Page 1

Low noise operation allows for better

work site communication and safety.

72 db @ 7 m (no load—idle),

78 db @ 7 m (full load—high speed).

Processes

MIG (GMAW)

Flux Cored (FCAW)

Stick (SMAW)

TIG (GTAW)

Air Carbon Arc (CAC-A)

Cutting and Gouging

thru 1/4 in Carbons

Air Plasma Cutting

and Gouging with Optional

Spectrum Models

Output Range CC/DC: 20–350 A

CV/DC: 10–34 V

CC/AC: 35–250 A

Weld Output Rated at 104˚ F (40˚ C)

CC/DC and CV/DC: 300 A at 32 VDC, 100% Duty Cycle

350 A at 28 VDC, 60% Duty Cycle

CC/AC: 200 A at 25 VAC, 60% Duty Cycle

Generator Power Rated at 104˚ F (40˚ C)

12,000 watts continuous

Weight Net: 998 lb (453 kg)

Quick

Specs

Trailblazer®Pro 350 D

Diesel Engine-Driven

Welder/Generator

Issued March 2006 • Index No. ED/4.65

The professional welder’s choice with higher outputs is

designed to deliver the best arc performance with enough

weld power to dominate larger diameter flux cored wires

and air carbon arc gouging thru 1/4 in carbons.

Weld at Idle

™

—lock in idle and weld in

DC up to 180 A.

12,000 watts of generator power is

regulated to provide constant, strong

power and very good motor starting

characteristics. Power is independent

of weld control settings so that the

correct voltage is available at all times.

Even better weld performance

with an arc that dominates the

competition. In Stick mode, you

get a smooth E7018 and a great

E6010 arc with Arc-Drive and

Hot Start

™

standard. Great

MIG/FCAW arc and machine idles

with feeders hooked up. More

stable AC TIG and excellent starts

in DC scratch start TIG.

The Power of Blue®.

Welder/generator is warranted for 3 years, parts and labor.

Engine is warranted separately by the engine manufacturer.

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

Industrial Applications

Mechanical Contractors

Rig Owners

Structural Steel Work

Process Plant Piping

Fabrication

With a compact and lightweight

design at only 998 lb, a smaller

truck can be used, and related

transportation costs will be reduced.

Low height allows the driver to see

over the machine when mounted

on a truck bed and the machine fits

sideways in a standard pickup.

Weld meters now standard.

Automatic Start at Idle

™

idles engine

immediately when started, extending

engine life and reducing

fuel consumption and noise.

Toolless top and side engine access

allows easy and faster maintenance

with little clearance space needed.

Toolless remote oil drain is standard.

Standard 14-pin receptacle easily

connects feeders or remote controls

for enhanced process operation.

Automatic idle in all processes,

including MIG/FCAW with feeders

to save fuel and reduce noise.

26 HP, 3-cylinder Kubota diesel

engine with its durable, proven

liquid-cooled design is the world

standard for small diesel engines.

Engine shutdowns standard.

Cold weather starting aids such as

standard glow plugs and block heater

ensure good starts in cold weather.

Strong 120/240 V power while welding

to run tools and inverter welders. See

page 3 of literature.

Page 2

Welding

Mode

CC/DC

CV/DC

CC/AC

Weld Output Rated at

104˚ F (40˚ C)

300 A, 32 VDC, 100% Duty Cycle

350 A, 28 VDC, 60% Duty Cycle

200 A, 25 VAC, 60% Duty Cycle

Output

Range

20–350 A

10–34 V

35–250 A

Max. Open-Circuit

Voltage DC

80

50

70

CSA approved. *Net weight with 2 gal of fuel. Add 40 lb for shipping weight.

