Page 1

January 1997 Form: OM-175 104B

Gasoline Engine

Effective With Serial No. KG191348

OWNER’S

MANUAL

Welding

Mode

CC/AC 50

CC/DC

CV/DC

cover_om 4/95 – Ref. ST-801 188-A PRINTED IN USA

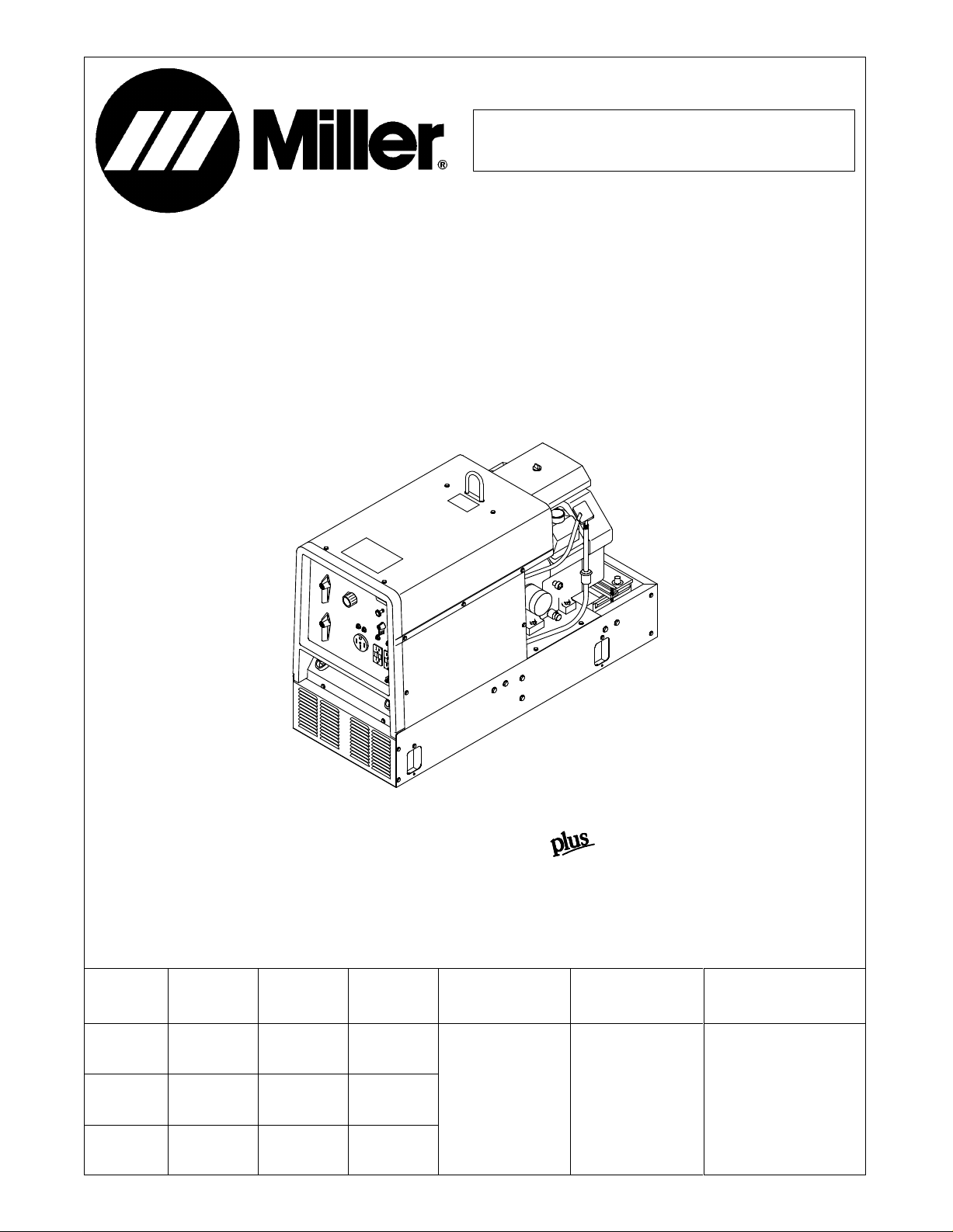

Bobcat 225G

(Kohler-Powered)

CC/CV AC/DC Welding Generator For SMAW, FCAW, GMAW, GTAW Welding

Weld

Output

Range

– 225 A

50 – 210 A

17 – 28 V

Rated

Welding

Output

225 A, 25 V

100% Duty

Cycle

210 A, 25 V

100% Duty

Cycle

200 A, 20 V

100% Duty

Cycle

Maximum

Open-Circu

it Voltage

,

,

,

Auxiliary Power

Rating

80

72

33

Single-Phase,

8 kVA/kW

120/240 V AC, 60 Hz

1997 MILLER Electric Mfg. Co.

, 70/35 A,

Fuel Capacity Engine

8.5 gal (32 L) T

ank

Kohler CH18

Air-Cooled, T

Four-Cycle, 18 HP

Gasoline Engine

wo-Cylinder,

Page 2

TABLE OF CONTENTS

SECTION 1 – SAFETY PRECAUTIONS FOR ARC WELDING 1.

