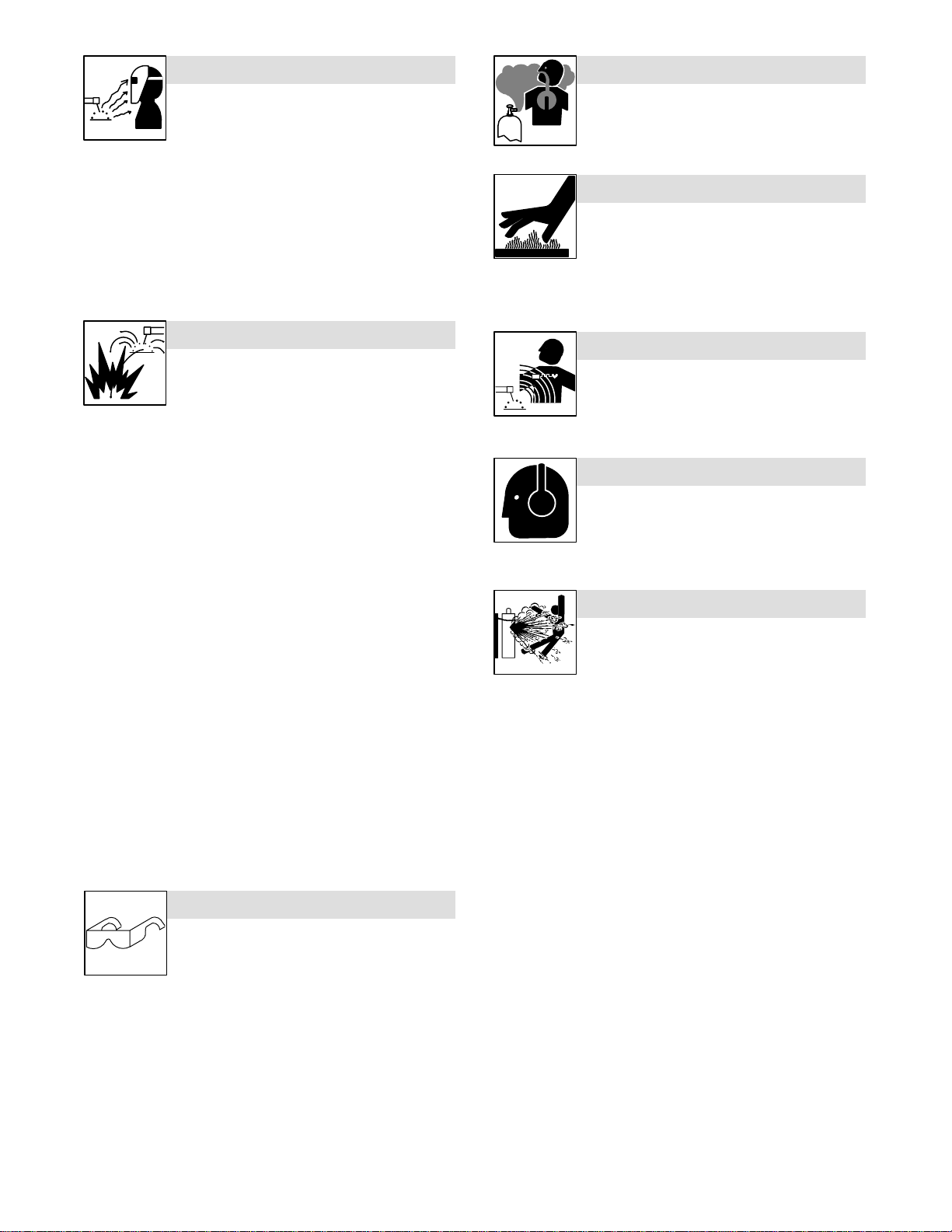

1-2. Arc Welding Hazards

Y The symbols shown below are used throughout this manual to

call attention to and identify possible hazards. When you see

the symbol, watch out, and follow the related instructions to

avoid the hazard. The safety information given below is only

a summary of the more complete safety information found in

the Safety Standards listed in Section 1-5. Read and follow all

Safety Standards.

Y Only qualified persons should install, operate, maintain, and

repair this unit.

Y During operation, keep everybody, especially children, away.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks

or severe burns. The electrode and work circuit is

electrically live whenever the output is on. The input

live when power is on. In semiautomatic or automatic wire welding, the

wire, wire reel, drive roll housing, and all metal parts touching the

welding wire are electrically live. Incorrectly installed or improperly

grounded equipment is a hazard.

D Do not touch live electrical parts.

D Wear dry, hole-free insulating gloves and body protection.

D Insulate yourself from work and ground using dry insulating mats

or covers big enough to prevent any physical contact with the work

or ground.

D Do not use AC output in damp areas, if movement is confined, or if

there is a danger of falling.

D Use AC output ONLY if required for the welding process.

D If AC output is required, use remote output control if present on

unit.

D Additional safety precautions are required when any of the follow-

ing electrically hazardous conditions are present: in damp

locations or while wearing wet clothing; on metal structures such

as floors, gratings, or scaffolds; when in cramped positions such

as sitting, kneeling, or lying; or when there is a high risk of unavoidable or accidental contact with the workpiece or ground. For these

conditions, use the following equipment in order presented: 1) a

semiautomatic DC constant voltage (wire) welder, 2 ) a D C manual

(stick) welder, or 3) an AC welder with reduced open-circuit voltage. In most situations, use of a DC, constant voltage wire welder

is recommended. And, do not work alone!

D Disconnect input power or stop engine before installing or

servicing this equipment. Lockout/tagout input power according to

OSHA 29 CFR 1910.147 (see Safety Standards).

D Properly install and ground this equipment according to its

Owner’s Manual and national, state, and local codes.

D Always verify the supply ground − check and be sure that input

power cord ground wire is properly connected to ground terminal in

disconnect box or that cord plug is connected to a properly

grounded receptacle outlet.

D When making input connections, attach proper grounding conduc-

tor first − double-check connections.

D Frequently inspect input power cord for damage or bare wiring −

replace cord immediately if damaged − bare wiring can kill.

power circuit and machine internal circuits are also

This group of symbols means Warning! Watch Out! possible

ELECTRIC SHOCK, MOVING PARTS, and HOT PARTS hazards.

Consult symbols and related instructions below for necessary actions

to avoid the hazards.

D Turn off all equipment when not in use.

D Do not use worn, damaged, undersized, or poorly spliced cables.

D Do not drape cables over your body.

D If earth grounding of the workpiece is required, ground it directly

with a separate cable.

D Do not touch electrode if you are in contact with the work, ground,

or another electrode from a different machine.

