Miller Electric Legend AEAD-200LE Technical Manual

February 1996 Form: TM-428

Effective With Serial No. JH242114

TECHNICAL MANUAL

Service And Parts

cover_tm 4/95 – ST-140 091-E PRINTED IN USA

1996 MILLER Electric Mfg. Co.

Miller Legend

(Formerly The Legend AEAD-200LE)

CC AC/DC Welding Generator For SMAW, GMAW, GTAW Welding

Welding

Mode

Weld

Output

Range

Rated

Welding

Output

Maximum

Open-Circu

it Voltage

Auxiliary Power

Rating

Fuel Capacity Engine

CC/AC 35

– 225 A

225 A, 25 V

,

100% Duty

Cycle

80

Single-Phase,

5 kVA/kW

, 42/21 A,

120/240 V AC, 60 Hz

Onan P218 Air-Cooled,

-

-

CC/DC

25 – 200 A

200 A, 25 V

,

100% Duty

Cycle

72

And

Single-Phase,

1 kVA/kW

, 9 A,

1

15 V AC, 100 Hz

7.5 gal (28 L) T

ank

T

wo-Cylinder, Four-Cycle,

Gasoline Engine

OM-428N 1/96 – SPM-428C 6/94

H CALL:

Miller Customer Service

Department at

414-735-4505

WHO DO I CONTACT FOR HELP?

H FAX:

800-637-2348

(in USA),

or

414-735-4136 (outside USA)

H WRITE:

Miller Electric Mfg. Co.

P

.O. Box 1079

Appleton, WI 54912 USA

Always provide Model Name and Serial or Style Number

TABLE OF CONTENTS

SECTION 1 – SAFETY PRECAUTIONS FOR SERVICING 1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. Symbol Usage 1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. Servicing Hazards 1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3. EMF Information 2.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – INSTALLATION 3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

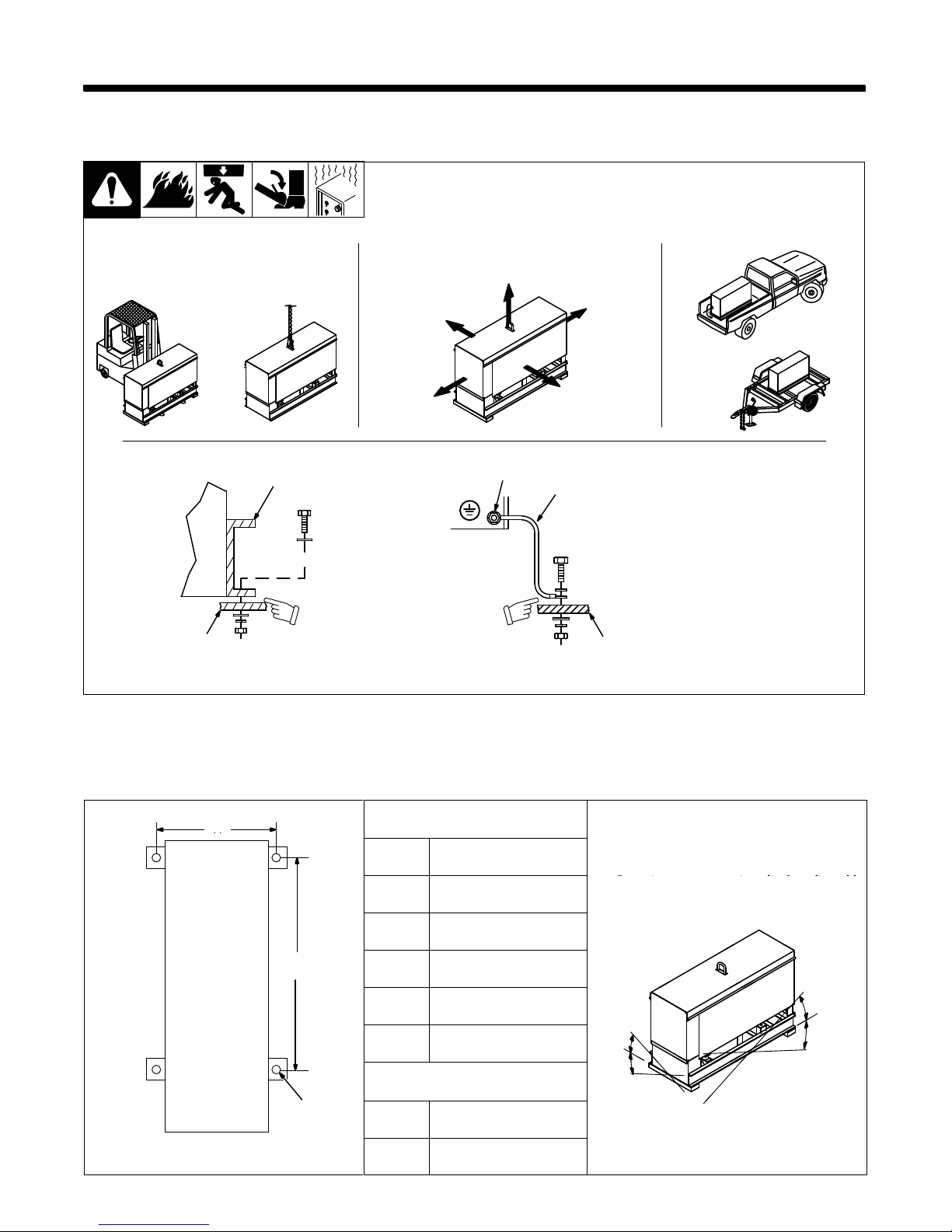

2-1. Installing Welding Generator 3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2. Dimensions, Weights, And Operating Angles 3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

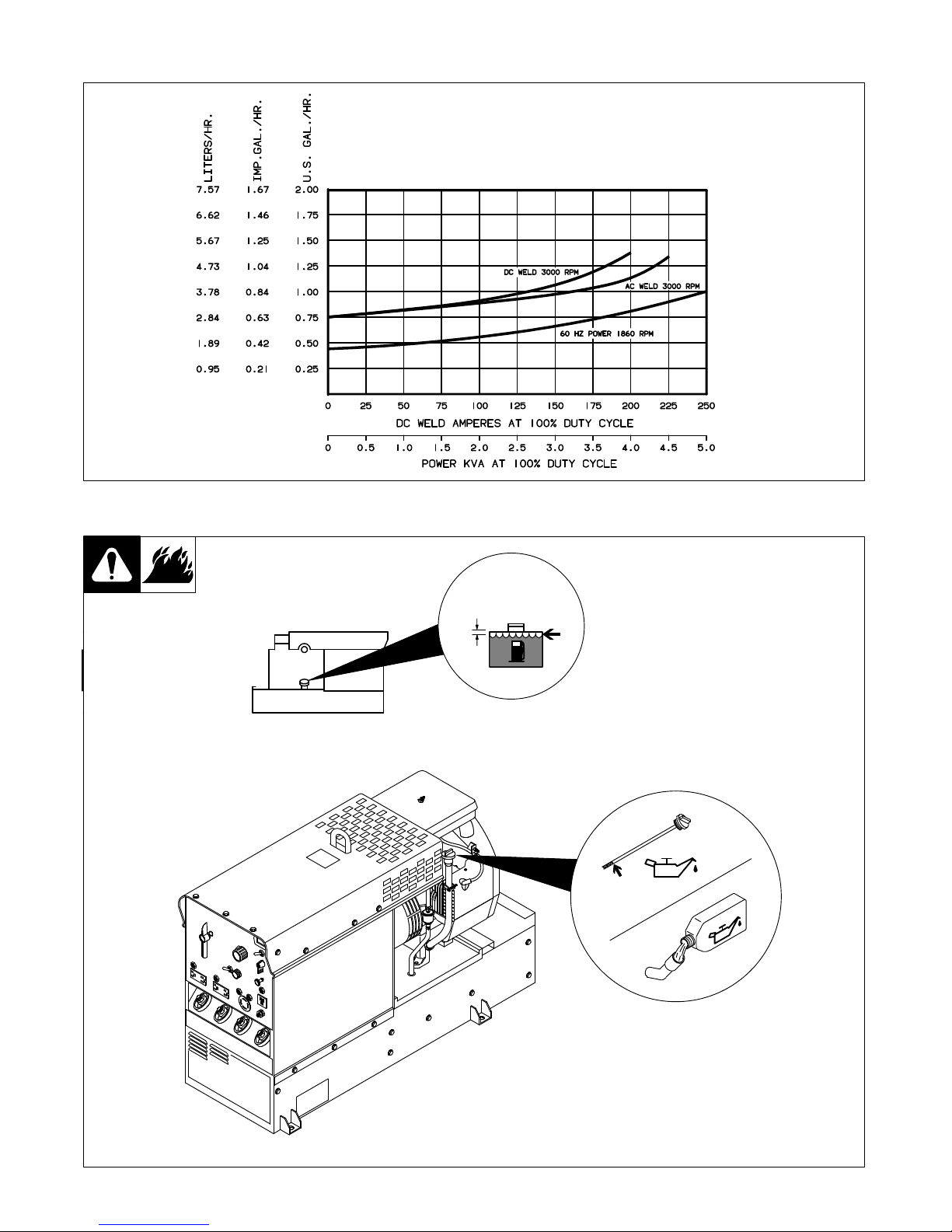

2-3. Fuel Consumption 4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4. Engine Prestart Checks 4.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

