Page 1

OM-530J May 1993

Eff. w/Serial Number KC237900

Processes

TIG (GTAW) Welding

Stick (SMAW) Welding

Descriptio n

Enables Welding Power Source to

provide TIG as well as Stick capability

TIG-RIG (Basic) Models And Models With

Optional Pulser And Electroslope

Shielded Metal Arc

(Stick) Welding

Automatic Welding

Page 2

From Miller to You

Thank you and congratulations on choosing Miller. Now

you can get the job done and get it done right. We know

you don’t have time to do it any other way.

That’s why when Niels Miller first started building arc

welders in 1929, he made sure his products offered

long-lasting value and superior quality. Like you, his

customers couldn’t afford anything less. Miller products

had to be more than the best they could be. They had to

be the best you could buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and service

that meets the high standards of quality and value established in 1929.

This Owner’s Manual is designed to help you get the most out of your

Miller products. Please take time to read the Safety precautions. They will

help you protect yourself against potential hazards on the worksite. We’ve

made installation and operation quick and easy.

With Miller you can count on years of reliable

service with proper maintenance. And if for

some reason the unit needs repair, there’s a

Troubleshooting section that will help you

Miller is the first welding

equipment manufacturer in

the U.S.A. to be registered to

the ISO 9001 Quality System

Standard.

Miller Electric manufactures a full line

of welders and welding related equipment.

For information on other quality Miller

products, contact your local Miller distributor

to receive the latest full line catalog or

individual catalog sheets. To locate your nearest

distributor or service agency call 1-800-4-A-Miller,

or visit us at www.MillerWelds.com on the web.

figure out what the problem is. The parts list

will then help you to decide which exact part

you may need to fix the problem. Warranty and

service information for your particular model

are also provided.

Working as hard as you do

– every power source from

Miller is backed by the most

hassle-free warranty in the

business.

Miller offers a Technical

Manual which provides

more detailed service and

parts information for your

unit. T o obtain a Technical

Manual, contact your local

distributor. Your distributor

can also supply you with

Welding Process Manuals

such as SMAW, GTAW,

GMAW, and GMA W-P.

Page 3

TABLE OF CONTENTS

SECTION 1 – SAFETY PRECAUTIONS AND SIGNAL WORDS

1-1. General Information And Safety 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. Safety Alert Symbol And Signal Words 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – SPECIFICATIONS

2-1. Description 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – INSTALLATION OR RELOCATION

3-1. Site Selection 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. Transporting Methods 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. Component Installation On Factory Installed Units 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4. Field Installation Of TIG-Unit 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5. Field Installation Of Pulser 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6. Field Installation Of Electroslope 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7. Procedure For Remote TIG-Unit Installation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8. Field Installation Of Optional Preflow Timer 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9. Field Installation Of Optional Spot Timer 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10. Remote 14 Receptacle Information And Connections 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11. Gas Connections 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-12. Coolant Connections (Optional) 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-13. 115 Volts AC Duplex Receptacle And Circuit Breaker 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 – OPERATOR CONTROLS

4-1. Amperage Adjustment Control And Remote Amperage Switch 12. . . . . . . . . . . . . . . . . . . . . . .

4-2. Polarity Switch 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3. Gas/Coolant Switch 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4. Gas/Coolant Postflow Control 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5. Remote Hand Controls 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6. High Frequency Switch 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7. High Frequency Control 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8. Meters (Optional) 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9. Pulser Switch (Pulser Models Only) 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10. % “On Time” Control (Pulser Models Only) 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-11. Pulses/Second Control (Pulser Models Only) 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-12. Background Control (Pulser Models Only) 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-13. Electroslope (Electroslope Models Only) 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-14. Electroslope Switch (Electroslope Models Only) 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-15. Percentage Initial Amperage Control (Electroslope Models Only) 16. . . . . . . . . . . . . . . . . . . . .

4-16. Percentage Upslope Rate Control (Electroslope Models Only) 16. . . . . . . . . . . . . . . . . . . . . . .

4-17. Percentage Downslope Rate Control (Electroslope Models Only) 17. . . . . . . . . . . . . . . . . . . . .

4-18. Percentage Final Amperage Control (Electroslope Models Only) 17. . . . . . . . . . . . . . . . . . . . .

4-19. Preflow Time Control & Switch (Optional) 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-20. Spot Time Control And Switch (Optional) 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 – SEQUENCE OF OPERATION

5-1. Gas Tungsten Arc Welding 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2. Shielded Metal Arc Welding With TIG-Unit 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3. Shutting Down 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – MAINTENANCE & TROUBLESHOOTING

6-1. Routine Maintenance 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2. Tungsten Electrode 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3. Spark Gap Adjustment 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4. Overload Protection 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5. Circuit Board Handling Precautions 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6. Troubleshooting 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OM-530J - 5/93

Page 4

SECTION 7 – ELECTRICAL DIAGRAMS

Diagram 7-1. Circuit Diagram For TIG-Unit With Options 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 7-2. Circuit Diagram For Postflow Timer 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 7-3. Circuit Diagram For Pulser (Optional) 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 7-4. Circuit Diagram For Electroslope (Optional) 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 7-5. Circuit Diagram For Preflow Timer (Optional) 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 7-6. Circuit Diagram For Spot Timer (Optional) 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8 – CERTIFICATION FOR HIGH FREQUENCY ARC WELDING EQUIPMENT

8-1. General 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2. Definitions 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3. High-Frequency Radiation 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-4. Location 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5. General Installation Procedures 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-6. Guidelines For Installation Of High-Frequency Assisted Arc Welding Power Sources 31. . . .

8-7. Installation Guidelines Checklist 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9 – PARTS LIST

Figure 9-1. Main Assembly 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-2. Panel, Control Rear w/Components 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-3. HF Panel 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-4. Panel, Front w/Components 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-5. Switch, Polarity (300 & 400A Models) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-6. Pulser (Optional) 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-7. Electroslope 9 (Optional) 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-8. Switch, Polarity (500 & 600A Models) 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-9. Panel, Control Front w/Components 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Equipment 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF CHARTS AND TABLES

Table 2-1. Specifications 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-1. Maintenance Schedule 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-2. Tungsten Size Chart 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-3. Troubleshooting 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

SECTION 1 – SAFETY PRECAUTIONS AND SIGNAL WORDS

1-1. GENERAL INFORMATION AND SAFETY

A . General

Information presented in this manual and on various labels, tags, and plates on the unit pertains to equipment

design, installation, operation, maintenance, and

troubleshooting which should be read, understood, and

followed for the safe and ef fective use of this equipment.

The nameplate of this unit uses international symbols

for labeling the front panel controls. The symbols also

appear at the appropriate section in the text.

B . Safety

The installation, operation, maintenance, and troubleshooting of arc welding equipment requires practices

and procedures which ensure personal safety and the

safety of others. Therefore, this equipment is to be installed, operated, and maintained only by qualified persons in accordance with this manual and all applicable

codes such as, but not limited to those listed in the Arc

Welding Safety Precautions in the welding power

source Owner’s Manual.

SECTION 2 – SPECIFICATIONS

1-2. SAFETY ALERT SYMBOL AND SIGNAL

WORDS

The following safety alert symbol and signal words are

used throughout this manual to call attention to and

identify different levels of hazard and special instructions.

This safety alert symbol is used with the signal

words WARNING and CAUTION to call attention to the safety statements.

WARNING statements identify procedures or

practices which must be followed to avoid serious personal injury or loss of life.

CAUTION statements identify procedures or

practices which must be followed to avoid minor

personal injury or damage to this equipment.

IMPORTANT statements identify special instructions

necessary for the most efficient operation of this equipment.

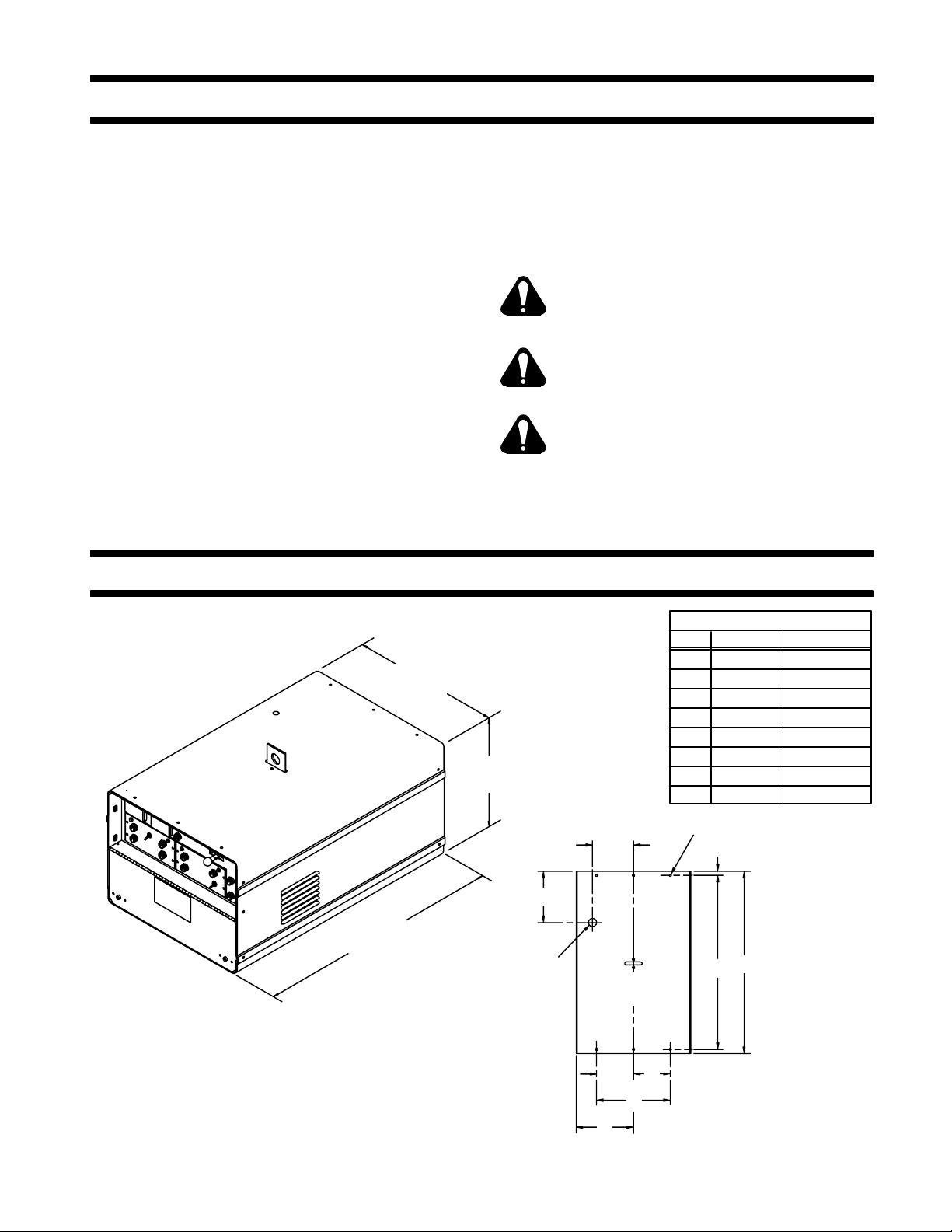

22-1/4 in.