D Do not touch electrode holders connected to two welding ma-

chines at the same time since double open-circuit voltage will be

present.

D Use only well-maintained equipment. Repair or replace damaged

parts at once. Maintain unit according to manual.

D Wear a safety harness if working above floor level.

D Keep all panels and covers securely in place.

D Clamp work cable with good metal-to-metal contact to workpiece

or worktable as near the weld as practical.

D Insulate work clamp when not connected to workpiece to prevent

contact with any metal object.

D Do not connect more than one electrode or work cable to any

single weld output terminal.

SIGNIFICANT DC VOLTAGE exists in inverter-type

welding power sources after removal of input

power.

D Turn Off inverter, disconnect input power, and discharge input

capacitors according to instructions in Maintenance Section

before touching any parts.

FUMES AND GASES can be hazardous.

Welding produces fumes and gases. Breathing

these fumes and gases can be hazardous to your

health.

D Keep your head out of the fumes. Do not breathe the fumes.

D If inside, ventilate the area and/or use local forced ventilation at the

arc to remove welding fumes and gases.

D If ventilation is poor, wear an approved air-supplied respirator.

D Read and understand the Material Safety Data Sheets (MSDSs)

and the manufacturer’s instructions for metals, consumables,

coatings, cleaners, and degreasers.

D Work in a confined space only if it is well ventilated, or while

wearing an air-supplied respirator. Always have a trained watchperson nearby. Welding fumes and gases can displace air and

lower th e oxygen level causing injury or death. Be sure the breathing air is safe.

D Do not weld in locations near degreasing, cleaning, or spraying op-

erations. The heat and rays of the arc can react with vapors to form

highly toxic and irritating gases.

D Do not weld on coated metals, such as galvanized, lead, or

cadmium plated steel, unless the coating is removed from the weld

area, the area is well ventilated, and while wearing an air-supplied

respirator. The coatings and any metals containing these elements

can give off toxic fumes if welded.

OM-215 092 Page 1

Page 6

ARC RAYS can burn eyes and skin.

BUILDUP OF GAS can injure or kill.

Arc rays from the welding process produce intense

visible and invisible (ultraviolet and infrared) rays

that can burn eyes and skin. Sparks fly off from the

weld.

D Wear an approved welding helmet fitted with a proper shade of fil-

ter lenses to protect your face and eyes when welding or watching

(see ANSI Z49.1 and Z87.1 listed in Safety Standards).

D Wear approved safety glasses with side shields under your

helmet.

D Use protective screens or barriers to protect others from flash,

glare and sparks; warn others not to watch the arc.

D Wear protective clothing made from durable, flame-resistant mate-

rial (leather, heavy cotton, or wool) and foot protection.

WELDING can cause fire or explosion.

Welding on closed containers, such as tanks,

drums, or pipes, can cause them to blow up. Sparks

can fly off from the welding arc. The flying sparks, hot

burns. Accidental contact of electrode to metal objects can cause

sparks, explosion, overheating, or fire. Check and be sure the area is

safe before doing any welding.

D Remove all flammables within 35 ft (10.7 m) of the welding arc. If

this is not possible, tightly cover them with approved covers.

D Do not weld where flying sparks can strike flammable material.

D Protect yourself and others from flying sparks and hot metal.

D Be alert that welding sparks and hot materials from welding can

easily go through small cracks and openings to adjacent areas.

D Watch for fire, and keep a fire extinguisher nearby.

D Be aware that welding on a ceiling, floor, bulkhead, or partition can

cause fire on the hidden side.

D Do not weld on closed containers such as tanks, drums, or pipes,

unless they are properly prepared according to AWS F4.1 (see

Safety Standards).

D Connect work cable to the work as close to the welding area as

practical to prevent welding current from traveling long, possibly

unknown paths and causing electric shock, sparks, and fire

hazards.

D Do not use welder to thaw frozen pipes.

D Remove stick electrode from holder or cut off welding wire at

contact tip when not in use.

D Wear oil-free protective garments such as leather gloves, heavy

shirt, cuffless trousers, high shoes, and a cap.

D Remove any combustibles, such as a butane lighter or matches,

from your person before doing any welding.

D Follow requirements in OSHA 1910.252 (a) (2) (iv) and NFPA 51B

for hot work and have a fire watcher and extinguisher nearby.

workpiece, and hot equipment can cause fires and

FLYING METAL can injure eyes.

D Welding, chipping, wire brushing, and grinding

cause sparks and flying metal. As welds cool,

they can throw off slag.

D Wear approved safety glasses with side

shields even under your welding helmet.

D Shut o ff shielding gas supply when not in use.

D Always ventilate confined spaces or use

approved air-supplied respirator.

HOT PARTS can cause severe burns.

D Do not touch hot parts bare handed.

D Allow cooling period before working on gun or

torch.

D To handle hot parts, use proper tools and/or

wear heavy, insulated welding gloves and

clothing to prevent burns.

MAGNETIC FIELDS can affect pacemakers.

D Pacemaker wearers keep away.

D Wearers should consult their doctor before

going near arc welding, gouging, or spot

welding operations.

NOISE can damage hearing.

Noise from some processes or equipment can

damage hearing.

D Wear approved ear protection if noise level is

high.

CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under high

pressure. If damaged, a cylinder can explode. Since

gas cylinders are normally part of the welding

process, be sure to treat them carefully .

D Protect compressed gas cylinders from excessive heat, mechani-

cal shocks, physical damage, slag, open flames, sparks, and arcs.

D Install cylinders in an upright position by securing to a stationary

support or cylinder rack to prevent falling or tipping.

D Keep cylinders away from any welding or other electrical circuits.

D Never drape a welding torch over a gas cylinder.

D Never allow a welding electrode to touch any cylinder.

D Never weld on a pressurized cylinder − explosion will result.

D Use only correct shielding gas cylinders, regulators, hoses, and fit-

tings designed for the specific application; maintain them and

associated parts in good condition.

D Turn face away from valve outlet when opening cylinder valve.

D Keep protective cap in place over valve except when cylinder is in

use or connected for use.

D Use the right equipment, correct procedures, and sufficient num-

ber of persons to lift and move cylinders.

D Read and follow instructions on compressed gas cylinders,

associated equipment, and Compressed Gas Association (CGA)

publication P-1 listed in Safety Standards.