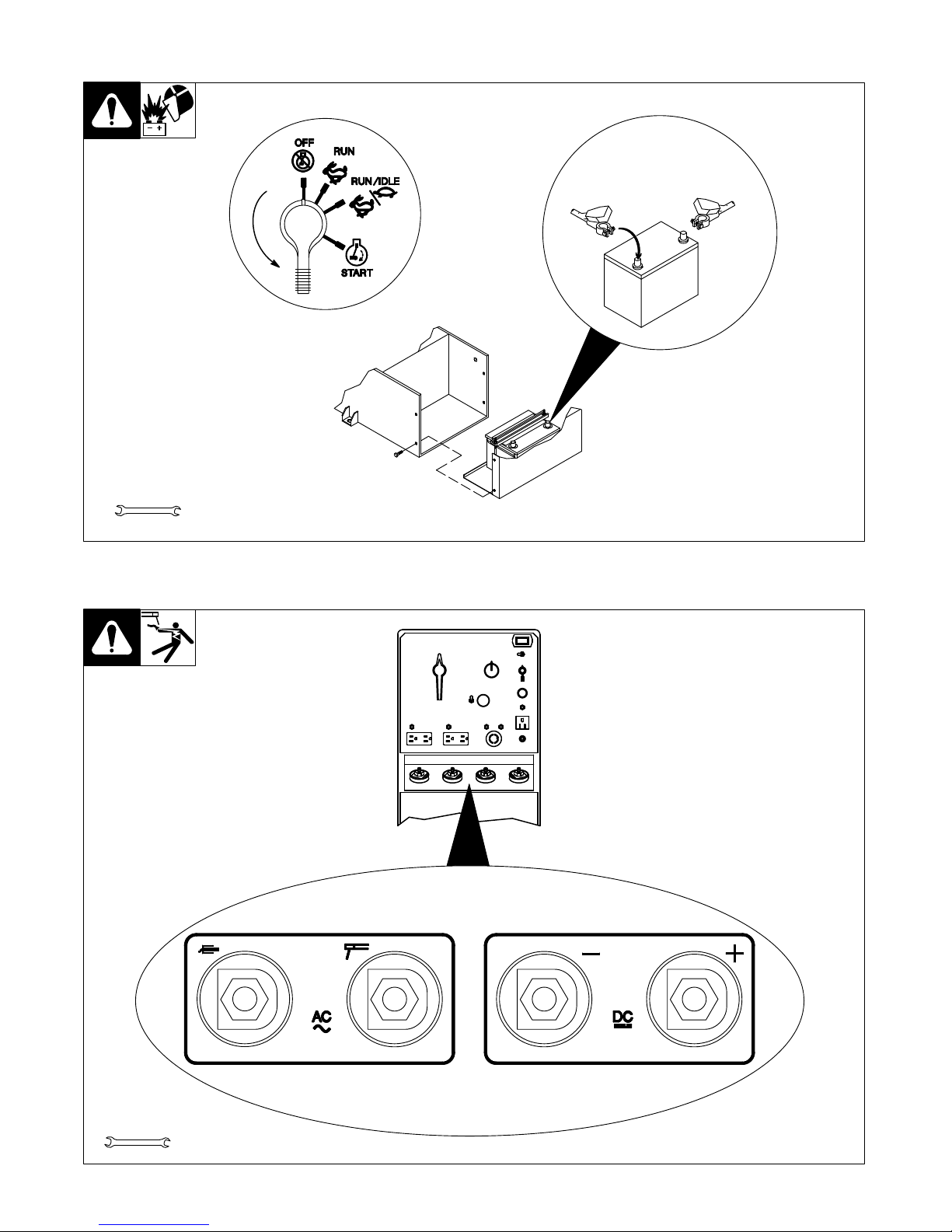

2-5. Connecting The Battery 5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-6. Connecting To Weld Output Terminals 5.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

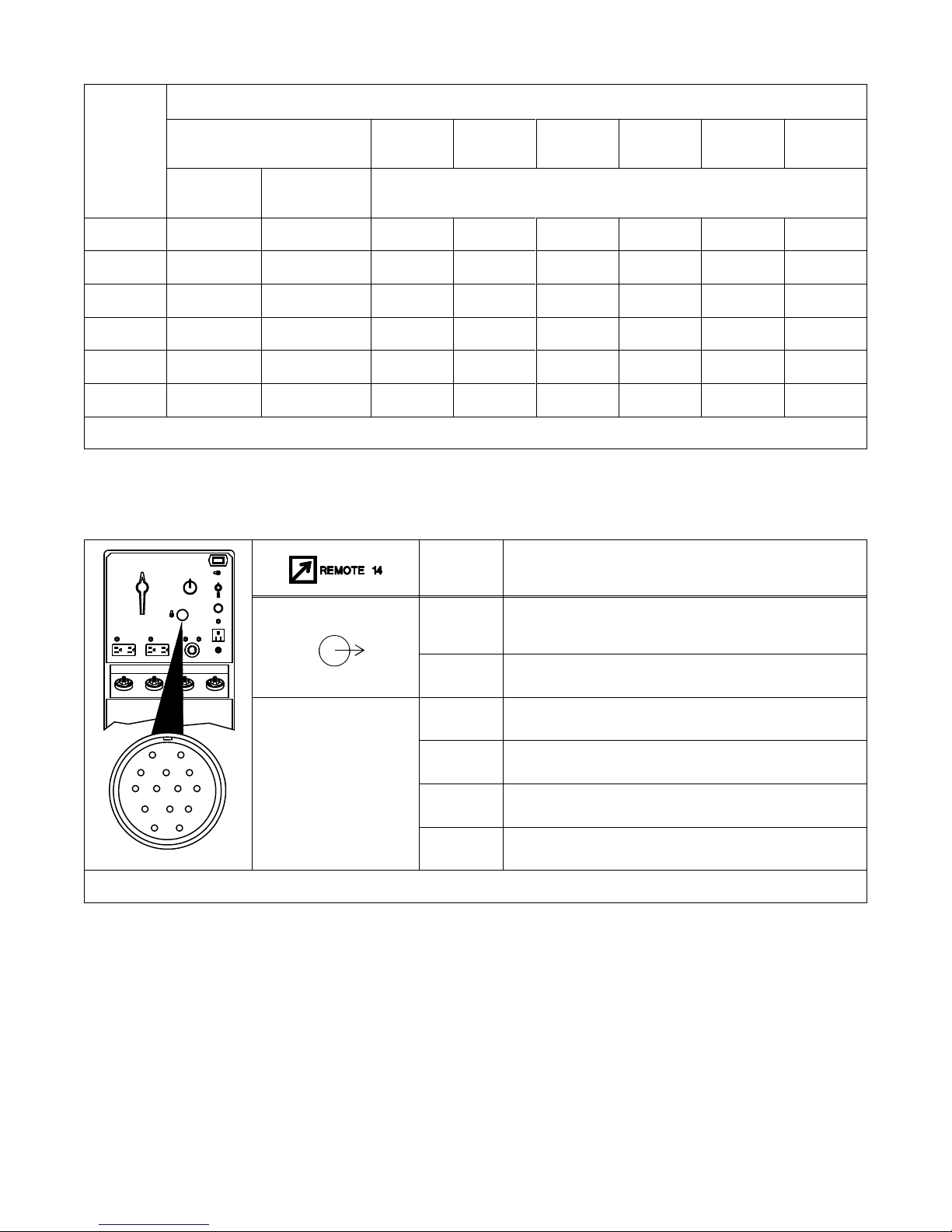

2-7. Selecting Weld Cable Sizes 6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8. Remote 14 Receptacle RC1 Information 6.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION

3 – OPERA

TING WELDING GENERATOR 7.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

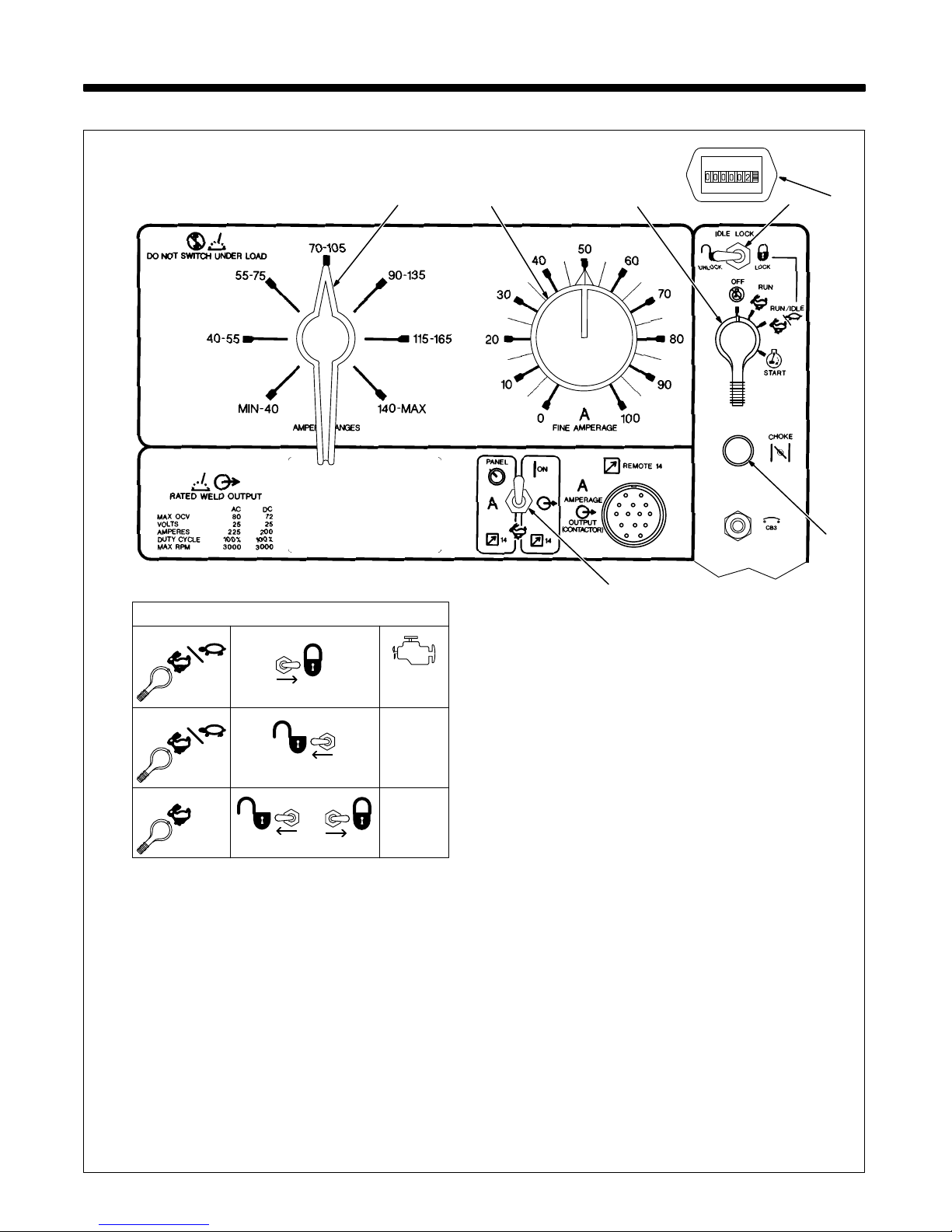

3-1. Front Panel Controls 7.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. Remote Control (Optional) 8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. Duty Cycle 8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4. Volt-Ampere Curves 9.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION

4 – OPERA

TING AUXILIAR

Y EQUIPMENT

10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. 100 Hz Auxiliary Power Receptacle And Circuit Breaker 10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2. AC Auxiliary Power Curve 10.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3. 60 Hz Auxiliary Power Receptacles And Circuit Breakers 11.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 – THEOR

Y OF OPERA

TION 12.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – TROUBLESHOOTING 15.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1. Troubleshooting Tables 15.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2. Troubleshooting Circuit Diagram For Welding Generator 18.

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3. Troubleshooting Circuit Diagram For Welding Generator With Optional Remote Control 20.

.

6-4. Waveforms For Sections 6-2 And 6-3 22.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5. Idle Control Board/Module PC1 Testing Information 23.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6. Troubleshooting Flowcharts For Idle Control Board/Module PC1 24.

. . . . . . . . . . . . . . . . . . . . .

6-7. Voltage Regulator Board PC2 Testing Information Prior To Serial No. KE604176 26.

. . . . . . .

6-8. Voltage Regulator Board PC2 Test Point Values Prior To Serial No. KE604176 26.

. . . . . . . .

6-9. Voltage Regulator Board PC2 Testing Information Effective With Serial No. KE604176 27.

. .

6-10. Voltage Regulator Board PC2 Test Point Values Effective With Serial No. KE604176 27.

. . .

