Page 1

OM-203 185F

2005−09

Processes

Induction Heating

Description

Single Induction Heating Power Source

Temperature Control/Recorder

IH/TS

Visit our website at

www.MillerWelds.com

File: Induction Heating

Page 2

From Miller to You

Thank you and congratulations on choosing Miller. Now you can get

the job done and get it done right. We know you don’t have time to do

it any other way.

That’s why when Niels Miller first started building arc welders in 1929,

he made sure his products offered long-lasting value and superior

quality. Like you, his customers couldn’t afford anything less. Miller

products had to be more than the best they could be. They had to be the

best you could buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and service

that meets the high standards of quality and value established in 1929.

This Owner’s Manual is designed to help you get the most out of your

Miller products. Please take time to read the Safety precautions. They

will help you protect yourself against potential hazards on the worksite.

We’ve made installation and operation quick

and easy. With Miller you can count on years

of reliable service with proper maintenance.

And if for some reason the unit needs repair,

there’s a Troubleshooting section that will

help you figure out what the problem is. The

Miller is the first welding

equipment manufacturer in

the U.S.A. to be registered to

the ISO 9001:2000 Quality

System Standard.

parts list will then help you to decide the

exact part you may need to fix the problem.

Warranty and service information for your

particular model are also provided.

Working as hard as you do

− every power source from

Miller is backed by the most

hassle-free warranty in the

business.

Miller Electric manufactures a full line

of welders and welding related equipment.

For information on other quality Miller

products, contact your local Miller distributor to receive the latest full

line catalog or individual specification sheets. To locate your nearest

distributor or service agency call 1-800-4-A-Miller, or visit us at

www.MillerWelds.com on the web.

Mil_Thank 4/05

Page 3

TABLE OF CONTENTS

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. Symbol Usage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. Induction Heating Hazards 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3. Additional Symbols for Installation, Operation, and Maintenance 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4. California Proposition 65 Warnings 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5. Principal Safety Standards 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-6. EMF Information 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 − MESURES DE SECURITE POUR LE CHAUFFAGE PAR INDUCTION 4 . . . . . . . . . . . . . . . . . . .

2-1. Dangers supplémentaires de mise en route, de fonctionnement et d’entretien 5 . . . . . . . . . . . . . . . . . . .

2-2. Informations concernant les champs électro-magnétiques (Information EMF) 6 . . . . . . . . . . . . . . . . . . .

2-3. PRINCIPALES NORMES DE SÉCURITÉ 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 − INTRODUCTION 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 − INSTALLATION 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. Specifications 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2. IH/TS Installation 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3. Connecting To Power Source 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4. Input 14 Pin Information For Receptacle RC1 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5. Connecting 25kW System Cords And Cables 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6. Connecting 5kW System Cords And Cables 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7. Connecting External Device 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 − COMPONENTS AND CONTROLS 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1. IH/TS Front Panel 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2. IH/TS Rear Panel 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3. Controller 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 − SETUP AND OPERATION 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1. Safety Equipment 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2. IH/TS Setup 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-1. Select Power Source 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2. Time Date Setup − Digital 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2-1. Digital Recorder Controls 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2-2. Login As Engineer 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2-3. Go To Operator Screen 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2-4. Locale Setup 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2-5. Time And Date Setup 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2-6. Login As User 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2-7. Go To Home Screen 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2-2-8. Channel Cycling On/Off And Notes 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3. Operation 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-1. 2408 Controller 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-1-1. 2408 Controller Operation 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-2. Programming The 2408 Controller 21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3. Batch Recording Using 5100 Digital Recorder 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-1. Login As User 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-2. Start Recording 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-3. Stop Recording 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-4. Saving Data To A Disk (Recommended After Each Batch) 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-5. Saving Data To A PC (Alternative To Floppy Disk) 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-5-1. Review Software − First Time Setup 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-5-2. Creating A Shortcut − First Time Setup 27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-5-3. Changing IP Address To Connect The IH/TS 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-5-4. Downloading Files From Recorder 28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-5-5. Troubleshooting Connection Problems 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-3-5-6. Resetting IP Address (Necessary To Connect User’s PC To Company’s Network) 29 . . . . .

6-3-4. Running A Program To Preheat Or Stress Relief 30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

TABLE OF CONTENTS

6-3-5. Recovering From An Interruption 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-6. Viewing Data In Review Software 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-6-1. Installing Review Software And First Time Setup 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-6-2. Backing Up The Database 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-7. Running Review Software 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3-8. Typical Profile Chart Printout 47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7 − CONFIGURING CONTROLLER AND RECORDER 48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1. Changing Controller Operating Window, Ramp, Dwell, Or Temperature Units 48 . . . . . . . . . . . . . . . . . . . .

7-2. Changing 5100V Recorder From Degrees F to Degrees C And Change TC Descriptor 49 . . . . . . . . . . .

7-3. Restoring Recorder Configuration From A Floppy Disk

(For 5100 Digital Recorder) 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3-1. Load File 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3-2. Date Setup 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3-3. Time Setup 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3-4. Login As User 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3-5. Go To Home Screen 51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8 − MAINTENANCE & TROUBLESHOOTING 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1. Routine Maintenance 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2. Troubleshooting 52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3. Diagnostic Procedures For IH/TS 55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-4. Resetting All RAM Variables In The Event Of Display Errors 58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5. Factory Set Parameters 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5-1. Controller Version Number 59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5-2. 2408 Controller Edit Parameters 60 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5-3. 2408 Controller Full Parameters (Prior To Version V4.09) 61 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5-4. 2408 Controller Configure Parameters (Prior To Version V4.09) 62 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5-5. 2408 Controller Full Parameters (Effective w/Version V4.09) 63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5-6. 2408 Controller Configure Parameters (Effective w/Version V4.09) 64 . . . . . . . . . . . . . . . . . . . . . . . . . .

8-6. Calibration Certification Procedure 65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9 − ELECTRICAL DIAGRAMS 66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 10 − PARTS LIST 67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY

Page 5

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE

USING

Y Warning: Protect yourself and others from injury — read and follow these precautions.

1-1. Symbol Usage

Means Warning! Watch Out! There are possible hazards

with this procedure! The possible hazards are shown in

the adjoining symbols.

safety_ihom 5/05

Y Marks a special safety message.

. Means “Note”; not safety related.

1-2. Induction Heating Hazards

Y The symbols shown below are used throughout this manual to

call attention to and identify possible hazards. When you see

the symbol, watch out, and follow the related instructions to

avoid the hazard. The safety information given below is only a

summary of the more complete safety information found in the

Safety Standards listed in Section 1-5. Read and follow all Safety Standards.

Y Only qualified persons should install, operate, maintain, and

repair this unit.

Y During operation, keep everybody, especially children, away.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks

or severe burns. The power circuit and output bus

bars or connections are electrically live whenever

internal circuits are also live when power is on. Incorrectly installed or

improperly grounded equipment is a hazard.

D Do not touch live electrical parts.

D Enclose any connecting bus bars and coolant fittings to prevent

unintentional contact.

D Wear dry, hole-free insulating gloves and body protection.

D Insulate yourself from work and ground using dry insulating mats or

covers big enough to prevent any physical contact with the work or

ground.

D Additional safety precautions are required when any of the follow-

ing electrically hazardous conditions are present: in damp locations

or while wearing wet clothing; on metal structures such as floors,

gratings, or scaffolds; when in cramped positions such as sitting,

kneeling, or lying; or when there is a high risk of unavoidable or accidental contact with the workpiece or ground. For these

conditions, see ANSI Z49.1 listed in Safety Standards. And, do not

work alone!

D Disconnect input power before installing or servicing this equip-

ment. Lockout/tagout input power according to OSHA 29 CFR

1910.147 (see Safety Standards).

D Use only nonconductive coolant hoses with a minimum length of 18

inches (457 mm) to provide isolation.

D Properly install and ground this equipment according to its Owner’s

Manual and national, state, and local codes.

D Always verify the supply ground − check and be sure that input pow-

er cord ground wire is properly connected to ground terminal in

disconnect box or that cord plug is connected to a properly grounded

receptacle outlet.

D When making input connections, attach proper grounding

conductor first − double-check connections.

the output is on. The input power circuit and machine

This group of symbols means Warning! Watch Out! possible

ELECTRIC SHOCK, MOVING PARTS, and HOT PARTS hazards.

Consult symbols and related instructions below for necessary actions

to avoid the hazards.

D Frequently inspect input power cord for damage or bare wiring − re-

place cord immediately if damaged − bare wiring can kill.

D Turn off all equipment when not in use.

D Do not use worn, damaged, undersized, or poorly spliced cables.

D Do not drape cables over your body.

D Do not touch power circuit if you are in contact with the work, ground,

or another power circuit from a different machine.

D Use only well-maintained equipment. Repair or replace damaged

parts at once. Maintain unit according to manual.

D Wear a safety harness if working above floor level.

D Keep all panels and covers securely in place.

SIGNIFICANT DC VOLTAGE exists in inverter-type

power sources after removal of input power.

D Turn Off inverter, disconnect input power, and discharge input

capacitors according to instructions in Maintenance Section before

touching any internal parts.

FUMES AND GASES can be hazardous.

Induction Heating of certain materials, adhesives,

and fluxes can produce fumes and gases. Breathing

these fumes and gases can be hazardous to your

health.

D Keep your head out of the fumes. Do not breathe the fumes.

D If inside, ventilate the area and/or use local forced ventilation to re-

move fumes and gases.

D If ventilation is poor, wear an approved air-supplied respirator.

D Read and understand the Material Safety Data Sheets (MSDSs)

and the manufacturer’s instruction for adhesives, fluxes, metals,

consumables, coatings, cleaners, and degreasers.

D Work in a confined space only if it is well ventilated, or while wearing

an air-supplied respirator. Always have a trained watchperson nearby. Fumes and gases from heating can displace air and lower the

oxygen level causing injury or death. Be sure the breathing air is

safe.

