Miller Electric Shopmate User Manual

Shopmate 300 Processes

MIG (GMAW)

Flux Cored (FCAW)

Shopmate 300 DX Processes

MIG (GMAW)

Flux Cored (FCAW)

Stick (SMAW)

DC Lift-Arc

™

TIG (GTAW)

Light Industrial Applications

Recreational Vehicle

Trailer Manufacturing

MRO — Maintenance/Repair

Education

Farm/Home

Quick

Specs

Shopmate™Series

MIG/Multiprocess Welding

Power Sources

Issued August 2007 • Index No. DC/12.7

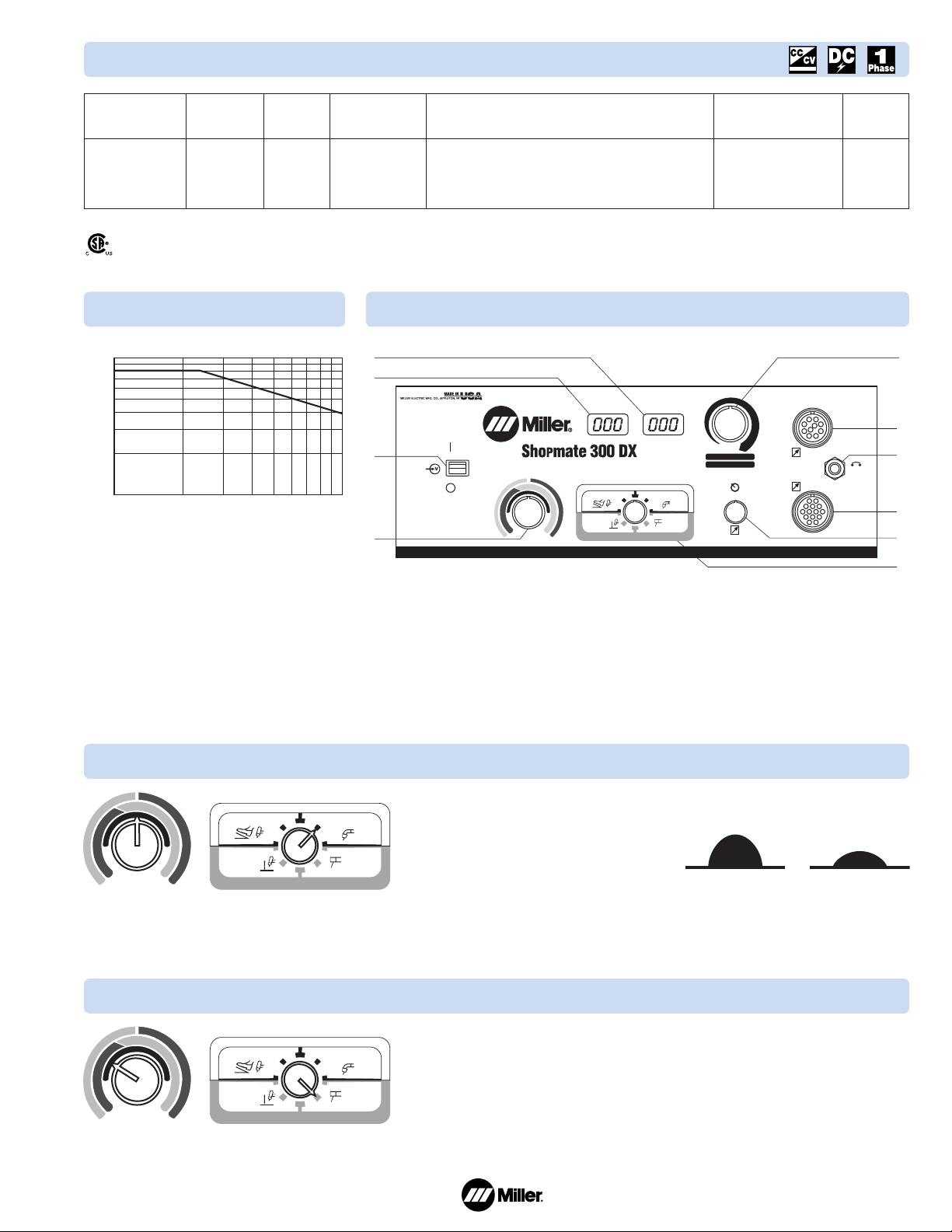

Built-in 10-pin

connector for

direct hookup of

Spoolmatic

®

15A

or 30A spool guns.