6-11. Optional Remote Control Board PC3 Testing Information 28.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

6-12. Optional Remote Control Board PC3 Test Point Values 28.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-13. Optional Remote Capacitor Board PC5 Testing Information Effective With

Serial No. KD346698 29.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-14. Optional Remote Capacitor Board PC5 Test Point Values Effective With

Serial No. KD346698 29.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-15. Replacing Brushes And Cleaning Slip Rings 30.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-16. Checking Unit Output After Servicing 32.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7 – DISASSEMBL

Y AND REASSEMBL

Y 33.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1. Disassembly Of Unit 33.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2. Disassembly Of Generator 34.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8 – MAINTENANCE 35.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1. Routine Maintenance 35.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2. Maintenance Label 36.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3. Servicing Air Cleaner 37.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-4. Changing Engine Oil, Oil Filter, And Fuel Filter 38.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5. Adjusting Engine Speed 39.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-6. Overload Protection 40.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-7. Inspecting And Cleaning Optional Spark Arrestor 40.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9 – ELECTRICAL DIAGRAMS 41.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 10 – PARTS LIST 51.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TM-428 Page 1

Miller Legend

SECTION 1 – SAFETY PRECAUTIONS FOR SERVICING

safety_rtm1 4/95

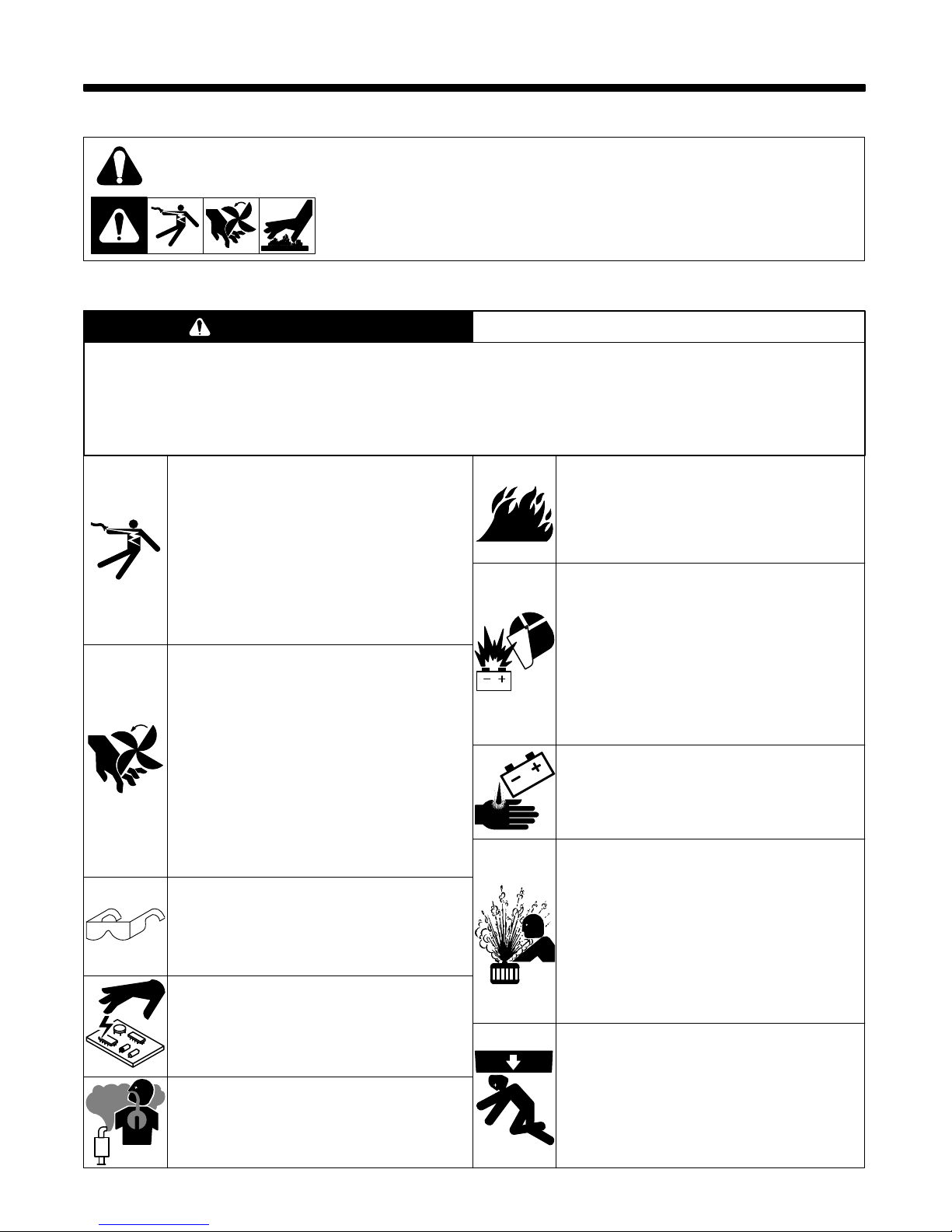

1-1. Symbol Usage

Means Warning! Watch Out! There are possible hazards with this

procedure!

The possible hazards are shown in the adjoining symbols.

This group of symbols means Warning! Watch Out! possible ELECTRIC SHOCK, MOVING

PARTS,

and HOT PARTS hazards. Consult symbols and related instructions below for necessary

actions

to avoid the hazards.

Y

Marks a special safety message.

.

Means NOTE; not safety related.

1-2. Servicing Hazards

ELECTRIC SHOCK can kill.

1. Do

not touch live electrical parts.

2. Stop

engine before testing or repairing unit unless

the procedure specifically requires an energized

unit.

3. Insulate yourself from ground by standing or

working on dry insulating mats big enough to

prevent

contact with the ground.

4.

Do not leave live unit unattended.

5. When

testing live unit, use

the one-hand method.

Do not put both hand inside unit. Keep one

hand

free.

MOVING PARTS can cause injury.

1. Keep

away from moving

parts such as fans, belts,

and

rotors.

2. Have only qualified people remove guards or

covers for maintenance and troubleshooting as

necessary.

3. Keep hands, hair, loose clothing, and tools away

from

moving parts.

4. Before

working on generator

, remove spark plugs

or injectors to keep engine from kicking back or

starting.

5. Block

flywheel so that it will not

turn while working

on

generator components.

6.

Reinstall panels or

guards and close doors when

servicing is finished and before starting engine.

FLYING

PIECES

OF MET

AL or DIRT can

cause injury.

1. Always wear safety glasses with side shields or

face

shield during servicing.

2. Be

careful not to short metal tools, parts, or wires

together

during testing and servicing.

STATIC

ELECTRICITY

can damage parts

on circuit boards.

1. Put on grounded wrist strap BEFORE handling

boards

or parts.

2. Use proper static-proof bags to store, move, or

ship

PC boards.

ENGINE EXHAUST GASES can kill.

1. Do

not breathe exhaust fumes.

2. Use in open, well-ventilated areas, or vent

exhaust outside and away from any building air

intakes.

ENGINE FUEL can cause fire or

explosion.

1. Stop

engine before fueling.

2. Do not fuel while smoking or near sparks or

flames.

3. Do

not overfill tank; clean up any spilled fuel.

BATTERY EXPLOSION can BLIND and

INJURE.

1. Always wear a face shield when working on a

battery.

2. Stop engine before disconnecting or connecting

battery

cables.

3. Do

not allow tools to cause sparks when working

on a battery

.

4. Do

not use welder to charge batteries or jump

start

vehicles.

5. Observe

correct polarity (+ and –) on batteries.

BATTERY ACID can BURN SKIN.

1. Do

not tip.

2.

Replace damaged battery

.

3.

Flush eyes and skin immediately with water

.

STEAM AND PRESSURIZED HOT

COOLANT can burn face, eyes, and

skin.

1. Check coolant level when

engine is cold to avoid

scalding.

2. If the engine is warm and checking is needed,

follow

steps 3 and 4.

3. Wear

safety glasses and gloves and put a rag over

cap.

4. Turn cap slightly and let pressure escape slowly

before

completely removing cap.

FALLING EQUIPMENT can cause

serious personal injury and equipment

damage.

1. Use equipment of adequate capacity to lift

components.

2. Use

a lifting eye to lift unit only, NOT running gear

,

gas cylinders, or any other accessories.

3.

Securely attach components to lifting

equipment.

The symbols shown below are used throughout this manual to call attention to and identify possible

hazards. When you see the symbol, watch out, and follow the related instructions to avoid the hazard.

Only qualified persons should service, test, maintain, and repair this unit.

During servicing, keep everybody, especially children, away.

WARNING

TM-428 Page 2

Miller Legend

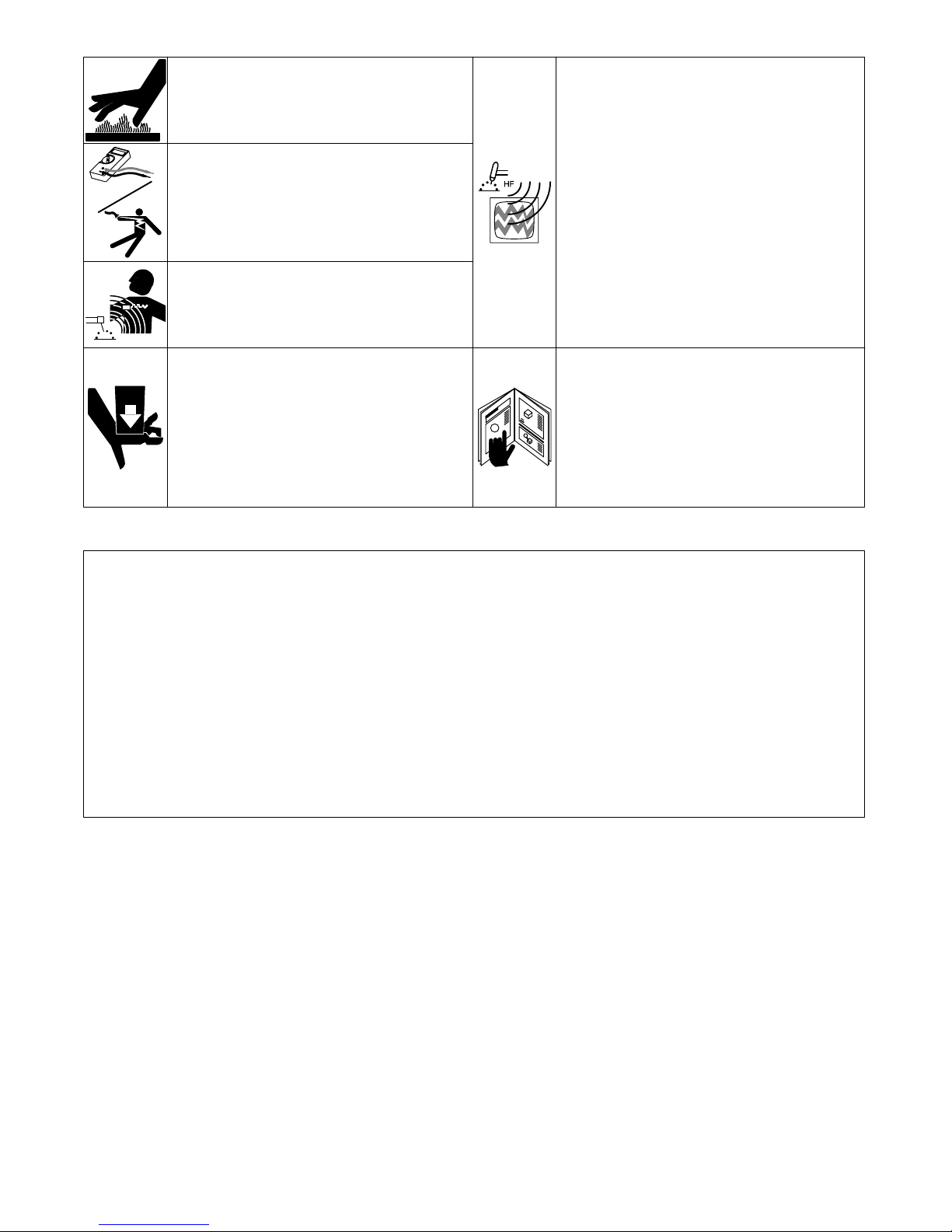

HOT PARTS can cause severe burns.

