Page 1

Process

Resistance Spot Welding

Work Capacity 20 kVA units

weld total thicknesses up to 1/4 in

(6.3 mm). Not recommended for

aluminum or copper alloys.

Rated Output 20 kVA at 40% duty cycle

depending on model, based

on 10-second time period

Weight SSW 170– 185 lb (77 –84 kg) Depending on model

Applications

Sheet Metal Work

Light Fabrication

Maintenance Work

Quick

Specs

SSW Series Spot Welders

Water-Cooled Resistance

Spot Welders

Issued April 2009 • Index No. SW/3.1

The Power of Blue®.

SSW foot switch permits user to use both hands

to position weldment between tongs. Can be held

longer if longer hold time is desired.

All spot welders operate on single-phase input

power, and require an air supply of 60 PSI

(414 kPa) minimum.

SSW models are designed for stationary

use and come with an all-steel pedestal

which houses timers and controls.

SSW models come complete with:

Stationary welding head

Remote foot switch

Pedestal inclusive of controls

and timer

Air filter/regulator assembly

Order tongs/tips separately to

match your applications

Air filter/regulator

assembly included.

Set-up/weld switch permits checking of

tong pressure and alignment without

making a weld.

Built-in squeeze/weld timer makes it quick

and easy to set or adjust squeeze and/or

weld time in hundredths of a second.

LED display makes it easy to read and

see timer settings.

Ten-step current control adjusts output current

with no change in duty cycle.

Cam-operated locking device simplifies

installation and adjustment of bottom tong.

Power switch/power “on” light/circuit breaker

protects control circuitry. Easy reset.

Adjustable tong pressure nuts to adjust tong

pressure for different thicknesses and applications.

Model

SSW-2020 ATT

Stationary

SSW-2040 ATT

Stationary

Work

Capacity*

1/4 in

(6.3 mm)

Input

50/60 Hz

230 VAC

90 Amps

460 VAC

45 Amps

Rated

Out put**

20 kVA at

40% Duty

Cycle

Rated Output (Calibrated w/ standard-type tongs)

6 in (152 mm) 12 in (305 mm) 18 in (457 mm)

12,500 A 10,500 A 9000 A

Specifications

(Subject to change without notice.)

Max. OpenCircuit Voltage

3.55

Dimensions

H x W x D

49 x 11 x

21-3/4 in

(1245 x 280

x 552 mm)

Net

Weight

185 lb

(84 kg)

*Combined thickness un coated mild steel using 6 in (152 mm) tongs.

**Duty Cycle based on 10-second time period. (40% duty cycle means unit can weld for 4 second out of each 10-second time period.)