(565 mm)

35-3/4 in.

(908 mm)

*Add 2-5/8 in. (67mm) For Lifting Eye

16-1/2 in.*

(419 mm)

3/4 in. (19.0 mm)

Dia. (1 Hole)

B

A

5/8 in. (15.9 mm)

Dia. (2 Holes)

F

Mounting Hole Dimensions

Inches Millimeters

A

B

C

D

E

F

G

H

9/32 in. (7.1 mm) Dia. (6 Holes)

C

E

10

8-1/8

1

35-3/4

33-3/4

7-1/2

15

11-1/8

D

254.0

206.4

25.4

908.1

857.3

190.5

381.0

282.6

G

H

Figure 2-1. Overall Dimensions And Mounting Hole Layout

ST-059 587-A

OM-530 Page 1

Page 6

Model

TIG-Unit

TIG-Unit 56

Table 2-1. Specifications

Rated

Amperes

400

600

Rated

Duty Cycle

60%

60%

SECTION 3 – INSTALLATION OR RELOCATION

Weight

175 lbs.

(79.4 kg)

183 lbs.

(83.9 kg)

2-1. DESCRIPTION

The TIG-Unit is an accessory package which enables

the solid-state welding power source to provide Gas

Tungsten Arc (GTAW) as well as Shielded Metal Arc

Welding (SMA W) capability. This unit has high frequency, polarity switch, gas and water valves, postflow timer,

and 115 volts ac auxiliary power as standard, with meters, electroslope, pulser, preflow timer, and spot timer

as options.

IMPORTANT: Read entire Section 8 on equipment that

produces output in the radio frequency range, such as

high-frequency starters, for site selection information

and installation requirements before beginning the installation procedures.

3-1. SITE SELECTION

Even though the TIG-Unit is an accessory package providing Gas Tungsten Arc W elding (GTAW) capability for

the solid-state welding power source, it is recommended that certain practices and procedures be followed to aid long life and efficient operation.

The TIG-Unit for 300 and 400 ampere welding power

sources is convection-cooled. It does not have or need a

fan to aide the cooling process. The TIG-Unit for 500

and 600 ampere welding power sources is fan-cooled.

However, it is recommended that a suitable location be

chosen to provide adequate airflow, not only for the

welding power source, but for the TIG-Unit as well. See

welding power source Owner’s Manual for proper installation site information.

WARNING: RESTRICTED AIRFLOW can

cause overheating and possible damage to

internal parts.

• Maintain at least 18 inches (457 mm) of

unrestricted space on all sides of unit, and keep

underside free of obstructions.

• Do not place any filtering device over the in-

take air passages that provide airflow for cooling

this unit.

Warranty is void if any type of filtering device is

used at intake air passages.

FALLING EQUIPMENT can cause serious

personal injury and equipment damage.

• Use lifting eye to lift unit only, NOT running

gear, gas cylinders, or any other heavy

accessories or devices.

• Use equipment of adequate capacity to lift

the unit.

• If lifting or moving this unit with lift forks under

the base, be sure that lift forks are long enough

to extend beyond opposite side of the base.

Using lift forks too short can damage internal

parts if tips of the lift forks penetrate the unit

base, or may cause personal injury and/or

equipment damage if unit falls off the lift forks.

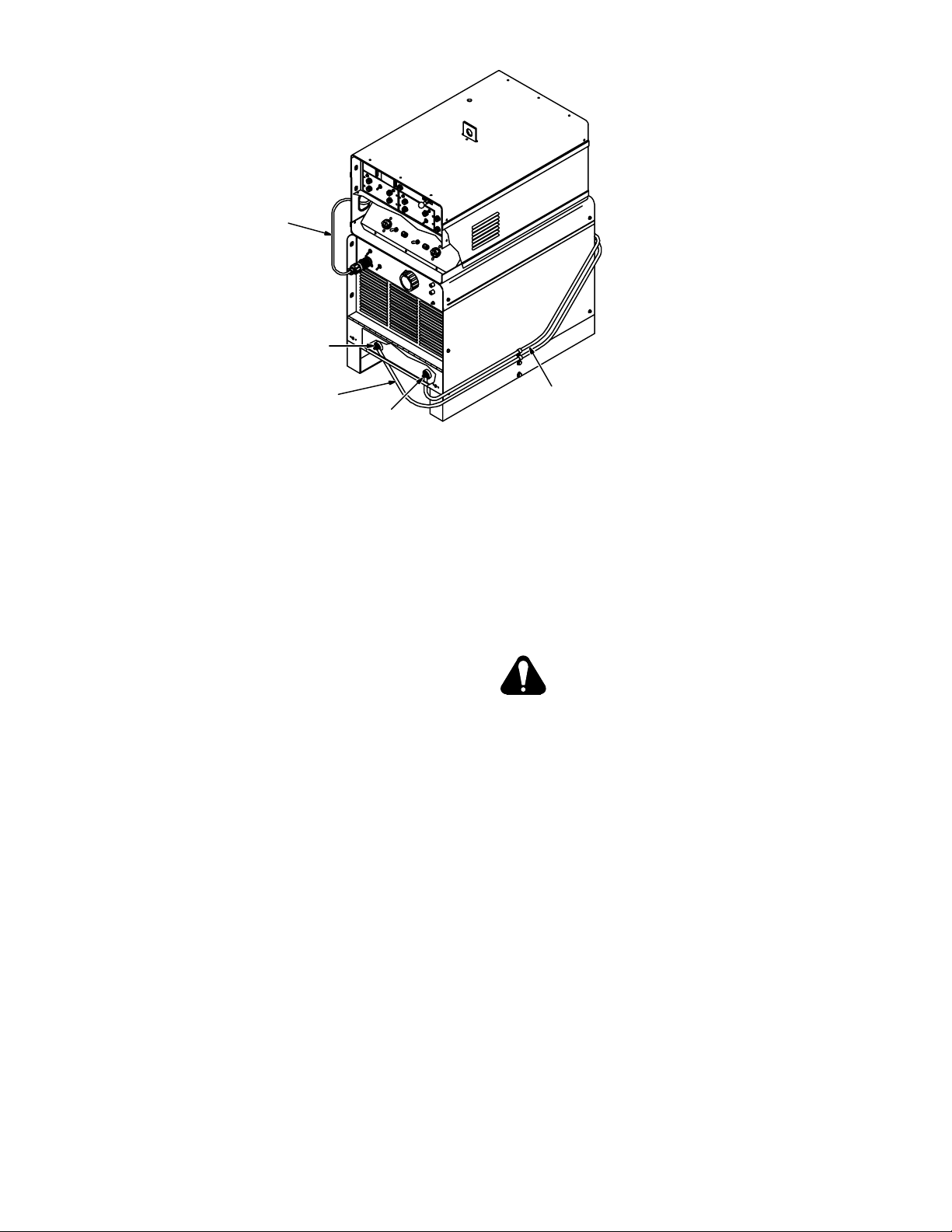

3-3. COMPONENT INSTALLATION ON FACTORY

INSTALLED UNITS (Figure 3-1)

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Shut down welding power source, and dis-

connect input power employing lockout/tagging

procedures before inspecting or installing.

Lockout/tagging procedures consist of padlocking line disconnect switch in open position,

removing fuses from fuse box, or shutting off

and red-tagging circuit breaker or other disconnecting device.

IMPORTANT: Read entire Section 8 on equipment that

produces output in the radio frequency range, such as

high-frequency starters, for site selection information

and installation requirements before beginning the installation procedures.

3-2. TRANSPORTING METHODS

This unit is equipped with a lifting eye for moving during

installation. W eight capacity of the lifting eye only allows

for supporting the unit and welding power source.

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Disconnect input power conductors from

deenergized supply line BEFORE moving unit

and welding power source.

OM-530 Page 2

The TIG-Unit was shipped installed on and wired into

the welding power source. To prepare the TIG-Unit for

operation, proceed as follows:

1. Open access door on lower front of TIG-Unit, remove component bag, and route short interconnecting cord (approximately 4 ft. or 1.2 m) with plug

attached through access opening on left side of

TIG-Unit. Connect plug to REMOTE 14 (Amperage

And Contactor Control) receptacle on welding power source; align keyway, insert plug, and rotate

threaded collar clockwise.

