Miller Electric MOTORIZED SLIDE, MSC-2 Owner's Manual

October

1985

FORM:

OM-1096A

OWN

ERS

MANUAL

rnIHEii

.~

MILLER

ELECTRIC

MFG.

CO.

718

S.

BOUNDS

ST.

P.O.

Box

1079

APPLETON,

WI

54912

USA

ADDITIONAL

COPY

PRICE

50

CENTS

IMPORTANT

_____________

Read

and

understand

the

entire

contents

of

both

this

manual

and

the

power

source

manual

used

with

this

unit,

with

special

emphasis

on

the

safety

material

throughout

both

manuals,

before

installing,

peratlng,

or

maintaining

this

equipment.

This

unit

and

these

instructions

are

for

use

only

by

persons

trained

and

experienced

in

the

safe

operation

of

welding

equipment.

Do

not

allow

untrained

persons

to

install,

operate,

or

maintain

this

unit.

Contact

your

dIstributor

If

you

do

not

fully

understand

these

instructions.

Effective

With

Serial

No.

JF.22

MODEL

MOTORIZED

SLIDE

MOTORIZED

SLIDE

CONTROL

MSC-2

NWSA

CODE

NO.

4579

PRINTEDINU.S.A.

LIMITED

WARRANTY

EFFECTIVE:

FEBRUARY

25,

1985

This

warranty

supersedes

all

previous

MILLER

warranties

and

is

ox

clusive

with

no

other

guarantees

or

warranties

expressed

or

implied.

LIMITED

WARRANTY

-

Subject

to

the

terms

and

condi-

In

the

case

of

Millers

breach

of

warranty

or

any

other

duty

I

tions

hereof,

Miller

Electric

Mfg.

Co.,

Appleton,

Wisconsin

with

respect

to

the

quality

of

any

goods,

the

exclusive

remedies

4

warrants

to

its

Distributor/Dealer

that

all

new

and

unused

therefore

shall

be,

at

Millers

option

(1)

repair

or

(2)

replacement

Equipment

furnishedbyMiller

is

free

from

defectinworkman-

or,

where

authorized

in

writing

by

Miller

in

appropriate

cases,

(3)

~

ship

and

material

as

of

the

time

and

place

of

delivery

by

Miller.

the

reasonable

cost

of

repair

or

replacement

at

an

authorized

~.!

No

warranty

is

made

by

Miller

with

respect

to

engines,

trade

Miller

service

station

or

(4)

payment

of

or

credit

for

the

purchase

~

~

accessories

or

other

items

manufactured

by

others.

Such

pnce

(less

reasonable

depreciation

based

upon

actual

use)

upon

~

engines,

trade

accessories

and

other

items

are

sold

subject

to

return

of

the

goods

at

Customers

risk

and

expense.

MILLERs

i~

the

warranties

of

their

respective

manufacturers,

if

any

.

A)l

optionofrepairorreplacement

will

be

FOB.,

Factory,

at

q

engines

are

warranted

by

their

manufacturer

for

one

year

from

Appleton,

Waconsin,orF.O.B.,

at

a

MILLER

authorized

service

~

~

date

of

original

purchase,

except

Tecumseh

engines

which

facility,

therefore,

no

compensation

for

transportation

costs

of

~.

~

have

a

two

year

warranty.

any

kind

will

be

allowed.

Upon

receipt

of

notice

of

apparent

defect

or

failure,

Miller

shall

instruct

the

claimantonthe

warranty

Except

as

specified

below,

Millers

warranty

does

not

apply

claim

procedures

to

be

followed.

to

components

having

normal

useful

life

of

less

than

one

(1)

year,

such

as

spot

welder

tips,

relay

and

contactor

points,

MILLERMATIC

parts

that

come

in

contact

with

the

welding

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

AND

~

wire

including

nozzles

and

nozzle

insulators

where

failure

does

ANY

IMPLIED

WARRANTY,

GUARANTY

OR

REPRESENTA

~

not

result

from

defect

in

workmanship

or

material.

TION

AS

TO

PERFORMANCE,

AND

ANY

REMEDY

FOR

BREACH

OF

CONTRACT

WHICH,

BUT

FOR

THIS

PROVISION,

Miller

shall

be

required

to

honor

warranty

claims

on

war-

MIGHT

ARISE

BY

IMPLICATION,

OPERATION

OF

LAW.

~

~

ranted

Equipment

in

the

event

of

failure

resulting

from

a

defect

CUSTOM

OF

TRADE

OR

COURSE

OF

DEALING,

INCLUDING

~.

~

within

the

following

periods

from

the

date

of

delivery

of

Equip-

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

OF

~

~

ment

to

the

original

user:

FITNESS

FOR

PARTICULAR

PURPOSE,

WITH

RESPECT

TO

ANY

AND

ALL

EQUIPMENT

FURNISHED

BY

MILLER

IS

EX

1.

