Miller Electric GPS-1000, GPS-1500A, GPS-1500V Owner's Manual

November

1986

FORM:

OM-267E

MILLER

ELECTRIC

MFG.

CO.

718

S.

BOUNDS

ST,

P.O.

Box

1079

APPLETON,

WI

54912

USA

IMPORTANT

Read

and

understand

the

entire

contents

of

this

manual,

with

special

emphasis

on

the

safety

material

throughout

the

manual,

before

installing,

operating,

or

maintaining

this

equip

ment.

This

unit

and

these

instructions

are

for

use

only

by

persons

trained

and

experienced

in

the

safe

operation

of

welding

equipment.

Do

not

allow

un

trained

persons

to

install,

operate,

or

maintain

this

unit.

Contact

your

distributor

if

you

do

not

fully

understand

these

instructions.

Effective

With

Serial

No.

JF887698

MODEL

GPS-1

000

G

PS-i

500A

GPS-1500V

OWN

ERS

MAN

UAL

A1IHER

*Ltlpv

PRINTED

IN

U.S.A.

LIMITED

WARRANTY

-

Subject

to

the

terms

and

condi

tions

hereof,

Miller

Electric

Mfg.

Co.,

Appleton,

Wisconsin

warrants

to

its

Distributor/Dealer

that

all

new

and

unused

Equipment

furnished

by

Miller

is

free

from

defectinworkman

Ship

and

material

as

of

the

time

and

placeofdelivery

by

Miller.

No

warranty

is

madebyMiller

with

respect

to

engines,

trade

accessories

or

other

items

manufactured

by

others.

Such

engines,

trade

accessories

and

other

items

are

sold

subject

to

the

warranties

of

their

respective

manufacturers,

if

any

.

All

engines

are

warranted

by

their

manufacturer

for

one

year

from

date

of

original

purchase,

except

Tecumseh

engines

which

have

a

two

year

warranty.

Except

as

specified

below,

Millers

warranty

does

not

apply

to

components

having

normal

useful

lifeofless

than

one

(1)

year,

such

as

spot

welder

tips,

relay

and

contactor

points,

MILLERMATIC

parts

that

come

in

contact

with

the

welding

wire

including

nozzles

and

nozzle

insulators

where

failure

does

not

result

from

defect

in

workmanship

or

material.

Miller

shall

be

required

to

honor

warranty

claims

on

war

ranted

Equipment

in

the

event

of

failure

resulting

from

a

defect

within

the

following

periods

from

the

date

of

delivery

of

Equip

ment

to

the

original

user:

Arc

welders,

power

sources,

robots,

and

components

1

year

Load

banks

1

year

Original

main

power

rectifiers

3

years

(labor

-

1

year

only)

All

welding

guns,

feeder/guns

and

plasma

torches...

90

days

All

other

Millermatic

Feeders

1

year

Replacement

or

repair

parts,

exclusive

of

labor..60

days

Batteries

6

months

In

the

case

of

Millers

breach

of

warranty

or

any

other

duty

with

respect

to

the

quality

of

any

goods,

the

exclusive

remedies

therefore

shall

be,

at

Millers

option

(1)

repair

or

(2)

replacement

or,

where

authorized

in

writing

by

Miller

in

appropriate

cases,

(3)

the

reasonable

cost

of

repairorreplacement

at

an

authorized

Miller

service

station

or

(4)

payment

of

or

credit

for

the

purchase

price

(less

reasonable

depreciation

based

upon

actual

use)

upon

return

of

the

goods

at

Customers

risk

and

expense.

MILLERs

option

of

repair

or

replacement

will

be

F.O.B.,

Factory,

at

Appleton,

Wisconsin,

or

F.O.B.,

at

a

MILLER

authorized

service

facility,

therefore,

no

compensation

for

transportation

costs

of

any

kind

willbeallowed.

Upon

receipt

of

notice

of

apparent

defect

or

failure,

Miller

shall

instruct

the

claimantonthe

warranty

claim

procedures

to

be

followed.

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

AND

ANY

IMPLIED

WARRANTY,

GUARANTY

OR

REPRESENTA

liON

AS

TO

PERFORMANCE,

AND

ANY

REMEDY

FOR

BREACH

OF

CONTRACT

WHICH,

BUT

FOR

THIS

PROVISION,

MIGHT

ARISE

BY

IMPLICATION,

OPERATION

OF

LAW,

CUSTOM

OF

TRADE

OR

COURSE

OF

DEALING,

INCLUDING

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

OF

FITNESS

FOR

PARTICULAR

PURPOSE,

WITH

RESPECT

TO

ANY

AND

ALL

EQUIPMENT

FURNISHED

BY

MILLER

IS

EX

CLUDED

AND

DISCLAIMED

BY

MILLER.

L

1

&~~L

LIMITED

WARRANTY

*

EFFECTIVE:

OCTOBER

1,

1986

This

warranty

supersedes

all

previous

MILLER

warranties

and

is

exclusive

withnoother

guarantees

or

warranties

expressed

or

implied.

*

*

2.

r

EXCEPT

AS

EXPRESSLY

PROVIDED

BY

MILLER

IN

!,

4.

WRITING.

MILLER

PRODUCTS

ARE

INTENDED

FOR

(

5.

ULTIMATE

PURCHASE

BY

COMMERCIAL/INDUSTRIAL

~

6.

USERS

AND

FOR

OPERATION

BY

PERSONS

TRAINED

AND

~

7.

EXPERIENCED

IN

THE USE

AND

MAINTENANCE

OF

WELDING

EQUIPMENT

AND

NOT

FOR

CONSUMERS

OR

~,)

provided

that

Millerisnotified

in

writing

within

thirty

(30)

days

CONSUMER

USE.

