Miller Electric Millermatic 155, M-15 Owner's Manual

June 1996 Form: OM-1314

And Dia

Effective With Serial No. KG171523

OWNER’S

MANUAL

Millermatic® 155 And M-15 Gun

Rated Welding

Output

130 A @ 20.5 Volts

DC, 30% Duty Cycle

Wire Type

* While idling

cover_om 4/95 − ST-800 091-C PRINTED IN USA

Amperage

Range

40 − 170

Solid/

Stainless

.023 − .035 in

(0.6 − 0.9 mm)

230 Volt Wire Welder

Maximum

Open-Circuit

Voltage DC

33

Flux Cored/

Aluminum

.030 − .045 in

(0.8 − 1.1 mm)

© 1996 MILLER Electric Mfg. Co.

Amperes Input at

Rated Load Output 115 V, 60 Hz,

Single-Phase

20.5

(0.27)*

Calculated Wire

Speed Range At

No Load

126 − 722 IPM

(3.2 − 18.3 m/min)

KVA KW Weight

4.7

(.05)*4(.04)*

Max Wire Feed Speed While Welding

80 lb

(36.3 kg)

500 IPM

(12.7 m/min)

Overall

Dimensions

Length: 17 in

(432 mm)

Width: 10 in

(254 mm)

Height: 15-1/2 in

(394 mm)