Large, dual digital

meters enable the

operator to preset

weld voltage in CV

mode and amperage

in the CC mode (DX

model only) before

striking an arc.

Arc control adjusts

inductance to optimize

MIG arc performance.

Line voltage

compen sation keeps

output power constant

even if input power

varies ±10%.

Built-in 14-pin

connector provides

quick, direct con nection for 14-pin

24 VAC Miller wire

feeders and

accessories.

Fan-On-Demand

™

operates only when

needed reducing

noise, power con sumption, and the

amount of airborne

contaminants

pulled through the

machine.

The Power of Blue®.

Power source is warranted for 3 years, parts and labor.

Original main power rectified parts are warranted for 5 years.

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

Input Power 1-Phase Power

(primary power cord not included)

Rated Output 250 A at 30 VDC, 60% Duty Cycle

300 A at 32 VDC, 40% Duty Cycle

Amperage Range in CC Mode 5 –400 A

Max. Open-Circuit Voltage 80 VDC

Voltage Range in CV Mode 10–35 VDC

Weight 300: 177 lb (80.3 kg) 300 DX: 177 lb (80.3 kg)

Shopmate 300

Single-phase MIG power source that

provides versatility and outstanding

arc performance in CV mode (MIG).

Shopmate 300

Shopmate 300 DX

Shopmate 300 DX

Single-phase MIG or

DC multi process

capability for versatility

with outstanding arc

performance in CV

mode (MIG) and CC

mode (Stick and TIG).

Shopmate 300 DX includes:

Process Selector Switch “operator-friendly”

single process switch eliminates confusion

caused by several switch combinations.

Lift-Arc TIG

™

allows DC/TIG starting without

the use of high-frequency. Starts the arc

without contaminating the weld with tungsten.

Shopmate 300 DX

MIG Packages

(see page 4)

VOLTA GE

VOLTAGE

PANE L

VOLTAGE CONTROL

AMPERAGE

ARC CONTROLPOWER

OFF

REMOTE 10

REMOTE 14

REMOTE 14

CBI

REMOTE

ON

S

T

L

M

I

G

S

S

M

I

G

A

L

M

I

G

1

2

3

4

5

6

7

8

9

WELDING AMPS

% DUTY CYCLE

DUTY CYCLE CHART

500

450

400

350

300

250

200

150

50

10 20

30

908070605040

100

100

Performance Data

2

Control Panel

Arc Control

Shopmate™300 Specifications (Subject to change without notice.)

Rated Output

250 A at 30 VDC,

60% Duty Cycle

Amperage

Range

5–400 A

Voltage

Range

10–35 V

Max. OpenCircuit Voltage

80 VDC

Dimensions

H: 24-1/2 in (622 mm)

including lift eye

W: 19 in (483 mm)

D: 25-1/2 in (648 mm)

Net

Weight

177 lb

(80.3 kg)

Example: Preset for MIG welding with steel wire

Control adjusts inductance for MIG welding. Set Arc

Control to desired wire type. Inductance determines the

“wetness” of the weld puddle. As setting is increased

(rotating Arc Control clockwise), wetness (puddle fluidity)

increases. For best results, preset Arc Control to the wire

type. Then either increase or decrease setting within wire

type scale to make fine adjustment to the welding arc.

1. Ammeter

2. Voltmeter

3. Power Switch

4. Arc Control

5. Voltage Adjustment Control

6. Remote 10 Receptacle

7. Supplementary Protector CBI

8. Remote 14 Receptacle

9. Voltage Control Switch

S

T

L

M

I

G

S

S

M

I

G

A

L

M

I

G

Amps Input at Rated Output, 60 Hz

208 V 230 V 460 V 575 V KVA KW

66 57 29 23 13 11.2

Certified to both the Canadian and U.S. Standards for welding equipment.