OM-215 092 Page 2

Page 7

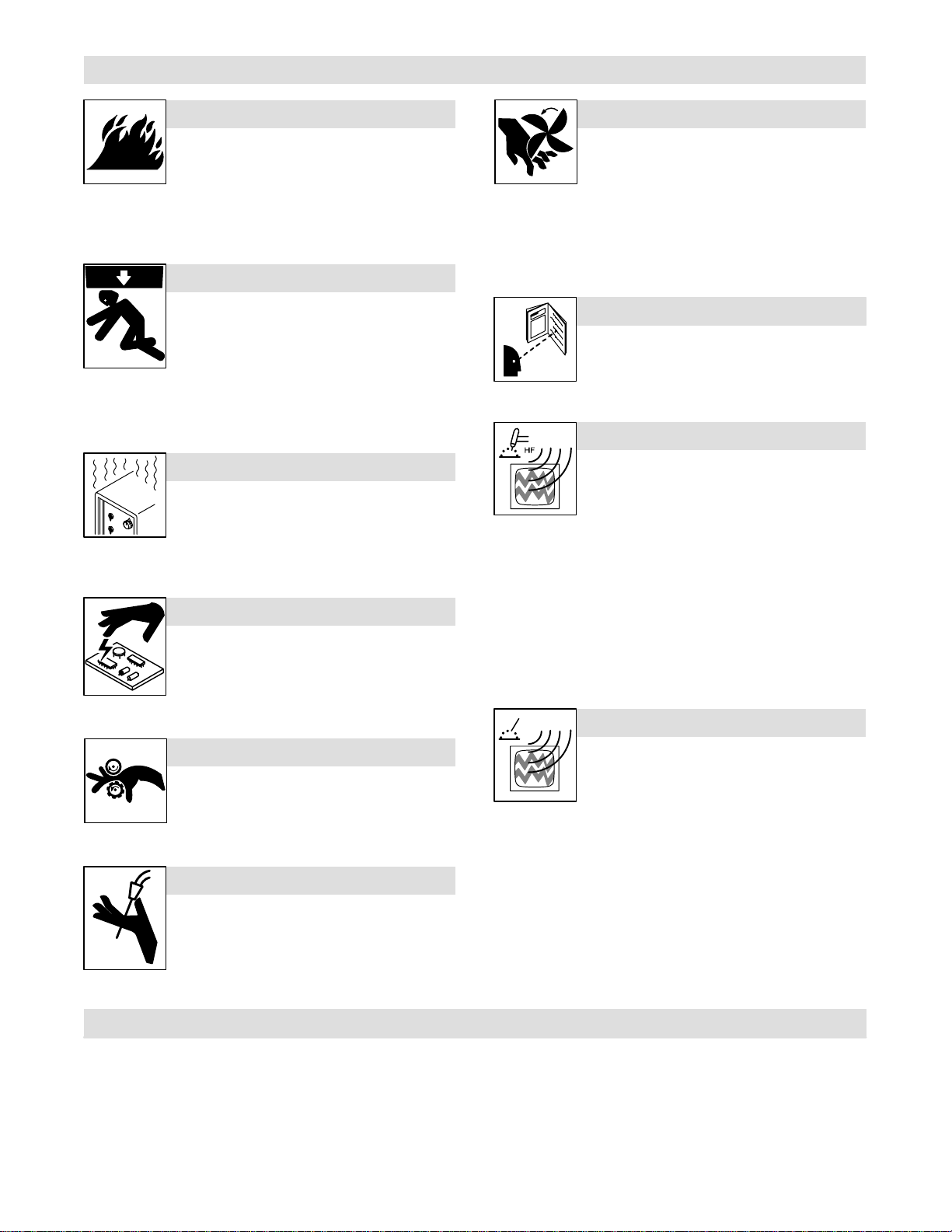

1-3. Additional Symbols For Installation, Operation, And Maintenance

FIRE OR EXPLOSION hazard.

D Do not install or place unit on, over, or near

combustible surfaces.

D Do not install unit near flammables.

D Do not overload building wiring − be sure power supply system is

properly sized, rated, and protected to handle this unit.

FALLING UNIT can cause injury.

D Use lifting eye to lift unit only, NOT running

gear, gas cylinders, or any other accessories.

D Use equipment of adequate capacity to lift and

support unit.

D If using lift forks to move unit, be sure forks are

long enough to extend beyond opposite side of

unit.

OVERUSE can cause OVERHEATING

D Allow cooling period; follow rated duty cycle.

D Reduce current or reduce duty cycle before

starting to weld again.

D Do not block or filter airflow to unit.

STATIC (ESD) can damage PC boards.

D Put on grounded wrist strap BEFORE handling

boards or parts.

D Use proper static-proof bags and boxes to

store, move, or ship PC boards.

MOVING PARTS can cause injury.

D Keep away from moving parts such as fans.

D Keep all doors, panels, covers, and guards

closed and securely in place.

D Have only qualified persons remove doors,

panels, covers, or guards for maintenance as

necessary.

D Reinstall doors, panels, covers, or guards

when maintenance is finished and before reconnecting input power.

READ INSTRUCTIONS.

D Read Owner’s Manual before using or servic-

ing unit.

D Use only genuine Miller/Hobart replacement

parts.

H.F. RADIATION can cause interference.

D High-frequency (H.F.) can interfere with radio

navigation, safety services, computers, and

communications equipment.

D Have only qualified persons familiar with

electronic equipment perform this installation.

D The user is responsible for having a qualified electrician prompt-

ly correct any interference problem resulting from the installation.

D If notified by the FCC about interference, stop using the

equipment at once.

D Have the installation regularly checked and maintained.

D Keep high-frequency source doors and panels tightly shut, keep

spark gaps at correct setting, and use grounding and shielding to

minimize the possibility of interference.

MOVING PARTS can cause injury.

D Keep away from moving parts.

D Keep away from pinch points such as drive

rolls.

WELDING WIRE can cause injury.

D Do not press gun trigger until instructed to do

so.

D Do not point gun toward any part of the body,

other people, or any metal when threading

welding wire.

1-4. California Proposition 65 Warnings

Y W elding or cutting equipment produces fumes or gases which

contain chemicals known to the State of California to cause

birth defects and, in some cases, cancer. (California Health &

Safety Code Section 25249.5 et seq.)

Y Battery posts, terminals and related accessories contain lead

and lead compounds, chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

ARC WELDING can cause interference.

D Electromagnetic energy can interfere with

sensitive electronic equipment such as

computers and computer-driven equipment

such as robots.

D Be sure all equipment in the welding area is

electromagnetically compatible.

D To reduce possible interference, keep weld cables as short as

possible, close together, and down low, such as on the floor.

D Locate welding operation 100 meters from any sensitive elec-

tronic equipment.

D Be sure this welding machine is installed and grounded

according t o this manual.

D If interference still occurs, the user must take extra measures

such as moving the welding machine, using shielded cables,

using line filters, or shielding the work area.