1. Allow

cooling period before servicing.

2. Wear

protective gloves and clothing when working

on

a hot engine.

ELECTRIC SHOCK HAZARD from

incorrect use of test equipment.

1. Stop engine before making or changing meter

lead

connections.

2. At

least one meter lead should be a self-retaining

spring

clip such as an alligator clamp.

3.

Read instructions for test equipment.

MAGNETIC FIELDS FROM HIGH

CURRENTS can affect pacemaker

operation.

1. Pacemaker wearers keep away from servicing

areas

until consulting your doctor

.

UNCONTROLLED TILTING OR TIPPING

OF UNIT can result in personal injury

and equipment damage.

1. Do

not put any body part under unit while lifting.

2. Use adequate blocks to support components as

needed

during job.

PINCH POINTS can injure.

1. Be careful when working on stator and rotor

assemblies.

HIGH-FREQUENCY RADIATION can

interfere with radio navigation, safety

services, computers, and

communications equipment.

1. Have only qualified persons familiar with

electronic

equipment perform this installation.

2. The user is responsible for having a qualified

electrician promptly correct any interference

problem

resulting from the installation.

3. If notified by the FCC about interference, stop

using

the equipment at once.

4. Have the installation regularly checked and

maintained.

5. Keep high-frequency source doors and panels

tightly shut, keep spark gaps at correct setting,

and use grounding and shielding to minimize the

possibility

of interference.

READ INSTRUCTIONS.

1. Use MILLER Testing Booklet (Part No. 150 853)

when

servicing this unit.

2. Consult the Owner’s Manual for welding safety

precautions.

3. Use

only genuine MILLER replacement parts.

4. Reinstall injectors and bleed air from fuel system

according to engine manual.

1-3. EMF Information

Considerations

About W

elding And The Ef

fects Of Low

Frequency

Electric

And Magnetic Fields

The

following is a quotation from the

General Conclusions Section

of

the U.S. Congress, Of

fice of T

echnology Assessment,

Biological

Effects of Power Frequency Electric & Magnetic Fields –

Background Paper

, OTA-BP-E-53 (Washington, DC: U.S.

Government Printing Office, May 1989): “. . . there is now a very

large volume of scientific findings based on experiments at the

cellular

level and from studies with

animals and people which clearly

establish that low frequency magnetic fields can interact with, and

produce

changes in, biological systems.

While most of this work is of

very high quality, the results are complex. Current scientific

understanding does not yet allow us to interpret the evidence in a

single coherent framework. Even more frustrating, it does not yet

allow us to draw definite conclusions about questions of possible

risk

or to of

fer clear science-based advice on strategies to minimize

or

avoid potential risks.”

To reduce magnetic fields in the workplace, use the following

procedures:

1. Keep

cables close together by twisting or taping them.

2.

Arrange cables to one side and away from the operator

.

3.

Do not coil or drape cables around the body

.

4.

Keep welding power source and cables as far away as

practical.

5.

Connect work clamp to workpiece as close to the weld as

possible.

About Pacemakers:

The above procedures are also recommended for pacemaker

wearers.

Consult your doctor for complete information.

TM-428 Page 3

Miller Legend

SECTION 2 – INSTALLATION

2-1. Installing Welding Generator

install1 10/95 – Ref. ST-800 652 / Ref. ST-800 477-A / ST-158 936-A / S-0854

1

2

Electrically

bond

generator frame to

vehicle frame by metal-to-metal

contact.

GND/PE

3

4

1 Generator Base

2

Metal V

ehicle Frame

3

Equipment Grounding

Terminal

4

Grounding Cable

Use #10 AWG or larger insulated

copper

wire.

Y If unit does not have GFCI

receptacles, use GFCI-protected

extension cord.

2

OR

18 in

(460 mm)

18 in

(460 mm)

18 in

(460 mm)

18 in

(460 mm)

18 in

(460 mm)

OR

Movement Airflow Location

Grounding

OR

Y Do Not Lift Unit From End

2-2. Dimensions, Weights, And Operating Angles

A

Dimensions

A

Height 31-5/8

in (803 mm)

Y Do not exceed operating angles while

running

or engine damage will occur

.

Width 18

in (457 mm)

Y Do

not move or operate unit where it could

tip.

Depth 45

in (1

143 mm)

B

A 16-1/2

in (419 mm)

B 32-3/4

in (832 mm)

25°

C 13/16

in (21 mm) Dia.

25°

°

25°

Weight

25°

C

Net 559

lb (254 kg)

Engine End

Ship 600

lb (272 kg)

TM-428 Page 4

Miller Legend

2-3. Fuel Consumption

SB-115 572

2-4. Engine Prestart Checks

ST-140 091-E / Ref. ST-151 983

Check

all fluids daily

. Engine must

be

cold and on a level surface.

Engine stops if oil pressure gets

too

low

.

1/2 in

(13 mm)

Full

Full

TM-428 Page 5

Miller Legend

2-5. Connecting The Battery

Tools

Needed:

+

–

3/8, 1/2 in

Y

Connect (–) cable last.

Ref. ST-144 839-F / Ref. ST-168 046 / Ref. S-0756-D

2-6. Connecting To Weld Output Terminals

Y Use ONLY one set of termi-

nals at a time. Disconnect

weld

cables from

set of weld

output

terminals not in use.

ST-140 092-B / Ref. ST-168 046

Tools

Needed:

3/4 in

TM-428 Page 6

Miller Legend

2-7. Selecting Weld Cable Sizes

Total Cable (Copper) Length In Weld Circuit Not Exceeding

100 ft (30 m) Or Less

150 ft

(45 m)

200 ft

(60 m)

250 ft

(70 m)

300 ft

(90 m)

350 ft

(105 m)

400 ft

(120 m)

Welding

Amperes

10 – 60%

Duty Cycle

60 – 100%

Duty Cycle

10 – 100% Duty Cycle

100 4 4 4 3 2 1 1/0 1/0

150 3 3 2 1 1/0 2/0 3/0 3/0

200 3 2 1 1/0 2/0 3/0 4/0 4/0

250 2 1 1/0 2/0 3/0 4/0 2-2/0 2-2/0

300 1 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-3/0

350 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-3/0 2-4/0

Weld cable size (A

WG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere.

S-0007-D

2-8. Remote 14 Receptacle RC1 Information

Socket* Socket Information

A Contact

closure to B completes 15 volts dc contactor control

circuit.

B 15 volts dc.

C +4.5

volts dc output to remote control.

AJ

B

K

I

D Remote

control circuit common.

B

C

L

NH

D

M

G

A

E 0

to +4.5 volts dc input command signal from remote control.

ST-140 092-B

E

F

K Chassis

common.

*The remaining sockets are not used.

TM-428 Page 7

Miller Legend

SECTION 3 – OPERATING WELDING GENERATOR

3-1. Front Panel Controls

Ref. ST-168 046

4

2

1 Engine

Control Switch S2

Use switch to start engine, select speed,

and stop engine. In Run/Idle position, engine

runs at power/idle rpm at no load, and

weld/power

rpm under weld or 100 Hz auxil

-

iary

power receptacle load. In Run

position,

engine

runs at weld rpm.

2

Idle Lock Switch S1

Use switch to lock engine at power/idle

speed (see Table). In Unlock position, Engine Control switch and optional Remote

Control

switch determine engine speed.

3

Engine Choke Control

Use control to change engine air-fuel mix.

To Start: pull out choke and turn Engine

Control switch to Start position. Release

switch and slowly push choke in when engine starts. Do not crank engine while flywheel

is turning.

To Stop: turn Engine Control switch to Off

position.

4 Remote

Control Switch S4

Use switch to select front panel or remote

amperage

control (see Section 3-2).

5

Ampere Ranges Switch S5

Use

switch to select weld amperage range.

.

For best arc starts, use lowest amperage

range possible.

6

Fine Amperage Control R1

Use

control to select

weld amperage within

the range selected by the Ampere Ranges

switch.

Control

may be adjusted while weld

-

ing.

Scale is

for reference only

. W

eld output

would be 88 A DC with control settings as

shown

(50% of 70 to 105 A).

7

Engine Hour Meter HM

15

Using Idle Lock Switch

RUN/IDLE

LOCK

UNLOCK

1860 rpm

RUN/IDLE

OR

RUN

LOCKUNLOCK

(Power/Idle)

1860 rpm

(Power/Idle)

No Load:

3000 rpm

Load:

3000 rpm

(Weld)

6 7

3

(Weld)

TM-428 Page 8

Miller Legend

3-2. Remote Control (Optional)

Y Weld output terminals are

energized when Remote

Control switch S4 is in Panel/On

position and engine is

running.

1 Remote

14 Receptacle RC1

Connect

optional remote control

to

RC1

(see Section 2-8).

