Page 1

Comes Complete With:

ICE-55C hand-held torch with 25 ft

(7.6 m) or 50 ft (15.2 m) cable,

or ICE-55CM machine-held torch

with 50 ft (15.2 m) cable. Extra

consumables supplied

Heavy-duty work clamp with

25 ft (7.6 m) or 50 ft (15.2 m) cable

10 ft (3 m) power cord

Spectrum®2050

Air Plasma

Cutting and Gouging

Issued April 2008 • Index No. PC/7.0

The Power of Blue®.

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

The ICE-55C torch includes a drag

shield that attaches to the cup and

holds the tip 1/8 in (3.2 mm) off the

workpiece. This permits the operator to

drag the torch on the work piece while

cutting at full output, which increases

operator comfort and makes template

cutting easier.

Auto-Line

™

automatically links the

Spectrum

®

2050 to any primary input

voltage from 208 to 575 V, single- or

three-phase, 50 or 60 Hz.

A standard feature, the pilot arc

switch in expanded metal mode

allows operator to cut grates, chain

link fence, and other perforated

metals without retriggering the gun.

Consumables storage compartment

provides convenient access to

consumables and parts.

Can be powered by any Miller

engine drive with generator power

(e.g. Bobcat

™

) or equivalent

competitive equipment. See page 3

for engine drive compatibility and

recommended settings.

Postflow cooling circuit cools

consumables and torch with postflow air

after you release the trigger. This feature

extends life of the torch and

consumables.

Starts without high-frequency so it

will not interfere with or damage

controls or computers.

Built-in gas/air filter/regulator is

housed inside the power source for

protection from transportation

damage. A standard air connection is

also provided on the back panel for

easy gas or air hookup.

Wind Tunnel Technology

™

prevents

abrasive dust and particles from

damaging internal components. Also, the

Fan-On-Demand

™

cooling system only

operates when needed. In dirty or dusty

environments, this feature reduces the

amount of airborne dust/dirt pulled

through the unit.

Portable, easy-to-carry unit weighs

only 86 lb (39 kg).

Power source is warranted for 3 years, parts and labor.

ICE torch is warranted for 1 year, parts and labor.

ICE-55C torch offers improved plasma

flow characteristics for increased

cutting speeds and longer consumable

set life.

Rated Output

55 A at 110 VDC,

60% Duty Cycle, 3-Phase

55 A at 110 VDC,

50% Duty Cycle, 1-Phase

Cutting Capability

Rated: 7/8 in (22.2 mm)

Sever: 1-1/8 in (28.6 mm)

Weight

With torch: 86 lb (39 kg)

Required Input

Pressure/Flow

6 SCFM (170 L/min) at

90 PSI MIN (621 kPa)

120 PSI MAX (828 kPa)

Industrial Applications

Construction

Maintenance/Repair

Fabrication

Processes

Air Plasma Cutting

and Gouging

Quick

Specs

Spectrum Plasma Cutters offer

reliability and performance that

others can’t match! See more at

MillerWelds.com/reliable

Page 2

2

Rated Output

55 A at 110 VDC,

60% duty cycle,

3-Phase

55 A at 110 VDC,

50% duty cycle,

1-Phase

Amps Input at Rated Output

208 V 230 V 380 V 400 V 415 V 460 V 575 V KVA KW

21 20 10 10 10 9 8 7.6 7.4

(7.9 @ 575 V)

36 33 — — — 16 13 7.5 7.4

Max.

Open-Circuit

Voltage

280 VDC

Plasma

Gas

Air or

Nitrogen

only

Weight

with

Torch

Net:

86 lb

(39 kg)

Ship:

93.5 lb

(42.4 kg)

Specifications (Subject to change without notice.)

