Page 1

Processes

Stick (SMAW) CC

TIG (GTAW) CC

Air Carbon Arc (CAC-A)

Cutting and Gouging CC

Flux Cored (FCAW) CV

MIG Spray Transfer (GMAW)

with Voltage-Sensing Feeder CV

Heavy Industrial Applications

Construction

Rental Fleets

Fab Shops

Petro Chemical

Shipbuilding

Training Facilities

Maintenance

Quick

Specs

Rugged and durable enclosure

steel frame protects system.

Mark VI

Multiple Arc

Welding System

Issued January 2006 • Index No. DC/9.8

Work connections are electrically isolated

from the frame, and service panels in

chassis provide easy access to internal

parts for routine maintenance.

Capable of four to six welding arcs,

Miller’s unique modules are designed

for easy removal and connection.

If you need only four arcs today,

purchase the Mark VI-2. If you

have a requirement for more arcs,

additional modules (CC or CV)

are available for purchase.

Optional Low OCV in CC/CV modules reduces maximum

open-circuit voltage to 26 volts in CC and CV modes when

not welding.

The Power of Blue®.

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

Voltage Range CC: 20–315 A

CV: 10–30 V (with CC/CV Module)

Max. Open-Circuit Voltage

CC: 75 VDC CV: 38 VDC

CC/CV Low OCV Module: 26 VDC ±2 V

Weight Mark VI: 1725 lb (784 kg)

Mark VI-2: 1575 lb (718 kg)

Adjustable arc control lets you get in

tight without sticking the electrode. An

electrode compensation circuit ensures

arc control performance regardless of

the electrode size.

Multiple capabilities CC or CC/CV.

Versatility and outstanding arc

welding performances in both CV

(MIG) and CC (TIG and Stick). The

CC/CV module has a high quality

arc for welding with cored wires.

Miller does not recommend that

the CC/CV module be used for short

circuit transfer MIG welding. The CC

module has the same great arc

characteristic as the Gold Star 302.

Operator identification label helps

operators remember who is using

which module.

Welder is warranted for 3 years, parts and labor.

Original main power rectified parts are warranted for 5 years.

14-pin receptacle provides quick, direct

connection to Miller wire feeders and

accessories.

Weighs less than one ton which

makes it portable when secured on a

flatbed, construction truck, or when

moved by one-ton hoist. Fits through

36 in (914 mm) door opening.

60 Hz models have two 115 V GFCI duplex

receptacles which supply 15 amps of

auxiliary power. 50 Hz models have one

220 V and one 115 V duplex receptacle.

Line voltage compensation keeps

output power constant even if primary

input power varies by ±10%, ensuring

consistent weld performance.

Hot Start

™

makes it easy to start difficultto-start Stick electrodes, such as E-6010

and E-7018.