ST-140 092-B

1

Min (70

A DC)

Max (88

A DC)

Adjust Remote Control

Set Range

Set Percentage

Min = 70

A DC

Percentage Of Range = 50%

Max = 88 A DC (50% of 70 to 105)

In Example:

Set Switch

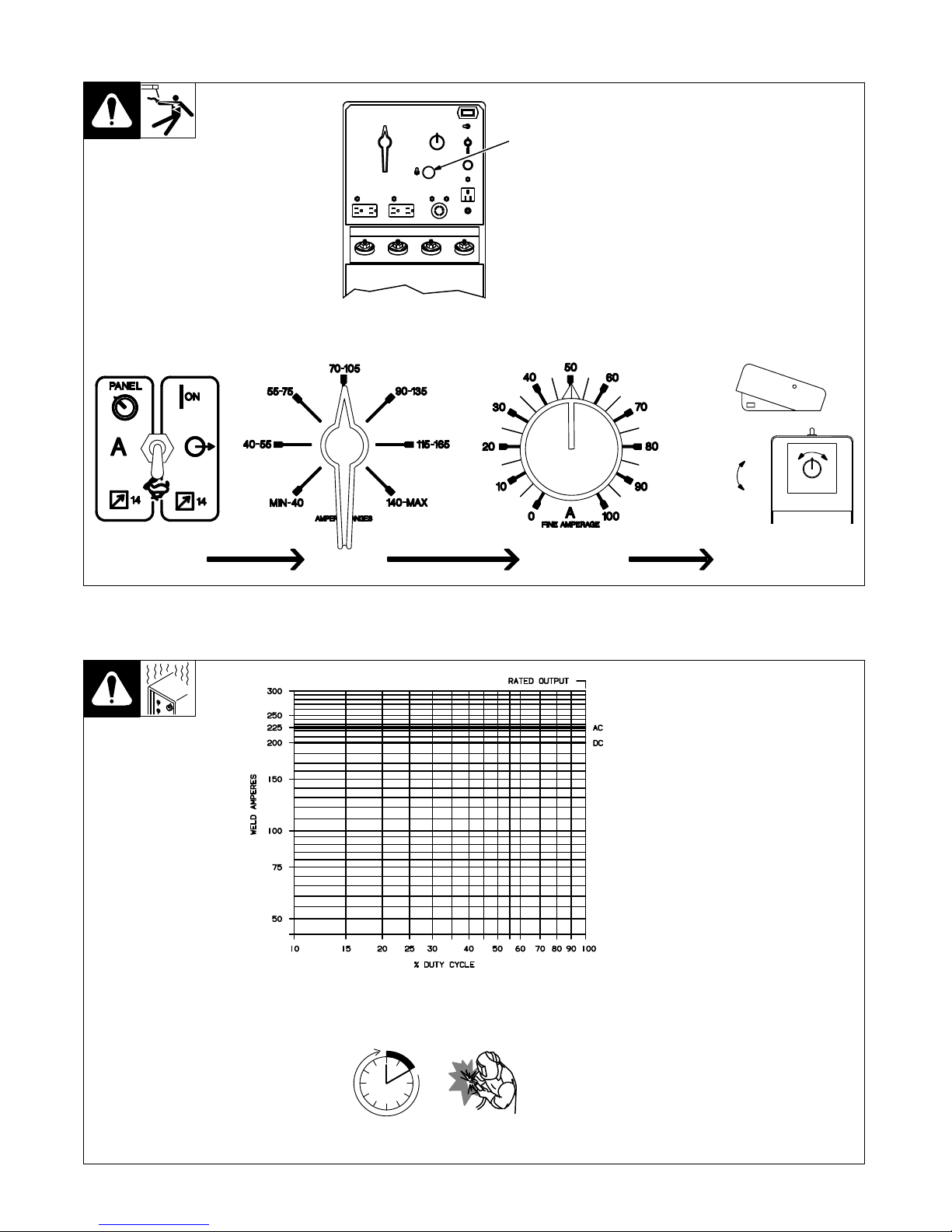

3-3. Duty Cycle

SB-115 570

Duty

cycle is the percentage of 10

minutes

that unit can weld at

rated

load

without overheating.

Y Exceeding duty cycle can

damage unit and void warranty.

Continuous Welding

100% Duty Cycle at 225 Amperes AC

TM-428 Page 9

Miller Legend

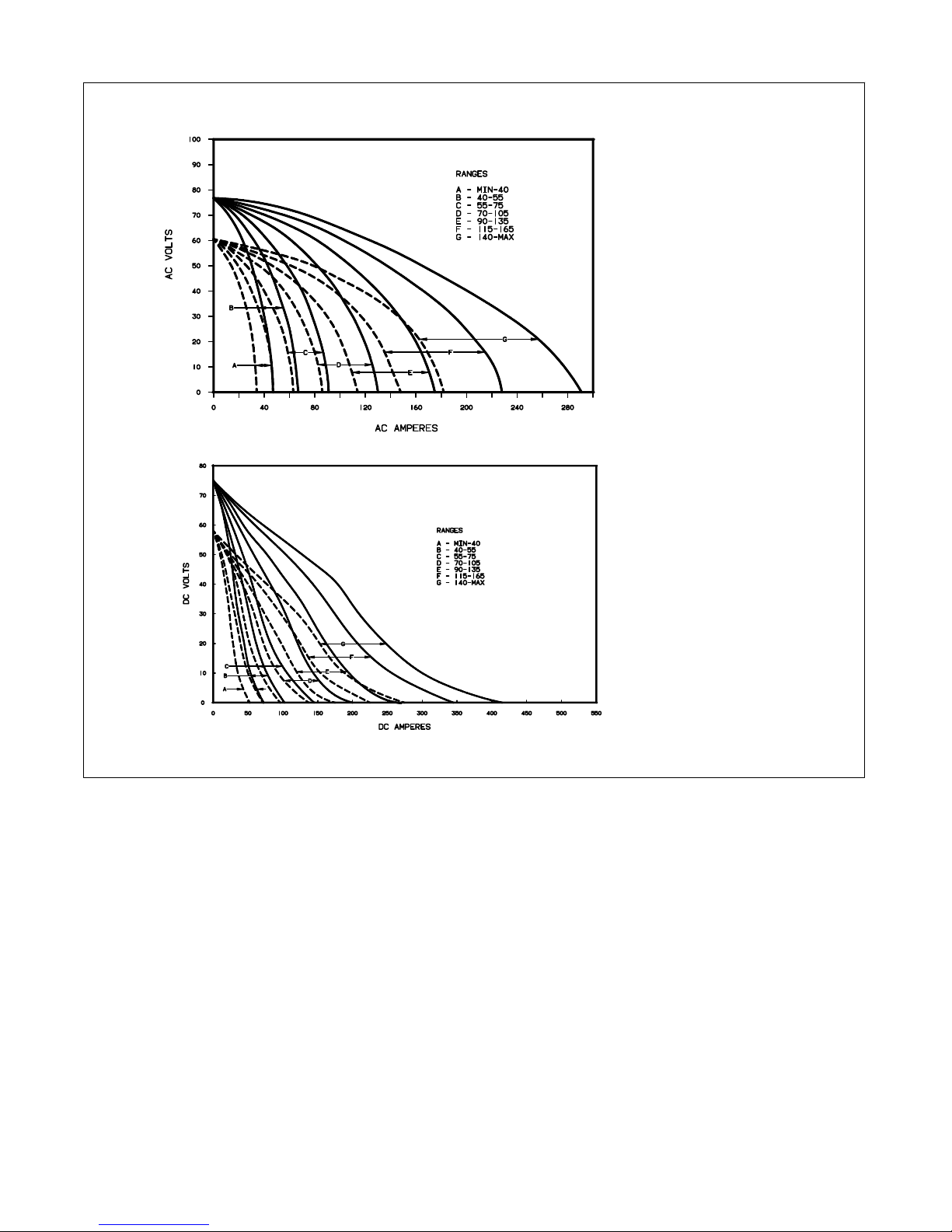

3-4. Volt-Ampere Curves

SB-115 529-A / SB-115 528-A

The volt-ampere curves show the

minimum and maximum voltage

and amperage output capabilities

of

the welding generator

. Curves of

other settings fall between the

curves

shown.

TM-428 Page 10

Miller Legend

SECTION 4 – OPERATING AUXILIARY EQUIPMENT

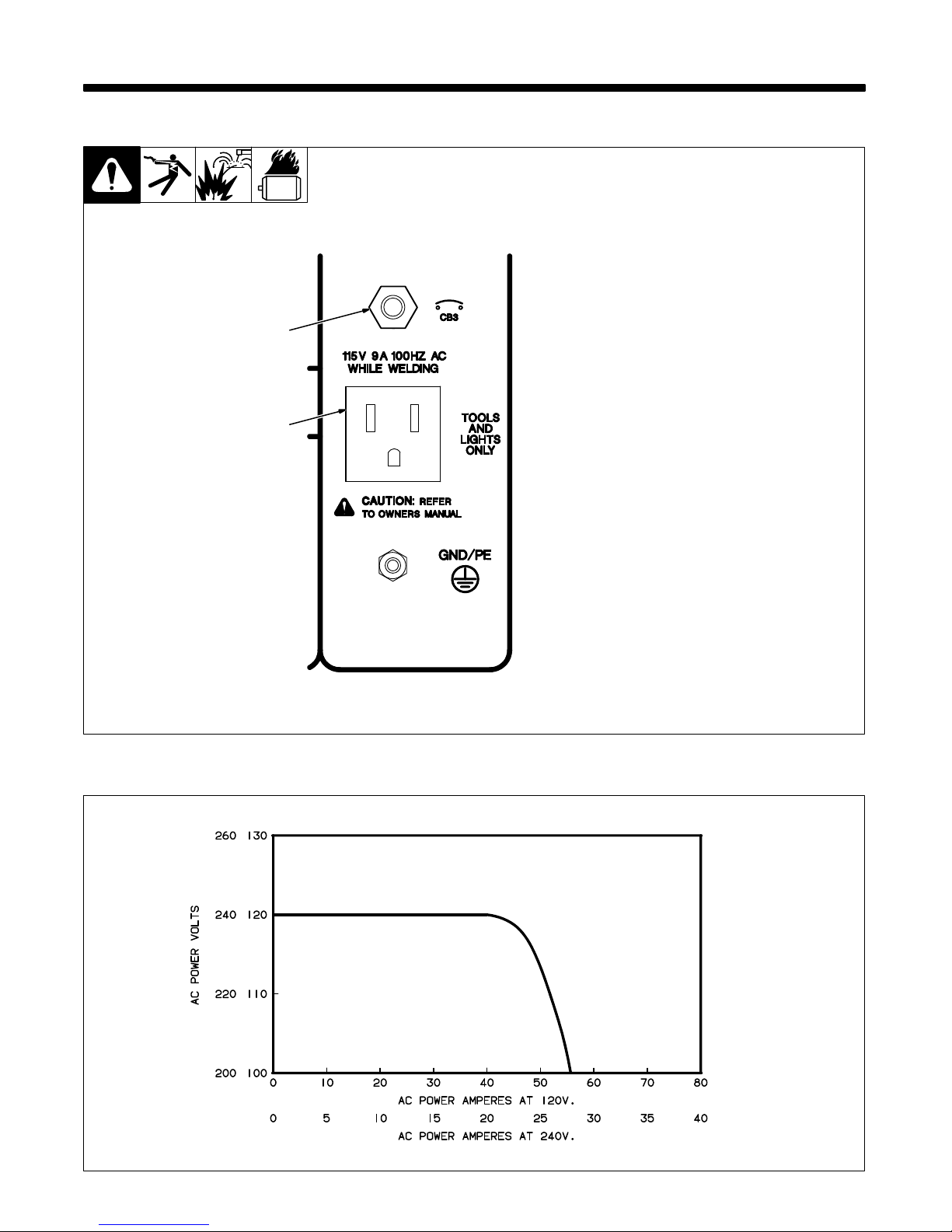

4-1. 100 Hz Auxiliary Power Receptacle And Circuit Breaker

Y Do not operate 50/60 Hz or

60 Hz equipment from 100

Hz

receptacle.

11

15 V 9 A 100 Hz AC Recep

-

tacle RC4

Receptacle supplies single-phase

power at weld speed only. Total

output

available is 1 kV

A/kW.

2 Circuit Breaker CB3

CB3 protects receptacle from

overload.

If CB3 opens, receptacle

does

not work.