For Gasoline Engines:

Y Engine exhaust contains chemicals known to the State of

California t o cause cancer, birth defects, or other reproductive

harm.

For Diesel Engines:

Y Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

OM-215 092 Page 3

Page 8

1-5. Principal Safety Standards

Safety i n W elding, Cutting, and Allied Processes, ANSI Standard Z49.1,

from Global Engineering Documents (phone: 1-877-413-5184, website:

www.global.ihs.com).

Recommended Safe Practices for the Preparation for Welding and Cutting of Containers and Piping, American Welding Society Standard

AWS F4.1 from Global Engineering Documents (phone:

1-877-413-5184, website: www.global.ihs.com).

National Electrical Code, NFPA Standard 70, from National Fire Protection Association, P.O. Box 9101, 1 Battery March Park, Quincy, MA

02269−9101 (phone: 617−770−3000, website: www .nfpa.org).

Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet P-1,

from Compressed Gas Association, 1735 Jefferson Davis Highway,

Suite 1004, Arlington, VA 22202−4102 (phone: 703−412−0900, website: www.cganet.com).

Code for Safety in Welding and Cutting, CSA Standard W1 17.2, from

Canadian Standards Association, Standards Sales, 178 Rexdale

1-6. EMF Information

Considerations About Welding And The Effects Of Low Frequency

Electric And Ma g netic Fields

Welding current, as it flows through welding cables, will cause electromagnetic fields. There has been and still is some concern about such

fields. However, after examining more than 500 studies spanning 17

years of research, a special blue ribbon committee of the National

Research Council concluded that: “The body of evidence, in the

committee’s judgment, has not demonstrated that exposure to powerfrequency electric and magnetic fields is a human-health hazard.”

However, studies are still going forth and evidence continues to be

examined. Until the final conclusions of the research are reached, you

may wish to minimize your exposure to electromagnetic fields when

welding or cutting.

To reduce magnetic fields in the workplace, use the following

procedures:

Boulevard, Rexdale, Ontario, Canada M9W 1R3 (phone:

800−463−6727 or in Toronto 416−747−4044, website: www.csa−international.org).

Practice For Occupational And Educational Eye And Face Protection,

ANSI Standard Z87.1, from American National Standards Institute, 11

West 42nd Street, New York, NY 10036−8002 (phone: 212−642−4900,

website: www.ansi.org).

Standard for Fire Prevention During Welding, Cutting, and Other Hot

Work, NFP A Standard 51B, from National Fire Protection Association,

P .O. Box 9101, 1 Battery March Park, Quincy, MA 02269−9101 (phone:

617−770−3000, website: www.nfpa.org).

OSHA, Occupational Safety and Health Standards for General Industry, Title 29, Code of Federal Regulations (CFR), Part 1910, Subpart Q,

and Part 1926, Subpart J, from U.S. Government Printing Office, Superintendent of Documents, P.O. Box 371954, Pittsburgh, PA 15250 (there

are 10 Regional Offices−−phone for Region 5, Chicago, is

312−353−2220, website: www.osha.gov).

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cables around your body.

4. Keep welding power source and cables as far away from operator as practical.

5. Connect work clamp to workpiece as close to the weld as possible.

About Pacemakers:

Pacemaker wearers consult your doctor before welding or going near

welding operations. If cleared by your doctor, then following the above

procedures is recommended.

OM-215 092 Page 4

Page 9

SECTION 2 − DEFINITIONS

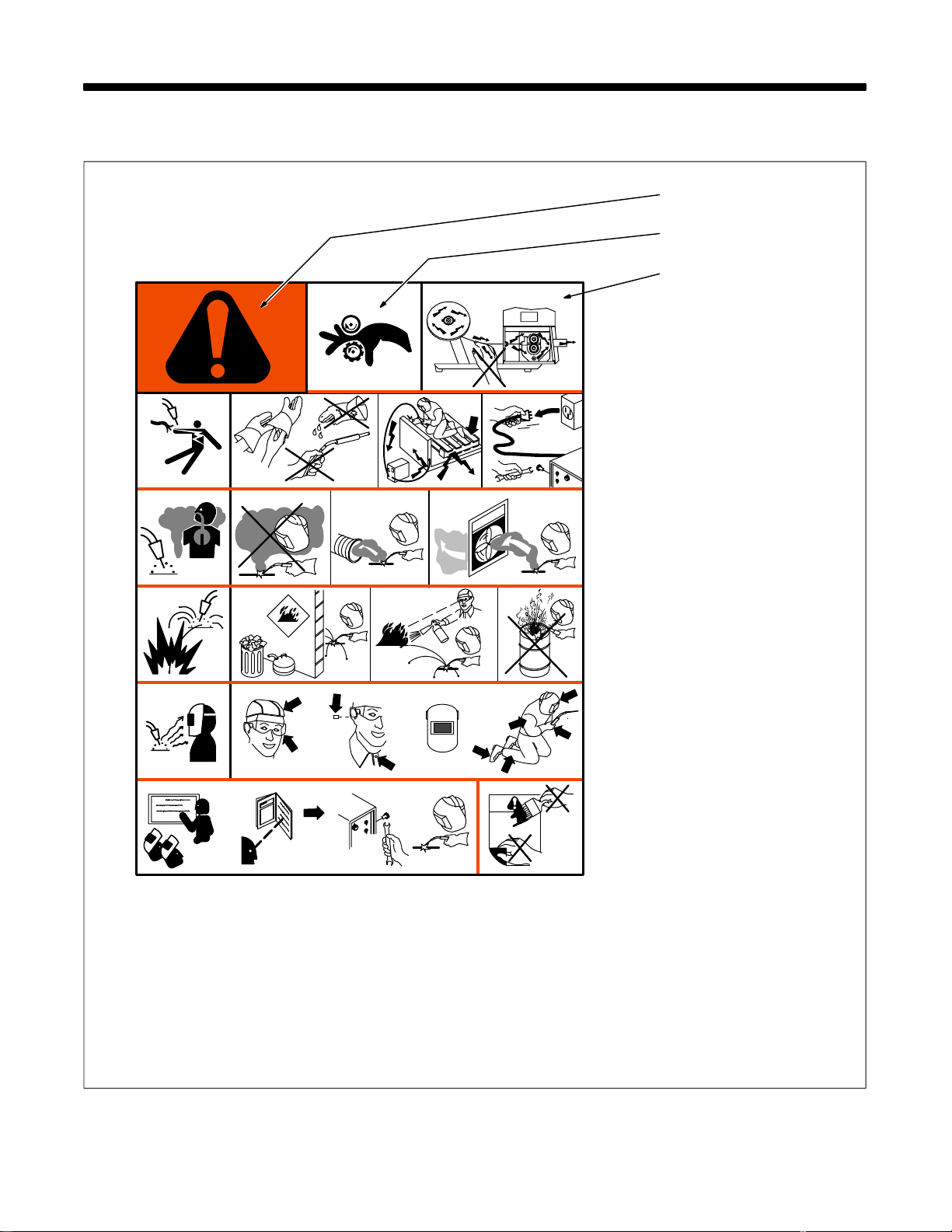

2-1. Warning Label Definitions

1 1.1 1.2 1.3

2

3 3.1 3.2 3.3

4 4.1

2.1

2.2

+

56

+

+

2.3

+

S-178 936

Warning! Watch Out! There are

possible hazards as shown by the

symbols.

