Page 1

Processes

TM-353E January 2001

Eff. w/Serial Number JJ339876

Description

TIG (GTAW) Welding

Stick (SMAW) Welding

Arc Welding Power Source

Syncrowave 250

60 Hz, 50 Hz

R

Visit our website at

www.MillerWelds.com

Page 2

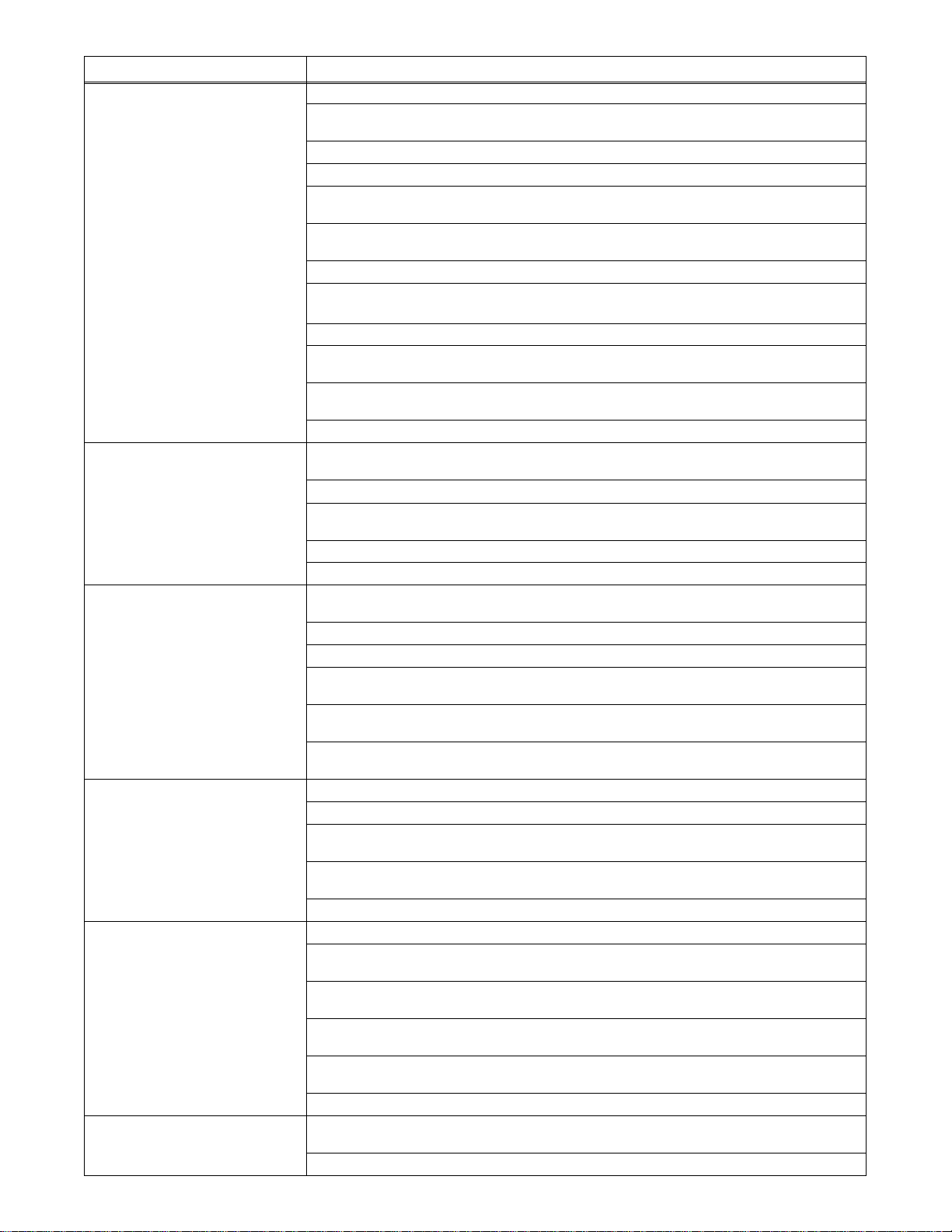

TABLE OF CONTENTS

1. Safety Precautions – Read Before Using 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Symbol Usage 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Servicing Hazards 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 EMF Information 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – DEFINITIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. Warning Label Definitions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2. Rating Label For CE Products 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3. Symbols And Definitions 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – INSTALLATION 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. Specifications 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. Volt-Ampere Curves 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. Duty Cycle And Overheating 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4. Selecting A Location 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5. Dimensions And Weights 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6. Tipping 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7. Weld Output Terminals And Selecting Cable Sizes 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8. Remote 14 Receptacle 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9. 115 Volts AC Duplex Receptacle And Shielding Gas Connections 10. . . . . . . . . . . . . . . . . . . . . .

3-10.Electrical Service Guide 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11.Placing Jumper Links And Connecting Input Power 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 – OPERATION 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. Controls 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2. Output Selector Switch 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3. Meters 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

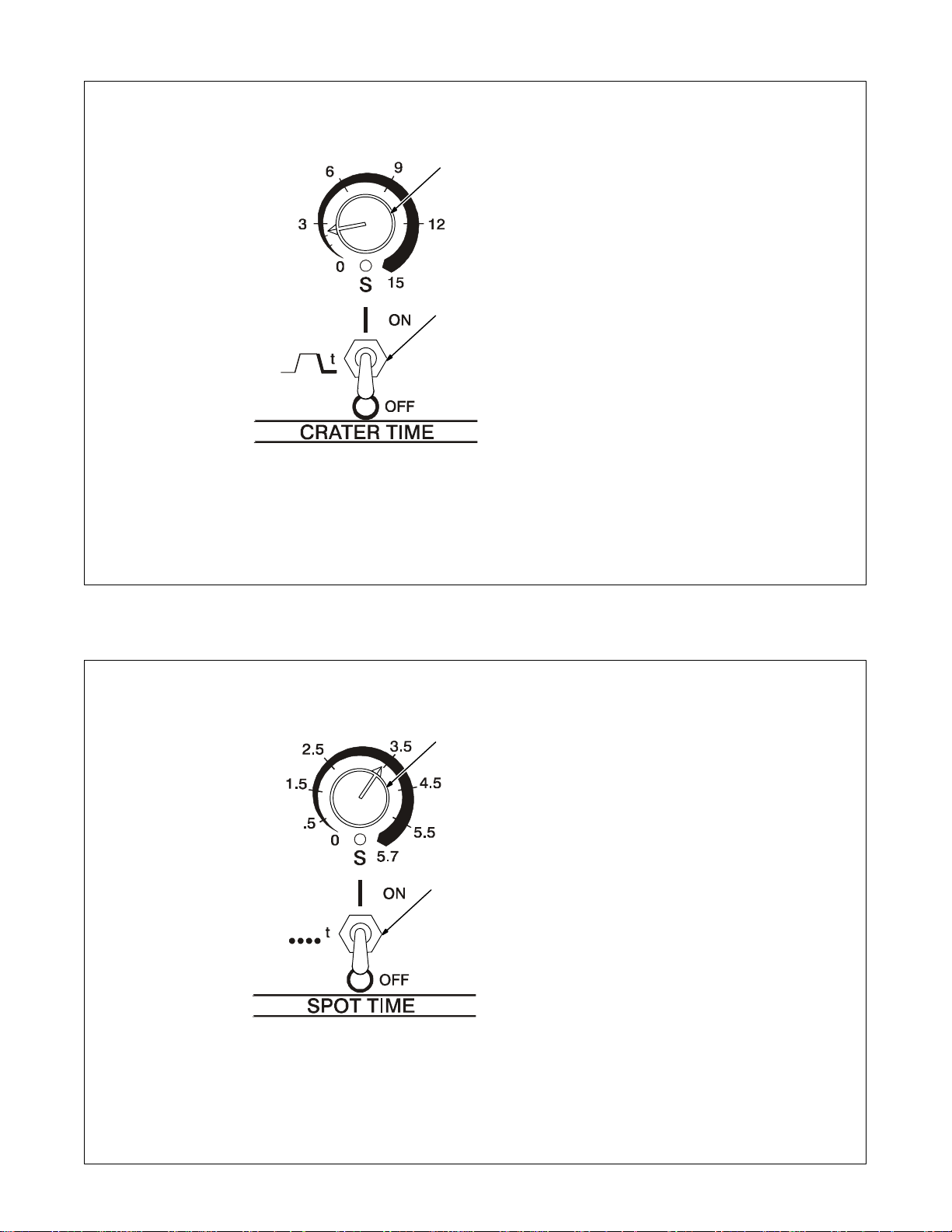

4-4. Crater Time Controls 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5. Spot Time Controls 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

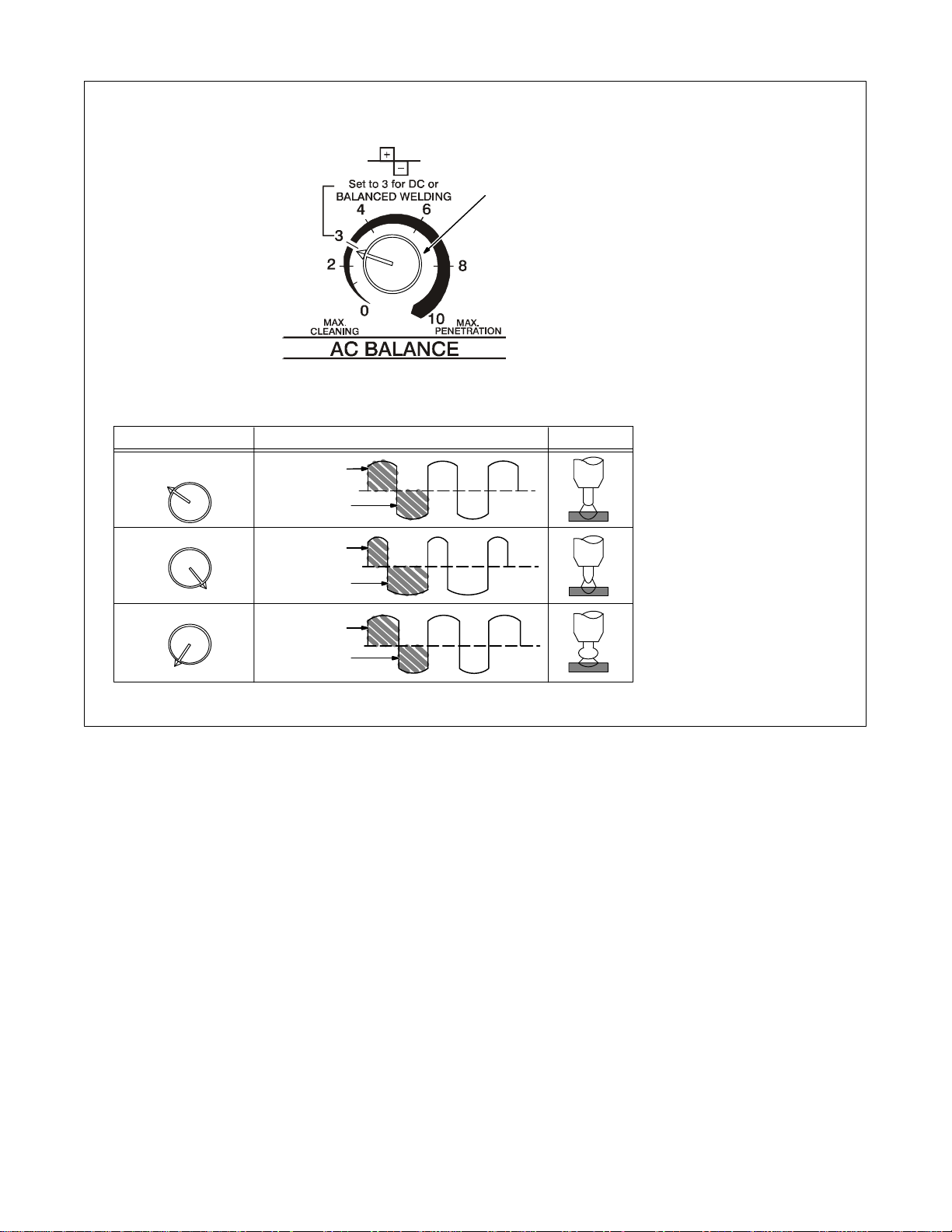

4-6. AC Balance Control 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

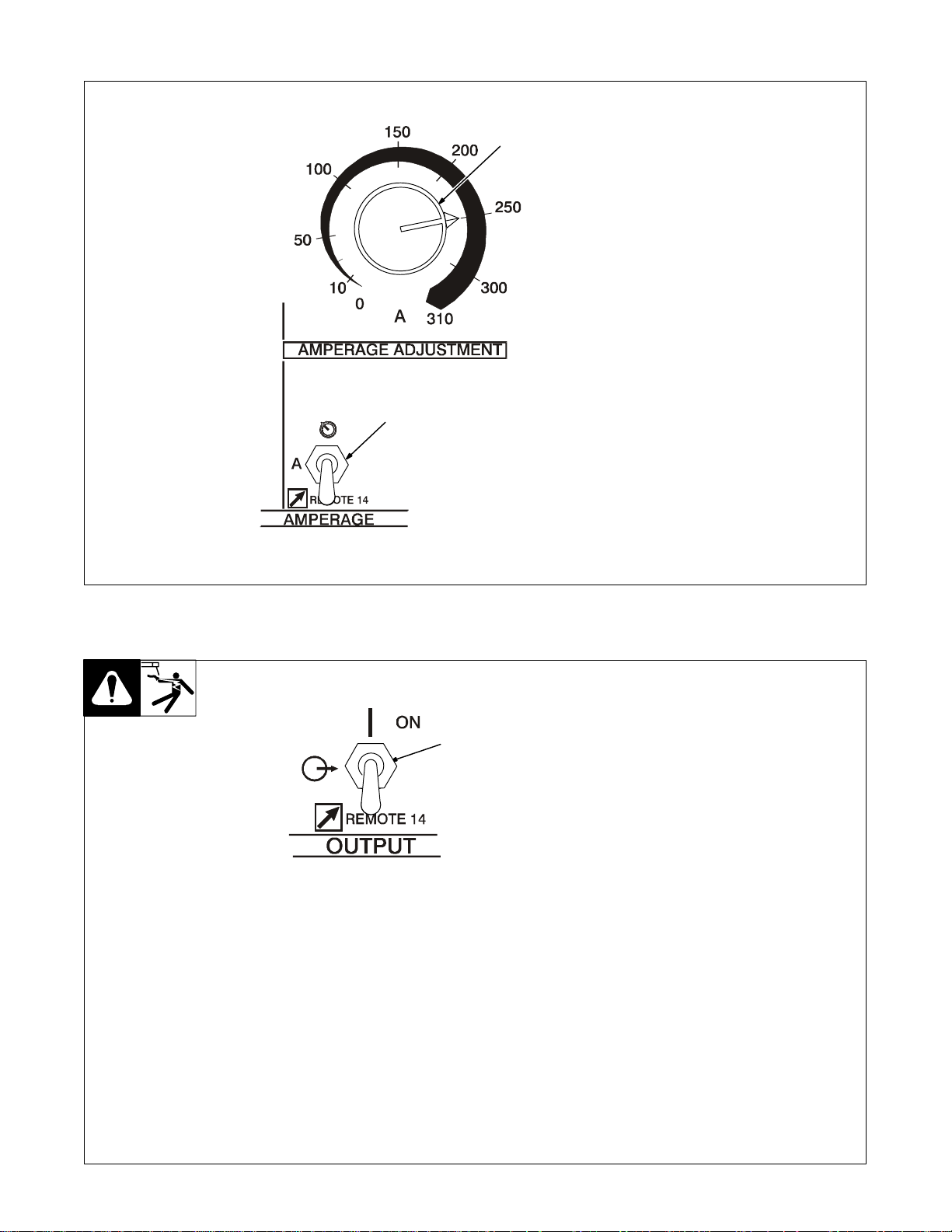

4-7. Amperage Adjustment Controls 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8. Output (Contactor) Control Switch 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

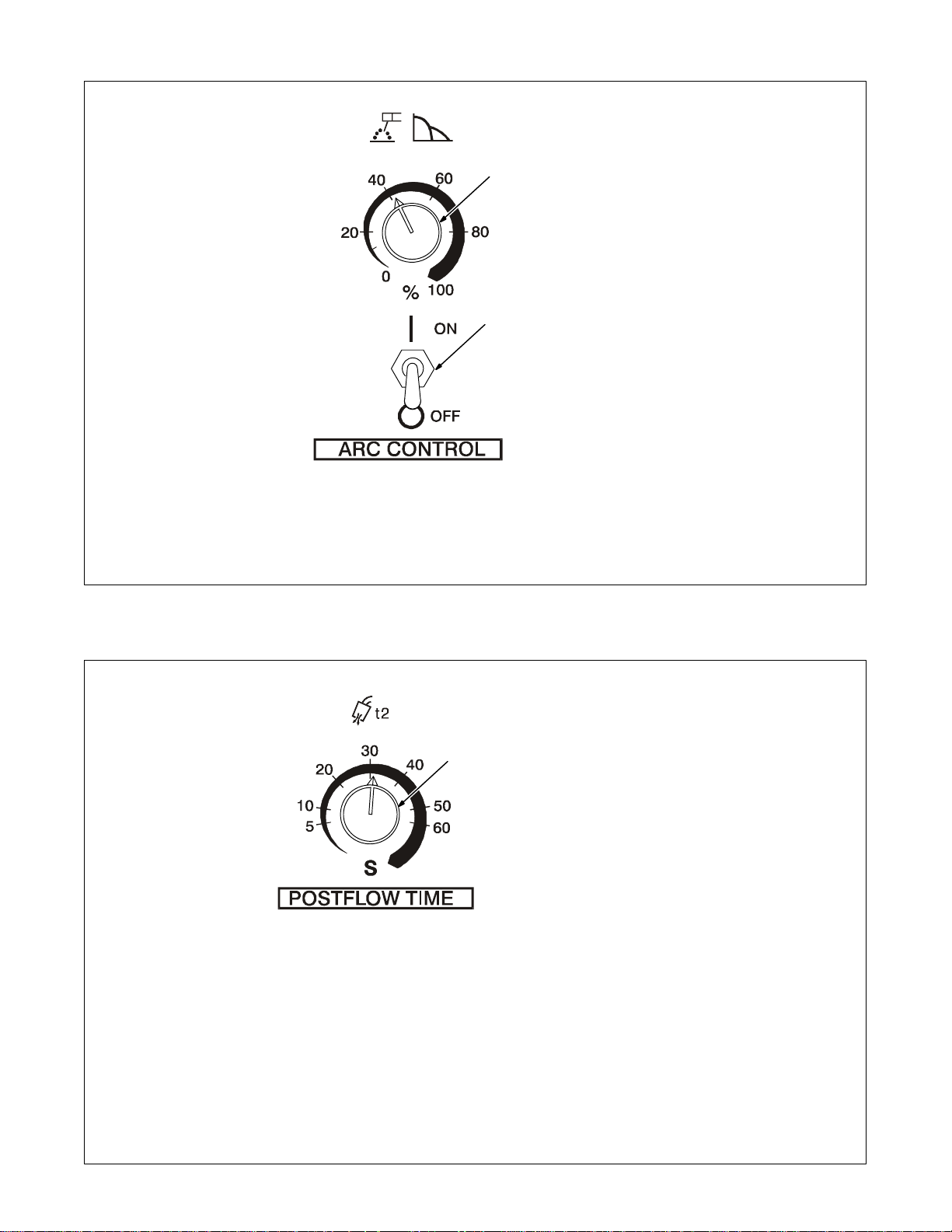

4-9. Arc Controls 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10.Postflow Time Control 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