2

1

Ref. ST-168 046

4-2. AC Auxiliary Power Curve

SB-115 571

TM-428 Page 1

1

Miller Legend

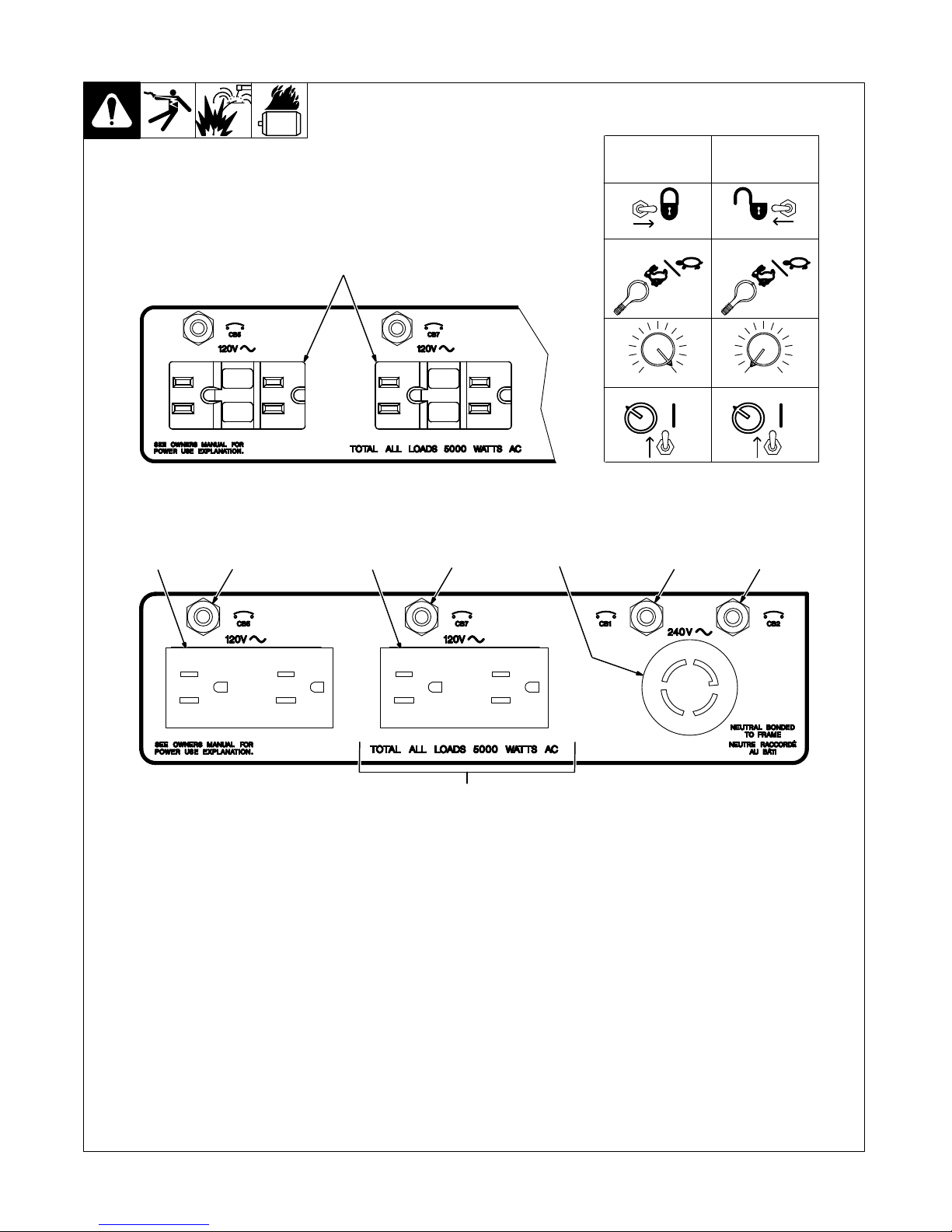

4-3. 60 Hz Auxiliary Power Receptacles And Circuit Breakers

Ref. ST-168 046

5 7812

9

3

4

6

YIf unit does not have GFCI recep-

tacles, use GFCI-protected extension

cord.

1 120

V 15 A AC

Duplex Receptacle RC1

2

120 V 15 A AC Duplex Receptacle RC2

3 240

V 30 A T

wistlock Receptacle RC3

Receptacles supply 60 Hz single-phase

power at power/idle speed only. Maximum

output

from each duplex receptacle

is is 2.5

kVA/kW

. Maximum output from twistlock re

ceptacle is 5 kVA/kW. For 60 Hz auxiliary

power,

set controls as shown in table.

4

120 V 15 A AC Duplex GFCI Recep

-

tacles GFCI1 And GFCI2 (Optional)

If a ground fault is detected, the GFCI recep

-

tacle Reset button pops out and the circuit

opens to disconnect the faulty equipment.

Check

for damaged tools, cords, plugs, etc.

connected

to the receptacle. Press button to

reset

receptacle and resume operation.

.

At least once a month, run engine at

power/idle

speed and press T

est

button

to verify GFCI is working properly.

5 Circuit Breaker CB5

6 Circuit Breaker CB7

CB5 protects RC1 and CB7 protects RC2

from

overload. If CB5 or CB7 opens, the re

ceptacle does not work. Press button to reset

breaker

.

7 Circuit Breaker CB1

8 Circuit Breaker CB2

CB1 and CB2 protect all the 60 Hz recep-

tacles from overload. If CB1 or CB2 opens,

the 240 volt receptacle and one of the 120

volt receptacles does not work. 120 volts

may still be present at the 240 volt receptacle.

Press button to reset breaker

.

9T

otal Auxiliary Power Output

Combined output of receptacles limited to

the 5 kV

A/kW output of the generator:

EXAMPLE:

If 10 A is drawn from a 120 V du

-

plex

receptacle, only 16 A is available at the

240

V receptacle:

(120

V x 10 A) + (240 V x 16 A) = 5.0 kV

A/kW

PANEL

ON

0 100

LOCK UNLOCK

RUN/IDLE RUN/IDLE

PANEL

ON

0 100

For 60 Hz

Auxiliary Power

While W

elding

For 60 Hz

Auxiliary

Power Only

TM-428 Page 12

Miller Legend

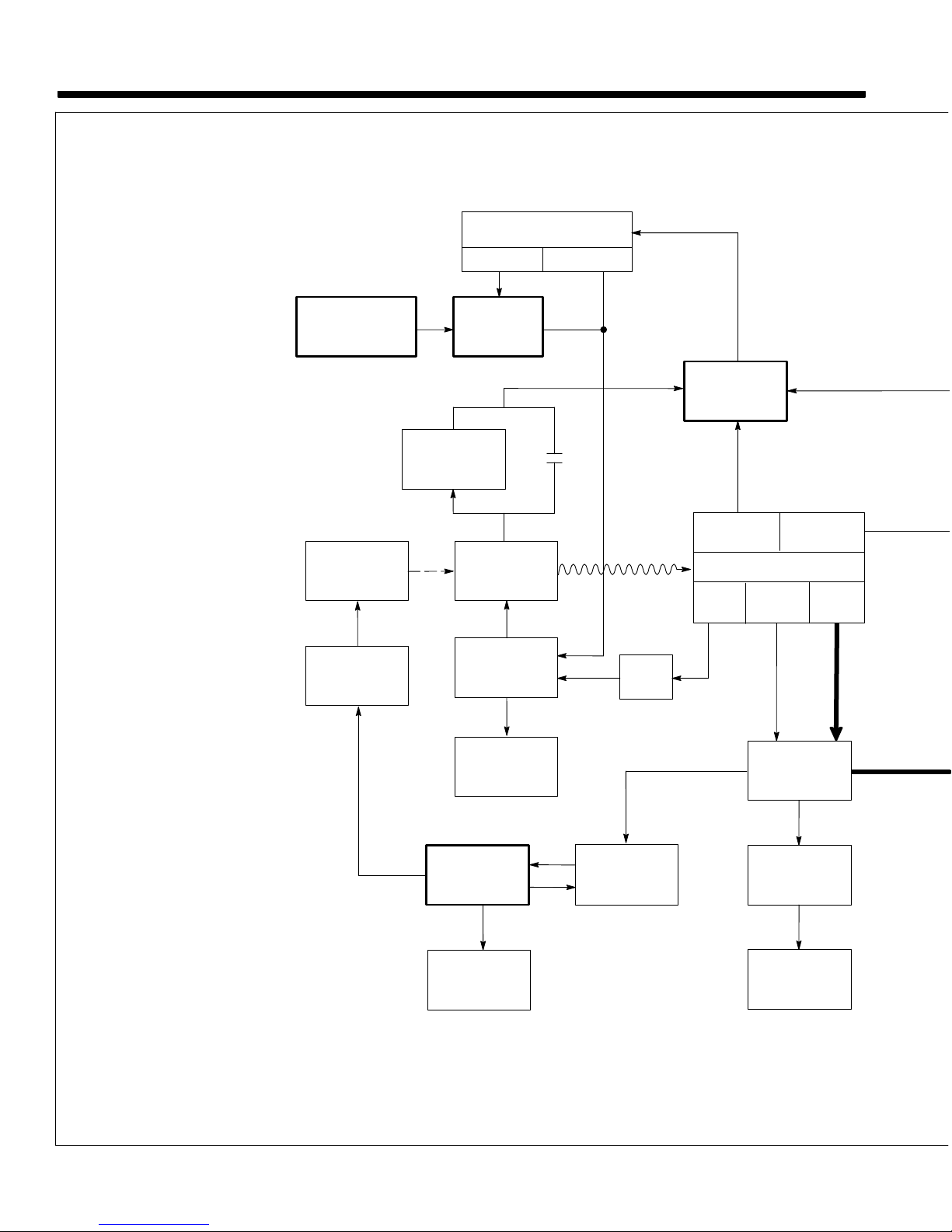

1 Engine

Supplies force to turn revolving

fields.

2 Revolving

Fields (Rotor)

Turn

at 1860 rpm maximum for pow

er/idle and 3000 rpm maximum for

weld.

The speed and excitation cur

rent of the field coils determine volt

ages in stator windings.

3

Stator Windings

Supply power to exciter, auxiliary

power,

and weld circuits.

4

Fuse F1

Protects exciter excitation winding

from

overload.

5

Integrated Rectifier SR2

Changes ac output of stator windings

to dc to supply excitation current

to

the exciter revolving field.

6

Control Relay CR5

Energizes

when voltage is present in

exciter stator to disconnect field

flashing circuit.

7

Idle Module PC1 And Idle Lock

Switch S1

PC1 and S1 control engine speed.

Without

a signal from CT1, PC1 low

-

ers engine speed to power/idle rpm.

8 Throttle

Solenoid TS1

Increases

engine speed to weld rpm

when

energized.

9

Current T

ransformer CT1

Senses output from either weld or

100 Hz auxiliary power windings,

and signals PC1 to increase to or

maintain

weld rpm.

10 Control Relays CR2, CR3, CR4

CR2

energizes at weld rpm to supply

power

to throttle solenoid TS1.

CR3 energizes at power/idle rpm to

bypass

fine amperage control R1.