MILLERS

WARRANTIES

DO

NOT

EXTEND

t~

t-

of

the

date

of

such

failure.

TO,

AND

NO

RESELLER

IS

AUTHORIZED

TO

EXTEND

As

a

matter

of

general

policy

only,

Miller

may

honor

claims

MILLERS

WARRANTIES

TO,

ANY

CONSUMER.

r

submittedbythe

original

user

within

the

foregoing

periods.

~

~.

,~.

~

...~

~

~ ~

,,t

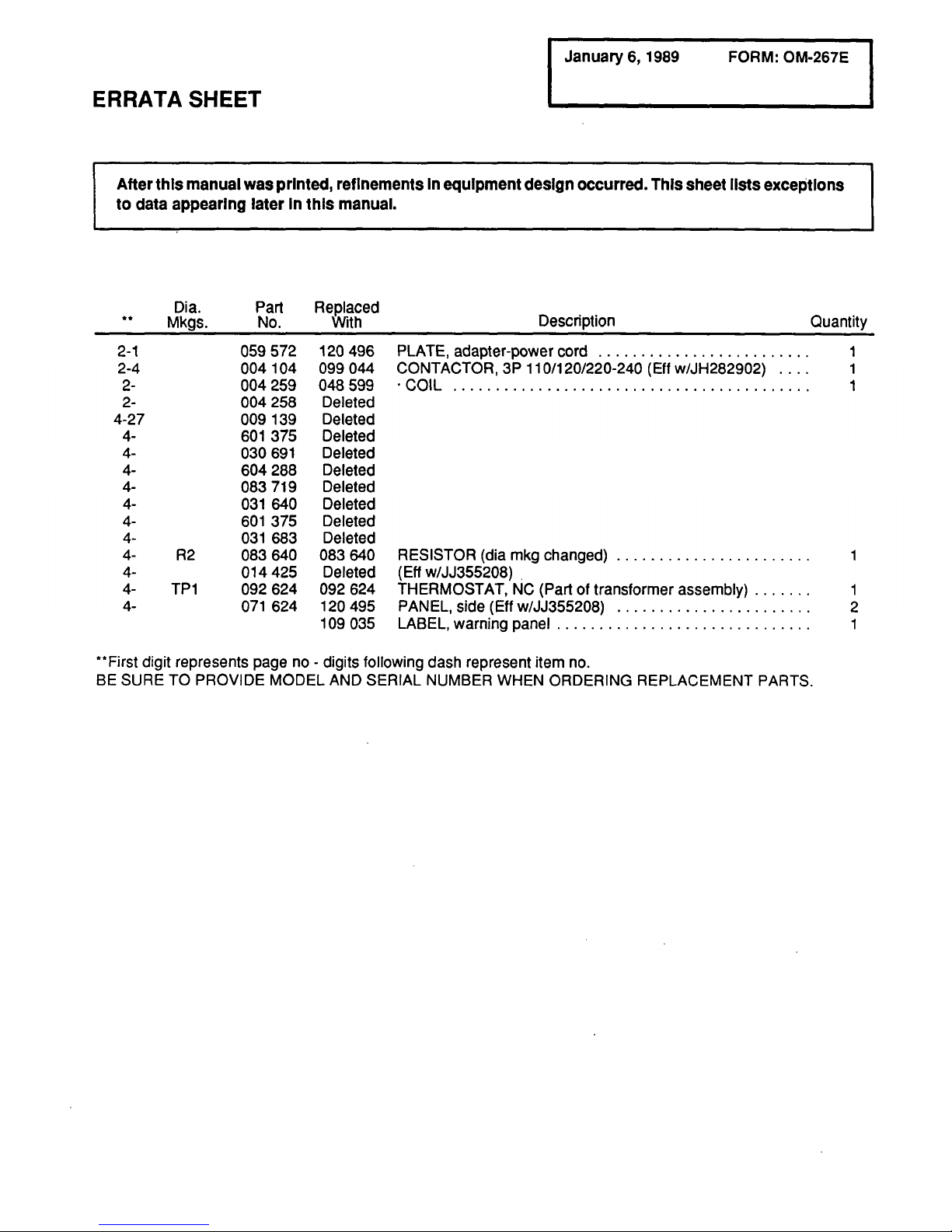

ERRATA

SHEET

After

this

manual

was

printed,

refinements

in

equipment

design

occurred.

This

sheet

lists

exceptions

to

data

appearing

later

in

this

manual.

**FirSt

digit

represents

page

no

-

digits

following

dash

represent

item

no.

BE

SURE

TO

PROVIDE

MODEL

AND

SERIAL

NUMBER

WHEN

ORDERING

REPLACEMENT

PARTS.

Dia.

**

Mkgs.

Part

No.

Replaced

With

Descnption

Quantity

2-1

2-4

2-

059

572

004

104

004259

120

496

099

044

048599

PLATE,

adapter-power

cord

CONTACTOR,

3P

110/120/220-240

(Eff

w/JH282902)

.

.

~COIL

..