D Do not heat in locations near degreasing, cleaning, or spraying oper-

ations. The heat can react with vapors to form highly toxic and

irritating gases.

D Do not overheat coated metals, such as galvanized, lead, or

cadmium plated steel, unless the coating is removed from the

heated area, the area is well ventilated, and while wearing an airsupplied respirator. The coatings and any metals containing these

elements can give off toxic fumes if overheated. See coating MSDS

for temperature information.

OM-203 185 Page 1

Page 6

FIRE OR EXPLOSION hazard.

INDUCTION HEATING can cause burns.

D Do not overheat parts and adhesive.

D Watch for fire; keep extinguisher nearby.

D Keep flammables away from work area.

D Do not locate unit on, over, or near combustible surfaces.

D Do not install unit near flammables.

D Do not operate unit in explosive atmosphere.

D Allow cooling period before handling parts or equipment.

D Keep metal jewelry and other metal personal items away from

head/coil during operation.

D Hot parts and equipment can injure.

D Do not touch or handle induction head/coil

during operation.

D Do not touch hot parts bare-handed.

1-3. Additional Symbols for Installation, Operation, and Maintenance

FALLING UNIT can cause injury.

D Use handle and have person of adequate

physical strength lift unit.

D Move unit with hand cart or similar device.

D For units without a handle, use equipment of

adequate capacity to lift unit.

D When using lift forks to move unit, be sure forks are long enough

to extend beyond opposite side of unit.

FLYING METAL OR ADHESIVE can injure eyes.

D Wear approved safety glasses with side

shields or wear face shield.

MOVING PARTS can cause injury.

D Keep away from moving parts such as fans.

D Keep all doors, panels, covers, and guards

closed and securely in place.

D Have only qualified person familiar with electronic equipment per-

form this installation.

D The user is responsible for having a qualified electrician promptly

correct any interference problem resulting from the installation.

D If notified by the FCC about interference, stop using the equip-

ment at once.

D Have the installation regularly checked and maintained.

D Keep high-frequency source doors and panels tightly shut.

STATIC (ESD) can damage PC boards.

D Put on grounded wrist strap BEFORE handling

boards or parts.

D Use proper static-proof bags and boxes to

store, move, or ship PC boards.

H.F. RADIATION can cause interference.

D High-frequency (H.F.) can interfere with radio

navigation, safety services, computers, and

communications equipment.

MAGNETIC FIELDS can affect pacemakers.

D Pacemaker wearers keep away.

D Wearers should consult their doctor before

going near induction heating operations.

OVERUSE can cause OVERHEATING

D Allow cooling period.

D Reduce output or reduce duty cycle before

starting to heat again.

D Follow rated duty cycle.

1-4. California Proposition 65 Warnings

Y Welding or cutting equipment produces fumes or gases which

contain chemicals known to the State of California to cause

birth defects and, in some cases, cancer. (California Health &

Safety Code Section 25249.5 et seq.)

Y Battery posts, terminals and related accessories contain lead

and lead compounds, chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

1-5. Principal Safety Standards

Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1,

from Global Engineering Documents (phone: 1-877-413-5184, website:

www.global.ihs.com).

Safety and Health Standards, OSHA 29 CFR 1910, from Superintendent

of Documents, U.S. Government Printing Office, Washington, D.C.

20402.

National Electrical Code, NFPA Standard 70, from National Fire Protec-

tion Association, Batterymarch Park, Quincy, MA 02269.

READ INSTRUCTIONS.

D Read Owner’s Manual before using or servic-

ing unit.

D Use only genuine Miller/Hobart replacement

parts.

For Gasoline Engines:

Y Engine exhaust contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive

harm.

For Diesel Engines:

Y Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and other reproductive harm.

Canadian Electrical Code Part 1, CSA Standard C22.1, from Canadian

Standards Association, Standards Sales, 178 Rexdale Boulevard,Rexdale, Ontario, Canada M9W 1R3.

Practice For Occupational And Educational Eye And Face Protection,

ANSI Standard Z87.1, from American National Standards Institute, 11

West 42nd Street, New York, NY 10036−8002 (phone: 212−642−4900,

website: www.ansi.org).

OM-203 185 Page 2

Page 7

1-6. EMF Information

Considerations About Induction Heating And The Effects Of Low Frequency Electric And Magnetic Fields

The following is a quotation from the General Conclusions Section of the

U.S. Congress, Office of Technology Assessment, Biological Effects of

Power Frequency Electric & Magnetic Fields − Background Paper, OTA-

BP-E-53 (Washington, DC: U.S. Government Printing Office, May

1989): “. . . there is now a very large volume of scientific findings based

on experiments at the cellular level and from studies with animals and

people which clearly establish that low frequency magnetic fields can interact with, and produce changes in, biological systems. While most of

this work is of very high quality, the results are complex. Current scientific understanding does not yet allow us to interpret the evidence in a

single coherent framework. Even more frustrating, it does not yet allow

us to draw definite conclusions about questions of possible risk or to offer clear science-based advice on strategies to minimize or avoid

potential risks.”

To reduce magnetic fields in the workplace, use the following procedures:

1. Arrange output cable to one side and away from the operator.

2. Do not coil or drape output cable around the body.

3. Keep power source and cable as far away from the operator as

practical.

About Pacemakers:

Pacemaker wearers consult your doctor before welding or going near

welding or induction heating operations. If cleared by your doctor, then

following the above procedures is recommended.

OM-203 185 Page 3

Page 8

SECTION 2 − MESURES DE SECURITE POUR LE

CHAUFFAGE PAR INDUCTION

ihom_fre 8/03

AVERTISSEMENT

LE CHAUFFAGE PAR INDUCTION peut être dangereux.

PRENDRE LES MESURES NECESSAIRES POUR EVITER LES RISQUES DE BLESSURES GRAVES, VOIRE

MORTELLES. TENIR LES ENFANTS A DISTANCE. LES PORTEURS D’UN STIMULATEUR CARDIAQUE DOIVENT

PREALABLEMENT CONSULTER LEUR MEDECIN.

Pendant les opérations de chauffage, comme dans la plupart des activités, l’opérateur s’expose à certains dangers.

Le chauffage n’est pas dangereux à condition de prendre certaines mesures. Les consignes de sécurité indiquées

ci-après ne sont qu’un résumé des informations plus détaillées se trouvant dans les normes de sécurité énumérées

à la page suivante. Lire et respecter toutes les normes de sécurité.

LES OPERATIONS D’INSTALLATION, DE FONCTIONNEMENT, DE MAINTENANCE ET DE REPARATION NE DOIVENT

ETRE CONFIEES QU’A DU PERSONNEL QUALIFIE.

Danger de mort PAR ELECTROCUTION.

Le contact de composants électriques peut

provoquer des accidents mortels ou des brûlures

graves. Le circuit de puissance et les connexions de

sortie sont sous tension lorsqu’on active la sortie. Le

circuit d’alimentation et les circuits internes de la

machine sont également sous tension lorsque

l’alimentation est sur marche. Des équipements

installés ou reliés à la borne de terre de manière

incorrecte sont dangereux.

1. Ne pas toucher des composants électriques sous tension.

2. Envelopper les connexions et raccords de refroidissement pour

éviter tout contact accidentel.

3. Porter des gants d’isolation secs, sans trous, et une protection

corporelle.

4. Isolez-vous de la pièce et du sol avec des tapis ou des

couvertures d’isolation suffisamment grands pour prévenir tout

contact physique avec la pièce ou la terre.

5. Déconnecter l’alimentation avant d’installer l’appareil ou d’en

effectuer l’entretien. Verrouiller ou étiqueter la sortie

d’alimentation selon la norme OSHA 29 CFR 1910.147

(se reporter aux Principales normes de sécurité).

6. Utiliser seulement des tuyaux non conducteurs avec une

longueur minimale de 460 mm pour assurer l’isolement.

7. Installer et mettre cet équipement correctement à la terre

conformément au manuel utilisateur et aux codes nationaux,

gouvernementaux et locaux.

8. Vérifier souvent la terre de l’alimentation − contrôler et s’assurer

que le conducteur de terre du câble d’alimentation est

correctement relié à la borne de terre dans le boîtier de

déconnexion ou que le connecteur est branché à une sortie de

boîtier correctement mise à la terre.

9. En réalisant des connexions d’entrée brancher d’abord le

conducteur de terre approprié − contrôler deux fois les

connexions.

10. Vérifier souvent le bon état du câble d’alimentation ou l’isolation

des fils − remplacer le câble immédiatement s’il est endommagé −

des fils dénudés peuvent provoquer des accidents mortels.

11. Arrêter tous les équipements lorsqu’ils ne sont pas utilisés.

12. Ne pas utiliser des câbles usés, endommagés, sous

dimensionnés ou mal épissés.

13. Ne pas porter les câbles autour de votre corps.

14. Ne pas toucher le circuit électrique si vous êtes en contact avec la

pièce, la terre ou le circuit électrique d’une autre machine.

15. Utiliser seulement des équipements bien entretenus. Réparer ou

remplacer immédiatement des composants endommagés.

Effectuer des travaux d’entretien sur l’appareil selon le manuel.

16. Porter un harnais de sécurité pour effectuer des travaux

au-dessus du sol.

17. Maintenir solidement en place tous les panneaux et couvercles.

LE CHAUFFAGE PAR INDUCTION peut

provoquer des blessures ou des

brûlures au contact de PIECES

CHAUDES OU DE L’EQUIPEMENT.

LE CHAUFFAGE PAR INDUCTION peut

provoquer un incendie.

1. Ne pas surchauffer les composants ni les

adhésifs.

2. Attention aux risques d’incendie: tenir un

extincteur à proximité.

3. Stocker des produits inflammables hors de la

zone de travail.

1. Ne pas toucher ou manipuler la tête/l’enroulement à induction

pendant le fonctionnement.

2. Tenir les bijoux et autres objets personnels en métal éloignés de

la tête/de l’enroulement pendant le fonctionnement.

