Page 1

OM-166 941C July 1999

Processes

Stick (SMAW) Welding

Flux Cored (FCAW) W elding

Air Carbon Arc (CAC-A)

Cutting and Gouging

Description

Engine Driven Welding Generator

CBI 801D

(Per NSPR 10202)

Page 2

Warranty

Effective January 1, 1999

(Equipment with a serial number preface of “KK” or newer)

This limited warranty supersedes all previous manufacturers

warranties and is exclusive with no other guarantees or

warranties expressed or implied.

LIMITED W ARRANTY − Subject to the terms and conditions

below, warrants to its original retail purchaser that new

equipment sold after the effective date of this limited warranty

is free of defects in material and workmanship at the time it is

shipped from factory. THIS WARRANTY IS EXPRESSLY I N

LIEU OF ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING THE WARRANTIES OF

MERCHANTABILITY AND FITNESS.

Within the warranty periods listed below, manufacturer will

repair or replace any warranted parts or components that fail

due to such defects in material or workmanship.

Manufacturer must be notified in writing within thirty (30) days

of such defect or failure, at which time manufacturer will

provide instructions on the warranty claim procedures to be

followed.

Manufacturer shall honor warranty claims on warranted

equipment listed below in the event of such a failure within the

warranty time periods. All warranty time periods start on the

date that the equipment was delivered to the original retail

purchaser, or one year after the equipment is sent to the

distributor.

1. 5 Years Parts − 3 Years Labor

* Original main power rectifiers

2. 3 Years — Parts and Labor

* T ransformer/Rectifier Power Sources

* Plasma Arc Cutting Power Sources

* Semi-Automatic and Automatic Wire Feeders

* Engine Driven Welding Generators

(NOTE: Engines are warranted separately by the

engine manufacturer.)

3. 1 Year — Parts and Labor

* Motor Driven Guns (w/exception of Spoolmate 185)

* Process Controllers

* Positioners and Controllers

* Automatic Motion Devices

* Robots

* RFCS Foot Controls

* Water Coolant Systems

* HF Units

* Grids

* Spot Welders

* Load Banks

* SDX Transformers

* Running Gear/Trailers

* Field Options

(NOTE: Field options are covered under the limited

warranty for the remaining warranty period of the

product they are installed in, or for a minimum of one

year — whichever is greater.)

4. 6 Months — Batteries

5. 90 Days — Parts and Labor

* MIG Guns/TIG Torches

* Plasma Cutting Torches

* Remote Controls

* Accessory Kits

* Replacement Parts

* Spoolmate 185

Limited Warranty shall not apply to:

1. Items furnished by manufacturer, but manufactured by

others, such as engines or trade accessories. These

items are covered by the manufacturer’s warranty, if

any.

2. Consumable components; such as contact tips, cutting

nozzles, contactors, relays, brushes, slip rings, or parts

that fail due to normal wear.

3. Equipment that has been modified by any party other

than manufacturer, or equipment that has been

improperly installed, improperly operated or misused

based upon industry standards, or equipment which has

not had reasonable and necessary maintenance, or

equipment which has been used for operation outside of

the specifications for the equipment.

MANUFACTURER’S PRODUCTS ARE INTENDED FOR

PURCHASE AND USE BY COMMERCIAL/INDUSTRIAL

USERS AND PERSONS TRAINED AND EXPERIENCED IN

THE USE AND MAINTENANCE OF WELDING

EQUIPMENT.

In the event of a warranty claim covered by this warranty, the

exclusive remedies shall be, at manufacturers option: (1)

repair; or (2) replacement; or, where authorized i n writing by

manufacturer in appropriate cases, (3) the reasonable cost

of repair or replacement at an authorized service station; or

(4) payment of or credit for the purchase price (less

reasonable depreciation based upon actual use) upon return

of the goods at customer’s risk and expense. manufacturer’s

option of repair or replacement will be F.O.B., Factory at

Appleton, Wisconsin, or F.O.B. at an authorized service

facility as determined by manufacturer. Therefore no

compensation or reimbursement for transportation costs of

any kind will be allowed.

TO THE EXTENT PERMITTED BY LAW, THE REMEDIES

PROVIDED HEREIN ARE THE SOLE AND EXCLUSIVE

REMEDIES. IN NO EVENT SHALL MANUFACTURER BE

LIABLE FOR DIRECT, INDIRECT, SPECIAL, INCIDENTAL

OR CONSEQUENTIAL DAMAGES (INCLUDING LOSS OF

PROFIT), WHETHER BASED ON CONTRACT, TORT OR

ANY OTHER LEGAL THEORY.

ANY EXPRESS WARRANTY NOT PROVIDED HEREIN

AND ANY IMPLIED WARRANTY, GUARANTY OR

REPRESENTATION AS TO PERFORMANCE, AND ANY

REMEDY FOR BREACH OF CONTRACT TORT OR ANY

OTHER LEGAL THEORY WHICH, BUT FOR THIS

PROVISION, MIGHT ARISE BY IMPLICATION,

OPERA TION O F L AW , CUSTOM OF TRADE OR COURSE

OF DEALING, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR PARTICULAR

PURPOSE, WITH RESPECT TO ANY AND ALL

EQUIPMENT FURNISHED BY MANUFACTURER IS

EXCLUDED AND DISCLAIMED BY MANUFACTURER.

Some states in the U.S.A. do not allow limitations of how long

an implied warranty lasts, or the exclusion of incidental,

indirect, special or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty

provides specific legal rights, and other rights may be

available, but may vary from state to state.

In Canada, legislation in some provinces provides for certain

additional warranties or remedies other than as stated

herein, and to the extent that they may not be waived, the

limitations and exclusions set out above may not apply. This

Limited Warranty provides specific legal rights, and other

rights may be available, but may vary from province to

province.

brand_warr 9/99

Page 3

Page 4

TABLE OF CONTENTS

Section No. Page No.

SECTION 1 − SAFETY RULES FOR OPERATION OF ARC WELDING POWER SOURCE

1-1. Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. General Precautions 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3. Arc Welding 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4. Standards Booklet Index 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 − SAFETY PRECAUTIONS AND SIGNAL WORDS

2-1. General Information And Safety 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2. Safety Alert Symbol And Signal Words 6. . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 − SPECIFICATIONS

3-1. Duty Cycle 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. Volt-Ampere Curves 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. Description 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OM-166 941C − 7/99

SECTION 4 − INSTALLATION OR RELOCATION

4-1. Location 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2. Exhaust Extension Installation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3. Connecting The Battery 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4. Fuel 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5. Lubrication 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-6. Equipment Grounding Terminal 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-7. Weld Output Connections 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-8. Remote Control Connections 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9. Air Compressor Connections 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-10. Ether Starting Aid (Optional) 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 − AUXILIARY POWER

5-1. General 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2. 120 Volt Terminals 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 − OPERATOR CONTROLS

6-1. Ampere Ranges Switch 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2. Amperage & Voltage Adjustment Control 16. . . . . . . . . . . . . . . . . . . . . . .

6-3. Engine Control Switch 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4. Remote Amperage & Voltage Control Switch 17. . . . . . . . . . . . . . . . . . . .

6-5. Output(Contactor) Switch 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6. Service Engine Air Cleaner Light 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-7. Check Alternator 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-8. Hour Meter 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-9. Fuel Gauge 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-10. Magnetic Shutdown Switch 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-11. Oil Temperature Gauge/Switch 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-12. Oil Pressure Gauge/Switch 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-13. Battery Gauge 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-14. Meters 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-15. Broken Cooling Belt Shutdown Switch 18. . . . . . . . . . . . . . . . . . . . . . . . .

6-16. Ether Starting Aid (Optional) 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

SECTION 7 − SEQUENCE OF OPERATION

7-1. Shielded Metal Arc Welding (SMAW) 19. . . . . . . . . . . . . . . . . . . . . . . . . .

7-2. Gas Metal Arc (GMAW) And Flux Cored Arc Welding (FCAW) 19. . . .

7-3. Air Carbon Arc Cutting And Gouging (CAC-A) 20. . . . . . . . . . . . . . . . . . .

7-4. Auxiliary Power Operation 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5. Air Compressor Operation 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6. Starting The Engine 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-7. Stopping The Engine 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8 − MAINTENANCE

8-1. Routine Maintenance 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2. Air Cleaner Service 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-3. Fuel/Water Separator And Sludge Drain Plug 26. . . . . . . . . . . . . . . . . . .

8-4. Fuel Filter 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-5. Battery Replacement Procedure 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-6. Maintenance-Free Battery Charging 27. . . . . . . . . . . . . . . . . . . . . . . . . . .

8-7. Governor 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-8. Engine Speed Adjustments 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-9. Brushes And Slip Rings 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-10. Ether Starting Aid (Optional) 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-11. Spark Arrestor 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-12. Run-In Procedure 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 8-1. Load Bank Connections 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram 8-2. Resistance Grid Connections 31. . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9 − TROUBLESHOOTING

9-1. General 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2. Booster Battery Jump Starting 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-3. Overload Protection 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-4. Circuit Board Handling Precautions 32. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-5. Troubleshooting 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 10 − ELECTRICAL DIAGRAMS

Diagram 10-1. Circuit Diagram For Welding Generator 36. . . . . . . . . . . . . . . . . .

SECTION 11 − PARTS LIST

Figure 11-1A. Main Assembly 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11-1B. Main Assembly 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11-2. Panel, Front w/Components 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11-3. Panel, Lower Front w/Components 46. . . . . . . . . . . . . . . . . . . . . . .

Figure 11-4. Control Box 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11-5. Generator 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LIST OF TABLES AND CHARTS

Table 3-1. Welding Generator Specifications 7. . . . . . . . . . . . . . . . . . . . . . . . . .

Chart 3-1. Volt-Ampere Curves 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart 3-2. Air Output Curve 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart 4-1. Fuel Consumption Curve 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-1. Weld Cable Size 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart 5-1. AC Power Curve For 120 Volt Terminals 15. . . . . . . . . . . . . . . . . . . . .