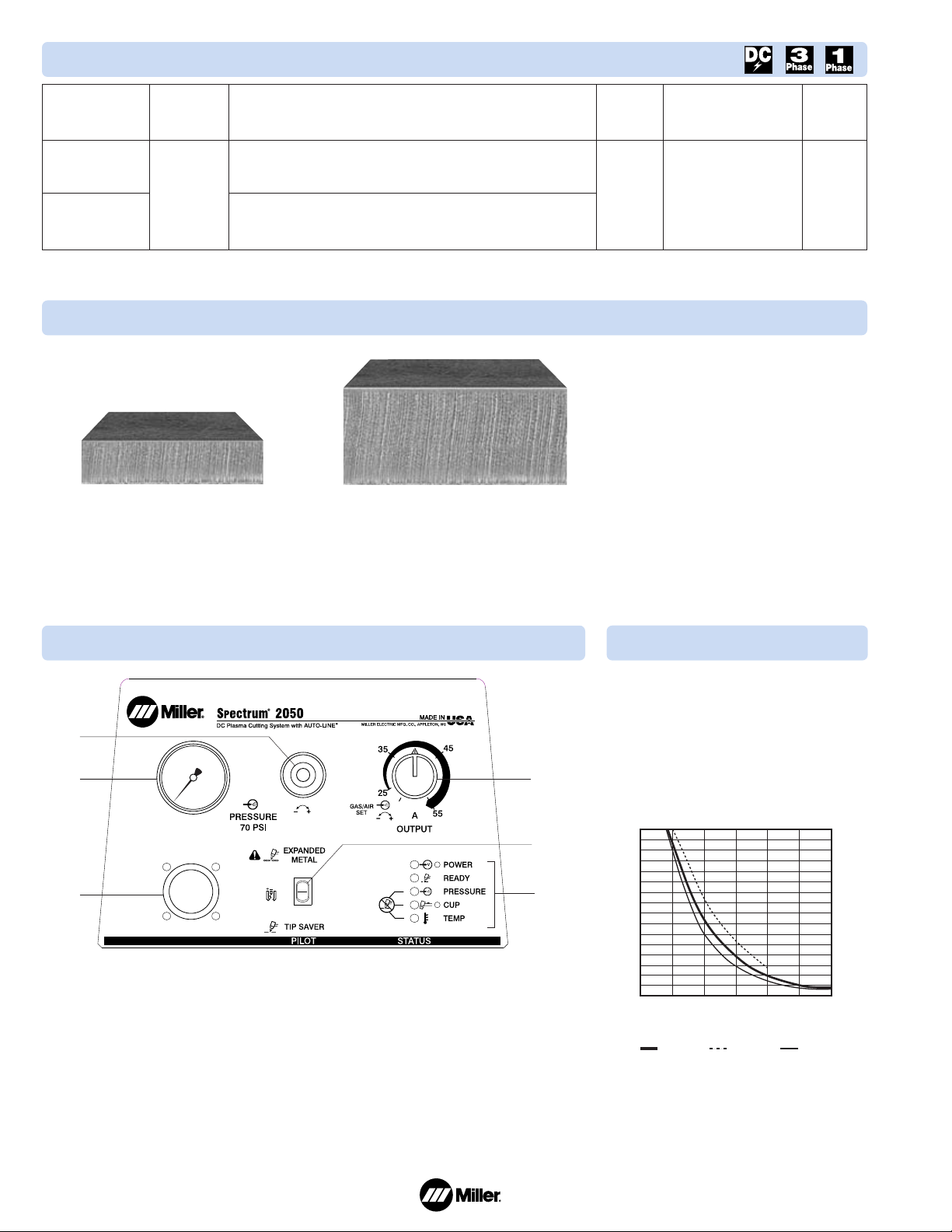

Control Panel

Mild Steel Cutting Capability

(Thickness to scale.)

Dimensions

H: 17 in (432 mm)

W: 12-1/2 in (318 mm)

D: 20-3/4 in (527 mm)

Note: For any single- or three-phase voltage from 208 V to 575 V, the Amps Input at Rated Output is the same for 50 or 60 Hertz input power.

Cutting Performance

1

2

4

6

5

3

1.Gas/Air Pressure Adjustment Control

2.Gas/Air Pressure Gauge

3.Torch Connection Receptacle

4.Output Control

5.Pilot Arc Mode Switch

6.Status and Troubleshooting Lights

To determine the maximum rated cutting

thick ness of mild steel, follow the line from

the 10 IPM (inches per minute) point on

the cutting chart. The point at which this

line intersects the cutting curve determines

the maximum recommended production

cutting thickness of the unit.

Note: The rating is based on 10 IPM because this is

the minimum speed at which the operator achieves a

smooth, steady cut when using a hand-held torch.

Note: Recommended maximum piercing capacity for hand-held applications is 7/16 in (11 mm).

Maximum Sever cut of 1-1/8 in (28.6 mm) a 3 IPM

For aluminum and other metals with high thermal conductivity, cutting capabilities will be derated as much as 30%.