Drive rolls can injure fingers

Welding wire and drive parts are at

welding voltage during operation −

keep hands and metal objects

clear.

1 Electric shock can kill.

1.1 Wear dry insulating gloves.

Do not touch electrode with

bare hand. Do not wear wet or

damaged gloves.

1.2 Protect yourself from electric

shock by insulating yourself

from work and ground.

1.3 Disconnect input plug or

power before working on

machine.

2 Breathing welding fumes can

be hazardous to your health.

2.1 Keep your head out of the

fumes.

2.2 Use forced ventilation or local

exhaust to remove the fumes.

2.3 Use ventilating fan to remove

fumes.

3 Welding sparks can cause

explosion or fire.

3.1 Keep flammables away from

welding. Don’t weld near

flammables.

3.2 Welding sparks can cause

fires. Have a fire extinguisher

nearby and have a watch

person ready to use it.

3.3 Do not weld on drums or any

closed containers.

4 Arc rays can burn eyes and

injure skin.

4.1 Wear hat and safety glasses.

Use ear protection and button

shirt collar. Use welding

helmet with correct shade of

filter. Wear complete body

protection.

5 Become trained and read the

instructions before working on

the machine or welding.

6 Do not remove or paint over

(cover) the label.

OM-215 092 Page 5

Page 10

2-2. Manufacturer’s Rating Label For CE Products

S/N:

X

IP

For label location

see Section 4-1.

U

24

1

=

=

I

10.0

1

U

2

=

2-3. Symbols And Definitions

NOTE

Output Input

Duty Cycle Wire Feed Percent

Input

Constant Current Circuit Breaker Constant Voltage Slow

Some symbols are found only on CE products.

V

A

I

V100 A500 X 100 %

2

MILLER ELECTRIC MFG. CO., APPLETON, WI USA

1

IP 23

=

A

Cold Jog (Inch) To-

wards Workpiece

Hz50/60

Amperes

Purge By Gas Fast

V

Volts

Degree Of Protec-

tion

Trigger Hold Off Trigger Hold On

Read Instructions

I

1

Primary Current

U

SECTION 3 − INSTALLATION

Primary Voltage

1

3-1. Specifications

T ype of

Input

Power

24 Volts AC

Single Phase

10 Amperes

50/60 Hz

Welding

Power

Source

Type

Constant

Voltage (CV)

DC With

14-Pin And

Contactor

Control

Wire Feed

Speed

Range

50 to 700 ipm

(1.3 To 17.8

mpm)

Wire

Diameter

Range

.023 To 5/64 in

(0.6 To 2 mm)

I

U

Input

Welding

Circuit

Rating

100 Volts,

500

Amperes,

100%

Duty Cycle

Rated Welding

2

2

Current

Conventional Load

Voltage Hz

IP

Rating

23

Max. Wire

Spool

Capacity

30 lb (13.6

12 in (304

kg),

mm)

Overall

Dimensions

Length: 20 in

(508 mm)

Width: 8 in

(203 mm)

Height: 15-1/2 in

(394 mm)

Increase

Hertz

Weight

25.5 lb

(11.6 kg)

OM-215 092 Page 6

Page 11

3-2. 14-Pin Plug Information

AJ

AJ

D

M

G

E

E

F

Pin* Pin Information

A 24 volts ac with respect to socket G.

B Contact closure to A completes 24 volts ac contactor control circuit.

K

I

B

L

NH

C

F

G Circuit common for 24 volts AC circuit.

C +10 volts dc input from power source to wire feeder with respect to socket D.

D Remote control circuit common.

E 0 to +10 volts dc output signal from wire feeder to power source with respect to socket D.

H V oltage feedback; 0 to +10 volts dc, 1 volt per 10 arc volts.

F Current feedback; 0 to +10 volts dc, 1 volt per 100 amperes.

*The remaining pins are not used.

3-3. Equipment Connection Diagram

1

2

3

1 Constant Voltage (CV)

Welding Power Source

Supplying 24 VAC To Feeder

Use optional PSA-2 adapter for

power sources having only 115

VAC supply.

2 Negative (−) Weld Cable

11

3 Positive (+) Weld Cable

4 Workpiece

5 Interconnecting Cord

(Customer Supplied)

6 14-Pin Plug And Cord

7 Wire Feeder

8 Gun

9 Gun Trigger Receptacle

10 Gas Hose

11 Gas Cylinder

. Shielding gas pressure not to

exceed 90 psi (620 kPa).

10

4

5

6

7

9

8

804 207-A

OM-215 092 Page 7

Page 12

3-4. Gun Recommendation Table

Process Gun

GMAW − Hard or Cored Wires T-400 MP

FCAW − Self-Shielding Wires T-400 MP + torch neck for self-sheilding wire

3-5. Consumable Parts and Spares for the T-400 MP Torch

1

2

A

The torch has adjustable neck and

is delivered complete with tools for

neck adjustment and contact tip

change. It is delivered with 3 m

cable, complete with liner and contact tips for 0.8–1.2 mm wire. The

teflon liner allows for all wire types

including aluminium.

10

9 8 7 5

A

B

Pos. Description Qty. Unit Product no.

1 Wire torch for T-400 MP for gas shielded wire with 3 m cable and con-

nector with 1.2 mm contact tip and steel liner (1.2 − 1.4 mm).

2 Torch neck 160 mm for self-shileded wire. To be mounted on wire

torch T-400 MP handle.

3 Torch neck 300 mm for self-shileded wire. To be mounted on wire

torch T-400 MP handle.

4 Tip insulation cup for self-shileded neck. pcs 193-607454

5 Gas nozzle for torch. pcs 193-613765

6 Contact tips −

0.8 mm

1.0-1.2 mm

1.2-1.4 mm

1.6-2.0 mm

7 Nozzle insulator. 5 set 193-613766

8 Gas diffuser for T-400. 5 set 193-613763

9 Neck insualtor for T-400. 5 set 193-613764

10 Torch liner, Teflon for 0.8-1.2 mm wire 4.5 m long.

Torch liner, Steel for 0.8-1.2 mm wire (blue) 3.0 m long.