2

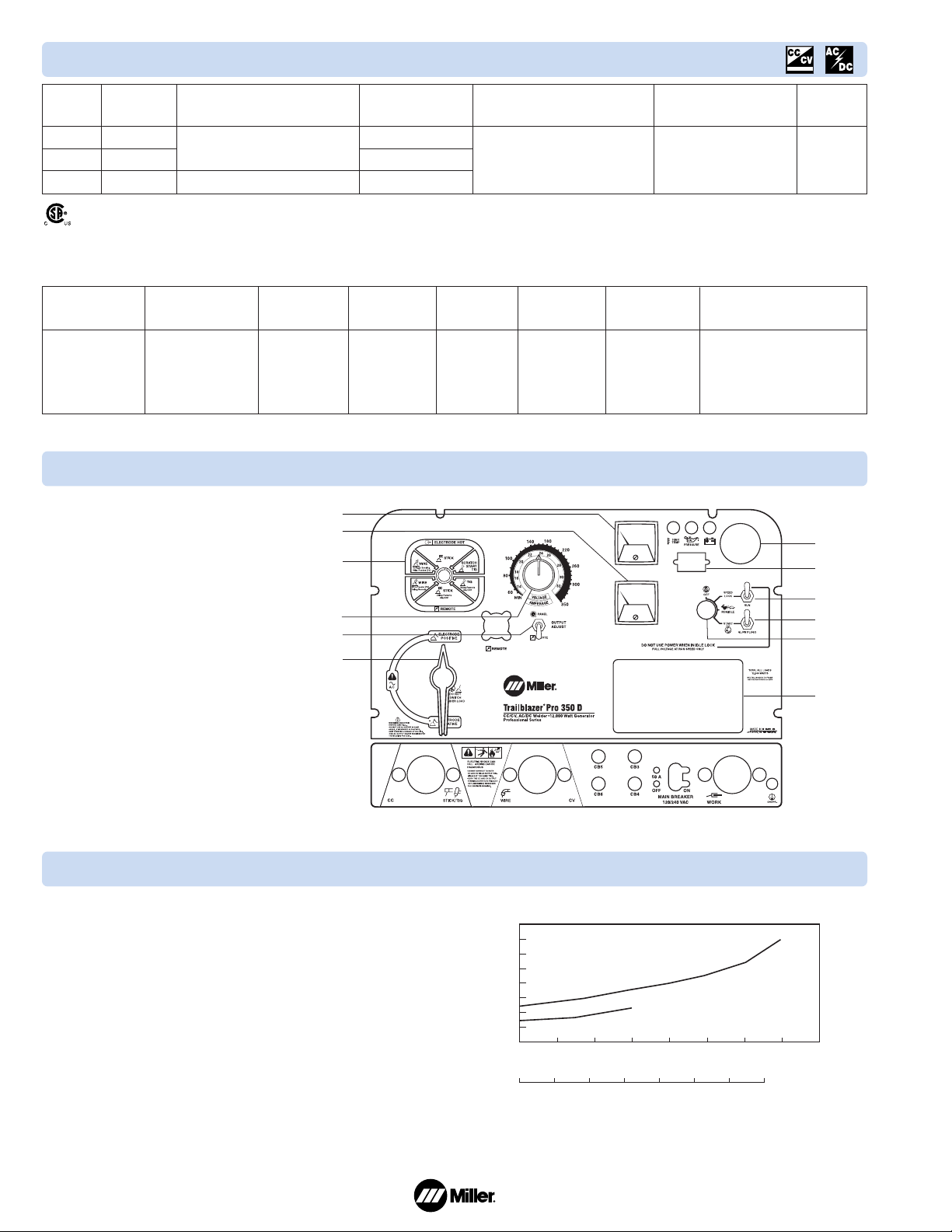

Control Panel

Weight*

Net: 998 lb

(453 kg)

Dimensions

H: 30 in (762 mm)

W: 24 in (610 mm)

D: 59-1/2 in (1511 mm)

Single-Phase Generator Power

Output Rated at 104˚ F (40˚ C)

12 kVA/KW, 120/240 VAC,

100/50 A, 60 Hz

Specifications (Subject to change without notice.)

1. Voltmeter

2. Ammeter

3. Process/Contactor Switch

4. Voltage/Amperage Adjustment Control

5. Voltage/Amperage Adjust Switch and

Remote 14 Receptacle

6. DC Polarity/AC Selector Switch

7. Fuel Gauge

8. Hour Meter

9. Engine Speed Switch

10. Glow Plug Switch

11. Engine Control Switch

12. 120/240 V Receptacles

Note: GFCIs are standard

Performance Data

FUEL CONSUMPTION DATA

• 13-gallon fuel capacity.

• Welding at 150 A at 40% duty cycle, uses only

.61 gallon per hour— over 20 hours of operation.

