Miller Electric ManHandler 8442SS-Z7/65FT, ManHandler 8442-Z7/65FT, ManHandler 8442SS/65FT, ManHandler 8442/100FT, ManHandler 8442-Z7/100FT User Instruction Manual

...Page 1

I136 Rev. E

34-9720047

December 2018

USER INSTRUCTION MANUAL

ManHandler

Page 2

2

Download this manual at: www.millerfallprotection.com

Téléchargez ce manuel à l’adresse: www.millerfallprotection.com

Puede bajar por Internet este manual en: www.millerfallprotection.com

TABLE OF CONTENTS

SOMMAIRE / ÍNDICE

Instructions for Use

Mode d’emploi / Instrucciones de uso

English .....................................................................3-6

Français ................................................................ 7-10

Español...............................................................11-14

Appendix A: Product Specifications ........................... 15-17

Annexe A: Spécifications de produit / Apéndice A: Especificaciones del

producto

Appendix B: Product Labels .................................................18

Annexe B: Étiquettes de produit et spécifications de performance /

Apéndice B: Etiquetas de producto y especificaciones de rendimiento

Appendix C: Inspection and Maintenance Log .............19

Annexe C: Registre D’inspection et D’entretien / Apéndice C: Registro de

Inspección y Mantenimiento

EN

FR

ES

Page 3

3

It is crucial that the authorized person/user

of this equipment read and understand

these instructions. In addition, federal law

requires employers to ensure that all users

are trained in the proper installation, use, inspection, and maintenance of fall protection

equipment. Fall protection training should

be an integral part of a comprehensive safety program.

Proper use of fall arrest systems can save

lives and reduce the potential of serious

injuries from a fall. The user must be aware

that forces experienced during the arrest of

a fall or prolonged suspension may cause

bodily injury. Consult a physician if there is

any question about the user’s ability to use

this product. Pregnant women and minor

children must not use this product.

MAN-RATED HOIST /

WORK WINCH

Thank you for your purchase of Honeywell

Miller fall protection equipment manufactured by Honeywell Industrial Safety.

WARNING

All persons using this equipment must

read, understand and follow all instructions. Failure to do so may result

in serious injury or death. Do not use

this equipment unless you are properly trained.

1.0 Purpose

The Miller ManHandler® Man-Rated Hoist/

Work Winch is a manually operated hoist/

winch designed for a range of applications

including:

• Confined space entry.

• Work positioning or suspension of

personnel

• Personnel/material handling; or

• Emergency rescue.

Except when used as an emergency

rescue device, independent fall

protection must be used in conjuction

with this unit to raise, lower, position or

suspend personnel.

2.0 General Fall Protection

Requirements

2.1 General Requirements

All warnings and instructions shall be

provided to authorized persons/users.

All authorized persons/users must

reference the regulations governing

occupational safety (including confined

space regulations), as well as applicable

ANSI or CSA standards. Please refer

to product labeling for information on

specific OSHA regulations, and ANSI and

CSA standards met by product.

All authorized persons/users of this

equipment must be trained in proper

confined space procedures.

Proper precautions should always be taken

to remove any obstructions, debris, material,

or other recognized hazards from the work

area that could cause injuries or interfere

with the operation of the system.

All equipment must be inspected before

each use according to the manufacturer’s

instructions.

All equipment should be inspected by a

qualified person on a regular basis.

This unit must be removed from service

if any part of the system appears to be

damaged or does not pass inspection.

To minimize the potential for accidental

disengagement, a competent person must

ensure system compatibility.

Equipment must not be altered in any way.

Do not attempt to service this device.

Repairs must be performed only by the

manufacturer, or persons or entities

authorized in writing by the manufacturer.

The authorized person/user shall have

a rescue plan and the means at hand to

implement it when using this equipment.

Any equipment subjected to the forces of

arresting a fall or affecting a rescue must

be removed from service.

Never use fall protection equipment for

purposes other than those for which it was

INSTRUCTIONS FOR USE

EN

Page 4

4

ing should be conducted periodically and

without exposing the trainee to a fall hazard.

3.0 System Compatibility

The Miller ManHandler Hoist/Winch is

designed for use with Miller approved

components. Substitution or replacement

with non-approved component

combinations or subsystems or both may

affect or interfere with the safe function of

each other and endanger the compatibility

within the system. This incompatibility may

affect the reliability and safety of the total

system

.

Anchorage Requirements

For applications requiring the use of a personal fall arrest system in conjunction with

this unit, anchorages must be capable of

supporting 5,000 lbs.(22.2kN) per worker or

meet OSHA requirements for a safety factor

of two. Anchorage requirements based on

ANSI are as follows:

• For fall arrest systems, anchorages must

withstand a static load of 5,000 lbs.

(22.2kN) for non-certified anchorages or

two times the maximum arresting force for

certified anchorages.

• For positioning systems, anchorages

must withstand a static load of 3,000 lbs.

(13.3kN) for non-certified anchorages or

two times the foreseeable force for certified

anchorages.

• For rescue systems, anchorages must

withstand a static load of 3,000 lbs. (13.3kN)

for non-certified anchorages or five-times

the applied load for certified anchorages.

• When more than one personal fall arrest

system is attached to an anchorage,

the above anchorage strengths must be

multiplied by the number of personal fall

arrest systems attached to the anchorage.

4.0 Installation

4.1 General Installation and

Making Connections

The ManHandler Hoist/Winch is equipped

with a built-in bracket for attachment to

approved anchorage systems and devices,

such as the Miller DuraHoist™ Confined

Space System and Miller Tripods, Quad

Pods, Davit Systems, Wall Mounts, etc.

To install the ManHandler Hoist/Winch,

simply align the holes on the built-in

mounting bracket with the holes on the

mounting device being used (i.e., tripod or

designed.

Environmental hazards should be

considered when selecting fall protection

equipment. Equipment must not be exposed

to chemicasl which may produce a harmful

effect. Use in highly corrosive or caustic

environments dictates a more frequent

inspection and servicing program to ensure

the integrity of the device is maintained.

Do not allow equipment to come in contact

with anything that will damage it including,

but not limited to, sharp, abrasive, rough or

high-temperature surfaces, heat sources,

electrical hazards, or moving machinery.

Equipment must be kept clean and free of

contaminants. Do not lubricate this unit.

Never remove product labels, which include

important warnings and information for the

authorized person/user.

2.2 Warnings and Limitations

Capacity

For use by ONE person only. Maximum

capacity is 350 lbs. (159 kg), including

body weight, clothing and tools, unless

labeled otherwise. - DO NOT EXCEED THIS

WEIGHT.

*ANSI Z359.4 capacity range is 130 lbs.

(59kg) to 310 lbs. (140kg).

Force Required for Rescue

Force required to operate rescue features

when device is loaded to capacity is 22 lbs.

(98N).

Lifeline Warnings

Check the maximum cable length required

for the application before using to ensure

that the unit has sufficient capacity.

When lifeline is attached to a worker’s

harness, it must remain taut. Never allow

lifeline to become slack or to pass under or

entwine around user’s arms, legs, neck or

any other obstacle.

Lifeline must be kept clean.

Do not allow lifeline to come in contact

with sharp edges or abrasive surfaces.