Torch liner, Steel for 3 m for 1.4-2.0 mm wire (red) 3.0 m long

6

3

4

10

10

10

10

B

pcs 193-607451

pcs 193-607452

pcs 193-607453

set

set

set

set

pcs

pcs

pcs

193-594622

193-594630

193-607455

193-607456

193-594606

193-594614

193-607457

OM-215 092 Page 8

Page 13

3-6. Installing And Aligning Wire Guide And Drive Rolls

Installing Wire Guide

And Drive Rolls

5

4

3

1

2

Aligning Wire Guide And Drive Rolls

Installing Wire Guide And Drive

Rolls:

1 Drive Roll Nut

2 Drive Roll Carrier

Turn nut one click until lobes of nut

line u p with lobes of drive roll carrier.

3 Drive Roll

Slide drive roll onto drive roll carrier.

Turn nut one click.

Repeat procedure for top drive roll.

4 Inlet Wire Guide Screw

5 Inlet Wire Guide

Loosen securing screw. Install inlet

guide so inlet guide screw is

centered i n groove in guide, or so tip

is as close to drive rolls as possible

without touching. Tighten screw .

Aligning Wire Guide And Drive

Rolls:

View is from top of drive rolls looking down with pressure assembly

open.

6 Drive Roll Securing Nut

7 Drive Roll

8 Wire Guide

9 Welding Wire

10 Drive Gear

Turn screw in or out until drive roll

groove lines up with wire guide.

Close pressure roll assembly.

Only bottom drive roll alignment is

adjustable. Turn adjustment screw

in or out until groove in drive roll

lines up with wire guide as shown.

Cleaning Drive Rolls:

Remove drive rolls, and clean

grooves using a wire brush.

Correct Incorrect

8

7

6

9

Tools Needed:

10

3/16 in

3/8 in

804 210-A

OM-215 092 Page 9

Page 14

3-7. Connecting Welding Gun

3-8. Connecting Shielding Gas

Internal SideView

1 Gun Securing Knob

2 Gun Block

3 Gun Outlet Wire Guide

2

1

3

Loosen knob, insert gun end into

block. Position outlet wire guide as

close as possible to drive rolls without touching. Tighten knob.

4 Gun Trigger Plug

5 Gun Trigger Receptacle

3

4

5

1 Gas Hose With 5/8-18

Right-hand Thread Fittings

(Customer Supplied)

2 Shielding Gas Cylinder

804 209-A

. Shielding gas pressure not to

exceed 90 psi (620 kPa).

4

Rear View

2

5

3 Valve

4 Flowmeter

5 14-Pin Plug

Close valve on cylinder when fin-

ished welding.

Tools Needed:

OM-215 092 Page 10

5/8 in

1

804 208-A

Page 15

3-9. Connecting Weld Cable

From Wire Feeder

1 User-Suppled Weld Cable

Follow wire manufacturer’s recom-

mendations for weld cable polarity.

2 User-Suppled Male Connector

3 User-Suppled Female

Connector

Push female connector over male

connector, and turn 1/4 turn clockwise.

1

3

2

3-10. Installing And Threading Welding Wire

1

2

Hold wire tightly to keep it

from unraveling.

3

804 211-A

Installing Wire And Adjusting

Hub Tension:

1 Retaining Nut

2 Hub Tension Adjustment

Screw

Remove retaining ring, and install

spool so hub pin fits spool hole. Reinstall retaining nut.

Adjust tension nut so only a slight

force is needed to turn spool.

Threading Welding Wire:

3 Pressure Assembly

Adjustment Knob

Lay gun cable out straight.

Open pressure assembly, hold wire

tightly, and cut off end. Push wire

through g u i d e s i n t o g u n .

Close and tighten pressure assembly. Press Jog switch until wire

comes out gun.

Feed wire against wooden surface,

and tighten knob so wire does not

slip.

Cut off wire, and close door .

WOOD

6 in

(150 mm)

Pull and hold wire; cut off end.

Tighten

Clockwise

Tools Needed:

9/16 in

804 212-A

OM-215 092 Page 11

Page 16

4-1. Controls

SECTION 4 − OPERATION

2

3

4

5

6

VOLTAGE WIRE SPEED

Front Panel

OFF

ON

POWERPURGE

1

7

1 Power Control Switch

2 Trigger Hold Switch (Optional)

Depress the upper part of the switch

(turns trigger hold On) to weld without

holding gun trigger throughout the

weld cycle.

To start weld, press and release gun

trigger. To end weld, press and release gun trigger.

Depress the lower part of the trigger

hold switch to turn trigger hold Of f.

3 Purge Switch

Press switch to momentarily energize

gas solenoid and purge air from gun,

and to adjust shielding gas regulator.

4 Meter Display (Optional)

5 Volts, Wire Feed Speed Or

Amps Select Switch (Optional)

. Meter is factory set to display

voltage and wirefeed speed. To

display voltage and amps refer to

Section 4-2 for DIP switch settings.

6 Voltage Control

7 Wire Speed Control

Use control to adjust wire speed with-

in range selected by switch.

8 Jog Switch

Use Jog position to momentarily feed

welding wire at speed set on Wire

Speed control without energizing

welding circuit or shielding gas valve.

Close and latch door.

Internal Side View

8

JOG

Internal Control Panel

804 213-A

OM-215 092 Page 12

Page 17

4-2. Setting Digital Meter Board PC4 DIP Switches

1

2

3

Meter DIP switches are

factory set to display wirefeed

speed and voltage using 14 pin

feedback. Meter hold feature is

factory set to off position.

Wire Feed Speed Display

Meters Per MinuteInches Per Minute

1 Front Meter Panel

2 S1 DIP Switch

3 S2 DIP Switch

If the DIP switches are set to a Meter

Hold (ON) position, the meter value

will hold 5 seconds after gun is triggered. The meter value will continue

to hold for 8 seconds after trigger is

released or until gun is re-triggered.

. When using power sources

without 14 pin voltage/current

feedback − optional remote

voltage/current kit 195194 is

required.

Indicates this DIP switch setting has

no effect on this function.

14 Pin

Voltage

Feedback

S2

S1

Voltage/Current

Sense Kit

(195194)

(ON)

S1

Meter Hold

Amps Display

S2S2S2

14 Pin

Voltage

Feedback

S1

Voltage/Current

Sense Kit

(195194)

(OFF)

S1

S2

S2

14 Pin

Current

Feedback

Voltage/Current

Sense Kit

(195194)

803 141/ Ref. 803 124

OM-215 092 Page 13

Page 18

SECTION 5 − MAINTENANCE & TROUBLESHOOTING

5-1. Routine Maintenance

Y Disconnect power

before maintaining.