Table 7-1. Suggested Electrode Diameter For Amperage Range (CAC-A Only) 20

Table 7-2. Flow Of Free Air (CFM) Through Orifices Of Various Diameters 21

Table 7-3. Approximate Air Consumption (Cubic Feet) Required To Operate

Various Pneumatic Equipment At Pressure Range 70-90 P.S.I.G. 22. . . . . . . .

Table 8-1. Maintenance Schedule 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8-2. Air Cleaner Service 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-1. Weld/Power Troubleshooting 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-2. Auxiliary Power Troubleshooting 34. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-3. Engine Troubleshooting 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-4. Air Compressor Troubleshooting 34. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

SECTION 1 − SAFETY RULES FOR OPERATION OF ARC WELDING POWER SOURCE

1-1. INTRODUCTION

We learn by experience. Learning safety through personal experience, like a child touching a hot stove is

harmful, wasteful, and unwise. Let the experience of

others teach you.

Safe practices developed from experience in the use of

welding and cutting are described in this manual. Research, development, and field experience have

evolved reliable equipment and safe installation, operation, and servicing practices. Accidents occur when

equipment is improperly used or maintained. The reason for the safe practices may not always be given.

Some are based on common sense, others may require

technical volumes to explain. It is wiser to follow the

rules.

Read and understand these safe practices before attempting to install, operate, or service the equipment.

Comply with these procedures as applicable to the particular equipment used and their instruction manuals,

for personal safety and for the safety of others.

Failure to observe these safe practices may cause serious injury or death. When safety becomes a habit, the

equipment can be used with confidence.

These safe practices are divided into two Sections:

1-General Precautions, common to arc welding and cutting; and 2-Arc Welding (and Cutting) (only).

Reference standards: Published Standards on safety

are also available for additional and more complete procedures than those given in this manual. They are listed

in the Standards Index in this manual. ANSI Z49.1 is the

most complete.

The National Electrical Code, Occupational Safety and

Health Administration, local industrial codes, and local

inspection requirements also provide a basis for equipment installation, use, and service.

1-2. GENERAL PRECAUTIONS

Different arc welding processes, electrode alloys,

and fluxes can produce different fumes, gases, and

radiation levels. In addition to the information in

this manual, be sure to consult flux and electrode

manufacturers Material Safety Data Sheets

(MSDSs) for specific technical data and precautionary measures concerning their material.

A. Burn Prevention

Wear protective clothing-gauntlet gloves designed for

use in welding, hat, and high safety-toe shoes. Button

shirt collar and pocket flaps, and wear cuffless trousers

to avoid entry of sparks and slag.

Wear helmet with safety goggles and glasses with side

shields underneath, appropriate filter lenses or plates

(protected by clear cover glass). This is a MUST for

welding or cutting, (and chipping) to protect the eyes

from radiant energy and flying metal. Replace cover

glass when broken, pitted, or spattered. See 1-3A.2.

Avoid oily or greasy clothing. A spark may ignite them.

Hot metal such as electrode stubs and workpieces

should never be handled without gloves.

Medical first aid and eye treatment. First aid facilities

and a qualified first aid person should be available for

each shift unless medical facilities are close by for immediate treatment of flash burns of the eyes and skin

burns.

Ear plugs should be worn when working on overhead or

in a confined space. A hard hat should be worn when

others work overhead.

Flammable hair preparations should not be used by persons intending to weld or cut.

B. Toxic Fume Prevention

Severe discomfort, illness or death can result from

fumes, vapors, heat, or oxygen enrichment or depletion

that welding (or cutting) may produce. Prevent them

with adequate ventilation as described in ANSI Standard Z49.1 listed in Standards Index. NEVER ventilate

with oxygen.

Lead -, cadmium -, zinc -, mercury -, and beryllium-bearing and similar materials, when welded (or cut) may produce harmful concentrations of toxic fumes. Adequate

local exhaust ventilation must be used, or each person

in the area as well as the operator must wear an air-supplied respirator. For beryllium, both must be used.

Metals coated with or containing materials that emit

toxic fumes should not be heated unless coating is removed from the work surface, the area is well ventilated

and, if necessary , while wearing an air-supplied respirator.

Work in a confined space only while it is being ventilated

and, if necessary , while wearing an air-supplied respirator.

Gas leaks in a confined space should be avoided.

Leaked gas in large quantities can change oxygen concentration dangerously . Do not bring gas cylinders into a

confined space.

Leaving confined space, shut OFF gas supply at source

to prevent possible accumulation of gases in the space if

downstream valves have been accidentally opened or

left open. Check to be sure that the space is safe before

re-entering it.

Vapors from chlorinated solvents can be decomposed

by the heat of the arc (or flame) to form PHOSGENE, a

highly toxic gas, and other lung and eye irritating products. The ultraviolet (radiant) energy of the arc can also

decompose trichloroethylene and perchloroethylene

vapors to form phosgene. DO NOT WELD or cut where

solvent vapors can be drawn into the welding or cutting

OM-166 941 Page 1

Page 7

atmosphere or where the radiant energy can penetrate

to atmospheres containing even minute amounts of

trichloroethylene or perchloroethylene.

C. Fire and Explosion Prevention

Causes of fire and explosion are: combustibles reached

by the arc, flame, flying sparks, hot slag or heated material; misuse of compressed gases and cylinders; and

short circuits.

BE AWARE THA T flying sparks or falling slag can pass

through cracks, along pipes, through windows or doors,

and through wall or floor openings, out of sight of the

goggled operator. Sparks and slag can fly 35 feet.

To prevent fires and explosion:

Keep equipment clean and operable, free of oil, grease,

and (in electrical parts) of metallic particles that can

cause short circuits.

If combustibles are in area, do NOT weld or cut. Move

the work if practicable, to an area free of combustibles.

Avoid paint spray rooms, dip tanks, storage areas, ventilators. If the work cannot be moved, move combustibles at least 35 feet away out of reach of sparks and

heat; or protect against ignition with suitable and snugfitting, fire-resistant covers or shields.

Walls touching combustibles on opposite sides should

not be welded on (or cut). Walls, ceilings, and floor near

work should be protected by heat-resistant covers or

shields.

Fire watcher must be standing by with suitable fire extinguishing equipment during and for some time after welding or cutting if:

a. appreciable combustibles (including building

construction) are within 35 feet

b. appreciable combustibles are further than 35

feet but can be ignited by sparks

c. openings (concealed or visible) in floors or walls

within 35 feet may expose combustibles to

sparks

d. combustibles adjacent to walls, ceilings, roofs,

or metal partitions can be ignited by radiant or

conducted heat.

Hot work permit should be obtained before operation to

ensure supervisor’s approval that adequate precautions have been taken.

After work is done, check that area is free of sparks,

glowing embers, and flames.

An empty container that held combustibles, or that can

produce flammable or toxic vapors when heated, must

never be welded on or cut, unless container has first

been cleaned as described in AWS Standard A6.0,

listed 7 in Standards Index.

This includes: a thorough steam or caustic cleaning (or

a solvent or water washing, depending on the combustible’s solubility) followed by purging and inerting with nitrogen or carbon dioxide, and using protective equip-

OM-166 941 Page 2

ment as recommended in A6.0. Waterfilling just below

working level may substitute for inerting.

A container with unknown contents should be cleaned

(see preceding paragraph). Do NOT depend on sense

of smell or sight to determine if it is safe to weld or cut.

Hollow castings or containers must be vented before

welding or cutting. They can explode.

Explosive atmospheres. Never weld or cut where the air

may contain flammable dust, gas, or liquid vapors (such

as gasoline).

D. Compressed Gas Equipment

Standard precautions. Comply with precautions in this

manual, and those detailed in CGA Standard P-1, SAFE

HANDLING OF COMPRESSED GASES IN CYLINDERS, listed 11 in Standards Index.

1. Pressure Regulators

Regulator relief valve is designed to protect only the

regulator from overpressure; it is not intended to protect

any downstream equipment. Provide such protection

with one or more relief devices.

Never connect a regulator to a cylinder containing gas

other than that for which the regulator was designed.

Remove faulty regulator from service immediately for

repair (first close cylinder valve). The following symptoms indicate a faulty regulator:

Leaks-if gas leaks externally.

Excessive Creep-if delivery pressure continues to rise

with downstream valve closed.

Faulty Gauge-if gauge pointer does not move off stop

pin when pressurized, nor returns to stop pin after pressure release.

Repair. Do NOT attempt to repair. Send faulty regulators for repair to manufacturer’s designated repair center, where special techniques and tools are used by

trained personnel.

2. Cylinders

Cylinders must be handled carefully to prevent leaks

and damage to their walls, valves, or safety devices:

Avoid electrical circuit contact with cylinders including

third rails, electrical wires, or welding circuits. They can

produce short circuit arcs that may lead to a serious accident. (See 1-3C.)

ICC or DOT marking must be on each cylinder. It is an

assurance of safety when the cylinder is properly handled.

Identifying gas content. Use only cylinders with name of

gas marked on them; do not rely on color to identify gas

content. Notify supplier if unmarked. NEVER DEFACE

or alter name, number, or other markings on a cylinder. It

is illegal and hazardous.

Empties: Keep valves closed, replace caps securely;

mark MT; keep them separate from FULLS and return

promptly.

Prohibited use. Never use a cylinder or its contents for

other than its intended use, NEVER as a support or

roller.

Page 8

Locate or secure cylinders so they cannot be knocked

over.

outlet away from people and sources of ignition. Wipe

with a clean lintless cloth.

Passageways and work areas. Keep cylinders clear of

areas where they may be struck.

Transporting cylinders. With a crane, use a secure support such as a platform or cradle. Do NOT lift cylinders

off the ground by their valves or caps, or by chains,

slings, or magnets.