1

1

1

2-

004

258

Deleted

4-27

009

139

Deleted

4-

601

375

Deleted

4-

030

691

Deleted

4-

604

288

Deleted

4-

083

719

Deleted

4-

031

640

Deleted

4-

601

375

Deleted

4-

031

683

Deleted

4-

4-

4-

4-

R2

TP1

083

640

014

425

092

624

071

624

083

640

Deleted

092

624

120

495

109

035

RESISTOR

(dia

mkg

changed)

(Eff

w/JJ355208)

THERMOSTAT,

NC

(Part

of

transformer

assembly)

PANEL,

side

(Effw/JJ355208)

LABEL,

warning

panel

1

1

2

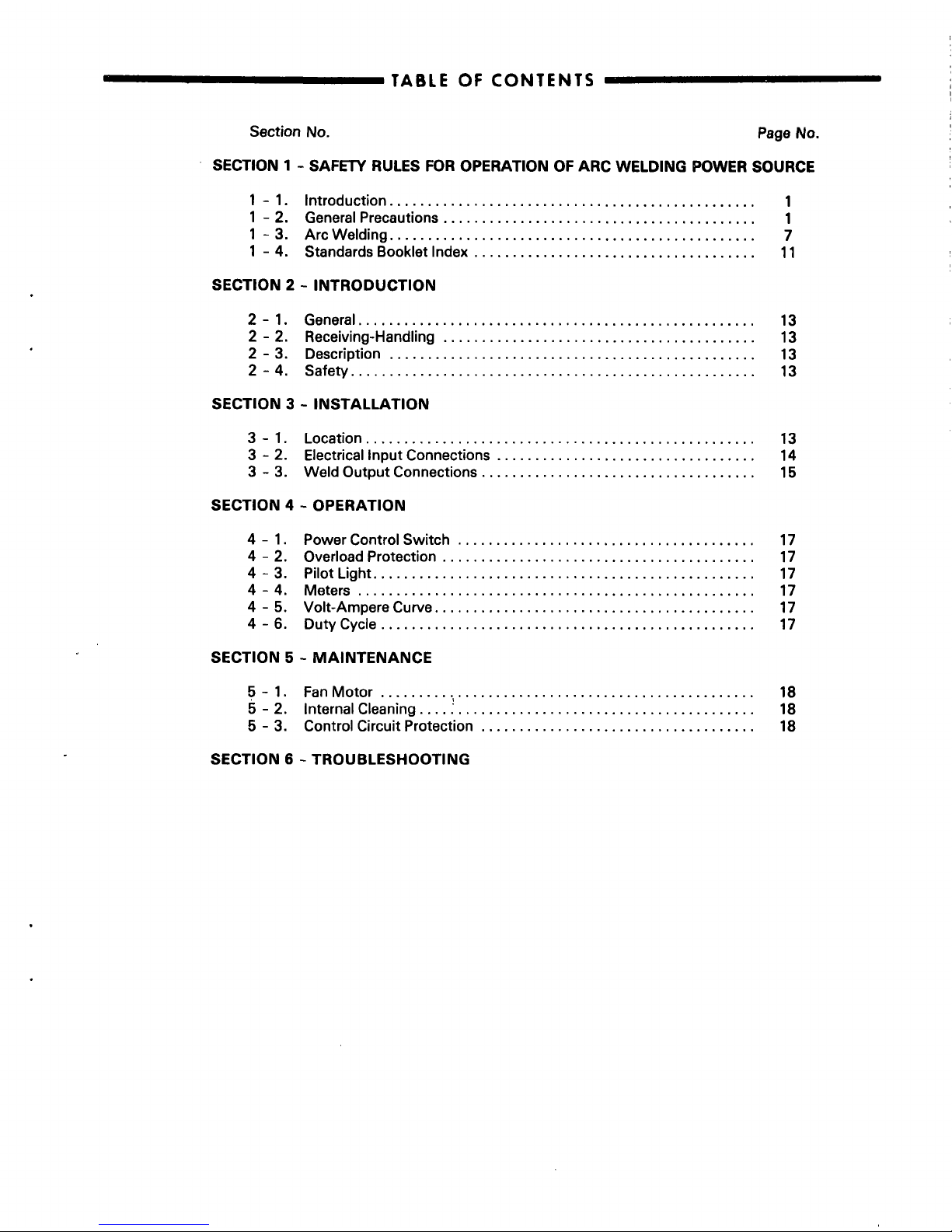

TABLE

OF

CONTENTS

Section

No.

Page

No.

SECTION

1

-

SAFETY

RULES

FOR

OPERATION

OF

ARC

WELDING

POWER

SOURCE

1-1.

Introduction

1

1

-

2.

General

Precautions

1

1

-3.

ArcWelding

7

1

-

4.

Standards

Booklet

Index

11

SECTION

2

-

INTRODUCTION

2-1.

General

13

2

-

2.

Receiving-Handling

13

2

-

3.

Description

13

2-4.

Safety

13

SECTION

3

-

INSTALLATION

3-1.

Location

13

3

-

2.

Electrical

Input

Connections

14

3

-

3.

Weld

Output

Connections

15

SECTION

4

-

OPERATION

4-1.

Power

Control

Switch

17

4

-

2.

Overload

Protection

17

4-3.

Pilot

Light

17

4

-

4.

Meters

17

4

-5.

Volt-Ampere

Curve

17

4

-

6.

Duty

Cycle

17

SECTION

5

-

MAINTENANCE

5-1.

Fan

Motor

18

5-2.

Internal

Cleaning

18

5-3.

Control

Circuit

Protection

18

SECTION

6

-

TROUBLESHOOTING

SECTION

1

-

SAFETY

RULES

FOR

OPERATION

OF

ARC

WELDING

POWER

SOURCE

SECTION

1

-

REGLES

DE

SECURITE

POUR

LE

FONCTIONNEMENT

DU

POSTE

DE

SOUDAGE

A

LARC

1-1.

INTRODUCTION

-

We

learn

by

experience.

Learning

safety

through

personal

experience,

like

a

child

touching

a

hot

stove

is

harmful,

wasteful,

and

un

wise.

Let

the

experience

of

others

teach

you.

Safe

practices

developed

from

experience

in

the

use

of

welding

and

cutting

are

described

in

this

manual.