3. Laisser refroidir les composants ou équipements avant de les

manipuler.

La mise en place de l’appareil sur, au-dessus ou à

proximité de surfaces inflammables peut être source

d’INCENDIES OU d’EXPLOSION.

1. Ne pas placer l’appareil sur, au-dessus ou à proximité de

surfaces infllammables.

2. Ne pas installer l’appareil à proximité de produits inflammables

3. Ne pas faire fonctionner l’appareil en atmosphère explosive.

OM-203 185 Page 4

Page 9

DES FUMEES ET DES GAZ peuvent

être dangereux pour votre santé.

Le chauffage à induction génère des fumées et des

gaz. Leur inhalation peut être dangereuse pour votre

santé.

1. Eloigner la tête des fumées. Ne pas respirer les fumées.

2. A l’interieur, ventiler la zone et/ou utiliser un extracteur pour

l’évacuation des fumées et des gaz.

3. Si la ventilation est insuffisante, utiliser un respirateur à

alimentation d’air homologué.

4. Lire les spécifications de sécurité des matériaux (MSDSs) et les

instructions du fabricant concernant les adhésifs, les métaux, les

consommables, les revêtements, les nettoyants et les

dégraisseurs.

5. Travailler dans un espace fermé seulement s’il est bien ventilé ou

en portant un respirateur. Demander toujours à un surveillant

dûment formé de se tenir à proximité. Des fumées et des gaz

provenant du chauffage peuvent déplacer l’air, abaisser le niveau

d’oxygène, et provoquer des lésions ou des accidents mortels.

S’assurer que l’air ambiant ne présente aucun danger.

6. Ne pas chauffer dans des endroits se trouvant à proximité

d’opérations de dégraissage, de nettoyage ou de pulvérisation. La

chaleur peut réagir en présence de vapeurs et former des gaz

hautement toxiques et irritants.

7. Ne pas chauffer des métaux munis d’un revêtement tels que l’acier

galvanisé, plaqué au plomb ou au cadmium, à moins que le

revêtement ne soit enlevé de la zone chauffée, que la zone soit

bien ventilée et, si nécessaire, en portant un respirateur. Les

revêtements et tous les métaux contenant ces éléments peuvent

dégager des fumées toxiques s’ils sont chauffés.

2-1. Dangers supplémentaires de mise en route, de fonctionnement et d’entretien

LA CHUTE DE MATERIEL peut provoquer

des blessures personnelles graves et endommager les équipements.

1. Utiliser la poignée et demander à une personne

ayant la force physique nécessaire pour soulever

l’appareil.

2. Déplacer l’appareil à l’aide d’un charriot ou d’un

engin similaire.

3. Pour les appareils sans poignée utiliser un équipement d’une capacité appropriée pour soulever

l’appareil.

4. En utilisant des fourches de levage pour déplacer

l’unité, s’assurer que les fourches sont suffisamment

longues pour dépasser du côté opposé de l’appareil.

UNE UTILISATION INTENSIVE peut provoquer un SURCHAUFFEMENT DU MATERIEL.

1. Prévoir une période de refroidissement

2. Réduire le courant de sortie ou le facteur de marche

avant de recommencer le chauffage.

3. Respecter le facteur de marche nominal.

L’ELECTRICITE STATIQUE peut endommager les composants des tableaux électriques.

1. Etablir la connexion avec la barrette de terre avant

de manipuler des cartes ou des pièces.

2. Utiliser des pochettes et des boîtes antistatiques

pour stocker, déplacer ou expédier des cartes PC.

LA PROJECTION DE PIECES DE METAL ou

DE COLLE peut provoquer des blessures

aux yeux.

1. Porter des lunettes de protection avec des protections latérales.

DES ORGANES MOBILES peuvent

provoquer des blessures.

1. S’abstenir de toucher des organes mobiles tels que

des ventilateurs.

2. Maintenir fermés et fixement en place les portes, panneaux, recouvrements et dispositifs de protection.

DES CHAMPS MAGNETIQUES CREES PAR

DES COURANTS ELEVES peuvent affecter le

fonctionnement du stimulateur cardiaque.

1. Porteurs de stimulateur cardiaque, restez à distance.

2. Les porteurs d’un stimulateur cardiaque doivent d’abord consulter leur médecin avant de s’approcher

des opérations de chauffage à induction.

Il subsiste DU COURANT CONTINU IMPORTANT après la mise hors tension de l’alimentation électrique.

1. Avant de toucher des organes internes, arrêter la

source électrique, débrancher l’alimentation, et décharger les condensateurs d’alimentation conformément aux instructions indiquées dans la partie maintenance.

LE RAYONNEMENT HAUTE FREQUENCE

peut provoquer des interférences avec les

équipements de radio-navigation et de communication, les services de sécurité et les ordinateurs.

• Demander seulement à des personnes qualifiées

familiarisées avec des équipements électroniques

de faire fonctionner l’installation.

• L’utilisateur est tenu de faire corriger rapidement par

un électricien qualifié les interférences résultant de

l’installation.

• Si le FCC signale des interférences, arrêter immé-

diatement l’appareil.

• Effectuer régulièrement le contrôle et l’entretien de

l’installation.

• Maintenir soigneusement fermés les portes et les

panneaux des sources de haute fréquence.

OM-203 185 Page 5

Page 10

2-2. Informations concernant les champs électro-magnétiques (Information EMF)

Considérations relatives au chauffage à induction et aux effets des

champs électriques et magnétiques basse fréquence.

Le texte suivant est extrait des conclusions générales Département

du Congrès U.S., Office of Technology Assessment, Effets

biologiques des champs magnétiques et électriques basse

fréquence − Background Paper, OTA-BP-E-53 (Washington, DC:

U.S. Government Printing Office, May 1989): “. . . on dispose

maintenant d’importantes découvertes scientifiques reposant sur

des expériences effectuées dans le domaine cellulaire et des études

réalisées sur des animaux et des personnes qui démontrent

clairement que des champs magnétiques basse fréquence peuvent

avoir une interaction et produire des changements dans les

systèmes biologiques. Alors que la plus grande partie de cet ouvrage

est d’une très grande qualité, les résultats sont complexes. La

compréhension scientifique courante ne nous permet pas encore

d’interpréter la preuve fournie dans un seul ouvrage cohérent. Il est

encore plus frustrant de ne pas pouvoir tirer des conclusions

définitives en ce qui concerne les problèmes de risque possible ou de

proposer des recommandations scientifiques claires pour des

stratégies à suivre en vue de minimiser ou de prévenir des risques

potentiels.”

Pour réduire les champs magnétiques sur le poste de travail,

appliquer les procédures suivantes :

4. Disposer le câble de sortie d’un côté à distance de l’opérateur

5. Ne pas enrouler ou draper le câble électrique autour du corps.

6. Placer la source de courant et le câble le plus loin possible de

l’opérateur.

En ce qui concerne les stimulateurs cardiaques

Les procédures ci-dessus concernent également les porteurs de

stimulateur cardiaque. Consulter votre médecin pour un complément

d’information.

2-3. PRINCIPALES NORMES DE SÉCURITÉ

Normes de sécurité et de santé, OSHA 29 CFR 1910, from

Superintendent of Documents, U.S. Government Printing Office,

Washington, D.C. 20402.

Code électrique national, NFPA Standard 70, from National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

Code électrique du Canada, partie 1, CSA Standard C22.1, from

Canadian Standards Association, Standards Sales, 178 Rexdale

Boulevard,Rexdale, Ontario, Canada M9W 1R3.

Safe Practices For Occupation And Educational Eye And Face

Protection, ANSI Standard Z87.1, from American National Standards

Institute, 1430 Broadway, New York, NY 10018.

OM-203 185 Page 6

Page 11

SECTION 3 − INTRODUCTION

The Induction Heating Temperature Station (IH/TS) is designed to be used with Induction Heating Systems for

pre-heat and post-heat (stress relieving) applications. The station is built in two different configurations; as a controller

only or as a controller with a digital recorder.

The controller in the IH/TS comes pre-programmed from the factory with a typical stress relieving temperature profile

that can be easily changed to match specific customer stress relief requirements. Also, the controller can be

programmed to operate in a pre-heat mode. These instructions will guide the operator in the proper use of the station

which includes programming and setting up the controller, and operating the recorder.

OM-203 185 Page 7

Page 12

SECTION 4 − INSTALLATION

4-1. Specifications

Specification Description

Overall Dimensions Height: 10 in (254 mm); Width: 14-1/2 in (368 mm); Depth: 16 in (406 mm)

Weight Net: IH/TS (no recorder) 13.1 lb (5.9 kg); IH/TS (digital recorder) 21.1 lb (9.6 kg)

Type Of Input Power 24 Volts DC, 115 Volts AC

Memory Capacity One Program Up To 8 Segments

Control Capacity Single Power Source Control

Operating Temperature Range 41° To 104° F (5° To 40° C)

Storage Temperature Range −4° To 122° F (−20° To 50° C)

Reference the controller and recorder manuals for additional information.