Arc

welders,

power

sources

and

components

....

1

year

CLUDED

AND

DISCLAIMED

BY

MILLER.

r~

2.

Original

main

power

rectifiers

3

years

(labor

-

1

year

only)

3.

Allweldingguns,feeder/gunsandplasmatorches...

90days

EXCEPT

AS

EXPRESSLY

PROVIDED

BY

MILLER

IN

4.

All

other

Millermatic

Feeders

1

year

WRITING,

MILLER

PRODUCTS

ARE

INTENDED

FOR

5.

Replacement

or

repair

parts,

exclusive

of

labor

..

60

days

ULTIMATE

PURCHASE

BY

COMMERCIAL/INDUSTRIAL

~

6.

Batteries

6

months

USERS

AND

FOR

OPERATION

BY

PERSONS

TRAINED

AND

4

EXPERIENCED

IN

THE

USE

AND

MAINTENANCE

OF

?

provided

that

Millerisnotified

in

writing

within

thirty

(30)

days

WELDING

EQUIPMENT

AND

NOT

FOR

CONSUMERS

OR

of

the

date

of

such

failure.

CONSUMER

USE.

MILLERS

WARRANTIES

DO

NOT

EXTEND

~

r~

. .

.

TO,

AND

NO

RESELLER

IS

AUTHORIZED

TO

EXTEND

~

submitted

by

the

ori~nal

user

wittun

the

foregoing

periods

MILLERS

WARRANTIES

TO,

ANY

CONSUMER.

~

~

~

~

ji

~,

~

~

~

~ ~

J~

ERRATA

SHEET

r

After

this

manual

was

printed,

refinements

In

equipment

design

occurred.

This

sheet

lists

exceptions

to

data

appearing

laterInthis

manual.