Page 7

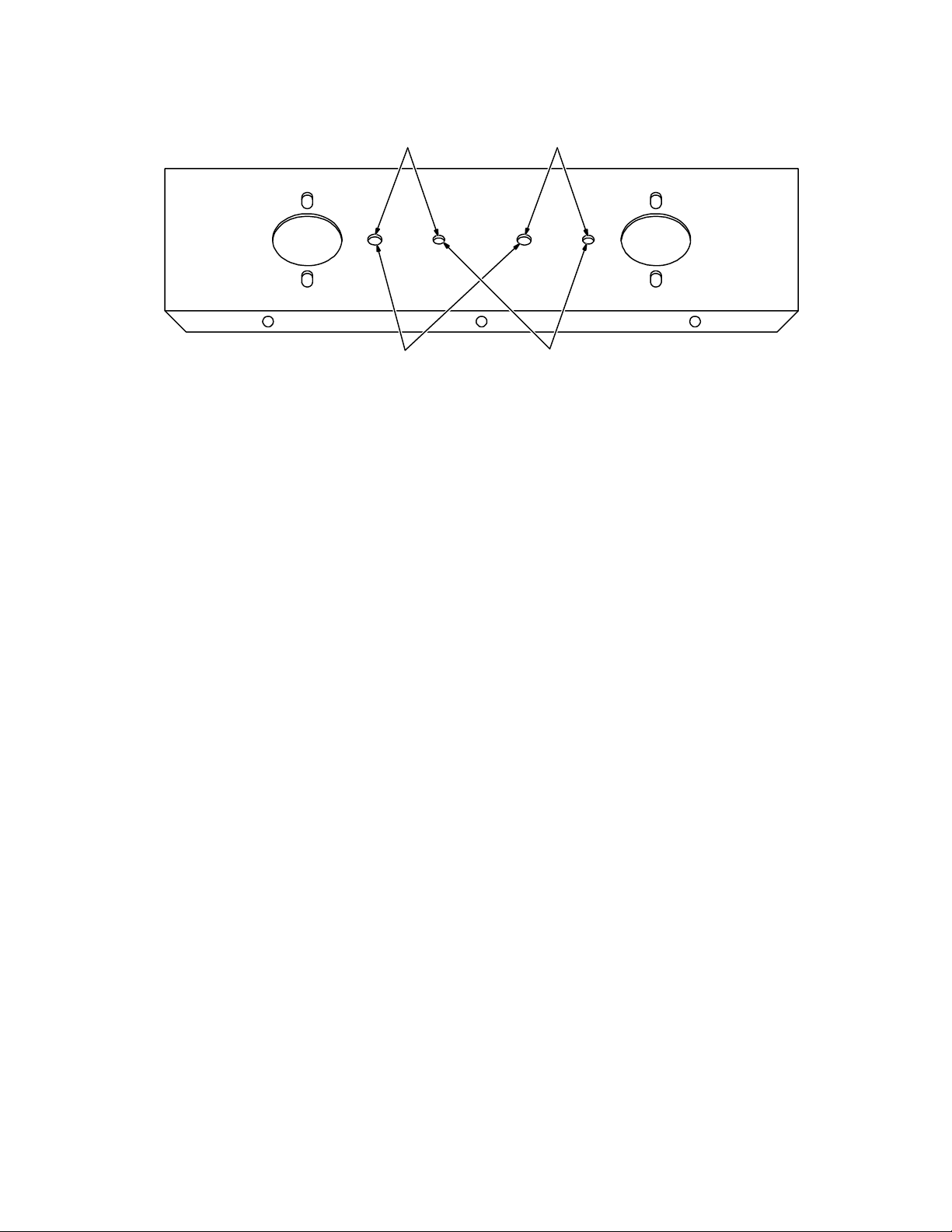

Interconnecting

Cord

Positive Lead

Positive

Output

Terminal

(No. 17)

Negative Lead

Negative

Output

Terminal

(No. 12)

Figure 3-1. Component Installation

ST-059 589-A

2. Attach plug from remote control cord (long cord, approximately 28 ft. or 8.5 m) to amphenol receptacle

on left side of TIG-Unit (under front access door);

align keyway, insert plug, and rotate threaded collar

clockwise. Route remote control cord through access opening on left side of TIG-Unit to desired location.

3. Remove and discard bottom center sheet-metal

screw from right side panel of welding power

source.

4. Route welding cables (labeled POSITIVE and

NEGATIVE) from rear of TIG-Unit down right side of

welding power source.

5. Slide supplied clamps (in bag) over welding cables,

and attach clamps with new sheet-metal screw (in

bag) to bottom center hole on right side panel of

welding power source. Before securing sheet-metal

screw, route welding cables from rear of TIG-Unit to

output terminals under front access door on welding

power source and connect POSITIVE lead (No. 17)

and NEGA TIVE lead (No. 12) to correspondingly labeled terminals on the welding power source (see

Figure 3-1). Secure clamps with sheet-metal

screw; secure cables to terminals.

6. Make the necessary connections to the gas and water valves also located behind access door on lower

front panel of TIG-Unit in a proper manner. The

valves are labeled; ensure that connections are correct (see Figure 4-1 and Sections 3-11 and 3-12).

7. Install proper welding cables (see welding power

source’s Owner’s Manual for correct size) to the

weld output terminals behind access door on TIGUnit (see Figure 4-1).

3-4. FIELD INSTALLATION OF TIG-UNIT

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Shut down welding power source, and dis-

connect input power employing lockout/tagging

procedure before beginning this installation.

Lockout/tagging procedures consist of padlocking line disconnect switch in open position,

removing fuses from fuse box, or shutting off

and red-tagging circuit breaker or other disconnecting device.

IMPORTANT : Although this unit was primarily designed

to be mounted directly to the welding power source, remote installation is possible if necessary. For remote installation procedures, see Section 3-7. All directions,

such as left or right, are with respect to the operator facing the welding power source front panel. Retain all

hardware removed during this procedure for reinstallation. For installation onto 600 ampere welding power

sources which require different mounting instructions,

see Section 3-4C.

IMPORTANT: There are two methods for supplying

power to the TIG-Unit, one of which must be chosen at

the beginning of this installation. Never use both methods. After choosing the desired method, follow the accompanying instructions for that particular installation.

The first method (A) is to connect the TIG-Unit to an out-

OM-530 Page 3

Page 8

side 115 volts ac power supply. The second method (B)

is to connect the TIG-Unit to 230 volts ac inside the

welding power source.

A. Procedure When Using An External 115 Volts

AC Power Supply

IMPORTANT: Read entire Section 8 on equipment that

produces output in the radio frequency range, such as

high-frequency starters, for site selection information

and installation requirements before beginning the installation procedures.

1. Remove the six sheet-metal screws from top cover

of welding power source (three from each end). It is

not necessary to remove the two screws next to lifting eye (top cover of welding power source is not removed).

2. Remove top cover from TIG-Unit, and lay it aside.

IMPORTANT : The TIG-Unit is shipped with two 5 ft. (1.5

m) leads (with terminal lugs attached) inside component

bag under front access door of TIG-Unit. These leads

are for 230 volts ac internal connections only (Procedure B), and should be discarded when a 115 volts ac

external power supply is used.

3. Place TIG-Unit on top of welding power source

(controls facing same direction); lifting eye from

welding power source fits through bottom of TIGUnit (into U-shaped section at bottom of TIG-Unit’s

lifting eye bracket.)

4. Insert supplied 3/4 in. (19mm) diameter bolt (in bag)

through U-shaped section at bottom of TIG-Unit’s

lifting eye bracket and lifting eye of welding power

source; before securing bolt, align end hole in bottom of TIG-Unit with end holes in top of welding

power source.

5. Install the six sheet-metal screws (removed in Step

1) into end holes to secure TIG-Unit to top of welding power source. Secure 3/4 in. (19mm) diameter

bolt.

6. Make up a cord (16/3 is recommended) of the desired length to connect the 115 volts ac power supply.

7. Route cord through supplied connector on rear of

TIG-Unit, and attach it to terminal labeled 115V on

terminal strip TE1 located on center mounting panel

toward back of TIG-Unit (see Figure 3-2). (A ground

stud is provided at extreme rear end of this terminal

strip; use if desired.) Secure cord in connector.

8. Attach an appropriate plug to the remaining end of

the 115 volts ac cord.

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Do not connect the 115 volts ac plug to its

power supply until this entire installation is complete and the TIG-Unit is ready to be put in operation.

OM-530 Page 4

9. Open access door on lower front of TIG-Unit, remove component bag, and route short interconnecting cord(approximately 4 ft or 1.2 m; see

Figure 3-1) with plug attached through access

opening on left side of TIG-Unit. Connect plug to

REMOTE 14 (Amperage And Contactor Control)

receptacle on welding power source; align keyway,

insert plug, and rotate threaded collar clockwise.

10. Attach plug from remote control cord (long cord, a p proximately 28 ft. or 8.5 m) to amphenol receptacle

on left side of TIG-Unit (under front access door);

align keyway, insert plug, and rotate threaded collar

clockwise. Route remote control cord through access opening on left side of TIG-Unit to desired location.

11. Ensure that the AMPERAGE control switch and

OUTPUT (CONTACTOR) switch on welding power

source are both in the REMOTE position.

12. Open access door on front of welding power source,

and remove welding cables from the output terminals.

13. Reinstall welding cables to proper output terminals

on front of TIG-Unit (labeled ELECTRODE and

WORK).

14. Remove and discard bottom center sheet-metal

screw from right side panel of welding power

source.

15. Route welding cables (labeled POSITIVE and

NEGATIVE) from rear of TIG-Unit down right side of

welding power source (see Figure 3-1).

16. Slide supplied clamps (in bag) over welding cables,

and attach clamps with new sheet-metal screw (in

bag) to bottom center hole on right side panel of

welding power source; before securing sheet-metal

screw, route welding cables from rear of TIG-Unit to

output terminals under front access door on welding

power source; connect POSITIVE lead (No. 17) an d

NEGATIVE lead (No. 12) to correspondingly labeled terminals on the welding power source (see

Figure 3-1).

17. If an Electroslope and/or Pulser is to be installed,

see Section 3-5 and/or 3-6, and install the desired

units at this point.

18. Reinstall cover onto TIG-Unit, and connect the necessary associated equipment (shielding gas, water,

etc.).

B. Procedure When Using 230 Volts AC Internal

Power

IMPORTANT: Read entire Section 8 on equipment that

produces output in the radio frequency range, such as

high-frequency starters, for site selection information

and installation requirements before beginning the installation procedures.

1. Remove top cover from welding power source, and

lay it aside.

2. Remove top cover from TIG-Unit, and place it on

welding power source. Be sure that front of cover is

Page 9

placed on front of welding power source. Secure in

place with two sheet-metal screws, one on either

side of lifting eye near center of cover. Do not install

the remaining sheet-metal screws (three on each

end) until instructed to do so.

3. Remove blank snap-in from access hole toward

rear of cover installed on welding power source. Install supplied grommet into access hole.

4. Place TIG-Unit on top of welding power source

(controls facing same direction); lifting eye from

welding power source fits through bottom of TIGUnit (into U-shaped section at bottom of TIG-Unit’s

lifting eye bracket).

5. Insert supplied 3/4 in. (19 mm) diameter bolt (in

component bag under front access door of TIGUnit) through U-shaped section at bottom of TIGUnit’s lifting eye bracket and lifting eye of welding

power source; before securing bolt, align end holes

in bottom of TIG-Unit with end holes in top of welding power source.

6. Install the six sheet-metal screws (three in each

end) into end holes to secure TIG-Unit (and cover)

to top of welding power source. Secure 3/4 in. (19

mm) diameter bolt.

7. Remove left side panel from welding power source.

8. Locate the two 5 foot (1.5 m) leads (with terminal

lugs attached) inside component bag which are to

be used for obtaining 230 volts ac from the welding

power source.