SECTION 1 − INSTALLATION

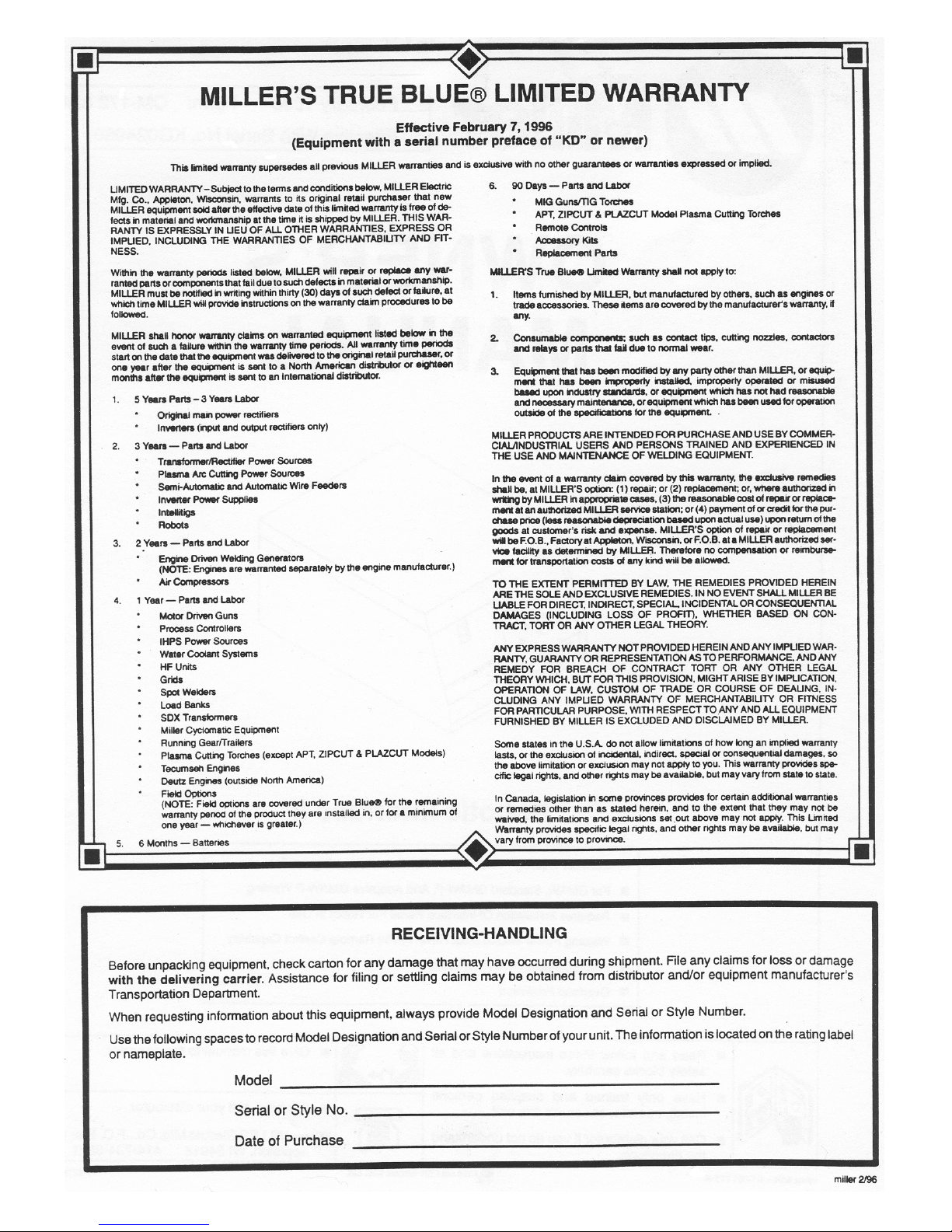

1-1. Installing Work Clamp

Tools Needed:

3/8, 7/16 in

1

6

5

3

4

2

1 Insulator

2 Bolt

3 Smaller Hole

4 Work Clamp Tabs

Bend tabs around work cable.

5 Work Cable From Unit

6 Nut

1-2. Installing Welding Gun And Setting Gun Polarity For Wire Type

1 Gun Opening

2 Gun Trigger Receptacle

3 Gun Securing Nut

4 Drive Assembly

5 Gun End

. Follow wire manufacturer’s recommendation.

Flux Cored Wires

(FCAW−Without Gas)

Aluminum Wires

(GMAW−With Gas)

Solid Steel Or

Loosen securing nut. Insert gun

end through opening until it bottoms

against drive assembly. Tighten

nut.

6 Gun Trigger Plug

Insert plug into receptacle, and

tighten threaded collar.

Close door.

Ref. ST-025 190-D

Straight Polarity

DCEN

Reverse Polarity

DCEP

1

2

Front Panel Openings

3

4

Tools Needed:

56

ST-149 328-B / Ref. ST-159 270

5/16 in

OM-1314 Page 5

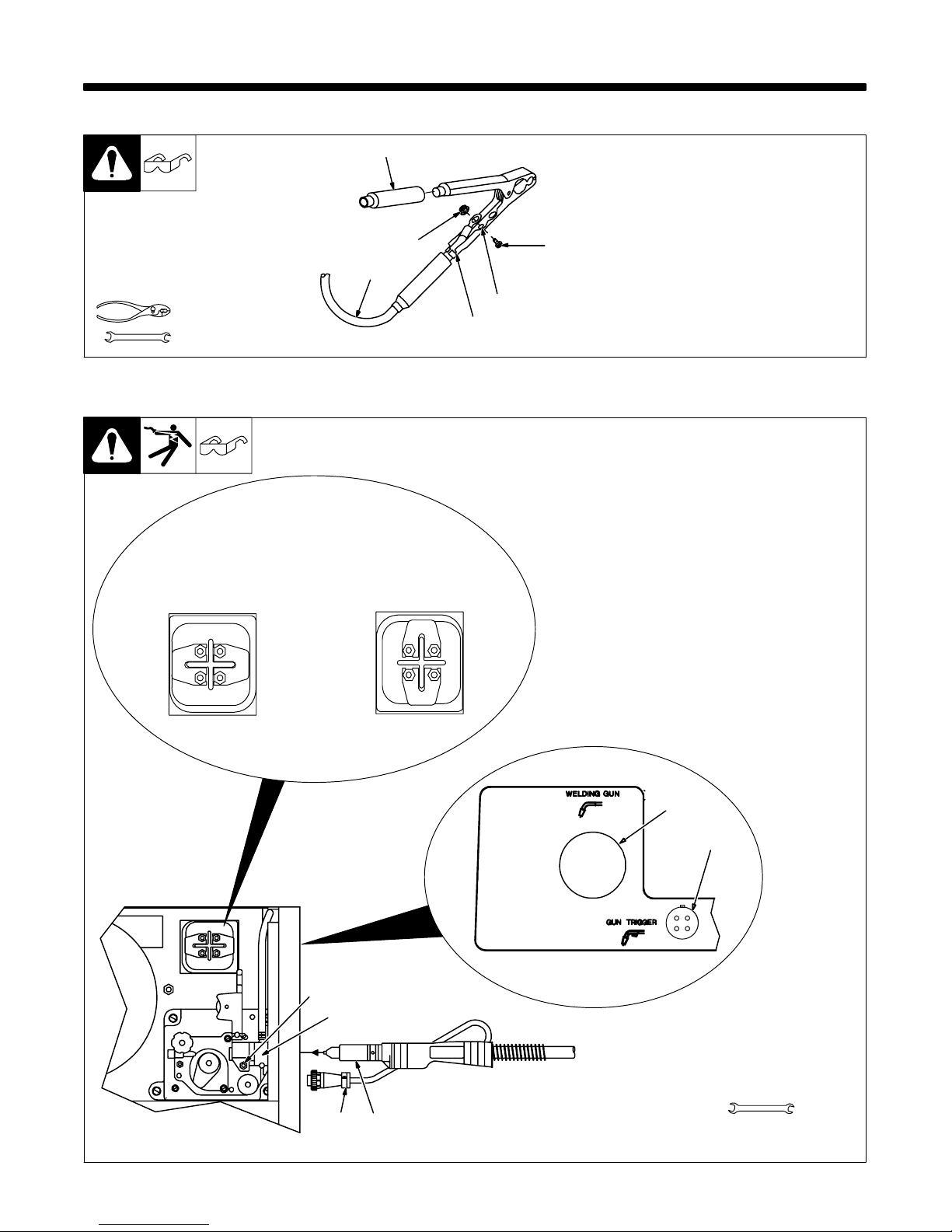

1-3. Electrical Service Guide

Input Voltage

Input Amperes At Rated Output

Max Recommended Standard Fuse Or Circuit Breaker Rating In Amperes

Min Input Conductor Size In AWG/Kcmil

Max Recommended Input Conductor Length In Feet (Meters)

Min Grounding Conductor Size In AWG/Kcmil

Reference: 1996 National Electrical Code (NEC) S-0092-J

230

20.5

25

14

64 (19)

14

1-4. Selecting A Location And Connecting Input Power

1 Rating Label

Supply correct input power.

2 Plug

3 Receptacle

Connect plug to receptacle.

18 in (457 mm) of

space for airflow

4

L1

4 Line Disconnect Device

See Section 1-3.

Y Special installation may be

required where gasoline or

volatile liquids are present −

see NEC Article 511 or CEC

Section 20.

Y Always connect

grounding

conductor first.

= GND/PE

L2

1

2

Y Do not move or operate unit

where it could tip.

3

L2

L1

230 VAC, 1

OM-1314 Page 6

ssb2.2* 1/94 − ST-801 504

1-5. Installing Wire Spool And Adjusting Hub Tension

Standard Wire Spool

Tools Needed:

1 Lb Wire Spool

When a slight force is needed

to turn spool, tension is set.