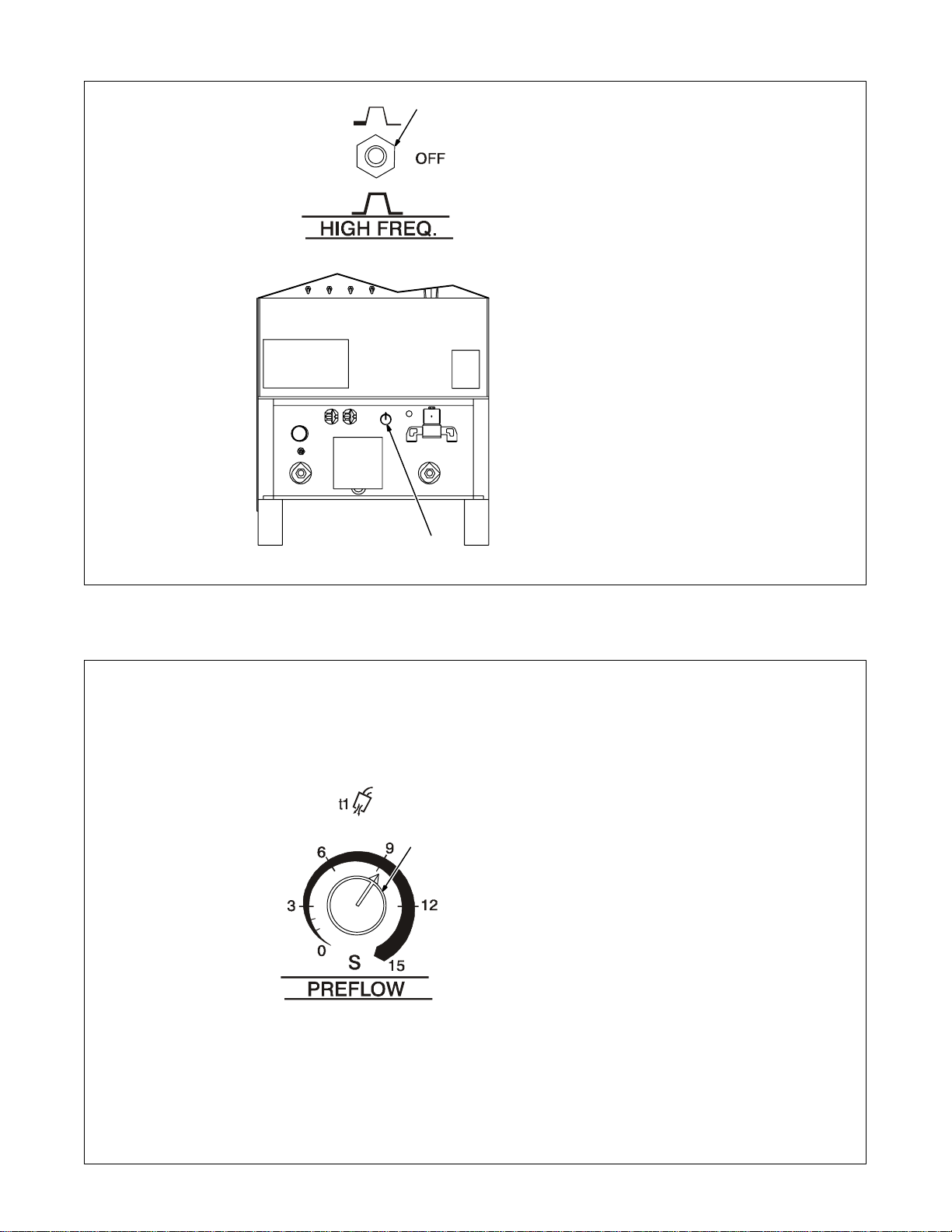

4-11.High Frequency Controls 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

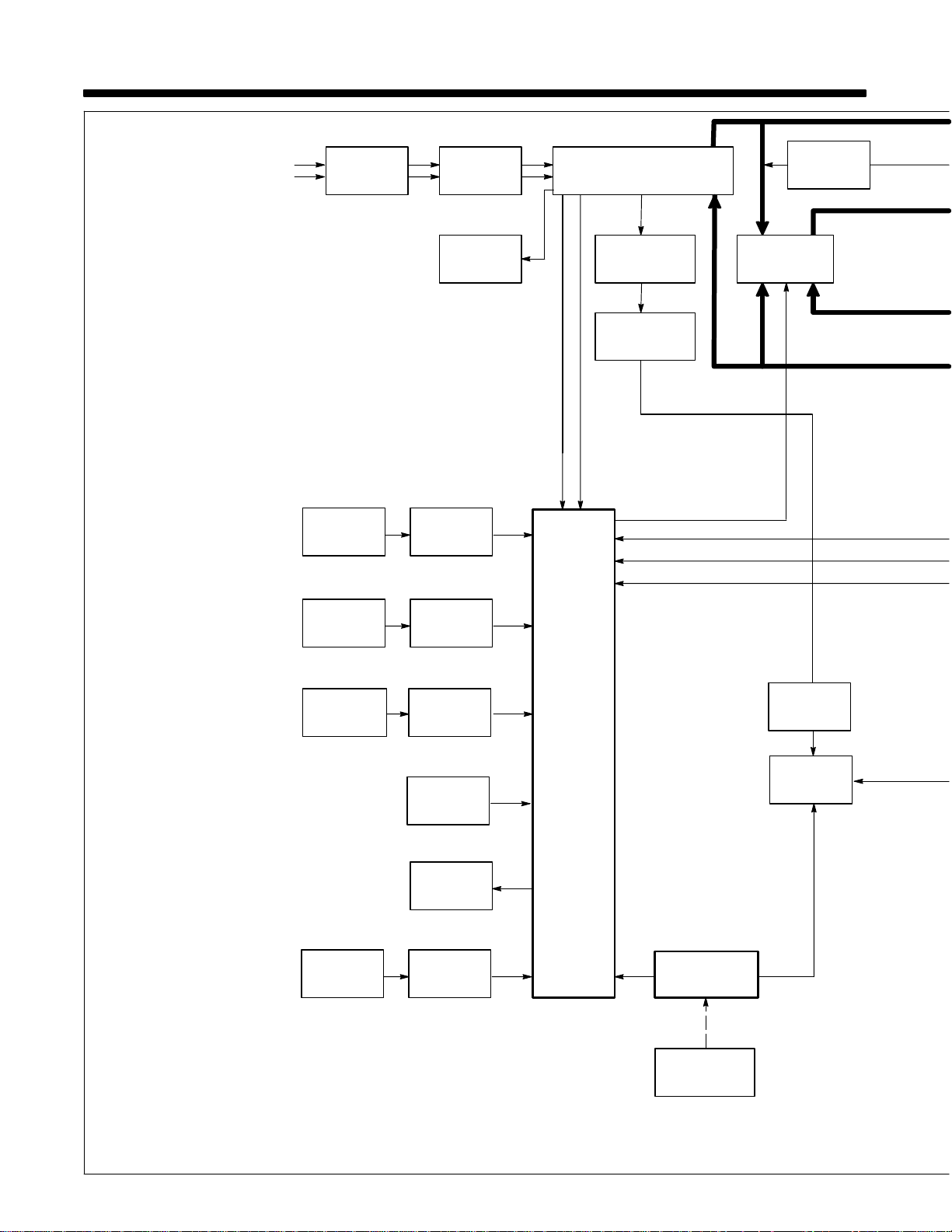

4-12.Preflow Time Control (Optional) 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

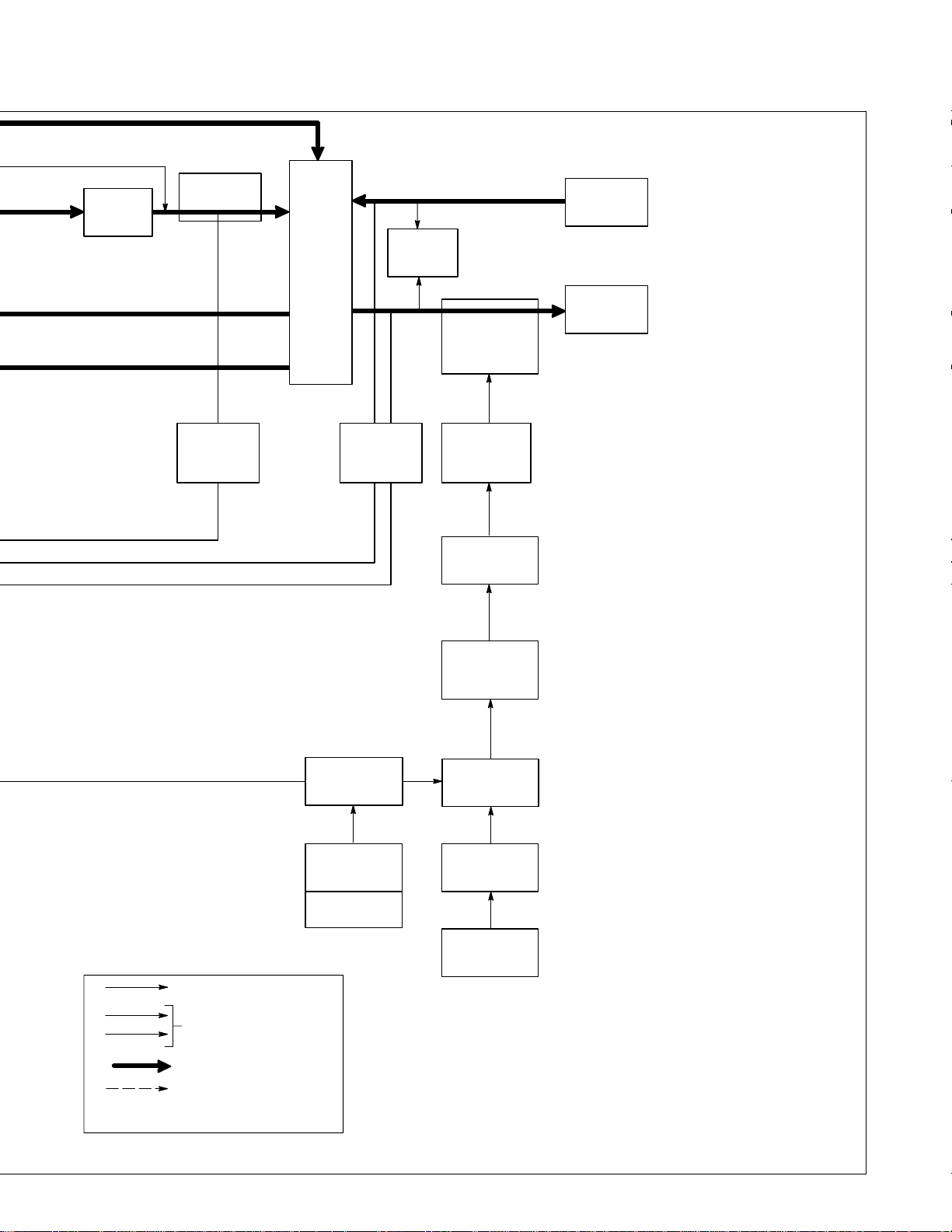

SECTION 5 – THEORY OF OPERATION 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – TROUBLESHOOTING 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1. Troubleshooting Table 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2. Troubleshooting Circuit Diagram For Welding Power Source 26. . . . . . . . . . . . . . . . . . . . . . . . . .

6-3. Waveforms For Section 6-2 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4. Control Board PC1 Testing Information (Use With Section 6-5) 30. . . . . . . . . . . . . . . . . . . . . . . .

6-5. Control Board PC1 Test Point Values 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6. Remote Board PC2 Testing Information (Use With Section 6-7) 33. . . . . . . . . . . . . . . . . . . . . . . .

6-7. Remote 14 Filter Board PC2 Test Point V alues (Use With Section 6-2 And Section 6-6) 34. . . .

6-8. Meter Calibration 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-9. Input Voltage Labels And Connections 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7 – MAINTENANCE 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1. Routine Maintenance 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2. Circuit Breaker CB1 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3. Fuses F1 And F2 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4. Adjusting Spark Gaps 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8 – HIGH FREQUENCY (HF) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1. Welding Processes Using HF 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2. Sources Of HF Radiation From Incorrect Installation 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3. Correct Installation 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

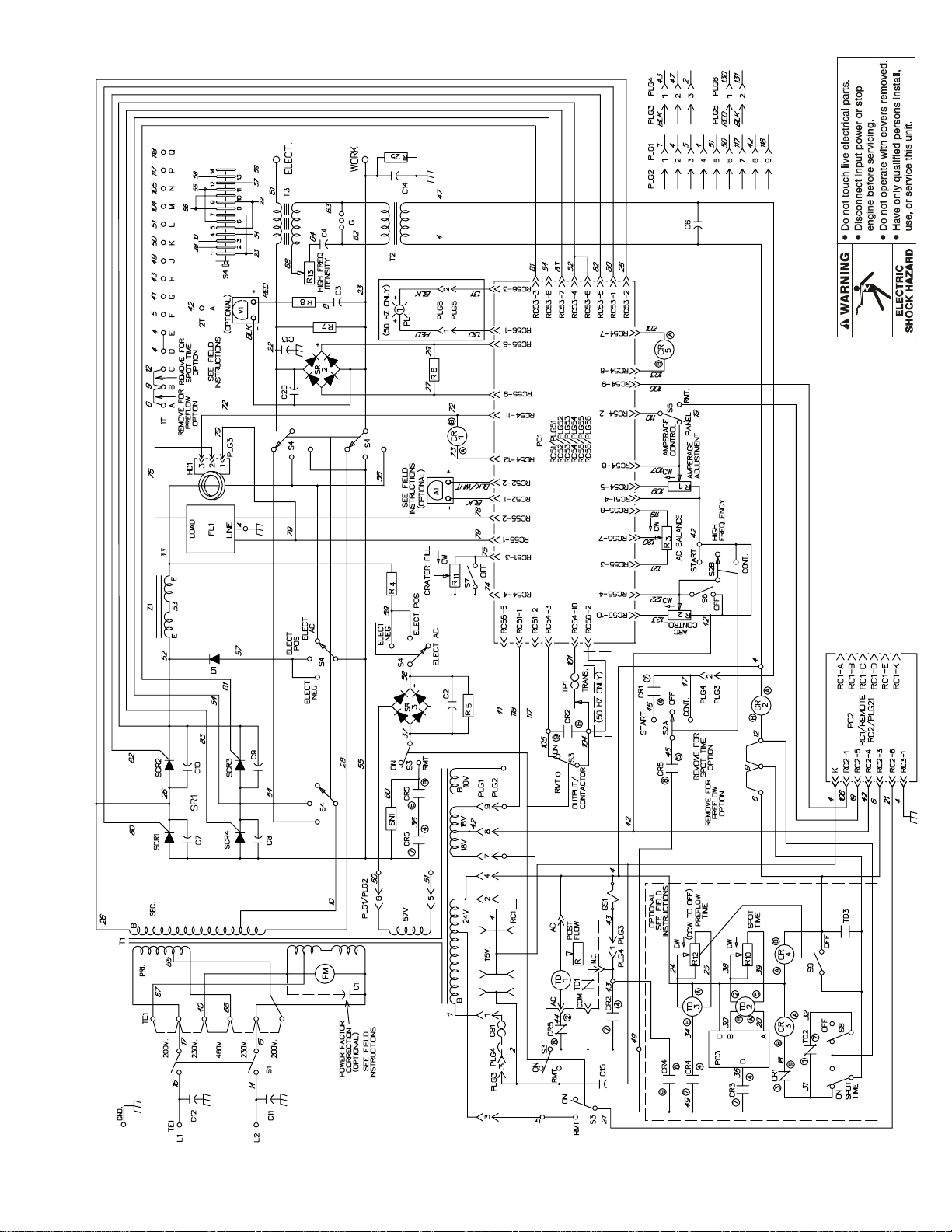

SECTION 9 – ELECTRICAL DIAGRAMS 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 10 – PARTS LIST 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM-353D

Page 3

Declaration of Conformity For

European Community (CE) Products

NOTE

Manufacturer’s Name: Miller Electric Mfg. Co.

Manufacturer’s Address: 1635 W. Spencer Street

This information is provided for units with CE certification (see rating label on unit.)

Appleton, WI 54914 USA

Declares that the product: Syncrowave 250

conforms to the following Directives and Standards:

Directives

Low Voltage Directive: 73/23/EEC

Machinery Directives: 89/392/EEC, 91/368/EEC, 93/C 133/04, 93/68/EEC

Electromagnetic Capability Directives: 89/336, 92/31/EEC

Standards

Safety Requirements for Arc Welding Equipment part 1: EN 60974-1: 1990

Arc Welding Equipment Part 1: Welding Power Sources: IEC 974-1

(April 1995 – Draft revision)

Degrees of Protection provided by Enclosures (IP code): IEC 529: 1989

Insulation coordination for equipment within low-voltage systems:

Part 1: Principles, requirements and tests: IEC 664-1: 1992

Electromagnetic compatibility (EMC) Product standard for arc welding equipment:

EN50199: August 1995

European Contact: Mr. Luigi Vacchini, Managing Director

MILLER Europe S.P.A.

Via Privata Iseo

20098 San Giuliano

Milanese, Italy

Telephone: 39(02)98290-1

Fax: 39(02)98281-552

dec_con1 10/95

Page 4

Page 5

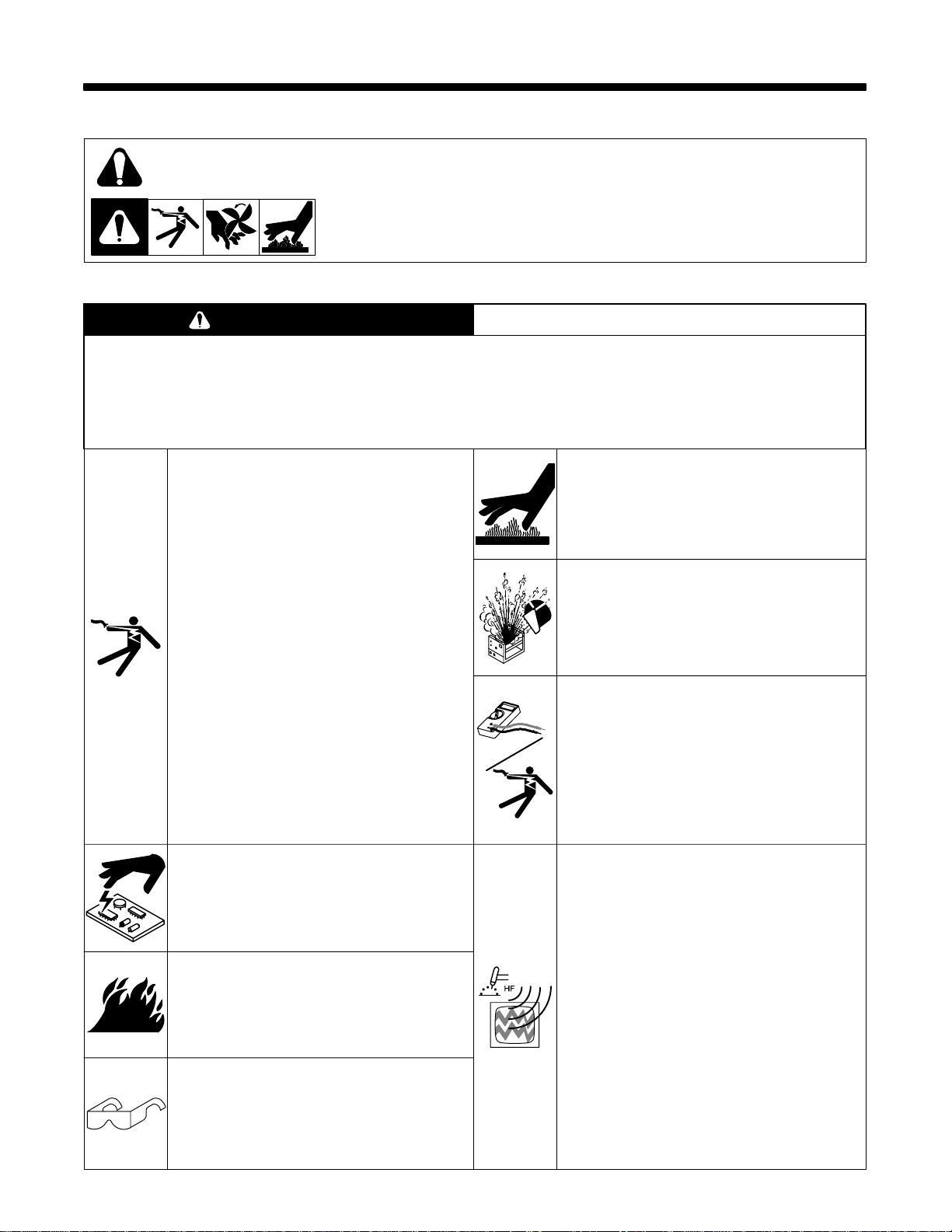

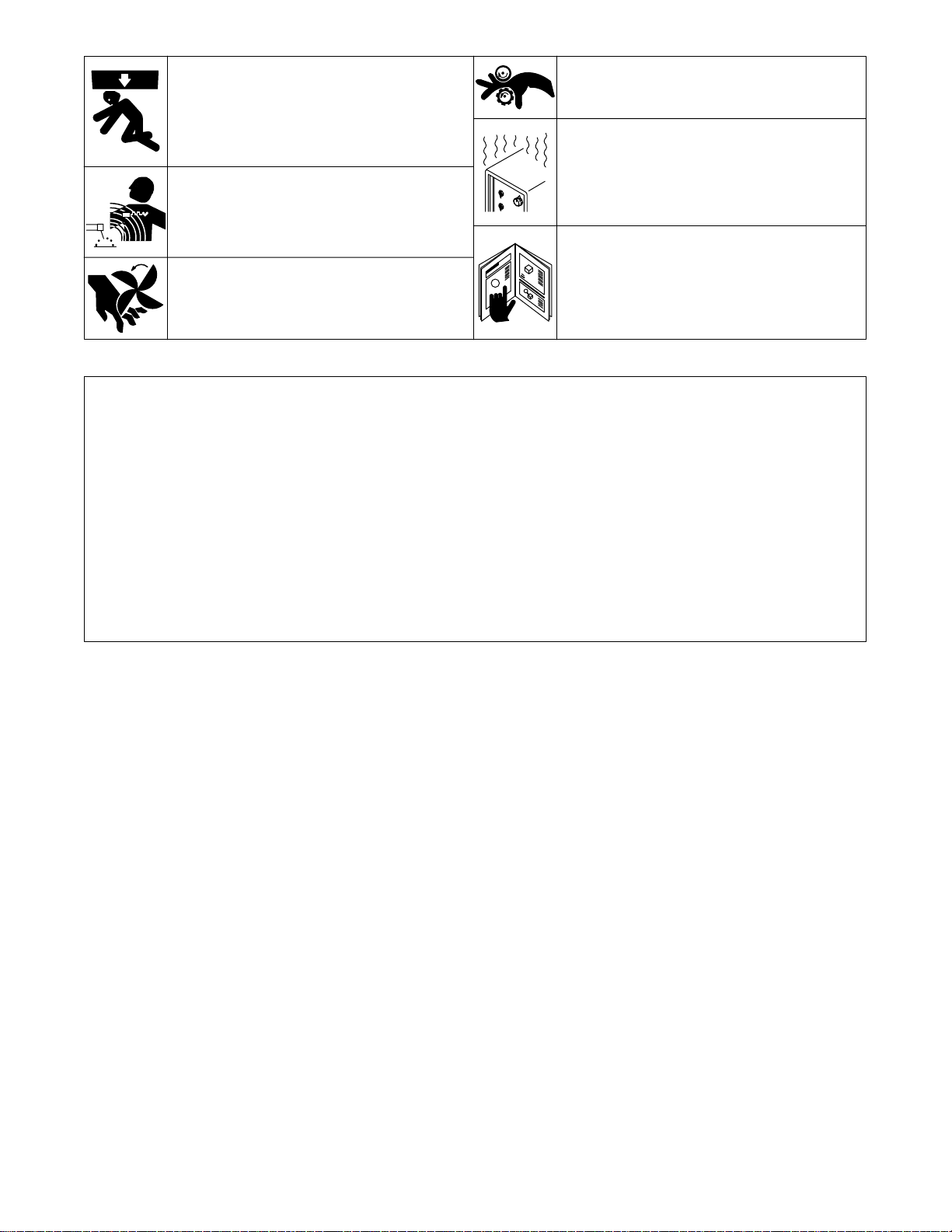

SECTION 1 – SAFETY PRECAUTIONS FOR SERVICING

1-1. Symbol Usage

safety_stm1 4/95

Means Warning! Watch Out! There are possible hazards with this

procedure! The possible hazards are shown in the adjoining symbols.