Training

The purchaser of this equipment must ensure that all personnel using this equipment are familiar with these instructions

and are properly trained in the operation, limitations, installation, inspection

and maintenance of this product. Train-

Page 5

5

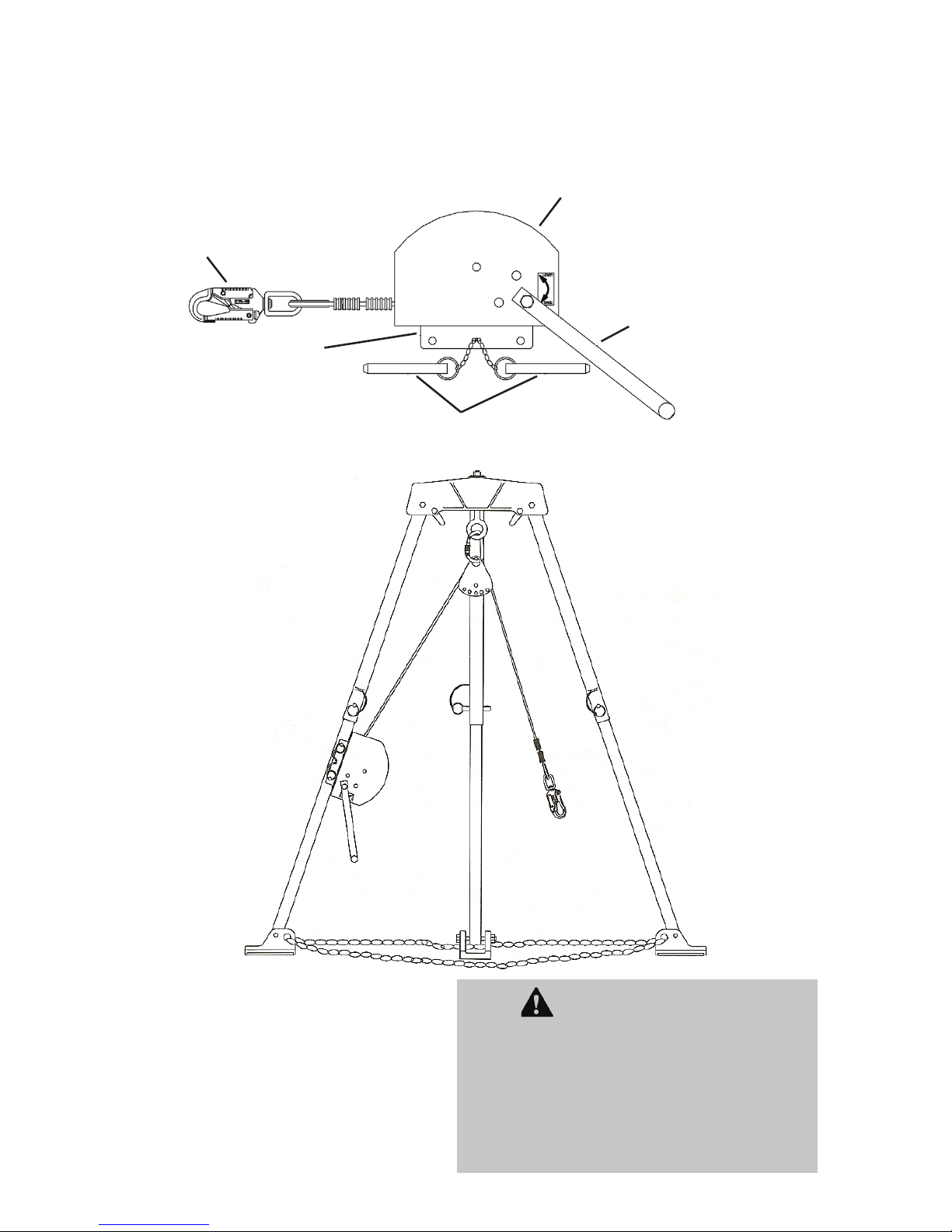

MOUNTING BRACKET

CRANK HANDLE

HOUSING

SWIVEL SNAP HOOK

PUSH PINS

Fig. 1

The ManHandler Hoist/Winch must be

inspected before each use as described in

section 5.1 Inspection and Operation of

this manual.

TYPICAL

INSTALLATION

Fig. 2

MILLER MANHANDLER

MOUNTED TO

MILLER TRIPOD

WARNING

Always ensure that the snap hook of the ManHandler unit

is properly secured to a compatible connection, such as

a worker’s harness back D-ring, and is closed and locked

when in use. Independent fall protection must be utilized

if the ManHandler Hoist/Winch is being used to raise,

lower, position, or suspend personnel in a non-emergency

situation. A Miller retractable lifeline or a Miller retractable lifeline with recovery capabilities is recommended.

other approved anchorage) and insert the

push pins completely through the bracket

(see Fig. 1 & 2).

Page 6

6

5.0 Inspection, Operation

and Maintenance

5.1 Inspection and Operation

WARNING

The ManHandler Hoist/Winch must be

inspected before each use. If the unit is

used as an emergency retrieval device,

it must be inspected prior to personnel

entering the confined space in order to

facilitate a quick recovery. In addition

to the inspection required before each

use, a competent person must inspect

this unit at least annually. This periodic

inspection should be set by the user’s

employer. Annual factory recertification

is not required unless the unit is

subjected to the forces of arresting a fall

or affecting a rescue

CAUTION

Always wear gloves when inspecting

wire rope/cable units; broken strands

can cause injury!

1. Device Housing and Parts/Mounting

Bracket: Inspect the unit for bent,

cracked, distorted, worn, malfunctioning

or damaged parts; loose fasteners

or missing parts/components;

deterioration; deformation; corrosion;

or any other indications of damage/

problems that may affect the integrity

and operation of the product. If in doubt,

contact the manufacturer.

2. Lifeline: The entire length of the lifeline

should be checked for signs of damage.

Inspect for cuts or broken strands,

unusual wearing patterns, corrosion,

kinks, or chemical damage.

3. Lowering and Raising Operation: Apply

a light tension [50 lbs. (23kg) minimum]

on the cable lifeline, and:

a) Rotate the crank handle in a counter

clockwise direction to extend cable from

the unit (lower).

Note: When the cranking is stopped,

the friction brakes must securely

hold the load without the crank

handle rotating. Should this brake

malfunction, an independent

overspeed braking system will be

activated.

b) Rotate the crank handle clockwise to

return the cable to the unit (raise). There

should be a clicking noise heard while

the cable is being cranked into the unit.

4. Snap Hook: Check the snap hook to be

sure that the gate operates freely, the

locking mechanism functions properly,

and the swivel rotates smoothly. The

gate should seat into the nose without

binding and should not be distorted

or obstructed. The gate spring should

exert sufficient force to firmly close

the gate. The locking mechanism must

prevent the gate from opening when the

gate is closed. Inspect the snap hook

for any signs of damage to the gate;

bent, cracked, or distorted components;

corrosion or pitted surfaces.

5. Anchorage Connection: Make sure

the unit is properly anchored to the

mounting device and the push pins are

properly installed through the mounting

bracket. If the system is equipped with a

sheave and carabiner, check to ensure

the carabiner is properly seated and in

the locked position between the sheave

and anchorage point.

UNITS THAT DO NOT PASS INSPECTION

OR HAVE BEEN SUBJECTED TO THE

FORCES OF ARRESTING A FALL OR

AFFECTING A RESCUE MUST BE

REMOVED FROM SERVICE.

5.2 Maintenance

Basic care of all safety equipment will prolong the durable life of the unit and will contribute toward the performance of its vital

safety function.

Servicing

Servicing of the Miller ManHandler

Hoist/Winch must only be carried out

by Miller Fall Protection or persons or

entities authorized in writing by Miller Fall

Protection. A record log of all servicing

and inspection dates for this device

must be maintained. Only original Miller

replacement parts are approved for use

in this device. Repairable devices must be

returned to our facilities or an approved

service center for physical inspection and

recertification whenever they do not pass

inspection or have been subjected to the

forces of arresting a fall or affecting a

rescue. Non-repairable devices that do not

pass inspection must be disposed of in a

manner to prevent inadvertent further use.