3 Months

Replace

Damaged Or

Unreadable

Labels

6 Months

Clean

Drive

Rolls

5-2. Overload Protection And Thermostat Protection

. Maintain more often

during severe conditions.

Replace Damaged

Gas Hose

Repair Or Replace

Cracked Cables

And Cords

Blow Out Or

Vacuum Inside

Internal Side View

CB1

Y Turn Off wire feeder and

welding power source. Stop

engine on welding

generator.

1

1 Circuit Breaker CB1

CB1 protects wire feeder from over-

load. Correct problem and reset

CB1.

Close and latch door.

Thermostat Protection

Unit has internal thermostat protection and will not feed wire if overheating occurs (see Section 5-3).

OM-215 092 Page 14

804 213-A

Page 19

5-3. Troubleshooting

-

Trouble Remedy

Wire does not feed, unit completely inop

erative.

Wire does not feed.

Wire feeds erratically.

Wire feeds when Jog switch is pressed

but not when gun trigger is pressed.

Wire feeds as soon as power is applied. Check gun trigger. See gun Owner’s Manual.

Wire does not feed until trigger is

pressed but continues to feed after trigger is released.

Turn Power switch On.

Check 14−pin plug PLG2 connections.

Check input power .

Check circuit breaker CB1. (see Section 5-2).

Check gun trigger connection at wire feeder . Check gun trigger leads and trigger switch. See gun Owner’s

Manual.

Have Factory Authorized Service Agent check drive motor and control board PC1.

Readjust hub tension and drive roll pressure (see Section 3-10).

Use correct size drive roll (see Parts Listing).

Clean or replace dirty or worn drive roll (see Section 3-6).

Remove weld spatter around nozzle opening.

Replace contact tip or liner. See gun Owner’s Manual.

Have Factory Authorized Service Agent check drive motor and control board PC1.

Check gun trigger connection at wire feeder . Check gun trigger leads and trigger switch. See gun Owner’s

Manual.

Check for short between gun trigger leads and weld cable. Repair or replace gun trigger leads.

Gas valve rattles loudly and wire feeds

slowly or erratically.

Gas does not flow; wire feeds. Check gas valve.

Check for short between gun trigger leads and weld cable. Repair or replace gun trigger leads.

OM-215 092 Page 15

Page 20

Notes

OM-215 092 Page 16

Page 21

SECTION 6 − ELECTRICAL DIAGRAMS

Figure 6-1. Circuit Diagram For Wire Feeder

223 794-B

OM-215 092 Page 17

Page 22

SECTION 7 − PARTS LIST

. Hardware is common and

not available unless listed.

3

2

1

8

70

9

10

32

22

21

4

19

5

6

12

17

48

7

15

13

11

20

14

47

51

18

49

16

9

50

24

23

26

25

52

46

53

54

55

56

45

42

43

27

28

29

30

31

69

41

44

39

40

33

34

35

36

37

35

38

68

67

66

OM-215 092 Page 18

65

64

63

62

59

60

61

Figure 8-1. Complete Assembly

58

57

804 214-D

Page 23

ty

Dia.

Item

No.

Mkgs.

Part

No.

Description

Figure 7-1. Complete Assembly

1 M1 ME220 195 Motor, Right Angle 24VDC 145 Rpm 37.5 Ratio W/Plug 1. . . . . . . . . . . . . . . . . . . . . . . . .

2 ME207 679 Insert, Corner 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 ME124 778 Knob, T 2.000 Bar W/.312−18 Stud 1.000 Lg Plstc 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 ME172 076 Carrier, Drive Roll W/Components Keyed 24 Pitch 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 ME092 865 Key, Stl .1215/.1230 x .750 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 ME079 625 Washer, Wave .500idx0.750odx.015t Stl Lbs 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 ME010 224 Pin, Spring Cs .187 X 1.000 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 ME144 172 Ftg, Hose Brs Barbed M 3/16 Tbg X .250−20 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 ME098 615 Hose, Sae .187 Id X .410 Od X 20.000 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 ME225 306 Insulator, Motor 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 ME151 828 Pin, Cotter Hair .042 X .750 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 ME079 634 Pin, Hinge 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 ME166 071 Lever, Mtg Pressure Gear 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 ME085 243 Knob, Adjust Tension 1.250 Dia X .312−18 Thrd Stl 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 ME085 244 Washer, Cupped .328IDX .812ODX16GAX.125 Lip 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 ME089 562 Fastener, Pinned 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17 ME172 075 Carrier, Drive Roll W/Components 24 Pitch 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 ME220 221 Thermostat, NC Open 140C Close 110C Snap Action 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 ME225 934 Bus Bar, Interconnecting 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 ME026 947 Stand−Off, Insul .250−20 X 1.000 Lg X .312 Thd 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21 ME600 324 Cable, Weld Cop Strd No 4/0 Epdm Jkt As Rqd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22 ME221 347 Grommet, Bus Bar 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23 PC30 ♦ME211 444 Circuit Card Assy Trigger Hold/Burnback (Meter Option) 1. . . . . . . . . . . . . . . . . . . . .

24 ♦ME097 132 Stand-Off, No 6-32 X .375 Lg (Meter Option) 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25 PC1 ME218 488 Circuit Card Assy, Motor Speed Control 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26 ME097 132 Stand-Off, No 6-32 X .375 Lg 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27 ME210 133 Bracket, Capacitor Support SC12 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28 C1 ME177 360 Capacitor, Elctlt 20000 Uf 45 VDC Can 1.40 Dia 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29 ME207 678 Insulator, Capacitor 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30 ME211 989 Fitting, W/Screen 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31 ME220 805 Nut, 750-14 Knurled1.48hex .41h Nyl 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32 ME209 450 Nut, Hub 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33 ME172 919 Knob, Brake Adjust 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34 ME172 918 Spring 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35 ME201 309 Washer, Anti−turn 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36 ME225 069 Hub, Spool W/Threads 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37 ME058 424 Washer, Fibre (Brake) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38 ME221 052 Shroud, Wire 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

39 ME222 294 Clip, Wire/Cord .380 Bundle .250Hole .105 Thk Blk 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40 ME222 103 Support, Spool 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41 ME210 364 Cable, Power 17 In (Includes) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ME079 739 Conn, Circ Cpc Clamp Str Rlf Size 17−20 .703od 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ME600 797 Cable, Port No 16 8/C Type So Rb Jkt 1.4 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG9 ME141 162 Housing Plug+Pins, (Service Kit) As Rqd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG21 ME115 093 Housing Plug+Skts, (Service Kit) As Rqd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG41 ME131 204 Housing Plug+Skts, (Service Kit) As Rqd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42 ME139 041 Bushing, Strain Relief .481/.617 Id X1.115 Mtg Hole 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