This group of symbols means Warning! Watch Out! possible ELECTRIC SHOCK, MOVING P ARTS,

and HOT P ARTS hazards. Consult symbols and related instructions below for necessary actions to

avoid the hazards.

Y Marks a special safety message.

. Means NOTE; not safety related.

1-2. Servicing Hazards

WARNING

The symbols shown below are used throughout this manual to call attention to and identify possible

hazards. When you see the symbol, watch out, and follow the related instructions to avoid the hazard.

Only qualified persons should service, test, maintain, and repair this unit.

During servicing, keep everybody, especially children, away.

ELECTRIC SHOCK can kill.

1. Do not touch live electrical parts.

2. Stop engine or turn OFF welding power source and

wire feeder, and disconnect and lockout input

power using line disconnect switch, circuit

breakers, or by removing plug from receptacle

before servicing unless the procedure specifically

requires an energized unit.

3. Insulate yourself from ground by standing or

working on dry insulating mats big enough to

prevent contact with the ground.

4. Do not leave live unit unattended.

5. When testing a live unit, use the one-hand method.

Do not put both hands inside unit. Keep one hand

free.

6. Disconnect input power conductors from

deenergized supply line BEFORE moving a

welding power source.

SIGNIFICANT DC VOLTAGE exists after

removal of input power on inverters.

7. Turn Off inverter, disconnect input power, and

discharge input capacitors according to

instructions in Maintenance Section before

touching any parts.

STATIC ELECTRICITY can damage

parts on circuit boards.

1. Put on grounded wrist strap BEFORE handling

boards or parts.

2. Use proper static-proof bags to store, move, or ship

PC boards.

FIRE OR EXPLOSION can result from

placing unit on, over, or near

combustible surfaces.

1. Do not place unit on, over, or near combustible

surfaces.

2. Do not service unit near flammables.

FLYING PIECES OF METAL or DIRT can

injure eyes.

1. Wear safety glasses with side shields or face shield

during servicing.

2. Be careful not to short metal tools, parts, or wires

together during testing and servicing.

HOT PARTS can cause severe burns.

1. Do not touch hot parts bare handed.

2. Allow cooling period before servicing welding gun

or torch.

EXPLODING PARTS can cause injury.

1. Failed parts can explode or cause other parts to

explode when power is applied to inverters.

2. Always wear a face shield and long sleeves when

servicing inverters.

ELECTRIC SHOCK HAZARD from

incorrect use of test equipment.

1. Turn Off welding power source and wire feeder or

stop engine before making or changing meter lead

connections.

2. At least one meter lead should be a self-retaining

spring clip such as an alligator clamp.

3. Read instructions for test equipment.

HIGH-FREQUENCY RADIATION can

interfere with radio navigation, safety

services, computers, and

communications equipment.

1. Have only qualified persons familiar with electronic

equipment perform this installation.

2. The user is responsible for having a qualified

electrician promptly correct any interference

problem resulting from the installation.

3. If notified by the FCC about interference, stop using

the equipment at once.

4. Have the installation regularly checked and

maintained.

5. Keep high-frequency source doors and panels

tightly shut, keep spark gaps at correct setting, and

use grounding and shielding to minimize the

possibility of interference.

TM-353 Page 1Syncrowave 250

Page 6

FALLING EQUIPMENT can cause

serious personal injury and equipment

damage.

1. Use lifting eye to lift unit only, NOT running gear,

gas cylinders, or any other accessories.

2. Use equipment of adequate capacity to lift unit.

MAGNETIC FIELDS FROM HIGH

CURRENTS can affect pacemaker

operation.

1. Pacemaker wearers keep away from servicing

areas until consulting your doctor.

MOVING PARTS can cause injury.

1. Keep away from moving parts such as fans.

2. Keep all doors, panels, covers, and guards closed

and securely in place.

1-3. EMF Information

MOVING PARTS can cause injury.

1. Keep away from moving parts.

2. Keep away from pinch points such as drive rolls.

OVERUSE can cause OVERHEATED

EQUIPMENT.

1. Allow cooling period.

2. Reduce current or reduce duty cycle before

starting to weld again.

3. Follow rated duty cycle.

READ INSTRUCTIONS.

1. Use MILLER Testing Booklet (Part No. 150 853)

when servicing this unit.

2. Consult the Owner ’s Manual for welding safety

precautions.

3. Use only genuine MILLER replacement parts.

Considerations About Welding And The Effects Of Low Frequency

Electric And Ma g netic Fields

The following is a quotation from the General Conclusions Section of

the U.S. Congress, Office of Technology Assessment, Biological

Effects of Power Frequency Electric & Magnetic Fields – Background

Paper, OTA-BP-E-53 (Washington, DC: U.S. Government Printing

Office, May 1989): “. . . there is now a very large volume of scientific

findings based on experiments at the cellular level and from studies

with animals and people which clearly establish that low frequency

magnetic fields can interact with, and produce changes in, biological

systems. While most of this work is of very high quality , the results are

complex. Current scientific understanding does not yet allow us to

interpret the evidence in a single coherent framework. Even more

frustrating, i t does not yet allow us to draw definite conclusions about

questions of possible risk or to offer clear science-based advice on

strategies to minimize or avoid potential risks.”

To reduce magnetic fields in the workplace, use the following

procedures:

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cables around the body.

4. Keep welding power source and cables as far away as

practical.

5. Connect work clamp to workpiece as close to the weld as

possible.

About Pacemakers:

The above procedures are also recommended for pacemaker

wearers. Consult your doctor for complete information.

TM-353 Page 2 Syncrowave 250

Page 7

SECTION 2 – DEFINITIONS

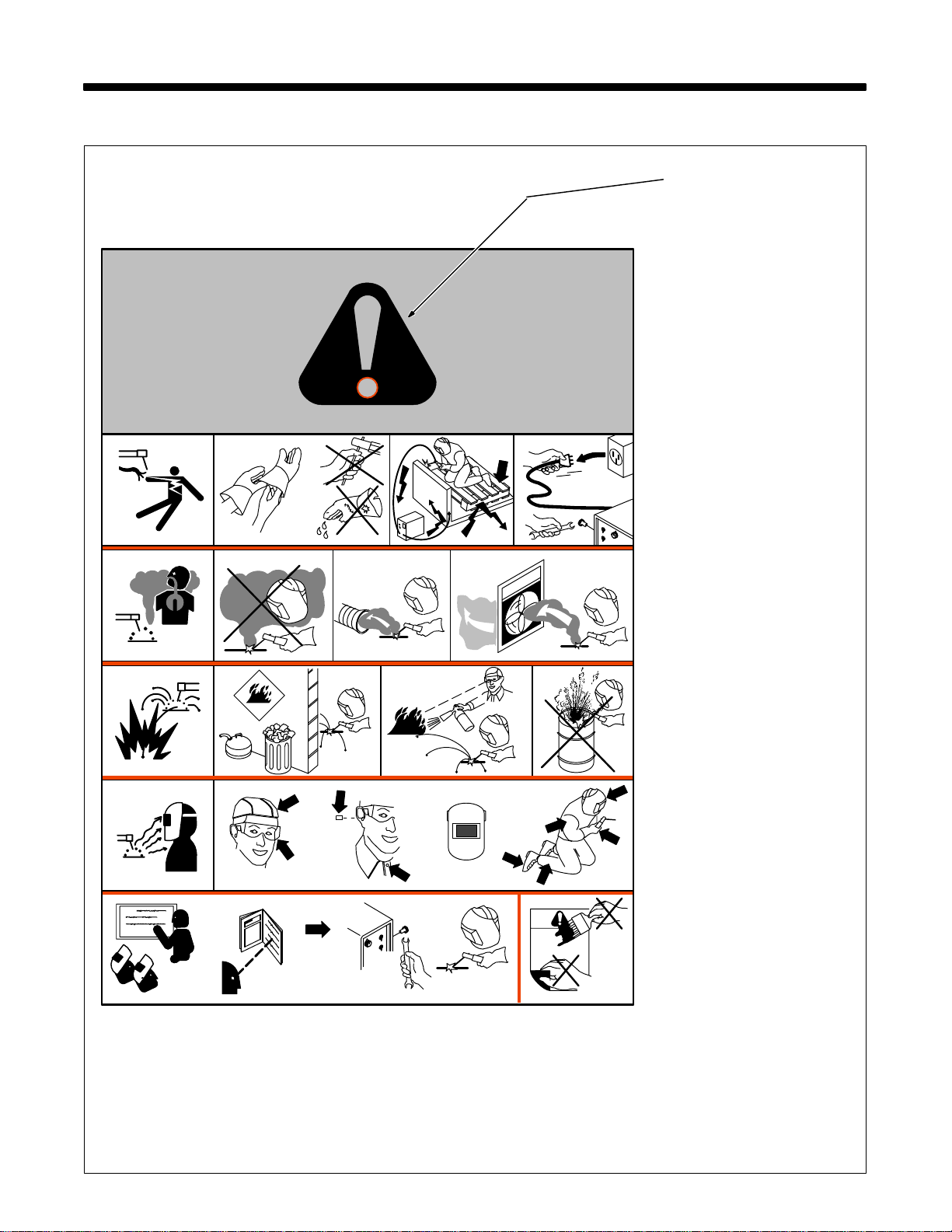

2-1. Warning Label Definitions

1 1.1 1.2

2

3 3.1 3.2 3.3

4 4.1

2.1

+

2.2

2.3

+

+

1.3

Warning! Watch Out! There are

possible hazards as shown by the

symbols.

1 Electric shock from welding

electrode or wiring can kill.

1.1 Wear dry insulating gloves.

Do not touch electrode with

bare hand. Do not wear wet or

damaged gloves.

1.2 Protect yourself from electric

shock by insulating yourself

from work and ground.

1.3 Disconnect input plug or

power before working on

machine.

2 Breathing welding fumes can

be hazardous to your health.

2.1 Keep your head out of the

fumes.

2.2 Use forced ventilation or local

exhaust to remove the fumes.

2.3 Use ventilating fan to remove

fumes.

3 Welding sparks can cause

explosion or fire.

3.1 Keep flammables away from

welding. Don’t weld near

flammables.

3.2 Welding sparks can cause

fires. Have a fire extinguisher

nearby and have a watch

person ready to use it.

3.3 Do not weld on drums or any

closed containers.

4 Arc rays can burn eyes and

injure skin.

4.1 Wear hat and safety glasses.

Use ear protection and button

shirt collar. Use welding

helmet with correct shade of

filter. Wear complete body

protection.

5 Become trained and read the

instructions before working on

the machine or welding.

6 Do not remove or paint over

(cover) the label.

5 6

+

S-176 254-A

TM-353 Page 3Syncrowave 250

Page 8

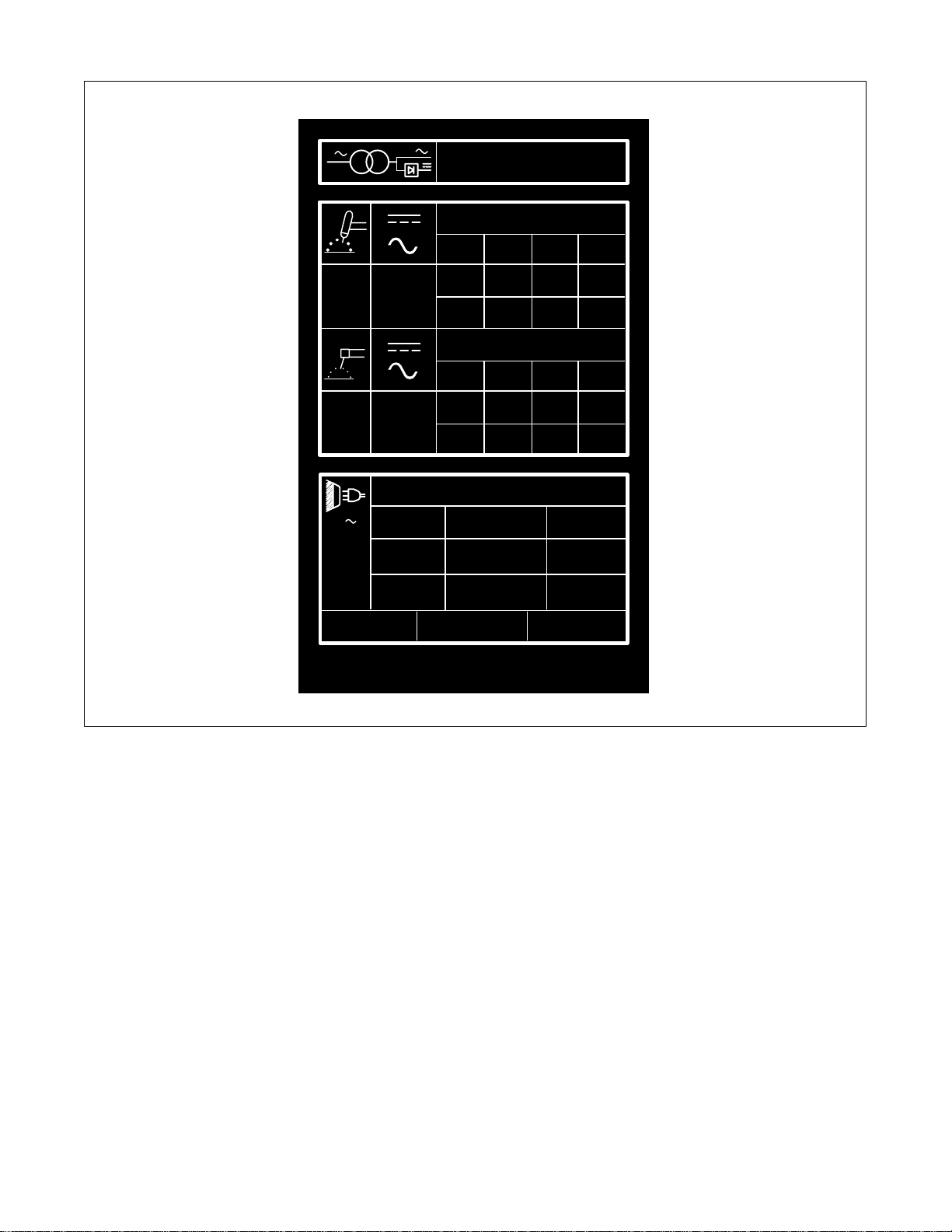

2-2. Rating Label For CE Products

1

1

50 Hz

1

= 80V

U

0

= 80V

U

0

U

= 220 I

1

U

= 380 I

1

U

= 415 I

1

ISO/IEC 974-1

7A/10.2V 310A/22.4V

X 25% 60% 100%

I

U

5A/20.2V 310A/32.4V

X 25% 60% 100%

I

U

310A 200A 155A

2

22.4V 18V 16.2V

2

310A 200A 155A

2

32.4V 28V 26.2V

2

= 117.2A I

1max

= 72.2A I

1max

= 63.8A I

1max

1Eff

1Eff

1Eff

= 59A

= 36A

= 32A

IP 21S

S-178 813-A

TM-353 Page 4 Syncrowave 250

Page 9

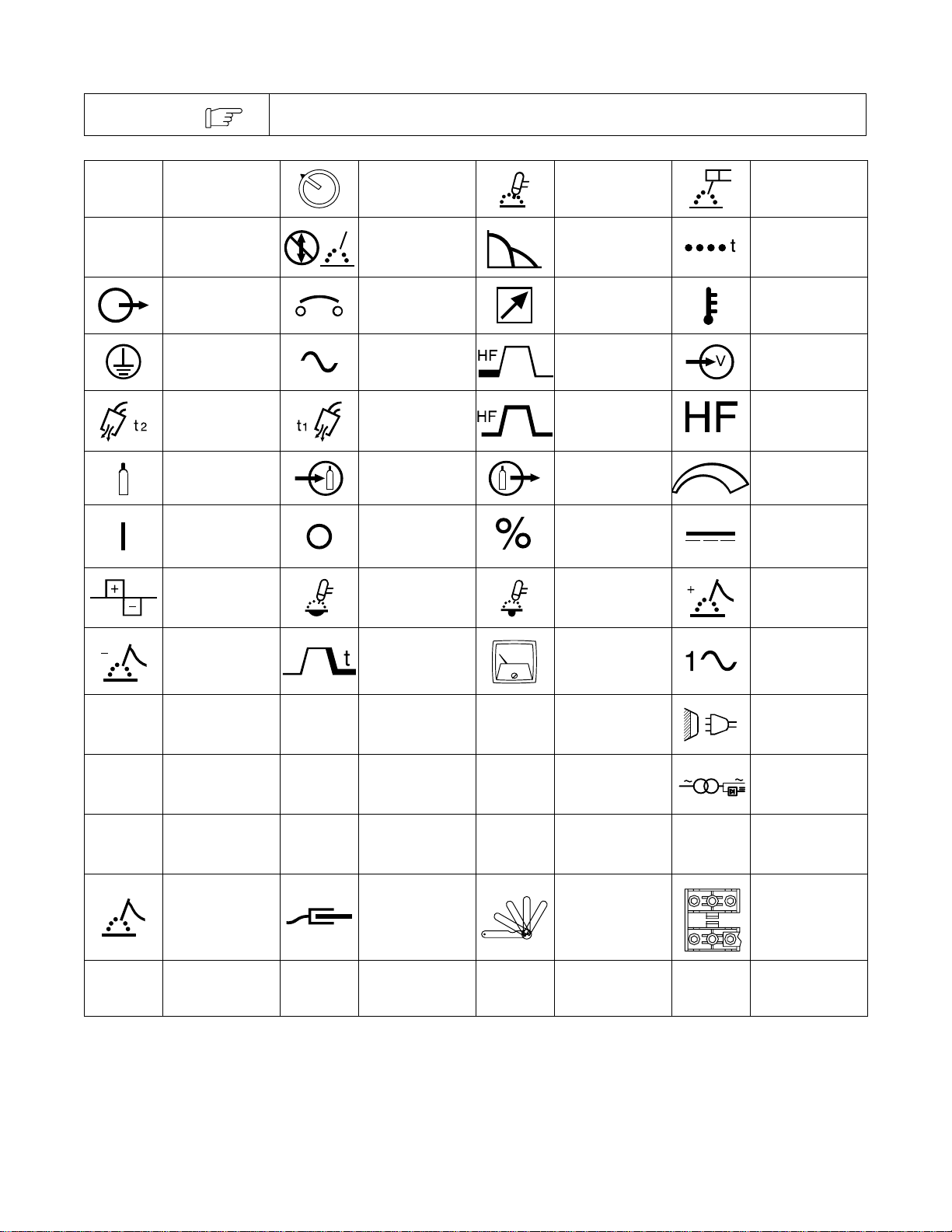

2-3. Symbols And Definitions

NOTE

A

V

Some symbols are found only on CE products.