Page 2

2

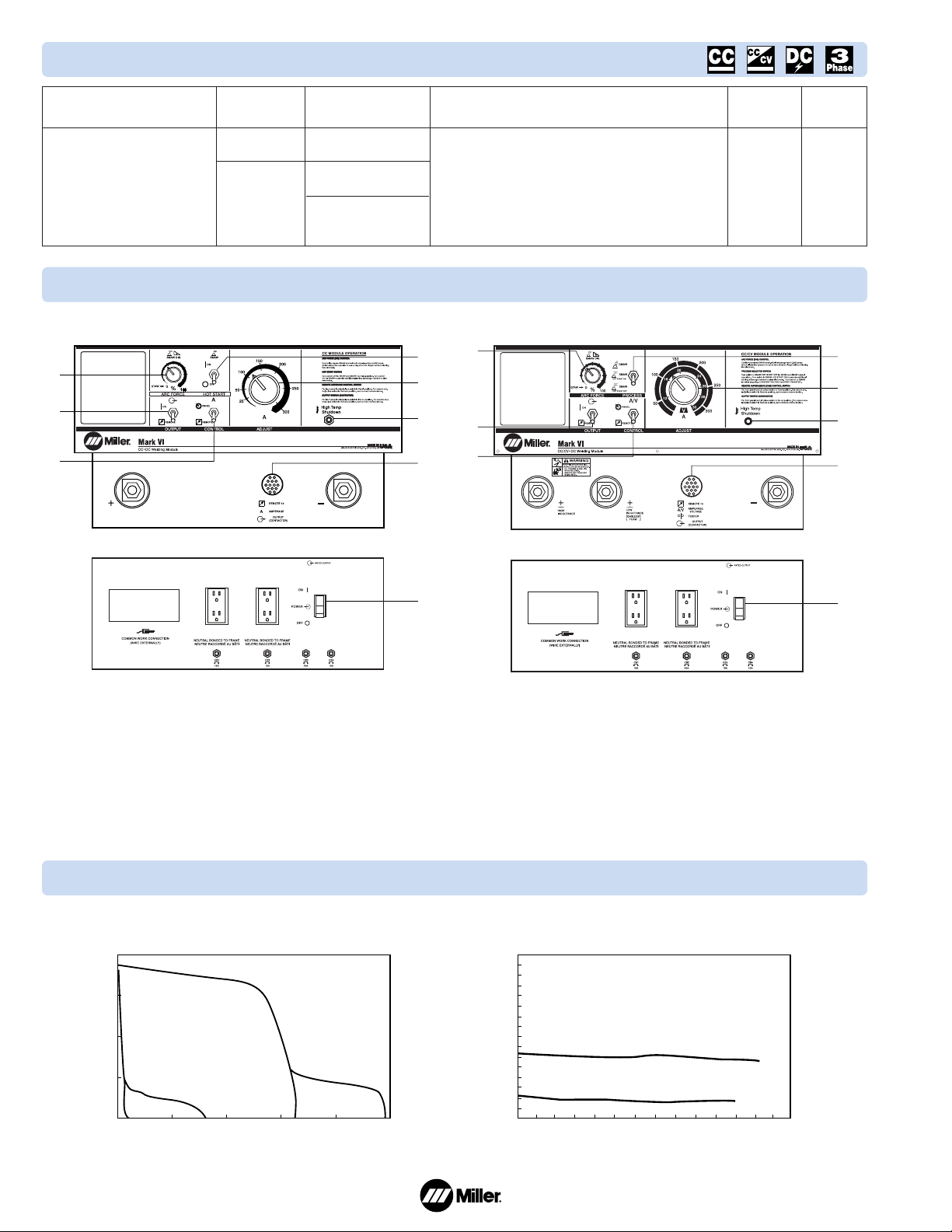

Control Panel

Performance Data

Specifications (Subject to change without notice.)

DC Amperage/

Voltage Range

20–315 A

in CC Mode

10–30 V in

CV Mode with

CC/CV Module

Max. Open-Circuit

Voltage (DC)

75 VDC in CC Mode

38 VDC in CV Mode

with CC/CV Module

26 VDC ±2 V

with CC/CV Module

and low OCV

Amps Input at 750 Amps Output, 50/60 Hz

230 V 380 V 400 V 415 V 440 V 460 V 575 V KVA KW

164 97 92 91 84 82.5 66.1 65.2 41.9

Dimensions

H: 65 in

(1651 mm)

W: 56-3/4 in

(1442 mm)

D: 34-1/4 in

(870 mm)

Net

Weight

Mark VI :

1725 lb

(784 kg)

Mark VI-2:

1575 lb

(718 kg)

Rated Welding Output

at 44 Volts DC

Single Module

250 A at 60% Duty Cycle

Main Transformer

60 Hz: 750 A at 100% Duty Cycle

1500 A at 25% Duty Cycle

50 Hz: 750 A at 60% Duty Cycle

1160 A at 25% Duty Cycle

8

7

UPPER PANEL FOR CC UNITS

LOWER PANEL

6

4

5

1

2

3

SINGLE MODULE

VOLTS 30

AMPERES 250

DUTY CYCLE 60%

MAX OCV 75 VDC

TOTAL MACHINE

60Hz - 750 Amps @ 100% Duty Cycle

50Hz - 750 Amps @ 60% Duty Cycle

6

8

4

5

7

1

2

3

UPPER PANEL FOR CC/CV UNITS

LOWER PANEL

SINGLE MODULE

VOLTS 30

AMPERES 250

DUTY CYCLE 60%

MAX OCV 75 VDC

TOTAL MACHINE

60Hz - 750 Amps @ 100% Duty Cycle

50Hz - 750 Amps @ 60% Duty Cycle

1. Arc Force Control

2. Remote/On Output Contactor Control

3. Remote/Panel Output Amperage Control

4. Hot Start On/Off Switch

5. Amperage Adjustment Control

6. High-Temperature Shut Off Indicator

7. 14-Pin Remote Receptacle

8. Power On/Off Switch

1. Arc Force Control

2. Remote/On Output Contactor Control

3. Remote/Panel Output Amperage Control

4. Process Selector

5. Amperage/Voltage Adjustment Control

6. High-Temperature Shut Off Indicator

7. 14-Pin Remote Receptacle

8. Power On/Off Switch

CC VOLT/AMP CURVES

FOR EACH MODULE

DC VOLTS

DC AMPS

80

60

40

20

0

0 100 200 300 400 500

CV VOLT/AMP CURVES

FOR EACH MODULE

VOLTS

AMPS

80

70

60

50

40

30

20

10

0

0 100 200 300 400 500 600 700

Page 3

3

Process Selector Control #042 872

Allows you to easily change weld processes

without changing cables—from MIG to TIG

or TIG to Stick. Also for use with dual wire

feeders and applications where electrical

isolation and/or polarity reversing of weld

current is required.

Stick Hook-up Kit

#173 851 50 ft (15.2 m) 2/0 cable

Includes electrode holder, weld cable

and work cable with clamp.

MIG Hook-Up Kit

#173 856 25 ft (7.6 m) 2/0 cable

Includes gas hose assembly, lugged weld

cable assembly and work cable with clamp.

HF-251D-1 High-Frequency Arc

Starter/Stabilizer #042 388

This portable 250 A, 60% duty cycle unit

adds high frequency to the welding circuit to

help start the arc when using the TIG (GTAW)

process. Operates on 115 VAC 50/60/100 Hz.