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

Equipment Sales US and Canada

Phone: 866-931-9730

FAX: 800-637-2315

International Phone: 920-735-4554

International FAX: 920-735-4125

Page 2

2

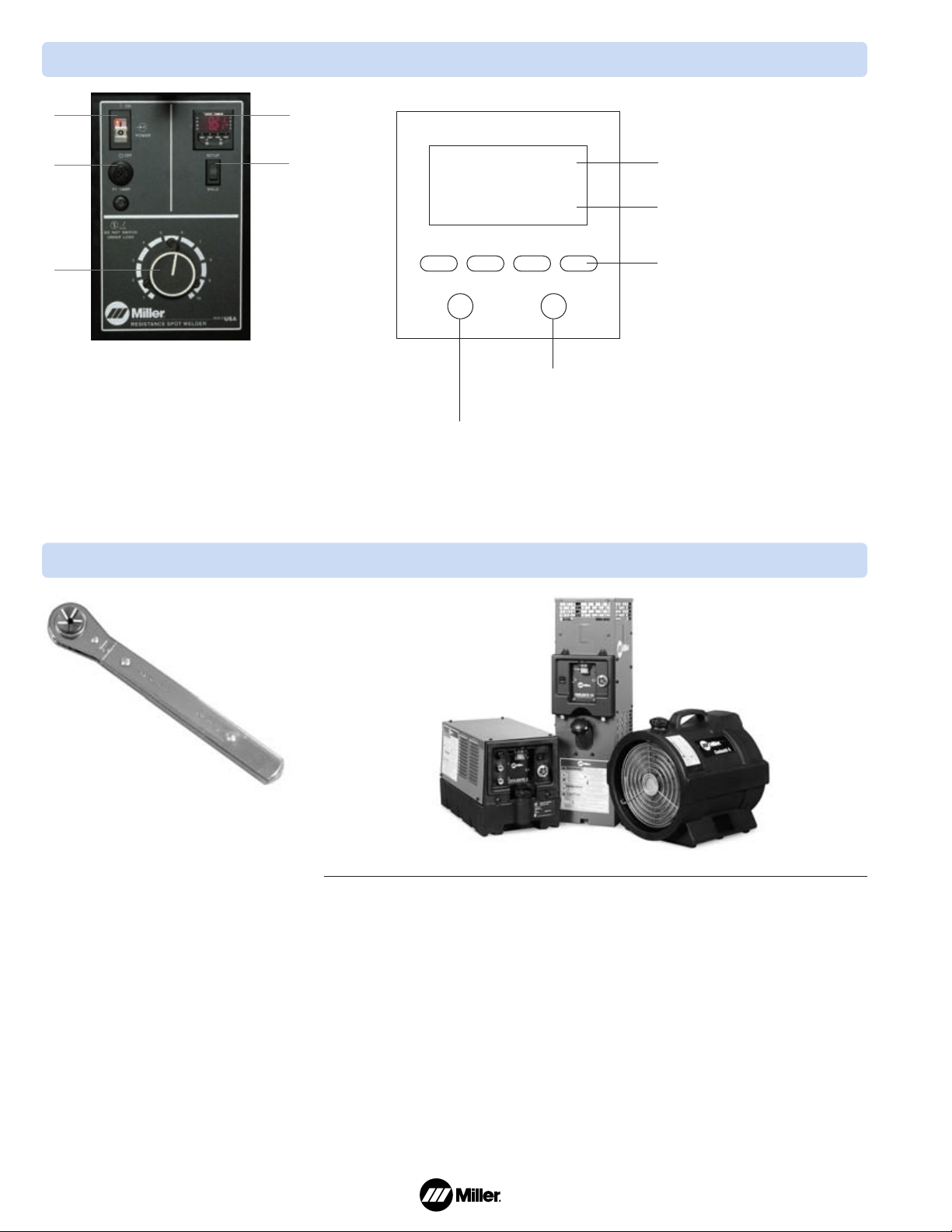

Control Panel

1. Power “On” Light/Circuit Breaker/Switch

2. Fuse to Protect Control Transformer

3. Weld Amperage Control

4. LED Display

5. Set-Up/Weld Switch

Place rocker switch in Set-Up position to

check tong pressure and alignment without

making weld.

Place in Weld position when ready to

activate actual squeeze and weld time.

SPOT TIMER

4 3 2 1

ST WT

LED Display

Sets times from 9.99

to 0.01 seconds

ST Selector Button

Set squeeze time with buttons

(3), (2), (1). Set enough time

for tongs to close before weld

amperage starts.

WT Selector Button Set weld

time with buttons (3), (2), (1).

Second row of LEDs displays

squeeze time set or weld time set.

First row of LEDs displays

actual times.

1 4

5

2

3

Tip Dresser #040 228

For use with pointed tips.

Genuine Miller Accessories

Coolmate 3 Coolmate 4

Coolmate V3

Coolmate™3

#043 007 115 VAC

#043 008 230 VAC

For use with water-cooled torches rated up

to 600 amps. Unique paddle-wheel indicator,

external filter and easy-fill spout.

Coolmate

™

V3 #043 009 115 VAC

For use with water-cooled torches rated up

to 500 amps. Vertical design conveniently

mounts to Miller cylinder rack in place of

one cylinder.

Coolmate

™

4 #042 288

For use with water-cooled torches rated up

to 600 amps. Tough molded polyethylene

case with carrying handle.

Coolants

#043 810 Coolant, low-conductivity

#043 809 Coolant, aluminum protecting

Sold in cases of four 1-gallon recyclable

plastic bottles. Miller coolants contain a

base of ethylene glycol and deionized water

to protect against freezing to -37˚F (-38˚C) or

boiling to 227˚F (108˚C). Both also contain

a compound that resists algae growth.

Water Coolant Systems

For more information, see the Miller Coolant Systems literature sheet, Index No. AY/7.2.

Page 3

3

Tongs and Tips

(Must be ordered separately from spot welders. One pair of tips are supplied with each set of tongs.)

Notes for tongs and tips:

Tongs and tips shown to the

left can be used with all PSW

and SSW model spot welders.

Recommended max. tong

length is 18 in (457 mm).

Tong throat-height dimen sion

for standard 90° and 45° tongs

is 4-1/4 in (108 mm). Throat

length is measured from the

center of the spot tips to the

front water hose connection.

X = tong length.

One set of tips is supplied with

each set of tongs.

Tips are made of RWMA Class

2 alloy.

Maximum welding capabilities

are obtained with minimum

tong length.