Amperes Panel–Local

Volts

Output Circuit Breaker Remote Temperature

Protective Earth

(Ground)

Postflow Timer Preflow Timer

Gas (Supply) Gas Input Gas Output

On Off Percent Direct Current

Do Not Switch

While Welding

Alternating Current

Gas Tungsten Arc

Welding (GT AW)

Arc Force (DIG) Spot Timer

High Frequency -

Start

High Frequency -

Continuous

Shielded Metal Arc

Welding (SMAW)

High Frequency

Increase/Decrease

Of Quantity

Input

U

I

1

IP

S

Balance Control Maximum Cleaning

Electrode

Negative

Voltage (A verage)

0

Rated No Load

Primary Current

Degree Of

Protection

Electrode Work Thickness Gauge Spark Gap

Seconds

U

I

I

1eff

1

2

Maximum

Penetration

Crater Time Meter Single-Phase

Primary Voltage

Rated Welding

Current

Maximum Effective

Supply Current

U

X

I

1max

Conventional Load

2

Rated Maximum

Supply Current

Voltage

Duty Cycle

1

Hz

Electrode Positive

Line Connection

Single-Phase

1

Combined AC/DC

Power Source

Hertz

TM-353 Page 5Syncrowave 250

Page 10

3-1. Specifications

Rated

Rated

Welding Output

NEMA Class II

(40) – 250

Amperes, 30 Volts

AC, 40% Duty

Cycle

*While idling

**Power Factor Correction

Rated

Welding

PFC

Output

NEMA

Class I

(60) – 200

Amperes,

28 Volts

AC, 60%

Duty Cycle

*While idling

**Power Factor Correction

PFC85(4.6*)77(4.2*)74(4*)65(3.5*)45(2.4*)41(2.2*)37(2*)33(1.8*)30(1.6*)17(0.9*)

With

PFC55(57*)64(51*)48(49*)48(49*)37(30*)34(27*)24(25*)48(49*)19(20*)11(11*)

PFC**

No

PFC

With

PFC

200V220V230V260V380V415V460V520V575

**

No

SECTION 3 – INSTALLATION

Amperes Input at AC Balanced

Rated Load Output,

50/60 Hz, Single-Phase

200 V 230 V 460 V 575 V

106

(4.6*)

76 66 33 26 15.2 11.4

92

(4*)

46

(2*)

37

(1.6*)21(0.89*)

Amperes Input at AC Balanced

Rated Load Output,

50/60 Hz, Single-Phase

KVA KW

11.4

(0.68*)

V

KVA KW

Amp

Range

5–310 A 80 V 21

8.3

(0.7*)

8.3

(0.6*)

Max

OCV

Amp

Range

5–310 A 80 V 21

Rating

Max

OCVIPRating

IP

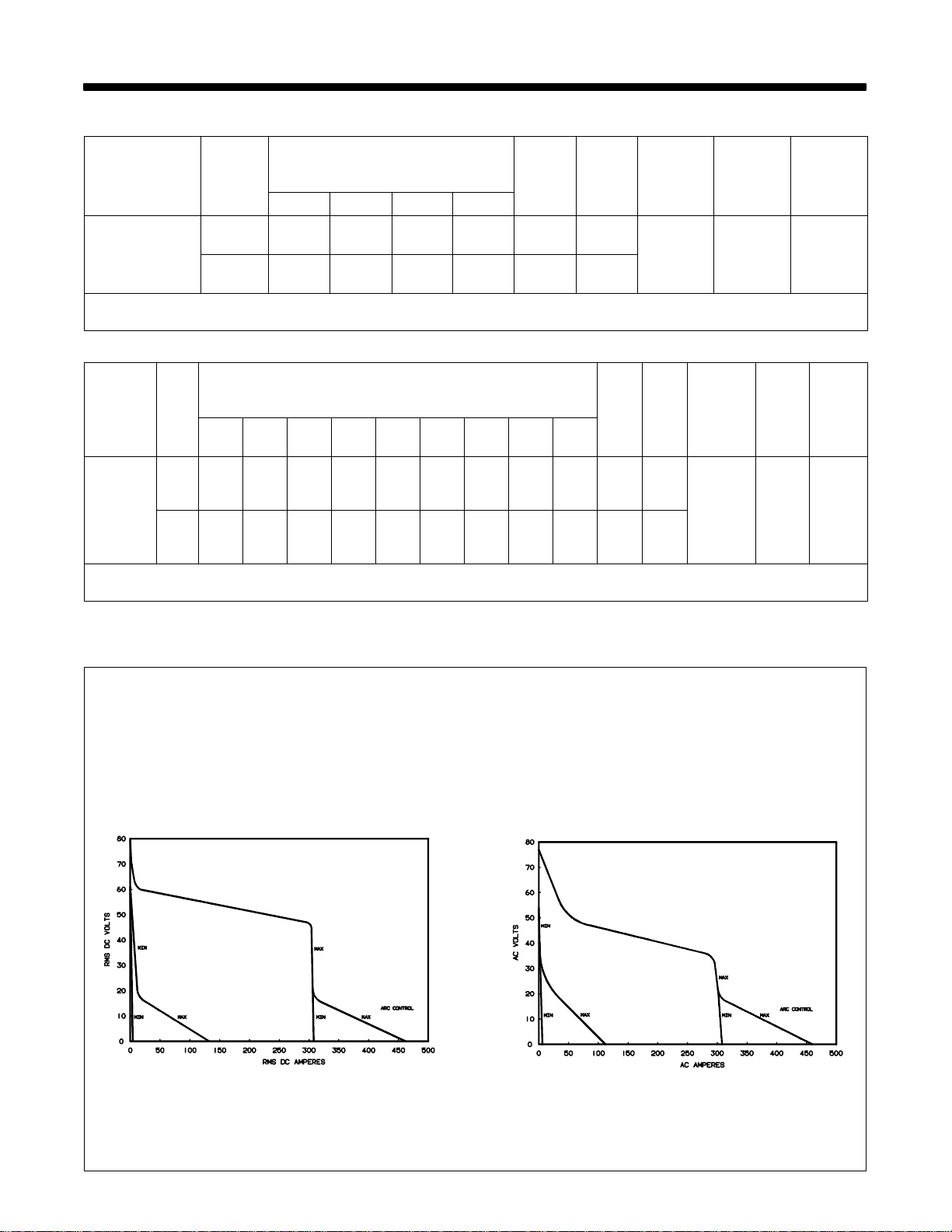

3-2. Volt-Ampere Curves

A. DC Mode

The volt-ampere curves show the

minimum and maximum voltage

and amperage output capabilities of

the welding power source. Curves

of other settings fall between the

curves shown.

B. AC Mode

ssb1.1 10/91 – SB-116 199 / SB-116 200

TM-353 Page 6 Syncrowave 250

Page 11

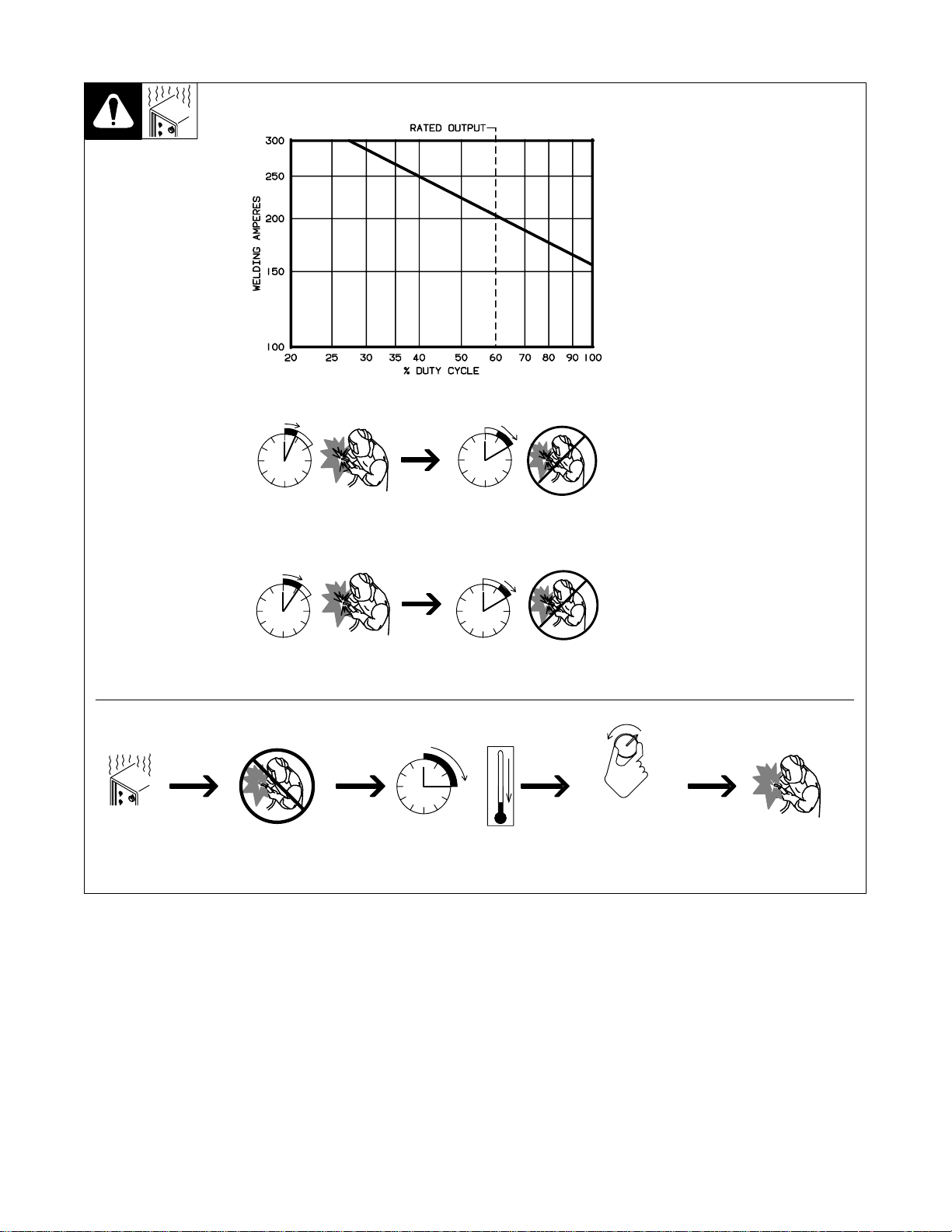

3-3. Duty Cycle And Overheating

40% Duty Cycle At 250 Amperes (60 Hz Models Only)

4 Minutes Welding 6 Minutes Resting

Duty Cycle is percentage of 10 mi n utes that unit can weld at rated load

without overheating.

If unit overheats, thermostat opens,

output stops, light goes on (CE

models only), and cooling fan runs.

Wait fifteen minutes for unit to cool.

Reduce amperage or duty cycle before welding.

Y Exceeding duty cycle can

damage unit and void

warranty.

Overheating

60% Duty Cycle At 200 Amperes

6 Minutes Welding 4 Minutes Resting

0

15

Minutes

A

OR

Reduce Duty Cycle

duty1 4/95 / SB-116 198

TM-353 Page 7Syncrowave 250

Page 12

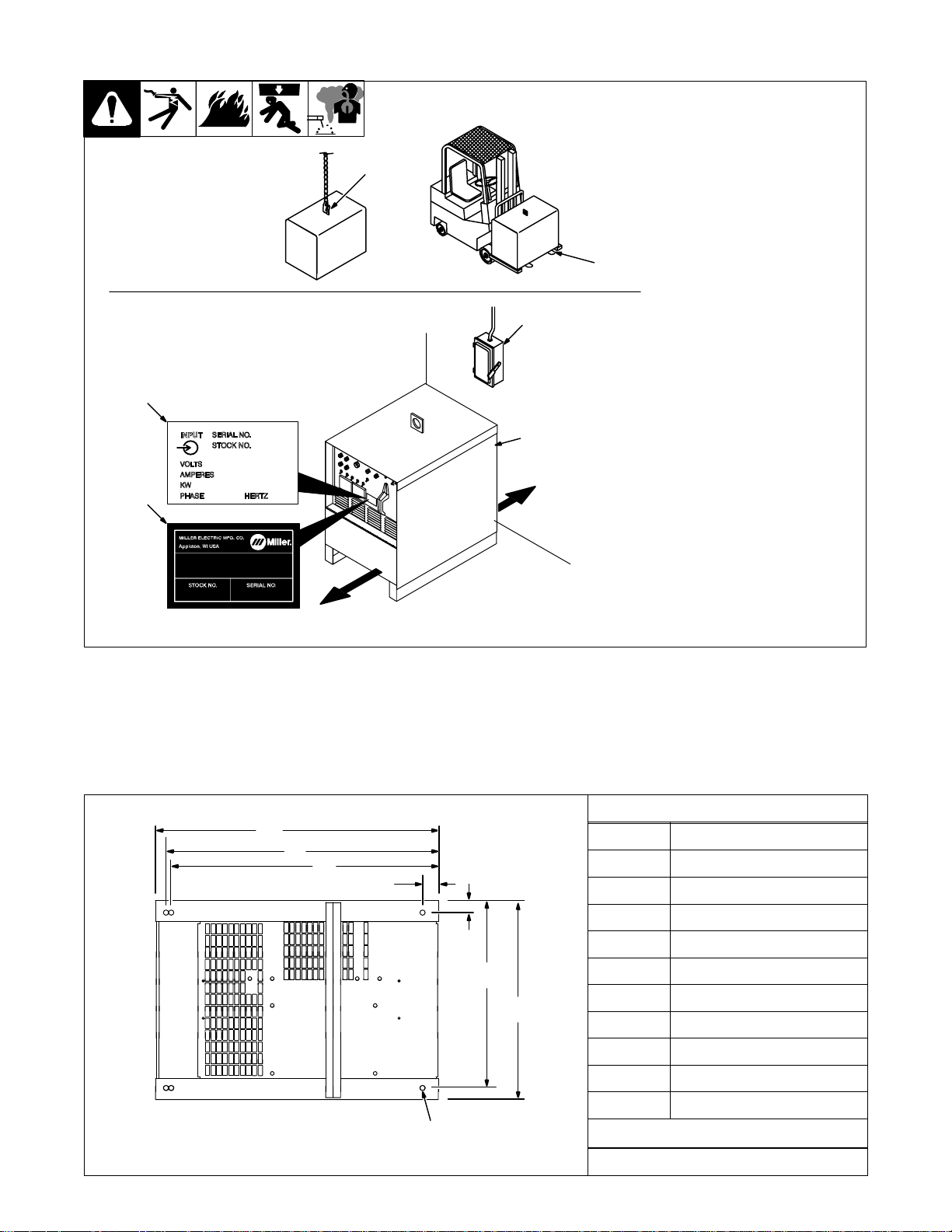

3-4. Selecting A Location

Movement

Location And Airflow

3

5

1 Lifting Eye

2 Lifting Forks

Use lifting eye or lifting forks to

move unit.

1

OR

2

6

4

18 in (460

mm)

If using lifting forks, extend forks

beyond opposite side of unit.

3 Rating Label (Non CE Models

Only)

4 Rating Label (CE Models

Only, See Section 2-2)

Use rating label to determine input

power needs. CE label located on

rear panel.

5 Plate Label (CE Models Only)

6 Line Disconnect Device

Locate unit near correct input pow-

er supply.

Y Special installation may be

required where gasoline or

volatile liquids are present –

see NEC Article 511 or CEC

Section 2 0 .

18 in (460

mm)

3-5. Dimensions And Weights

A

B

C

Front

ST-800 402 / ST-117 264-F

Dimensions

Height 30-3/4 in (781 mm)

D

E

F

F

G

Width 19-3/4 i n (502 mm)

Length 27-1/2 i n (698 mm)

A 27 in (686 mm)

B 26 in (661 mm)

C 25-1/4 i n (642 mm)

D 1-1/2 in (38 mm)

E 1-1/8 (29 mm)

F 17-7/8 (454 mm)

G 19-1/4 (489 mm)

H 1/2 in (13 mm) Dia

6 Holes

H

TM-353 Page 8 Syncrowave 250

ST-154 792-B

Weight

355 lbs (161 kg)

Page 13

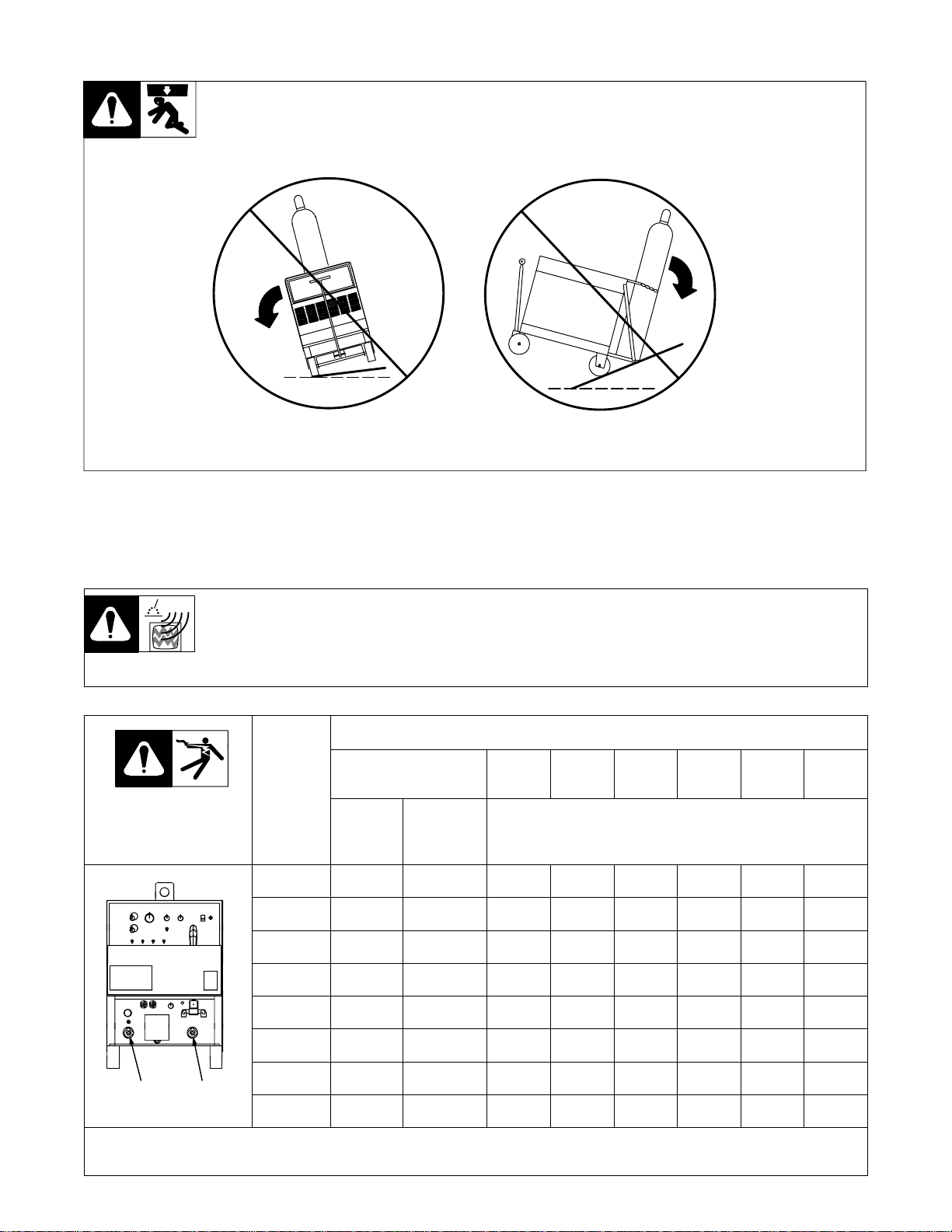

3-6. Tipping

Y Be careful when placing or

moving unit over uneven

surfaces.

3-7. Weld Output Terminals And Selecting Cable Sizes

Y ARC WELDING can cause Electromagnetic Interference.

To reduce possible interference, keep weld cables as short as possible, close together, and down low, such as on the floor.

Locate welding operation 100 meters from any sensitive electronic equipment. Be sure this welding machine is installed

and grounded according to this manual. If interference still occurs, the user must take extra measures such as moving

the welding machine, using shielded cables, using line filters, or shielding the work area.

