Page 1

Delta-Fab

Input Power

3-Phase, 230/460/575 V

Rated Output

375 A at 100% Duty Cycle

450 A at 60% Duty Cycle

Voltage 10 – 45 V

Weight 374 lb (170 kg)

Industrial Applications

Heavy-to-Light Fabrication

Processes

MIG (GMAW)

with mild steel, flux cored,

stainless steel, and

aluminum wires

Quick

Specs

Delta-Fab System

MIG Welding

Power Source

Issued April 2008 • Index No. DC/15

Miller Electric Mfg. Co.

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

Web Site

www.MillerWelds.com

International Headquarters

Phone: 920-735-4505

USA FAX: 920-735-4134

Canadian FAX: 920-735-4169

International FAX: 920-735-4125

24A Wire Feeder

Input Power

24 VAC / 7A

Electrode Wire Diameter Capacity

.023– 3/32 in (0.08 –2.4 mm)

Wire Speed 75 – 750 IPM (1.9–16.5 m/min)

Remote Voltage Control Standard

Weight 40 lb (18 kg)

Large analog volt and ammeters for

easy viewing.

Solid-state weld contactor provides

longevity to match the ultra-durable

and reliable reputation of the Delta-Fab.

Large output voltage range provides

more flexibility on a variety of wire

diameters. Also aids operator with

voltage losses that occur when operating

long distances from power source.

115 VAC duplex receptacle provides

15 amps of auxiliary power.

Four-Drive-Roll feeding system with

independent tension control handles

small and large diameter wires. (Drive

rolls and guides ordered separately.)

Remote voltage control is standard.

Parameter adjustments can be made

in weld cell or at a remote location.

Run-in standard on 24A for better

arc-starting performance on a variety

of wires.

14-pin select is easy to set up with

no external switches to put in the

wrong position.

14-pin receptacle provides quick,

direct connection to wire feeders and

accessories.

The Power of Blue®.

Welder is warranted for 3 years, parts and labor.

Original main power rectified parts are warranted for 5 years.

See option and package

descriptions on page 3.

Line voltage compensation keeps

welding parameters constant even

when input voltages change ±10%.

Eliminates need to change welding

parameters throughout the day.

Material specific output studs

provide the flexibility to produce the

optimal arc characteristics for

aluminum, stainless steel and all

other materials.

Thermal overload protection

auto matically shuts down the system

to prevent high repair costs.

Auto Remote Sense

™

automatically

selects remote control requirements

through the 14-pin receptacle.

Eliminates switches and confusion

for the operator.

Delta-Fab

™

System

MIGRunner®Package shown

NEW! MIG Power Source Solutions

Page 2

1

2

3

4

Delta-Fab

CV Welding Power Source

High Temp

Shutdown

ON

OFF

MILLER ELECTRIC MFG. CO., APPLETON, WI.