1-1. Symbol Usage 1.

1-2. Arc Welding Hazards 1.

1-3. Engine Hazards 2.

1-4. Additional Installation, Operation, And Maintenance Hazards 3.

1-5. Principal Safety Standards 3.

1-6. EMF Information 3.

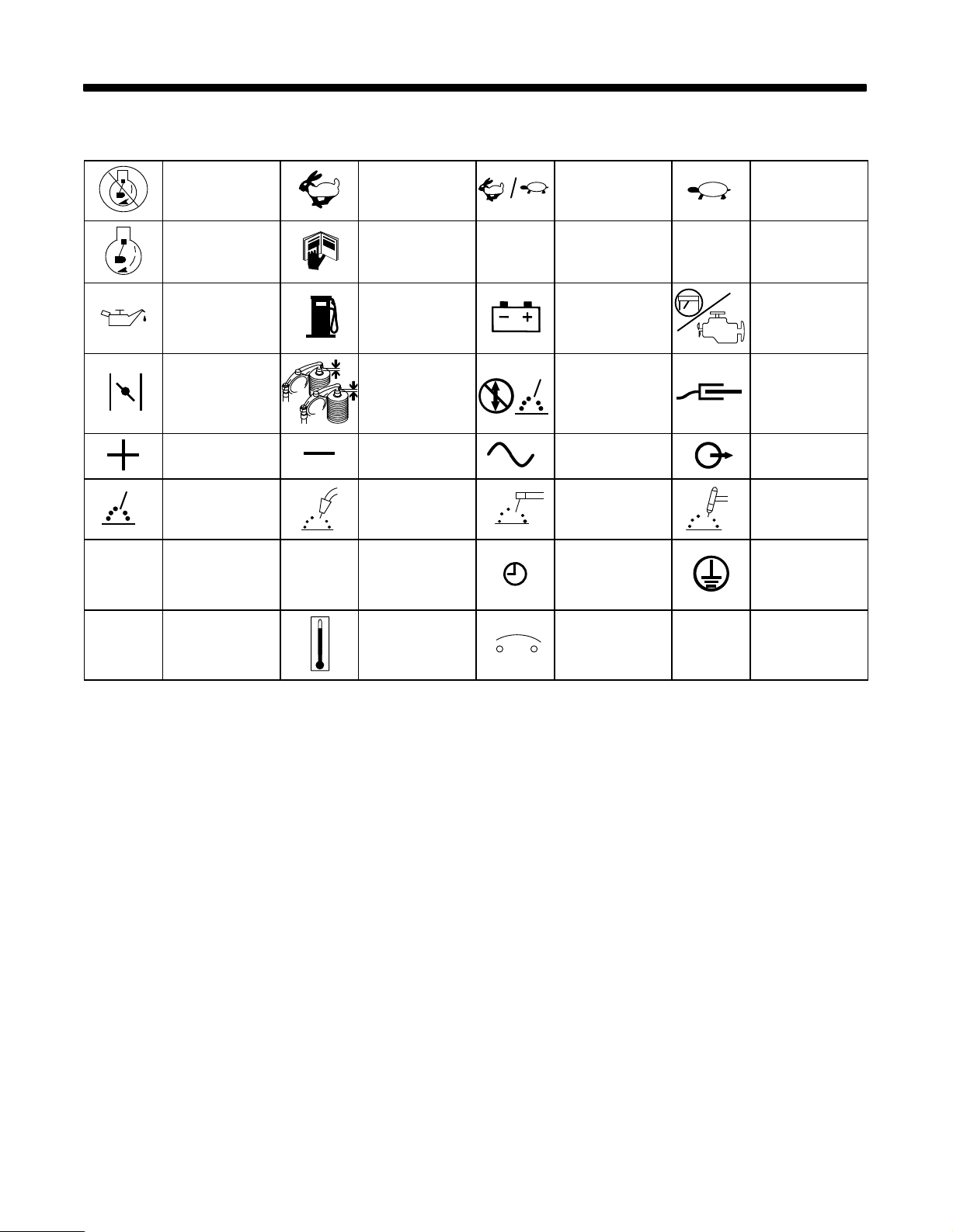

SECTION 2 – DEFINITIONS 4.