Contact your Miller distributor for a return

authorization number.

Cleaning and Storage

Periodically clean the exterior of the device

and wipe the lifeline using a damp cloth

and mild detergent. Towel dry. Store in a

clean, dry location when not in use. The

lifeline should be fully retracted into the

device when not in use.

Page 7

7

Il est essentiel que la personne autorisée à

utiliser cet équipement de protection contre

les chutes lise et comprenne ces instructions. De plus, la loi fédérale oblige les employeurs à s’assurer que tous les utilisateurs

ont reçu une formation sur la manière appropriée d’installer, d’utiliser, d’inspecter et

d’entretenir les équipements antichute et

les équipements pour espaces restreints.

La formation sur la protection contre les

chutes devrait faire partie intégrante d’un

programme global de sécurité.

L’utilisation adéquate de systèmes d’arrêt

de chute peut épargner des vies et réduire

le risque de blessures graves consécutives à

une chute. L’utilisateur doit être sensibilisé

au fait que les forces subies lors d’un arrêt

de chute ou d’une suspension prolongée

peuvent causer des blessures corporelles.

Dans l’incertitude sur la capacité de la personne à utiliser ce produit, consulter un médecin. Les femmes enceintes et les mineurs

ne doivent pas utiliser ce produit.

LE TREUIL DE LEVAGE

POUR PERSONNES À

FONCTIONNEMENT MANUEL

Nous vous remercions d’avoir acheté les

équipements antichute Miller fabriqués par

Honeywell Safety Products. Les produits

de marque Miller sont fabriqués selon des

normes de qualité des plus rigoureuses,

dans notre usine certifiée ISO 9001. Bien

entretenu, un équipement Miller s’utilise

des années durant.

1.0 Objet

Le treuil de levage pour personnes

ManHandler Miller est un treuil de levage

à fonctionnement manuel se prêtant à de

nombreux usages dont :

• accès à des espaces clos,

2.0 Exigences Générales de

Protection contre les Chutes

2.1 Exigences Générales

Les avertissements et instructions devront

être mis à la disposition des personnes/

utilisateurs autorisés.

Les personnes/utilisateurs autorisés

doivent se reporter à la réglementation

applicable en matière de sécurité en milieu

de travail, ainsi qu’aux normes ANSI ou

CSA pertinentes.

Veuillez vous reporter aux étiquettes

apposées sur les produits pour des

informations plus détaillées sur les

règlements OSHA, ainsi que les normes

ANSI et CSA auxquelles ces produits sont

conformes.

Toutes les personnes qui utilisent cet

équipement doivent être formées au mode

d’emploi adéquat dans les espaces clos.

Des précautions doivent être prises afin

d’éliminer de la zone de travail les obstacles,

débris, matériaux ou autres éléments

présentant un danger et qui pourraient

causer des blessures ou nuire au bon

fonctionnement du système.

L’équipement doit être inspecté avant

chaque utilisation selon les directives du

fabricant.

L’équipement doit être régulièrement

inspecté par une personne qualifiée.

Cette unité doit être mise hors service si une

partie quelconque du système semble être

endommagée ou si elle ne satisfait pas aux

critères de l’inspection.

Pour minimiser le risque de décrochage

accidentel, une personne compétente doit

s’assurer de la compatibilité du système.

Pour minimiser le risque de décrochage

accidentel, une personne compétente doit

MODE D’EMPLOI

• positionnement de travail ou suspension

de personnes,

• maniement de personnes et de matériaux,

• sauvetage d’urgence.

À l’exception de l’utilisation de ce

dispositif en cas de sauvetage d’urgence,

une protection indépendante contre les

chutes doit être utilisée en association

avec cette unité pour élever, abaisser,

positionner ou suspendre des personnes.

FR

AVERTISSEMENT

Toutes les personnes utilisant cet équipement doivent lire, comprendre et observer l’intégralité des instructions. Le

non-respect de cette consigne peut entraîner des blessures graves, ou même

la mort. Ne pas utiliser cet équipement

à moin d’avoir reçu une formation adéquate.

Page 8

8

FORCE REQUISE POUR LE SAUVETAGE

Force requise pour utiliser les fonctions de

sauvetage quand le dispositif est chargé à

capacité limite : 98 N (22 lbf)

AVERTISSEMENTS AU SUJET DU FILIN

• Vérifiez la longueur de câble maximale

requise pour l’application avant l’utilisation

afin de vous assurer que l’unité a une

capacité suffisante.

• Un filin attaché au harnais d’un travailleur

doit rester tendu. Ne laissez jamais le filin

avoir du mou ni passer ou s’enrouler autour

des bras, des jambes, du cou ou de tout

autre obstacle.

• Le filin doit être tenu toujours propre.

• Ne laissez pas un filin venir en contact avec

des arêtes vives ou des surfaces abrasives.

3.0 Compatibilité du

Système

Le treuil de levage ManHandler Miller est

conçu pour être utilisé avec des pièces

approuvées par Miller. Les substitutions ou

les remplacements par des combinaisons

de composants ou de sous-systèmes non

approuvés peuvent nuire à leur sécurité de

fonctionnement réciproque et ainsi remettre

en cause la compatibilité des éléments du

système. Cette incompatibilité peut nuire à

la sécurité et à la fiabilité de l’ensemble du

système.

EXIGENCES D’ANCRAGE

Pour les applications exigeant l’utilisation

d’un système d’arrêt de chute individuel en

association avec cette unité, les ancrages

doivent pouvoir supporter 22,2 kN (5 000

lbs) par travailleur ou être conformes aux

règlements de l’OSHA pour un facteur de

sécurité de deux.

Les exigences ANSI qui s’appliquent aux

ancrages sont les suivantes :

• L’ancrage non certifié d’un dispositif anti-

chute doit supporter une charge statique

de 5000 lb (22.2 kN), tandis qu’un

ancrage certifié doit supporter deux fois la

force maximale mise en jeu lors de l’arrêt

d’une chute.

• Dans le cas d’un dispositif de maintien,

l’ancrage non certifié doit supporter une

charge statique de 3000 lb (13.3 kN), tandis qu’un ancrage certifié doit supporter

deux fois la force prévisible.

• Dans le cas d’une limitation de déplacement, l’ancrage non certifié doit supporter

une charge statique de 1000 lb (4.5 kN),

tandis qu’un ancrage certifié doit supporter deux fois la force prévisible.

• L’ancrage utilisé dans un système servant

au sauvetage doit supporter une charge

statique de 3000 lb (13.3 kN) s’il n’est pas

s’assurer de la compatibilité du système.

Il est interdit de modifier l’équipement, de

quelque façon que ce soit.

N’essayez pas d’effectuer des opérations

de service en rapport avec ce dispositif.

Les réparations doivent être effectuées

uniquement par le fabricant de l’équipement,

ou par des personnes ou entités autorisées

par écrit par le fabricant.

L’utilisateur doit posséder un plan de

sauvetage et avoir les moyens de le mettre en

œuvre lorsqu’il utilise cet équipement.

Tout équipement sujet à des forces d’arrêt de

chute ou utilisé pour un sauvetage doit être

mis hors service.

Ne jamais utiliser un équipement de

protection contre les chutes dans un but

autre que celui pour lequel il a été prévu.

Dans la sélection d’équipement de

protection contre les chutes, on doit tenir

compte des risques environnementaux.

On ne doit pas exposer l’équipement aux

produits chimiques susceptibles de causer

un effet nocif. Pour utiliser l’équipement dans

des environnements hautement corrosifs

ou caustiques, il faut mettre en place un

programme d’inspection et d’entretien

à intervalles rapprochés pour maintenir

l’intégrité du dispositif. En cas de doute,

communiquer avec les services techniques

de Miller.