15/16 in

S-0499

OM-1314 Page 7

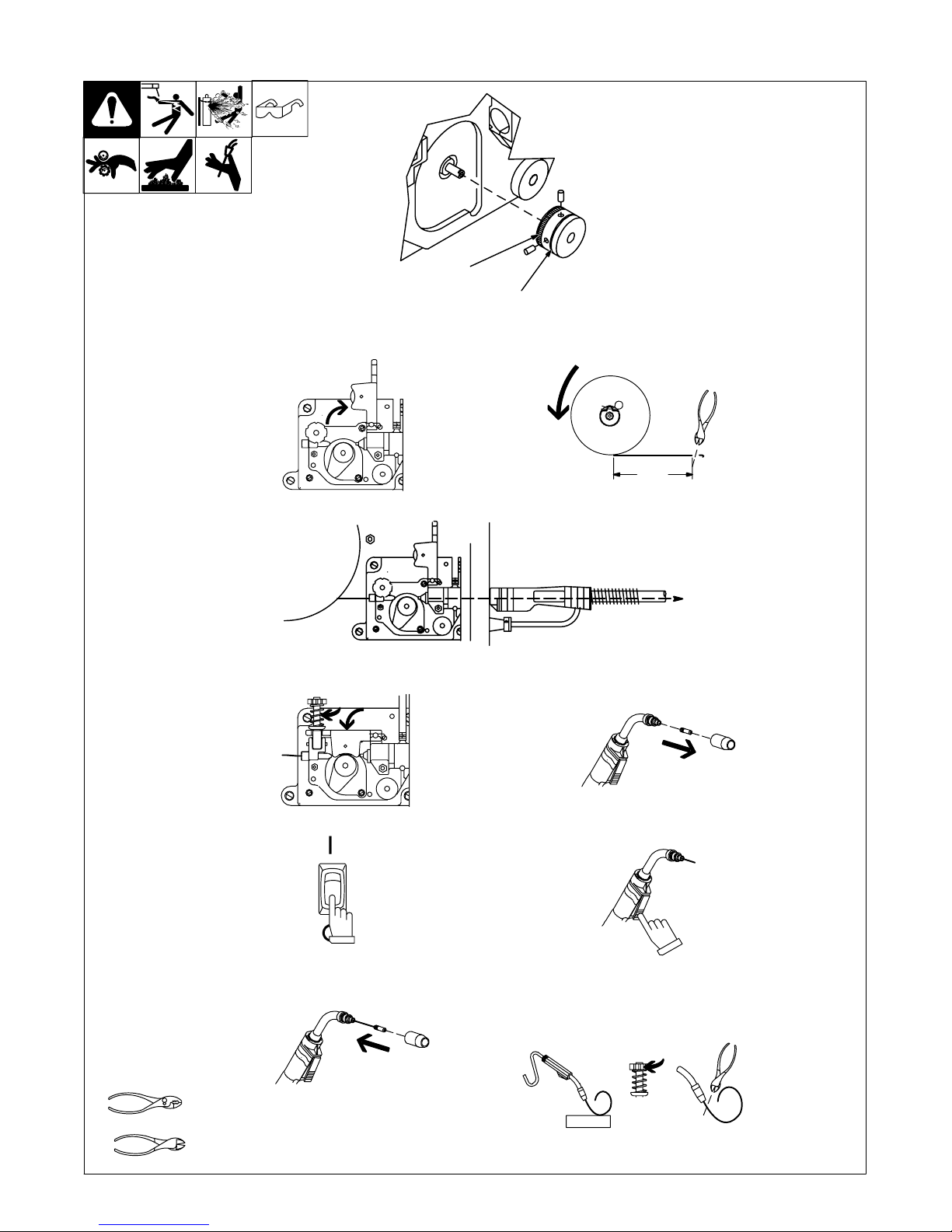

1-6. Installing Drive Roll And Threading Welding Wire

1 Install drive roll.

For Flux Cored Wire

For Solid Wire

Install drive roll onto shaft with desired groove in, and one set screw

facing flat side of shaft. Tighten both

set screws.

2 Open pressure assembly.

4 Push wire thru guides into gun;

continue to hold wire.

5 Close and tighten pressure assembly,

and let go of wire.

3 Pull and hold wire; cut off end.

6 in

(150 mm)

6 Remove gun nozzle and contact tip.

7 Turn power On.

9 Reinstall contact tip and nozzle.

Tools Needed:

OM-1314 Page 8

8 Press gun trigger until wire comes out

of gun.

10 Feed wire to check drive roll

pressure. Tighten knob enough to

prevent slipping. Cut off wire; leave

1/4−1/2 in (6−13 mm). Close and

latch door.