Research,

development,

and

field

experience

have

evolved

reliable

equipment

and

safe

installation,

opera

tion,

and

servicing

practices.

Accidents

occur

when

equipment

is

improperly

used

or

maintained.

The

reason

for

the

safe

practices

may

not

always

be

given.

Some

are

based

on

common

sense,

others

may

require

technical

volumes

to

explain.

It

is

wiser

to

follow

the

rules.

Read

and

understand

these

safe

practices

before

at

tempting

to

install,

operate,

or

service

the

equipment.

Comply

with

these

procedures

as

applicable

to

the

par

ticular

equipment

used

and

their

instruction

manuals,

for

personal

safety

and

for

the

safety

of

others.

Failuretoobserve

these

safe

practices

may

cause

serious

injury

or

death.

When

safety

becomes

a

habit,

the

equipment

can

be

used

with

confidence.

These

safe

practices

are

divided

into

two

Sections:

1

-

General

Precautions,

common

to

arc

welding

and

cutting;

and

2-Arc

Welding

(and

Cutting)

(only).

Reference

standards:

Published

Standards

on

safety

are

also

available

for

additional

and

more

complete

pro

cedures

than

those

given

in

this

manual.

They

are

listed

in

the

Standards

Indexinthis

manual.

ANSI

Z49.1

is

the

most

complete.

The

National

Electrical

Code,

Occupational

Safety

and

Health

Administration,

local

industrial

codes,

and

local

inspection

requirements

also

provide

a

basis

for

equip

ment

installation,

use,

and

service.

1-2.

GENERAL

PRECAUTIONS

Different

arc

welding

processes,

electrode

alloys,

and

fluxes

can

produce

different

fumes,

gases,

and

radiation

levels.

In

addition

to

the

information

in

this

manual,

be

sure

to

consult

flux

and

elec

trode

manufacturers

for

specific

technical

data

and

precautionary

measures

concerning

their

material.

A.

Burn

Prevention

Wear

protective

clothing

-

gauntlet

gloves

designed

for

use

in

welding,

hat,

and

high

safety~toe

shoes.

Button

shirt

collar

and

pocket

flaps,

and

wear

cuffless

trousers

to

avoid

entry

of

sparks

and

slag.

Wear

helmet

with

safety

goggles

or

glasses

with

side

shields

underneath,

appropriate

filter

lenses

or

plates

(protected

by

clear

cover

glass).

This

is

a

MUST

for

welding

or

cutting,

(and

chipping)

to

protect

the

eyes

1-1.

INTRODUCTION

-

Contrairement

a

lappren

tissage

de

Ia

vie,

lapprentissage

de

Ia

sØcuritØ

par

ox

pØrience

personnelle,

comme

lenfant

qui

touche

un

poŒle

chaud,

est

dangereux,

imprudent

at

inutile.

lnstruisez-vous

donc

de

lexpØrience

dautrui.

Des

mØthodes

de

sØcuritØ

issues

de

Iexperience

du

soudage

et

du

coupage

sont

dØcrites

dans

le

manuel.

La

recherche,

le

progres

at

lexpØrience

dans

ce

domaine

ont

dØveloppØ

an

matØrial

fiable

at

des

mØthodes

do

sØcuritØ

pour

linstallation,

le

fonctionnement

et

lentre

tien.

Des

accidents

so

produisent

lorsque

le

matØrial

est

inadequatement

utilisØ

ou

entretenu.

La

raison

do

ces

mØthodes

de

sØcuritØ

peut

ne

pas

Œtre

toujours

donnØe.

Certaines

sont

fondØes

sur

Ia

sens

commun,

dautres

demanderont

a

Œtre

expliquØes

par

des

livres

techni

ques.

II

est

plus

sage

de

suivre

los

regles.

Lisez

at

comprenez

ces

mØthodes

de

sØcuritØ

avant

dessayer

dinstaller,

de

faire

fonctionner

ou

de

rØparer

lappareil.

Pour

votre

sØcuritØ

personnelle

at

celle

dautrui,

conformez-vous

a

ces

regles

et

aux

manuels

dinstructions.

Manquer

dobserver

ces

mØthodes

de

sØcuritØ

pourrait

entrainer

des

blessures

graves

ou

mŁme

Ia

mort.

Quand

Ia

sØcuritØ

deviant

une

habitude,

le

matØrial

pout

alors

Œtre

utilisØ

en

toute

confiance.

Ces

mØthodes

do

sØcuritØ

sont

divisØesendeux

sec

tions:

1

-

Precautions

gØnØrales,

communes

au

soudage

et

au

coupage

a

larc,

at

2

-

Soudage

a

larc

(et

coupage)

(uniquement).

Normes

de

rØfØrence:

Des

publications

des

normes

amØricaines

de

sØcuritØ

sont

aussi

a

votre

disposition

pour

dautres

modes

opØratoires

plus

complets

quo

ceux

du

present

manuel.

Elles

sont

donnØes

dans

lln

dex

des

Normes

de

ces

rŁgles

de

sØcuritØ.

ANSI

Z49-1

est

Ia

plus

complete.

Les

codes

do

IACNOR,

los

codes

provinciaux

et

municipaux

donnent

aussi

les

exigonces

pour

une

in

stallation,

une

utilisation

et

an

entretien

s~rs.

1-2.

PRECAUTIONS

GENERALES

Plusiours

procØdØs

du

soudage

a

Iarc,

des

Ølec

trodes

allies,

at

las

flux

peuvent

produire

des

vapeurs,

gaz,

at

niveaux

do

rayonnoment

diffØrents.

