Miller Electric Engine-Driven Welder/ AC Generator/Air Compressor, Big Blue Air Pak Specifications

Quick

Specs

Quiet at only 70 dB (95 Lwa) when idle,

79 dB (104 Lwa) at maximum output.

Improves work site communications.

Meter maintenance displays

• Fuel gauge

• Hour meter function

• Oil change interval

• High coolant temperature and

low oil pressure shutdowns

• Low fuel shutdown — engine shuts

down before system runs out of

fuel, making restarts easy.

Low maintenance with easy single-side

access to engine and 500 hour oil changes

for both engine and compressor.

Arc-Drive

™

makes welding easy.

Automatically enhances Stick

welding, especially on pipe, by

focusing the arc and preventing

the electrode from going out.

Optional

AC/DC/battery charge/

jump-start for AC TIG welding

and 12 or 24 volt batteries. Simply

select the battery voltage and

connect cables to the separate

battery output studs.

(High-frequency unit required for

AC TIG.)

Big Blue®Air Pak

™

Engine-Driven Welder/

AC Generator/Air Compressor

Issued September 2010 • Index No. ED/10.5

Hot Start™provides positive stick

electrode starts to make it easy to

start all types of electrodes.

Enclosed robust case design protects

internal components from impact and

allows air flow to cool and prolong the life

of the engine. Also reduces sound levels.

Welder/generator/air compressor.

One machine that will do it all. Designed

and built to be the most reliable highoutput system in the world.

Weatherproof Lexan

®

nameplate

resists cracking and fading, and is

color-coded for ease of operation.

GFCI receptacle as required on most

job sites to protect operators from

electrical hazards.

Heavy-duty low-speed

industrial turbocharged

diesel engine provides

ample power at high altitudes.

Independent compressor controls.

On/off switch for applications not

requiring compressed air. At idle

speed will produce 100 PSI at 40 CFM.

Ultra-reliable industrial rotary screw

air compressor. Belt-driven with

automatic belt tensioner with a life

expectancy of 30,000 hrs.

The Power of Blue®.

Welder/Generator/Air Compressor is warranted

by Miller for 3 years, parts and labor.

Engine is warranted by Deutz for 3 years.

Heavy Industrial

Applications

Railroad Maintenance

Mining Maintenance

Maintenance and Repair Rigs

Processes

DC Stick (SMAW)

AC Stick (SMAW)*

MIG (GMAW)

Flux Cored (FCAW)

DC TIG (GTAW)

AC TIG (GTAW)*

Submerged Arc (SAW)

Stud Welding — 1/2 in (12.7 mm)

Air Carbon Arc (CAC-A)

1/2 in (12.7 mm) Carbons

Air Plasma Cutting

with Optional Spectrum Models

Battery Charging/Jump-Starting*

Air Compressor

Output Range

DC Stick 45–750 A AC Stick 35–575 A*

MIG/FCAW 14–40 V

DC TIG 20–450 A AC TIG 20–375 A*

Battery Charge 12/24 V, 50–750 A*

*Deluxe Model Only.

Weld Output Rated at 104°F (40°C)

Stick 600 A at 44 V (26.4 kW), 40% Duty Cycle

Stick 550 A at 42 V (23.1 kW), 60% Duty Cycle

MIG/FCAW 500 A at 40 V (20 kW), 100% Duty Cycle

AC TIG 400 A at 26 V (10.4 kW), 100% Duty Cycle*

Air Compressor 100 PSI, 60 CFM, 100% Duty Cycle

Generator Output Rated at 104°F (40°C)

5,500 Watts Peak— 4,000 Watts Continuous

20,000 Watts 3-Phase/

12,000 Watts 1-Phase Continuous*

Accu-Rated

™

–Not Inflated

Generator Power

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

Equipment Sales US and Canada

Phone: 866-931-9730

FAX: 800-637-2315

International Phone: 920-735-4554

International FAX: 920-735-4125

EPA Tier 4i

Compliant

Big Blue Air Pak Deluxe Model shown.