MADE IN

1

2

4

3

5

6

2

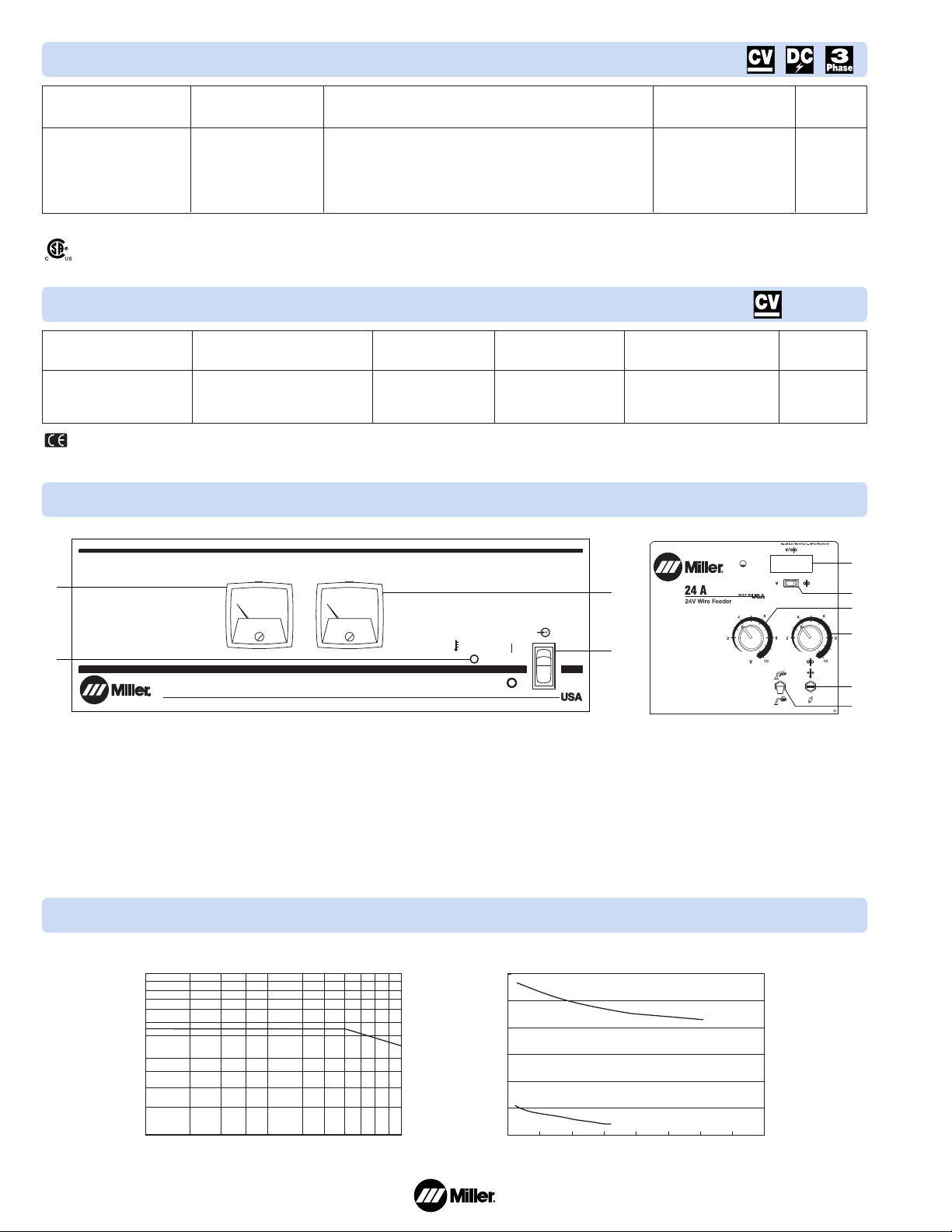

Control Panels

Performance Data

1. Voltage Meter

2. High Temperature Shutdown Light

3. Amperage Meter

4. Power Switch with Indicator Light

Note: Weld output studs are energized by controls on the wirefeeder.

Turn off power before connecting remote device.

1. Voltage/Wire Speed Meter*

2. Voltage/Wire Speed Switch*

3. Remote Voltage Control Standard

4. Wire Speed Control

5. Jog/Purge Switch

6. Trigger Hold Switch

*Optional

Note: Power switch is on rear panel.

Rated Welding Output

375 A at 35 VDC,

100% Duty Cycle

Voltage Range DC

10–45

Amps Input at Rated Load Output, 60 Hz, Three-Phase

230 V 460 V 575 V KVA KW

69 34.5 27.5 27.5 17.5

4* 2* 1.6* 1.61* 0.46*

Dimensions

H: 30 in (762 mm)

(including lift eye)

W: 23 in (585 mm)

D: 30-1/2 in (775 mm)

(including strain relief)

Net

Weight

374 lb

(170 kg)

Delta-Fab Specifications (Subject to change without notice.)

24A Wire Feeder Specifications (Subject to change without notice.)

*While idling.

VOLT/AMP CURVE – DELTA-FAB

800

600

500

400

1000

100

% DUTY CYCLE

WELDING AMPS

DUTY CYCLE CHART – DELTA-FAB

1510

20 50403025

60 70 80 90 100

DC AMPS

1000

200 600500400300

700 800

200

250

150

40

30

50

60

0

DC VOLTS

20

10

300

MAX

MIN

Input Power

24 VAC, 7 A, 60 Hz

Electrode Wire

Diameter Capacity

.023–3/32 in (0.08– 2.4 mm)

Maximum Spool

Size Capacity

60 lb (27.2 kg)

Wire Speed

75 – 750 IPM

(1.9 – 16.5 m/min)

(Use with CV

Power Sources.)

Conforms to European standards.

Certified to both the Canadian and U.S. Standards for welding equipment.

Dimensions

H: 11 in (279 mm)

W: 10-3/4 in (273 mm)

D: 23-1/2 in (597 mm)

Net Weight

40 lb (18 kg)

Page 3

3

Genuine Miller Options

Digital Meter #186 498 Field

Dual-function, back-lit LCD digital meter

with selector switch. The digital meter

allows the wire feed speed to be preset in

meters per minute or inches per minute.

The voltage function will only monitor and

display the arc voltage. The voltage display

can also be calibrated if required.

Preflow/Postflow and Spot Control

#186 496 Field

Installs inside feeder under an easy access

hinged cover. Provides up to 5 seconds of

spot weld time and has adjustable timers

(0.25 to 5 sec.) for controlling gas flow

prior to arc initiation and after completion

of weld.