See Lit. Index No. AY/5.1.

Wire Feeders

SuitCase™8RC #194 938

SuitCase™12RC #194 940

Compact, portable, constant-speed wire

feeder with remote voltage control. For

.030– 5/64 in (0.8–2 mm) hard and flux

cored wires. Holds up to an 8 in, 14 lb (8RC)

or 12 in, 44 lb (12RC) spool of wire.

See Lit. Index No. M/6.5.

SuitCase™8VS Wire Feeder #194 890

SuitCase

™

X-TREME™12VS

Wire Feeder #195 500

Lightweight, portable, voltage-sensing

wire feeders include secondary contactor

and gas valve. Require drive roll kit.

See Lit. Index Nos. M/6.4 and M/6.41.

Remote Controls and Switches

RFCS-14 Foot Control #043 554

Heavy-duty foot current and contactor

control. Includes 20 ft (6 m) cord and

14-pin plug.

RCC-14 Remote Contactor and

Current Control #151 086

Rotary-motion fingertip control. Fastens to

TIG torch using two Velcro strips. Allows

complete current and contactor control at

operator’s fingertips. Includes 28 ft (8.5 m)

cord and plug.

RCCS-14 Remote Contactor and

Current Control #043 688

Up-and-down rotary-motion fingertip

control. Great for applications that require

a finer amperage control. Includes 28 ft

(8.5 m) control cord.

Genuine Miller Accessories

Performance Data (continued)

60 Hz DUTY CYCLE CHART

WELD AMPS

% DUTY CYCLE

80 90 100

Total Machine Output

750 A at 100% Duty Cycle

Each Module Output

194 A at 100% Duty Cycle

70605040302010

1000

2000

1800

1600

1200

1400

800

300

200

100

50 Hz DUTY CYCLE CHART

WELD AMPS

% DUTY CYCLE

80 90

100

Total Machine Output

750 A at 60% Duty Cycle

Each Module Output

194 A at 100% Duty Cycle

70605040302010

1000

2000

1800

1600

1200

1400

800

300

600

200

100

Page 4

Litho in USA

Distributed by:

Ordering Information

Power Source and Options Stock No. Description Qty. Price

Mark VI-2 (Four Modules) #903 588 230/460/575 V, 60 Hz

#903 588-01-1 With Tweco connectors

Mark VI CC (Six Modules) #903 512 230/460/575 V, 60 Hz

#903 569 380/400/415/440-460 V, 50/60 Hz

Mark VI CC/CV (Six Modules) #903 645 230/460/575 V, 60 Hz

#903 660 380/400/415/440 –460 V, 50/60 Hz

#903 645-01-1 Low OCV modules

#903 645-02-1 With Cam-Lok connectors and Low OCV

Single CC Module #903 661 CC module, 50/60 Hz

Single CC/CV Modules #903 646 CC/CV module, 60 Hz

#903 659 CC/CV module, 50/60 Hz

#903 899 CC/CV, Low OCV modules

Stick Accessories

Stick Hook-up Kit #173 851 2/0 cable, 50 ft. Includes electrode holder, weld cable and work cable with clamp

Stick Electrodes

TIG Accessories

HF-251D-1 #042 388 HF arc starter/stabilizer

Torch and Consumables

Tungsten

MIG Accessories

SuitCase™8RC #194 938 See Lit. Index No. M/6.5

SuitCase™12RC #194 940 See Lit. Index No. M/6.5

SuitCase™8VS #194 890 See Lit. Index No. M/6.4

SuitCase™X-TREME™12VS #195 500 See Lit. Index No. M/6.41

MIG Hook-Up Kit #173 856 2/0 cable, 25 ft. Includes gas hose, weld cable, work cable w/ clamp, and regulator/flowmeter

Remote Controls

RFCS-14 #043 554 Foot control

RCC-14 #151 086 Fingertip control

RCCS-14 #043 688 Fingertip control

RHC-14 #129 340 Hand control

RMLS-14 #129 337 Momentary- and maintained-contact switch

Extension Cords #122 973 25 ft (7.6 m)

#122 974 50 ft (15.2 m)

#122 975 75 ft (22.9 m)

Miscellaneous

Process Selector Control #042 872

Primary Power Cord

Gas Cylinder

Gas Hose and Fittings

Date: Total Quoted Price:

Genuine Miller Accessories

(continued)

Remote Controls and Switches

RHC-14 Hand Control

#129 340

Miniature hand control

for remote current and

contactor control.

Dimensions: 4 x 4 x

3-1/4 in (102 x 102 x

82 mm). Includes 20 ft (6 m) cord and

14-pin plug.

RMLS-14 #129 337

Momentary- and maintained-contact rocker

switch for contactor control. Push forward

for maintained contact and back for momentary contact. Includes 20 ft (6 m) cord and

14-pin plug.

Extension Cables for 14-Pin Plugs to

14-Pin Sockets

#122 973 25 ft (7.6 m)

#122 974 50 ft (15.2 m)

#122 975 75 ft (22.8 m)

Extension cords make a direct connection

between the power source and the

accessory control. No messy splicing or

adapting required.

Loading...

Loading...