Do NOT expose cylinders to excessive heat, sparks,

slag, and flame, etc. that may cause rupture. Do not allow contents to exceed 130°F. Cool with water spray

where such exposure exists.

Protect cylinders particularly valves from bumps, falls,

falling objects, and weather. Replace caps securely

when moving cylinders.

Stuck valve. Do NOT use a hammer or wrench to open a

cylinder valve that can not be opened by hand. Notify

your supplier.

Mixing gases. Never try to mix any gases in a cylinder.

Never refill any cylinder.

Cylinder fittings should never be modified or ex-

changed.

3. Hose

Prohibited use. Never use hose other than that designed for the specified gas. A general hose identification rule is: red for fuel gas, green for oxygen, and black

for inert gases.

Use ferrules or clamps designed for the hose (not ordinary wire or other substitute) as a binding to connect

hoses to fittings.

No copper tubing splices. Use only standard brass fittings to splice hose.

Match regulator to cylinder. Before connecting, check

that the regulator label and cylinder marking area, and

that the regulator inlet and cylinder outlet match.

NEVER CONNECT a regulator designed for a particular

gas or gases to a cylinder containing any other gas.

Tighten connections. When assembling threaded connections, clean and smooth seats where necessary.

Tighten. If connection leaks, disassemble, clean, and

retighten using properly fitting wrench.

Adapters. Use a CGA adapter (available from your supplier) between cylinder and regulator, if one is required.

use two wrenches to tighten adapter marked RIGHT

and LEFT HAND threads.

Regulator outlet (or hose) connections may be identified

by right hand threads for oxygen and left hand threads

(with grooved hex on nut or shank) for fuel gas.

5. Pressurizing Steps:

Drain regulator of residual gas through suitable vent before opening cylinder (or manifold valve) by turning adjusting screw in (clockwise). Draining prevents excessive compression heat at high pressure seat by allowing

seat to open on pressurization. Leave adjusting screw

engaged slightly on single-stage regulators.

Stand to side of regulator while opening cylinder valve.

Open cylinder valve slowly so that regulator pressure in-

creases slowly. When gauge is pressurized (gauge

reaches regulator maximum) leave cylinder valve in following position: For oxygen, and inert gases, open fully

to seal stem against possible leak. For fuel gas, open to

less than one turn to permit quick emergency shutoff.

Use pressure charts (available from your supplier) for

safe and efficient, recommended pressure settings on

regulators.

Avoid long runs to prevent kinks and abuse. Suspend

hose off ground to keep it from being run over, stepped

on, or otherwise damaged.

Coil excess hose to prevent kinks and tangles.

Protect hose from damage by sharp edges, and by

sparks, slag, and open flame.

Examine hose regularly for leaks, wear, and loose con-

nections. Immerse pressured hose in water; bubbles indicate leaks.

Repair leaky or worn hose by cutting area out and splicing (1-2D3). Do NOT tape.

4. Proper Connections

Clean cylinder valve outlet of impurities that may clog

orifices and damage seats before connecting regulator.

Except for hydrogen, crack valve momentarily, pointing

Check for leaks on first pressurization and regularly

there-after. Brush with soap solution (capfull of Ivory

Liquid* or equivalent per gallon of water). Bubbles indicate leak. Clean off soapy water after test; dried soap is

combustible.

E. User Responsibilities

Remove leaky or defective equipment from service immediately for repair . See User Responsibility statement

in equipment manual.

F. Leaving Equipment Unattended

Close gas supply at source and drain gas.

G. Rope Staging-Support

Rope staging-support should not be used for welding or

cutting operation; rope may burn.

*Trademark of Proctor & Gamble.

OM-166 941 Page 3

Page 9

1-3. ARC WELDING

Comply with precautions in 1-1, 1-2, and this section.

Arc Welding, properly done, is a safe process, but a

careless operator invites trouble. The equipment carries

high currents at significant voltages. The arc is very

bright and hot. Sparks fly , fumes rise, ultraviolet and infrared energy radiates, weldments are hot, and compressed gases may be used. The wise operator avoids

unnecessary risks and protects himself and others from

accidents. Precautions are described here and in standards referenced in index.

A. Burn Protection

Comply with precautions in 1-2.

The welding arc is intense and visibly bright. Its radiation

can damage eyes, penetrate lightweight clothing, reflect

from light-colored surfaces, and burn the skin and eyes.

Skin burns resemble acute sunburn, those from gasshielded arcs are more severe and painful. DON’T GET

BURNED; COMPLY WITH PRECAUTIONS.

1. Protective Clothing

Wear long-sleeve clothing (particularly for gas-shielded

arc) in addition to gloves, hat, and shoes (1-2A). As necessary, use additional protective clothing such as

leather jacket or sleeves, flame-proof apron, and fire-resistant leggings. Avoid outer garments of untreated cotton.

Bare skin protection. Wear dark, substantial clothing.

Button collar to protect chest and neck and button pockets to prevent entry of sparks.

2. Eye and Head Protection

Protect eyes from exposure to arc. NEVER look at an

electric arc without protection.

Welding helmet or shield containing a filter plate shade

no. 12 or denser must be used when welding. Place over

face before striking arc.

Protect filter plate with a clear cover plate.

Cracked or broken helmet or shield should NOT be

worn; radiation can pass through to cause burns.

Cracked, broken, or loose filter plates must be replaced

IMMEDIATELY. Replace clear cover plate when broken,

pitted, or spattered.

Flash goggles with side shields MUST be worn under

the helmet to give some protection to the eyes should

the helmet not be lowered over the face before an arc is

struck. Looking at an arc momentarily with unprotected

eyes (particularly a high intensity gas-shielded arc) can

cause a retinal burn that may leave a permanent dark

area in the field of vision.

3. Protection of Nearby Personnel

Enclosed welding area. For production welding, a separate room or enclosed bay is best. In open areas, surround the operation with low-reflective, non-combustible screens or panels. Allow for free air circulation, particularly at floor level.

OM-166 941 Page 4

Viewing the weld. Provide face shields for all persons

who will be looking directly at the weld.

Others working in area. See that all persons are wearing

flash goggles.

Before starting to weld, make sure that screen flaps or

bay doors are closed.

B. Toxic Fume Prevention

Comply with precautions in 1-2B.

Generator engine exhaust must be vented to the out-

side air. Carbon monoxide can kill.

C. Fire and Explosion Prevention

Comply with precautions in 1-2C.

Equipment’s rated capacity. Do not overload arc weld-

ing equipment. It may overheat cables and cause a fire.

Loose cable connections may overheat or flash and

cause a fire.

Never strike an arc on a cylinder or other pressure ves-

sel. It creates a brittle area that can cause a violent rupture or lead to such a rupture under rough handling.

D. Compressed Gas Equipment

Comply with precautions in 1-2D.

E. Shock Prevention

Exposed hot conductors or other bare metal in the welding circuit, or in ungrounded, electrically-HOT equipment can fatally shock a person whose body becomes a

conductor. DO NOT STAND, SIT, LIE, LEAN ON, OR

TOUCH a wet surface when welding, without suitable

protection.

To protect against shock:

Wear dry insulating gloves and body protection. Keep

body and clothing dry. Never work in damp area without

adequate insulation against electrical shock. Stay on a

dry duckboard, or rubber mat when dampness or sweat

can not be avoided. Sweat, sea water, or moisture between body and an electrically HOT part or grounded

metal reduces the electrical resistance, and could enable dangerous and possibly lethal currents to flow

through the body.

A voltage will exist between the electrode and any conducting object in the work circuit. Examples of conducting objects include, but are not limited to, buildings, electrical tools, work benches, welding power source cases,

workpieces, etc. Never touch the electrode and any

metal object unless the welding power source is

off.

1. Grounding the Equipment

Arc welding equipment must be grounded according to

the National Electrical Code, and the work must be

grounded according to ANSI Z49.1 “Safety In Welding

And Cutting.”

When installing, connect the frames of each unit such a s

welding power source, control, work table, and water circulator to the building ground. Conductors must be ade-

Page 10

quate to carry ground currents safely. Equipment made

electrically HOT by stray current may shock, possibly

fatally. Do NOT GROUND to electrical conduit, or to a

pipe carrying ANY gas or flammable liquid such as oil or

fuel.

Three-phase connection. Check phase requirements of

equipment before installing. If only 3-phase power is

available, connect single-phase equipment to only two

wires of the 3-phase line. Do NOT connect the equipment ground lead to the third (live) wire, or the equipment will become electrically HOT-a dangerous condition that can shock, possibly fatally.

Before welding, check ground for continuity. Be sure

conductors are touching bare metal of equipment

frames at connections.

If a line cord with a ground lead is provided with the

equipment for connection to a switchbox, connect the

ground lead to the grounded switchbox. If a three-prong

plug is added for connection to a grounded mating receptacle, the ground lead must be connected to the

ground prong only. If the line cord comes with a threeprong plug, connect to a grounded mating receptacle.

Never remove the ground prong from a plug, or use a

plug with a broken off ground prong.

2. Electrode Holders

Fully insulated electrode holders should be used. Do

NOT use holders with protruding screws.

3. Connectors

Fully insulated lock-type connectors should be used to

join welding cable lengths.

4. Cables

Frequently inspect cables for wear , cracks and damage.

IMMEDIATELY REPLACE those with excessively worn

or damaged insulation to avoid possibly-lethal shock

from bared cable. Cables with damaged areas may be

taped to give resistance equivalent to original cable.

Keep cable dry, free of oil and grease, and protected

from hot metal and sparks.

5. Terminals And Other Exposed Parts

Terminals and other exposed parts of electrical units

should have insulating covers secured before operation.