Total Cable (Copper) Length In Weld Circuit Not Exceeding

Weld Output

Terminals

100 ft (30 m) Or Less

Welding

Amperes

100 4 4 4 3 2 1 1/0 1/0

150 3 3 2 1 1/0 2/0 3/0 3/0

200 3 2 1 1/0 2/0 3/0 4/0 4/0

250 2 1 1/0 2/0 3/0 4/0 2-2/0 2-2/0

300 1 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-3/0

10 – 60%

Duty

Cycle

60 – 100%

Duty

Cycle

150 ft

(45 m)

200 ft

(60 m)

250 ft

(70 m)

300 ft

(90 m)

10 – 100% Duty Cycle

350 ft

(105 m)

400 ft

(120 m)

350 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-3/0 2-4/0

ElectrodeWork

ST-154 795-C

Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. Contact your distributor for the mm2 equivalent weld cable sizes. S-0007-E

400 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-4/0 2-4/0

500 2/0 3/0 4/0 2-2/0 2-3/0 2-4/0 3-3/0 3-3/0

TM-353 Page 9Syncrowave 250

Page 14

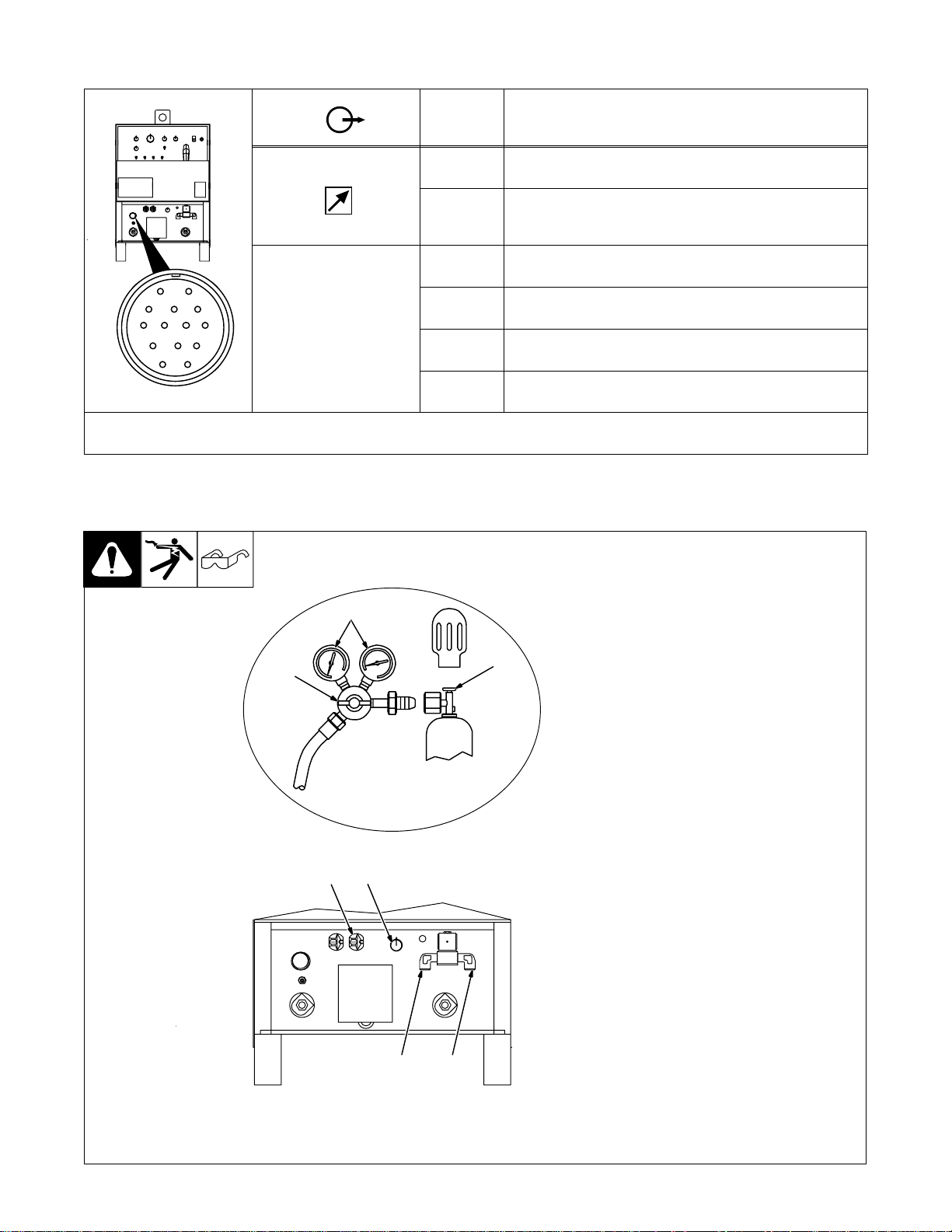

3-8. Remote 14 Receptacle

F

Socket* Socket Information

A 24 volts ac.

AJ

K

B

L

C

D

*The remaining sockets are not used.

I

NH

M

G

F

E

ST-154 795-C

B Contact closure to A completes 24 volts ac contactor control

C Command reference; 0 to +10 volts dc output to remote control.

D Remote control circuit common.

A

E 0 to +10 volts dc input command signal from remote control.

K Chassis common.

circuit.

3-9. 115 Volts AC Duplex Receptacle And Shielding Gas Connections

Y Turn Off power before

connecting to receptacle.

1 115 V AC Receptacle

5

6

1 7

4

Receptacle is protected from overload by circuit breaker CB1 (see

Section 7-2).

2 Gas Valve In Fitting

3 Gas Valve Out Fitting

Fittings have 5/8-18 right-hand

threads

4 Cylinder Valve

Open valve slightly so gas flow

blows dirt from valve. Close valve.

5 Regulator/Flow Gauge

6 Flow Adjust

Typical flow rate is 20 cfh (cubic feet

per hour) (9.4 L/min)

7 High Frequency Control (see

Section 4-1)

3 2

Ref. ST-154 795-C / Ref. ST-157 858

TM-353 Page 10 Syncrowave 250

Page 15

3-10. Electrical Service Guide

NOTE

60 Hertz Models

Input Voltage

Input Amperes At Rated Output

Max Recommended Standard Fuse Or Circuit

Breaker Rating In Amperes

Min Input Conductor Size In AWG/Kcmil

Max Recommended Input Conductor Length

In Feet (Meters)

Min Grounding Conductor Size In AWG/Kcmil

Reference: 1996 National Electrical Code (NEC) S-0092-J

50 Hertz Models Without Power Factor Correction

Input Voltage

Input Amperes At Rated Output

All values calculated at 60% duty cycle.

Without Power Factor

Correction

200 230 460 575 200 230 460 575

85 74 37 30 55 48 24 19

125 110 60 45 80 70 35 30

4 6 10 10 8 8 12 14

173

(53)

6 6 10 10 8 8 12 14

220 260 380 415 520 220 380 415

77 65 45 41 33 64 37 34

158

(48)

291

(89)

455

(139)

With Power Factor Correction

86

(26)

114

(35)

186

(58)

189

(48)

With Power Factor

Correction

Max Recommended Standard Fuse Or Circuit

Breaker Rating In Amperes

Min Input Conductor Size In AWG/Kcmil

Max Recommended Input Conductor Length

In Feet (Meters)

Min Grounding Conductor Size In AWG/Kcmil

Reference: 1996 National Electrical Code (NEC) S-0092-J

125 100 70 60 50 90 60 50

6 6 8 8 10 6 10 10

145

(44)

6 8 8 10 10 6 8 10

202

(62)

291

(89)

347

(106)

372

(113)

145

(44)

291

(89)

347

(106)

TM-353 Page 11Syncrowave 250

Page 16

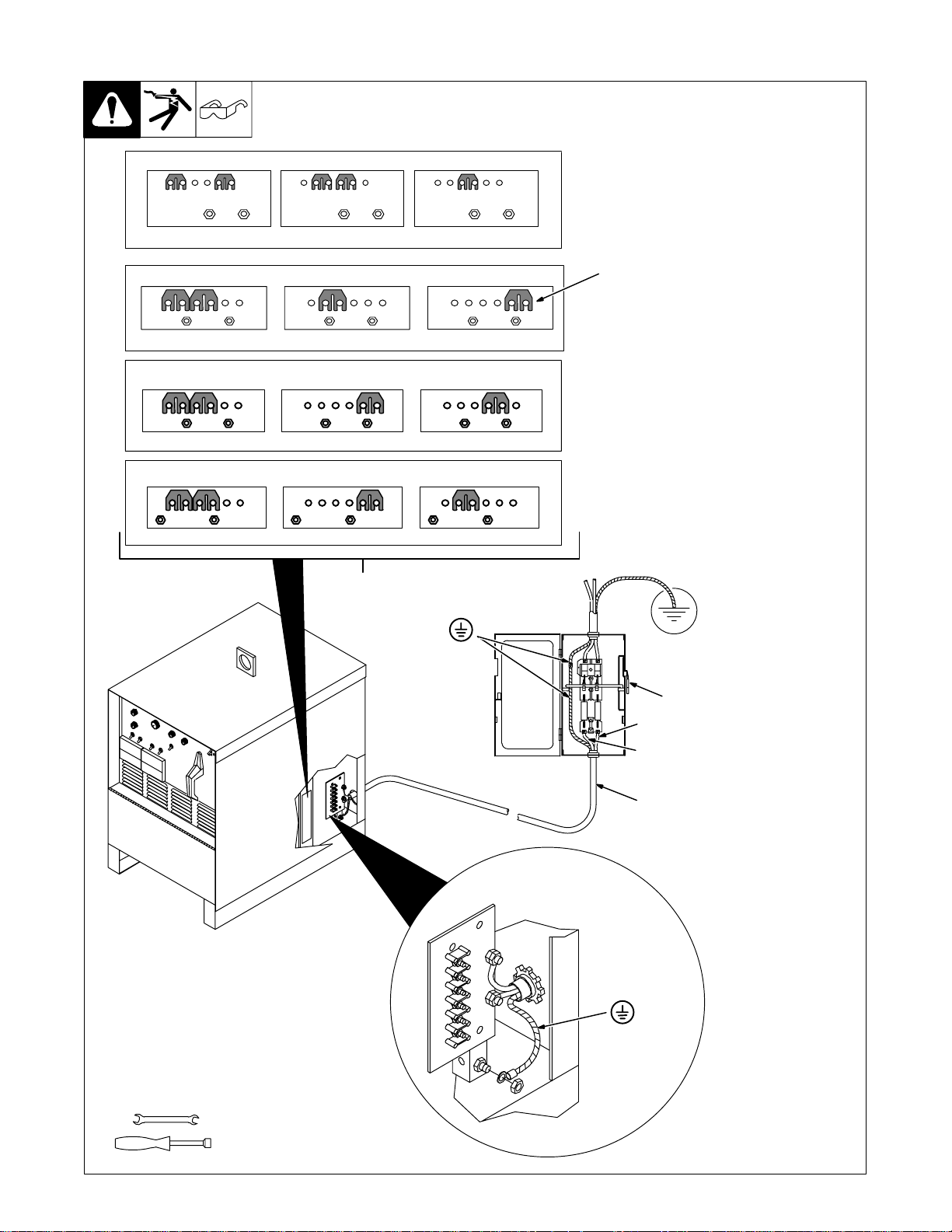

3-11. Placing Jumper Links And Connecting Input Power

230 VOLTS 460 VOLTS200 VOLTS

LL LL LL

S-083 566-C

230 VOLTS

LL

220 VOLTS

LL

260 VOLTS

LL

460 VOLTS

LL

380 VOLTS

LL

380 VOLTS

LL

1

575 VOLTS

LL

S-010 587-B

415 VOLTS

LL

S-131 783-A

520 VOLTS

LL

S-047 672-A

Connect GND/PE

Conductor First

Check input voltage available at

site.

1 Jumper Link Label

Check label inside your unit–

only one label is on unit.

Y Only make connections for

the voltages shown on the label inside your unit. Do not

make connections for any

other voltages. If jumper link

label is missing from inside

2

unit, check rating label (see

Section 3 - 4 ) f o r a l lowable i nput voltages.

2 Jumper Links

Move jumper links to match input

voltage.

3 Input And Grounding

Conductors

Select size and length using

Section 3-10.

4 Line Disconnect Device

Select type and size of overcurrent

protection using Section 3-10.

Reinstall side panel.

Y Special installation may be

required where gasoline or

volatile liquids are present –

see NEC Article 511 or CEC

Section 2 0 .

Tools Needed:

GND/PE

Earth Ground

4

L1 (U)

L2 (V)

3

Connect GND/PE

Conductor First

3/8 in

3/8, 1/2, 7/16 in

ST-117 263-K

TM-353 Page 12 Syncrowave 250

Page 17

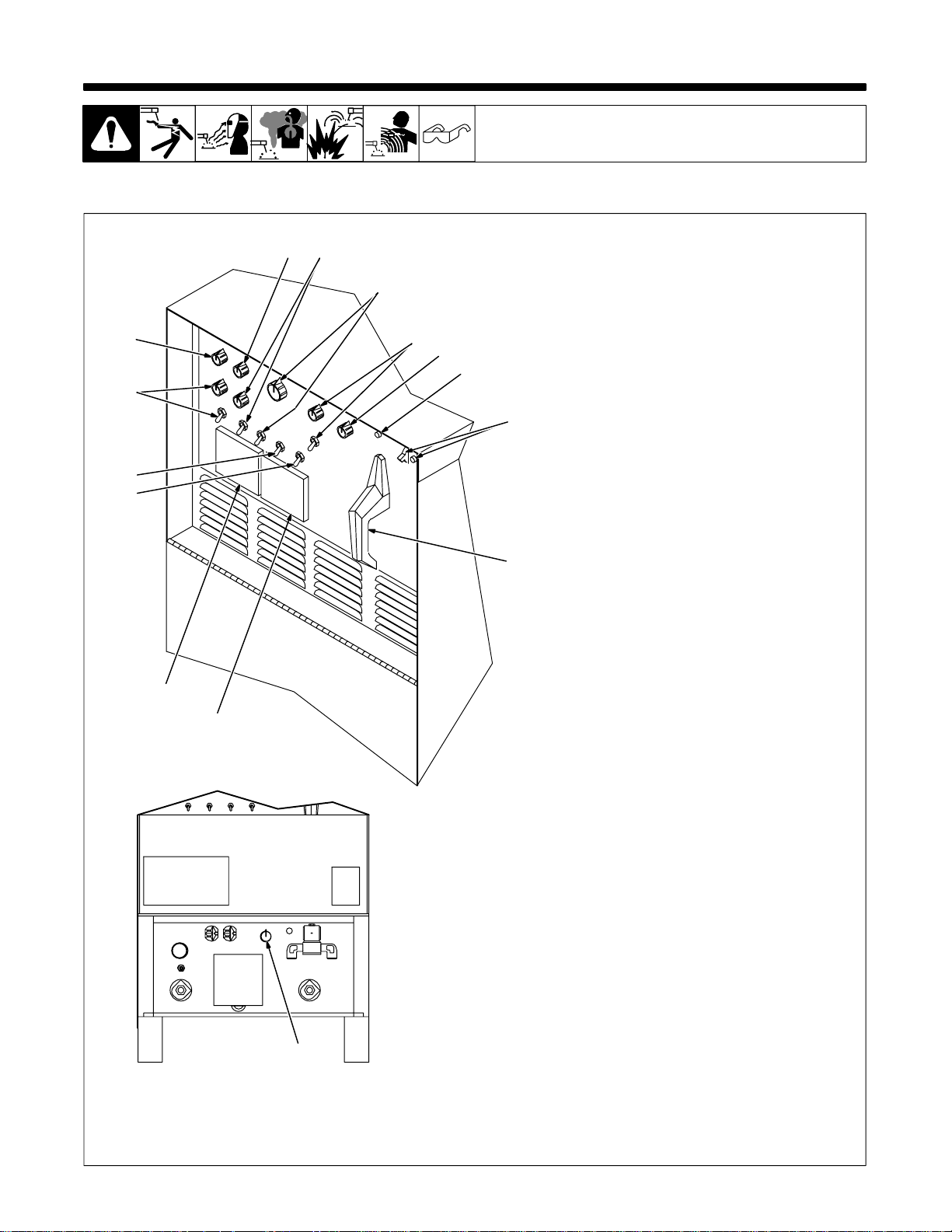

4-1. Controls

6

5

4

3

2

SECTION 4 – OPERATION

1 Ammeter

87

9

10

11

12

13

14

1

See Section 4-3.

2 Voltmeter

See Section 4-3.

3 High Frequency Switch

See Section 4-11.

4 Output (Contactor) Switch

See Section 4-8.

5 Spot Time Switch And Control

(Optional)

See Section 4-5.

6 Preflow Time Control (Optional)

See Section 4-12.

7 AC Balance Control

See Section 4-6.

8 Crater Time Control And Switch

See Section 4-4.

9 Amperage Adjustment Control And

Switch

See Section 4-7.

10 Arc Force (Dig) Switch And Control

See Section 4-9.

11 Postflow Time Control

See Section 4-10.

12 High Temperature Shutdown Light

(CE Models Only)

Lights when unit overheats and shuts

down (see Section 3-3).

13 Power Switch And Pilot Light

Use switch to turn unit and light On and

Off.

14 Output Selector Switch

See Section 4-2.

15 High Frequency Control

See Section 4-11.

15

Ref. ST-117 264-F / Ref. ST-154 795-C

TM-353 Page 13Syncrowave 250

Page 18

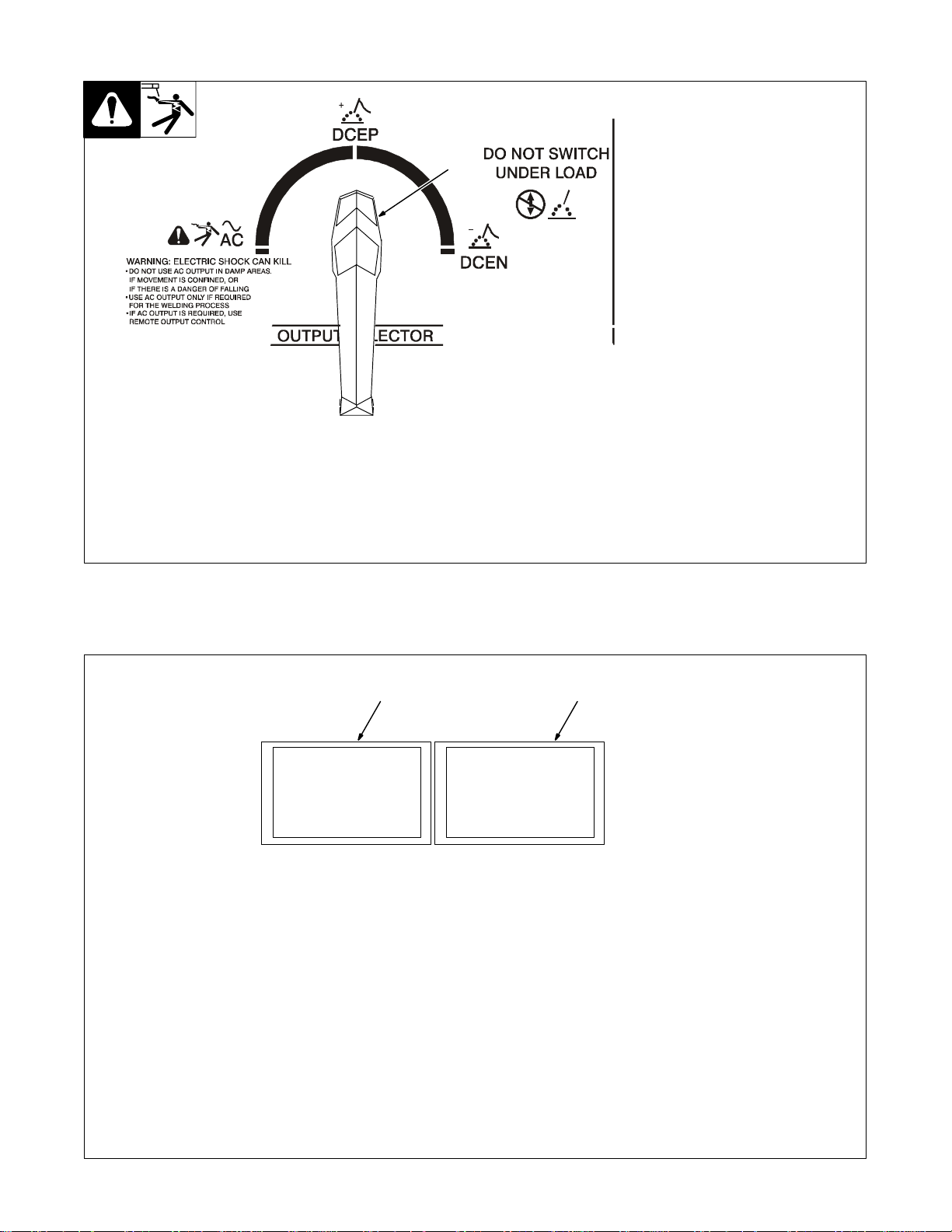

4-2. Output Selector Switch

1 Output Selector Switch

Y Do not use AC output in

damp areas, if movement is

confined, or if there is dan-

1

ger of falling. Use AC output

ONLY if required for the

welding process, and then

use a remote control.