Éviter tout contact entre un équipement

et un objet susceptible de l’endommager,

incluant notamment, sans que la liste soit

exhaustive : des arêtes vives, une surface

abrasive, rugueuse ou à haute température,

du matériel de soudage, une source de

chaleur, un appareil électrique présentant un

danger ou une machine mobile.

L’équipement doit être tenu toujours propre

et sans saleté. Ne graissez pas l’unité.

Ne jamais ôter une étiquette apposée sur un

produit; des informations et avertissements

importants y sont en effet inscrits à l’intention

de la personne/de l’utilisateur autorisé.

2.2 Avertissements et Limitations

CAPACITÉ

Pour utilisation par UNE seule personne. La

capacité maximale est de 350 lb (159 kg),

y compris le poids corporel, les vêtements

et les outils sauf mention contraire sur

l’étiquette. - NE PAS DÉPASSER CE POIDS.

*Zone de capacité ANSI Z359.4 : 59 kg (130

lbs) à 140 kg (310 lbs).

Page 9

9

certifié ou de cinq fois la charge appliquée

s’il est certifié.

• Lorsque plusieurs dispositifs anti-chute

individuels sont fixés à un} même

ancrage, les résistances d’ancrage ci-dessus doivent être multipliées par le nombre

de dispositifs anti-chute rattachés à

l’ancrage.

4.0 Installation

Le treuil de levage ManHandler est équipé

d’un support intégreé pour s’attacher à des

systèmes et dispositifs d’ancrage approuvés, tels les systèmes d’espace clos

DuraHoist™ Miller et les systèmes Miller de

trépieds (Tripods), de quadripieds (Quad

Pods), de bossoir (Davit), de montage mural

(Wall Mounts), etc.

Pour installer le treuil de levage

ManHandler, il suffit d’aligner les trous du

support de montage intégré avec les trous

du dispositif de montage utilisé (ex. trépied

ou autre ancrage approuvé) et d’introduire

les goupilles-poussoirs complètement à

travers le support (voir Fig. 1 et 2).

Le treuil de levage ManHandler doit être

inspecté avant chaque utilisation comme

décrit à la section 4.1 Inspection et fonctionnement de ce manuel.

FORMATION

L’utilisateur et l’acheteur de cet équipement

doivent s’assurer de bien connaître ces instructions et d’être adéquatement formés au

fonctionnement, aux limites, à l’installation,

à l’inspection et à l’entretien de ce produit.

La formation doit se donner périodiquement

et sans exposer l’apprenti à des dangers de

chute.

SUPPORT DE MONTAGE

MANCHE DE LA MANIVELLE

LOGEMENT

MOSQUETON SUR PIVOT

GOUPILLES-POUSSOIRS

Fig. 1

INSTALLATION

TYPIQUE

Fig. 2

MANHANDLER MILLER

MONTÉ SUR TRÉPIED

MILLER

AVERTISSEMENT : Assurez-vous

toujours que le mousqueton de

l’unité ManHandler est fixé correctement à une connexion compatible, tel un anneau en D au

dos du harnais d’un travailleur,

et est fermé et verrouillé pendant

son utilisation. Une protection indépendante contre les chutes doit

être utilisée si le treuil de levage

ManHandler sert à élever, abaisser,

positionner ou suspendre des personnes dans une situation sans

urgence. Un filin rétractable Miller

ou un filin rétractable Miller avec

capacité de rétablissement est recommandé.

Page 10

10

5.0 Fonctionnement et

Entretien

5.1 Inspection et Fonctionnement

AVERTISSEMENT

Le treuil de levage ManHandler doit

être inspecté avant chaque utilisation.

Si l’unité sert de dispositif de sauvetage

en cas d’urgence, elle doit être inspectée

avant que le personnel pénètre

dans l’espace clos afin de faciliter

un rétablissement rapide. En plus de

l’inspection requise avant chaque

utilisation, une personne compétente

doit inspecter cette unité au moins une

fois par an. Cette inspection régulière

doit être déterminée par l’employeur de

l’utilisateur. Une recertification annuelle

en usine n’est pas obligatoire à moins que

l’unité soit soumise aux forces d’arrêt de

chute ou affectant un sauvetage.

ATTENTION

Toujours porter des gants lorsqu’on

inspecte les cordes / câbles métalliques;

des brins brisés peuvent causer des

blessures !

1. Logement du dispositif et pièces/

support de montage : Inspectez l’unité

afin de voir s’il y a des pièces courbées,

fendues, tordues, usées, fonctionnant mal

ou endommagées, des attaches lâches ou

des pièces ou composants manquant, des

détériorations, déformations, des signes

de corrosion ou toute autre indication de

dommages ou problèmes pouvant affecter

l’intégrité et le fonctionnement du produit.

En cas de doute, contactez le fabricant.

2. Filin : Le filin doit être examiné sur toute

sa longueur pour voir s’il est endommagé.

Regardez s’il y a des entailles ou des fibres

brisées, des signes d’usure inhabituels et de

corrosion, des vrillages ou des dommages

provenant de produits chimiques.

3. Opération de descente et de remontée :

Appliquer une légère tension [23 kg (50 lbs)

minimum] au filin et :

a) Tournez le manche de la manivelle en

sens anti-horaire pour allonger le câble

venant de l’unité (descente). Remarque :

Quand la manivelle est à l’arrêt, les freins

à frottement doivent tenir la charge avec

sécurité sans que le manche de la manivelle

tourne. En cas de mauvais fonctionnement

de ce frein, un système de freinage de

survitesse indépendant sera activé.

b) Tournez le manche de la manivelle en sens

horaire pour rappeler le câble dans l’unité

(remontée). Un bruit de cliquètement doit se

faire entendre pendant que le câble s’enroule

dans l’unité.

4. Mousqueton : Inspectez le mousqueton

afin de vous assurer que le loquet se

déplace librement, que le mécanisme de

verrouillage fonctionne correctement et

que le pivot tourne sans heurt. Le loquet

doit prendre appui sans blocage contre le

nez du crochet et ne doit pas être déformé

ni obstrué. Le ressort du loquet doit exercer

une force suffisante pour fermer solidement

le loquet. Le dispositif de verrouillage doit

empêcher le loquet de s’ouvrir quand il est

fermé. Examinez le mousqueton pour voir si

le loquet est endommagé, s’il y a des pièces

courbées, fissurées ou déformées ou s’il y a

des surfaces corrodées ou piquées.

5. Connexion d’ancrage : Assurez-vous que

l’unité est correctement ancrée au dispositif

de montage et que les goupilles-poussoirs

sont correctement installées à travers le

support de montage. Si le système est

équipé d’une poulie et d’un mousqueton,

vérifiez que le mousqueton est correctement

installé en position verrouillée entre la

poulie et le point d’ancrage.

LES UNITÉS QUI NE SATISFONT PAS AUX

CRITÈRES D’INSPECTION OU QUI ONT

ÉTÉ SUJETTES À DES FORCES D’ARRÊT DE

CHUTE OU AFFECTANT UN SAUVETAGE

DOIVENT ÊTRE MISES HORS SERVICE.

5.2 Entretien

Grâce à un entretien de base, on prolonge

la durée de vie des équipements antichute

et on leur permet de mieux remplir leur

fonction de sécurité vitale.

L’entretien du treul de levage pour

personnes Honeywell Miller ManHandler

ne doit être effectué que par Honeywell

Safety Products ou par des personnes ou

entités autorisées par écrit par Honeywell.

On doit tenir un registre de toutes les dates

d’entretien et d’inspection pour ce dispositif.