Pour

tout

rensoignomont

supplØmon

taire

a

ce

manual,

consultez

aussi

lea

fabricants

des

electrodes

et

des

flux

af

In

dobtenir

los

rensoignements

techniques

spØcifiques

at

los

mesures

do

precaution

concarnant

laura

matØriaux.

A.

Prevention

des

brOlures

Portez

des

vŒtements

de

protection

-

des

gants

a

crispin

spØcialement

dØsignØs

pour

le

soudage,

un

casque

at

des

chaussures

de

sØcuritØ.

Boutonnez

le

col

de

votre

chemise

at

les

pattes

de

vos

poches,

et

portez

des

pan-

talons

sans

revers

pour

Øviter

qua

des

Otincelles

et

du

laitier

ne

sy

introduisent.

Portez

un

masque

avec

lunettesdesØcuritØ

ou

avec

Øcrans

latØ-raux

de

protection,

des

lunettes

filtrantes

ou

des

couvre-lentilles

(proteges

par

an

verre

clair).

Pour

Is

soudage

ou

le

coupage

(et

le

burinage),

il

est

OM-267

Page

1

from

radiant

energy

and

flying

metal.

Replace

cover

glass

when

broken,

pitted,

or

spattered.

See

1-3A.2.

Avoid

oily

or

greasy

clothing.

A

spark

may

ignite

them.

Hot

metal

such

as

electrode

stubs

and

workpieces

should

never

be

handled

without

gloves.

Medical

first

aid

and

eye

treatment.

First

aid

facilities

and

a

qualified

first

aid

person

should

be

available

for

each

shift

unless

medical

facilities

are

close

by

for

im

mediate

treatment

of

flash

burns

of

the

eyes

and

skin

burns.

Ear

plugs

should

be

worn

when

working

on

overhead

or

in

a

confined

space.

A

hard

hat

should

be

worn

when

others

work

overhead.

Flammable

hair

preparations

should

not

be

used

by

per

Sons

intending

to

weld

or

cut.

B.

Toxic

Fume

Prevention

Severe

discomfort,

illness

or

death

can

result

from

fumes,

vapors,

heat,

or

oxygen

enrichment

or

depletion

that

welding

(or

cutting)

may

produce.

Prevent

them

with

adequate

ventilation

as

described

in

ANSI Stan

dard

Z49.1

listed

1

in

Standards

index.

NEVER

ventilate

with

oxygen.

Lead

-,

cadmium

-,

zinc

-,

mercury

-,

and

beryllium

-

bearing

and

similar

materials,

when

welded

(or

cut)

may

produce

harmful

concentrations

of

toxic

fumes.

Ade

quate

local

exhaust

ventilation

must

be

used,

or

each

person

in

the

area

as

well

as

the

operator

must

wear

an

air-supplied

respirator.

For

beryllium,

both

must

be

us

ed.

Metals

coated

with

or

containing

materials

that

emit

toxic

fumes

should

not

be

heated

unless

coating

is

removed

from

the

work

surface,

the

area

is

well

ven

tilated,

or

the

operator

wears

an

air-supplied

respirator.

Work

in

a

confined

space

only

while

it

is

being

ven

tilated

and,

if

necessary,

while

wearinganair-supplied

respirator.

Gas

leaks

inaconfined

space

should

be

avoided.

Leaked

gas

in

large

quantities

can

change

oxygen

con

centration

dangerously.

Do

not

bring

gas

cylinders

into

a

confined

space.

Leaving

confined

space,

shut

OFF

gas

supply

at

source

to

prevent

possible

accumulation

of

gases

in

the

space

if

downstream

valves

have

been

accidently

opened

or

left

open.

Check

to

be

sure

that

the

space

is

safe

before

re-entering

it.

Vapors

from

chlorinated

solvents

can

be

decomposed

by

the

heat

of

the

arc

(or

flame)

to

form

PHOSGENE,

a

highly

toxic

gas,

and

other

lung

and

eye

irritating

pro

ducts.

The

ultraviolet

(radiant)

energy

of

the

arc

can

also

decompose

trichloroethylene

and

per

chioroethylene

vapors

to

form

phosgene.

DO

NOT

WELD

or

cut

where

solvent

vapors

can

be

drawn

into

the

welding

or

cutting

atmosphere

or

where

the

radiant

OBLIGATOIRE

do

proteger

ses

yeux

contre

lØnergie

de

rayonnement

et

los

Øclats

de

metal.

Romplacez

le

verre

protecteur

lorsquil

est

brisØ,

piquØ

ou

quil

a

recu

des

projections.

Voir

1.3A.2.

Evitez

de

porter

des

habits

impregnØs

dhuile

ou

de

graisse.

Une

Øtincelle

pourrait

les

enflammer.

Ne

manipulez

jamais

sans

gants

un

metal

chaud

tel

que

des

chutes

dØlectrode

et

des

piŁces

a

souder.

Premiers

soins

et

traitement

des

yeux:

Tout

atelier

devrait

avoir

a

sa

disposition

un

poste

de

premiers

soins

ainsi

quune

personne

compØtente,

a

moms

quur,

ser

vice

medical

ne

soit

a

proximitØ

pour

soigner

immediate

ment

les

brlures

des

yeux

et

de

Ia

peau.

Portez

des

bouche-oreilles

lorsque

vous

travaillez

au

plafond

ou

dans

un

espace

restreint.

Portez

un

casque

lorsque

dautres

personnes

travaillent

au

plafond.

Les

personnes

devant

souder

ou

couper

ne

doivent

pas

employer

des

preparations

inflammablos

pour

lours

cheveux.

B.

Prevention

des

gax

toxiques

Les

gaz,

les

vapeurs,

Ia

chaleur,

un

enrichissement

ou

un

manque

doxygŁne

peuvent

entralner

un

malaise,

une

maladie

ou

mŒme

Ia

mort.