43 ME215 980 Bushing, Strain Relief .709/.984 Id X1.375 Mtg Hole 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44 ME214 860 Nut, Ln Pg21 1.26Hex .14H Nickel Plated Brass 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

45 ME222 067 Insulator, Rear Panel 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46 ME182 445 Nut, Conduit 1.000 Npt Pld 1.688 Od X .200 Thk 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

47 GS1 ME216 126 Valve, Gas W/Fittings 24VAC 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

48 ME222 181 Grommet, Scr No 8/10 Panel Hole .281 Sq .031 High 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

49 ME221 051 Chassis, Control Box 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

50 ME208 000 Washer, Shldr.260 Id 0.630 Od X.125T .327Od X .062T Nyl 4. . . . . . . . . . . . . . . . . . . . . . . . .

OM-215 092 Page 19

Quanti

Page 24

ty

Dia.

Item

No.

Mkgs.

51 ME081 895 Nut, 010−32 Rubber .75Dia .81l Insert In .38Hole 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

52 ME147 195 Nut, 375−27 .54Hex .25h Nyl Flange .62D 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

53 S3 ME200 640 Switch, Rocker Dpdt 8A 125VAC On−None−(On) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

54 ME210 141 Nameplate, Inner 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

55 ME208 076 Panel, Inner 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

56 CB1 ME083 432 Circuit Breaker, Man Reset 1P 10A 250VAC Frict 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

57 ME208 015 Handle, Rubberized Carrying 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

58 ME221 050 Case, Control Feeder Plastic 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

59 PC4 ♦2ME10 768 Circuit Card Assy, Meter (Meter Option) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60 R1, R50 ME073 562 Pot, Cp Std Slot 1t 2. W 10k Linear 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61 ME225 312 Panel, Front 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

62 ME225 313 Nameplate 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

62 ♦ME225 370 Nameplate, (Meter Option) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

63 S1 ME111 997 Switch, Rocker Spst 10A 250VAC On−Off Visi Red Rock 1. . . . . . . . . . . . . . . . . . . . . . . .

64 S31 ♦ME120 376 Switch, Rocker Spdt 4A 250VAC On−None−On Spade Ter 1. . . . . . . . . . . . . . . . . . . .

65 S2 ME200 640 Switch, Rocker Dpdt 8A 125VAC On−None−On Black 1. . . . . . . . . . . . . . . . . . . . . . . . . .

66 ME193 920 Knob, Pointer .840 Dia X .250 Id W/One Set Screw 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

66 ♦ME093 551 Knob, Pointer (Meter Option) 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

67 ME070 654 Bushing, Strain Relief .300 Id X .550 Mtg Hole 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

68 ME221 998 Cable, Trigger 25 In (Includes) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

69 ME107 983 Blank, snap-in, nylon, .500 mounting hole, black 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

70 ME222 159 Spring, torsion 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RC2 ME048 834 Conn, Circ Cpc Clamp Str Rlf Size 11 .329OD 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG6 ME115 094 Housing Plug+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

♦ME133 644 Frame, Snap-In Switch Rocker Panel Mtg 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG1 ME115 093 Housing Plug+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG3 ME115 092 Housing Plug+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG4 ME115 091 Housing Plug+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG7 ME131 056 Housing Rcpt+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG8 ♦ME115 093 Housing Plug+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG13 ME131 054 Housing Rcpt+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG15 ♦ ME130 203 Housing Plug+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG16 ♦ ME131 055 Housing Rcpt+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG17 ♦ ME191 929 Housing, Wire To Board Crimp Spox 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG31 ♦ ME153 501 Housing Plug Pins+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG32 ♦ ME164 899 Housing Plug Pins+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG33 ME131 054 Housing Rcpt+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG34 ♦ME115 093 Housing Plug+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLG43 ♦ ME131 204 Housing Plug+Skts, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RC6 ME115 090 Housing Plug+Pins, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RC7 ME131 058 Housing Plug+Skts,(Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RC8, RC21 ME131 059 Housing Plug+Pins, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RC13 ME135 635 Housing Plug+Pins, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RC42 ME131 203 Housing Plug+Pins, (Service Kit) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part

No.

Figure 7-1. Complete Assembly (Continued)

ME049 455 Cable, Port No 18 2/C Type sjo nprn Jkt 3 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ME080 328 Rcpt W/Skts, Free Hanging 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ME223 814 Label, Warn Gen Precaution Suitcase 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ME223 815 Label, Warn Gen Precaution Suitcase (CE) 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ME196 596 Label, Warning Electric Shock And Pinch Wordless 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description

Quanti

. Meter/Trigger Hold feature optional in non-CE models, standard in CE models

♦ Optional

+When ordering a component originally displaying a precautionary label, the label should also be ordered.

To maintain the factory original performance of your equipment, use only Manufacturer’s Suggested

Replacement Parts. Model and serial number required when ordering parts from your local distributor.

OM-215 092 Page 20

Page 25

Table 7-1. Drive Roll And Wire Guide Kits for Wire Feeder SC 12 RC

Drive roll kit Product no. For Unitor welding wire

V-Groove 0.8 mm (0.030 in) 193-603118* GSP-W-200 0.8 mm

Ialbro-W-237 0.8 mm

Icuni-W-239 0.8 mm

V-Groove 1.2 mm (0.45 in) 193-603340

V-Groove 1.6 mm (1/16 in) 193-603373

V-Groove Knurled 0.9 mm (0.035 in) 193-603142 HST-SF-203 1.0 mm

S-316M-GF-221 0.9 mm

S-309M-GF-222 0.9 mm

V-Groove Knurled 1.8 mm (0.068/0.072 in) 193-603126** HST-SF-232 1.7 mm

U-Groove 0.9 mm (0.035 in) 193-603134 Alumag-W-235 1.0 mm

U-Groove 1.6 mm (1/16 in) 193-603498

* Included in wire feeder when first received.

** This wire comes in the form of coil with 245 mm dia x 75 mm (6.1 kg) and requires a spool adapter product no. 193-602839.

OM-215 092 Page 21

Page 26

Notes

Page 27

Notes

Page 28

Unitor ASA

Drammensveien 175

P.O. Box 300 Skoyen

N−0212 Oslo

Norway

Tel: +47 22 13 14 15

PRINTED IN USA 1/04

Loading...

Loading...