Seules les pièces de rechange Miller

d’origine sont approuvées pour être utilisées

dans ce dispositif. Le dispositifs réparables

doivent être reournés à nos établissements

ou à un centre de service approuvé chaque

fois qu’ils on été soumis à des contraintes

d’arrêt de chute, pour fins d’inspection et de

recertification. Dans le cas des dispositifs

non réparables qui ne sont pas acceptés à

l’inspection, on doit s’en défaire de façon à

éviter qu’on les utilise éventuellement par

inadvertance. Communiquer avec votre

distributeur Miller ou appeler les Services

techniques de Miller Fall Protection au 1

(800) 873-5242 pour obtenir un numéro

d’autorisation de retour.

Nettoyage et entreposage

Nettoyer périodiquement l’extérieur du

dispositif et essuyer la longe ou le câble de

sécurité à l’aide d’un chiffon humide et d’un

détersif doux. Éponger avec une serviette.

Entreposer dans un endroit propre et sec.

La longe ou le câble de sécurité doivent

être rentrés complètement dans le

dispositif lorsqu’ils ne sont pas en usage.

Page 11

11

ES

Es muy importante que la persona o el usuario autorizados de este equipo lean y entiendan estas instrucciones. Además, la ley

federal exige que los empleadores garanticen que todos los usuarios estén capacitados en la correcta instalación, el uso, la

inspección y el mantenimiento de los equipos de protección contra caídas. La capacitación en la protección contra caídas debería

ser una parte esencial de un programa de

seguridad integral.

El uso adecuado de los sistemas de detención de caídas puede salvar vidas y reducir

la posibilidad de lesiones graves causadas

por una caída. El usuario debe saber que

las fuerzas experimentadas durante la detención de una caída o la suspensión prolongada pueden causar lesiones corporales.

Consulte con un médico si tiene alguna pregunta acerca de la capacidad del usuario

para utilizar este producto. Las mujeres embarazadas y los niños menores de edad no

deben usar este producto.

MALACATE/CABRESTANTE

MANHANDLER PARA

MANEJO DE PERSONAS

Gracias por comprar el equipo de protección

contra caídas Miller fabricado por

Honeywell Safety Products. Los productos

de la marca Miller son manufacturados

para cumplir con las más altas normas de

calidad en nuestra fábrica, la cual posee

la certificación ISO 9001. Cuidados como

es debido, los equipos anticaídas Miller le

servirán muchos años.

ADVERTENCIA

Todas las personas que usen este equipo deben leer, entender y seguir las

instrucciones. Su incumplimiento puede causar lesiones graves o incluso la

muerte. No utilice este equipo si no se

ha capacitado debidamente.

1.0 Objetivo

La cuerda salvavidas autorretráctil Miller

MightEvac con izador para rescate de

emergencia es un dispositivo retráctil

diseñado para fines de protección contra

caídas en espacios confinados con un

mecanismo de rescate de activación rápida

para evacuaciones de emergencia.

2.0 Requisitos, Advertencias

y Limitaciones Generales

2.1 Requisitos generales

Deben suministrarse a las personas y

usuarios autorizados todas las advertencias

e instrucciones.

Todas las personas y usuarios autorizados

deben consultar los reglamentos de

seguridad laboral y las normas ANSI o

CSA que correspondan. Las etiquetas del

producto contienen información sobre los

reglamentos OSHA y las normas ANSI y

CSA que cumple el producto.

Todas las personas o usuarios autorizados

de este equipo deben ser entrenados en

los debidos procedimientos en espacios

confinados.

Siempre deben tomarse las debidas

precauciones al retirar del área de trabajo

obstrucciones, basura, material y otros

peligros reconocidos que pudieran causar

lesiones o interferir en el funcionamiento

del sistema.

Todo el equipo debe ser inspeccionado

visualmente antes de cada uso de

conformidad con las instrucciones del

fabricante.

Todo el equipo debe ser inspeccionado con

regularidad por una persona calificada.

Esta unidad debe ser retirada y puesta

fuera de servicio si cualquier parte del

sistema parece estar dañada o no pasa una

inspección.

A fin de reducir al mínimo las posibilidades

de un desenganche accidental, una

persona competente debe garantizar la

compatibilidad del sistema.

El equipo no debe ser alterado de ninguna

forma. Las reparaciones deben ser

efectuadas exclusivamente por el fabricante

del equipo o bien por personas o entidades

autorizadas por escrito por el fabricante.

El usuario debe contar con un plan y medios

de rescate a mano para poder aplicarlos al

usar este equipo.

Todo producto con deformidades, desgaste

anormal o deterioro debe ser desechado de

inmediato.

Todo equipo sometido a una caída debe ser

puesto fuera de servicio.

Jamás lo utilice para fines distintos al

proyectado. No use jamás el equipo para re-

INSTRUCCIONES DE USO

Page 12

12

salvavidas esté floja, que pase por debajo,

ni que se enrolle, alrededor de los brazos,

piernas o cuello del usuario, ni de cualquier

otro obstáculo.

La cuerda salvavidas debe mantenerse

limpia.

No permita que la cuerda salvavidas entre

en contacto con bordes afilados ni con

superficies abrasivas.

ENTRENAMIENTO

Tanto el usuario como el comprador de

este equipo deben familiarizarse con estas instrucciones y deben entrenarse debidamente en manejo, limitaciones, instalación, inspección y mantenimiento

de este producto. Deben llevarse a cabo

entrenamientos periódicos, sin exponer a

la persona en capacitación a peligros de

caídas.

3.0 Compatibilidad del

Sistema

El malacate/cabrestante ManHandler

de Miller ha sido diseñado para utilizarse

con componentes aprobados de Miller.

La sustitución o reemplazo de dichos

componentes con combinaciones no

aprobadas de componentes o subsistemas,

puede afectar o interferir en el funcionamiento

seguro de cada componente y poner en

peligro la compatibilidad dentro del sistema.

Esta incompatibilidad puede afectar la

fiabilidad y seguridad del sistema total.

3.1 Requisitos del Anclaje

Para aplicaciones que, junto con esta unidad, requieran el uso de un sistema de

amortiguación de caídas, los anclajes

deben ser capaces de soportar 5000 lbs.

(22.2kN) por trabajador, o de satisfacer los

requisitos de OSHA para un coeficiente de

seguridad de dos.

Los requisitos para el anclaje basados en

las normas ANSI son como sigue:

• Para los sistemas de detención de caídas,

los anclajes deben poder soportar una

carga estática de 5,000 lb (22.2 kN) en el

caso anclajes no certificados o dos veces

la fuerza de detención máxima en el caso

de anclajes certificados.

• Para los sistemas de detención de posicionamiento, los anclajes deben poder

soportar una carga estática de 3,000 lb

(13.3 kN) en el caso anclajes no certificados o dos veces la fuerza previsible en el

caso de anclajes certificados.

molcar o izar objetos.

Al seleccionar equipo anticaídas

deben tomarse en cuenta los riesgos

medioambientales. El equipo no debe

ser expuesto a los peligros ambientales y

químicos que pueden producir un efecto

dañino. El uso del equipo en entornos muy

corrosivos o cáusticos exige un programa

de inspecciones y servicio más frecuentes

para garantizar la integridad continuada del

dispositivo.

No permita que la cuerda o el tejido entren

en contacto con cualquier cosa que pueda

dañarlos, como superficies afiladas,

abrasivas, ásperas o a alta temperatura,

soldadura, fuentes de calor, peligros

eléctricos o maquinaria en movimiento.

El equipo debe ser mantenido limpio y libre

de contaminantes. No lubrique esta unidad.