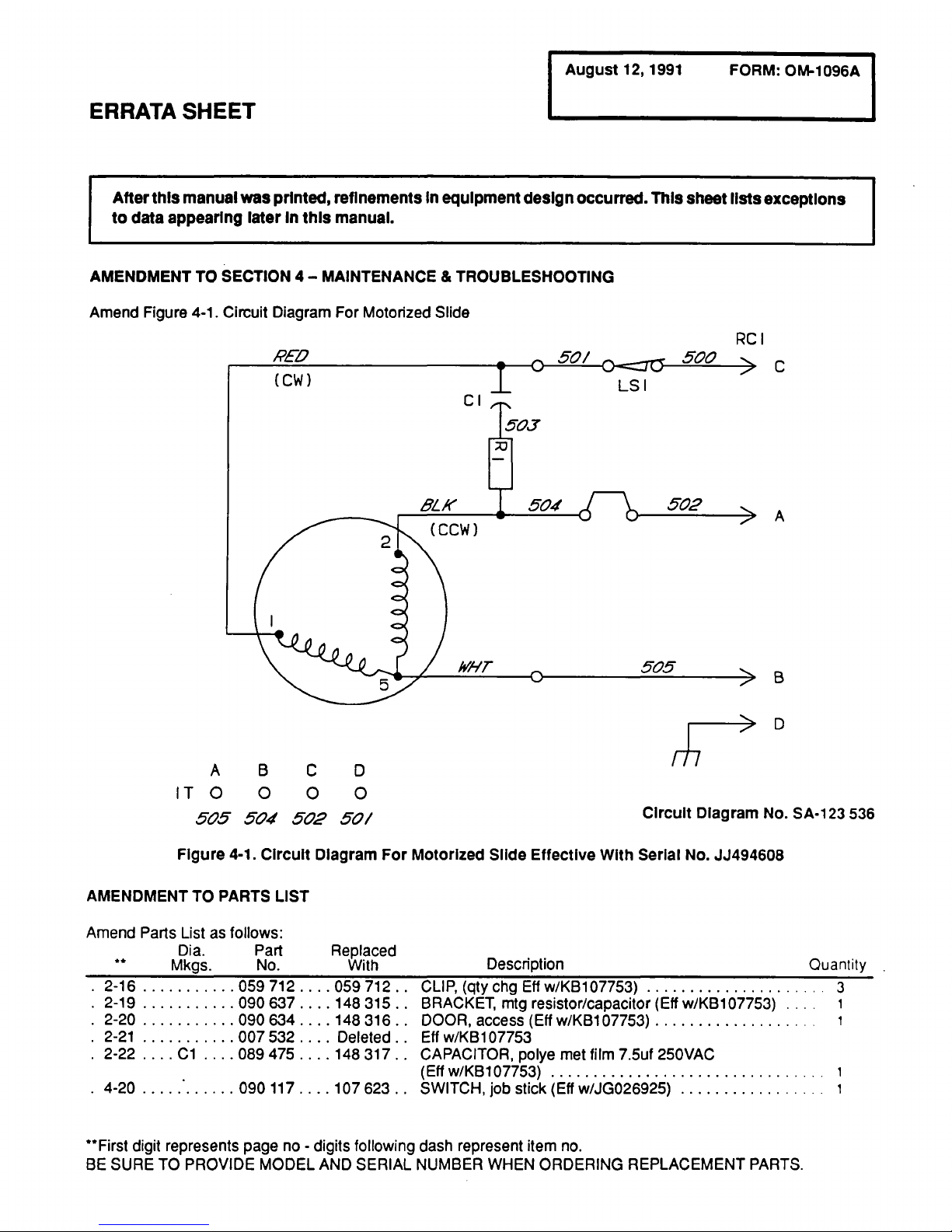

AMENDMENT

TO

SECTION

4

MAINTENANCE

&

TROUBLESHOOTING

Amend

Figure

4-1.

Circuit

Diagram

For

Motorized

Slide

Figure

4-1.

Circuit

Diagram

For

Motorized

Slide

Effective

With

Serial

No.

JJ494608

AMENDMENT

TO

PARTS

LIST

**Fjrst

digit

represents

page

no

-

digits

following

dash

represent

item

no.

BE

SURE

TO

PROVIDE

MODEL

AND

SERIAL

NUMBER

WHEN

ORDERING

REPLACEMENT

PARTS.

RED

(CW)

Cl

RC

I

LS

I

C

A

B

D

A

B

C

0

ITO

0

0 0

505

504

502

50/

147

Amend

Parts

List

as

follows:

Dia.

Part

**

Mkgs.

No.

Circuit

Diagram

No.

SA-1

23

536

Replaced

With

Description

.

2-16

059712...

.059712.

.

.

2-19

090637...

.148315.

.

.

2-20

090634...

.148316.

.

.

2-21

007

532..

.

.

Deleted.

.

.

2-22

.

..

.C1

.

. .

.089475...

.148317.

.

4-20

090117..

Quantity

CLIP,

(qty

chg

Efl

w/KB107753)

BRACKET,

mtg

resistor/capacitor

(Eff

w/KB107753)

DOOR,

access

(Elf

w/KB1

07753)

Elf

w/KB1

07753

CAPACITOR,

polye

met

film

7.5uf

250

VAC

(Elf

w/KB107753)

107

623..

SWITCH,

job

stick

(Eff

w/JG026925)

.3

TABLE

OF

CONTENTS

Section

No.

Page

No.

SECTION

1

-

INTRODUCTION

1

-

1.

General

Information

And

Safety

2

1

-

2.

Receiving-Handling

2

1

-

3.

Description

3

SECTION

2-INSTALLATION

2-1.

Location

4

2

-

2.

Interconnecting

Cord

Installation

From

Motorized

Slide

To

MSC-2

4

2

-

3.

Electrical

Connection

From

An

Automatic

Device

(Weld

Control)

To

The

MSC-2

4

2

-

4.

Electrical

Input

Connection

For

MSC-2

4

2

-

5.

Electrical

Connection

To

Motorized

Slide

With

System

9 5

2

-

6.

Optional

Motorized

Slide

Control

With

System

9

Connections

6

2

-

7.

Gun

Mounting

Plate

6

SECTION

3

-

OPERATOR

CONTROLS

3

-

1.

Limit

Switch

6

3

-

2.

Limit

Switch

(Customer

Supplied)

6

3-3.

MSC-2

7

3

-

4.

Motorized

Slide

Control

(Joystick;

Standard

On

MSC-2

And

Optional

With

The

SYSTEM

9)

7

SECTION

4

-

MAINTENANCE

&

TROUBLESHOOTING

4

-

1.

Interconnecting

Cords

7

4-2.

Slide

7

4

-

3.

Drive

Belt

7

4-4.

Fuse

Protection

8

4

-

5.