EPA Tier 4i

EPA Tier 4i

EPA Tier 4i

Compliant

Compliant

Compliant

Welding

Mode

CC/DC

CV/DC

CC/AC*

Battery*

Charge

Jump-Start

Weld Output Rated at 104˚F (40˚C)

NEMA Amperage and Voltage

600 A at 44 V (26.4 kW), 40% Duty Cycle

550 A at 42 V (23.1 kW), 60% Duty Cycle

500 A at 40 V (20 kW), 100% Duty Cycle

500 A at 40 V (20 kW), 100% Duty Cycle

400 A at 36 V (14.4 kW) 100% Duty Cycle

750 A, 12 V, Jump-Start

750 A, 24 V, Jump-Start

Weld

Output

Range

20– 750 A

14– 40 V

20– 575 A

12/24 V

Max. OpenCircuit

Voltage

95

56

64

14/28

*Deluxe model only. **Additional 7 in (178 mm) to top of exhaust. ***Additional 190 lb (86 kg) when fuel tank is full.

Compressor

Brand

CE55 G1

Free Air

Delivery at

1850 RPM

60 cfm

(1.70 m

3

/min)

Free Air

Delivery at

1235 RPM

40 cfm

(1.13 m3/min)

Idle

Features

Rotary screw with electric clutch for on/off.

Oil change intervals 500 hrs (same as engine).

Life expectancy 30,000 hrs.

Working

Pressure

Constant

100 psig

7 bar

Duty

Cycle

100%

Oil

Capacity

5 qt (4.7 L)

Automatic

Compressor

Shutdowns

Oil Temperature

Engine Brand

TD2011L04w

Features

EPA Tier 4i compliant, turbocharged,

direct-injected, liquid-cooled (oil) engine.

Right-side service access with 500 hr intervals

for oil and filters.

Type

Four-cylinder,

industrial, liquidcooled engine

Engine

Speeds

1850 Run

1250 Idle

HP

63.4

Fuel

Capacity

25 gal

(95 L)

Automatic Engine

Shutdowns

Low Oil Pressure,

High Coolant

Temperature,

Low Fuel Level

Oil

Capacity

11 qt

(10.4 L)

Engine

2

Control Panel

Weight

Without Fuel***

Net: 1931 lb

(876 kg)

Ship: 1982 lb

(899 kg)

Deluxe Model

Net: 1956 lb

(887 kg)

Ship: 2007 lb

(910 kg)

Dimensions**

H: 43 in

(1092 mm)

W: 28-1/2 in

(724 mm)

D: 69-1/2 in

(1765 mm)

Generator Output

Rated at 104˚F (40˚C)

Peak: 5500 watts

Continuous: 4000 watts, 34/17 A,

120/240 VAC, 60 Hz while welding

Additional Generator Power for

Deluxe Models (while NOT welding)

3-phase: 20 kW, 48 A, 240 VAC or

1-phase: 12 kW, 50 A, 120/240 VAC

Specifications

(Subject to change without notice.)