2-1. Symbol Definitions 4.

SECTION 3 – INSTALLATION 5.

3-1. Installing Welding Generator 5.

3-2. Dimensions, Weights, And Operating Angles 5.

3-3. Fuel Consumption 6.

3-4. Engine Prestart Checks 6.

3-5. Connecting The Battery 7.

3-6. Weld Output Terminals And Selecting Cable Sizes 7.

SECTION

4 – OPERA

4-1. Front Panel Controls 8.

4-2. Duty Cycle 9.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TING WELDING GENERATOR 8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

SECTION

SECTION 6 – MAINTENANCE AND TROUBLESHOOTING 13.

SECTION 7 – ELECTRICAL DIAGRAM 20.

SECTION 8 – PARTS LIST 21.

5 – OPERA

5-1. Standard Receptacles 10.

5-2. Optional Auxiliary Power Receptacles 11.

5-3. Wiring Optional 240 Volt Plug 12.

6-1. Routine Maintenance 13.

6-2. Maintenance Label 14.

6-3. Servicing Air Cleaner 14.

6-4. Changing Engine Oil, Oil Filter, And Fuel Filter 15.

6-5. Adjusting Engine Speed 16.

6-6. Overload Protection 17.

6-7. Inspecting And Cleaning Optional Spark Arrestor 17.

6-8. Troubleshooting 18

TING AUXILIAR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Y EQUIPMENT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.

OM-175 104B – 1/97

Page 3

SECTION 1 – SAFETY PRECAUTIONS FOR ARC WELDING

safety_rom1 4/95

1-1. Symbol Usage

Y

Means Warning! Watch Out! There are possible hazards with this

procedure!

The possible hazards are shown in the adjoining symbols.

This group of symbols means Warning! Watch Out! possible ELECTRIC SHOCK, MOVING

and HOT PARTS hazards. Consult symbols and related instructions below for necessary

PARTS,

actions

to avoid the hazards.

1-2. Arc Welding Hazards

WARNING

The symbols shown below are used throughout this manual to call attention to and identify possible hazards.

When you see the symbol, watch out, and follow the related instructions to avoid the hazard. The safety

information given below is only a summary of the more complete safety information found in the Safety

Standards listed in Section 1-5. Read and follow all Safety Standards.

Only qualified persons should install, operate, maintain, and repair this unit.

During operation, keep everybody, especially children, away.

Marks a special safety message.

.

Means NOTE; not safety related.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal

shocks or severe burns. The electrode and work

circuit

is electrically live whenever the

The input power circuit and machine internal

circuits are also live when power is on. In

semiautomatic

wire reel, drive roll housing, and all metal parts

touching the welding wire are electrically live.

Incorrectly installed or improperly grounded

equipment

1.

Do not touch live electrical parts.

2. W

ear dry

, hole-free insulating gloves and body protection.

3. Insulate yourself from work and ground using dry insulating

mats

or covers big enough to prevent any

the

work or ground.

4. Disconnect input power or stop engine before installing or

servicing

to

5. Properly install and ground this equipment according to its

Owner’s

6. Always

power cord ground wire is properly connected to ground

this equipment. Lockout/tagout input power

OSHA 29 CFR 1910.147 (see Safety Standards).

Manual and national, state, and local codes.

verify the supply ground – check and be

or automatic wire welding, the wire,

is a hazard.

output is on.

physical contact with

according

sure that input

ARC RAYS can burn eyes and skin;

NOISE can damage hearing; FLYING

SLAG OR SPARKS can injure eyes.

Arc

rays from the welding process produce intense

visible and invisible (ultraviolet and infrared) rays

that can burn eyes and skin. Noise from some

processes can damage hearing. Chipping,

grinding, and welds cooling throw off pieces of

metal

NOISE

1.

Use approved ear plugs or ear muf

or slag.

fs if noise level is high.

terminal in disconnect box or that cord plug is connected to a

properly

grounded receptacle outlet.

7. When making input connections, attach proper grounding

conductor

8. Frequently

replace

9. T

urn of

10. Do not use worn, damaged, undersized, or poorly spliced

cables.

11. Do

earth grounding of the workpiece is required,

12. If

with

13. Do not touch electrode if you are in contact with the work,

ground,

14. Use only well-maintained equipment. Repair or replace

damaged

15. W

16.

Keep all panels and covers securely in place.