9. Connect the two leads to the welding power source

as follows:

a. For 60 Hertz Welding Power Sources

Locate fan motor leads 9 and 36. Trace these

leads to the inside of the primary terminal

board. Connect the 230 volts leads to the two

terminals on inside (not jumper link side) of primary terminal board where fan motor leads 9

and 36 are connected.

b. For 50 Hertz Welding Power Sources

Locate fan motor leads 9 and 20. T race lead 9 to

the inside of the primary terminal board. Connect one of the 230 volts leads to this terminal

on inside (not jumper link side) of primary terminal board where lead 9 is connected. Trace fan

motor lead 20 to splice (covered with sleeving)

near main transformer. Slide sleeving back to

expose the connection, and splice remaining

230 volts lead to this connection in a proper

manner.

10. Maintain a proper lead dress around fan and wind

tunnel, and route leads through access hole in cover

into TIG-Unit.

12. Repeat Steps 9 through 17 from method A.

13. Reinstall cover (set aside in Step 1) onto TIG-Unit

and right side panel onto welding power source, and

connect the necessary associated equipment

(shielding gas, water, etc.).

C. Procedure When Mounting To 600 Ampere

Welding Power Sources.

For installation onto 600 ampere welding power

sources, the mounting procedure is different since the

holes in t h e bottom of the TIG-Unit do not line up with the

top of the welding power source. The rest of the installation is the same. To mount the TIG-Unit to a 600 ampere

welding power source, proceed as follows:

1. Remove top cover from TIG-Unit, and lay it aside.

2. Place TIG-Unit on top of welding power source

(controls facing same direction); lifting eye from

welding power source fits through bottom of TIGUnit (into U-shaped section at bottom of TIG-Unit’s

lifting eye bracket). Insert supplied 3/4 in. (19 mm)

diameter bolt (in bag) through U-shaped section at

bottom of TIG-Unit’s lifting eye bracket and lifting

eye of welding power source; do not secure bolt at

this time.

3. Using bottom of TIG-Unit as a template, mark locations for mo unting holes and location of lead access

hole (if 230 volts ac from the welding power source

is to be used for operational power).

4. Remove 3/4 in. (19 mm) bolt, and remove TIG-Unit

from top of welding power source.

CAUTION: METAL FILINGS AND/OR TOOL

CONTACT WITH INTERNAL COMPONENTS

can damage unit.

• Cover internal components.

• Clean unit, and remove internal covering ma-

terial before resuming operation.

5. Drill six 5/32 in. (3.9 mm) holes in marked locations

for mounting TIG-Unit to welding power source.

6. If desired, drill a 1/2 in. (12.7 mm) lead access hole

in marked location.

7. Place TIG-Unit on top of welding power source, insert 3/4 in. (19 mm) bolt, and install the six supplied

sheet-metal screws. Tighten screws and secure

bolt. Install supplied grommet into access opening,

if applicable.

1 1. Connect the two leads to the terminal labeled 230V

on rear terminal strip TE1 (on center mounting panel; see Figure 3-2).

8. Proceed to Section 3-4A Step 6, or Section 3-4B

Step 7 as selected, and follow the remaining instructions for the chosen procedure.

OM-530 Page 5

Page 10

3-5. FIELD INSTALLATION OF PULSER

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Shut down welding power source, and dis-

connect input power employing lockout/tagging

procedure before beginning this installation.

Lockout/tagging procedures consist of padlocking line disconnect switch in open position,

removing fuses from fuse box, or shutting off

and red-tagging circuit breaker or other disconnecting device.

1. Remove top cover from TIG-Unit, if applicable.

2. Remove right blank panel from front of TIG-Unit.

Save screws; discard blank panel.

3. Examine inside of TIG-Unit behind front panel for location of lead harnesses, etc.

4. Carefully slide Pulser unit into opening on front panel of TIG-Unit. Secure Pulser with the four screws

removed from blank panel in Step 2.

5. Route leads from Pulser down top of center mounting panel and then to right of terminal strip 1T. (The

terminal strip is located on top of center mounting

panel toward rear of TIG-Unit; the terminals are labeled directly below the strip; see Figure 3-2.)

6. Remove jumper link 4 (across terminals 84 and 83)

on terminal strip 1T. See Circuit Diagram 7-1.

7. Connect Pulser leads to correspondingly numbered

terminals (41, 42, 43, 84, 83, 72) on terminal strip

1T. The leads from Pulser are all numbered.

8. Connect grey lead 42 from rear of Pulser case to

front center mounting panel where existing grey

lead 42 is connected to chassis (not to terminal

strip).

9. Secure leads to existing harness with nylon cable

ties or tape to maintain a proper lead dress.

10. Reinstall cover onto TIG-Unit, if applicable.

3-6. FIELD INSTALLATION OF ELECTROSLOPE

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Shut down welding power source, and dis-

connect input power employing lockout/tagging

procedure before beginning this installation.

Lockout/tagging procedures consist of padlocking line disconnect switch in open position,

removing fuses from fuse box, or shutting off

and red-tagging circuit breaker or other disconnecting device.

1. Remove top cover from TIG-Unit, if applicable.

2. Remove left blank panel from front of TIG-Unit.

Save screws; discard blank panel.

3. Examine inside of TIG-Unit behind front panel for location of lead harnesses, etc.

OM-530 Page 6

4. Carefully slide Electroslope unit into opening on

front panel of TIG-Unit. Secure Electroslope with

the four screws removed from blank panel in Step 2.

5. Route leads from Electroslope down top of center

mounting panel and then to right of terminal strip 1T.

(The terminal strip is located on top of center mounting panel toward rear of TIG-Unit; the terminals are

labeled directly below the strip; see Figure 3-2.)

6. Connect grey lead 42 from rear of Electroslope case

to front center mounting panel where existing grey

lead 42 is connected to chassis (not to terminal

strip).

7. Remove jumper links 1 (across terminals 3 and 2),

2 (across terminals 71 and 70), and 3 (across terminals 76 and 78) on terminal strip 1T. See Circuit Diagram 7-1.

8. For Models Effective With Serial No. HK261770:

Connect Electroslope leads to correspondingly

numbered terminals (3, 2, 5, 6, 7, 41, *42, 43, 71,

70, 56, 61, *42, 62, 76, 78, 72, 58, 59) on terminal

strip 1T. Connect Electroslope leads 30 and 37 to

corresponding terminal on terminal strip 2T. The

leads from Electroslope are all numbered. Connect

lead 60 from Electroslope to terminal 1 on relay CR2

(see Figure 3-2).

*Connect only one lead 42 to each 42 terminal.

The leads are cut to proper length and will only

reach the appropriate segment of the terminal

strip.

9. For Models Prior To Serial No. HK261770: Connect

Electroslope leads to correspondingly numbered

terminals (3, 2, 5, 6, 7, 41, *42, 43, 71, 70, 56, 61,

*42, 62, 76, 78, 72) on terminal strip 1T. Connect

Electroslope lead 60 to terminal 1 on relay CR2.

If The Unit DOES NOT Have Preflow:

c. Replace existing connector on Electroslope

lead 59 with a 3/16 in. female friction connector,

and connect lead 59 to terminal 4 on relay CR2.

d. Individually tape and tie remaining Electroslope

leads 30, 37, and 58 to existing wiring harness.

If The Unit DOES Have Preflow:

a. Replace existing connectors on Electroslope

leads 30 and 37 with a 1/4 in. piggyback (dual

friction) connector.

b. Disconnect leads 30 and 37 from Preflow

switch S200.

c. Reconnect lead 30 (from Step b) to piggyback

connector on Electroslope lead 30, and reconnect lead 37 (from Step b) to piggyback connector on Electroslope lead 37.

d. Install piggyback connector on Electroslope

lead 30 onto terminal of Preflow switch from

which lead 30 (from Step b) was removed.

e. Install piggyback connector on Electroslope

lead 37 onto terminal of Preflow switch from

which lead 37 (from Step b) was removed.

Page 11

f. Cut off and discard existing connectors on Elec-

troslope leads 58 and 59.

CAUTION: SOLDER can damage unit.

• Do not allow solder to fall into unit.

• Cover exposed area of unit when soldering

connections.

• Remove cover(s) and clean unit when fin-

ished soldering.

g. Splice and solder Electroslope lead 59 to lead

59. (Make connection near Preflow Circuit

Board.) Insulate connection with tape.

h. Connect lead 58, originating at Preflow Circuit

Board, to terminal 4 of relay CR2.

i. Splice and solder Electroslope lead 58 to lead

58. (Make connection near terminal 4 of relay

CR2.) Insulate connection with tape.

10. Secure leads to existing harness with nylon cable

ties or tape to maintain a proper lead dress.