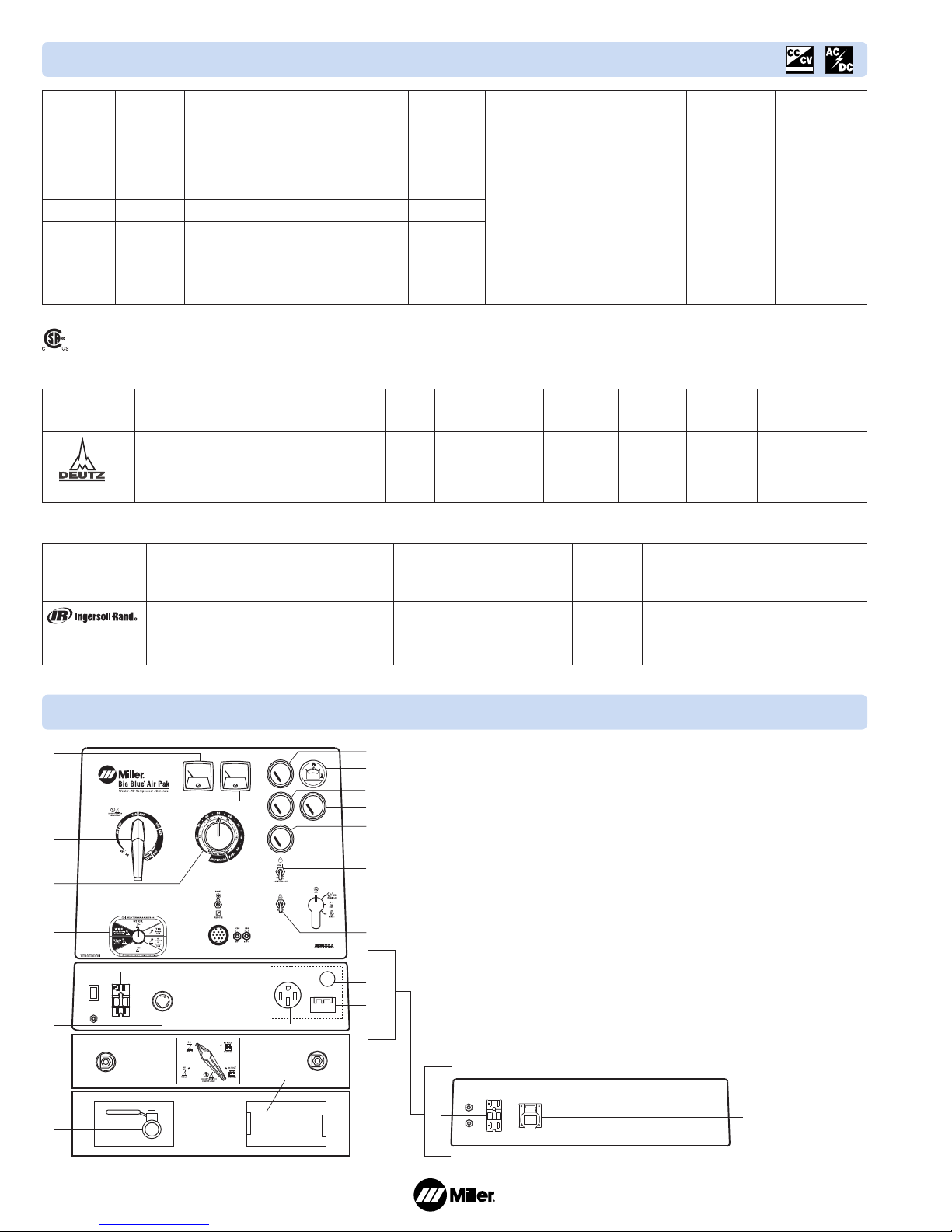

1. AC/DC Voltmeter*

2. AC/DC Ammeter*

3. Amperage Range Switch

4. Amperage/Voltage Adjust Control

5. Amperage/Voltage Adjust Switch

and Remote Amperage/Voltage

Adjust 14-Pin Receptacle

6. Process/Contactor

Selector Switch

7. 120 VAC, 20 A GFCI

Duplex Receptacle

8. 240 VAC, 30 A TwistLock

Receptacle (NEMA L6-30)

9. Air Outlet Valve 3/4 in NPT

10. Engine Oil Pressure Gauge

11. Fuel Gauge—displays engine

hours and oil change intervals

12. Engine Coolant Temperature Gauge

13. Battery Voltmeter

14. Air Compressor Pressure Gauge

15. Air Compressor On/Off Switch

16. Engine Control Switch

17. Starting Aid Switch*

18. 20 kW, 3-Phase Generator*

19. Strain Relief*

20. 50 A, 3-Phase Circuit Breaker*

21. 50 A, 1-Phase 120/240 V

Receptacle (NEMA 14-50)*

22. AC/DC/Battery Charge/

Jump-Start Switch*

23. International Model—240 VAC,

16 A Pin and Sleeve Receptacle

*On Select Models

Air Compressor

Meets NEMA and IEC output ratings.