Option #1: Delta-Fab™System

Option #2: Delta-Fab™System Stationary Package

Option #3: Delta-Fab™System MIGRunner®Package

Packages

Purchase running gear and MIG kit

separately.

Delta-Fab

™

System

#951 022 (230/460/575 V, 60 Hz)

Comes complete With:

Delta-Fab™power source

24A wire feeder

Bernard®Q-Gun

™

Stationary display without running

gear/cylinder rack.

Delta-Fab

™

System Stationary Package

#951 083 (230/460/575 V, 60 Hz)

Comes complete With:

Delta-Fab™power source

24A wire feeder

Bernard®Q-Gun

™

Industrial MIG 4/0 Kit:

Smith®regulator/flowmeter with 10 ft

(3 m) gas hose, 10 ft (3 m) 4/0 feeder

weld cable with lugs, and 15 ft (4.6 m)

work cable with 600-amp C-clamp

MIGRunner system with factory-installed

running gear/cylinder rack.

Delta-Fab™System MIGRunner Package

#951 111 (230/460/575 V, 60 Hz)

Comes complete With:

Delta-Fab

™

power source

24A wire feeder

Bernard®Q-Gun

™

Industrial MIG 4/0 Kit:

Smith®regulator/flowmeter with 10 ft

(3 m) gas hose, 10 ft (3 m) 4/0 feeder

weld cable with lugs, and 15 ft (4.6 m)

work cable with 600-amp C-clamp

Factory installed running gear/cylinder

rack

NEW! MIG Power Source Solutions

Page 4

NEW!

Industrial MIG 4/0 Kit #300 390

Consists of Smith®regulator/flowmeter

with 10 ft (3 m) gas hose, 10 ft (3 m)

4/0 feeder weld cable with lugs, and 15 ft

(4.6 m) work cable with 600-amp C-clamp.

Standard Running

Gear #042 886

The large 10 in

(254 mm) rear

wheels and 5 in

(127 mm) front

casters on this

running gear provide excellent mobility on

the shop floor, making it easier to move the

power source. Very easy to install. Handles

double as weld cable holder.

Standard Cylinder Rack #042 887

Holds two cylinders. Only installs on

Standard Running Gear.

Turntable Assembly #146 236

Allows rotation of the feeder as the operator

changes work positions. Reduces strain

and bend ing on the gun cable.

Wire Reel Assembly #108 008

For 60 lb (27 kg) coil of wire.

(Cannot use when handle is installed.)

Feeder Cart #043 698 Field

A low-profile creeper cart with high-quality

rubber casters, front swivel and rear rigid.

Carrying Handle #193 762

For lifting and moving feeder.

Spool Cover #057 607

For 12 in (304 mm) spool.

Hanging Bail #058 435

Suspends feeder over the work area.

Reel Cover #058 256

For 60 lb (27.2 kg) coil.

Spool Adapter #047 141

For use with 14 lb (6.4 kg) spool

of Lincoln self-shielding wire.

Extension Cords

#122 973 25 ft (7.6 m)

#122 974 50 ft (15.2 m)

#122 975 75 ft (22.8 m)

Used to extend interconnecting cords.

Distributed by:

Equipment and Options Stock No. Description Qty. Price

Delta-Fab System Power Source, Feeder & Gun Only #951 022 230/460/575 V, 60 Hz

Delta-Fab System Stationary Package #951 083 230/460/575 V, 60 Hz

Delta-Fab System MIGRunner Package #951 111 230/460/575 V, 60 Hz

Digital Meter #186 498 Field

Preflow/Postflow and Spot Control #186 496 Field

Accessories

Industrial MIG 4/0 Kit #300 390 Includes Smith regulator/flowmeter with 10 ft (3 m) gas hose,

10 ft (3 m) 4/0 feeder weld cable with lugs, and 15 ft (4.6 m) work cable

with 600-amp C-clamp

Standard Running Gear #042 886

Standard Cylinder Rack #042 887

Wire Reel Assembly #108 008 For 60 lb (27.2 kg) coil

Feeder Cart #043 698 Field

Carrying Handle #193 762

Turntable Assembly #146 236

Hanging Bail #058 435

Spool Cover #057 607 For 12 in ( 304 mm) spool

Reel Cover #058 256 For 60 lb (27.2 kg) coil

Spool Adapter #047 141 For 14 lb (6.4 kg) Lincoln spool

Extension Cords

Date: Total Quoted Price:

Ordering Information

Litho in USA

Hanging Bail

Spool Cover

Feeder Cart

Turntable

Assembly

Wire Reel

Assembly

Carrying Handle

Genuine Miller Accessories

Loading...

Loading...