11. Reinstall cover onto TIG-Unit.

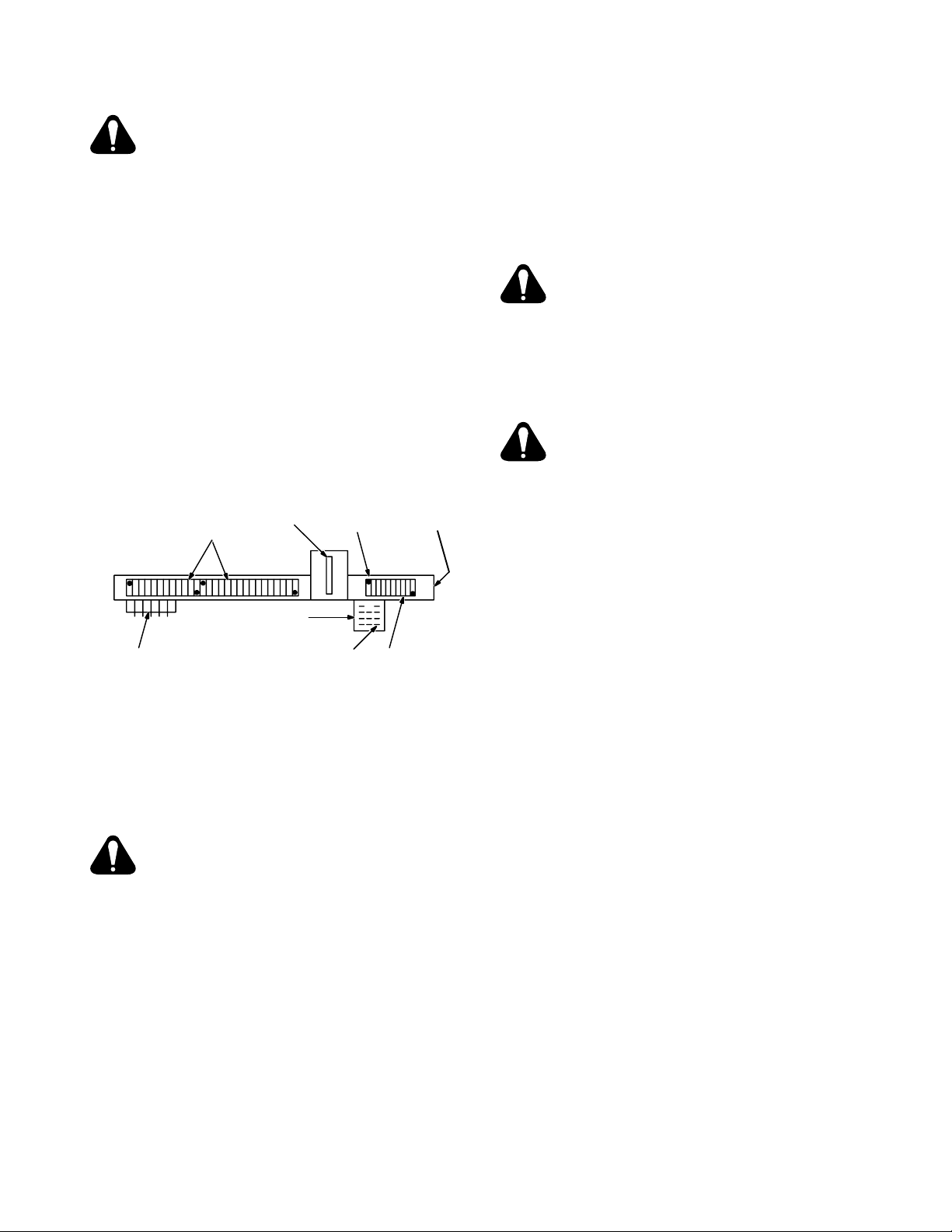

Terminal

Primary Connection

Terminal Strip TE1

Strips

1T

Lifting

Eye

Relay CR2

Lead 60 From

Electroslope

TOP VIEW

Front Center

Mounting Panel

Terminal

Strip 2T

ST-081 854-C

Front Of

Tig-Unit

Figure 3-2. Location Of Relay CR2 And Other

Components

3-7. PROCEDURE FOR REMOTE TIG-UNIT INSTALLATION

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Shut down welding power source, and dis-

connect input power employing lockout/tagging

procedures before inspecting or installing.

Lockout/tagging procedures consist of padlocking line disconnect switch in open position,

removing fuses from fuse box, or shutting off

and red-tagging circuit breaker or other disconnecting device.

1. Remove top cover from TIG-Unit, and lay it aside.

IMPORTANT : The TIG-Unit is shipped with two 5 ft. (1.5

m) leads (with terminal lugs attached) inside component

bag under front access door of TIG-Unit. These leads

are for 230 volts ac internal connections only (Section

3-4, Procedure B), and should be discarded when a 1 15

volts ac external power supply is used.

2. Make up cord (16/3 is recommended) of the necessary length to connect to a 115 volts ac power supply. (The 230 volts procedure from Section 3-4, Procedure B must not be employed.)

3. Route cord through supplied connector on rear of

TIG-Unit, and attach it to terminals labeled 115V on

terminal strip TE1 located on center mounting panel

toward back of TIG-Unit (see Figure 3-2). A ground

stud is provided at extreme rear end of the terminal

strip and must be used.

CAUTION: LACK OF GROUND CONNECTION will damage the Pulser.

• Ground TIG-Unit back to welding power

source or to a good building ground whenever

TIG-Unit is separated from welding power

source.

4. Attach an appropriate plug to the remaining end of

the 115 volts ac cord.

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Do not connect the 115 volts ac plug to its

power supply until this entire installation is complete and the TIG-Unit is ready to be put in operation.

5. Open access door on lower front of TIG-Unit, remove component bag, and route short interconnecting cord (approximately 4 ft or 1.2 m) with plug

attached through access opening on left side of

TIG-Unit. Connect extension cord (not supplied; optional) to short cord from TIG-Unit, and then connect plug (remaining end) to REMOTE 14 (Amperage And Contactor Control) receptacle on welding

power source; align keyway, insert plug, and rotate

threaded collar clockwise.

6. Attach plug from remote control cord (long cord, approximately 28 ft. or 8.5 m) to amphenol receptacle

on left side of TIG-Unit (under front access door);

align keyway, insert plug, and rotate threaded collar

clockwise. Route remote control cord through access opening on left side of TIG-Unit to desired location.

7. Ensure that the AMPERAGE control switch and

OUTPUT(CONTACTOR) switch on welding power

source are both in the REMOTE position.

8. Open access door on front of welding power source,

and remove welding cables from the output terminals.

9. Reinstall welding cables to proper output terminals

on front of TIG-Unit (labeled ELECTRODE and

WORK).

10. Route welding cables (labeled POSITIVE and

NEGATIVE) from rear of TIG-Unit in direction of

welding power source.

1 1. Connect (with bolts) power cables (not supplied) of

adequate size and length to the welding cables of

the TIG-Unit, and then connect the remaining ends

OM-530 Page 7

Page 12

to proper output terminals on welding power source;

ensure that proper polarity is maintained.

ELECTRIC SHOCK can kill.

• Secure and insulate with sleeving any ex-

posed cable connections to prevent contact with

personnel, equipment, etc.

12. If an Electroslope and/or Pulser is to be installed,

see Section 3-5 and/or 3-6, and install the desired

units at this point.

13. Reinstall cover onto TIG-Unit and connect the necessary associated equipment (shielding gas, water,

etc.).

3-8. FIELD INSTALLATION OF OPTIONAL PREFLOW TIMER

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Shut down welding power source, and dis-

connect input power employing lockout/tagging

procedure before beginning this installation.

Lockout/tagging procedures consist of padlocking line disconnect switch in open position,

removing fuses from fuse box, or shutting off

and red-tagging circuit breaker or other disconnecting device.

IMPORTANT: All directions, such as left or

right, are with respect to the operator facing the

welding power source front panel. Retain all

hardware removed during this procedure for reinstallation.

A. Mechanical Installation (Figure 3-3)

1. Remove TIG-Unit top cover and left side panel.

CAUTION: METAL FILINGS AND/OR TOOL

CONTACT WITH INTERNAL COMPONENTS

can damage unit.

• Cover internal components.

• Clean unit, and remove internal covering ma-

terial before resuming operation.

2. Mount Preflow ON/OFF switch S200 in the 1/2 in.

(12.7 mm) diameter hole using supplied hardware.

3. Mount Preflow Time control with attached printed

circuit card assembly TD2 in the 3/8 in. (9.5 mm) diameter hole using supplied hardware.

4. Affix supplied PREFLOW TIME label to front panel

over both controls.

5. Attach supplied knob to Preflow Time control shaft.

B. Electrical Installation (Figure 3-2)

IMPORTANT: Before preceeding with this installation

familiarize yourself with the circuit diagram provided in

this manual.

For All Models:

1. Remove and discard jumper lead 70 from terminal

70 on terminal strip 1T and terminal 73 on terminal

strip 2T.

2. Connect new lead 70 from the preflow timer assembly to terminal 70 on 1T.

3. Connect lead 73 from preflow timer assembly to terminal 73 on 2T.

4. Connect lead 33 from preflow timer assembly to terminal 33 on 1T.

5. For Models With Electroslope:

a. Disconnect lead 6 from electroslope edge con-

nector pin X. Tape and tie off lead 6.

b. Insert new lead 92 into pin X where lead 6 was

removed in Step a.

c. Connect new lead 6 from preflow timer assem-

bly to terminal 6 on 1T.

6. For Models Without Electroslope: Tape and tie off

leads 6 and 92.

7. For Models Effective With Serial No. JA373511:

a. Remove jumper link 6 from terminals 58 and 59

on terminal strip 1T

b. Connect lead 32 from preflow timer assembly to

terminal 32 on 1T.

c. Connect new lead 30 from preflow timer as-

sembly to terminal 30 on 2T.

d. Connect lead 37 from preflow timer assembly to

terminal 37 on 2T.

e. Connect lead 59 from preflow timer assembly to

terminal 59 on 1T.

OM-530 Page 8

Page 13

f. Connect lead 58 from preflow timer assembly to

terminal 58 on 1T.

Pre-Flow

Assembly

1/2 in.

(12.7 mm) Dia.

Figure 3-3. Front Panel Mounting Hole Layout

g. Remove jumper link 7 from terminals 89 and 90

on 2T.

h. Connect lead 89 from preflow timer assembly to

terminal 89 on 2T.

i. Connect lead 90 from preflow timer assembly to

terminal 90 on 2T.

j. Discard supplied leads 30, 37, and 58.

k. Tape or tie new leads together to maintain a

proper lead dress inside the unit.

l. Replace left side panel and top cover.

8. For Models Effective With Serial No. HK261770

Thru JA373510:

a. Remove jumper link 6 from terminals 58 and 59

on terminal strip 1T.

b. Connect lead 32 from preflow timer assembly to

terminal 32 on 1T.

c. Connect new lead 30 from preflow timer as-

sembly to terminal 30 on 2T.

d. Connect lead 37 from preflow timer assembly to

terminal 37 on 2T.

e. Connect lead 59 from preflow timer assembly to

terminal 59 on 1T.

f. Connect lead 58 from preflow timer assembly to

terminal 58 on 1T.

g. Disconnect lead 89, originating at CR1, from

terminal 89 on 2T.

h. Splice lead 89 (disconnected in Step g) to lead

90 originating at preflow timer switch S200.

i. Connect lead 89, originating at preflow timer

switch S200, to terminal 89 on 2T.

j. Discard supplied leads 30, 37, and 58.

k. Tape or tie new leads together to maintain a

proper lead dress inside the unit.

Spot Time

Assembly

3/8 in.

(9.5 mm) Dia.

ST-048 698-A

l. Replace left side panel and top cover.

9. For Models Prior to Serial No. HK261770:

a. Locate lead 32 between transformer T1 and in-

tegrated rectifier SR2. Splice lead 32, originating at the preflow circuit card, onto lead 32 be-

tween T1 and SR2.

b. Disconnect lead 30 from fuse F1.

c. Connect lead 30, originating at CR3, to F1

where lead 30 was removed in Step b.

d. Connect lead 30 disconnected in Step b to the

dual terminal friction connector on lead 30 at

F1.

e. If applicable, insulate leads 89 and 90 from pre-

flow timer assembly, and secure to wiring har-

ness.

f. For models with Electroslope proceed to Step

g. For all other models, isolate remaining wires

by taping ends and proceed to Step o.

g. Remove electroslope box cover.