Engine Specifications (Subject to change without notice.)

Engine Brand

Kubota DH905

2-year limited

North American

Manufacturer

Warranty

Horsepower (HP)

26 at 3600 RPM

Weld Speed

3600 RPM

Idle Speed

2525 RPM

Type

3-cylinder,

industrial,

liquid-cooled

diesel

Fuel

Capacity

13 gal (49 L)

Oil

Capacity

5.4 qt (5.1 L)

High Coolant Temp/

Low Oil Pressure Shutdown

Standard

1

2

3

4

5

6

7

8

9

10

11

12

7.57

LITERS/HR.

2.00

1.756.62

1.505.67

1.254.73

1.003.78

0.752.84

0.501.98

0.250.95

IDLE

00

0 50 150100 200 250 300 400350

FUEL CONSUMPTION

DC STICK/AUX POWER

(HIGH SPEED)

DC STICK

(LOW SPEED)

DC POWER AMPS AT 100% DUTY CYCLE

02146810

POWER KVA AT 100% DUTY CYCLE

U.S. GAL/HR.

12

Page 3

3

Performance Data (continued)

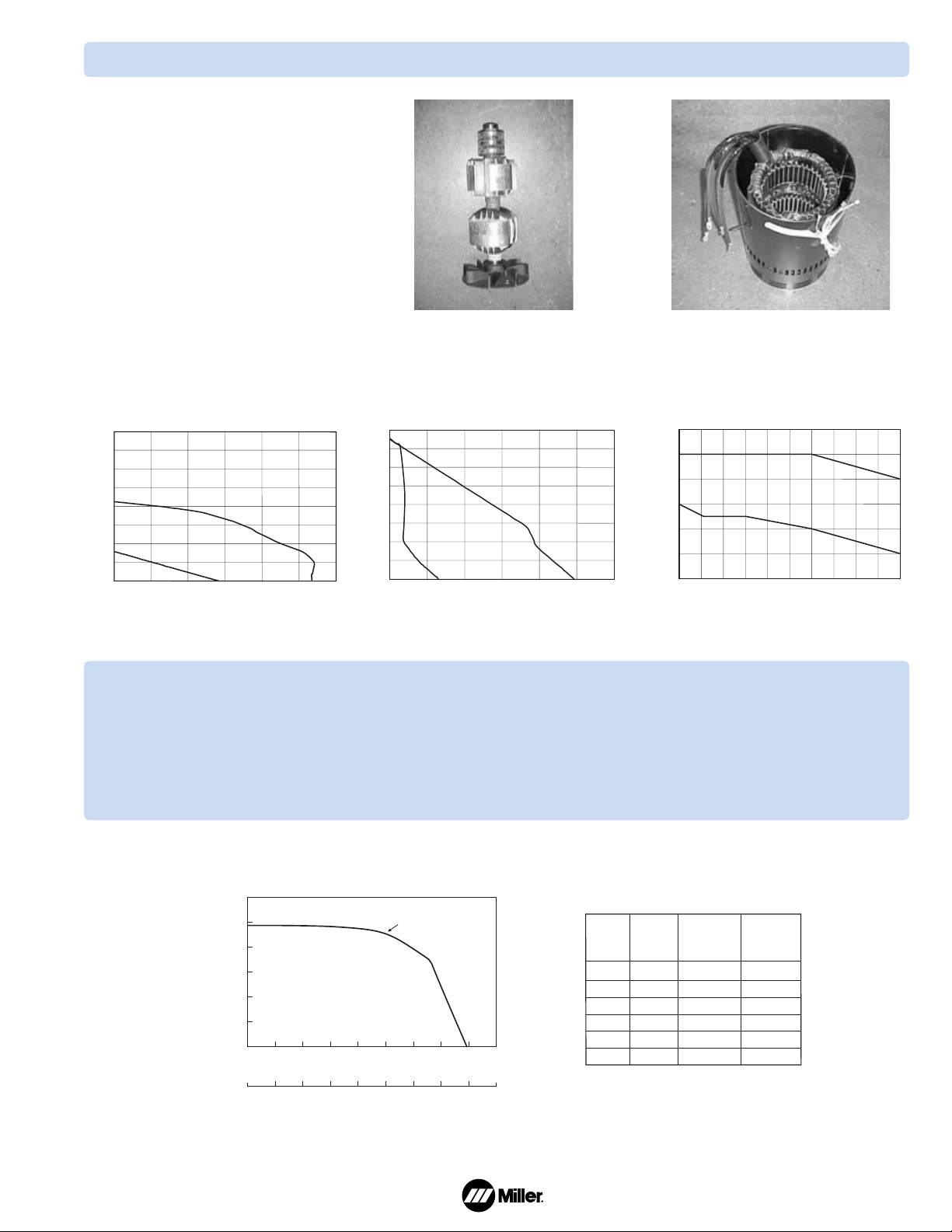

All Trailblazers have 2 generators—

a 4-pole, 3-phase weld generator and a

strong power generator.

TRAILBLAZER ADVANTAGE: No interaction

between grinders, power tools, etc. and

the welding arc. Generator power is also

independent of weld control settings.

POWER IS IN THE NUMBERS

• Tested and rated at higher temperatures, 104˚ F (40˚ C), to ensure consistent operation in all climates.

• Patented generator control technology matches the generator’s output to engine horsepower providing maximum efficiency

and more weld output.

• The generator is voltage regulated to provide strong power while keeping the voltage 120/240 volts. This increases

tool/motor performance and tool/motor life.

StatorRotor

MINIMUM AND MAXIMUM - MIG MODE

VOLT/AMP CURVES

80

70

60

50

40

VOLTS

30

20

10

0

0 100 200 300 400 500 600

AMPERES

MINIMUM AND MAXIMUM - STICK MODE

80

70

60

50

40

VOLTS

30

20

10

0

0 100 200 300 400 500 600

VOLT/AMP CURVES

AMPERES

DUTY CYCLE CHART

400

350

DC Weld

300

250

AC Weld

200

WELD AMPERES

150

100