7/8 in (22.2 mm) at 10 IPM1/2 in (12.7 mm) at 27 IPM

Maximum Sever cut of

1-1/8 in (28.6 mm) at 3 IPM

Rated cut capacity is based on traveling

approximately 10 inches per minute to achieve

a steady, precise cut. This is the key rating that

should meet or exceed your typical cutting

thickness requirements.

Rated

Rated

Cutting Speed vs. Material Thickness

160

150

140

130

120

110

100

90

80

70

60

50

40

30

Cutting Speed Inches/Minute

20

10

0

0

1/4

(6.4)

3/8

(9.5)

Aluminum

5/8

(15.9)

1/8

(3.2)

Material Thickness Inches (mm)

Mild Steel

(22.2)

7/8

Stainless

1

(25.4)

4.0

3.0

2.0

1.0

0.0

Cutting Speed Meters/Minute

Page 3

3

Genuine Miller Accessories

No. 50HD Cart

#300 026

This heavy-duty cart

accommodates the

Spectrum 125C, 375,

625, 2050, 1000 and

1251.

No. 30A Economy

Running Gear and Cord

Wrap #195 093

Economical running

gear with angle for easy

front panel access

provides storage for

gloves and tools.

Protective Cover

#195 271

Mildew-resistant,

odor-free, waterproof

cover protects your

machine’s finish.

Adapter Cord, Full KVA #300 158

NEMA 14-50P to NEMA 6-50R. Adapts

engine drive 120/240 V plug to Spectrum

®

240 V plug.

RTI Filter and Bracket

#195 425

Dryer will remove water, dirt

and oil as small as one

micron with 99.9% efficiency.

Can be mounted on plasma

cutter or on wall. Install as

close as possible to point of

air consumption.

Motor Guard Air Filter #042 306

This filter is equipped with a mounting

bracket that allows installation on the top,

side, or rear panel of most plasma cutters.

The filter is equipped with a 1/4 in NPT port

to match the fittings on most plasma systems;

it has a rated airflow of over 45 SCFM.

Miller Service Parts Accessories

The following accessories must be

ordered from Miller Service Parts.

RTI Replacement Filter Element #212 771

Replacement filter for #195 425.

Motor Guard Replacement Filter Element

#042 312

Carton of four filters for use with motor

guard air filter #042 306.

Remote Pendant Control #180 605

Provides remote start and stop of the arc

for the ICE-55CM machine-held torch.

ICE-55C Consumable Kit

#222 941

Consumable kit includes

4 standard electrodes, 4

standard tips, 2 ext

electrodes, 2 ext tips, 1

gouge tip, 1 gouge shield, 1 drag shield, 1

retaining cup, 3 o-rings and silicone grease.

Plasma Circle-Cutting

Guide #195 981

Cut straight lines or

circles up to 12"

diameter with ease.

Suction/Magnetic

Pivot Base

#195 979

Add this to your cutting guide for convenient

attachment to all flat surfaces. The extended

arm accommodates holes up to 30" diameter.

Torch Cable Covers

#231 867 25 ft (7.6 m)

#231 868 50 ft (15.2 m)

240 V Plug #119 172

For connection to Bobcat,

Trailblazer or Hobart Champion

10,000 with a minimum of

8 KVA auxiliary power.

In-Line Air Filter Kit

#228 926

Mounts to the back of the

Spectrum®375 X-TREME™, 375,

625, 2050, 1000, 1251. Includes

male and female1/4 in NPT quick

disconnect fittings and hose for easy on/off

connection. The replaceable filter element

filters to .85 microns.

In-Line Air Filter Replacement Element

#228 928

Includes 1 replacement filter for in-line filter

#228 926.

MIG Gloves

#227 821 Small

#227 822 Medium

#227 823 Large

#227 824 X-Large

For medium-duty MIG welding and

metalworking tasks.

Combination of

durable top grain cowhide palm and

abrasion-resistant pig split back sewn with

Kevlar

®

thread.

Metalworker Gloves

#227 817 Small

#227 818 Medium

#227 819 Large

#227 820 X-Large

Designed for the daily demands of the

metalworker and material handler.

Padded,

goatskin palm with textured G-Grip™patch

for excellent grip. Neoprene wrist with

Velcro

®

closure for improved fit. NOT

intended for use while welding.