WOOD

Ref. ST-149 266-B / Ref. ST-149 326-B / Ref. 150 093-A / Ref. 180 968 / S-0627-A

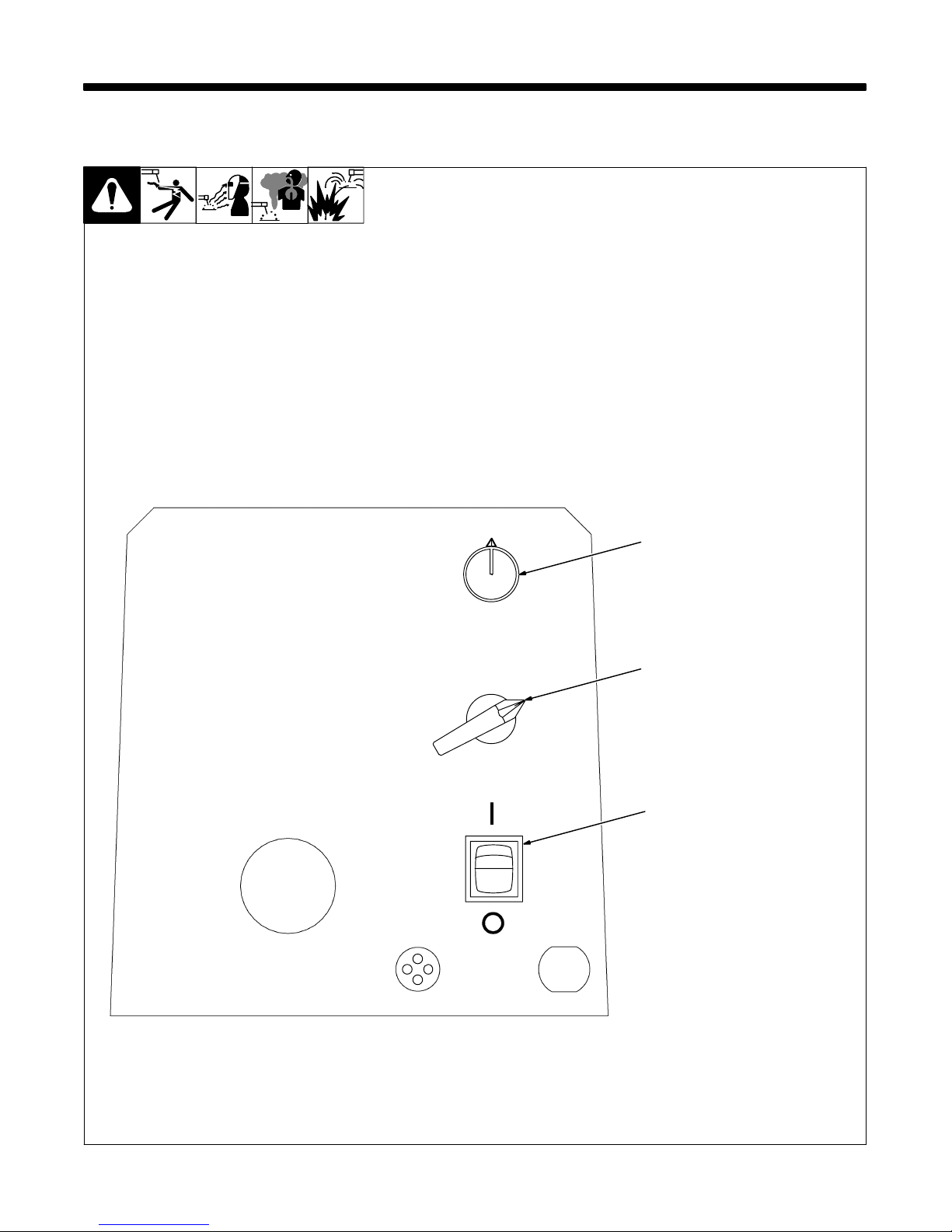

2-1. Controls

SECTION 2 − OPERATION

1 Wire Speed Control

Use control to select a wire feed

speed. As Voltage switch setting increases, wire speed range also increases.

2 Voltage Switch

The higher the selected number,

the thicker the material that can be

welded. Do not switch while

welding.