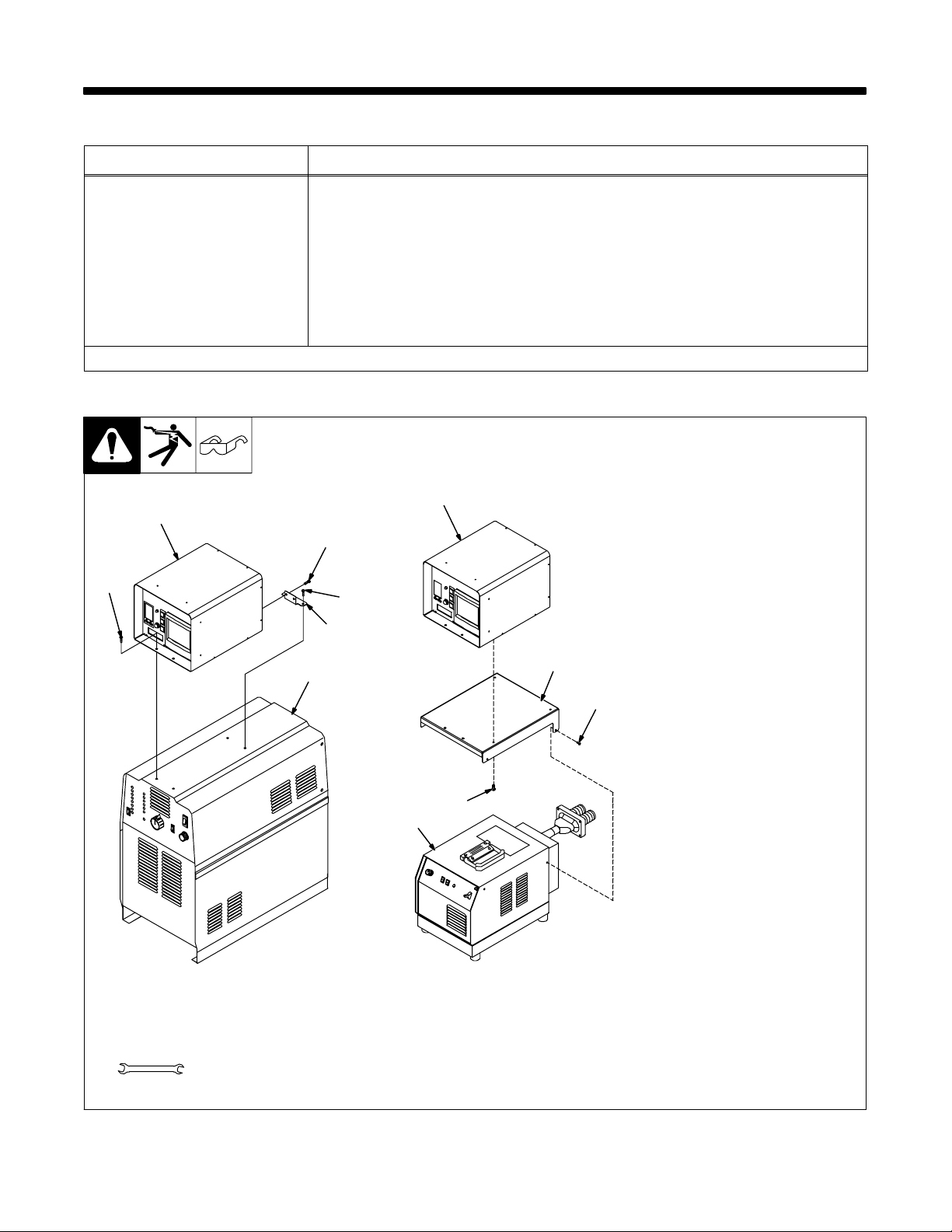

4-2. IH/TS Installation

Y Turn Off and disconnect

input power.

5 kW System

1

1

8

4

8

7

2

6

5

3

4

1. Temperature

Control/Recorder

2. 5kW Mounting Bracket

3. Screw, 10-32 (4)

Install and secure IH/TS to mounting bracket using supplied #10

screws.

4. 5kW Power Source Case

5. Case Sheet Metal Screw (4)

Remove case sheet metal screws

from both top left and right sides of

unit. Install mounting bracket to

power source and secure by reinstalling sheet metal screws.

25 kW System

6. 25 kW Power Source Case

7. Rear Mounting Bracket

8. Screw, 1/4-20 (2)

Remove front and middle mounting

screws from top of Item 6 case. Locate IH/TS and reinstall front

mounting screws. Locate rear

mounting bracket, and secure with

supplied 1/4-20 screws. Reinstall

middle mounting screws to secure

bracket to case.

Tools Needed:

OM-203 185 Page 8

3/8, 5/16 in

Ref. 802 905-A / 802 900

Page 13

4-3. Connecting To Power Source

R

R

l

R

*

5

Turn Off power source.

1. IH/TS

JA

K

B

I

H

C

L

N

G

D

M

E

F

1

2. Interconnecting Cord

3. 14-Socket Plug

4. 14-Pin Plug

Obtain cord with 14-socket plug on

one end and 14-pin plug on other

end.

5. Keyway

6. Remote 14 Receptacle RC1

(See Section 4-4)

6

To connect cord to a receptacle,

align keyway, insert plug, and

tighten threaded collar.

To connect remaining end of cord to

power source, align keyway, insert

plug, and tighten threaded collar.

4

3

2

sb7.1* 3/93 - Ref. S-0004-A / S-0750 / Ref. 802 926 / Ref. 801 049 / 801 825-B / Ref. 803 004-A

4-4. Input 14 Pin Information For Receptacle RC1

REMOTE 14

emote Contactor

emote Output Contro

Power Source Fault

emote Metering

*See power source Owner’s Manual for scaling information.

Pin Pin Information

A +24 volts dc from power source.

B Contact closure to A completes power source +24 volts dc contactor control circuit.

D Control circuit common.

E 0 to +10 volts dc signal for power source output control.

F, J Absence of contact closure from power source indicates power source output failure.

I Actual frequency input signal.

L Average power input signal.

M Voltage input signal RMS.

N Current input signal RMS.

OM-203 185 Page 9

Page 14

4-5. Connecting 25kW System Cords And Cables

Blue

Hose From Cooler To

Power Source

14-Pin

Control Cable

Yellow

Front Rear

110 Volt From

Cooler

Output

Connectors

Blue

Hose From

IH/TS To

Cooler

Red

Yellow

Hose

From Power

Source

To IH/TS

110 Volt From

IH/TS

Red

Connect the power output cable and

coolant lines as shown.

Connect 110-volt power cable as shown.

Plug the 110-volt cooler power cord into

the duplex at the rear of the power source

cart. On the 25kW system, the cooler must

be plugged into the right side duplex. This

is identified with a label that reads

“switched receptacle.” The ON-OFF

switch located to the left operates this

plug.

The IH/TS Control is plugged in the left

side duplex. Do not use these duplex

connections for operating auxiliary tools,

such as grinders, drills, lights, etc.

Connect output power cables to the output

connectors.

. All coolant connections have 5/8-18

left-hand threads.

803 036-C

D Connect the “coolant out” line from

the cooler directly to the output extension cable.

D Connect the “coolant in” line on

the IH/TS directly to the remaining

output extension cable connection.

D Connect the “coolant out” line from

the IH/TS to the “coolant in” line on

the cooler.

OM-203 185 Page 10

Page 15

4-6. Connecting 5kW System Cords And Cables

Front Rear

Output

Connectors

Hose From

Output Extension Cable

To IH/TS

Hose From IH/TS To

Cooler

Connect the power output cable and

coolant lines as shown.

Connect 110-volt power cable as shown.

Plug the 110-volt cooler power cord into

the duplex at the rear of the power source

cart.

Hose From Cooler To

Output Extension Cable

The IH/TS Control is plugged in the left

side duplex. Do not use these duplex

connections for operating auxiliary tools,

such as grinders, drills, lights, etc.

D Connect the “coolant out” line from

the cooler directly to the output extension cable.

803 040-A

D Connect the “coolant in” line on

the IH/TS directly to the remaining

output extension cable connection.

D Connect the “coolant out” line from

the IH/TS to the “coolant in” line on

the cooler.

OM-203 185 Page 11

Page 16

4-7. Connecting External Device

2

The IH/TS must have (as a

minimum) one thermocouple

connected to receptacle TC1. If

multiple thermocouples are

desired, either use individual

thermocouple plugs or the

1

6

5

4

3

thermocouple extension cable.

To connect thermocouples to the

control, proceed as follows:

Turn Off power source.

1. Temperature Controller

2. Thermocouple Receptacles

3. Individual Thermocouple Plug

4. Thermocouple Extension

Cable

Align plug pins with receptacle

sockets and push plug into

receptacle.

5. Coolant Line From Coil

6. Coolant Line To Cooler

“Coolant In” Port

The IH/TS is supplied with an

internal coolant flow switch.

Coolant hoses must be connected

to the IH/TS for proper operation.

Connect coolant hoses (supplied

with post-heat systems) to coolant

fittings on unit as described in

Section 4-5.

Tools Needed:

OM-203 185 Page 12

11/16 in

Ref. 803 003-B

Page 17

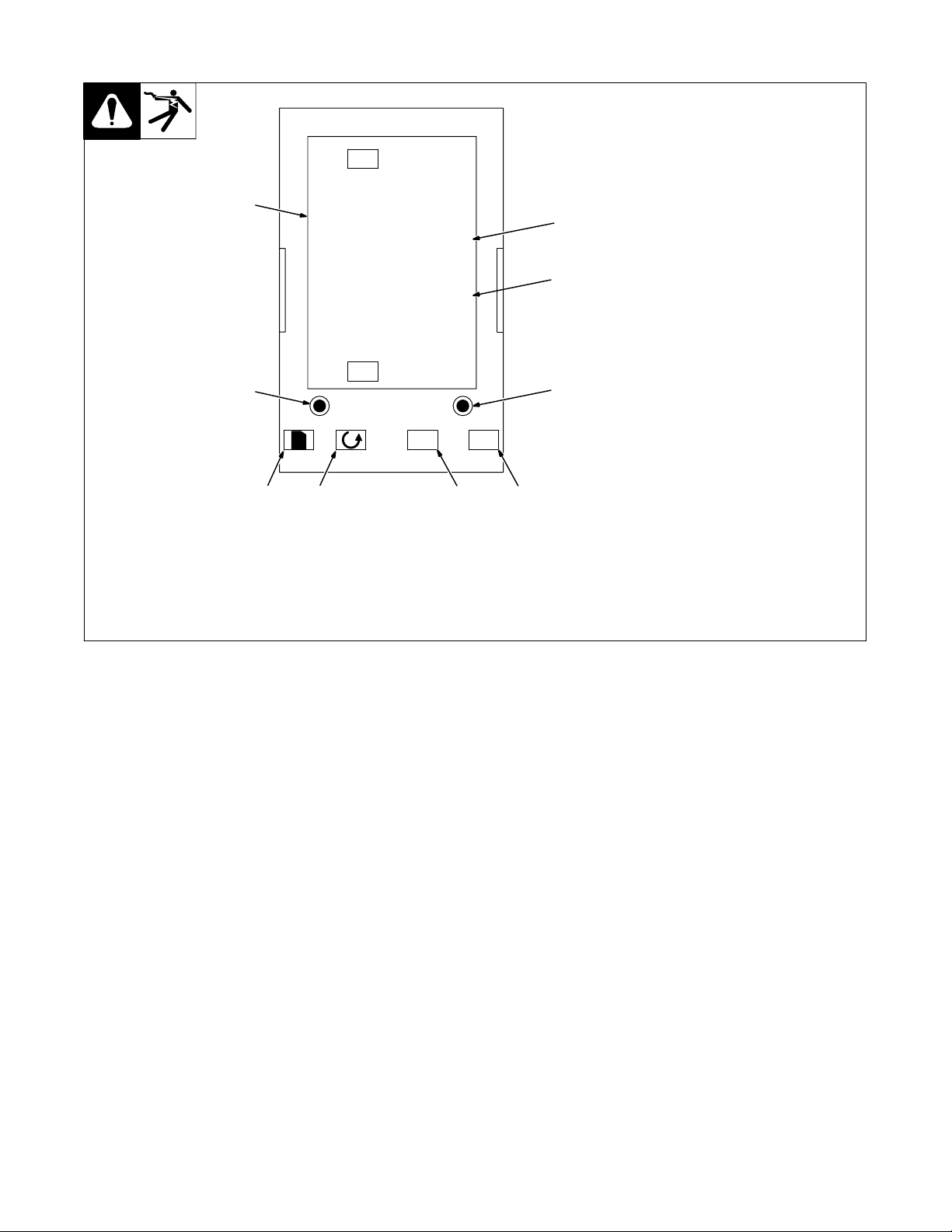

SECTION 5 − COMPONENTS AND CONTROLS

5-1. IH/TS Front Panel

3

Y Keep all panels, doors, and

covers closed and secure

during programming.

1. Temperature Controller

5

6

7

2. Parameter Display Screen

3. Heat On Pilot Light

4. Fault/ Limit Light

5. Run Button

6. Hold Button

7. Stop Button

8. Recorder (If Equipped)

1

2

4

8

Ref. 803 004

OM-203 185 Page 13

Page 18

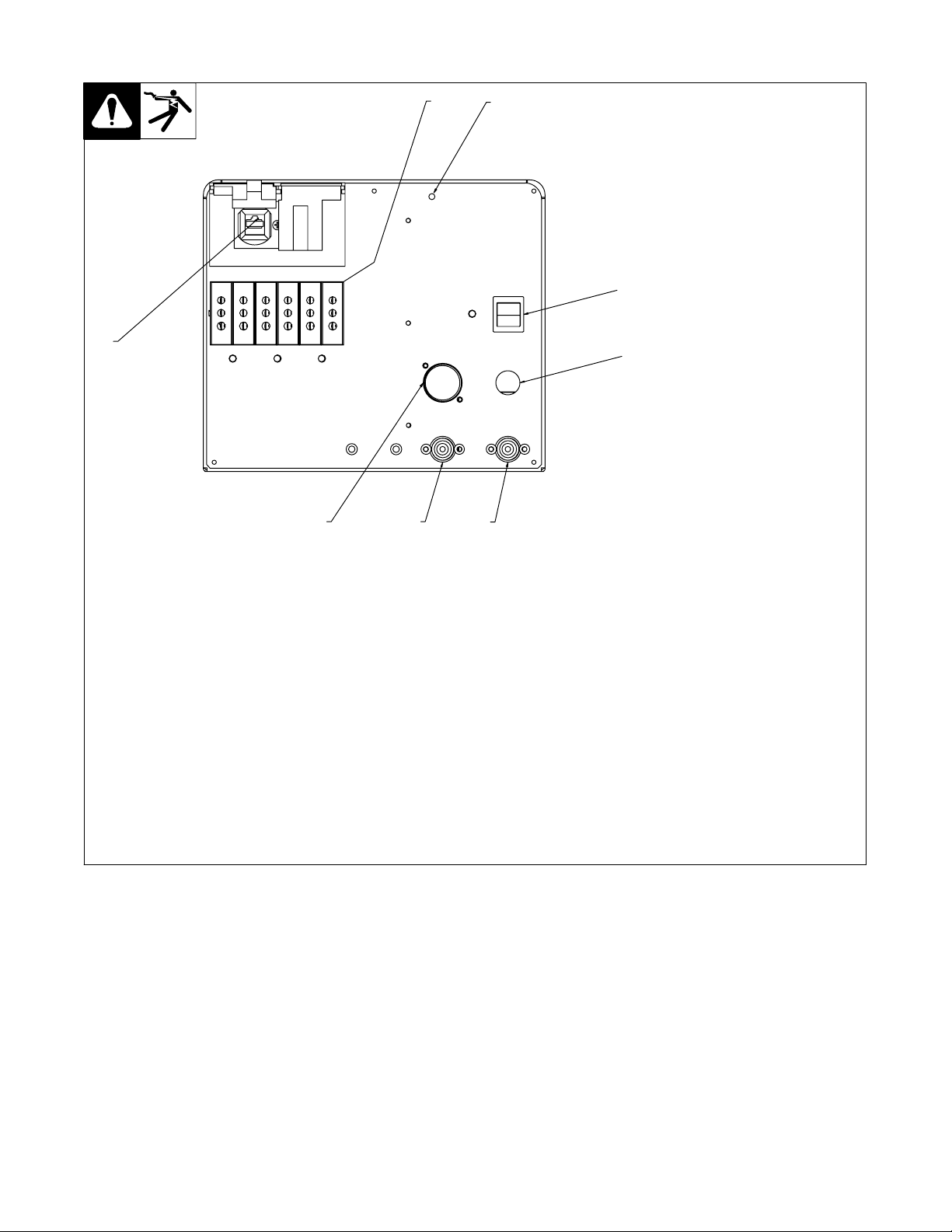

5-2. IH/TS Rear Panel

1

8

4 5 6

7

Y Keep all panels, doors, and

covers closed and secure

during programming.

1. Thermocouple Connectors

2. On/Off Power Switch

3. 115 VAC Power Cord

4. 14-Pin Receptacle

5. Coolant Flow Switch “IN”

Fitting

6. Coolant Flow Switch “OUT”

2

3

Fitting

7. Power Source Select Switch

8. Network Connection

OM-203 185 Page 14

Ref. 803 004-A

Page 19

5-3. Controller

Y Keep all panels, doors, and

covers closed and secure

during programming.

OP1

1

6

200.0

7

200.0

SP2

8

AUTO

MAN

RUN

HOLD

B Y

9

1. Digital Display

2. Page Forward Button

3. Scroll Button

4. Down Button

5. Up Button

6. Actual Temperature

7. Setpoint Temperature

8. Auto/Man Button (Disabled)

9. Run/Hold Button (Disabled)

2

345

OM-203 185 Page 15

Page 20

SECTION 6 − SETUP AND OPERATION

6-1. Safety Equipment

12

Wear the following during

operation:

1. Dry, Insulating Gloves

2. Safety Glasses With Side

Shields

DO NOT wear rings or watches

during operation.

sb3.1* 1/94

6-2. IH/TS Setup

6-2-1. Select Power Source

Energize the power source, cooler, and IH/TS. A power source selection will appear in the top right corner of the

IH/TS front panel Parameter Display. Press the recessed Power Source Select button on the IH/TS rear panel to

toggle through and select the appropriate power source maximum output. This selection will provide the proper output scaling in the parameter display screen for the power source that is attached to the IH/TS.

Parameter Display

0 . 0 K W P w r PS 2 5

0Amps (rms)

0Volts (rms)