Engine Drive Compatibility

Female

Receptacle

Equipment Generator Power Steel Quality Cut (Approximate) Spectrum Output Amp Setting

Bobcat™250, Trailblazer®302 & 275 DC 11 kW 3/4 in 50 A, 240 V, full KVA plug

Bobcat™225 10.5 kW 3/4 in 50 A, 240 V, full KVA plug

Miller Legend®302 5 KW 1/2 in while not welding 35 A, 240 V, full KVA plug

PipePro®304, PRO 300 12 kW 3/4 in 55 A, 240 V, full KVA plug

Big 40®CC/CV 15 kW (optional) 3/4 in 55 A, 240 V, full KVA plug

Big Blue

®

500 CC/CV 20 kW (optional) 5/8 in 55 A, 240 V, full KVA plug

Note: Includes Spectrum 2050 models manufactured after (and including) serial number KJ283702. LP powered machines need to be derated 15%.

Page 4

Litho in USA

Distributed by:

Power Source and Options Stock No. Description Qty. Price

Spectrum

®

2050 #903 777-01-2* With ICE-55C, 25 ft (7.6 m) hand-held torch

Single-/three-phase, 208–575 VAC, 50/60 Hz #903 777-01-3* With ICE-55C, 50 ft (15.2 m) hand-held torch

Note: Each Spectrum unit includes extra consumables

#903 777-02-2* With ICE-55CM, 50 ft (15.2 m) machine-held torch

(2 standard electrodes, 2 standard tips, 1 ext. electrode, (Machine torch package includes remote pendant

1 ext. tip and 1 deflector). control #180 605)

Replacement Torches

ICE-55C Hand-Held Torch #193 347 25 ft (7.6 m).

Order from Miller Service Parts

#193 348 50 ft (15.2 m).

Order from Miller Service Parts

ICE-55CM Machine-Held Torch #193 349 50 ft (15.2 m).

Order from Miller Service Parts

Consumables See above.

Order from Miller Service Parts

Accessories

No. 50HD Cart #300 026

No. 30A Economy Cart #195 093

Protective Cover #195 271

Adapter Cord, Full KVA #300 158 Adapts engine drive 120/240 V plug to Spectrum®240 V plug

RTI Filter and Bracket #195 425

Motor Guard Air Filter #042 306

Order from Miller Service Parts

RTI Filter Replacement Element #212 771 For RTI filter #195 425.

Order from Miller Service Parts

Motor Guard Replacement Filter Element #042 312 For air filter #042 306.

Order from Miller Service Parts

Remote Pendant Control #180 605

Order from Miller Service Parts

ICE-55C Consumable Kit #222 941 See page 3 for contents.

Order from Miller Service Parts

Plasma Circle-Cutting Guide #195 981

Order from Miller Service Parts

Suction/Magnetic Pivot Base #195 979

Order from Miller Service Parts

Torch Cable Covers See page 3.

Order from Miller Service Parts

240 V Plug #119 172

Order from Miller Service Parts

In-Line Air Filter Kit #228 926

Order from Miller Service Parts

In-Line Air Filter Replacement Element #228 928

Order from Miller Service Parts

MIG/Metalworker Gloves See page 3.

Order from Miller Service Parts

Date: Total Quoted Price:

Ordering Information

®

Certified by Canadian Standards Association to both Canadian and U.S. Standards.

NRTL/C

*

Replacement Torch and Consumables

ICE-55C Hand-Held Torch

#193 347 25 ft (7.6 m)

#193 348 50 ft (15.2 m)

ICE-55CM Machine-Held Torch

#193 349 50 ft (15.2 m)

*For drag cutting with extended

parts, recommended 40 amp

maximum output. A 1/8 in (3 mm)

standoff is required for output over

40 amps.

Standard

Cutting

Extended

Cutting

Drag

Shield

#192 053

Deflector

#177 888

Retaining

Cup

#192 050

Retaining

Cup

#192 050

Standard

Tip

#192 051

Extended

40 A Tip

#192 052

Standard

Electrode

#192 047

Extended

Electrode

#192 048

Swirl

Ring

#192 049

O-ring

#169 232

Gouging

Gouge

Shield

#192 203

Retaining

#192 050

Extended 55 A Tip*

Cup

#192 056

Gouge Tip

#192 204

Standard

Electrode

#192 047

Loading...

Loading...