RemØdiez-y

par

Ia

ven

tilation

dØcrite

dans

Ia

Norme

ANSI

Z49.1

paragraphe

1

de

llndex

des

Normes.

NE

ventilez

JAMAIS

a

Iox

ygŁne.

En

soudant

ou

en

coupant,

los

p10mb,

cadmium,

zinc,

mercure

et

beryllium

ou

autres

matØriaux

semblables

peuvent

crØer

des

concentrations

nocives

de

gaz

taxi

quos.

On

doit

avoir

recours

a

une

ventilation

aspirante

adequate

du

local,

ou

alors

toute

personne

sur

les

Ileux,

de

mŒme

que

le

soudeur,

doit

porter

un

masque

a

ad

duction

dair.

On

doit

employer

los

deux

pour

lo

beryllium.

Les

mØtaux

enrobØs

ou

composes

do

matØriaux

Ømet

tant

des

gaz

toxiques

no

doivent

pas

Œtro

chauffØs

a

moms

que

lenrobage

ne

salt

tØ

do

Ia

surface

a

travailler,

quo

le

localnosalt

bien

ventilØ,

ou

quo

to

soudour

no

porte

un

masque

a

adduction

dair.

No

travaillez

dans

un

ospaco

rostroint

que

sil

est

bion

ventilØ

ot,

si

nØcessaire,

portez

un

masque

a

adduction

dair.

On

doit

Øviter

los

fuites

do

gaz

dans

un

ospaco

rostroint.

Los

fuites

do

gaz

on

grando

quantitO

peuvont

transformer

dangoreusoment

Ia

concentration

dox

ygeno.

Namonoz

pas

do

boutoillos

do

gaz

dans

un

ospace

rostreint.

En

quittant

un

ospace

restreint,

FERMEZ

to

robinot

dalimentation

do

gaz

do

Ia

boutoillo.

Ainsi

on

pourra

rontror

en

touto

sØcuritØ

dans

Ia

piŁce,

memo

si

los

robinets

aval

ant

ØtØ

ouvorts

par

accident,

ou

si

on

los

a

laissØs

ouvertS.

Les

vapeurs

do

dissolvants

chiorØs

peuvent

Œtro

dØcom

posØes

par

Ia

chaleur

do

larc

(ou

de

Ia

flammo)

et

former

du

PHOSGENE,

gaz

trØs

toxique,

ot

dautres

produits

irritant

les

poumons

et

los

yeux.

LØnorgio

ultra-violette

do

larc

peut

aussi

dØcomposer

los

vapeurs

de

trichloroØthylŁne

et

de

porchloroØthylŁne

pour

former

du

phosgeno.

NE

SOUDEZ

PAS

ou

no

coupoz

pas

dans

dos

ondroits

oC~

los

vapeurs

de

dissolvants

peu

vent

Œtre

attirØes

dans

IatmosphŁro

do

soudage

ou

do

OM-267

Page

2

energy

can

penetrate

to

atmospheres

containing

even

minute

amounts

of

trichloroethylene

or

per

chioroethylene.

C.

Fire

and

Explosion

Prevention

Causes

of

fire

and

explosion

are:

combustibles

reached

by

the

arc,

flame,

ftying

sparks,

hot

slag

or

heated

material;

misuse

of

compressed

gases

and

cylinders;

and

short

circuits.

BE

AWARE

THAT

flying

sparks

or

falling

slag

can

pass

through

cracks,

along

pipes,

through

windows

or

doors,

and

through

wall

or

floor

openings,

out

of

sight

of

the

goggled

operator.

Sparks

and

slag

can

fly

35

feet.

To

prevent

fires

and

explosion:

Keep

equipment

clean

and

operable,

free

of

oil,

grease,

and

(in

electrical

parts)

of

metallic

particles

that

can

cause

short

circuits.

If

combustibles

are

in

area,

do

NOT

weld

or

cut.

Move

the

work

if

practicable,

to

an

area

free

of

combustibles.

Avoid

paint

spray

rooms,

dip

tanks,

storage

areas,

yen

tilators.

If

the

work

cannot

be

moved,

move

com

bustibles

at

least

35

feet

away

out

of

reach

of

sparks

and

heat;

or

protect

against

ignition

with

suitable

and

snug-fitting,

fire-resistant

covers

or

shields.

Walls

touching

combustibles

on

opposite

sides

should

not

be

welded

on

(or

cut).

Walls,

ceilings,

and

floor

near

work

should

be

protected

by

heat-resistant

covers

or

shields.

Fire

watcher

must

be

standing

by

with

suitable

fire

ex

tinguishing

equipment

during

and

for

some

time

after

welding

or

cutting

if:

a.

appreciable

combustibles

(including

building

construction)

are

within

35

feet

b.

appreciable

combustibles

are

further

than

35

feet

but

can

be

ignited

by

sparks

c.

openings

(concealed

or

visible)

in

floors

or

walls

within

35

feet

may

expose

com

bustibles

to

sparks

d.

combustibles

adjacent

to

walls,

ceilings,

roofs,

or

metal

partitions

can

be

ignited

by

radiant

or

conducted

heat.

Hot

work

permit

should

be

obtained

before

operation

to

ensure

supervisors

approval

that

adequate

precautions

have

been

taken.

After

work

is

done,

check

that

area

is

free

of

sparks,

glowing

embers,

and

flames.

An

empty

container

that

held

combustibles,

or

that

can

produce

flammable

or

toxic

vapors

when

heated,

must

never

be

welded

on

or

cut,

unless

container

has

first

been

cleaned

as

described

in

AWS

Standard

A6.O,

listed

3inStandards

index.