CR4 energizes at power/idle rpm to

provide 50/60 Hz auxiliary power

output.

11 Voltage

Regulator Board PC2

And T

ransformer T1

PC2 monitors 50/60 Hz auxiliary

power

voltage through T1, and main

-

tains

proper output by adjusting

field

current.

12 Capacitor

Board PC5, Remote

14 Receptacle RC1, Remote

Control Board PC3

PC5

protects unit from high frequen

-

cy.

RC1

connects remote amperage

and contactor control to unit through

control

board PC3.

SECTION 5 – THEORY OF OPERATION

Voltage

Regulator

Board PC2

Current

Transformer

CT1

Circuit

Breaker

CB3

100 Hz

Auxiliary Power

Receptacle RC4

Fuse

F1

Integrated

Rectifier SR2

Revolving

Fields (Rotor)

Fine

Amperage

Control R1

Remote Control

Switch S4

Remote 14

Panel

Remote

Control Board

PC3

Capacitor Board

PC5

And Remote 14

Receptacle RC1

Engine

Idle Module

Control Relays

CR2, CR3, CR4

Idle Lock

Switch S1

12

1

7

10

5

7

16

17

♦

13

♦

12

♦

4

11

9

18

2

PC1

CR3

Throttle

8

Solenoid

TS1

Control

Relay

6

CR5

♦

Voltage

Regulator

60 Hz Auxiliary

Power

Exciter

Stator Windings

3

Weld

100 Hz

Auxiliary

Power

TM-428 Page 13

Miller Legend

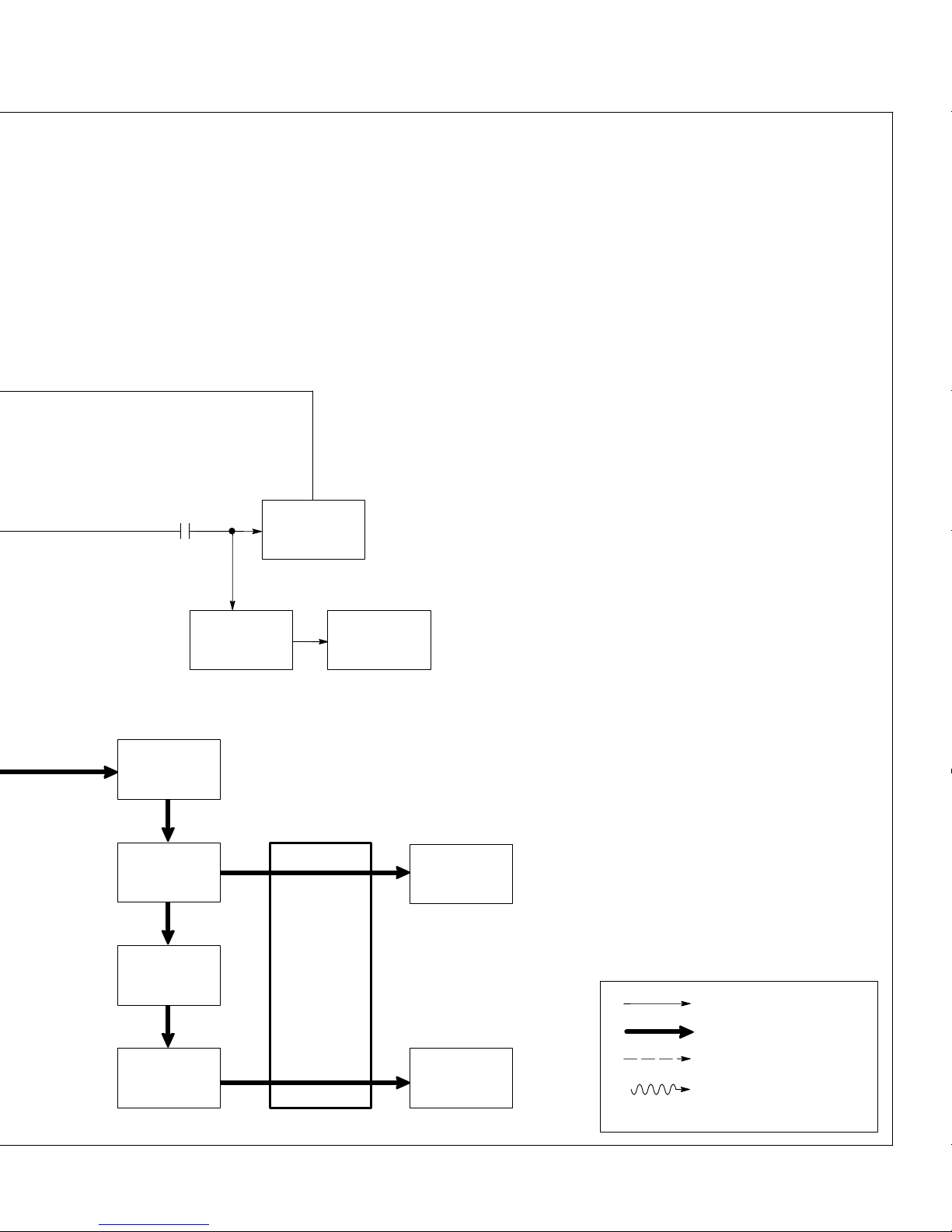

13

Remote Control Switch S4

Selects

Panel or remote

amperage

control.

14 Circuit Breakers CB1, CB2,

CB5, And CB7

Protect 50/60 Hz auxiliary power

receptacles RC1, RC2, and RC3

from

overload.

15

50/60 Hz Auxiliary Power Re

ceptacles RC1, RC2, And

RC3

Provide connection points and

power

for auxiliary equipment.

16 Circuit Breaker CB3

Protects

100 Hz auxiliary power

re

-

ceptacle

RC4 from overload.

17 100 Hz Auxiliary Power Re-

ceptacle RC4

Provides connection point and

power for auxiliary equipment

while

welding.

18

Fine Amperage Control R1

Adjusts

amperage

within range se

lected by Ampere Ranges switch

S5.

19 Ampere

Ranges Switch S5

Selects coarse range of weld output

from weld stator

.

20 Reactor AC-Z

Tapped reactor limits weld output

and

provides coarse ranges.

21

Main Rectifier SR1

Changes ac output from weld

windings

to dc.

22

Stabilizer DC-Z

Smooths out current to dc weld

output

terminals.

23

HF Filter Board PC4

Protects unit from high frequency

.

24

Positive (+) And Negative (–)

DC W

eld Output T

erminals

Provide dc weld output.

25

Electrode And W

ork AC Weld

Output T

erminals

Provide ac weld output.

Stabilizer

Main

Rectifier

SR1

Ampere

Ranges

Switch S5

Reactor

AC-Z

DC-Z

HF Filter

Board

PC4

Positive (+)

And

Negative (–) DC

W

eld Output

Terminals

Transformer

T1

Circuit

Breakers

CB1, CB2,

50/60 Hz

Auxiliary Power

Receptacles

RC1, RC2, RC3

19

20

21

22

11

14 15

23

25

24

Electrode

And

Work AC Weld

Output

T erminals

AC Or DC Control Circuits

Mechanical Coupling

W

eld Current Circuit

Magnetic Coupling

♦ Optional

CR4

CB5, CB7

TM-428 Page 14

Miller Legend

NOTES

TM-428 Page 15

Miller Legend

SECTION 6 – TROUBLESHOOTING

6-1. Troubleshooting Tables

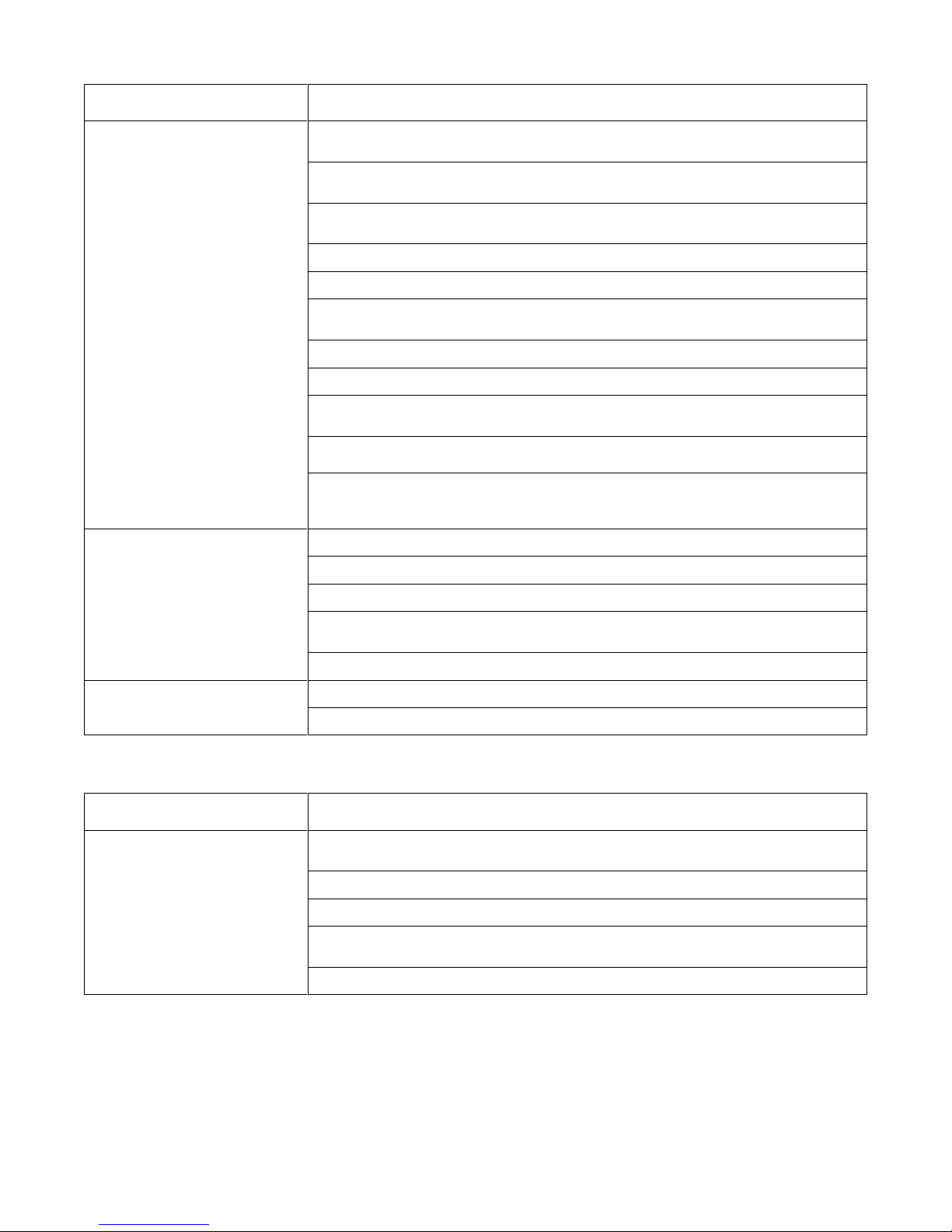

A. Welding

.