6. Electrode

a. Equipment with output on/off control (contac-

tor)

Welding power sources for use with the gas

metal arc welding (GMAW), gas tungsten arc

welding (GTAW) and similar processes normally are equipped with devices that permit onoff control of the welding power output. When

so equipped the electrode wire becomes electrically HOT when the power source switch is

ON and the welding gun switch is closed. Never

touch the electrode wire or any conducting ob-

ject in contact with the electrode circuit unless

the welding power source is off.

b. Equipment without output on/off control (no

contactor)

Welding power sources used with shielded

metal arc welding (SMAW) and similar processes may not be equipped with welding power

output on-off control devices. With such equipment the electrode is electrically HOT when the

power switch is turned ON. Never touch the

electrode unless the welding power source is

off.

7. Safety Devices

Safety devices such as interlocks and circuit breakers

should not be disconnected or shunted out.

Before installation, inspection, or service, of equipment,

shut OFF all power and remove line fuses (or lock or

red-tag switches) to prevent accidental turning ON of

power. Disconnect all cables from welding power

source, and pull all 115 volts line-cord plugs.

Do not open power circuit or change polarity while welding. If, in an emergency , it must be disconnected, guard

against shock burns, or flash from switch arcing.

Leaving equipment unattended. Always shut OFF and

disconnect all power to equipment.

Power disconnect switch must be available near the

welding power source.

F. Protection For Wearers of Electronic Life Sup-

port Devices (Pacemakers)

Magnetic fields from high currents can affect pacemaker operation. Persons wearing electronic life support

equipment (pacemaker) should consult with their doctor

before going near arc welding, gouging, or spot welding

operations.

1-4. STANDARDS BOOKLET INDEX

For more information, refer to the following standards or

their latest revisions and comply as applicable:

1. ANSI Standard Z49.1, SAFETY IN WELDING

AND CUTTING obtainable from the American

Welding Society, 550 N.W. LeJeune Rd, Miami,

FL 33126.

2. NIOSH, SAFETY AND HEALTH IN ARC WELDING AND GAS WELDING AND CUTTING obtainable from the Superintendent of Documents,

U.S. Government Printing Office, Washington,

D.C. 20402.

3. OSHA, SAFETY AND HEALTH STANDARDS,

29CFR 1910, obtainable from the Superintendent of Documents, U.S. Government Printing

Office, Washington, D.C. 20402.

4. ANSI Standard Z87.1, SAFE PRACTICES FOR

OCCUPATION AND EDUCATIONAL EYE AND

FACE PROTECTION obtainable from the American National Standards Institute, 1430 Broadway, New York, NY 10018.

OM-166 941 Page 5

Page 11

5. ANSI Standard Z41.1, STANDARD FOR MEN’S

SAFETY-TOE FOOTWEAR obtainable from the

American National Standards Institute, 1430

Broadway, New York, NY 10018.

6. ANSI Standard Z49.2, FIRE PREVENTION IN

THE USE OF CUTTING AND WELDING PROCESSES obtainable from the American National

Standards Institute, 1430 Broadway, New York,

NY 10018.

7. AWS Standard A6.0, WELDING AND CUTTING

CONTAINERS WHICH HAVE HELD COMBUSTIBLES obtainable from the American Welding

Society, 550 N.W. LeJeune Rd, Miami, FL 33126.

8. NFPA Standard 51, OXYGEN-FUEL GAS SYSTEMS FOR WELDING, CUTTING, AND ALLIED

PROCESSES obtainable from the National Fire

Protection Association, Batterymarch Park,

Quincy, MA 02269.

9. NFPA Standard 70, NATIONAL ELECTRICAL

CODE obtainable from the National Fire Protection Association, Batterymarch Park, Quincy , MA

02269.

10. NFPA Standard 51B, CUTTING AND WELDING

PROCESSES obtainable from the National Fire

Protection Association, Batterymarch Park,

Quincy, MA 02269.

11. CGA Pamphlet P-1, SAFE HANDLING OF

COMPRESSED GASES IN CYLINDERS obtainable from the Compressed Gas Association,

1235 Jefferson Davis Highway, Suite 501, Arlington, VA 22202.

12. CSA Standard W117.2, CODE FOR SAFETY IN

WELDING AND CUTTING obtainable from the

Canadian Standards Association, Standards

Sales, 178 Rexdale Boulevard, Rexdale, Ontario, Canada M9W 1R3.

13. NWSA booklet, WELDING SAFETY BIBLIOGRAPHY obtainable from the National Welding

Supply Association, 1900 Arch Street, Philadelphia, PA 19103.

14. American Welding Society Standard AWSF4.1,

RECOMMENDED SAFE PRACTICES FOR

THE PREPARATION FOR WELDING AND

CUTTING OF CONTAINERS AND PIPING

THAT HAVE HELD HAZARDOUS SUBSTANCES, obtainable from the American Welding Society, 550 N.W. LeJeune Rd, Miami, FL

33126.

15. ANSI Standard Z88.2, PRACTICE FOR RESPIRATORY PROTECTION, obtainable from the

American National Standards Institute, 1430

Broadway, New York, NY 10018.

SECTION 2 − SAFETY PRECAUTIONS AND SIGNAL WORDS

2-1. GENERAL INFORMATION AND SAFETY

A. General

Information presented in this manual and on various labels, tags, and plates on the unit pertains to equipment

design, installation, operation, maintenance, and

troubleshooting which should be read, understood, and

followed for the safe and ef fective use of this equipment.

The nameplate of this unit uses international symbols

for labeling the front panel controls. The symbols also

appear at the appropriate section in the text.

B. Safety

The installation, operation, maintenance, and troubleshooting of arc welding equipment requires practices

and procedures which ensure personal safety and the

safety of others. Therefore, this equipment is to be installed, operated, and maintained only by qualified persons in accordance with this manual and all applicable

codes such as, but not limited to, those listed at the end

of Section 1 − Safety Rules For Operation Of Arc Welding Power Source.

2-2. SAFETY ALERT SYMBOL AND SIGNAL

WORDS

The following safety alert symbol and signal words are

used throughout this manual to call attention to and

identify different levels of hazard and special instructions.

This safety alert symbol is used with the signal

words WARNING and CAUTION to call attention to the safety statements.

WARNING statements identify procedures or

practices which must be followed to avoid serious personal injury or loss of life.

CAUTION statements identify procedures or

practices which must be followed to avoid minor

personal injury or damage to this equipment.

IMPORTANT statements identify special instructions

necessary for the most efficient operation of this equipment.

OM-166 941 Page 6

Page 12

SECTION 3 − SPECIFICATIONS

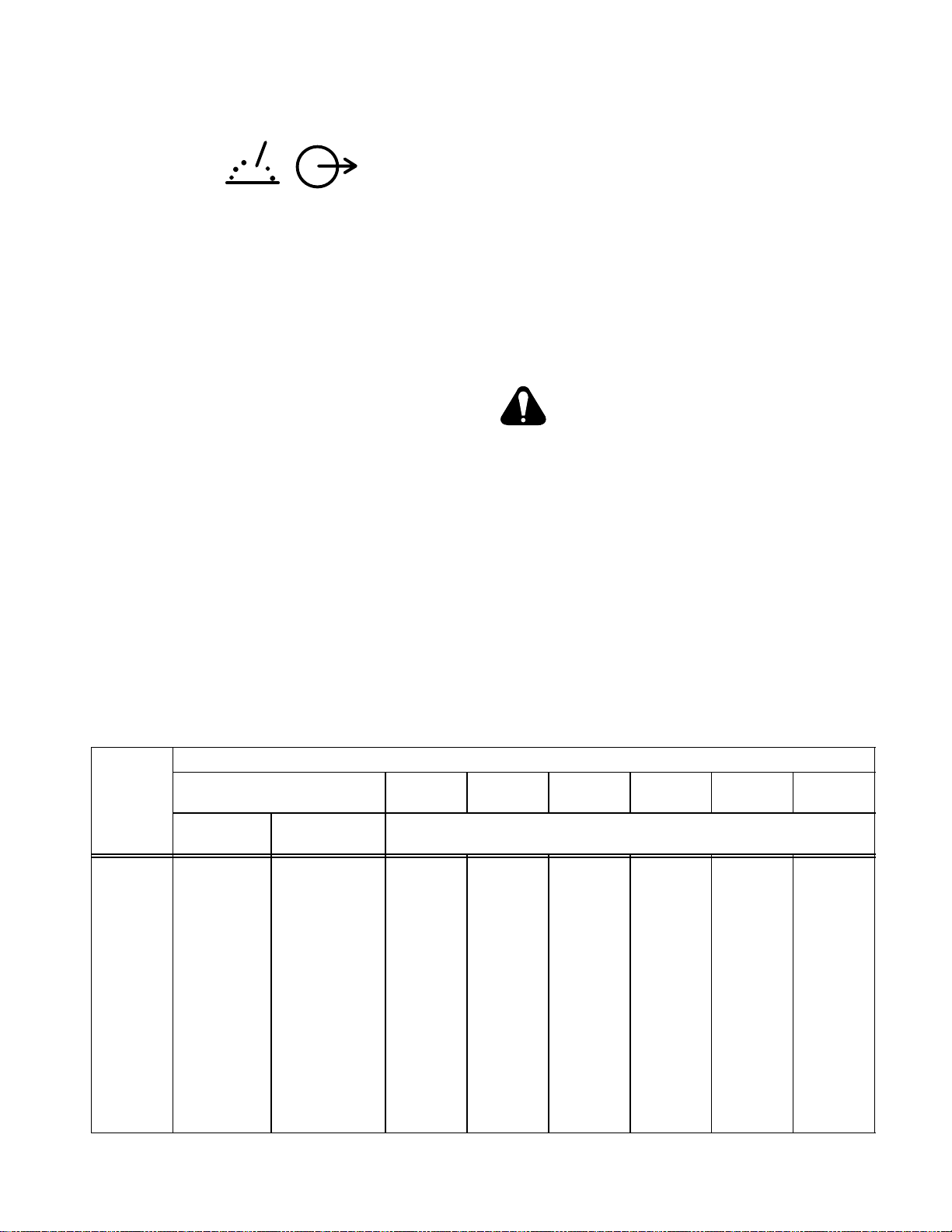

Table 3-1. Welding Generator Specifications

Rated Output

At 100%

Duty Cycle

800 Amperes

At 36 Volts DC

Welding

Range

100 to 800

Amps DC

Maximum

Open-Circuit

Voltage

(OCV)

95 Volts DC

80 Volts DC

Maximum

Engine Speed

(No Load)

1860 RPM

Single-Phase

Auxiliary Power

While Welding

3 kVA/kW 60 Hz

26 Amperes At 120 Volts

Weight

Net Ship

2150 lbs.