IMPORTANT: This procedure is only applicable on

models with the proper electroslope. If questions arise,

contact the factory Service Department.

h. Locate terminal FF on electroslope circuit card.

Route supplied lead 30 through the grommet in

the electroslope box and connect it to terminal

FF on the electroslope circuit card. Connect re-

maining end of lead 30 to fuse F1 in addition to

existing leads 30.

i. Locate terminal GG on electroslope circuit

card. Route supplied lead 37 through the grom-

met in the electroslope box and connect it to ter-

minal GG on the electroslope circuit card. Con-

nect remaining end of lead 37 to preflow timer in

addition to existing lead 37.

j. Remove lead 59 from control relay CR2.

k. Splice lead 59, originating at the preflow circuit

card, to lead 59 that was removed from CR2.

OM-530 Page 9

Page 14

l. Connect lead 58, originating at the preflow cir-

cuit card, to the terminal on CR2 where lead 59

was removed in Step j.

m. Locate terminal JJ on electroslope circuit card.

Route supplied lead 58, through the grommet in

the electroslope box and connect it to terminal

HH on the electroslope circuit card. Connect remaining end of lead 58 to CR2 in addition to ex -

isting lead 58.

n. Replace electroslope box cover.

o. Cover all splices with electrical tape. Tape or tie

new or unused leads to existing wiring har-

nesses.

p. Replace left side panel and top cover.

3-9. FIELD INSTALLATION OF OPTIONAL SPOT

TIMER (Figure 3-3)

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Shut down welding power source, and dis-

connect input power employing lockout/tagging

procedure before beginning this installation.

Lockout/tagging procedures consist of padlocking line disconnect switch in open position,

removing fuses from fuse box, or shutting off

and red-tagging circuit breaker or other disconnecting device.

IMPORTANT: All directions, such as left or

right, are with respect to the operator facing the

welding power source front panel. Retain all

hardware removed during this procedure for reinstallation.

2. Connect lead 32 from spot time assembly to terminal 32 on 1T.

3. Connect lead 89 from spot time assembly to terminal 89 on terminal strip 2T.

4. Connect lead 88 from spot time switch S201 to terminal 88 on 1T.

5. Connect lead 33 from S201 to terminal 33 on 1T.

6. Tape or tie new leads together to maintain a proper

lead dress inside the unit.

7. Replace both side panels and top cover.

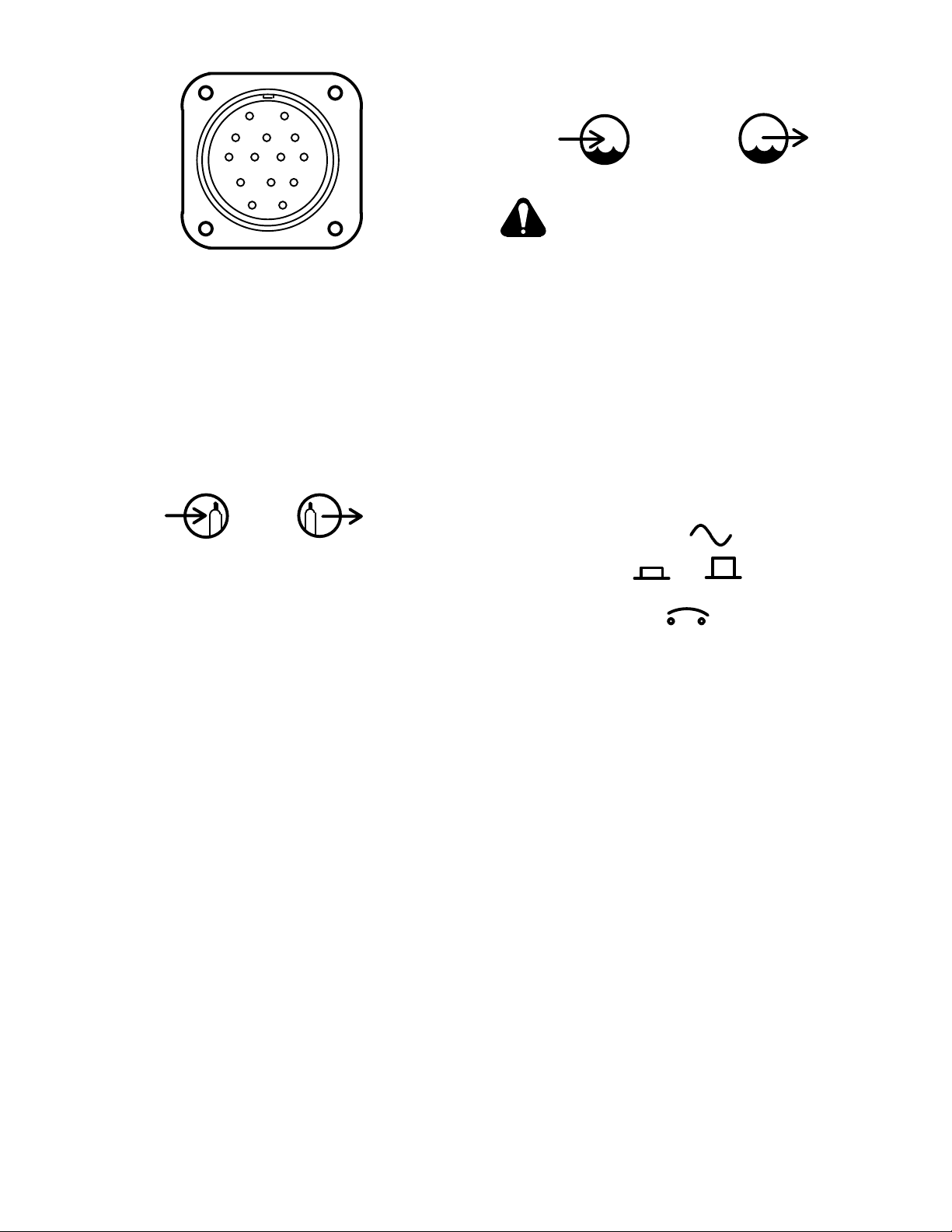

3-10. REMOTE 14 RECEPTACLE INFORMATION

AND CONNECTIONS (Figure 3-4 And Figure 4-1)

REMOTE 14

AMPERAGE

A

OUTPUT

(CONTACTOR)

REMOTE 14 receptacle RC2 is used to connect any of

the following equipment to the welding power source circuitry:

a. Remote Contactor

b. Remote Amperage control

c. Combination of the above.

To make connections, align keyway , insert plug, and rotate threaded collar fully clockwise.

A. Mechanical Installation (Figure 3-3)

1. Remove TIG-Unit top cover and both side panels.

2. Mount Spot Time switch S201 in the 1/2 in. (12.7

mm) diameter hole using supplied hardware.

3. Mount Spot Time control with attached printed circuit card assembly TD3 in the 3/8 in. (9.5 mm) diameter hole using supplied hardware.

4. Affix supplied SPOT TIME label to front panel over

both controls.

5. Attach supplied knob to Spot Time control shaft.

B. Electrical Installation (Figure 3-2)

IMPORTANT: Before preceeding with this installation

familiarize yourself with the circuit diagram provided in

this manual.

For All Models:

1. Remove jumper link 5 from terminals 33 and 88 on

terminal strip 1T.

OM-530 Page 10

The following socket information is included in case the

supplied cord is not suitable, and it is necessary to wire a

plug or cord to interface with REMOTE 14 receptacle

RC2.

IMPORTANT: When contact closure is provided between sockets A and B, the welding power source output/contactor control circuit is energized.

Receptacle RC2 socket connections to the TIG-Unit

control circuitry are as follows;

Socket A: Contactor control switch connection.

Socket B: Contactor control switch connection.

Socket C: Amperage control connection (maximum

side).

Socket D: Amperage control connection (minimum

side).

Socket E: Amperage control connection (wiper con-

tact).

IMPORTANT: The remaining sockets in the receptacle

are not used.

Page 15

AJ

K

B

L

C

M

D

I

NH

G

F

E

Ref. S-0004-A

Figure 3-4. Front View Of REMOTE 14 Receptacle

With Socket Locations

3-11. GAS CONNECTIONS (Figure 4-1)

3-12. COOLANT CONNECTIONS (Optional)

(Figure 4-1)

COOLANT IN COOLANT OUT

CAUTION: OVERHEATING Gas Tungsten

Arc Welding (GTAW) torch can damage

torch.

• If using a water-cooled torch and recirculating

coolant system, make connections from the

coolant system directly to the torch hoses. Do

not use water connections on the TIG-Unit.

The COOLANT IN and COOLANT OUT fittings have

5/8-18 left-hand threads. Obtain proper size, type, and

length hose, and make connections as follows:

1. Connect hose from coolant supply to COOLANT IN

fitting.

2. Connect coolant hose from torch to COOLANT

OUT fitting.

3-13. 115 VOLTS AC DUPLEX RECEPTACLE AND

CIRCUIT BREAKER (Figure 4-1)

GAS IN GAS OUT

The GAS IN and GAS OUT fittings have 5/8-18 righthand threads. Obtain proper size, type, and length

hose, and make connections as follows:

1. Connect hose from shielding gas supply regulator/

flowmeter to GAS IN fitting.

2. Connect shielding gas hose from torch to GAS OUT

fitting.

115V 15A AC

ON OFF

OVERLOAD

PRESS TO START

A grounded duplex receptacle, located behind the front

access door of the TIG-Unit, is provided to furnish up to

2 kva of 115 volts ac to operate external accessories. A

15 ampere circuit breaker, located next to the receptacle, protects this circuit in case overloading of the duplex receptacle occurs.