Nunca desprenda etiquetas de los productos, las cuales pueden incluir importantes

advertencias e información para la persona

o usuario autorizado.

2.2 Advertencias y Limitaciones

Capacidad

Para uso de UNA sola persona. La capacidad

máxima es de 159kg (350 lb)*, incluyendo

el peso corporal, la ropa y las herramientas.

- NO EXCEDA ESTE PESO.

*El rango de capacidad ANSI Z359.4 es de

130 lbs. (59kg) a 310 lbs. (140kg).

FUERZA REQUERIDA PARA RESCATES

La fuerza requerida para utilizar las

características de rescate o salvamento,

cuando el dispositivo está cargado a su

capacidad máxima, es de 22 lbf. (98N).

RETRACCIÓN Y BLOQUEO DE LA

CUERDA DE SEGURIDAD

No use el dispositivo si no se retrae. Siempre mantenga tensión en la cuerda salvavidas mientras se retrae.

El aseguramiento del dispositivo debe probarse antes de cada uso. No use el dispositivo si no se activa el freno.

ADVERTENCIAS DE CUERDA

SALVAVIDAS

Antes de utilizar, para cerciorarse de que

la unidad tenga la capacidad suficiente,

verifique la longitud máxima de cable

requerida por la aplicación.

La cuerda salvavidas debe permanecer

tensa cuando se conecte al arnés de un

trabajador. Nunca permita que la cuerda

Page 13

13

• Para limitación de desplazamiento, los

anclajes deben poder soportar una carga

estática de 1,000 lb (4.5 kN) en el caso

anclajes no certificados o dos veces la

fuerza previsible en el caso de anclajes

certificados.

• Para los sistemas de rescate, los anclajes

deben poder soportar una carga estática

de 3,000 lb (13.3 kN) en el caso anclajes

no certificados o cinco veces la carga aplicada en el caso de anclajes certificados.

• Cuando se sujeta más de un sistema personal de detención de caídas a un anclaje,

se deben multiplicar las fuerzas de anclaje

indicadas arriba por el numbero de siste-

mas sujetos a dicho anclaje.

4.0 Instalación

El malacate/cabrestante ManHandler está

equipado con un soporte integrado para

poder fijarse a sistemas y dispositivos de

anclaje aprobados, como el Sistema

DuraHoist™ para espacios restringidos de

Miller, y los trípodes, Quad Pods, sistemas

Davit, montajes de pared, etc. de Miller.

Para instalar el malacate/cabrestante

ManHandler, simplemente alinee los huecos del soporte integrado con los huecos

del dispositivo de montaje que se esté

usando (p.ej. un trípode u otro anclaje aprobado) e inserte completamente las clavijas

de empuje a través del soporte (ver Figs. 1 y

2).

El malacate/cabrestante ManHandler debe

ser inspeccionado antes de cada vez que se

use, como se describe en la sección 4.1

Inspección y operación de este manual.

SOPORTE DE MONTAJE

MANGO DE LA MANIVELA

CAJA

MOSQUETÓN GIRATORIO

CLAVIJAS DE EMPUJE

Fig. 1

INSTALACIÓN

TÍPICA

Fig. 2

MANHANDLER MILLER

MONTADO EN EL TRÍPODE

MILLER

ADVERTENCIA: Siempre cerciórese de

que el gancho con resorte de la unidad

ManHandler esté asegurado correctamente a una conexión compatible, como

a una argolla “D” de la parte trasera del

arnés de un trabajador, y de que este cerrado y asegurado mientras se lo utilice. En

una situación no de emergencia, se debe

utilizar una protección contra caídas independiente, cuando el malacate/cabrestante ManHandler esté siendo usado para

izar, bajar, colocar en posición, o suspender en el aire a una persona. Se recomienda

utilizar una cuerda salvavidas retráctil de

Miller o una cuerda salvavidas retráctil

con capacidad de recuperación de Miller.

Page 14

14

5.0 Inspección, Operación y

Mantenmiento

5.1 Inspección y Operación

Siempre póngase guantes al inspeccionar las unidades de cuerda o cable; ¡Las

hebras rotas pueden causar lesiones!

PRECAUCIÓN

1. Alojamiento y piezas del dispositivo/

Soporte de montaje: Inspeccione la unidad

para ver si tiene elementos de sujeción

sueltos o piezas dobladas, agrietadas,

deformes, gastadas, en mal funcionamiento

o dañadas.

2. Cuerda salvavidas:

Se debe revisar toda la longitud de la cuerda

salvavidas para ver si hay señales de daño.

Inspecciónela para ver si hay cortes o hebras

rotas, patrones de desgaste inusuales,

corrosión, vueltas, o daños químicos.

3. Operación para bajar e izar: Aplique una

ligera tensión [50 lbs. (23kg) mínimo] a la

cuerda salvavidas de cable, y:

a) Haga girar el mango de la manivela en la

dirección contraria a las manecillas del reloj

para extender el cable lejos de la unidad

(bajar).

Nota: Cuando se deja de hacer girar a la

manivela, los frenos de fricción deben

sostener a la carga de una manera segura,

sin que el mango de la manivela gire.

Si este freno funciona mal, se activará

un sistema de frenado para velocidad

excesiva.

b) Haga girar el mango de la manivela en la

dirección de las manecillas del reloj para hacer

regresar el cable a la unidad (izar). Cuando se

esté haciendo regresar el cable a la unidad se

debe escuchar un ruido de “clics”.

4. Gancho con resorte: Revise el gancho

con resorte para asegurarse de que

la compuerta funcione libremente, de

que el mecanismo del seguro funcione

correctamente, y de que el eslabón giratorio

gire suavemente. La compuerta debe

asentarse dentro de su retén sin atascarse

y no debe estar distorsionada ni obstruida.

El resorte de la compuerta debe ejercer

suficiente fuerza para cerrar la compuerta

firmemente. El mecanismo del seguro debe

impedir que la compuerta se abra cuando la

misma esté cerrada. Inspeccione el gancho

con resorte para ver si hay indicios de

algún daño de la compuerta; componentes

doblados, agrietados o distorsionados;

corrosión o superficies con hoyos.

5. Conexión de anclaje: Cerciórese de que

la unidad esté anclada correctamente al

dispositivo de montaje y de que las clavijas

de empuje estén instaladas correctamente a

través del soporte de montaje. Si el sistema

está equipado con una polea y mosquetón,

revise para cerciorarse de que el mosquetón

este asentado correctamente, y en la

posición asegurada, entre la polea y el punto

de anclaje.

LAS UNIDADES QUE NO PASEN

LA INSPECCIÓN O HAYAN SIDO

SOMETIDAS A FUERZAS DE

DETENCIÓN DE CAÍDAS DEBEN

RETIRARSE DEL SERVICIO.

5.2 Mantenimiento

Con un cuidado básico de todo el equipo de

protección contra caídas se prolonga la vida

de servicio de la unidad y se contribuye al

correcto desempeño de su vital función de

seguridad.

Servicio

Sólo Honeywell Safety Products o personas

o entidades autorizadas por escrito por

Honeywell deben realizar la reparación de

los malacates/cabrestantes ManHandler

de Miller. Debe llevarse un registro con

todas las fechas de servicio e inspecciones

realizados al dispositivo. Sólo las piezas de

repuesto originales de Miller se aprueban

para ser usadas en este dispositivo. Los

dispositivos reparables deben enviarse a

nuestras instalaciones o a un centro de

servicio autorizado cuando hayan sido

sometidas a fuerzas de detención de caídas

para su inspección física y recertificación.

Aquellos dispositivos no reparables que no

pasen la inspección deben desecharse de

tal manera que se prevenga su posterior uso

por accidente. Contacte a su distribuidor

Honeywell o llame a los Servicios Técnicos

de Honeywell al 1-800-873-5242 (presione

4) para recibir un número de autorización de

devolución.