(975 kg)

2280 lbs.

(1034 kg)

Nominal

Conforms with NEMA EW1 (ANSI C87.1), “ELECTRIC ARC WELDING POWER SOURCES,” Class I (100).

47 in.

(1194 mm)

Inches

A

62-3/8

B

50-1/2

C

46-1/2

D

E

F

G

H

J

K

36

28-3/16

13-3/4

9-3/4

6-1/8

29-7/8

1-1/16 27

72 in.

(1829 mm)

32 in.

(813 mm)

21/32 in. (16.7 mm)

Dia. All Holes

Millimeters

1584

1283

1181

914

716

349

248

156

759

JK

Figure 3-1. Overall Dimensions And Mounting Hole Locations

A

B

C

DE

F

G

H

ST-147 323-B

OM-166 941 Page 7

Page 13

3-1. DUTY CYCLE

The duty cycle of a welding generator is the percentage

of a ten minute period that a welding generator can be

operated at a given output without causing overheating

and damage to the unit. This welding generator is rated

at 100 percent duty cycle when operated at 800 amperes. This means that the welding generator can be operated at 800 amperes continuously without causing

damage to the unit.

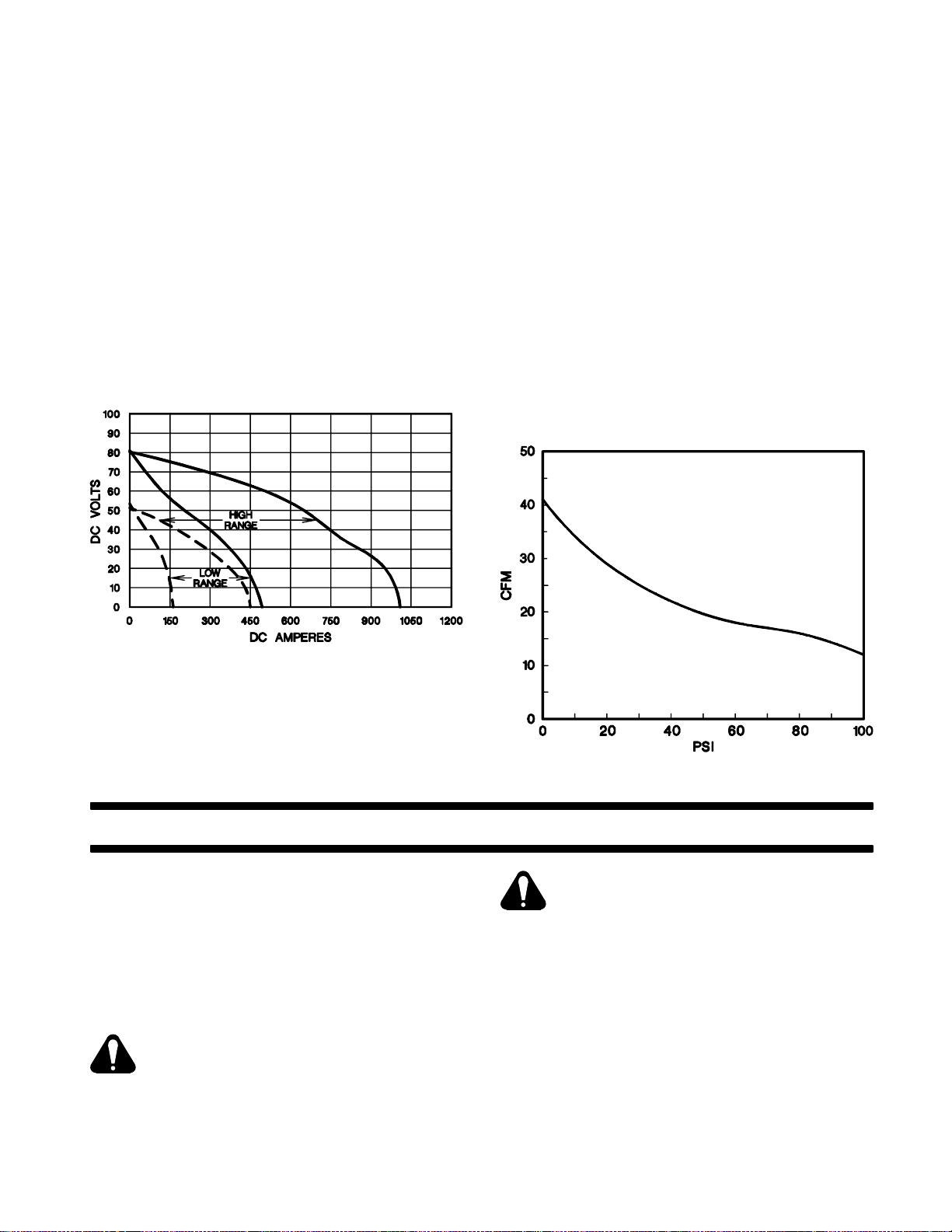

3-2. VOLT-AMPERE CURVES (Chart 3-1)

The volt-ampere curves show the voltage and amperage output capabilities of the welding generator at minimum and maximum of each coarse range. Curves of

other settings fall between the curves shown.

Chart 3-1. Volt-Ampere Curves

and Air Carbon Arc Cutting And Gouging (CAC-A) processes.

The unit is equipped with a four-cylinder, air-cooled,

Deutz diesel engine (F4L-912). The air compressor in

this unit is mounted on the front of the engine, and it operates whenever the engine is running. The compressor

delivers 12 cfm of air at a pressure of 100 psi (see Chart

3-2).

In addition to welding and air compressor operation, this

unit can provide up to 3 kVA/kW of 120 volts (26 amperes) ac electrical power for operating 50/60 Hz or 60

Hz auxiliary equipment while welding.

This unit is specially prepared for operation in harsh and

corrosive environments.

An optional Ether Starting Aid can be provided on the

welding generator and is covered within this Owner’s

Manual.

Chart 3-2. Air Output Curve

SB-168 387

3-3. DESCRIPTION

This unit is a constant current (CC) dc arc welding generator designed for use with the Shielded Metal Arc

Welding (SMAW), Flux Cored Arc Welding (FCAW),

SECTION 4 − INSTALLATION OR RELOCATION

IMPORTANT: Unless otherwise specified, all direc-

tions, such as left or right, are with respect to the operator facing the welding generator front panel.

4-1. LOCATION (Figure 3-1)

A proper installation site should be selected for the welding generator if the unit is to provide dependable service

and remain relatively maintenance free.

WARNING: ENGINE EXHAUST GASES can

kill.

• Operate in open, well-ventilated areas or if

operated indoors, vent engine exhaust outside the building.

• Keep engine exhaust vent outlet away from

building air intakes.

SB-143 883

CAUTION: RESTRICTED AIRFLOW causes

overheating and possible damage to internal parts.

• Maintain at least 18 inches (457 mm) of unre-

stricted space on all sides of unit, and keep

underside free of obstructions.

• Do not place any filtering device over the

intake air passages of this welding generator.

Warranty is void if any type of filtering device is

used.

The service life and operating efficiency of this

unit are reduced when the unit is subjected to

extreme levels of dust, dirt, moisture, corrosive

vapors, and extreme heat.

OM-166 941 Page 8

Page 14

A. Lifting Of Equipment

WARNING: INCORRECT LIFTING will damage internal parts; FALLING EQUIPMENT

can cause serious personal injury and

equipment damage.

• Use lifting eye to lift unit only, NOT gas cylin-

ders, trailer, or any other heavy options, accessories, or devices.

• Use equipment of adequate capacity to lift the

unit.

• Use lift forks at least 42 in. (1067 mm) long.

• Lift only from engine-end (end opposite front

panel).