OM-530 Page 11

Page 16

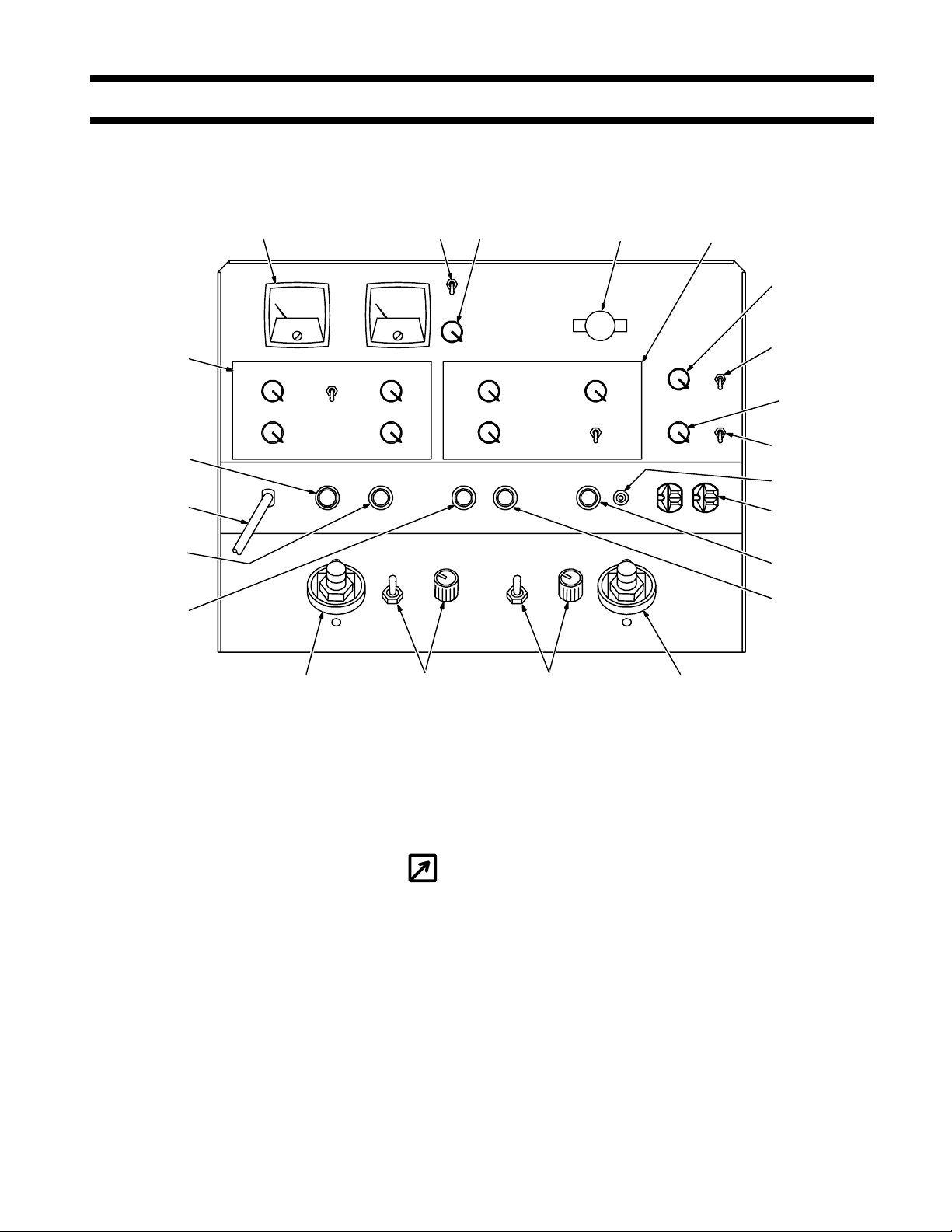

SECTION 4 – OPERATOR CONTROLS

♦Electroslope

Remote 14

Receptacle

Interconnecting

Cord

Coolant Valve

Inlet

Coolant Valve

Outlet

Remote

♦Meters ♦Pulser

Amperage

Switch

Amperage

Adjustment

Control

Polarity

Switch

Postflow

Control

Gas/Coolant

Switch

High

Frequency

Control

High

Frequency

Switch

Circuit Breaker

(See Section 6-4)

115 Volts AC

Duplex Receptacle

Gas Valve

Outlet

Gas Valve

Inlet

Work

Output

Terminal

♦Preflow Time

Control And

Switch

Figure 4-1. Front Panel View

4-1. AMPERAGE ADJUSTMENT CONTROL AND

REMOTE AMPERAGE SWITCH (Figure 4-1)

14

A

AMPERAGE

ADJUSTMENT

IMPORTANT: The AMPERAGE ADJUSTMENT con-

trol may be adjusted while welding.

A. Without Electroslope

When not using an Electroslope and the AMPERAGE

switch on the TIG-Unit is in the PANEL position, the AMPERAGE ADJUSTMENT control on the TIG-Unit always functions as a fine amperage adjustment (calibrated in percent) of the AMPERAGE ADJUSTMENT

control on the welding power source. If a remote control

is used and the AMPERAGE switch on the TIG-Unit is in

OM-530 Page 12

A

AMPERAGE

PANEL

♦Spot Time

Control And

Switch

Electrode

Output

Terminal

TB-059 588-A

the REMOTE 14 position, the remote control always

functions as a fine amperage adjustment (in percent) of

the AMPERAGE ADJUSTMENT control on the welding

power source.

B. With Electroslope

IMPORTANT : For the TIG-Unit to function properly, en-

sure the the AMPERAGE control switch on the welding

power source is always in the REMOTE 14 position. Th e

position of the OUTPUT (CONTACTOR) control switch

on the welding power source is determined by the situation. If Remote Contactor Control is desired, place the

switch in the REMOTE 14 position. If Remote Contactor

Control is not desired, place the switch in the ON position.

When using an Electroslope, the AMPERAGE switch

on the TIG-Unit must be in the PANEL position and then

the AMPERAGE ADJUSTMENT control on the TIGUnit has complete control of the current of the welding

power source.

Page 17

4-2. POLARITY SWITCH (Figure 4-1)

POLARITY SWITCH

LECTRODE

NEGATIVE

()

+()

ELECTRODE

POSTIVE

DO NOT SWITCH

WHILE WELDING

CAUTION: ARCING can damage switch

contacts.

• Do not change POLARITY SWITCH position

while welding or under load.

The POLARITY switch provides a means of selecting either electrode negative or electrode positive weld output

polarity without having to change the output cable connections.

Placing the POLARITY switch in the ELECTRODE

NEGATIVE position causes the ELECTRODE output

terminal to be negative and the WORK output terminal

to be positive. Conversely, if the POLARITY switch is

placed in the ELECTRODE POSITIVE position, the

ELECTRODE output terminal is positive and WORK

output terminal is negative.

4-3. GAS/COOLANT SWITCH (Figure 4-1)

GAS/COOLANT

ON

/

OFF

The function of the GAS/COOLANT switch is to govern

the operation of the gas and water solenoids and the

POSTFLOW timer. When this switch is in the OFF position, the gas and coolant valves and POSTFLOW timer

are disabled (out of the circuit). When this switch is in the

ON position, the gas and coolant valves and POSTFLOW timer are energized (in the circuit). The ON position of this switch is normally used for Gas Tungsten A r c

Welding applications; the OFF position is used for

Shielded Metal Arc Welding applications.

4-4. GAS/COOLANT POSTFLOW CONTROL

(Figure 4-1)

POSTFLOW

t

2

IMPORTANT: The POSTFLOW timer is disabled

whenever the GAS/COOLANT switch is in the OFF position.

An adjustable 0 to 60 seconds gas-coolant POSTFLOW

time control is provided for controlling the period of time

shielding gas and coolant are allowed to flow after the

arc is extinguished. The POSTFLOW time control governs the operation of a postflow timer within the TIGUnit.

Rotating the control in a clockwise direction increases

the postflow time. The scale surrounding the POSTFLOW time control is calibrated in seconds to aid in the

selection of a postflow time period suited to the individual welding operation.

As soon as the contactor is deenergized, the postflow

timer begins to time out the selected period of postflow

time. Once the timer has timed out, the gas and coolant

valves close and thereby cut off shielding gas and coolant flow. The timer automatically resets and is ready for

another weld cycle.

4-5. REMOTE HAND CONTROLS

WARNING: ELECTRIC SHOCK can kill; UNEXPECTED HIGH FREQUENCY DURING

PREFLOW can cause serious injury and

equipment damage.

• Do not allow electroslope switch or other unit

control switch to be maintained closed during

preflow time.

• Always close and immediately open control

switch to ensure that high frequency will not be

present during preflow.

If the unit is equipped with the optional electroslope and preflow timer, it is possible to have

high frequency present during preflow without

machine contactor energized.

A fingertip control (RCC-14) is supplied with every unit.

This control is a maintained-contact type switch used for

remote Amperage and Output (Contactor) control. The

fingertip control must be connected to the REMOTE 14

receptacle (see Figure 4-1 and Section 3-10) under the

front access door of the TIG-Unit to be functional. This

control is designed to be strapped to the torch handle for

convenient operation.

IMPORTANT: When employing the RCC-14 remote

control, the AMPERAGE switch on the TIG-Unit must

be in the REMOTE position for proper remote control

operation.

A momentary-contact type switch (RMLS-14) is additionally supplied with each unit equipped with an Electroslope. This control must be connected to the REMOTE 14 receptacle (see Figure 4-1 and Section 3-10)

under the front access door of the TIG-Unit to be functional. It is necessary to press this switch each time a

new or dif ferent weld condition is desired. This switch allows the operator to manually control the selection of the

welding conditions and duration of that condition. It further gives the operator the capability of moving rapidly

from one condition to the next, if desired. It is necessary

to press this switch four times to advance the unit

through a complete weld cycle. Anytime that the arc is

broken (except during the initial condition), the Electroslope will automatically reset to Off. During the initial

OM-530 Page 13

Page 18

condition resetting to Off is accomplished manually by

pushing the switch once, provided that an arc has not

been established. This control is designed to be taped to

the torch handle for convenient operation.

4-6. HIGH FREQUENCY SWITCH (Figure 4-1)

HIGH

ON

FREQUENCY

switch (RMLS-14) is closed. High frequency will remain

energized until an arc is established or only as long as

the momentary-contact switch is held closed. Provided

that an arc has been established, releasing the momentary-contact switch will deenergize the high frequency. If

an arc is not established, the high frequency will remain

energized until an arc is established or until the momentary-contact switch is pushed again shutting the unit

down.

4-7. HIGH FREQUENCY CONTROL (Figure 4-1)

OFF

WARNING: USING HIGH FREQUENCY WITH

THE SHIELDED METAL ARC WELDING

PROCESS can result in serious personal injury.

• Place the HIGH FREQUENCY switch in the

OFF position before using Shielded Metal Arc

Welding process.

The attempted use of high frequency to establish an arc with a stick electrode could cause an

arc to form between the electrode holder and

operator.

The HIGH FREQUENCY switch provides two positions:

ON and OFF.

When the HIGH FREQUENCY switch is in the OFF position, high frequency will not be available. The OFF position should be used for Shielded Metal Arc Welding

applications. When the HIGH FREQUENCY switch is in

the ON position, high frequency will be in a ready status

and will be present when the contactor in the welding

power source is closed until an arc is established. The

ON position is normally used for Gas Tungsten Arc

Welding applications.