Y Do not change position of

switch while welding or

while under load.

Use switch to select (DCEN) Direct

Current Electrode Negative, AC, or

(DCEP) Direct Current Electrode

Positive output without changing

weld output cable connections.

4-3. Meters

1 2

Ref. ST-181 675-A

1 Voltmeter

Voltmeter displays voltage at the

weld output terminals, but not necessarily the welding arc due to

cable resistance, poor connections, etc.

2 Ammeter

Ammeter displays weld amperage

output o f unit.

TM-353 Page 14 Syncrowave 250

Page 19

4-4. Crater Time Controls

1 Crater Time Control

Use control to reduce current over a

set period of time (0–15 seconds) at

1

2

the end of the weld cycle when NOT

using a remote current control.

2 Crater Time Switch

ON – provides crater time.

OFF – provides no crater time.

Place switch in the OFF position for

Shielded Metal Arc Welding

(SMAW).

Application:

Crater Time should be used while

GTAW welding materials that are

crack sensitive, and/or the operator

wants to eliminate the crater at the

end of the weld.

Note: This applies if the operator is

using an on/off only type control to

start and stop the welding process.

4-5. Spot Time Controls

1 Spot Time Switch

Place switch in the ON position to

turn on spot weld circuitry.

2

1

The (GTAW) TIG Spot process is

generally used with a direct current

electrode negative (DCEN) set-up.

Place switch in the OFF position to

turn off spot weld circuitry. Put

switch in the OFF position while doing Shielded Metal Arc Welding

(SMAW).

2 Spot T ime Control

Use control to set time (0–5.7 sec-

onds) for Gas Tungsten Arc

(GTAW) spot welds. Spot time begins at arc initiation. If the arc is broken during the spot time cycle, the

timer stops but does not reset.

When the spot time has ended,

weld output stops. Postflow starts

when the remote contactor is

opened. The spot timer resets after

the contactor opens.

Application:

TIG spot welding is used for joining

thinner materials that are in close

contact, with the fusion method. A

good example would be joining coil

ends.

TM-353 Page 15Syncrowave 250

Page 20

4-6. AC Balance Control

Balanced

3

More Penetration

10

More Cleaning

0

50% Electrode

Positive

50% Electrode

Negative

32% Electrode

Positive

68% Electrode

Negative

55% Electrode

Positive

45% Electrode

Negative

1 AC Balance Control

Balance Control (AC GTAW):

Control changes the AC output

square wave. Rotating the control

towards 10 provides deeper pene-

1

Output Waveforms ArcSetting

tration. Rotating the control towards

0 provides more cleaning action of

the workpiece.

When the control is in the Balanced

position, the wave shape provides

equal penetration and cleaning

action.

Application:

When welding on oxide forming materials such as aluminum or magnesium, excess cleaning is not necessary. To produce a good weld, only

a minimal amount, approximately a

0.10 in (2.5mm) of etched zone

along the weld toes is required.

Set control to 7 and adjust as necessary. Joint configuration, set-up,

process variables, and oxide thickness may affect setting.

Arc rectification can occur when

welding above 200 amps and/or

while welding with helium gas. If this

condition occurs, increasing the

Balance control towards maximum

penetration, may help to restabilize

the arc.

Ref. S-0795-A

TM-353 Page 16 Syncrowave 250

Page 21

4-7. Amperage Adjustment Controls

2

1 Amperage Adjustment Control

Use control to adjust amperage,

1

and preset amperage on ammeter

(see Sect i o n 4 - 3 ) . T h i s c o n t r o l m a y

be adjusted while welding.

For remote amperage control,

front panel control setting is the

maximum amperage available. For

example: I f front panel control is set

to 200 A, the range of the remote

amperage control is 5 to 200 A.

For spot welding, use Amperage

Adjust control to select from 5–310

amps of peak amperage (see Section 4-5).

2 Amperage Control Switch

Use switch to select way of control-

ling amperage adjustment.

For front panel control, place switch

in the PANEL position.

For remote control, place switch in

REMOTE 14 position, and connect

remote control device (see Section

3-8).

4-8. Output (Contactor) Control Switch

Y Weld output terminals are

energized when Output

(Contactor) switch is On and

Power is On.

1

1 Output/Contactor Switch

Use switch to select way of control-

ling unit output.

For front panel control, place switch

in ON position.

When On is selected, HF and gas

control are disabled.

For remote control, place switch in

REMOTE 14 position, and connect

remote control device (see Section

3-8).

TM-353 Page 17Syncrowave 250

Page 22

4-9. Arc Controls

1 Arc Control (Dig)

For AC And DC SMAW Welding

When set at 0, short-circuit amperage at low arc voltage is the same

1

2

as normal welding amperage.

When setting is increased, short-

circuit amperage at low arc voltage

increases.

Set at 0 for GTA W welding.

2 Arc Control Switch

Place switch in the ON position to

turn on arc control circuitry. When

switch is i n the OFF position, no additional amperage is available at

low arc voltages. Place switch in

the OFF position while performing

Gas Tungsten Arc Welding

(GTAW).

Application:

Control helps arc starting or making

vertical or overhead welds by increasing amperage at low arc voltage, and reduces electrode sticking

while welding.

4-10. Postflow Time Control

1 Postflow Time Control

Use control to set length of time

(0–70 seconds) gas flows after

welding stops. It is important to s e t

enough time to allow gas to flow un-

1

til after the tungsten and weld

puddle has cooled down.

Application:

Postflow is required to cool tungsten and weld, and to prevent contamination of tungsten and weld. Increase postflow time if tungsten or

weld are dark in appearance.

TM-353 Page 18 Syncrowave 250

Page 23

4-11. High Frequency Controls

1

2

Y Place High Frequency

switch in Off position before

using the shielded metal arc

welding (SMAW) process.

1 High Frequency Switch

START – (Up position) provides H F

for arc starting only. High frequency

turns on to help start arc when output is enabled. High frequency

turns off when arc is started, and

turns on whenever arc is broken to

help restart arc.

Application:

HF Start is used when the DCEN

GTA W process is required.

OFF – provides no HF. Use OFF for

SMAW (stick electrode) welding.

CONTINUOUS – (Down position)

provides HF continuously throughout the weld.

Application:

HF Continuous is used when the

AC GTAW process is required.

2 High Frequency Intensity

Control

Use control to change amount of

HF energy used to start and maintain the arc. Set as low as practical

to prevent interfering with electronic

equipment.

4-12. Preflow Time Control (Optional)

1 Preflow Time Control

Use control to set the length of time

(0–15 seconds) that gas flows before an arc is started.

Application:

Preflow is used to purge the immediate weld area of atmosphere. Preflow also aids in consistent arc

starting.

1

TM-353 Page 19Syncrowave 250

Page 24

TM-353 Page 20 Syncrowave 250

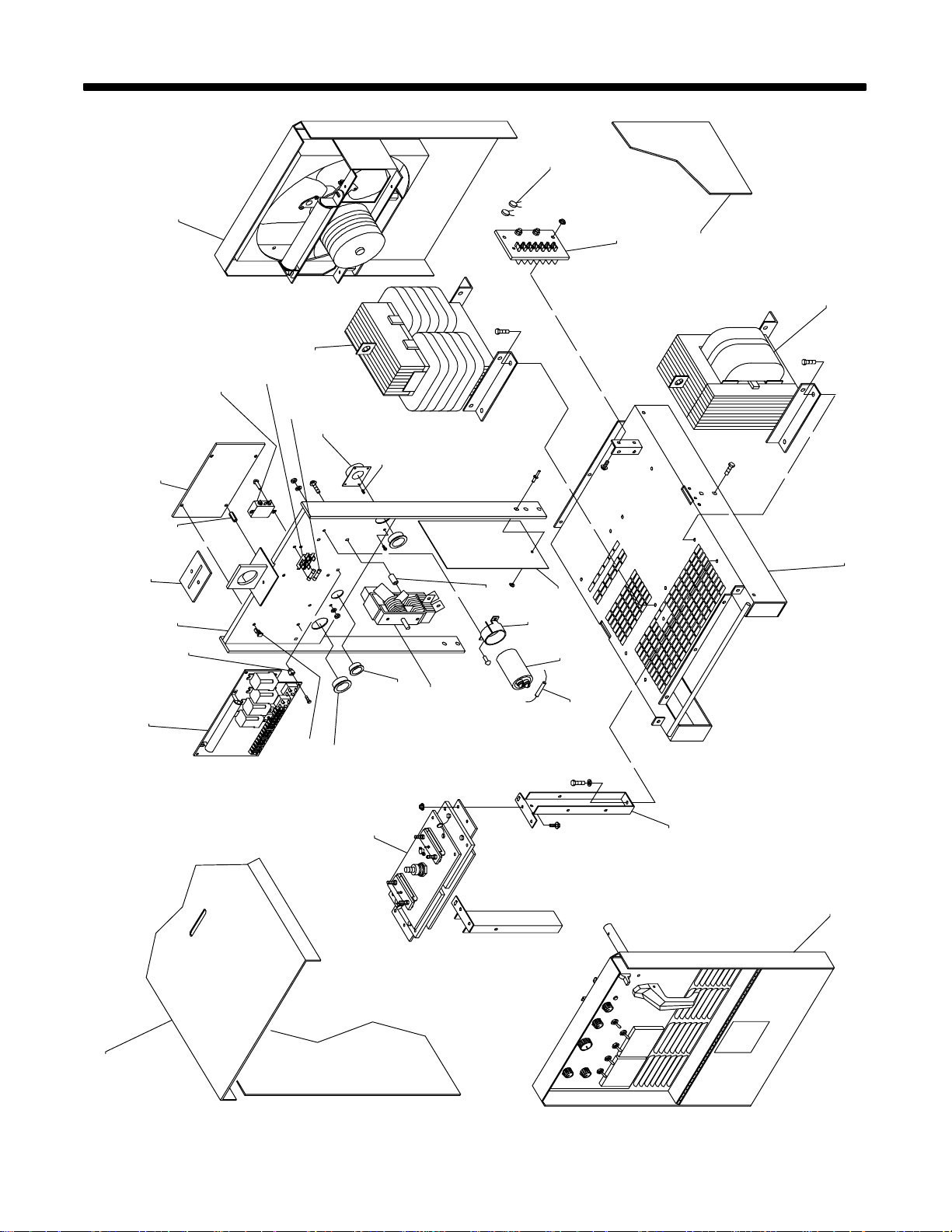

1 Input Terminal Board TE1

Provides means for operation on

different input voltages.

2 Power Switch S1

Provide on/off control of unit.

3 Fan Motor FM

Provides cooling of internal compo-

nents.

4 Main T ransformer T1

Supplies power to weld output cir-

cuit, various control circuits, main

control board PC1, and fan motor

FM.

5 Control Board PC1

Controls weld output by changing

the SCR gate pulses (conduction

times) after comparing current

feedback to selected amperage

signal.

Also provides input connections for

switches S3, S5, S6, and S7.

6 Arc Control Switch S6 And

Control R2

R2 selects short-circuit amperage

when S6 i s O n , and High Frequency control R13 is Off.

7 Crater Time Switch S7 And

Control R11

R11 selects crater time when S7 is

on, and Amperage Control switch

S5 is in Panel position.

8 Thermostat TP1

If T1 overheats, TP1 opens stop-

ping all weld output.

9 Output (Contactor) Switch S3

Selects On or remote contactor

control.

10 AC Balance Control R3

Controls changes to ac output

square wave.

11 Ammeter A1 And Voltmeter

V1

Display weld amperage and voltage while welding.

12 Amperage Control Switch S5

And Adjustment Control R1

R1 selects weld output amperage

when S5 is in Panel.

13 Remote 14 Filter Board

PC2/Remote 14 Receptacle

RC1

PC2 protects unit from high frequency, and RC1 connects remote

amperage and contactor controls to

power source.

14 Circuit Breaker CB1

Protects 115 volts ac duplex recep-

tacle RC2 from overload.

SECTION 5 – THEORY OF OPERATION

1-Phase

Input

Terminal

Board TE1

Power

Switch

S1

Main

Transformer

T1

Circuit

Breaker

CB1

115 VAC

115 VAC Duplex

Receptacle

RC2

Fan

Motor

FM

Control

Board

PC1

Arc Control

Output

Amperage

Crater Time

Switch

S6

Control

Switch S5

Switch

S7

AC

115 VAC

Thermostat

TP1

Line

Input

Power

DC

Synchronization

Signal

SCR

Gating

Signals

Main

Rectifier

SR1

1

φ1φ

124

31423

15

6

9

12

7

5

8

Arc Control

R2

Amperage

Adjustment

Control R1

Crater Time

Control

R11

AC Balance

Control

R3

10

Ammeter

A1

11

Postflow

Timer

TD1

16

Gas

Valve

GS1

17

6

12

Remote

13

Remote 14

Filter Board

PC2

13

7

1φ

, 10 VAC

(Contactor)

Switch S3

24

Background

Power

Source

Amperage

Control

♦

Page 25

TM-353 Page 21Syncrowave 250

15 115 Volts AC Duplex Recep-

tacle RC2

Provides connection point for auxiliary equipment.

16 Postflow Timer TD1

Controls shielding gas and coolant

postflow time.

17 Gas Valve GS1

Provides shielding gas during the

weld cycle.

18 Preflow Timer TD3, Control

R12, And Switch S9

R12 selects time shielding gas

flows before arc starts. S9 is an integral part of R12 so that when R12

is turned past zero (0), TD3 is off.

19 Spot Timer TD2, Switch S8,

And Control R10

R10 selects time output is available

when spot welding. S8 selects Off

or spot welding with remote contactor control.

20 High Frequency Transformer

T2

Steps up input voltage and charges

capacitor C4 .

21 Spark Gaps G And High Fre-

quency Coupling Coil T3

G provides path for C4 to discharge

into T3. T3 supplies high-frequency

to welding circuit.

22 High Frequency Intensity

Control R13

Changes amount of HF energy

used to sta r t and maintain the arc.

23 Main Rectifier SR1

Changes the ac output from T1 to

full-wave rectified dc.

24 Background Power Source

Provides reduced weld output rip-

ple at low weld output levels.

25 Stabilizer Z1

Smooths dc welding current.

26 Hall Device HD1

Provides current feedback signal to

PC1 through line filter FL1.

27 Line Filter FL1

Filters current feedback signal.

28 Output Selector Switch S4

Provides either AC or DC and out-

put polarity.

29 Integrated Rectifier SR2

Provides dc voltage feedback to

PC1.

30 Electrode And Work W eld

Output Terminals

Provide weld output.

Hall Device

HD1

Optional

AC Or DC Control

External Circuits

Weld Current Circuit

Stabilizer

Z1

Work Weld

Electrode

Output

Terminal

Weld Output

Terminal

High

Frequency

Coupling

Coil T3

Current Feedback

Voltage Feedback

High

Frequency

Intensity

Control R13

Spark Gaps G

High

Frequency

Transformer

T2

♦

1φ Power

25

26

28

30

21

30

22

21

20

Capacitor

C4

Integrated

Rectifier

SR2

29

Line

Filter

FL1

Preflow

Timer

TD3

Preflow Time

Control

R12

Switch

S9

♦

♦

Spot

Timer

TD2

Spot Time

Control

R10

♦

♦

Voltmeter

V1

18

18

19

19

11

27

115 VAC

Spot Time

19♦

Switch

S8

Output

Selector

Switch

S4

Voltage Feedback

♦

Page 26

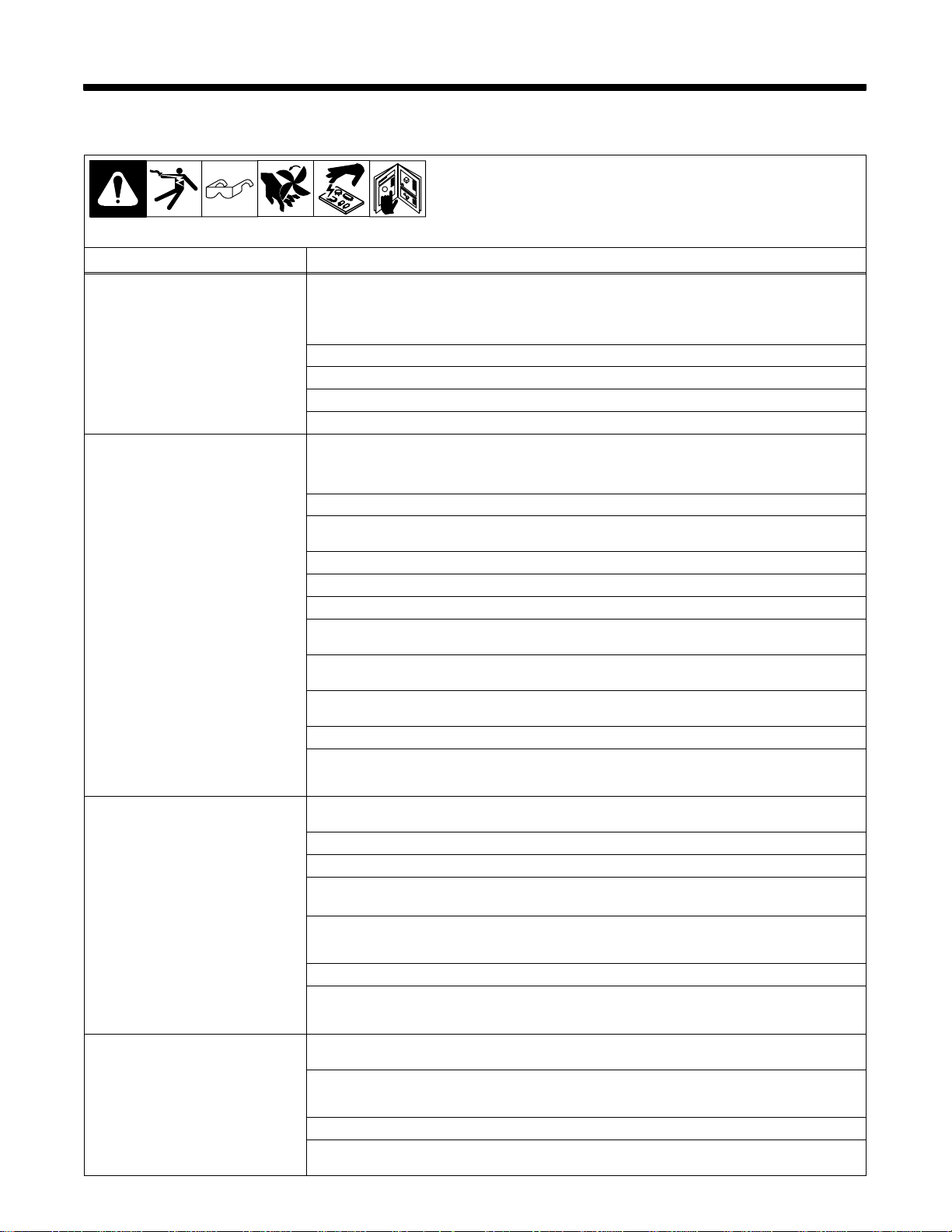

SECTION 6 – TROUBLESHOOTING

6-1. Troubleshooting Table

. See Section 6-2 for test points and values and

Section 10 for parts location.

. Use MILLER Testing Booklet (Part No. 150 853)

when servicing this unit.

Trouble Remedy

Prior to Serial No. KG164875, no weld

output; unit completely inoperative –

Effective with Serial No. KG164875,

no weld output; unit completely inoperative; PL2 off.

Replace building line fuse(s) or reset circuit breaker(s) if open.

Check for proper electrical input connections (see Section 3-11).

Check for proper jumper link position (see Section 3-11).

Check Power switch S1 and replace if necessary.

Prior to Serial No. KG164875, no weld

output; fan runs – Effective with Serial

No. KG164875, no weld output; fan

runs; PL2 on.

Check, repair or replace remote control device.

Allow a cooling period of approximately 15 minutes. If thermostats TP1 remain open, check continuity

Check circuit breaker CB1, and reset if open (see Section 7-2).

Place Output Selector switch S4 in desired position (see Section 4-2).

Check optional preflow timer board TD3, and replace if necessary.

Check optional spot timer relay TD2 for proper connections and resistance. Replace TD2 if

Check continuity of Spot Time switch S8. Check condition of contacts. Repair or replace S8 if neces-

Check SR1, and replace necessary components. If components are replaced, check capacitors C7

Unit provides only minimum weld

output.

Check control board PC1 and connections, and replace if necessary.