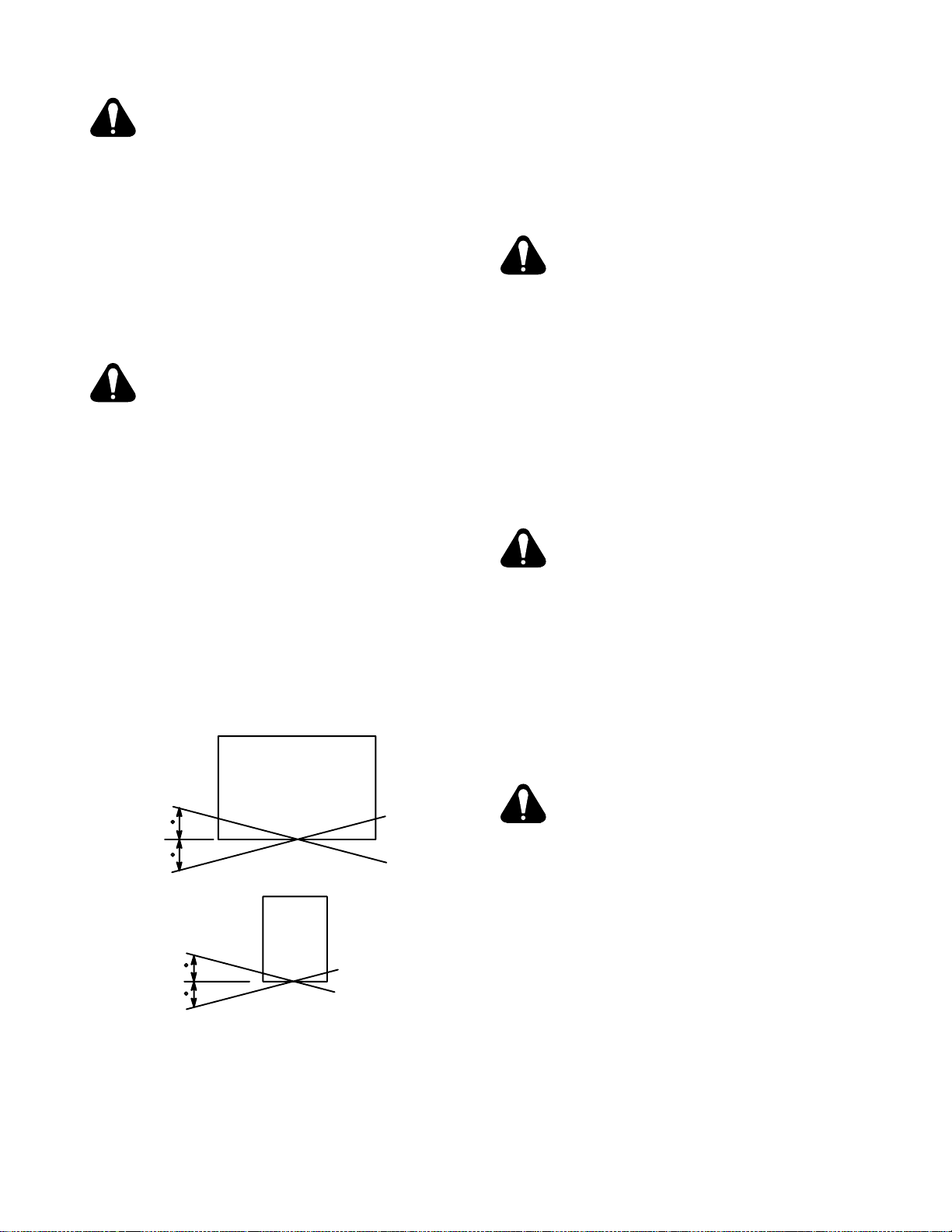

B. Trailer Mounting

CAUTION: UNCONTROLLED TILTING OF

TRAILER can result in personal injury or

equipment damage.

• Distribute weight so that trailer tongue weight

is approximately 10% of gross trailer weight.

• Follow trailer manufacturer’s instructions

when mounting welding generator onto

trailer.

OPERATION ON UNLEVEL SURFACE can

cause improper lubrication and result in

severe engine damage.

• Operate unit in an approximately level posi-

tion.

• See Figure 4-1 for maximum allowable tilt for

proper operation.

• Check crankcase oil level with unit on a level

surface.

Exceeding the s e l i m i t s c a n c a use severe engine

damage and improper operation.

Front

Panel

17.5

15

37.5

45

Figure 4-1. Allowable Tilt Angles For Welding

Holes are provided in the base for securing the unit in a

permanent location or to a trailer or transport vehicle.

Figure 3-1 gives overall dimensions and base mounting

hole layout.

Side View Of Unit

Front

Panel

End View Of Unit

Generator Engine

Ref. S-0024

The mounting location should allow sufficient room to

remove the top cover and side panels for maintenance

and repair functions.

Use a properly fitting cover (optional) over the welding

generator when not in operation to protect the unit from

the environment. Be sure unit is cool before installing

any cover.

C. Spark Arrestor Considerations

WARNING: ENGINE EXHAUST SPARKS can

cause fire.

• Exhaust spark arrestor must be installed in

accordance with local, state, and federal

regulations.

The engine exhaust system on this welding generator is

not equipped with a spark arrestor. A spark arrestor,

maintained in effective working order, is mandatory if

this welding generator is to be operated in a National

Forest or on California Grasslands, brush, or forest covered land (see Section 4442 of California Public Resources Code). For other areas, check your state and

local laws. If a spark arrestor (optional) is desired, contact your dealer/distributor.

4-2. EXHAUST EXTENSION INSTALLATION

WARNING: HOT ENGINE PARTS can cause

severe burns.

• If applicable, shut down engine and allow ex-

haust system to cool before installing exhaust

extension.

1. Install exhaust extension through top cover

opening, over muffler extension elbow. (Be sure

to face end of extension away from air cleaner;

see Figure 3-1).

2. Secure exhaust extension to top cover of unit using supplied hardware.

4-3. CONNECTING THE BATTERY

WARNING: BATTERY ACID can burn eyes

and skin and destroy clothing and other material.

• Wear a face shield and proper protective

clothing when working with batteries.

ABNORMAL VOLTAGE can cause damage

to engine electrical components.

• Do not operate engine without the battery

connected.

• Do not disconnect the battery while the en-

gine is running.

IMPORTANT: Be sure the Engine Control switch is in

the OFF position before connecting battery.

This unit is equipped with a maintenance-free battery.

To place the unit in service, remove the left, rear side

panel, connect the negative (−) battery cable to the negative battery terminal, and reinstall the side panel. No

other preparation should be required. If the battery does

not supply enough power to crank the engine, charge

the battery according to Section 8-6.

OM-166 941 Page 9

Page 15

4-4. FUEL

WARNING: REMOVE FUEL CAP SLOWLY;

FUEL SPRAY may cause injury; FUEL may

be under pressure.

• Rotate fuel cap slowly and wait until hissing

stops before removing cap.

ENGINE FUEL can cause fire or explosion.

• Stop engine before checking or adding fuel.

• Do not spill fuel; if spilled, wipe up.

• Do not refuel if engine is hot or running.

• Do not refuel near sparks or open flame.

• Do not smoke while refueling.

• Do not fill fuel tank to top; allow 1/2 in. (13

mm) from fuel to tank top for expansion.

• Do not weld on fuel tank.

IMPORTANT: Fill fuel tank up to 1/2 in. (13 mm) from

top with fresh fuel before starting engine the first time.

Rust and corrosion preventative was added to inside of

fuel tank and engine at the factory and could cause

rough engine running if not properly diluted with a full

tank of fresh fuel.

The capacity of the fuel tank is 30 gallons U.S. Measure

(114 liters). See the Engine Manufacturer’s Manual for

fuel recommendations. Chart 4-1 illustrates typical fuel

consumption under specific load conditions. Fuel consumption varies from one engine to another. Different

brands of fuel, operating conditions, condition of the engine, etc., also affect the fuel consumption level.

Keep the fuel tank filled to ensure that the injector system receives an adequate supply of fuel. The fuel cap is

located on the lower front panel, behind the right access

door (see Figure 4-2). If the fuel tank is allowed to empty,

air will enter the system, causing starting problems. The

Engine Manufacturer’s Manual outlines procedures for

air bleeding the fuel system.

4-5. LUBRICATION (Figure 4-2)

A. Oil And Oil Level Indicator

The engine is shipped with its crankcase filled with SAE

20 break-in oil. An oil level indicator is provided on the

Chart 4-1. Fuel Consumption Curve

lower front panel of this unit (see Figure 4-2). If oil level is

below the lower pointer when engine is running, add oil

according to the recommendations in the Engine Manufacturer’s Manual (F4L-912 engine). The oil cap is located under the access door on the top cover.

IMPORTANT : This engine is equipped with a n Oil Pressure Shutdown gauge/switch and an Oil Temperature

Shutdown gauge/switch. If oil pressure becomes too

low or oil temperature rises to a level that may cause engine damage, the respective gauge/switch shuts down

the engine. The shutdown oil pressure has been factory

set at 30 psi (207 kPa), and the shutdown oil temperature has been set at 265°F (130°C).

B. Wetstacking Considerations

Wetstacking is an accumulation of unburned fuel and oil

in the exhaust pipe. The engine may use oil and wetstacking may occur during the run-in period if the piston

rings are not seated properly. If oil consumption and

wetstacking occur during run-in period, see Section

8-12.

4-6. EQUIPMENT GROUNDING TERMINAL

GROUND

This unit is equipped with a grounding terminal for

grounding the generator case. The grounding terminal

is located on the lower front panel (see Figure 4-2).

Since the generator neutral is connected to the frame,

the equipment grounding terminal must be connected to

a proper earth ground. Additionally, comply with all national, regional, and local codes concerning portable

generators for the specific application.

For detailed grounding instructions consult your national, regional, and local codes. If additional information regarding your operating circumstances and/or

grounding requirements is needed, consult a qualified

electrician or your dealer. After determining the extent to

which any grounding requirements apply to your particular situation, follow them explicitly.

OM-166 941 Page 10

SB-168 472

Page 16

4-7. WELD OUTPUT CONNECTIONS (Table 4-1

And Figure 4-2)

RATED WELD OUTPUT

To obtain full rated output from this unit, it is necessary to

select, prepare, and install proper weld cables. Failure

to comply in any of these areas may result in

unsatisfactory welding performance.

A. Weld Cable Selection

B. Weld Cable Preparation

1. Install electrode holder to cable following manufacturer’s instructions. Always use an insulated

electrode holder to ensure operator safety.

2. Install correct size lugs onto ends of both cables

for connecting to work clamp, electrode holder or

wire feeder, and weld output terminals.

3. Install work clamp onto cable.

C. Weld Output Connections

Use the following guidelines to select weld cables:

1. Use the shortest possible cables, and place

cables close together. Excessive cable lengths

may reduce output or cause unit overload due to

added resistance.

2. Use weld cable with an insulation voltage rating

equal to or greater than the maximum open-circuit voltage (ocv) of the welding generator (see

Table 3-1 for unit maximum ocv rating).

3. Select weld cable size according to maximum

weld output and total length of connecting cables

in weld circuit. For example, if a 25 foot (7.5 m)

wire feeder or electrode holder cable is used with

a 25 foot (7.5 m) work cable, select the cable size

recommended in Table 4-1 for 50 feet (15 m).