0 102030405060708090100

% DUTY CYCLE

300

GENERATOR POWER CURVE

150

250

125

200

100

150

75

AC VOLTS

100

50

50

25

0

0

0 10203040 506070 8090

0 20 40 60 80 100 120 140 160 180

AC AMPERES IN 240V MODE

AC AMPERES IN 120V MODE

12 kW

SIMULTANEOUS WELDING

AND GENERATOR POWER

Weld

Current

(Amps) Watts

0

100

150

200

300

350

Receptacle

12,000

11,000

9,500

7,500

3,000

1,000

120V 1P

Amps

100

90

80

62

25

10

240V 1P

Receptacle

Amps

50

45

40

31

12

5

Page 4

4

Genuine Miller Options

Lockable Flame Arrestor Fuel Cap

#043 947 Field

Spark Arrestor Kit #194 871 Field

Full KVA Plug Kit

#119 172 Field

240/120 VAC singlephase, 50 amp plug

(NEMA 14-50P) to fit

full KVA receptacle.

Protective Cover

#195 125 Blue, with Miller logo

Attractive, waterproof cover resists stains

and mildew, and protects the finish of

your welder.

Multioperator

CST™280 #907 244

The CST 280 CC/DC power source can be

run off the machine’s generator to provide

two arcs with only one engine. At only 41 lb

(18.6 kg), it is portable enough to take

anywhere. See Lit. Index No. DC/29.55.

Plasma Cutters

Spectrum®625 #907 058

Economical plasma cutting system

rated to cut 7/8 in. See Lit. Index

No. PC/9.5.

Spectrum 2050 #903 777-01-2

Portable, easy-to-carry unit is an excellent

choice for cutting jobs up to 3/4 in. See Lit.

Index No. PC/7.0.

MIG/Flux Cored Welding

SuitCase™8VS Wire Feeder #194 890

SuitCase™X-TREME™12VS Wire Feeder

#195 500

Lightweight, portable, voltage-sensing

wire feeders include secondary contactor

and gas valve. Require drive roll kit.

See Lit. Index No. M/6.4, M/6.41.

SuitCase

™

8RC Wire Feeder #194 938

SuitCase™12RC Wire Feeder #194 940

Lightweight, modular design and flexible

enough to run a variety of wires up to

.062 in diameter. Comes standard with

remote voltage control. See Lit. Index

No. M/6.5.