Unit provides only maximum weld

output.

Check connections for continuity to shunt device on units with Serial No. prior to KB110695.

TM-353 Page 22 Syncrowave 250

Be sure line disconnect switch is in the On position.

If using remote control, place Output (Contactor) switch S3 in Remote 14 position, and connect remote control to Remote 14 receptacle RC1 (see Sections 3-8 and Section 4-8). If remote is not being

used, place Output switch S3 in On position.

and replace if necessary (see Section 3-3).

necessary.

sary.

thru C10. Replace capacitor(s) if necessary.

Check control board PC1 and connections, and replace if necessary.

Effective with Serial No. KB1 10695, check resistance and connections of HD1; HD1 is 1600 ohms

±10% between pins 1 and 3 of plug PLG3. Check input and output voltages. Replace HD1 if

necessary.

Check position of Amperage Control switch S5 (see Section 4-7).

Increase Amperage Adjustment control R1 setting if a remote control is used (see Section 4-7).

Check, repair or replace remote control device.

Check resistance and connections of Amperage Adjustment control R1; R1 is 1000 ohms ±10%.

Replace R1 if necessary.

Check SCRs in main rectifier SR1, and replace if necessary. If any SCRs are replaced, Check capacitors C7 through C10 for a short or open, and check for proper connections. Replace C7 through C10

if necessary.

Effective with Serial No. KB1 10695, check resistance and connections of HD1; HD1 is 1600 ohms

±10% between pins 1 and 3 of plug PLG3. Check input and output voltages. Replace HD1 if

necessary.

Check Amperage Adjustment control R1 for proper connections and resistance; R1 is 1000 ohms

±10%. Replace R1 if necessary.

Effective with Serial No. KB1 10695, check resistance and connections of HD1; HD1 is 1600 ohms

±10% between pins 1 and 3 of plug PLG3. Check input and output voltages. Replace HD1 if

necessary.

Check bypass capacitors C13, C14, C16, C17, C18, and C19 for broken leads, shorts, and leakage.

Replace if necessary.

Page 27

Trouble Remedy

Check SCRs in main rectifier SR1, and replace if necessary. If any SCRs are replaced, Check capacitors C7 through C10 for a short or open, and check for proper connections. Replace C7 through C10

if necessary.

Check control board PC1 and connections, and replace if necessary.

Check connections to line filter FL1. Check input to PC1. Replace FL1 if necessary.

Erratic weld output.

No or limited ac balance control. Check AC Balance control R3 for proper connections and resistance; R3 is 5000 ohms ±10%.

Check control board PC1 and connections, and replace if necessary.

Check SCRs in main rectifier SR1, and replace if necessary. If any SCRs are replaced, Check capac-

No crater fill time. Check position of Crater switch S7 (see Section 4-4).

Be sure arc voltage is below 24 volts (see Section 3-2. Volt-Ampere Curves).

Check position of Amperage Control switch S5, S5 must be in Panel position (see Section 4-7).

Check control board PC1 and connections, and replace if necessary.

Crater fill time too long or does not

time out.

Check for poor or improper input or output connections. See Sections 3-11 and 3-8.

Replace electrode.

Check torch assembly, and replace if necessary.

Check fuse F2 in rectifier SR3 circuit, and replace if necessary.

If Amperage Control switch S5 is in the Remote position check, repair, or replace remote amperage

control device if necessary.

Check connections for continuity to shunt device on units with Serial No. prior to KB110695.

Check Amperage Adjustment control R1 for proper connections and resistance; R1 is 1000 ohms

±10%. Replace R1 if necessary.

Check bypass capacitors C13, C14, C16, C17, C18, and C19 for broken leads, shorts, and leakage.

Replace if necessary.

Check SCRs in main rectifier SR1, and replace if necessary. If any SCRs are replaced, Check capac-

itors C7 through C10 for a short or open, and check for proper connections. Replace C7 through C10

if necessary.

Check control board PC1 and connections, and replace if necessary.

Replace R3 if necessary.

itors C7 through C10 for a short or open, and check for proper connections. Replace C7 through C10

if necessary.

Check position of Crater control R11 (see Section 4-4).

Check position of Crater control R11 (see Section 4-4).

Check resistance and connections of Crater control R11; R11 is 5 meg ohms ±10%. Replace R11 if

necessary.

Check control board PC1 and connections, and replace if necessary.

No arc control.

Lack of high frequency at tungsten

electrode; difficulty in starting an arc.

Use shortest possible cables (see Section 3-7).

Check cables and torch for cracked or deteriorated insulation or bad connections. Repair or replace

Be sure to disconnect SMAW electrode cable from weld output terminal when GT AW welding.

Decrease gas flow setting.

Use properly prepared tungsten.

Increase setting of High Frequency Intensity control R13 (see Section 4-11).

Check spark gaps G, and readjust if necessary (see 7-4).

Place Arc Control switch S6 in the On position.

Place High Frequency switch S2 in the Off position.

Be sure arc voltage is below 24 volts (see Section 3-2. Volt-Ampere Curves).

Check position of Arc Control R2 (see Section 4-9).

Check fuse F1 in rectifier SR3 circuit, and replace if necessary.

Check resistance and connections of Arc control R2; R2 is 1000 ohms ±10%. Replace R1 if

necessary.

Check control board PC1 and connections, and replace if necessary.

Use proper size tungsten for welding application.

necessary parts.

TM-353 Page 23Syncrowave 250

Page 28

Trouble Remedy

No high frequency at spark gaps G.

No preflow time (optional). Place Output (Contactor) switch S3 in Remote position and be sure remote control is connected to

Check continuity of Preflow Time switch S9. Check condition of contacts. Repair or replace S9 if nec-

Remove jumper link 1 on terminal strip 1T.

Check optional preflow timer board TD3, and replace if necessary.

Optional spot timer relay TD2 does not

time out.

Remove jumper link 2 from terminal strip 1T.

Place Spot Time control R10 in desired position.

Check coil voltage and connections of spot timer relay TD2. Check continuity of coil and condition of

Check coil voltage and connections of control relay CR3. Check continuity of coil and condition of

Check coil voltage and connections of control relay CR1. Check continuity of coil and condition of

Postflow timer does not time out. Check position of Postflow Time control setting (see Section 4-10).

Check Control relay CR5 contacts 2 and 5 for proper operation. Replace CR5 if necessary.

Check coil voltage and connections of gas valve GS1. Check continuity of coils. Replace GS1 if nec-

Check control board PC1 and connections, and replace if necessary.

No postflow time. Check position of Postflow Time control setting (see Section 4-10).

Place Output(Contactor) switch S3 in the Remote position, and connect a remote control to recep-

Check coil voltage and connections of control relay CR5. Check continuity of coil and condition of

Check control board PC1 and connections, and replace if necessary.

No gas flow. Place Output(Contactor) switch S3 in the Remote position, and connect a remote control to recep-

TM-353 Page 24 Syncrowave 250

Check position of High Frequency switch S2 (see Section 4-11).

Place Output (Contactor) switch S3 in Remote position and be sure remote control is connected to

Remote receptacle RC1 (see Section 3-8).

Check circuit breaker CB1, and reset if open (see Section 7-2).

Check fuse F1 in rectifier SR2 circuit, and replace if necessary.

Check coil voltage and connections of contactor control relay CR1. Check continuity of coil and con-

dition of contacts. Replace CR1 if necessary.

Check coil voltage and connections of contactor control relay CR5. Check continuity of coil and con-

dition of contacts. Replace CR5 if necessary.

Check spark gaps G, and readjust if necessary (see Section 7-4).

Check resistance and connections of High Frequency Intensity control R13; R13 is 1.5 ohms ±10%.

Replace R1 if necessary.

Check capacitor C4 for a short or open, and check for proper connections. Replace C4 if necessary.

Check transformer T2 for signs of winding failure. Check continuity across windings, and check for

proper connections. Check secondary voltages. Replace T2 if necessary.

Check coupling coil T3 for signs of winding failure. Check continuity across windings, and check for

proper connections. Replace T3 if necessary.

Check control board PC1 and connections, and replace if necessary.

Remote receptacle RC1 (see Section 3-8).

Check position of Preflow Time control R12.

essary.

Place Spot Time switch S8 in the On position.

contacts. Replace TD2 if necessary.

contacts. Replace CR3 if necessary.

contacts. Replace CR1 if necessary.

essary.

Check input voltage and connections to Postflow timer board TD1. Check continuity of contacts. Re-

place TD1 if necessary.

tacle RC1 according to Section 3-8.

contacts. Replace CR5 if necessary.

Check coil voltage and connections of gas valve GS1. Check continuity of coils. Replace GS1 if nec-

essary.

Check input voltage and connections to Postflow timer board TD1. Check continuity of contacts. Re-

place TD1 if necessary.

tacle RC1 according to Section 3-8.

Check circuit breaker CB1, and reset if open (see Section 7-2).

Page 29

Trouble Remedy

Check Control relay CR2 contacts 4 and 7 for proper operation. Replace CR2 if necessary.

Check coil voltage and connections of gas valve GS1. Check continuity of coils. Replace GS1 if nec-

No power output at 115 volts ac receptacle RC1; weld output available.

Fan motor FM does not run; weld output available. Effective with Serial No.

KG164875, unit is equipped with FanOn-Demand, which only runs when

cooling is required.

Check coil voltage and connections of fan motor FM, and replace if necessary.

Line fuse opens immediately when

solid-state contactor SR1 turns on in

DC mode only.

Check SCRs in main rectifier SR1, and replace if necessary. If any SCRs are replaced, Check capac-

No control of weld output. Check position of Amperage Control switch S5 (see Section 4-7).

Check control board PC1 and connections, and replace if necessary.

Tungsten electrode oxidizing and not

remaining bright after conclusion of

weld.

Check and tighten all gas fittings if necessary.

Increase gas flow setting.

Properly prepare tungsten.

Wandering arc - poor control of direction of arc.

Controls connected to Remote 14

receptacle RC1 do not work properly.

Ammeter A1 not displaying correct

weld output amperage.

Voltmeter V1 not displaying correct arc

voltage.

Electronic equipment in welding area

not working properly.

essary.

Check circuit breaker CB1, and reset if open (see Section 7-2).

Check and clear fan blade obstruction.

Check diode D1, and replace if necessary.

itors C7 through C10 for a short or open, and check for proper connections. Replace C7 through C10

if necessary.

Check resistance and connections of Amperage Adjustment control R1; R1 is 1000 ohms ±10%.

Replace R1 if necessary.

Check, repair or replace remote control device.

Effective with Serial No. KB1 10695, check resistance and connections of HD1; HD1 is 1600 ohms

±10% between pins 1 and 3 of plug PLG3. Check input and output voltages. Replace HD1 if

necessary.

Check position of Postflow Time control R12 (see Section 4-10).

Shield weld zone from drafts.

Place High Frequency switch S2 in Start or Continuous position.

Use proper size tungsten for welding application.

Properly prepare tungsten.

Check, repair or replace remote control device.

Check Amperage Control switch S5 position (see Section 4-7). Check and replace S5 if necessary.

Check Output (Contactor) switch S3 position (see Section 4-8). Check and replace S3 if necessary.

Check position of jumper links 1 and 2 on terminal strip 1T according to Section 6-2.

Check coil voltage and connections of control relay CR2. Check continuity of coil and condition of

contacts. Replace CR2 if necessary.

Prior to Serial No. KF959379, check choke RFC1 connections. Check continuity of RFC1. Replace if

necessary. Effective with Serial No. KF959379 check remote 14 filter board PC2 (see Section 6-6).

Replace PC2 if necessary.

Check control board PC1 and connections, and replace if necessary.

Calibrate ammeter as instructed in Section 6-8.

Check ammeter A1 voltage; +1 millivolts dc per 3 ampere of weld output. Replace A1 if necessary.

Check control board PC1 and connections, and replace if necessary.

Effective with Serial No. KB1 10695, check resistance and connections of hall device HD1; HD1 is

1600 ohms ±10% between pins 1 and 3 of plug PLG3. Check input and output voltages. Replace HD1

if necessary.

Check connections for continuity to voltmeter V1. Replace V1 if necessary.

HF interference problem. Check for proper installation, and correct problem (see Section 8).

TM-353 Page 25Syncrowave 250

Page 30

TM-353 Page 26 Syncrowave 250

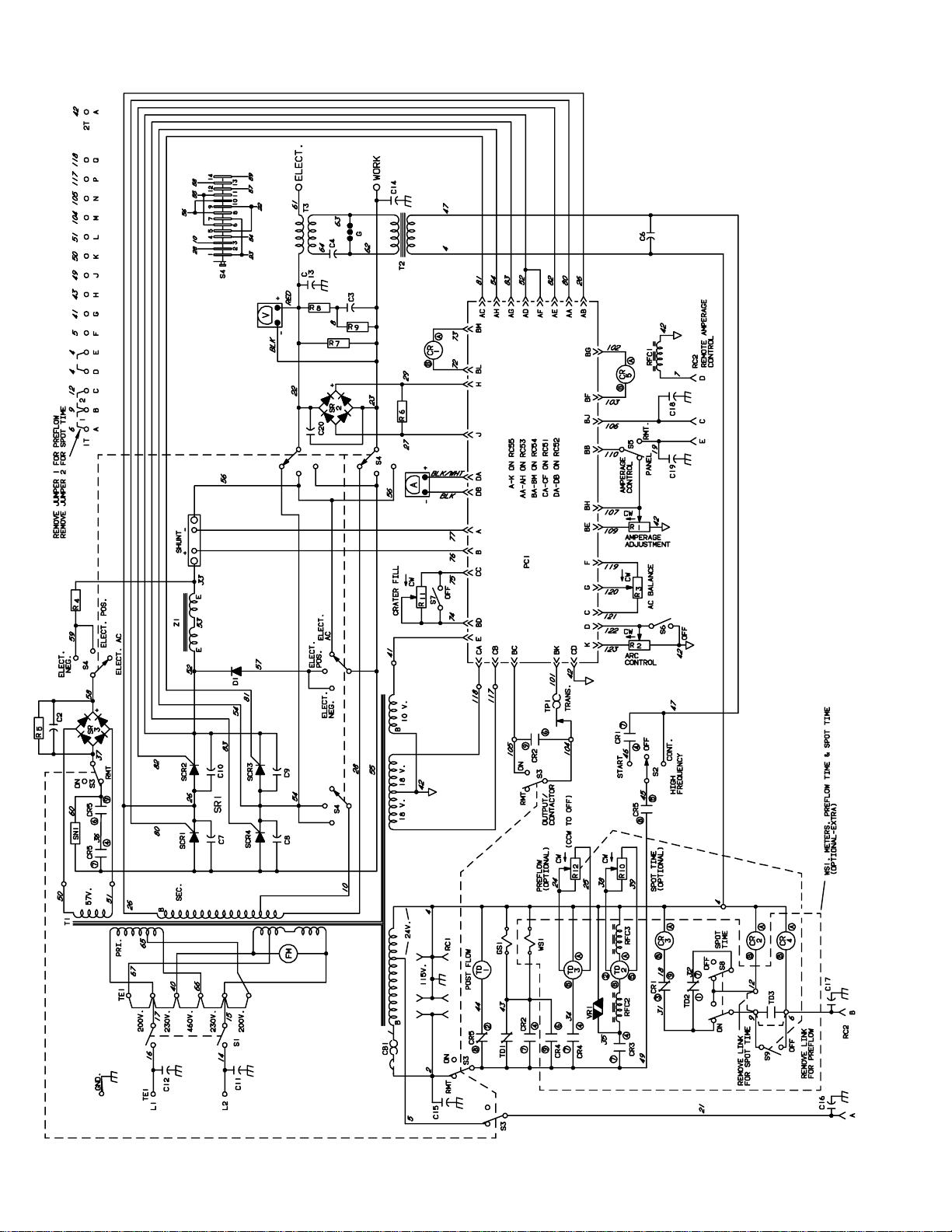

6-2. Troubleshooting Circuit Diagram For Welding Power Source

Y Disable high frequency by placing High Frequency

switch S2 in Off position before testing unit.

R1

V2

V3

V1

V4

V5

V6

V13

V14

V15

V16

Link 1 Link 2

V7

V8

V9

V10

V11

V17

V12

R1

R1

See Section 3-8

for RC1

information

TD1 begins to time out

when CR5 deenergizes

TD3 begins to time out

when CR4 energizes

See Figure 9-19

for PC3 circuit

CR3 energizes during spot time

when an arc is detected

CR4 energizes when remote contactor

switch closes

CR2 energizes when

remote contactor

switch closes

See Section 6-6

for PC2 data

R1

V25

Page 31

TM-353 Page 27Syncrowave 250

SC-188 161

Test Equipment Needed:

V24

V22

V21

R3

R2

V20

A

A

A

A

R1

V25

Resistance Values

a) Tolerance – ±10% unless specified

b) Turn Off unit and disconnect input

power before checking resistance

R1 All values for T1, Z1, and T3 are less

than 1 ohm

R2 5.3 ohms

R3 6.1 K ohms

Voltage Readings

a) Tolerance – ±10% unless

specified

b) Reference – to circuit

common (lead 42) unless

noted

c) Wiring Diagram – see

Section 10

V1 230 volts ac

V2 77 volts ac

V3 82.5 volts ac

V4 57 volts ac

V5, V6 115 volts ac

V7 24 volts ac

V8, V9 18 volts ac

V10 10 volts ac

V11 80 volts dc

V12. V13, V14 115 volts ac

V15, V16, V17 24 volts ac

V18 115 volts ac with S2

in Start or Continuous

V19 0 to +10 volts dc

with contactor on

V20, V21 24 volts dc

V22 0-80 volts dc (rec-

tified arc voltage)

V23 maximum 80 volts

ac/dc

V24 24 volts dc

V25 16.5 millivolts dc

per 1 ampere of

weld output

CR1 energizes

when open-circuit voltage

is present; denergizes

when an

arc is struck

See Figure 10-1 for

HD1 location

No calibration available

for voltmeter V1

R1

V23, B,

C, D, E

See Section 6-3

for waveforms

B, C, D, E

See also

Sections 6-4 and 6-5

for PC1 data

CR5 energizes when

contactor is on

See Section 6-8

for ammeter A1

calibration

V19

V18

See Section 6-3

for waveform A

Page 32

TM-353 Page 28 Syncrowave 250

6-3. Waveforms For Section 6-2

Waveforms shown are for 60 Hertz models;

waveforms for 50 Hertz models are similar.

5 ms 1 V

A. SR1 Gate Pulse With Respect To Cathode

At No Load

5 ms 50 V

B. DC Open-Circuit Voltage With Amperage

Adjustment Control At Maximum

5 ms 20 V

C. DC Output, 100 Amperes, 24 Volts DC

(Resistive Load)

5 ms 50 V

D. AC Open-Circuit Voltage With Amperage

Adjustment Control At Maximum

gnd

gnd

gnd gnd

Page 33

TM-353 Page 29Syncrowave 250

Test Equipment Needed:

5 ms 50 V

E. AC Output, 100 Amperes, 24 Volts AC (Re-

sistive Load)

gnd

Page 34

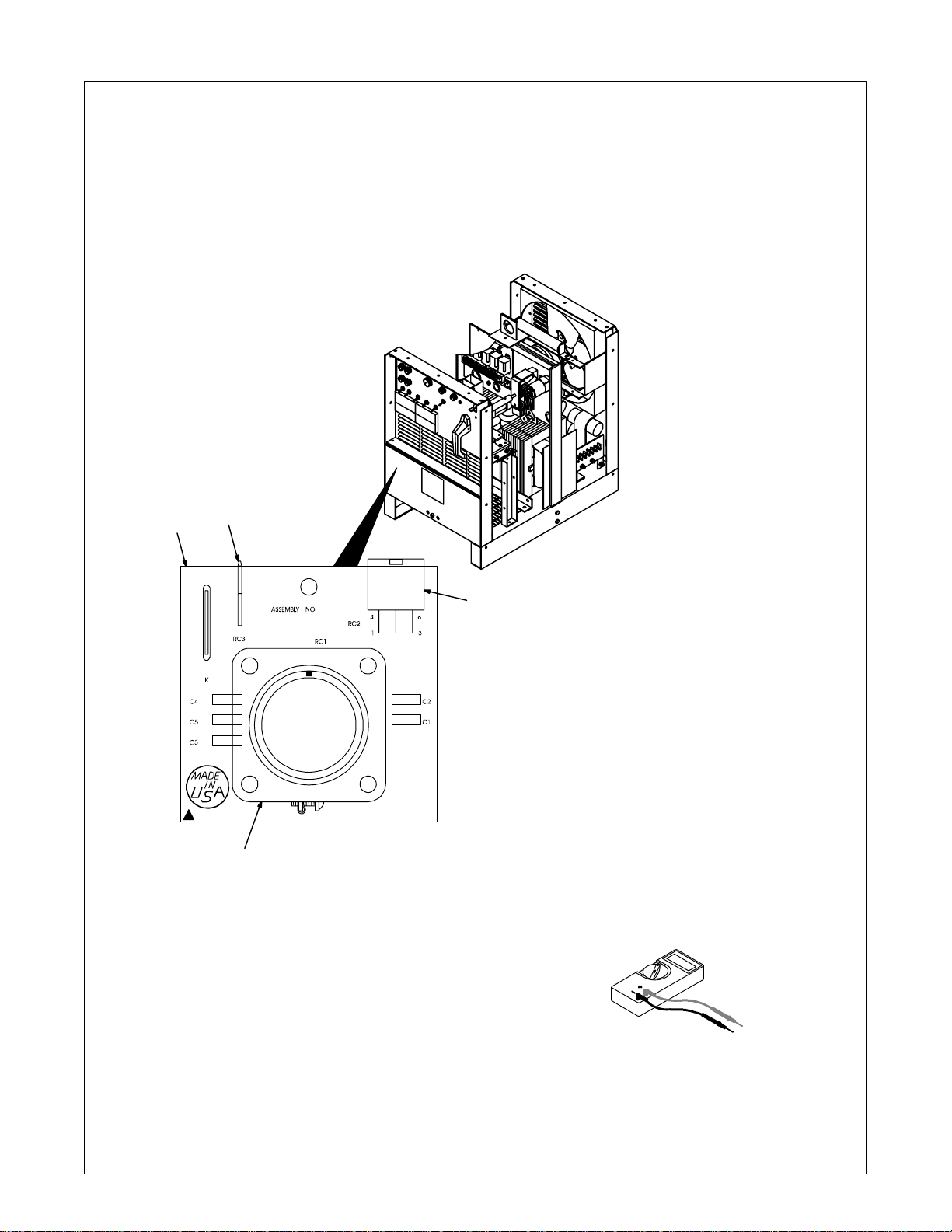

6-4. Control Board PC1 Testing Information (Use With Section 6-5)

Y Disable high frequency by

Be sure plugs are secure before

testing. See Section 6-5 for specific

values during testing.