4. Do not use damaged or frayed cables.

Table 4-1. Weld Cable Size*

T otal Cable (Copper) Length In Weld Circuit Not Exceeding

150 ft

(45 m)

Welding

Amperes

100 ft (30 m) Or Less

10 To 60%

Duty Cycle

60 Thru 100%

Duty Cycle

POSITIVE NEGATIVE

+

WARNING: ELECTRIC SHOCK can kill.

−

• Do not touch live electrical parts.

• Stop engine, and disconnect negative (−) bat-

tery cable before making any weld output

connections.

MOVING PARTS can cause serious injury.

• Keep away from moving parts such as fans,

belts, and rotors.

1. Open and secure the lower front panel access

door, and route weld cables through bracket on

front upright to the weld output terminals (see

Figure 4-2).

200 ft

(60 m)

250 ft

(70 m)

10 Thru 100% Duty Cycle

300 ft

(90 m)

350 ft

(105 m)

400 ft

(120 m)

100 4 4 4 3 2 1 1/0 1/0

150 3 3 2 1 1/0 2/0 3/0 3/0

200 3 2 1 1/0 2/0 3/0 4/0 4/0

250 2 1 1/0 2/0 3/0 4/0 2-2/0 2-2/0

300 1 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-3/0

350 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-3/0 2-4/0

400 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-4/0 2-4/0

500 2/0 3/0 4/0 2-2/0 2-3/0 2-4/0 3-3/0 3-3/0

600 3/0 4/0 2-2/0 2-3/0 2-4/0 3-3/0 3-4/0 3-4/0

700 4/0 2-2/0 2-3/0 2-4/0 3-3/0 3-4/0 3-4/0 4-4/0

800 4/0 2-2/0 2-3/0 2-4/0 3-4/0 3-4/0 4-4/0 4-4/0

900 2-2/0 2-3/0 2-4/0 3-3/0 3-4/0 4-4/0 4-4/0

*Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. S-0007-D

OM-166 941 Page 11

Page 17

2. For Shielded Metal Arc Welding (SMAW) and Air

Carbon Arc Cutting and Gouging (CAC-A) (Electrode Positive/Reverse Polarity), connect weld

cables as follows:

4-8. REMOTE CONTROL CONNECTIONS

A. Remote 9 Receptacle Information And

Connections (Figures 4-2 And 4-3)

a. Connect one end of work cable to NEGATIVE

(−) weld output terminal.

b. Connect end of electrode holder cable to POSI-

TIVE (+) weld output terminal.

IMPORTANT: For Electrode Negative/Straight Polarity

connections, reverse cable connections to weld output

terminals; electrode becomes negative.

3. For Wire Feeding Processes (GMAW, FCAW,

SAW) (Electrode Positive/Reverse Polarity),

connect weld cables as follows:

a. Connect one end of work cable to NEGATIVE

(−) weld output terminal.

b. Connect end of electrode holder cable to POSI-

TIVE (+) weld output terminal and remaining

end to terminal on the wire feeder drive housing

(see wire feeder Owner’s Manual for location).

4. Close and secure front panel access door.

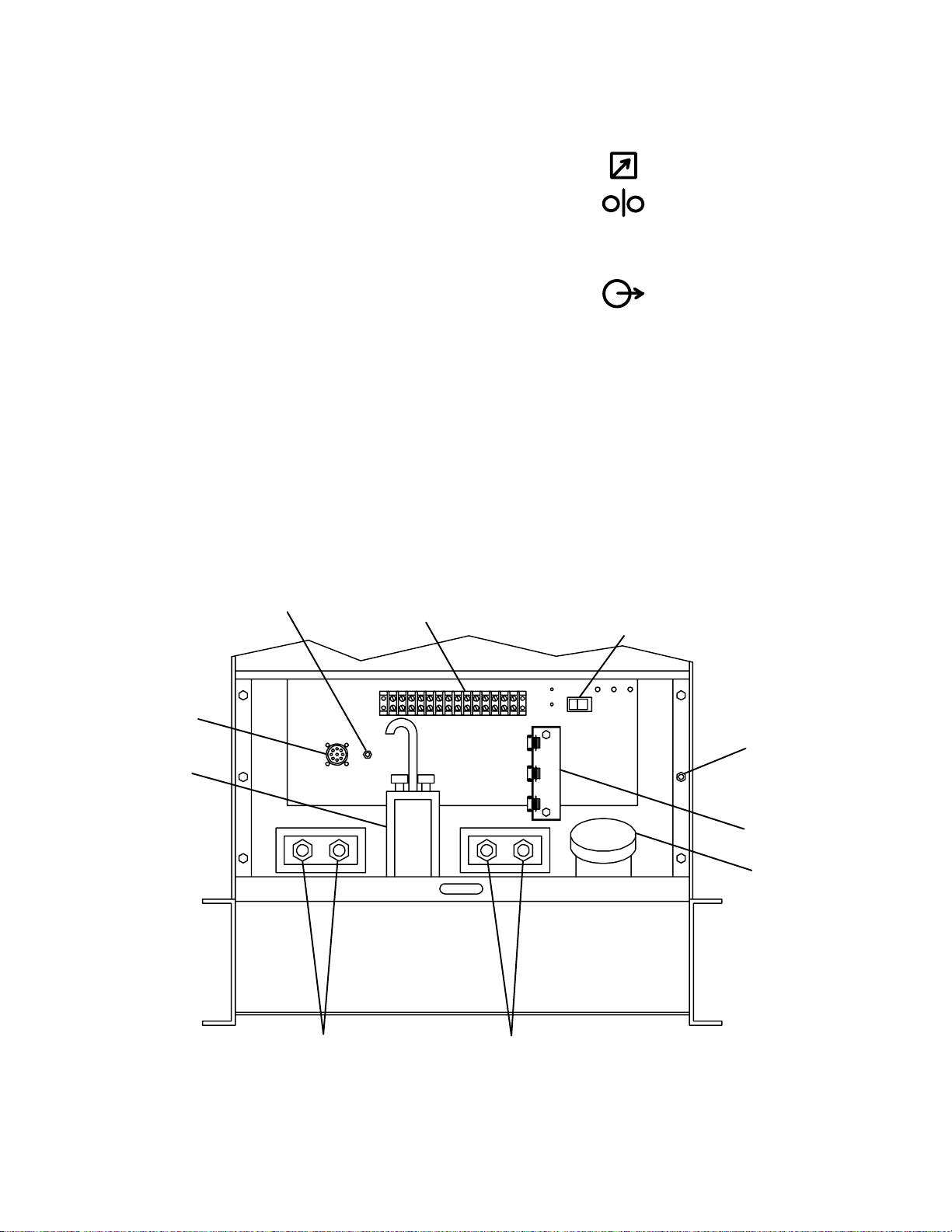

Circuit Breaker CB3

Terminal

Strip 3T

REMOTE 9

FEEDER

AMPERAGE/

A/V

VOLTAGE

OUTPUT

(CONTACTOR)

REMOTE 9 receptacle RC3, located under the lower

front panel access door (see Figure 4-2), is provided to

connect any of the following equipment to the welding

generator circuitry:

a. Remote Contactor

b. Remote Amperage or Voltage control

c. Wire feeder which provides contactor control to

the welding generator.

d. Combination of the above.

To Make connections, align keyway, insert plug, and rotate threaded collar fully clockwise.

Circuit Breaker CB1

(see Section 9-3)

Remote 9

Receptacle

Oil Level

Indicator

POSITIVE (+)

Weld Output

Terminals Terminals

NEGATIVE (−)

Weld Output

Figure 4-2. Lower Front Panel Components And Connections

Equipment

Grounding

Terminal

Strain Relief

Fuel Cap

Ref. ST-147 322-E

OM-166 941 Page 12

Page 18

If supplied remote control cord is not suitable for connecting to the REMOTE 9 receptacle RC3, proceed with

one of the following alternatives;

1. Wire a plug or cord to interface with REMOTE 9

receptacle RC3 using socket information in Section C.

2. Wire remote control cord directly to terminal strip

within unit according to Section B.

B. REMOTE Terminal Strip 3T Information And

Connections (Figures 4-2 And 4-4)

WARNING: ELECTRIC SHOCK can kill; UNEXPECTED OUTPUT can cause serious injury.

• Do not touch live electrical parts.

• Stop engine, and disconnect negative (−)

battery cable from battery before making any

internal inspection or connections.

• Do not connect to REMOTE 9 receptacle and

terminal strip at the same time.

Since the OUTPUT (CONT ACTOR) can be energized from either the receptacle or terminal

strip, it is vital to use only one remote control

method.

MOVING PARTS can cause serious injury.

• Keep away from moving parts such as fans,

belts, and rotors.

Terminal strip 3T, mounted on the lower front panel (see

Figure 4-2), is included in case the plug supplied on the

remote control cord is not suitable for connections to the

REMOTE 9 receptacle RC3.

To make connections, proceed as follows:

1. Remove existing plug from remote control cord.

2. Open and secure lower front door.

3. Locate strain reliefs provided on lower front panel

(see Figure 4-2).

4. Insert leads from cord through strain relief.

5. For Remote Electrical Cutoff Switch, remove

jumper link between terminals N and P.

6. Connect leads to terminal strip 3T using terminal

information provided in Section C.

7. Secure the cord in the strain relief.

8. Close and secure door.

C. Socket/Terminal Information (Figure 4-4)

The following lists the functions of the sockets of REMOTE 9 receptacle RC3 (see Figure 4-3), and the terminals of strip 3T (see Figure 4-4). The following socket/

terminal information is provided in case it is necessary to

wire the auxiliary equipment cord.

F

G

E

I

H

A

D

C

B

Ref. S-0706

Figure 4-3. Front View Of Remote 9 Receptacle

With Socket Locations

Socket A/Terminal A:

Contact closure to Socket B/Terminal B

completes the 115 volts ac contactor control circuit; protected by circuit breaker

CB3.

Socket B/Terminal B:

Contactor closure to Socket A/Terminal A

completes the 115 volts ac contactor control circuit.