Troubleshooting

Chart

8

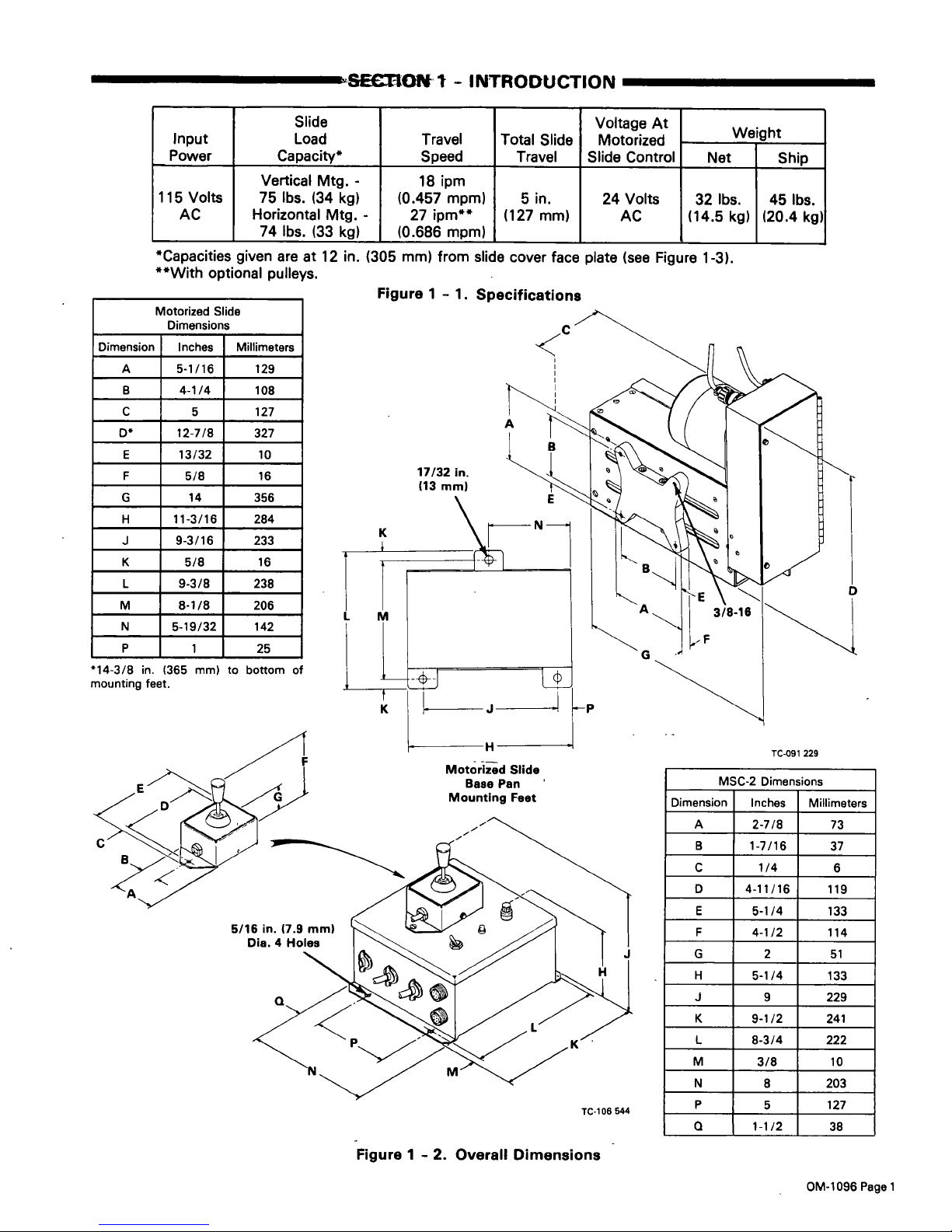

SEeBONt

-

INTRODUCTION

Input

Power

Slide

Load

Capacity*

Travel

Speed

Total

Slide

Travel

Voltage

At

Motorized

Slide

Control

ht

eig

Net

Ship

115

Volts

AC

Vertical

Mtg.

-

75

lbs.

(34

kg)

Horizontal

Mtg.

-

74

lbs.

(33

kg)

18

ipm

(0.457

mpm)

27

ipm**

(0.686

mpm)

5

in.

(127

mm)

24

Volts

AC

32

lbs.

(14.5

kg)

45

lbs.

(20.4

kg)

*Capacities

given

are

at

12

in.

**With

optional

pulleys.

(305

mm)

from

slide

cover

face

plate

(see

Figure

1-3).

Figure

1

-

1.

Specifications

Motorized

Slide

Dimensions

Dimension

Inches

Millimeters

A

5-1/16

129

B 4-1/4

108

C

5

127

0

12-7/8

327

E

13/32

10

F

5/8

16

G

14

356

H

11-3/16

284

J

9-3/16

233

K

5/8

16

L

9-3/8

238

M

8-1/8

206

N

5-19/32

142

P

1

25

14-3/8

in.

mounting

feet.

(365

mm)

to

bottom

of

MSC-2

Dimensions

Dimension

Inches

Millimeters

A

2-7/8

73

B

1-7/16

37

C

1/4

6

D

4-11/16

119

E

5-1/4

133

F

4-1/2

114

G

2

51

H

5-1/4

133

J

9

229

K

9-1/2

241

L

8-3/4

222

M

3/8

10

N

8

203

P

5

127

Q

1-1/2

38

Motorized

Slide

Base

Pan

Mounting

Feet

TC-091

229

a

TC-106

544

Figure

1

-

2.

Overall

Dimensions

OM-1096

Page

1

Loading...

Loading...