12 .5 KHs Fr equency

Power Source Max Output

OM-203 185 Page 16

Page 21

6-2-2. Time Date Setup − Digital

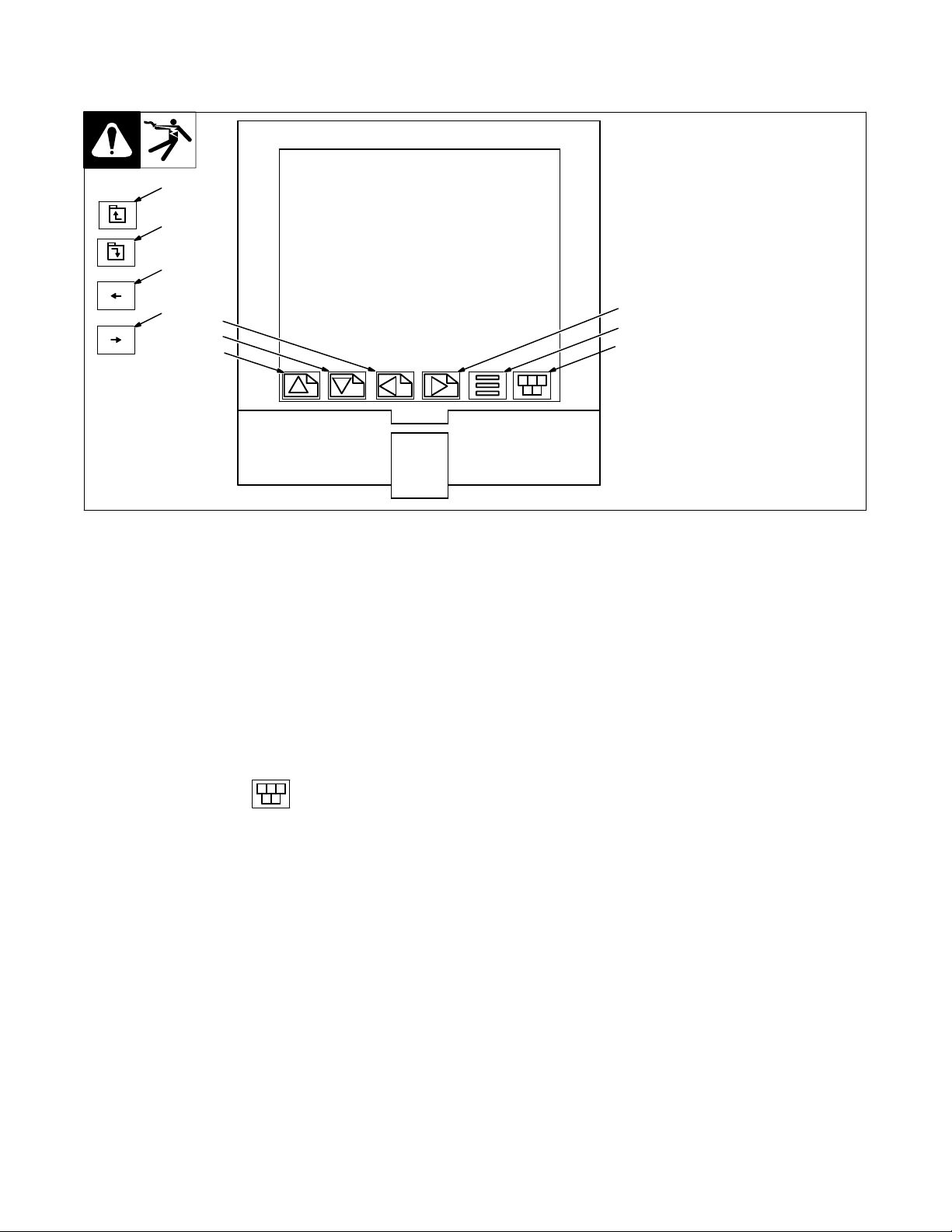

6-2-2-1. Digital Recorder Controls

7

8

9

10

3

2

1

Y Keep all panels, doors, and

covers closed and secure

during programming.

1. Page Up

2. Page Down

3. Left

4. Right

5. Option

6. Menu

Additional keys that appear as

4

needed for specific applications are

5

as follows:

6

7. Close Folder

8. Open Folder

9. Left Cursor

10. Right Cursor

6-2-2-2. Login As Engineer

1. Touch top left corner (Logged Out) or (User).

2. Touch Blue text (pull down menu) next to User.

3. Touch Engineer.

4. Touch Password field.

5. Touch Numeric.

6. Touch 1, then 0, and finally Ok. “Engineer” will appear in top left corner of display.

6-2-2-3. Go To Operator Screen

1. Touch the Menu key in bottom right corner to open Root Menu.

2. Touch Operator.

6-2-2-4. Locale Setup

1. Touch System.

2. Touch Locale.

3. Touch pull down next to Country.

4. Touch appropriate country.

5. Touch pull down next to Time Zone.

6. Touch appropriate time zone (i.e. CST Central). See “http://www.timeanddate.com” for additional information.

7. Set DST (Daylight Savings Time) if applicable. Place an “X” in the box next to “Use Summertime (DST)” to

enable this option.

OM-203 185 Page 17

Page 22

NOTE

In general, for those locations that observe DST:

DST begins at 2:00 am on the first Sunday in April.

DST ends at 2:00 am on the last Sunday in October.

See “http://deil.lang.uiuc.edu/web.pages/holidays/DST.html for exceptions.

8. Touch Apply.

6-2-2-5. Time And Date Setup

1. Touch System.

2. Touch Clock.

3. Adjust time and date, if necessary.

4. Touch Apply.

6-2-2-6. Login As User

1. Touch top left corner (Engineer).

2. Touch pull down next to User.

3. Touch User from pull down list.

6-2-2-7. Go To Home Screen

1. Touch the Menu key in bottom right corner to open Root Menu.

2. Touch Home.

6-2-2-8. Channel Cycling On/Off And Notes

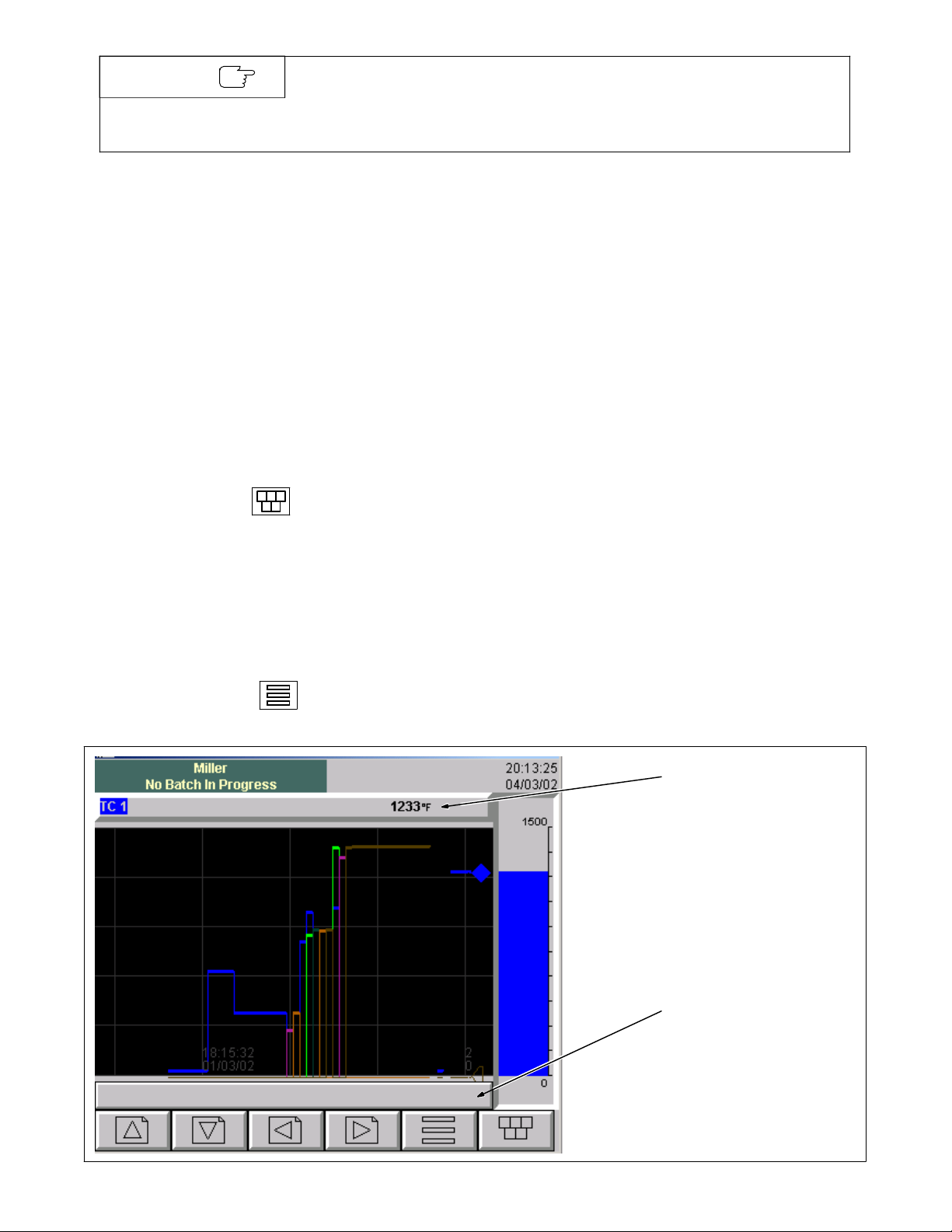

When Trend graphs are displayed, the operator has the option to sequentially display the TC readings for each

channel by activating the “Channel Cycling On”option. When channel cycling is off, recorder displays only the

selected TC value.

To activate/deactivate “Channel Cycling”:

1. Press the Option key to open options menu.

2. Press channel cycling On to activate cycling or press channel cycling Off to deactivate cycling.

To manually change which TC is

displayed, press the TC field to

advance to the next TC reading.

Notes can be added to a chart on

the recorder while viewing a trend

screen.

Press the “Option Menu” button.

Press “Note”.

Press the field next to “User Note”

and enter notes using keypad.

Press “OK”.

Press “OK”.

The note is added to the chart.

The note can be viewed on the

bottom of the screen or in the

history screen.

Press the Option key, press “Enter

History”.

To exit, press the Option key, then

press “Exit History”.

OM-203 185 Page 18

scrn34

Page 23

6-3. Operation

1. Energize IH/TS and power source. A coolant flow error should appear on the IH/TS display. Energize the

cooler and the error will clear from the display.

2. Set up Temperature Profile − per code requirements (see Section 6-3-2 Programming The 2408 Controller).

3. Set up and start Digital Recorder

Digital Recorder (see Section 6-3-3. Batch Recording On The 5100 Digital Recorder)

4. Run the heat process (see Section 6-3-4. Running A Heat Treat and the following tables).

5. Recover from an interruption, if applicable (see Section 6-3-5. Recovering From An Interruption).

6. Retrieve data

Digital Recorder (see Section 6-3-3-4. Batch Recording On The 5100 Digital Recorder)

View and print data (see Section 6-3-6 Review Software).

Table 6-1. Controller Display Definitions

Name Description

Home List (extra parameters may be present.)

Home Measured value and Setpoint

OP

% Output level

Table 6-2. Run List Sub-Menu Definitions

run program run List

StAt Program status (OFF, run, hoLd, HbAc, End)

PSP

SEG

StyP

SEG.t

tGt

rAtE

PrG.t

SEG.d

FASt

*This parameter can only be changed when the program is in reset.