See Sections 6-2 and 6-3 for test

points and values and Section 10

for

parts location.

Trouble Remedy

No weld output.

Check fuse F1, and replace if necessary (see Section 8-6).

Check integrated rectifier SR2, and replace if necessary

.

Check diode D4, and replace if necessary

.

Clean slip rings, and install new brushes if necessary (see Section 6-15).

Disconnect leads 21, 23, and 33 from brushes, and check continuity across slip rings. Replace rotor

if necessary.

Check resistance and connections of resistors R2 and R4; R2 and R4 are each 12 ohms

±10%.

Re

-

place resistor(s) if necessary

. Adjust R2 and R4 according to Section 6-16.

Check

resistance and connections of Fine Amperage Control

R1; R1 is 0 to 30 ohms ±10%. Replace

R1

if necessary (see Section 3-1).

Disconnect

leads 22 and 29 from SCR/integrated rectifier SR2, and check for continuity between leads

22

and 29. Replace exciter stator if necessary

.

For

units with optional remote control, check capacitor C5 for a short or open, and check for proper con

-

nections. Replace C5 if necessary.

Check voltage regulator board PC2 and connections, and replace if necessary (see Section 6-9).

No or erratic weld output.

Clean and tighten weld connections both inside and outside unit.

Check engine speed, and adjust if necessary (see Section 8-5).

Check

to make sure Ampere Ranges switch S5 is not between positions. Check continuity of S5, and

replace if necessary.

Check

reactor AC-Z for signs of winding failure. Check continuity across windings, and check for proper

connections. Replace AC-Z if necessary.

Check

resistance and connections of Fine Amperage control R1; R1 is 0 to 30 ohms ± 10%. Replace

R1 if necessary.

Disconnect leads 21, 23, and 33 from brushes, and check continuity across slip rings. Replace rotor

if necessary.

No or erratic DC weld output only

.

Check modular main rectifier SR1, and replace if necessary

.

Check stabilizer DC-Z for signs of winding failure. Check continuity across windings, and check for

proper connections. Replace DC-Z if necessary.

Low or high weld output.

Check engine speed, and adjust if necessary (see Section 8-5).

Adjust resistor R4 slider until 128 to 132 volts ac is obtained at 100 Hz receptacle RC4 (see Section

6-16).

Adjust

resistor R2 slider until proper open-circuit-voltage is obtained at

weld output terminals (see Sec

-

tion

6-16).

Check

resistance

and connections of resistor R3 on suppressor R3, VR1 module; R3 is 1000 ohms

±

10%.

Replace R3, VR1 module if necessary

.

Check

reactor AC-Z for signs of winding failure. Check continuity across windings, and check for proper

connections. Replace AC-Z if necessary.

TM-428 Page 16

Miller Legend

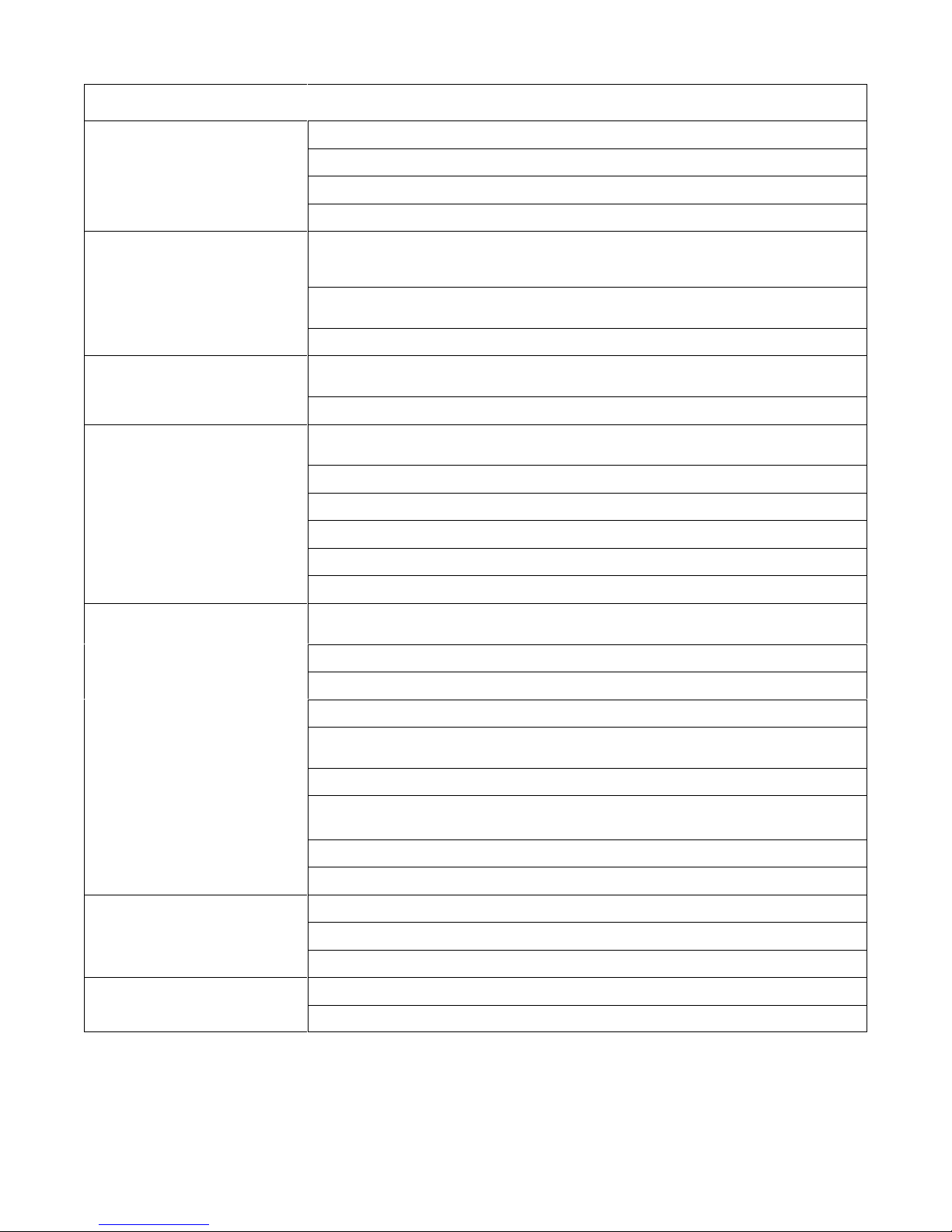

B. 50 Or 60 Hz Auxiliary Power

Trouble Remedy

No auxiliary power output at receptacles RC1, RC2, or RC3.

Run engine at power/idle speed.

Reset circuit breakers CB1 and CB2. Effective with Serial No. KE629034, also reset circuit breakers

CB5

and CB7 (see Section 4-3).

Check

receptacles RC1, RC2, RC3 for continuity and proper connections. Replace receptacle(s) if nec

-

essary.

Check

connections to terminal strip 1T

.

Clean slip rings, and install new brushes if necessary (see Section 6-15).

Check

coil voltage and connections of control relay CR4. Check continuity of coil and condition of

con

-

tacts. Replace CR4 if necessary.

Check diode D4, and replace if necessary

.

Check idle board/module PC1 and connections (see Section 6-5).

Check

control transformer T1 for signs of winding failure. Check continuity across windings, and check

for

proper connections. Check primary and secondary voltages. Replace T1 if necessary

.

Disconnect leads 21, 23, and 33 from brushes, and check continuity across slip rings. Replace rotor

if necessary.

Disconnect

leads 48 and 49

from voltage regulator board PC2, and check continuity between leads 48

and

49. Disconnect leads 50, 51, 52, and 53 from stator

. Check continuity between leads 50 and 51,

and 52 and 53. Replace stator if necessary

.

Low auxiliary power output.

Check connections to terminal strip 1T

.

Clean slip rings, and install new brushes if necessary (see Section 6-15).

Check integrated rectifier SR2, and replace if necessary

.

Check

coil voltage and connections of control relay CR3. Check continuity of coil and condition of

con

-

tacts. Replace CR3 if necessary.

Check voltage regulator board PC2 and connections, and replace if necessary

.

High auxiliary power output.

Check engine speed, and adjust if necessary

.

Check voltage regulator board PC2 and connections, and replace if necessary (see Section 6-9).

C. 100 Hz Auxiliary Power

Trouble Remedy

No

auxiliary power output at receptacle

RC4.

Run

engine at weld speed.

Reset circuit breaker CB3 (see Section 4-1).

Check receptacle RC4 for continuity and proper connections. Replace receptacle if necessary

.

Disconnect

leads 90, 91, 92, and 93 from stator

. Check continuity between leads 90 and 91, and 92 and

93. Replace stator if necessary.

Check diode D4, and replace if necessary

.

TM-428 Page 17

Miller Legend

D. Engine

Trouble Remedy

Engine will not start.

Check fuel level (see Section 2-4).

Check battery and engine charging system according to engine manual.

Check continuity of Engine Control switch S2, and replace if necessary

.

See engine manual.

Engine starts but

stops as soon as En

gine Control switch S2 returns to Run

position.

Check

oil

level (see Section 2-4). Check low oil pressure shutdown switch S3 (see engine parts manual

for

location). S3 should close when engine is running.

Check

and refill crankcase with proper

viscosity oil for operating temperature, if necessary (see engine

manual).

Check

continuity of Engine Control switch S2, and replace if necessary

.

Engine stopped during normal operation.

Check

oil

level (see Section 2-4). Check low oil pressure shutdown switch S3 (see engine parts manual

for

location). S3 should close when engine is running.

Check continuity of Engine Control switch S2, and replace if necessary

.

Battery discharges between uses.

Make

sure Engine Control switch

S2 is placed in the Of

f position when engine is not in use (see Section

3-1).

Prior

to Serial No. KA780044, check fuse F2 and replace if necessary

.

Clean battery, terminals and posts with baking soda solution; rinse with clear water

.

Periodically recharge battery (approximately every 3 months).

Check voltage regulator according to engine manual.

Replace battery

.

Engine idles, but does not come up to

weld

speed.

W

ait 10 seconds for throttle solenoid circuit breaker CB4 to reset (see Section 8-6).

Place Idle Lock switch S1 in Unlock position (see Section 3-1).

Check continuity and connections of current transformer CT1, and replace if necessary

.

Check continuity of Engine Control switch S2, and replace if necessary

.

Check

coil voltage and connections of control relay CR2. Check continuity of coil and condition of

con

-

tacts. Replace CR2 if necessary.

Check diode D6 in throttle solenoid TS1 circuit, and replace if necessary

.

Check resistance at throttle solenoid TS1 terminals. With plunger out, resistance is less than 1 ohm.

With plunger bottomed, resistance is 17 ohms

±10%.

Check throttle linkage for smooth, non-binding operation.

Check idle board/module PC1 and connections, and replace if necessary (see Section 6-5).

Engine does not return to idle speed.

Remove weld load.

Check continuity of Engine Control switch S2, and replace if necessary

.

Check throttle linkage for smooth, non-binding operation.

Unstable or sluggish engine speeds.

Readjust throttle linkage if necessary

.

T

une-up engine according to engine manual.

Loading...

Loading...