This

includes:

a

thorough

steam

or

caustic

cleaning

(or

a

solvent

or

water

washing,

depending

on

the

corn-

coupage

et

o~i

lØnergie

de

rayonnemont

peut

pØnØtrer

dans

des

atmospheres

contenant

des

quantitØs

memo

minuscules

de

trichloroØthylŁne

ou

de

per

chloroØthylŁne.

C.

Prevention

des

incendies

et

des

explosions

Les

causes

dincendie

et

dexplosion

sont

les

com

bustibles

atteints

par

(arc,Iaflamme,

les

Øtincelles,

le

laitier

chaud

ou

los

matØrlaux

chauffØs,

le

mauvais

emplol

des

gaz

comprimØs

et

des

bouteilles

ainsi

que

los

courts-circuits.

Sachez

que

les

Øclats

dØtincelles

ou

Ia

chutedulaitier

peuvent

sinfiltrer

dans

les

fissures,

le

long

des

tuyauteries,

par

les

fenŒtres

et

les

portes

et

par

los

couvertures

des

murs

ou

du

sol,

sans

que

le

soudeur

portant

des

lunettesneles

voie.

Les

Øtincelles

ot

les

scones

peuvent

voler

jusqu

35

pieds.

Pour

prØvenir

los

incendies

et

les

explosions:

Veillez

a

co

quo

votre

appareil

soit

propre

et

en

Øtat

de

marche,

dØnuØ

dhuileetde

graisse,

et

de

particules

do

metal

sur

les

piŁces

Ølectriques

qui

pourraient

entrainer

des

courts-circuits.

Si

des

combustibles

se

trouvent

a

proximite,

no

soudez

pas,

ne

coupez

pas.

Sipossible,

dØplacez

votre

travail

loin

des

combustibles.

Evitoz

les

ateliers

do

peinture

au

pistolet,

les

cuves

dimmersion,

les

entrepts,

les

yen

tilateurs.

Si

cela

nest

pas

possible,

placez

los

com

bustibles

a

au

moms

35

pieds

des

Øtince(les

et

de

(a

chaleur

et

protØgez-Ies

des

Øtincelles

avec

des

couver

tures

ou

des

Øcrans

protecteurs

adØquats,

bien

ajustØs

et

ignifugØs.

On

ne

dolt

pas

souder

(ou

couper)

le

ctØ

oppose

des

murs

touchant

les

combustibles.

Les

murs,

plafonds

et

planchers

proches

du

travail

doivent

Œtre

protØgØs

par

des

couvertures

ou

Øcrans

protecteurs

ignifuges.

Un

surveillant

dolt

se

tenir

a

proximitØ

avec

un

materiel

de

lutte

contre

Iincendie

adØquat,

pendant

et

quelque

temps

aprŁslesoudage

ou

le

coupage

Si:

a.

Des

quantites

apprØciables

de

combustibles

(y

compris

une

construction

on

chantier)

so

trouvent

Ł

moms

de

35

pieds.

b.

Des

quantitØs

appreciables

do

combustibles

sont

a

plus

de

35

pieds

mais

peuvent

Œtre

enflammØes

par

des

Øtincelles.

c.

Des

ouvertures

(cachØes

ou

visibles)

sur

los

planchers

ou

los

murs

a

moms

de

35

plods

peuvent

exposer

dos

combustibles

aux

Øtincelles.

d.

Les

combustibles

adjacents

aux

murs,

plafonds,

toits

ou

cloisons

mØtalliques

peu

vent

Œtre

enflammØs

par

une

chafeur

rayon

nante

ou

transmiso.

Avant

de

commencer,

avisezlecontremaltre

pour

quil

sassure

que

les

precautions

adØquates

solent

prisos.

Une

fois

le

travail

terminØ,

vØrifiez

quil

ny

ait

pas

dØtincelles,

de

cendres

ardentes

ou

do

flammes

dans

le

local.

On

ne

doit

jamais

souder

ni

couper

sur

un

recipient

ayant

contenu

dos

combustibles,

ou

pouvant

produire

des

vapeurs

inflammables

ou

toxiques

a

Ia

chauffe,

a

moms

que

le

recipient

nait

ete

(aye

au

prealable,

corn-

me

dØcrit

dans

Ia

Norme

AWS

A6.O,

figurant

au

paragraphe

3

de

l~lndex

des

Normes.

Cola

comprend:

un

nettoyage

a

fondaIa

vapeur

ou

au

caustique

(ou

un

lavage

avoc

dissolvant

ou

eau

solon

(a

solubilitØ

du

combustible)

suivi

dune

purge

et

dune

in

OM-267

Page

3

bustibles

solubility)

followed

by

purging

and

inerting

with

nitrogen

or

carbon

dioxide,

and

using

protective

equipment

as

recommended

in

A6.O.

Waterfilling

just

below

working

level

may

substitute

for

inerting.

A

container

with

unknown

contents

should

be

cleaned

(see

paragraph

above).

Do

NOT

depend

on

sense

of

smell

or

sight

to

determineifit

is

safe

to

weld

or

cut.

Hollow

castings

or

containers

must

be

vented

before

welding

or

cutting.

They

can

explode.

Explosive

atmospheres.

Never

weld

or

cut

where

the

air

may

contain

flammable

dust,

gas,

or

liquid

vapors

(such

as

gasoline).

D.

Compressed

Gas

Equipment

Standard

precautions.

Comply

with

precautions

in

this

manual,

and

those

detailed

in

CGA

Standard

P-i,

PRECAUTIONS

FOR

SAFE

HANDLING

OF

COM

PRESSED

GASES

IN

CYLINDERS,

listed

6inStan

dards

index.

1.