Socket H/Terminal J:

Command reference; +10 volts dc.

Socket F/Terminal G:

Control circuit common.

Socket G/Terminal H:

Input command signal from wiper of remote control potentiometer; 0 volts equals

machine minimum; +10 volts equals machine maximum.

Socket C/Terminal C:

115 volts ac circuit common; also connected to welding power source chassis.

Socket D/Terminal D:

Up to 10 amperes of 115 volts ac, 60 Hz,

with respect to terminal C (circuit

common).

Terminals L and M of 3T:

Terminals supply 30 amperes of 115 volts

ac, 60 Hz, auxiliary power. Terminal L is

circuit common.

Terminals E/Terminal E or F:

Weld Voltage Feedback. Polarity

determined by connection at terminal E (+)

or F (−).

Terminal N and P of 3T:

Closed circuit between terminals N and P

is normal condition. Open circuit between

terminals N and P is Remote Emergency

Electrical Cutoff condition.

Terminal I/Terminal K:

Machine chassis (Equipment Ground).

OM-166 941 Page 13

Page 19

4-9. AIR COMPRESSOR CONNECTIONS

This unit delivers 12 cfm of air at a pressure of 100 psi

whenever the engine is running. A 1/2 in. NPT fitting for

air compressor connections is provided on the top cover

of the unit.

To make connections to the air compressor, obtain and

install a quick-connect connector onto the air compressor fitting.

4-10. ETHER STARTING AID (Optional)

This unit is shipped without the ether cylinder. Before

this device is operational, an ether cylinder must be obtained and installed. To install the ether cylinder, proceed as follows:

WARNING: IMPROPER HANDLING OR EXPOSURE TO ETHER can seriously harm

your health.

• Follow the manufacturer’s safety instructions

on the cylinder when handling ether components.

IMPORTANT: Before installing the ether cylinder, clean

nozzle on ether cylinder and fitting into which the ether

cylinder is inserted. If dirt is present in either of these areas, the system may not work.

1. Open and secure right rear side door.

2. If applicable, remove protective cap from ether

valve, or remove old ether cylinder from unit.

3. Loosen cylinder clamp, install ether cylinder, an d

tighten clamp.

IMPORTANT: After installing or replacing ether cylinder, do not use or test ether start system for at least 10 to

15 minutes to allow particles in fuel to settle to prevent

atomizer plugging.

4. Using a liquid soap and water solution, check all

ether start system connections for leaks. If a leak

exists, escaping gas will produce bubbles in the

solution.

5. Close and secure side door.

OM-166 941 Page 14

Ref. ST-164 613-A

Figure 4-4. Terminal Strip 3T Information

Page 20

SECTION 5 − AUXILIARY POWER

WARNING: ELECTRIC SHOCK can kill.

−)

ng

y.

s,

s.

en

e-

POWER OUTPUT

WARNING: ELECTRIC SHOCK can kill;

MOVING PARTS can cause serious injury;

IMPROPER AIR FLOW AND EXPOSURE TO

ENVIRONMENT can damage internal parts.

• Do not touch live electrical parts.

• Stop the engine and disconnect negative (−)

battery cable from battery before making internal inspection or reconnection.

• Ground generator as required by any applica-

ble national, state, and local electrical codes.

The generator neutral is connected to the frame;

therefore, the equipment grounding terminal

must be connected to a proper earth ground.

• Do not connect to any electrical distribution

system normally supplied by utility power unless a proper transfer switch and grounding

procedure are employed.

• Keep away from moving parts such as fans,

belts, and rotors.

• Keep all covers and panels in place while op-

erating.

Warranty is void if unit is operated with any portion of the outer enclosure removed.

ELECTRIC SPARKS can cause fire.

• Disconnect weld cables when using auxiliary

power.

The weld output terminals are electrically energized when the engine is running and the contactor (if applicable) is energized.

• Watch for fire.

• Have a fire extinguisher nearby, and know

how to use it.

LOW VOLTAGE AND FREQUENCY can damage electrical equipment.

• Turn off or unplug all electrical equipment

connected to auxiliary power before starting

or stopping the engine.

When starting or stopping, the engine has low

speed which causes low voltage and frequency.

A brief period (less than 5 seconds) of large current draw

is required for starting motor-driven equipment. This

generator can supply 25% of rated current output at the

terminal strip for motor starting. Disconnect motor from

generator before starting engine. Use adequate size

cords so that voltage drop at the motor is not excessive.

Voltage drops significantly when starting motor-driven

equipment.

Ground fault circuit interrupters (GFCI) may be required. Check local and state codes, and the latest issue

of the National Electrical Code.

5-2. 120 VOLT TERMINALS (Chart 5-1, And

Figure 4-2)

• Do not touch live electrical parts.

• Stop engine, and disconnect negative (

battery cable from battery before beginni

this installation.

MOVING PARTS can cause serious injur

• Keep away from moving parts such as fan

belts, and rotors.

HOT SURFACES can cause severe burn

• Wear protective gloves and clothing wh

working near a hot engine.

• Allow components to cool completely b

fore touching.

IMPORTANT: All directions, such as left or right, are

with resp e c t t o t h e o perator facing the welding generator

front panel. Retain all hardware removed during this

procedure for reinstallation unless specifically told

otherwise.

Chart 5-1. AC Power Curve For 120 Volt Terminals

5-1. GENERAL

Calculate load requirements before connecting equipment to the auxiliary power terminals on terminal strip

3T. For best performance (voltage and frequency regulation), limit connected load to approximately 90% of

generator capability.

SB-109 365-B

OM-166 941 Page 15

Page 21

A. Auxiliary Equipment Connections To Terminal

Strip 3T (Figure 4-2)

WARNING: Read and follow safety information at beginning of entire Section 5-2

before proceeding.

Terminal strip 3T is provided to directly wire the auxiliary

power cord(s) into the unit. To make connections, proceed as follows:

1. Remove plug from auxiliary equipment cord(s), if

applicable.

2. Open and secure lower front door.

SECTION 6 − OPERATOR CONTROLS

3. Locate three strain reliefs on lower front panel.

4. Insert leads from cord(s) through a strain relief.

5. Connect leads to terminal strip 3T using terminal

information provided in Figure 4-4.

6. Secure the cord(s) in the strain relief(s).

7. Close and secure door.

B. Protection

Circuit breaker CB1 protects the 120 volts ac auxiliary

power terminals from overload. See Section 9-3 for CB1

location and resetting procedure.

Service Engine

Air Cleaner

Light

Engine Hours

Meter

Voltmeter

Ammeter

Ampere

Ranges

Switch

Amperage &

Voltage Adjustment

Control

Figure 8-1. Operator Controls

6-1. AMPERE RANGES SWITCH (Figure 6-1)

The Ampere Ranges switch provides two coarse amperage ranges. When in LOW OUTPUT, amperage

range is 100-350 amperes. When in HIGH OUTPUT,

amperage range is 300-800 amperes.

CAUTION: ARCING can damage switch

contacts.

• Do not change the position of the Ampere

Ranges switch while welding or under load.

Arcing causes the contacts to become pitted

and eventually inoperative.

Remote Amperage &

Voltage Switch

Oil Temperature

Gauge/Switch

Gauge/Switch

Output

(Contactor)

Switch

Oil Pressure

Check Alternator

Light

Engine Control

Switch

Fuel Gauge

Battery Ampere

Gauge

Ref. ST-147 322-E

The AMPERAGE & VOLTAGE ADJUSTMENT control

adjusts welding amperage within range selected by Ampere Ranges switch.The scale surrounding the control

is calibrated in percent and does not indicate an actual

amperage or voltage value.

IMPORTANT: The AMPERAGE & VOLTAGE ADJUSTMENT control may be adjusted while welding.

6-3. ENGINE CONTROL SWITCH (Figure 6-1)

6-2. AMPERAGE & VOLTAGE ADJUSTMENT

CONTROL (Figure 6-1)

A/V

AMPERAGE AND VOLTAGE

ADJUSTMENT

OM-166 941 Page 16

The Engine Control switch has three positions: START,

RUN, and OFF.

Page 22

A. START Position

If remote amperage or voltage is not desired, place the

AMPERAGE & VOLTAGE switch in the PANEL position. Only the AMPERAGE & VOLTAGE ADJUSTMENT control will adjust output.

Rotating the switch to the START position starts the engine. Release the switch as soon as the engine starts,

and the switch automatically returns to the RUN position.

B. RUN Position

RUN

When the Engine Control switch is in the RUN position,

engine speed remains at governed weld/power speed

(1860 rpm).

C. OFF Position

Rotating the Engine Control switch to the OFF position

disconnects battery voltage, thereby shutting down the

engine.

6-4. REMOTE AMPERAGE & VOLTAGE CON-

TROL SWITCH (Figure 6-1)

PANEL

REMOTE

A/V

6-5. OUTPUT(CONTACTOR) SWITCH (Figure

6-1)

ON

REMOTE

OUTPUT

(CONTACTOR)

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Do not touch the output terminals when the

contactor is energized.

• Do not touch welding wire or electrode and

work clamp at same time.

When the OUTPUT/CONTACTOR switch is in

the ON position, open-circuit voltage is present

at the weld output terminals for as long as the

engine is running.

If the OUTPUT(CONTACTOR) switch is in the ON position, open-circuit voltage will be present at the output

terminals whenever the engine is running.

If remote contactor control by means of a wire feeder or

remote device is desired, make connections to the REMOTE 9 receptacle or terminal strip 3T according to

Section 4-8, and place the OUTPUT(CONTACTOR)

switch in the REMOTE position. Open-circuit voltage is

present at the weld output terminals whenever the gun

switch or remote device is closed.

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Do not touch the output terminals when the

contactor is energized

• Do not touch welding wire or electrode and

work clamp at same time.

If remote amperage or voltage control is desired, make

connections to the REMOTE 9 receptacle terminal strip