Certified by Canadian Standards Association to both the Canadian and U.S. Standards.

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

20

21

22

International Model

9

7

23

3

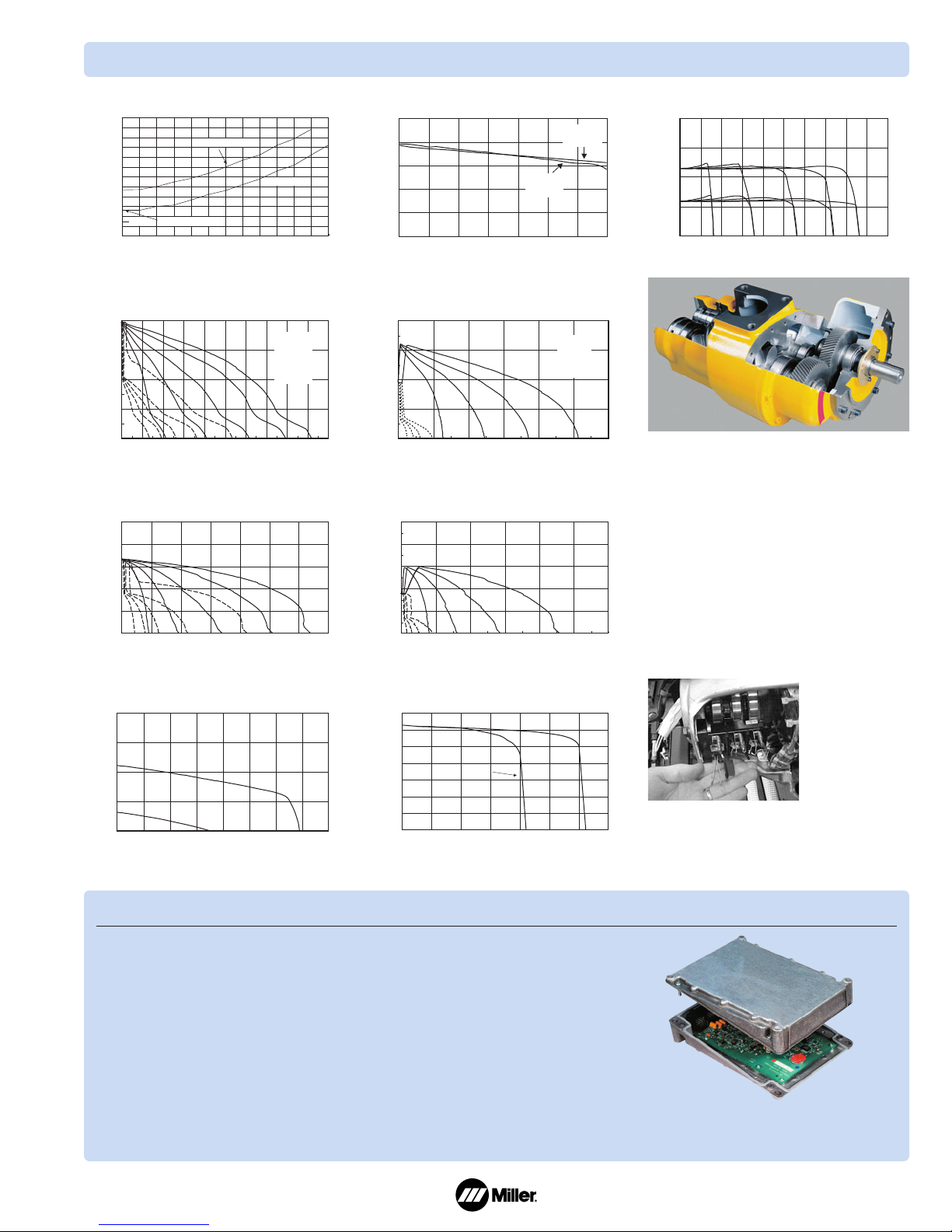

Performance Data

Ingersoll-Rand Rotary Screw Air

Compressor

This industrial grade compressor, has a life

expectancy of 30,000 hours, is belt driven and

utilizes an electric clutch control to allow the

compressor to be turned off if not needed.

This design increases efficiency, reduces fuel

consumption and saves you money at the

pump. An automatic belt tensioner provides

proper belt tension even after years of service.

The compressor is protected by a high

temperature shutdown switch.

Toolless

Generator

Brushes

100% copperwound

generator

features quick

and easy brush and slip ring inspection.

Brushes can be removed and/or replaced

in a matter of seconds.

The Vault

Superior Circuit Board Design

Miller’s critical circuit boards are engineered

to carry

low power

and

low heat

to reduce

thermal stress and minimize expansion and

contraction. In contrast, our competitor’s

boards carry

high power

and

high heat

, making

them more vulnerable to failure.

“The Vault” Makes Upgrading to Miller CC/CV

Units Worry-Free

Concerns with circuit board reliability have

resulted in some operators steering clear of

CC/CV welder/generators — even though they

offer a superior arc and multiple welding

processes. Miller’s circuit board reliability isn’t

a concern since all Big Blue multiprocess

industrial engine drives feature the Vault.

Created out of two aluminum halves sealed