Limpieza y almacenamiento

Limpie periódicamente la parte exterior del

dispositivo y limpie la cuerda de seguridad

con un paño húmedo y detergente suave.

Séquela con una toalla. Cuando no estén en

uso, almacénelas en un lugar limpio, seco.

La cuerda de seguridad o salvavidas

debe estar completamente retraída en el

dispositivo cuando no esté en uso.

ADVERTENCIA

El malacate/cabrestante ManHandler

debe ser inspeccionado antes de cada uso.

Si la unidad es usada como un dispositivo

de recuperación de emergencia, para

facilitar una recuperación rápida, debe

ser inspeccionada antes de permitir que

el personal entre al espacio restringido.

Además de la inspección requerida

antes de cada uso, esta unidad debe

ser inspeccionada por una persona

competente por lo menos una vez al

año. Esta inspección periódica debe ser

establecida por el empleador del usuario.

Una recertificación anuel de fábrica no

es necesaria, amenos que la unidad haya

estado sujeta a las fuerzas que ocurren

al amortiguar una caída, o que puedan

afectar a un rescate.

Page 15

15

CERTIFICATION:

All 8442 models meet OSHA.

8442-Z7 and 8442SS-Z7 models also meet

ANSI Z359.4.

CERTIFICATION:

Tous les modèles 8442 sont conformes à

OSHA.

Les modèles 8442-Z7 et 8442SS-Z7 sont

également conformes à ANSI Z359.4.

CERTIFICACIÓN:

Todos los modelos 8442 cumplen con OSHA.

Los modelos 8442-Z7 y 8442SS-Z7 también

cumplen con ANSI Z359.4.

APPENDIX A: PRODUCT SPECIFICATIONS

ANNEXE A: FICHE TECHNIQUE SUR LES PRODUITS

APÉNDICE A: ESPECIFICA

CIONES DE LOS PRODUCTOS

Model

Modèle/Modelo

Lifeline Material

Matériau du filin/Material de la cuerda

Length

Longueur/Largo

Weight

Poids/Peso

8442/65FT

8442-Z7/65FT*

3/16 in. galvanized cable

5mm câble galvanisé

5mm cable de acero galvanizado

65 ft.

(20m)

39 lbs. (18kg)

8442SS/65FT

8442SS-Z7/65FT*

3/16 in. stainless steel cable

5mm câble en acier inoxydable

5mm cable de acero inoxidable

65 ft.

(20m)

39 lbs. (18kg)

8442/100FT

8442-Z7/100FT*

3/16 in. galvanized cable

5mm câble galvanisé

5mm cable de acero galvanizado

100 ft.

(30.5m)

41.275 lbs. (19kg)

8442SS/100FT

8442SS-Z7/100FT*

3/16 in. stainless steel cable

5mm câble en acier inoxydable

5mm cable de acero inoxidable

100 ft.

(30.5m)

41.275 lbs. (19kg)

*Models with “Z7” in the part number have an ANSI Z359.1 compliant snap hook with a minimum gate load strength of 3,600 lbs. (16kN).

*Les modèles dont le numéro de référence comporte «27» comprennent un mousqueton conforme à ANSI Z359.1 avec une résistance de

charge de loquet minimale de 16 kN (3 600 lbs).

*Los modelos con “Z7” en el número de parte tienen un gancho con resorte que cumple con ANSI Z359.1, con una fuerza mínima de carga de

la compuerta de 3600 lbs. (16kN).

Page 16

16

TECHNICAL SPECIFICATIONS

SPÉCIFICATIONS TECHNIQUES / ESPECIFICACIONES TÉCNICAS

Maximum Capacity

Capacité maximale / Capacidad máxima

350 lbs. (159kg)

Maximum Working Length

Longueur de travail maximale / Longitud de trabajo máxima

100 ft. (30.5m) or 65 ft. (20m) depending on unit

30,5 m (100 pi) ou 20 m (65 pi) selon l’unité /

100 pies (30.5m) o 65 pies (20m) dependiendo de la unidad

Brake Systems

Systèmes de freinage / Sistemas de freno

Holding and Inertia - Friction Disk

Maintien et inertie – Disque de friction / Sujeción e inercia -Disco

de fricción

Gear Ratio

Rapport de démultiplication / Coeficiente de reducción

5:1

Retrieval Speed

Vitesse de récupération / Velocidad de recuperación

20 ft./min. (6.096m/min.)

6,096 m/min (20 pi./min) / 20 pies/min. (6.096m/min.)

Force Required to Operate Rescue Features when Device is Loaded

to Maximum Capacity / Force requise pour utiliser les fonctions de sauvetage quand le

dispositif est chargé à sa capacité maximale / Fuerza requerida para hacer funcionar las

características de rescate cuando el dispositivo está cargado a su máxima capacidad

22 lbs. (98N)

MATERIAL SPECIFICATIONS

SPÉCIFICATIONS DES MATÉRIAUX / ESPECIFICACIONES DE LOS MATERIALES

Housing

Logement / Caja

Steel Weldment, Yellow Chromate Plating

Soudure acier, chromaté / Soldadura de acero, plateado con cromato amarillo

Drum

Tambour / Tambor

Steel Weldment, Yellow Chromate Plating (Zinc)

Soudure acier, chromaté (zinc) / Soldadura de acero, plateado con cromato amarillo (Zinc)

Shaft

Arbre / Eje

4140 Steel

Acier 4140 / Acero 4140

Springs

Ressorts / Resortes

Stainless Steel

Acier inoxydable / Acero inoxidable

Brake Pawls

Cliquets de frein / Retenes del freno

1020 Steel, Yellow Chromate Plating

Acier 1020, chromaté / Acero 1020, plateado con cromato amarillo

Brake Pads

Patins de frein / Almohadillas del freno

Fiber Composite

Fibre composite / Compuesto de fibra

Bearings

Paliers / Cojinetes

Oil Impregnated Bronze

Bronze imprégné d’huile / Bronce impregnado en aceite

Hardware

Matériel / Ferretería

Grade 5, Zinc Plated

Grade 5, galvanisé / Grado 5, plateado con zinc

Snap Hook

Mousqueton / Gancho con resorte

Drop Forged Steel

Acier matricé / Acero forjado

Cable

Câble / Cable

Galvanized Steel or Stainless Steel

Acier galvanisé ou acier inoxydable / Acero galvanizado o acero inoxidable

Product specification sheets may be downloaded

at www.millerfallprotection.com.

Les fiches techniques des produits peuvent être

téléchargées au www.millerfallprotection.com.

Las hojas de especificaciones de los productos

pueden bajarse de www.millerfallprotection.com.

Page 17

17

RFID Remarks

Observations sur RFID / Observaciones sobre RFID

RFID (Radio Frequency Identification)

The following Honeywell Miller self-retracting lifelines and fall limiters incorporate a RFID (radio frequency identification) that can be used for asset tracking. The RFID specifies information including

model number, date of manufacture, inspection/lot number, length, and standards met, and varies from

model to model. In addition to the type of reader and RFID tag, optimal RFID read distance varies with

the reader and tag orientation, and the material of the medium between them.

RFID (Radio Frequency Identification)

Les suivant câbles de sécurité autorétractables et limiteurs de chute Miller comprennent une étiquette

RFID pour le repérage des biens. L’étiquette RFID indique les données qui varient d’un modèle à l’autre

(c.-à-d., numéro de modèle, date de fabrication, numéro d’inspection / de lot, longueur, et normes respectées par un modèle particulier). En plus du type de lecteur et de l’etiquette RFID, la distance optimale de lecture de RFID varie avec le lecteur, l’orientation de l’etiquette et le matériel du media entre eux.