Genuine Miller Accessories

Page 5

5

Genuine Miller Accessories

(Continued)

MIG/Flux Cored Welding (Continued)

Spoolmatic

®

30A #130 831

A 1-lb, air-cooled spool gun that extends

the weld process range by adding a handy

portable system for small wire MIG. Rated

200 A at 100% duty cycle. Includes 30 ft

(9.1 m) cable assembly. WC Control

required. See Lit. Index No. M/1.5.

WC-24 Control #137 549

To be used with Spoolmatic 30A.

XR Wire Feeders and Guns

Push-pull system designed to handle

difficult-to-feed soft alloy wires such as

aluminum. See Lit. Index No. M/1.7.

MIG (GMAW)/Flux Cored (FCAW) Guns

Miller produces a complete line of

dependable MIG guns. Check literature

for complete details. See Lit. Index Nos.

AY/16.0 and AY/17.0.

Stick (SMAW) Welding

Weld Leads

#173 851 2/0, 350 A, 100% duty cycle,

50 ft (15.2 m) stinger, 50 ft (15.2 m)

work cable.

#043 952 2/0, 300 A, 100% duty cycle,

100 ft (30.5 m) stinger, 50 ft (15.2 m)

work cable.

TIG (GTAW) Welding

HF-251 Series

#042 388 HF-251D-1, 115 VAC

High-frequency arc starter and stabilizer.

See Accessory Literature, Index No. AY/5.0.

Remote Controls and Switches

RFCS-14 HD Foot Control #194 744

For all Miller solid-state power sources

after serial number JK674521. This new

design increases stability with a larger

base, and durability with a heavier cord.

Maximum flexibility is accomplished with a

reconfigurable cord that can exit the front,

back or either side of the pedal. Foot pedal

provides remote current and contactor

control. Includes 20 ft (6 m) cord and

14-pin plug.

RHC-14 Hand Control #129 340

Miniature hand control for remote current

and contactor control. Dimensions: 4 x 4 x

3-1/4 in (102 x 102 x 82 mm). Includes

20 ft (6 m) cord and 14-pin plug.

RCC-14 Remote Contactor and Current

Control #151 086

Rotary-motion fingertip control. Fastens to

TIG torch using two Velcro strips. Allows

complete current and contactor control at

operator’s fingertips. Includes 28 ft (8.5 m)

cord and plug.

Extension Cords for 14-Pin

Remote Controls

#122 973 25 ft (7.6 m)

#122 974 50 ft (15.2 m)

#122 975 75 ft (22.9 m)

PRHC-14 Hand Control #195 511

For all solid-state power sources after

serial number JK674521. Complete current

or voltage control brings 120 volts GFCI

power to work area in a single cord.

Housed in a durable light aluminum case

and includes 125 ft (38 m) cord with plugs.

Page 6

Trailer Specifications (Subject to change without notice.)

Net

Payload

2650 lb

(1202 kg)

Gross Vehicle

Weight Rating

2960 lb

(1343 kg)

Gross Axle

Weight

Rating

3500 lb

(1588 kg)

Model

HWY-224

Height

of Bed

18-1/2 in

(470 mm)

Road

Clearance

7-1/2 in

(191 mm)

Net

Weight

355 lb

(161 kg)

Track

(Center to

center of tires)

52 in

(1321 mm)

Standard Tires

(Standard rating

or P-size rating)

B-78-13C

Dimensions

Length: 105-1/2 in (2680 mm)

Width: 61 in (1549 mm)*

*

Width at outside of fenders.

6

HWY-224 Trailer #043 805

A 2650 lb (1202 kg) capacity highway

trailer. Welded steel tubing frame, heavyduty axle with roller bearing hubs and leafspring suspension. The HWY-224 comes

with jack stand, 2 in (50 mm) ball hitch,

fenders and lights.

Note: Trailer is shipped unassembled.

Lunette Eye 2-1/2 in (64 mm) #043 824

For use with 224 trailer.

Cable Tree #043 826

Provides an area to conveniently wrap weld

cables and extension cords. For use with

224 trailer.

Trailers and Hitches

(For both models.)