3 Power Switch

1

2

3

Ref. ST-180 968

OM-1314 Page 9

NOTES

OM-1314 Page 10

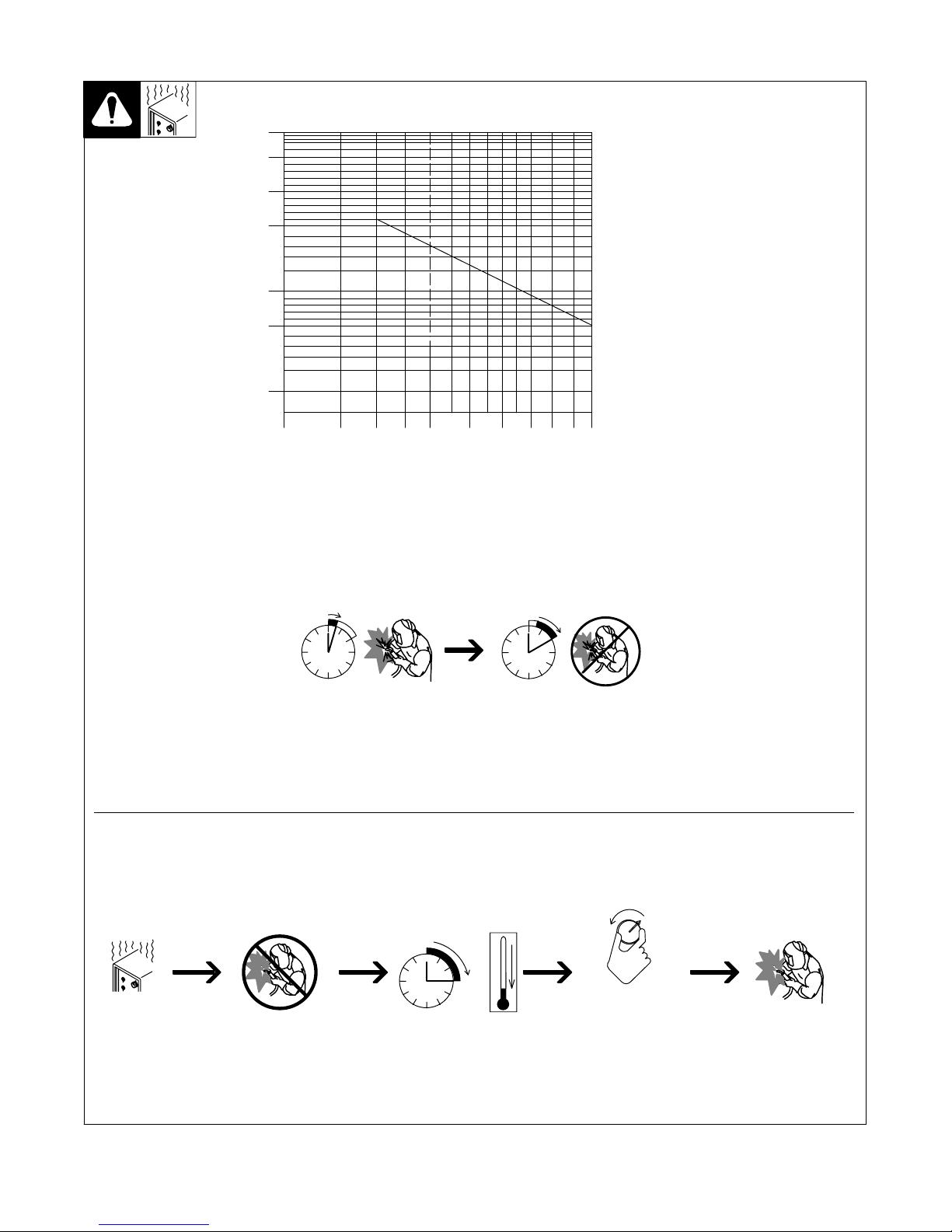

2-2. Duty Cycle And Overheating

300

250

200

150

100

DC AMPERES

75

50

10 15 20 25 30 40 50 60 70 80 100

Duty Cycle is percentage of 10 minutes that unit can weld at rated load

without overheating.

If unit overheats, thermostat(s)

opens, output stops, and cooling

fan runs. Wait fifteen minutes for

unit to cool. Reduce amperage or

duty cycle before welding.

Y Exceeding duty cycle can

damage unit or gun and void

warranty.

% DUTY CYCLE

Overheating

30% Duty Cycle At 130 Amperes

3 Minutes Welding 7 Minutes Resting

0

15

Reduce Duty Cycle

Minutes

A or V

OR

duty1 4/95 − SB-180 844

OM-1314 Page 11

Loading...

Loading...