A. Basic And Pulser Models Only

When in the ON position, high frequency will be present

at the welding electrode when the fingertip control

(RCC-14) is closed. The high frequency unit will remain

energized until an arc is established, at which point it will

deenergize. If an arc outage occurs, high frequency will

automatically be present until a new arc is established.

B. Electroslope Models Only

WARNING: ELECTRIC SHOCK can kill; UNEXPECTED HIGH FREQUENCY DURING

PREFLOW can cause serious injury and

equipment damage.

• Do not allow electroslope switch or other unit

control switch to be maintained closed during

preflow time.

• Always close and immediately open control

switch to ensure that high frequency will not be

present during preflow.

If the unit is equipped with the optional electroslope and preflow timer, it is possible to have

high frequency present during preflow without

machine contactor energized.

When in the ON position, high frequency will be present

at the welding electrode when the momentary-contact

OM-530 Page 14

HIGH

FREQUENCY

The HIGH FREQUENCY control is calibrated in percent

and determines the amount of high-frequency energy

that is available to initiate the arc. Rotating the control

clockwise increases the intensity of the high-frequency

energy. Normally the control needs to be adjusted only

initially.

IMPORTANT: As the high frequency is increased, the

possibility of causing interference with local radio and

television receivers also increases. It is recommended

that the HIGH-FREQUENCY control be set at as low a

position as practical while still maintaining a satisfactory

welding operation to avoid such interference.

4-8. METERS (Optional) (Figure 4-1)

The meters are provided to monitor the welding operation. They are not intended for exact amperage or voltage measurements. These meters are internally connected to the output terminals. The voltmeter will indicate the voltage at the output terminals, but not necessarily the actual voltage at the welding arc (due to cable

resistance, poor connections, etc.). The ammeter will

indicate the amperage output of the unit.

4-9. PULSER SWITCH (Pulser Models Only)

(Figure 4-1)

The PULSES switch governs the operation of the pulse

unit. By placing the PULSES switch in the ON position,

the welding power source output amperage will pulse

between the background amperage level and the peak

amperage level. By placing the PULSES switch in the

OFF position, the welding power source output will not

pulse, but rather remain at the peak amperage level.

The PULSES switch may be placed in either the ON or

OFF position prior to or during the welding operations. If

the PULSES switch is placed in the ON position prior to

welding operations, the output amperage may be at ei ther the peak or background amperage level. If the

PULSES switch is placed in the ON position during weld

operations, the pulsing begins with the output amperage

remaining at the peak amperage level, then pulsing to

the background amperage level.

There is no interaction between the BACKGROUND

control, PULSES/SECOND control, % “ON TIME” con-

trol, or the PULSES switch and any of the other controls.

Page 19

Pulsing operations may be performed when the POLARITY SWITCH is in either the ELECTRODE NEGATIVE or ELECTRODE POSITIVE position.

When remote control of the output amperage is

employed, only the peak amperage level is remotely

controlled; the background amperage level is still established by the position of the BACKGROUND control.

4-10. % “ON TIME” CONTROL (Pulser Models Only)

(Figure 4-1)

% “ON TIME”

The % “ON TIME” control provides pulse width selection

of the welding power source output amperage. The %

“ON TIME” control is operational only when the

PULSES switch is in the ON position.

Rotating the % “ON TIME” control in a clockwise direc-

tion increases the peak amperage “on-time” relative to

the entire pulse time; the balance of the time is background amperage. Hence, this control establishes the

peak amperage pulse width relative to the entire pulse

width.

The scale surrounding the % “ON TIME” control is cali-

brated in percent and does not indicate an actual time

value.

IMPORTANT: This control may be adjusted while

welding.

4-11. PULSES/SECOND CONTROL (Pulser Models

Only) (Figure 4-1)

PULSES/SECOND

The PULSES/SECOND control provides pulse frequency selection of the welding power source output amper-

age. The PULSES/SECOND control is operational only

when the PULSES switch is in the ON position.

Rotating the PULSES/SECOND control in a clockwise

direction increases the pulse frequency.

The scale surrounding the PULSES/SECOND control is

calibrated in pulses per second to aid in the selection of

a pulse frequency suitable for the application.

IMPORTANT: This control may be adjusted while

welding.

4-12. BACKGROUND CONTROL (Pulser Models

Only) (Figure 4-1)

BACKGROUND

The BACKGROUND and AMPERAGE ADJUSTMENT

control provide amperage selection within the welding

power source output amperage range being used. The

setting of the background control establishes the background level from which the output amperage travels to

the pulse level established by the setting of the AMPERAGE ADJUSTMENT control. When the AMPERAGE

ADJUSTMENT control is adjusted to a setting above the

BACKGROUND control, there will be positive pulse

peaking from the background reference level. This unit

does not have negative pulsing capability. The background amperage is always a percentage of the peak

amperage. If the peak amperage is adjusted (by means

of the AMPERAGE ADJUSTMENT control), the background amperage will always vary with it according to

the percentage setting of the BACKGROUND control.

The background amperage can never be higher than

the peak amperage. Rotating the AMPERAGE ADJUSTMENT control and BACKGROUND control in a

clockwise direction increases the output amperage.

OM-530 Page 15

Page 20

ST-009 477-D

OM-530 Page 16

ST-007 648-G

Page 21

The scale surrounding the BACKGROUND control is

calibrated in percentage and does not indicate an amperage or voltage value.

IMPORTANT: This control may be adjusted while

welding.

4-15. PERCENTAGE INITIAL AMPERAGE CONTROL (Electroslope Models Only) (Figure 4-1)

PERCENTAGE

INITIAL

AMPERAGE

4-13. ELECTROSLOPE (Electroslope Models Only)

ELECTROSLOPE 9

The Electroslope in this unit allows the operator (by

means of the momentary-contact switch, RMLS-14) to

manually select the welding condition and the duration

of that condition. The welding conditions that the Electroslope provides are PERCENTAGE INITIAL AMPERAGE, PERCENTAGE UPSLOPE RATE, PERCENTAGE DOWNSLOPE RATE, and PERCENTAGE FINAL

AMPERAGE. Additionally, adjustment of each condition

is provided by means of a control on the front panel of

the Electroslope.

IMPORTANT: A momentary-contact type switch

(RMLS-14) is supplied with each unit equipped with an

Electroslope, It is necessary to press the switch each

time a new or different weld condition is desired. This

switch allows the operator to manually control the selection of the welding condition and the duration of that condition. It further gives the operator the capability of moving rapidly from one condition to the next, if desired.

Anytime that the arc is broken (except during the initial

condition), the Electroslope will automatically reset to

Off. During the initial condition resetting to Off is accomplished manually by pushing the switch once, provided

that an arc has not been established. (For further explanation of this switch, see Section 4-5).

A

Adjust the PERCENTAGE INITIAL AMPERAGE control

for the approximate starting amperage desired. This

control is not linear and its settings represent a percentage of the AMPERAGE ADJUSTMENT control value in

use and not an actual amperage reading. Adjustment of

the PERCENTAGE INITIAL AMPERAGE control will

vary the amperage from minimum of the amperage

range used to the setting of the AMPERAGE ADJUSTMENT control in the TIG-Unit. For example: If the

Range Switch setting has a amperage range of 100 to

500 amperes and the AMPERAGE ADJUSTMENT control on the TIG–Unit is set for 300 amperes, the setting of

the PERCENTAGE INITIAL AMPERAGE control on the

Electroslope will then determine the initial amperage between 100 and 300 amperes. If the PERCENTAGE INITIAL AMPERAGE control is set at 50, initial amperage

will be approximately 200 amperes and will remain at

this amperage until the Upslope is energized. The initial

amperage can never be higher than the weld amperage

provided by the TIG-Unit.

IMPORTANT: This control may be adjusted while

welding.

4-16. PERCENTAGE UPSLOPE RATE CONTROL

(Electroslope Models Only) (Figure 4-1)

4-14. ELECTROSLOPE SWITCH (Electroslope

Models Only) (Figure 4-1)

ON

OFF

The Electroslope switch provides two positions: ON

and OFF.

When the Electroslope switch is in the OFF position, the

Electroslope will be bypassed or out of the welding power source control circuit. When the Electroslope switch

is in the ON position, the Electroslope will be connected

into the welding power source control circuit.

Ensure that the AMPERAGE switch on the TIG-Unit is in

the PANEL position whenever the Electroslope is to be

utilized. The AMPERAGE ADJUSTMENT control on

the TIG-Unit has complete control of the amperage at

this point.

PERCENTAGE

UPSLOPE

RATE

0.25-20 SEC.

t

0.25-20s

The PERCENTAGE UPSLOPE RATE control is calibrated in percent and can be adjusted for an upslope

rate of approximately .25 (FAST) to 20 (SLOW) seconds. With the control set at minimum, initial amperage

will rise immediately to the amperage setting of the TIGUnit AMPERAGE ADJUSTMENT control. When the

PERCENTAGE UPSLOPE RATE control is set at 50, it

takes approximately 10 seconds for initial amperage to

reach welding amperage provided that the difference

between initial amperage and weld amperage is great

enough. By increasing the control setting to 100, the

upslope rate will be approximately 20 seconds.

IMPORTANT: This control may be adjusted while

welding.

OM-530 Page 17

Page 22

4-17. PERCENTAGE DOWNSLOPE RATE CONTROL (Electroslope Models Only) (Figure 4-1)

PERCENTAGE

DOWNSLOPE

RATE

0.25-20 SEC.

t

0.25-20s

The PERCENTAGE DOWNSLOPE RATE control is

calibrated in percent and can be adjusted for a downslope rate of approximately .25 (FAST) to 20 (SLOW)

seconds. The settings of this control are comparable to

the PERCENTAGE UPSLOPE RA TE control and determine the time rate at which weld amperage will decrease to the setting of the PERCENTAGE FINAL AMPERAGE control.

IMPORTANT: This control may be adjusted while

welding.

4-18. PERCENTAGE FINAL AMPERAGE CONTROL

(Electroslope Models Only) (Figure 4-1)

PERCENTAGE

FINAL

AMPERAGE

An adjustable 0 to 15 second coolant-gas PREFLOW

TIME control can be provided for controlling the period

of time shielding gas and coolant flows before the arc is

initiated. The PREFLOW TIME control governs the operation of a preflow timer within the TIG-Unit.

Rotating the control in a clockwise direction increases

the preflow time. The scale surrounding the PREFLOW

TIME control is calibrated in seconds to aid in the selection of a preflow time period suited to the individual welding operation.

As soon as the remote contactor control switch has