with silicone, as well as watertight harness

connections, the Vault provides a clean circuit

board environment, protecting the electronics

— and controlling output — in heavy industrial

applications. No other competitor protects their

electronics with a sealed vault, leaving critical

circuit boards exposed to harsh elements that

can disrupt the machine’s electronics, and

therefore, its operation.

3.00

2.75

2.50

2.25

2.00

1.75

1.50

1.25

US Gal./Hr.

1.00

0.75

0.50

0.25

0.00

67.5

DC VOLTS

22.5

AC VOLTS

FUEL CONSUMPTION CURVE

WELD AND AIR

WELD ONLY

IDLE

IDLE WITH AIR

0 50 100 150 200 250 300 350 400 450 500 550 600

DC WELD AMPERES AT 100% DUTY CYCLE

VOLT/AMP CURVE – DC STICK MODE

90

45

0

0 100 200 300 400 500 600 700 800 900 1000

DC AMPERES

VOLT/AMP CURVE – AC STICK MODE

100

80

60

40

20

0

0 100 200 300 400 500 600 700

AC AMPERES

300–Max

185–525

125–400

85–250

55–125

GENERATOR POWER CURVE OPTION

280

260

240

220

AC VOLTS

200

180

0 10203040506070

AC AMPERES

VOLT/AMP CURVE – DC TIG MODE

100

75

50

DC VOLTS

25

0

0 100 200 300 400 500 600

DC AMPERES

VOLT/AMP CURVE – AC TIG MODE

100

80

60

40

AC VOLTS

20

0

0 100 200 300 400 500 600

AC AMPERES

20 kW

3-PHASE

12 kW

1-PHASE

60–450

40–330

30–220

20–110

50

37.5

25

DC VOLTS

12.5

BATTERY CHARGE OUTPUT

0

0 100 200 300 400 500 600 700 800 900 1000

DC AMPS

VOLT/AMP CURVE – MIG MODE

100

75

50

DC VOLTS

25

0

0 250 500 750 1000

MAX

MIN

DC AMPERES

140

120

100

80

PSI

60

40

20

0

0102030

AIR SUPPLY CURVE

IDLE

40 50 60 70

CFM

Loading...

Loading...