Mounting Specifications

4 Holes

G

A

B

C

D

E

F

Front Panel End

A. 23-5/8 in (600 mm)

B. 21-1/2 in (546 mm)

C. 1 in (25 mm)

D. 15-5/8 in (397 mm)

E. 26-3/8 in (679 mm)

F. 58-3/4 in (1492 mm)

G. 13/32 in (10 mm) Dia.

Overall Dimensions

Height: 30 in (762 mm)

36 in (914 mm)

to top of exhaust

Width: 24 in (610 mm)

Depth: 59-1/2 in (1511 mm)

Page 7

7

Applications

MIG (GMAW) Basic Equipment

SuitCase 8RC #194 938

SuitCase 12RC #194 940

MIG (GMAW) Basic Equipment

Spoolmatic 30A #130 831

WC-24 #137 549

Stick (SMAW) Basic Equipment

MIG Gun

SuitCase

8RC or 12RC

Work

Aluminum MIG with

Spoolmatic 30A Gun

WC-24

Work

Stick Electrode

Work

TIG Torch

TIG (GTAW) Basic Equipment

HF-251D-1 #042 388

Flux-Cored (FCAW) Basic Equipment

Suitcase 8VS #194 890

SuitCase X-TREME 12VS #195 500

Plasma Basic Equipment

HF-251D-1

Work

FCAW Gun

SuitCase

8VS or 12VS

Work

Cutting Torch

Spectrum

Work

Stick Electrode

Multiple Operator Basic Equipment

CST 280 #907 244

CST 280

Work

Any Weld Process

Page 8

Litho in USA

Distributed by:

Equipment and Options Stock No. Description Qty. Price

Trailblazer®Pro 350 D #907 068 Base machine, CC/CV, AC/DC, 12,000 Watts

Options

Spark Arrestor Kit #194 871 Field

Lockable Flame Arrestor Fuel Cap #043 947 Field

Full KVA Plug Kit #119 172 Field

Accessories

Protective Cover #195 125 Blue, with Miller logo

Remote Controls

RFCS-14 HD #194 744 Foot control

RHC-14 #129 340 Hand control

RMLS-14 #129 337 Momentary- and maintained-contact switch

RCC-14 #151 086 Fingertip control

PRHC-14 #195 511 Current/voltage hand control and 120 VAC power

Extension Cords #122 973 25 ft (7.6 m)

#122 974 50 ft (15.2 m)

#122 975 75 ft (22.9 m)

Stick Accessories

Weld Leads #173 851 2/0, 350 A, 100% duty cycle, 50 ft (15.2 m) stinger, 50 ft (15.2 m) work cable

#043 952 2/0, 300 A, 100% duty cycle, 100 ft (30.5 m) stinger, 50 ft (15.2 m) work cable

Stick Electrodes

Flux Cored/MIG Accessories

SuitCase™8VS #194 890 Includes contactor and gas valve. See Lit. Index No. M/6.4

SuitCase™X-TREME™12VS #195 500 Includes contactor and gas valve. See Lit. Index No. M/6.41

SuitCase™8RC #194 938 Includes contactor and gas valve. See Lit. Index No. M/6.5

SuitCase™12RC #194 940 Includes contactor and gas valve. See Lit. Index No. M/6.5

MIG (GMAW)/Flux Cored (FCAW) Guns See Lit. Index No. AY/16.0 and AY/17.0

Gun Consumables

Aluminum MIG Accessories

Spoolmatic®30A/WC-24 Control #130 831/#137 549 See Lit. Index No. M/1.5

XR Wire Feeder and Guns See Lit. Index No. M/1.7

Gun Consumables

TIG Accessories

HF-251D-1 #042 388 See Lit. Index No. AY/5.0

Water Coolant Systems See Lit. Index No. AY/7.2

TIG Torch

Consumables

Tungsten

Multiple Operator Accessories

CST™280 #907 244 See Lit. Index No. DC/29.55

Plasma Cutting Accessories

Spectrum®625 #907 058 See Lit. Index No. PC/9.5

Spectrum®2050 #903 777-01-2 See Lit. Index No. PC/7.0

Trailers and Hitches

HWY-224 Trailer #043 805

Lunette Eye #043 824 For use with 224 trailer

Cable Tree #043 826 For use with 224 trailer

Date: Total Quoted Price:

Ordering Information

Loading...

Loading...