MT = Morse Taper.

No. 1 Morse Taper has smaller

diameter than No. 2 Morse

Taper.

4-1/4 in

(108 mm)

4-1/4 in

(108 mm)

7-1/2 in

(190 mm)

(229 mm)

TONGS

6 in

(150 mm)

TONG LENGTH

12 in

(304 mm)

18 in

(457 mm)

TIPS INCLUDED

6-1/4 in

(159 mm)

STANDARD 90°

No. 1 Morse Taper

No. 2 Morse Taper

#040 218—#040 219—#040 220

#041 001

#040 223

#040 308

6-1/4 in

(159 mm)

STANDARD 45°

No. 1 Morse Taper

No. 2 Morse Taper

—

—

#041 004—#041 005

#040 296

#040 851

#040 225

X

TT-6W

No. 2 Morse Taper

— — #041 838 #040 308

X

9 in

TT-9W

No. 2 Morse Taper

— — #041 840 #040 308

TIPS

No. 1 MT (Pointed)

#040 223

No. 1 MT (Offset)

#040 224

No. 2 MT (Pointed)

#040 308

No. 1 MT (Offset)

#040 851

No. 1 MT (Offset)

#040 226

QUANTITY

2 tips

2 tips

2 tips

2 tips

2 tips

WHERE USED

Standard No. 1 Tongs, 90°

Standard No. 1 Tongs, 90°

Standard No. 2 Tongs, 90°

TT-6W Tongs

TT-9W Tongs

Standard No. 1 Tongs, 45°

Standard No. 1 Tongs, 90°

No. 1 MT (Offset)

#040 298

No. 2 MT (Offset)

#040 225

No. 1 MT (Flat Swivel Tip)

Matching Pointed Tip

#040 216

Adapter (adapts No. 1 Morse Taper Tip

to No. 2 receptacle)

#040 227

2 tips

2 tips

2 tips

2 adapters

Standard No. 1 Tongs, 90°

Standard No. 2 Tongs, 45°

Standard No. 1 Tongs, 90°

Standard No. 2 Tongs, 90°

TT-6W Tongs (top)

TT-9W Tongs (top)

Page 4

Litho in USA

Distributed by:

Equipment and Options Stock No. Description Qty. Price

SSW-2020 ATT #903 826 Stationary, air-operated, 230 VAC, 50/60 Hz

SSW-2040 ATT #903 827 Stationary, air-operated, 460 VAC, 50/60 Hz

Tongs

Order separately Ordered by the pair. One pair of tips included with each pair of tongs.

See page 3 for tong/tip combinations

Tips

Order spares or additional types One pair of tips included with each pair of tongs.

See page 3 for tips that can be ordered in pairs or individually

Accessories

Tip Dresser #040 228

Coolant Systems

Coolmate

™

3 #043 007 115 VAC 5/8-18 left-hand inlet/outlet receptacles

#043 008 230 VAC 5/8-18 left-hand inlet/outlet receptacles

Coolmate™V3 #043 009 115 VAC 5/8-18 left-hand inlet/outlet receptacles

Coolmate™4 #042 288 115 VAC 5/8-18 left-hand inlet/outlet receptacles

Coolant Solution

Low Conductivity #043 810 1 gallon, must be ordered in multiples of 4

Aluminum Protecting #043 809 1 gallon, must be ordered in multiples of 4

Miscellaneous

Coolant Hoses One coolant “out” and one coolant “in” hose required. One end 5/8-18

left-hand male fitting and the other end “slip-on” secured with hose clamp.

5/16 ID hoses must be compatible with coolant.

Air Hoses Air supply to air filter to back of controller.

Air Filter has 1/4 in pipe thread female fittings.

Controller has 5/8-18 left-hand thread female fittings.

Input Power Cord To be supplied by local source to meet local electrical codes and guidelines.

Date: Total Quoted Price:

Ordering Information

Normally 5/8-18 left-hand

threaded receptacles

Slip-on hoses

tighten with

hose clamps

Input power line

Foot switch

Coolmate

TM

V3

circulator

Air in

Coolant line

Coolant line

Air hose 60 – 100 PSI

SSW

Pedestal

Air filter/regulator

assembly

Order tongs and tips separately.

Also required:

Input power cord of proper size per

NEC and local codes.

Coolant source and two coolant

hoses (5/16 ID). Hoses must be

compatible with coolant.

Note: Oxy-acetylene hoses are not

compatible with ethylene glycol.

Air hoses.

Stationary Resistance Spot

Welding Basic Equipment

Typical Installations

Loading...

Loading...