1 Control Board PC1

2 Receptacle RC51

3 Receptacle RC52

4 Receptacle RC53

5 Receptacle RC54

6 Receptacle RC55

1 23

placing High Frequency

switch S2 in Off position

before testing unit.

4

6

5

Test Equipment Needed:

SB-178 976-A / ST-800 344-A

TM-353 Page 30 Syncrowave 250

Page 35

6-5. Control Board PC1 Test Point Values

PC1 Voltage Readings

Receptacle Pin Value

RC51 1 18 volts ac input

2 18 volts ac input

3 +10 volts dc output

4 Circuit common

5 Not used

6 Not used

RC52 1 Circuit common

2 +1 millivolt dc per 3 ampere of weld output

RC53 1 Gate pulse for SCR1 with respect to pin 2 (see Section 6-3)

2 Reference for gate pulse to SCR1

3 Gate pulse for SCR3 with respect to pin 4 (see Section 6-3)

4 Reference for gate pulse to SCR3

a) Tolerance –

±10% unless

specified

b) Reference – to circuit common

(lead 42) unless noted

5 Gate pulse for SCR2 with respect to pin 6 (see Section 6-3)

6 Reference for gate pulse to SCR2

7 Gate pulse for SCR4 with respect to pin 8 (see Section 6-3)

8 Reference for gate pulse to SCR4

RC54 1 Not used

2 0 to +10 volts dc input from min. to max. of Amperage Adjustment control R1 with Amperage Control

3 0 volts with Output (Contactor) switch S3 in On position or +7.8 volts dc with S3 in Remote position

4 0 to +10 volts dc input from min. to max. of Crater Control R11 with Crater Fill switch S7 in On posi-

5 +10 volts dc output with Output (Contactor) switch S3 in On position

6 –24 volts dc

7 –24 volts dc with contactor on or off

8 0 to +10 volts dc input from min. to max. of Amperage Adjustment control R1 with contactor on

9 0 to +10 volts dc input from min. to max. of Amperage Adjustment control R1 with contactor on

10 Circuit common

11 +24 volts dc

switch S5 in Panel position, and contactor on

tion, or +10 volts dc with S7 in Off position

12 0 volts during open-circuit voltage condition; +24 volts with arc on or contactor off

TM-353 Page 31Syncrowave 250

Page 36

Receptacle ValuePin

RC55 1 Circuit common

2 +1.65 volts dc per 100 amperes of weld output with respect to pin 1

3 –15 volts dc output

4 0 to +4 volts dc input from min. to max. of Arc Control R2 with Arc Control switch S6 On

5 10 volts ac input for synchronization

6 +5.8 volts dc output

7 –15 volts dc input from Max. Penetration setting of AC Balance control R3 to +5.8 volts dc input at

8 0 to 80 volts dc voltage feedback signal (rectified arc voltage) with respect to pin 9

9 0 to 80 volts dc voltage feedback signal (rectified arc voltage) with respect to pin 8

10 0 to +4 volts dc input from min. to max. of Arc Control R2 with Arc Control switch S6 Off

Max. Cleaning setting of R3

TM-353 Page 32 Syncrowave 250

Page 37

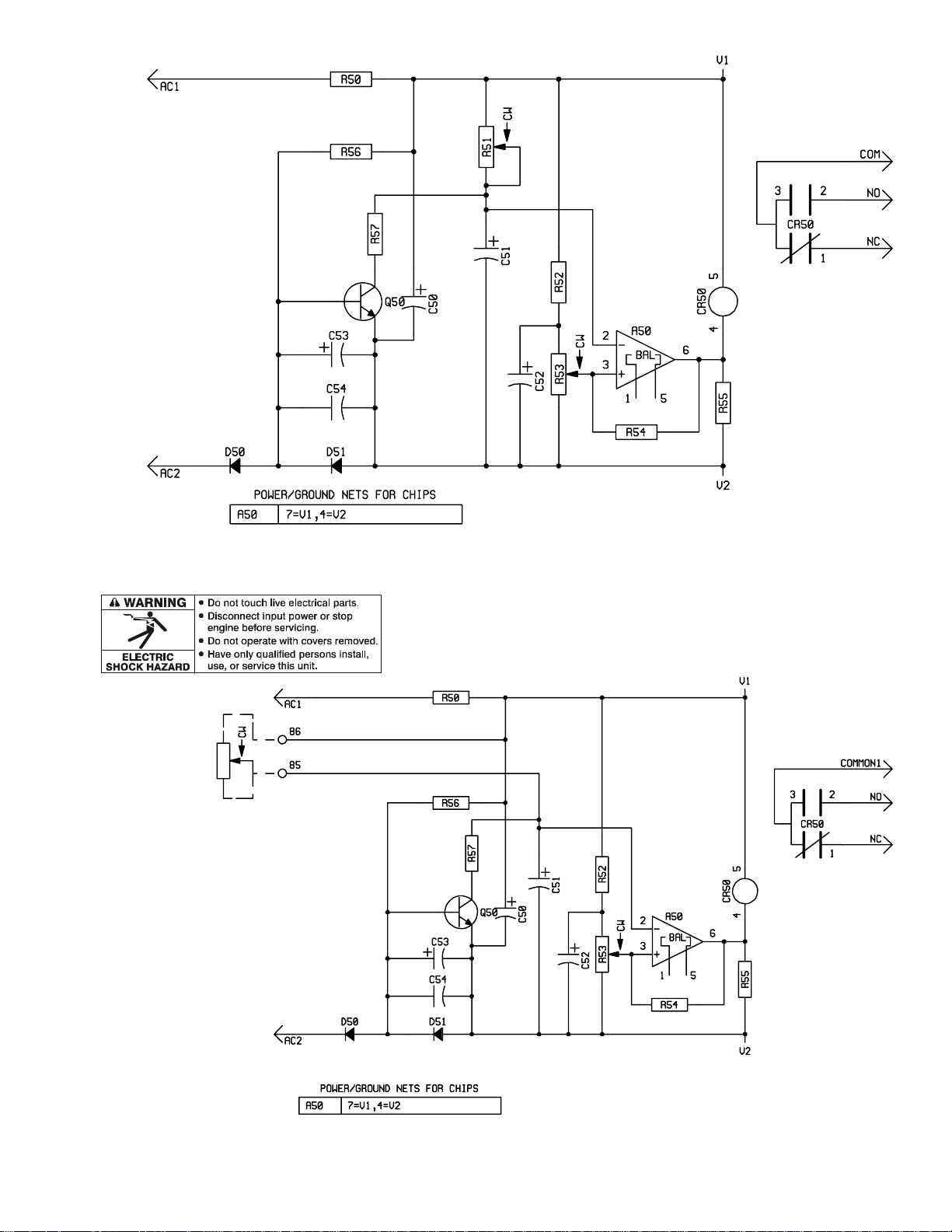

6-6. Remote Board PC2 Testing Information (Use With Section 6-7)

Y Disable high frequency by

Be sure plugs are secure before

testing. See Section 6-7 for specific

values during testing.

1 Remote 14 Filter Board PC2

2 Remote 14 receptacle RC1

See Section 3-8 for information.

3 Receptacle RC2

4 Receptacle RC3

placing High Frequency

switch S2 in Off position

before testing unit.

1

4

3

2

Test Equipment Needed:

ST-157 960-B / ST-800 344-A

TM-353 Page 33Syncrowave 250

Page 38

6-7. Remote 14 Filter Board PC2 Test Point Values (Use With Section 6-2 And Section 6-6)

PC2 Voltage Readings

Receptacle Pin Value

RC1 A 24 volts ac

B Contact closure to A completes 24 volts ac contactor control circuit

C Command reference; 0 to +10 volts dc output to remote control

D Remote control circuit common

E 0 to +10 volts dc input command signal from remote control

K Chassis common

RC2 1 Command reference; 0 to +10 volts dc output to remote control

3 Contact closure to A completes 24 volts ac contactor control circuit

4 Remote control circuit common

5 0 to +10 volts dc input command signal from remote control

6 24 volts ac

RC3 1 Chassis common

a) Tolerance –

±10% unless

specified

b) Reference – to circuit common

(lead 42) unless noted

TM-353 Page 34 Syncrowave 250

Page 39

6-8. Meter Calibration

No calibration available for ammeter

offset, or for voltmeter V1.

Be sure plugs are secure before

calibrating meter.

1 Control Board PC1

2 Voltmeter V1

3 Ammeter A1

1

Top View

R19

Amperes

Adjust R19 for amperage gain to

match external calibrated meter

using load bank set at desired

load.

2

3

SB-130 690-D / ST-800 344-A

TM-353 Page 35Syncrowave 250

Page 40

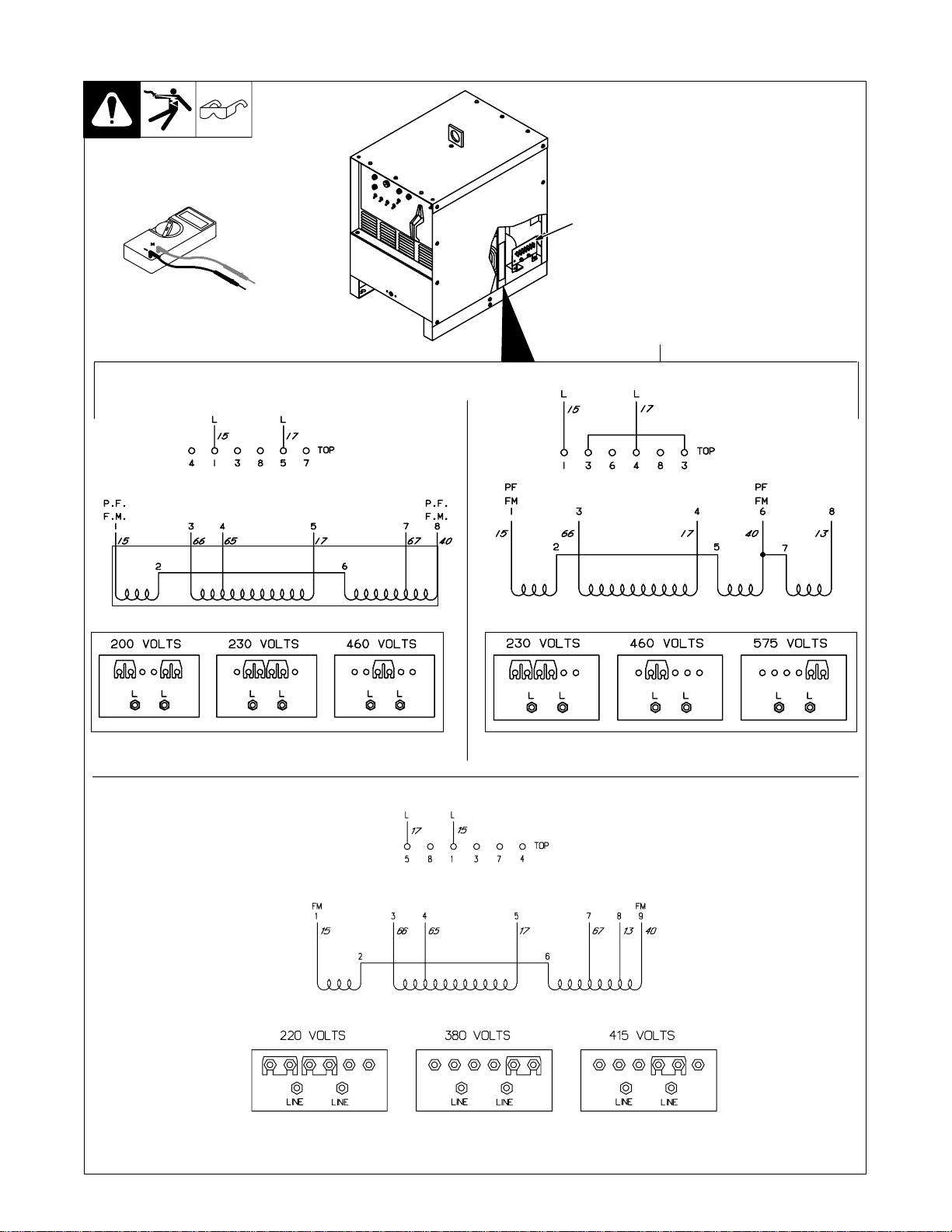

6-9. Input Voltage Labels And Connections

Test Equipment Needed:

1 Input Voltage Label A n d C o n -

nection Diagram – Only One

Label Is On Unit

2 Terminal Strip TE1

2

1

ST-154 793-A / ST-114 947-A / ST-121 000-A / ST-131 735

TM-353 Page 36 Syncrowave 250

Page 41

SECTION 7 – MAINTENANCE

7-1. Routine Maintenance

Y Disconnect power before maintaining.

3 Months

Replace

Unreadable

Labels

Adjust Spark

Gaps

7-2. Circuit Breaker CB1

14-Pin Cord Gas Hose

6 Months

Blow Out Or Vacuum

OR

Inside,

During Heavy Service,

Clean Monthly

Repair Or

Replace

Cracked

Weld

Cables

Clean An d

Tighten

Weld

Terminals

Replace

Cracked

Parts

Torch Cable

1 Circuit Breaker CB1

If CB1 opens, output to the 115 volts

ac duplex receptacle, high frequency, and gas flow stop. Press button

to reset breaker.

CB1

1

Ref. ST-154 795-C

TM-353 Page 37Syncrowave 250

Page 42

7-3. Fuses F1 And F2

1 Fuse F1 (See Parts List For

Rating)

Fuse F1 (between leads 50 and

150) protects wiring harness from

1

2

Tools Needed:

3/8 in

shorted SR2. If F1 opens, you may

experience problems with arc starting and arc performance in the DC

TIG mode.

2 Fuse F2 (See Parts List For

Rating)

Fuse F2 (between leads 22 and

149) protects wiring harness from

shorted SR3. If F2 opens, you may

experience problems with arc control, and no high frequency in start

high frequency.

7-4. Adjusting Spark Gaps

4

3

2

Tools Needed:

Y Turn Off power before

adjusting spark gaps.

4

3

1

Open access door.

1 Tungsten End Of Point

Replace point if tungsten end dis-

appears; do not clean or dress

tungsten.

2 Spark Gap

Normal spark gap is 0.008 in (0.203

mm).

If adjustment is needed, proceed as

follows:

3 Adjustment Screws

Loosen screws. Place gauge of

proper thickness in spark gap.

4 Pressure Point

Apply slight pressure at point until

gauge is held firmly in gap. Tighten

screws to 12 in/lbs torque (overtightening will deform plastic base). Adjust other gap.

Close access door.

Ref. ST-154 795-C / Ref. S-0043

TM-353 Page 38 Syncrowave 250

Page 43

SECTION 8 – HIGH FREQUENCY (HF)

8-1. Welding Processes Using HF

1

Work Work

1 HF V oltage

GTAW – helps arc jump air gap

between torch and workpiece and/

or stabilize the arc.

SAW – helps arc reach workpiece

2

1

through flux granules.

2 Flux

Gas Tungsten Arc

Welding (GT AW)

Submerged Arc

Welding (SAW)

8-2. Sources Of HF Radiation From Incorrect Installation

Weld Zone

11, 12

50 ft

(15 m)

10

9

8

7

3

13

1

2

high_freq1 7/95 – S-0693

14

Sources Of Direct HF Radiation

1 HF source (welding power source with

built-in HF or separate HF unit)

2 Weld Cables

3 Torch

4 Work Clamp

4 5 6

5 Workpiece

6 Work Table

Sources Of Conduction Of HF

7 Input Power Cable

8 Line Disconnect Device

9 Input Supply Wiring

S-0694

Sources Of Reradiation Of HF

10 Ungrounded Metal Objects

11 Lighting

12 Wiring

13 Water Pipes And Fixtures

14 External Phone And Power Lines

TM-353 Page 39Syncrowave 250

Page 44

8-3. Correct Installation

5

7

50 ft

(15 m)

Ground All

Metal Objects

And All Wiring

In Welding Zone

Using #12 AWG

Wire

Nonmetal

Building

1

Weld Zone

3

Ground

Workpiece

If Required

By Codes

6

50 ft

(15 m)

4

2

7

8

1 HF Source (Welder With Built-In HF Or

Separate HF Unit)

Ground metal machine case, work output

terminal, line disconnect device, input

supply, and worktable.

2 Welding Zone And Centerpoint

A circle 50 ft (15 m) from centerpoint

between HF source and welding torch in all

directions.

3 Weld Output Cables

Keep cables short and close together.

4 Conduit Joint Bonding And Grounding

7

10

9

Electrically join (bond) all conduit sections

using copper straps or braided wire. Ground

conduit every 50 ft (15 m).

5 Water Pipes And Fixtures

Ground water pipes every 50 ft (15 m).

6 External Power Or Telephone Lines

Locate HF source at least 50 ft (15 m) away

from power and phone lines.

7 Grounding Rod

Consult the National Electrical Code for

specifications.

7

Metal Building

Ref. S-0695 / Ref. S-0695

8 Metal Building Panel Bonding Methods

Bolt or weld building panels together, install

copper straps or braided wire across seams,

and ground frame.

9 Windows And Doorways

Cover all windows and doorways with

grounded copper screen of not more than

1/4 in (6.4 mm) mesh.

10 Overhead Door Track

Ground the track.

TM-353 Page 40 Syncrowave 250

Page 45

SECTION 9 – ELECTRICAL DIAGRAMS

. The circuits in this manual can be used for troubleshooting, but there might be minor circuit differences from your machine. Use circuit inside

machine case or contact distributor for more information.

The following is a list of all diagrams for models covered by this manual.

Model Serial Or Style Number Circuit Diagram Wiring Diagram

Syncrowave 250 JJ339876 thru JJ351864 SC-114 914 D-116 884-B♦♦

JJ351865 thru JJ365633 SC-120 877 D-120 878-B♦♦

JJ365634 thru JJ503983 SC-121 280 D-121 281-D♦♦

JJ503984 thru JK572897 SC-124 314 D-124 307-C♦♦

JK572898 thru JK617846 SC-124 785-B D-124 786-B♦♦

JK617847 thru JK682713 SC-124 785-B D-129 200-B♦♦

JK682714 thru JK690986 SC-124 785-B D-130 576-B♦♦

JK690987 thru KA806712 SC-132 697-A D-132 431-D♦♦

KA806713 thru KA877024 SC-137 431 D-137 430-A♦♦

KA877025 thru KB010829 SC-135 581 D-135 734-A♦♦

KB010830 thru KB110694 SC-142 524 D-142 525-A♦♦

KB110695 thru KC252675 SC-148 144 D-148 145-A♦♦

KC252676 thru KG029204 SC-154 649-C D-154 648-E♦♦

KG029205 thru KG062109 SC-178 835 D-174 039-A♦♦

KG062110 thru KG170300 SC-179 303-A D-179 305-A♦♦

KG170301 thru KH526230 SC-181 109-E SD-181 110-F♦♦

KH526231 and following SC-188 161-A SD-188162-A