Programmer setpoint

Active segment number

Active segment type

Segment time remaining in the segment units

Target setpoint

Ramp rate (if a rate segment)

Program time remaining in hours

*Flash active segment type in the lower readout of the home display (no/YES)

Runs through program 10 times faster than normal

OM-203 185 Page 19

Page 24

6-3-1. 2408 Controller

The 2408 controller in the IH/TS provides a means of establishing a heat profile for heating or stress relieving as

dictated by “code” requirements, and controls the power source to meet the programmed profile. The 2408 controller

has several screens (main and sub-menu) that are used to monitor status and program the control. The main

screens are as follows:

Home Screen: This screen is displayed after first turning on the unit. It has the actual temperature at the top of

the display and program temperature at the bottom of the display. Home Screen sub-menu and

definitions are shown in Table 6-1. Pressing the “Scroll”

sub-menus.

Run List: This screen is accessed by pushing the “Page” key twice. Run List allows the operator to

check the status of a program while the system is running. It also allows making changes to a

program by pressing the “Hold” button on the front of the IH/TS. Run List sub-menu

screens and their definitions are shown in Table 6-2.

Program List: This screen is accessed by pushing the “Page” key three times. Program List is used to

program the controller for a pre-heat or stress relieving temperature profile. Definitions of the

various terms found in the sub-menu screens are shown in Table 6-3. Typical programming

examples are shown in Figure 6-1, Figure 6-2 and Figure 6-3.

Access List: This screen is used to access the configuration and set-up sub-screens within the controller. This

area is password protected and should only be used by an experienced operator.

button will step through the

. Making changes in the Access List screens may cause the system to operate incorrectly.

A series of keys at the bottom of the 2408 controller are used to navigate between and change values in the various

screens on the controller display. Definition of the keys are as follows:

The “Page” key advances the controller display between main screens (Run List, Prog List and Accs List).

The “Scroll” key advances between various sub-menu screens in the main menus.

The “Up”

Y

and “Down”

B

keys are used to change values in the sub-menu screens.

. The two small round buttons on the front of the controller are disabled and nonfunctional.

6-3-1-1. 2408 Controller Operation

The 2408 controller is configured to control the power source to achieve the temperature program that is entered in

“Prog List”. The configuration of the controller contains two important elements that dictate how the controller

switches between segments and how it protects against over-temperature conditions.

One element is called “Holdback”. This is a temperature window that the controller uses to determine the point at

which it switches from segment-to-segment. The window is set to ±10°. When operating within a temperature profile, the controller will not advance to the next segment until the actual temperature comes within 10° of the target

temperature.

The second element is an alarm. This alarm value is set at 25° F. When the actual temperature exceeds the target

temperature by 25° F, the controller shuts off the power source contactor to prevent overheating the part. When the

temperature falls 2° F below the alarm temperature, the controller re-energizes the power source output.

OM-203 185 Page 20

Page 25

6-3-2. Programming The 2408 Controller

Identify the “code” requirements for the heat treat.

For Preheat program refer to Figure 6-1.

For Postweld stress relief program refer to Figure 6-2.

For a complex stress relief program (multiple temperature rise and cool rates) refer to Figure 6-3.

Use worksheet in Figure 6-4 to help prepare either a pre- or post-heat temperature profile.

Table 6-3. Program List Terms And Definitions

SEG.n

Step

(StEP)

Segment number

Segment Type Definitions

The setpoint steps instantaneously from its current value to a new value.

Dwell

(dwEl)

Ramp Time

(rmP.t)

Ramp Rate

(rmP.r)

End

(End)

The following parameters are available depending on the tYPE selected

The setpoint remains constant for a specified period.

Dwell units (dwL.U) are in hours.

The setpoint ramps linearly, from its current value to a new value, either at a

set rate (called ramp-rate programming), or in a set time (called time-to-target

programming). You must specify the ramp rate, or the ramp time, and the target

setpoint, when creating or modifying a program.

Ramp units (rmP.U) are in hours.

A program either ends in this segment or repeats. You specify which is the case

when you create or modify a program (see the final topic in this chapter). When

a program ends, the programmer is put into either a continuous Dwell state with

all outputs staying unchanged, or the Reset state.

StEP dwEl rmP.t rmP.r End

tGt √ √ √ Target setpoint for a “rmP“ or “StEP” segment.

rAtE √ Ramp rate for a “rmP.r” segment.

dur √ √ Dwell time for a “dwEl” segment.

End.t √ End of prog − dwEl, rSEt, S OP.

OM-203 185 Page 21

Page 26

Step to 300° F

as fast as

possible

Dwell @ 300° F

for 8 hours

Free fall to

ambient

SEG.n

tYPE

StEP

(step)

tGt

300

(deg)

SEG.n

1

2

tYPE

dwEl

(soak)

dur

8.0

(in hrs)

SEG.n

3

tYPE

End

(end)

End.t

S OP

(sets output to 0)

Example Pre−heat Profile

350

300

250

200

150

Degrees F

100

50

0

0 102030405060

Time (minutes)

Figure 6-1. Setting Pre-heat Profile Using Example Parameters

OM-203 185 Page 22

Page 27

Step to 600° F

as fast as

possible*

Ramp to 1350° F

@ 600° /hr

Dwell @ 1350°

F for 1/2 hour

Ramp to 600° F

@ 600° /hr

Free fall to

ambient

SEG.n

1

tYPE

StEP

(step)

tGt

600

(deg)

SEG.n

tYPE

rmP.r

(ramp rate)

tGt

1350

(deg)

rAtE

600

(deg/ hr)

1400

1200

1000

800

600

Degrees F

400

200

0

SEG.n

2

3

tYPE

dwEl

(soak)

dur

0.5

(in hrs)

SEG.n

tYPE

rmP.r

(ramp rate)

tGt

600

(deg)

rAtE

600

(deg/hr)

Example Stress Relief Profile

0 30 60 90 120 150 180

Time (minutes)

4

210 240 270

SEG.n

5

tYPE

End

(end)

End.t

S OP

(sets output to 0)

. *On small diameter pipe, it may be necessary to reduce the

output of the power source to achieve a “reasonable rate” in

Segment 1; thereafter, the program controls the rate of

temperature rise and the output power may be increased to

full if desired. To reduce output power, turn power source

output knob to desired setting.

Figure 6-2. Setting Stress Relief Profile Using Example Parameters

OM-203 185 Page 23

Page 28

Step to

600° F as

fast as

possible

Ramp to 800° F

@ 400° /hr

Ramp to 1250° F

@ 200° /hr

Dwell @ 1250° F

for 1 hour

Ramp to 800° F

@ 200° /hr

Ramp to 600° F

@ 400° /hr

Free fall to

ambient

SEG.n

1

tYPE

StEP

(step)

tGt

600

(deg)

SEG.n

2

tYPE

rmP.r

(ramp rate)

tGt

800

(deg)

rAtE

400

(deg/ hr)

1400

1200

1000

800

600

Degrees F

400

200

0

SEG.n

3

tYPE

rmP.r

(ramp rate)

tGt

1250

(deg)

SEG.n

4

tYPE

dwEl

(soak)

dur

1.0

(in hrs)

rAtE

200

(deg/ hr)

Example Multi−Step Stress Relief Profile

0.0 1.0 2.0 3.0 4.0 5.0 6.0

Time (hours)

SEG.n

5

tYPE

rmP.r

(ramp rate)

tGt

800

(deg)

rAtE

200

(deg/hr)

7.0

SEG.n

6

tYPE

rmP.r

(ramp rate)

tGt

600

(deg)

rAtE

400

(deg/hr)

SEG.n

7

tYPE

End

(end)

End.t

S OP

(sets output to 0)

. *On small diameter pipe, it may be necessary to reduce the

output of the power source to achieve a “reasonable rate”

in Segment 1; thereafter, the program controls the rate of

temperature rise and the output power may be increased

to full if desired. To reduce output power, turn power source

output knob to desired setting.

Figure 6-3. Setting A Complex Stress Relief Profile With Multiple Temperature Rise/Cool Rates

Using Example Parameters

OM-203 185 Page 24

Page 29

C

rAtE

B

TGT

F

rAtE

A

TGT

SEG.n

tYPE

StEP

(step)

A

TGT

(target)

(deg)

(°/hr)

D

dur

(°/hr)

E

TGT

(hrs)

SEG.n

1

2

tYPE

rmP.r

(ramp rate)

B

TGT

SEG.n

tYPE

dwEl

(soak)

D

dur

SEG.n

3

4

tYPE

rmP.r

(ramp rate)

E

TGT

SEG.n

5

tYPE

End

(end)

End.t

S OP

(target)

(deg)

C

rAtE

(duration

in hrs)

(target)

(deg)

F

rAtE

(sets output to 0)

(deg/hr)

1. Identify Target

temperatures, Ramp

Rates, and Dwell Time.

2. Insert Values into profile.

(deg/hr)

3. Program controller with

Profile using Navigating

buttons:

Press “Page” button until “ProG

LiSt” appears on the display.

Figure 6-4. Profile Set-Up Worksheet

Press “Scroll” button to advance

to each screen.

Press “Up” or “Down” button to

change values.

OM-203 185 Page 25

Page 30

6-3-3. Batch Recording Using 5100 Digital Recorder

The batch file generated by the recorder will consist of:

GroupDescriptor~BatchName~TimeDateStamp.uhh

The default Group Descriptor is set to “Group”. This setting may be changed to something that relates to the

application (i.e. Company, Contract, or Project name).

To change the Group Descriptor, proceed as follows:

1. Log in as an Engineer (see Section 6-2-2-2).

2. Touch Menu (bottom right).

3. Touch Operator.

4. Touch Config.

5. Touch Groups.

6. Touch the field next to Descriptor, a keypad will appear on the display.

7. Enter the desired name and touch Ok.

8. Touch Apply.

9. Touch Menu (bottom right).

10. Touch Home.

The Batch Name is entered by the operator. This should be a unique name that identifies the part being heated. Since

the same part may have Pre-heat (P), Bakeout (B), and Stress (S) procedures done to it, the batch name should include an indicator as to which process was done (i.e. W41-1307-2-S) where the S indicates a stress procedure.

The Time Date Stamp and .uhh file extension are both generated automatically by the recorder.

Begin Batch recording.