RFID (Identificación por Radiofrecuencia)

Las siguientes cuerdas salvavidas autorretráctiles y limitadores de caídas Honeywell Miller incorporan una etiqueta RFID la cual puede usarse para el seguimiento de activos. La etiqueta RFID indica

información que varía de un modelo a otro (o sea, número de modelo, fecha de fabricación, número de

inspección o lote y normas con que cumple cada modelo en particular). Adicionalmente al tipo de lector

y etiqueta RFID, la distancia de lectura de RFID óptima varia con el lector, la orientación de la etiqueta y

el material del medio entre ellas.

RFID TAGS

TYPE PRODUCTS LOCATION RFID READER

CHIP/

CLIP

Manhandler

(Cable Units)

Under the

rubber

handle,

between

two red

snap-on

clips

Reader must be Ultra

High Frequency (UHF)

Operating frequency:

US Region: 902-928 MHz

EU Region: 866-868 MHz

KEYRING ManHandler

(Kevlar)

Between

Kevlar Rope

Reader must be Ultra

High Frequency (UHF)

Operating frequency:

865-928 MHz

(UHF range)

Page 18

18

APPENDIX B: PRODUCT LABELS

ANNEXE B: ÉTIQUETTES SUR LES PRODUITS

APÉNDICE B: ETIQUETAS DE LOS PRODUCTOS

PRODUCT

LABEL / ÉTIQUETTE

DE PRODUIT / ETIQU-

ETA DEL PRODUCTO

WARNING

LABEL / ÉTIQUETTE

D’AVERTISSEMENT /

ETIQUETA DE

ADVERTENCIA

CRANK

ROTATION

LABEL / ÉTIQUETTE DE

ROTATION DE MANIVELLE /

ETIQUETA DE ROTACIÓN DE

LA MANIVELA

LOWER

RAISE

WARNING

Read, understand and follow all

instructions. Failure to do so may result

in serious injury or death.

Use of this equipment for the raising,

lowering, or suspension of personnel

in a non-emergency situation requires

the use of independent fall protection.

Page 19

19

INSPECTION DATE

DATE D’INSPECTION

FECHA DE INSPECCIÓN

INSPECTION

ITEMS NOTED

POINTS NOTÉS

LORS DE L’INSPECTION

PUNTOS DE INSPECCIÓN

RELEVANTES

CORRECTIVE

ACTION

ACTION CORRECTIVE

MEDIDA CORRECTIVA

MAINTENANCE

PERFORMED

ENTRETIEN EFFECTUÉ

MANTENIMIENTO

REALIZADO

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

DATE OF MANUFACTURE:_____________________________________________

DATE DE FABRICATION / FECHA DE FABRICACIÓN

MODEL NUMBER:____________________________________________________

NUMÉRO DE MODÈLE / NÚM. DE MODELO

DATE PURCHASED:__________________________________________________

DATE D’ACHAT / FECHA DE COMPRA

APPENDIX C: INSPECTION AND MAINTENANCE

LOG

ANNEXE C: REGISTRE D'INSPECTION ET D'ENTRETIEN

APÉNDICE C: REGISTRO DE INSPECCIÓN Y MANTENIMIENTO

Page 20

For more information

www.honeywellsafety.com

Honeywell Industrial Safety

P.O. Box 271, 1345 15th Street

Franklin, PA 16323 USA

Toll Free: 800.873.5242

Fax: 800.892.4078

E-mail: hsptechsupport@honeywell.com

HONEYWELL MILLER®

FALL PROTECTION PRODUCTS

TOTAL SATISFACTION ASSURANCE

At Miller Fall Protection, we have been providing

quality Miller brand fall protection equipment to

millions of workers worldwide since 1945.

LIMITED LIFETIME WARRANTY

BACKED BY OVER 65 YEARS IN THE FALL

PROTECTION BUSINESS

We sincerely believe that our fall protection equipment is the best in the world.

Our products endure rigorous tests to ensure that the

fall protection equipment you trust is manufactured

to the highest standards. Miller fall protection products are tested to withstand normal wear and tear, but

are not indestructible and can be damaged by misuse.

Our Limited Lifetime Warranty does not apply to normal wear and tear or abusive treatment of the product.

In the unlikely event that you should discover de-

fects in either workmanship or materials,

under our Limited Lifetime Warranty, we will repair or

replace the product at our expense.

If a replacement is necessary and your product is no lon-

ger available, a comparable product will be substituted.

Should a product issue surface, contact us at

800.873.5242.

Manufacturing specifications are subject to change without

notice.

PRODUITS HONEYWELL MILLER®

FALL PROTECTION

ASSURANCE DE SATISFACTION TOTALE

Chez Miller Fall Protection, nous fournissons des

équipements de protection contre les chutes de

marque Miller de qualité à des millions de travailleurs dans le monde entier depuis 1945.

GARANTIE LIMITÉE À VIE

ASSURÉE GRÂCE À PLUS DE 65 ANS PASSÉS

DANS LE DOMAINE DE LA PROTECTION CON-

TRE LES CHUTES

Nous croyons sincèrement que notre équipement de

protection contre les chutes est le meilleur au monde.

Nos produits sont soumis à des tests rigoureux, afin

d’assurer que les équipements de protection contre les

chutes dans lesquels vous avez confiance sont fabriqués selon les normes les plus exigeantes.

Les produits de protection contre les chutes Miller

sont soumis à des essais pour vérifier qu’ils résistent à

une usure normale; ils ne sont cependant pas indestructibles et peuvent s’endommager en cas de

mauvaise utilisation. Notre garantie limitée à vie

ne s’applique pas à l’usure normale ou à un usage

abusif du produit.

Dans le cas peu probable où vous découvririez des

défauts, soit de fabrication, soit de matériau, dans

le cadre de notre garantie à vie, nous réparerons

ou remplacerons le produit à nos frais. En cas de

remplacement, si votre produit n’est plus offert,

vous recevrez un produit comparable.

En cas de problème sur un produit, nous contacter au 800-873-5242.

Les caractéristiques de fabrication peuvent être modifiées sans préavis.

PRODUCTOS ANTICAÍDAS

HONEYWELL MILLER

®

GARANTÍA DE SATISFACCIÓN

TOTAL

En Miller Fall Protection, venimos suministrando desde 1945 los equipos de protección

anticaídas

con la calidad Miller a millones de trabajadores en todo el mundo.

GARANTÍA LIMITADA DE POR VIDA

NOS RESPALDAN MÁS DE 65 AÑOS EN LA

FABRICACIÓN DE EQUIPO ANTICAÍDAS

Sinceramente creemos que su equipo de protec-

ción contra caídas es el mejor del mundo. Nuestros

productos resisten rigurosas pruebas para garantizar que el equipo de protección contra caídas en

el que usted confía está fabricado de conformidad

con las normas más elevadas. Los productos anticaídas Miller son sometidos a pruebas para que

resistan el desgaste normal, pero no son indestructibles y su incorrecta utilización puede dañarlos.

Nuestra Garantía limitada de por vida no se aplica al

desgaste normal ni al maltrato del producto.

En el poco probable caso de que usted descubriera defectos de mano de obra o materiales,

por nuestra Garantía limitada de por vida, repararemos o sustituiremos el producto por cuenta

nuestra. Si un reemplazo es necesario y nuestro

producto ya no está disponible, se lo sustituiremos por otro comparable.

En caso de que surja un problema con el producto, contáctenos al 800.873.5242.

Las especificaciones de fabricación están sujetas a modificaciones sin previo aviso.

Loading...

Loading...