Pressure

Regulators

Regulator

relief

valve

is

designed

to

protect

only

the

regulator

from

overpressure;

it

is

not

intended

to

pro

tect

any

downstream

equipment.

Provide

such

protec

tion

with

one

or

more

relief

devices.

Never

connect

a

regulator

to

a

cylinder

containing

gas

other

than

that

for

which

the

regulator

was

designed.

Remove

faulty

regulator

from

service

immediately

for

repair

(first

close

cylinder

valve).

The

following

symp

toms

indicate

a

faulty

regulator:

Leaks

-

if

gas

leaks

externally.

Excessive

Creep

-

if

delivery

pressure

continues

to

rise

with

downstream

valve

closed.

Faulty

Gauge

-

if

gauge

pointer

does

not

move

off

stop

pin

when

pressurized,

nor

returns

to

stop

pin

after

pressure

release.

Repair.

Do

NOT

attempt

repair.

Send

faulty

regulators

for

repair

to

manufacturers

designated

repair

center,

where

special

techniques

and

tools

are

used

by

trained

personnel.

2.

Cylinders

Cylinders

must

be

handled

carefully

to

prevent

leaks

and

damage

to

their

walls,

valves,

or

safety

devices:

Avoid

electrical

circuit

contact

with

cylinders

including

third

rails,

electrical

wires,

or

welding

circuits.

They

can

produce

short

circuit

arcs

that

may

lead

toa

serious

ac

cident.

(See

1-3C.)

ICC

or

DOT

marking

must

beoneach

cylinder.

It

is

an

assurance

of

safety

when

the

cylinder

is

properly

handled.

jection

dazote

ou

de

gaz

carbonique,

en

utilisant

un

Øquipement

de

protection

comme

rocommandØ

dans

lA6-O.

LatmosphŁre

inerte

peut

Œtre

remplacØe

par

un

niveau

deau

arrivant

au-dessous

du

travailaeffectuer.

Vous

dovez

layer

un

recipient

dont

Ia

nature

de

contenu

est

inconnue

(voir

paragraphe

ci-dessus).

NE

vous

fiez

PAS

a

Iodorat

ou

a

Ia

vue

pour

dire

si

lon

peut

le

souder

ou

le

couper

en

toute

sØcuritØ.

Vous

devez

pratiquer

un

event

sur

Ies

piŁces

ou

rØci

pients

creux

avant

de

los

souder

ou

couper:

ils

peuvent

exploser.

Atmospheres

explosives:

Ne

soudez

ni

ne

coupez

jamais

dans

des

lioux

oCi

lair

peut

contenir

des

poussiŁres,

gaz

ou

vapeurs

liquides

inflammables

(tels

que

lessence).

D.

Gaz

comprimØ

Precautions

gØnØrales:

Suivez

los

precautions

do

ce

manuel,

et

celles

dØcrites

a

Ia

Norme

CGA

P-i

(PrØcau

tions

do

sØcuritØ

pour

Ia

manipulation

de

gaz

comprimØs

on

bouteilles),

paragraphe

6

do

Ilndex

des

Normes.

1.

DØtendeurs

de

pression

La

soupape

do

sretØ

dun

dØtondour

est

dostinØo

a

pro

tØger

seulement

le

dØtendeur

do

Ia

surpression.

Ello

na

pas

pour

but

do

protØger

los

boyaux

et

le

chalumoau:

on

protege

ceux-ci

par

des

soupapes

de

retenuo

concues

spØcialomont

pour

cette

fonction.

Ne

montoz

jamais

un

dØtendeur

sur

uno

bouteille

conte

nant

un

gaz

different

do

celui

pour

lequel

le

dØtendeur

a

ØtØ

concu.

Enlevez

immØdiatement

un

dØtondeur

dØfoctueux

pour

lo

faire

rØparer

(dabord,

formez

le

robinet

do

Ia

bouteille).

Los

symptomes

suivants

dØnotont

Ia

dØfec

tuositØ

du

dØtendeur:

Fuites

-

Si

le

gaz

fuit

extØrieurement.

Ascension

excessive-si Ia

pression

de

debit

continue

a

montor,

le

robinet

du

chalumeau

Øtant

fermØ.

ManomŁtre

dØfectuoux

-

si

laiguille

du

manomŁtre

no

sØcarte

pas

de

Ia

goupille

do

butØe

lorsdoIa

mise

en

prossion,

ou

no

reviont

pas

sur

Ia

goupille

aprŁs

lØchap

pement

de

Ia

prossion.

Reparation.

NESSAYEZ

PAS

do

reparer

vous-mŒmes.

Envoyoz

los

dØtendeurs

dØfectuoux

a

rØparer

aux

ateliers

do

reparation

agrees

du

fabricant,

oCi

des

techni

ques

ot

des

outils

spØciaux

sont

utilisØs

par

un

person

nel

formØ.

2.

Bouteilles

Les

bouteilles

doivent

Œtre

manipulees

avec

soin

pour

prØvonir

les

fuites

ou

dØgts

a

leurs

parois,

robinets

ou

systŁmes

de

sOretØ.

Evitez

quun

circuit

Ølectriquo

soit

en

contact

avoc

los

bouteilles,

y

compris

los

rails

do

con

tact,

les

fils

Ølectriques

ou

les

circuits

de

soudage.

Cela

pourrait

crØer

des

arcs

courts-circuits

pouvant

ontraIner

des

accidents

graves

(Voir

i.3C.).

Chaque

bouteille

doit

porter

les

inscriptions

ICC

ou

DOT.

Cest

un

gage

de

sØcuritØ

pourvu

quo

Ia

bouteillo

soit

bien

manipulØe.

OM-267

Page

4

Loading...

Loading...