6-3-3-1. Login As User

1. Touch top left corner.

2. Touch pull down next to User.

3. Touch User from pull down list.

6-3-3-2. Start Recording

1. Touch “No Batch In Progress”.

2. Touch “New”.

3. Touch field next to Job # (Batch Name). This will be the batch name.

4. Enter unique Batch Name (see Section 6-3-3).

5. Touch “Ok”.

6. Touch field next to User ID.

7. Enter User ID.

8. Touch “Ok”.

9. Touch field next to Comments.

10. Enter Comments or, at least, touch the blank key.

11. Touch “Ok”.

12. Scroll down to bottom of screen.

13. Touch field next to Rec. ID.

14. Touch the blank key (bottom right keyboard).

15. Touch “Ok”.

16. Touch “Start”.

17. Touch “Close”.

OM-203 185 Page 26

Page 31

6-3-3-3. Stop Recording

1. Touch the block with the batch name.

2. Touch “Stop”.

3. Touch “Close” − screen returns to the home screen and displays “No Batch In Progress”.

NOTE

6-3-3-4. Saving Data To A Disk (Recommended After Each Batch)

1. Insert floppy disk into recorder.

2. Login as User (see Section 6-3-3-1).

3. Touch key in bottom right corner to open Root Menu.

4. Touch “Operator”.

5. Touch “Archive”.

6. Touch “Disk”.

7. Select how much data to save to floppy (typically, Last Day is sufficient).

Last day saves from 12:00am until current time. Last week saves from 12:00am Monday until current time.

Scroll down and wait until archive transfer changes from active to inactive.

NOTE

8. Touch key in bottom right corner to open Root Menu.

If a batch file was not started, the temperature data is still recorded. The

Job# (Batch Name), User, Comments, and Recorder ID are not recorded.

DO NOT remove floppy disk before completion of data transfer.

9. Touch “Home”.

10. Remove floppy disk.

11. To view data, go to Section 6-3-6.

6-3-3-5. Saving Data To A PC (Alternative To Floppy Disk)

6-3-3-5-1. Review Software − First Time Setup

1. Start “Review” software (see Section 6-3-7).

2. Click on “Instrument”, “Setup”, “TCP/IP”.

3. Click on “Add Instrument”.

4. In the “TCP/IP Address or Host Name:” field, type “192.168.111.222”.

5. In the “Identifier:” field, type “Generic”.

6. Click on “OK”.

6-3-3-5-2. Creating A Shortcut − First Time Setup

Local Area Network Connection (Windows) 2000)

1. Click on “Start”, “Settings”, “Control Panel”.

2. Open “Network and Dial-up Connections”.

3. Right click on “Local Area Connection”.

4. Select “Create Shortcut”.

5. Click on “Yes” to create a shortcut on the desktop.

OM-203 185 Page 27

Page 32

6. Close the “Network and Dial-up Connection” window.

7. Close the “Control Panel”.

Network Connection (Windows) 95, 98, ME)

1. Click on “Start”, “Settings”, “Control Panel”.

2. Right click on “Network”.

3. Select “Create Shortcut”.

4. Click on “Yes” to create a shortcut on the desktop.

5. Close the “Control Panel”.

6-3-3-5-3. Changing IP Address To Connect The IH/TS

For Windows) 2000

1. Close any open network applications.

2. Double click “Local Area Connection” desktop shortcut.

3. Click on “Properties”.

4. Scroll down to “Internet Protocol (TCP/IP)”.

5. Click on “Internet Protocol (TCP/IP)” to highlight it.

6. Click on “Properties”.

7. Click on “Use the following IP address:”.

8. In the “IP address” field, type “192.168.111.221”.

9. Click on “OK”.

10. Click on “OK” to add the subnet mask.

11. The “Subnet mask:” field should display “255.255.255.0”.

12. Click on “OK”.

13. Click on “OK”.

14. Click on “Close” to close the “Local Area Connection” window.

For Windows) 95, 98, ME

1. Close any open applications (Windows will restart to apply settings).

2. Double click “Network” desktop shortcut.

3. Scroll down to “Internet Protocol (TCP/IP)”.

4. Click on “Internet Protocol (TCP/IP)” to highlight it.

5. Click on “Properties”.

6. Click on “Specify an IP address:”.

7. In the “IP address” field, type “192.168.111.221”.

8. Click on “OK”.

9. Click on “OK”.

10. Click on “Yes” to restart the computer and have changes take effect.

6-3-3-5-4. Downloading Files From Recorder

1. Connect a crossover cable between the IH/TS recorder and the PC (a crossover cable is a special network

cable with pins 2 and 3 reversed on one end).

2. Start “Review” software (see Section 6-3-7).

OM-203 185 Page 28

Page 33

3. Click on “Instrument”, “File Services”.

4. Click on “Generic”.

5. Enter user name: “user” (leave password field blank).

6. Click on “OK”.

7. Right click on desired files and transfer them following the procedures in Sections 6-3-6 and 6-3-7.

6-3-3-5-5. Troubleshooting Connection Problems

1. Click on “Start”, “Programs”, “Accessories”, “Command Prompt”.

2. Type in “ping 192.168.111.222”.

3. Press “Enter”.

If the message “Timed Out” appears 4 times, the recorder is not responding. Check unit setup outlined previously

and verify crossover cable is connected properly.

6-3-3-5-6. Resetting IP Address (Necessary To Connect User’s PC To Company’s Network)

For Windows) 2000

1. Close any open network applications.

2. Double click “Local Area Connection” desktop shortcut.

3. Click on “Properties”.

4. Scroll down to “Internet Protocol (TCP/IP)”.

5. Click on “Internet Protocol (TCP/IP)” to highlight it.

6. Click on “Properties”.

7. Click on “Obtain an IP address automatically”.

8. Click on “OK”.

9. Click on “OK”.

10. Click on “Close” to close the “Local Area Connection” window.

For Windows) 95, 98, ME

1. Close any open applications (Windows will restart to apply settings).

2. Double click “Network” desktop shortcut.

3. Scroll down to “Internet Protocol (TCP/IP)”.

4. Click on “Internet Protocol (TCP/IP)” to highlight it.

5. Click on “Properties”.

6. Click on “Obtain an IP address automatically”.

7. Click on “OK”.

8. Click on “OK”.

OM-203 185 Page 29

Page 34

6-3-4. Running A Program To Preheat Or Stress Relief

To start the Heat Treat operation, proceed as follows:

Press the “RUN” button − The blue “Heat On” light turns on and the power source energizes.

The power source parameters are displayed on the “Parameter Display”.

The controller flashes “Hold” until the measured temperature climbs to within the

“Hold Back” window (10°) of the target temperature.

To adjust profile during the Heat Treat operation, proceed as follows:

Press the “HOLD” button − The controller displays “HOLD”, but the heat is maintained at the present target

temperature.

Press

Press “Scroll” button to select the desired parameter for changing.

Use

Press “Page” button until parameter screen appears on the display.

Press “RUN” button to resume program.

When cycle completes or to abort the process, fully press the “STOP” button − controller resets to segment 1 and

power source contactor relays open.

“Page” button until “ProG LiSt” appears on the display.

Y

or

B

“Up” or “Down” button to change value.

OM-203 185 Page 30

Page 35

6-3-5. Recovering From An Interruption

Press the “RUN” button to start profile.

NOTE

There are two conditions the controller looks at to determine:

1) If it should supply output power and

2) If the power source contactor should be on.

1) If the current temperature is more than 105 F above the target temperature in

segment 1, the IH/TS will not require output from the power source. The blue

Heat On light will be on and power source will not provide output. (Providing the

Panel/Remote switch on the power source is in the remote position.)

2) If the current temperature is more than 255 F above the target temperature in

segment 1, the blue Heat On light will be off and the system will not provide

power. (Regardless of Panel/Remote switch position.)

To continue from the current part temperature, rather than waiting for the part temperature to fall to within 10° of

segment 1’s target temperature:

Press the “HOLD” button − The controller displays “HOLD”.

Press “Page” button until “ProG LiSt” appears on the display.

Press “Scroll” button to SEG 1’s TGT temperature setting.

Use

Y

or

B

“Up” or “Down” button to adjust target temp to the current

temperature of +5° F.

Press “Page” button until parameter screen appears on the display.

Press “RUN” button to resume program − the controller will step to the new target

temperature setting and continue through the remainder of the profile.

9

OP1

7

200.0

8

11

12

200.0

13

SP2

1

2

AUTO

MAN

34 5

RUN

HOLD

B Y

106

Y Keep all panels, doors, and

covers closed and secure

during programming.

1. 2408 Controller

2. Page Forward Button

3. Scroll Button

4. Run/Hold Indicator

5. Down Button

6. Up Button

7. Actual Temperature

8. Setpoint Temperature

9. Heat On Pilot Light

10. Fault/ Limit Light

11. Run Button

12. Hold Button

13. Stop Button

OM-203 185 Page 31

Page 36

6-3-6. Viewing Data In Review Software

6-3-6-1. Installing Review Software And First Time Setup

Insert the “Chessell 5000 Series Data Management System” CD into the computer.

If the installation program does not automatically start, browse to the CD using “My Computer” and run

“Setup.exe”.

Place a check in the box next to “Review”. The other components are optional. Additional information about the

software can be found in the readme.txt file on the CD.

Click “Install Recorders Software” and accept the default settings of the software installation.

This Owner’s Manual will guide you through the steps to create and save a chart for a batch file. Additional informa-

tion on the Review software is available under Start\Programs\Eurotherm\Manuals\Review Manual.

The first time Review software is launched, a message box will be displayed to enable “Review Full features”. Place

a check in the box for “Don’t ask me this again”, then click “No”.

“Review” software first time setup

screen.

scrn35

6-3-6-2. Backing Up The Database

When Review software is used, archive data is stored in a database on the PC. As files are transferred to the database, the “Review.erv” file size increases. Data transferred into the database can be deleted, but not moved. If the

“Review.erv” file size reaches 1 gigabyte, data will need to be deleted or a new database will need to be created.