Note: For input conductor and fuse size information consult the Owner’s Manual.

Arc Control

(Counter Clockwise)

Low Inductance

Weld Bead

Arc Control

(Clockwise)

High Inductance

Weld Bead

Arc Control – Inductance/MIG

Arc Control – DIG/Stick

3

Shopmate™300 DX Specifications (Subject to change without notice.)

Rated Output

250 A at 30 VDC,

60% Duty Cycle

Amperage

Range

5–400 A

Voltage

Range

10–35 V

Max. OpenCircuit Voltage

80 VDC

Amps Input at Rated Output, 60 Hz

208 V 230 V 460 V 575 V KVA KW

66 57 29 23 13 11.2

Dimensions

H: 24-1/2 in (622 mm)

including lift eye

W: 19 in (483 mm)

D: 25-1/2 in (648 mm)

Net

Weight

177 lb

(80.3 kg)

S

T

L

M

I

G

S

S

M

I

G

6

0

1

0

S

T

I

C

K

7

0

1

8

S

T

I

C

K

A

L

M

I

G

TIG

MIG

STICK

LIFT-ARC

TIG™

VOLTA GE

VOLTAGE

AMPERAGE

PANE L

OUTPUT CONTROL

AMPERAGE

ARC CONTROLPOWER

OFF

REMOTE 10

REMOTE 14

REMOTE 14

CBI

REMOTE

ON

1

2

3

4

5

6

7

8

9

10

ELECTRODE HOT

WELDING AMPS

% DUTY CYCLE

DUTY CYCLE CHART

500

450

400

350

300

250

200

150

50

10 20

30

908070605040

100

100

Performance Data

Control Panel

1. Ammeter

2. Voltmeter

3. Power Switch

4. Arc Control

5. Voltage/Amperage Adjustment Control

6. Remote 10 Receptacle

7. Supplementary Protector CBI

8. Remote 14 Receptacle

9. Voltage/Amperage Control Switch

Control allows selection of either

panel or remote 14 for amperage or

voltage control.

10. Mode Switch

Switch determines both the process

and output On/Off control. Electrode

hot areas in gray are “contactor on”

positions.

Example: Preset for MIG process and steel wire

Control adjusts inductance for MIG welding.

Set Arc Control to desired wire type. Inductance

determines the “wetness” of the weld puddle.

As setting is increased (rotating Arc Control

clockwise), wetness (puddle fluidity) increases.

For best results, preset Arc Control to the wire

type. Then either increase or decrease setting

within wire type scale to make fine adjustment

to the welding arc.

Example: Stick Mode, 7018 Electrode

Control adjusts Dig when Stick mode is selected

on mode switch. Set Arc Control to desired

electrode type. For best results, preset Arc

Control in middle of the scale for appropriate

electrode type. Then either increase or decrease

setting within electrode type scale to make fine

adjustment to the welding arc.

ARC CONTROL

TIG

MIG

STICK

LIFT-ARC

TIG™

ELECTRODE HOT

S

T

L

M

I

G

S

S

M

I

G

6

0

1

0

S

T

I

C

K

7

0

1

8

S

T

I

C

K

A

L

M

I

G

ARC CONTROL

TIG

MIG

STICK

LIFT-ARC

TIG™

S

T

L

M

I

G

S

S

M

I

G

6

0

1

0

S

T

I

C

K

7

0

1

8

S

T

I

C

K

A

L

M

I

G

ELECTRODE HOT

Certified to both the Canadian and U.S. Standards for welding equipment.

Note: For input conductor and fuse size information consult the Owner’s Manual.

Arc Control

(Counter Clockwise)

Low Inductance

Weld Bead

Arc Control

(Clockwise)

High Inductance

Weld Bead

Loading...

Loading...