17. Clamp work cable with good metal-to-metal contact to

workpiece

ARC RAYS

2. Wear a welding helmet fitted with a proper shade of filter to

protect

Z49.1

3. W

4. Use protective screens or barriers to protect others from flash

and

5. Wear protective clothing made from durable, flame-resistant

material

first – double-check connections.

inspect input power cord for damage or bare wiring –

cord immediately if damaged – bare wiring can kill.

f all equipment when not in use.

not drape cables over your body

a separate cable – do not use work clamp or work cable.

or another electrode from a dif

parts at once. Maintain unit according to manual.

ear a safety harness if working above floor level.

or worktable as near the weld as practical.

your face and eyes when welding or

and Z87.1 listed in Safety Standards).

ear approved safety glasses with side shields.

glare; warn others not to watch the arc.

(wool and leather) and foot protection.

.

ground it directly

ferent machine.

watching (see ANSI

FUMES AND GASES can be hazardous

to your health.

Welding produces fumes and gases. Breathing

these fumes and gases can be hazardous to your

health.

1. Keep

2. If inside, ventilate the area and/or use exhaust at the arc to

3.

4. Read the Material Safety Data Sheets (MSDSs) and the

your head out of the fumes. Do not breathe the fumes.

remove

welding fumes and gases.

If ventilation is poor

manufacturer’s instruction for metals, consumables, coatings,

cleaners,

and degreasers.

, use an approved air-supplied respirator

.

5. Work in a confined space only if it is well ventilated, or while

wearing an air-supplied respirator. Always have a trained

watchperson

and

lower the oxygen level

breathing

6. Do

not weld

operations.

form

7. Do not weld on coated metals, such as galvanized, lead, or

cadmium plated steel, unless the coating is removed from the

weld area, the area is well ventilated, and if necessary, while

wearing

containing

nearby

. W

elding fumes and gases can displace air

air is safe.

in locations near degreasing, cleaning, or spraying

The

highly toxic and irritating gases.

heat and rays of the arc can react with vapors to

an air-supplied respirator

these elements can give of

causing injury or death. Be sure the

. The coatings and any

f toxic fumes if welded.

OM-175 104 Page 1

metals

Page 4

CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under high

pressure. If damaged, a cylinder can explode.

Since

gas cylinders are normally part of the welding

process,

be sure to treat them carefully

1. Protect compressed gas cylinders from excessive heat,

mechanical shocks, slag, open flames, sparks, and arcs.

2. Install

3. Keep cylinders away from any welding or other electrical

cylinders in an upright position by securing

support

or cylinder rack to prevent falling or tipping.

circuits.

.

to a stationary

4. Never

5.

6.

7. Use

8. Turn

9. Keep

10. Read and follow instructions on compressed gas cylinders,

drape a welding torch over a gas cylinder

Never allow a welding electrode to touch any cylinder

Never weld on a pressurized cylinder – explosion will result.

only correct shielding gas cylinders, regulators, hoses, and

fittings

designed for the specific application; maintain them and

associated

in

use or connected for use.

associated

Standards.

parts in good condition.

face away from valve outlet when opening cylinder valve.

protective cap in place over valve except when cylinder is

equipment, and CGA publication P-1

.

.

listed in Safety

WELDING can cause fire or explosion.

Welding on closed containers, such as tanks,

drums,

or pipes, can cause them to blow up. Sparks

can fly off from the welding arc. The flying sparks,

hot workpiece, and hot equipment

and

burns. Accidental contact of electrode to

objects

can cause sparks, explosion, overheating,

or fire. Check and be sure the area is safe before

doing

any welding.

1.

Protect yourself and others from flying sparks and hot metal.

2. Do

not weld where flying sparks can strike flammable material.

3. Remove

4. Be

5. Watch

all flammables within

this

is not possible, tightly cover them with approved covers.

alert that welding sparks and hot materials from welding can

easily go

through

small cracks and openings to adjacent areas.

for fire, and keep a fire extinguisher nearby

35 ft (10.7 m) of the welding arc. If

1-3. Engine Hazards

WARNING

ENGINE EXHAUST GASES can kill.

Engines

produce harmful exhaust gases.

ENGINE FUEL can cause fire or

explosion.

Engine

fuel is highly flammable.

1. Stop

engine and let it cool of

f before checking or adding fuel.

can cause fires

metal

.

aware that welding on a ceiling, floor

6. Be

can cause fire on the hidden side.

7. Do not weld on closed containers such as tanks, drums, or

pipes,

unless they are properly prepared according to A

(see

Safety Standards).

8. Connect

9.

10. Remove stick electrode from holder or cut off welding wire at

11. Wear

12. Remove

1.

2. If used in a closed area, vent engine exhaust outside and

2. Do

3.

4. Do not spill fuel. If fuel is spilled, clean up before starting

work cable to

practical

to prevent welding current from

unknown

Do not use welder to thaw frozen pipes.

contact

shirt, cuf

from

paths and causing electric shock and fire hazards.

tip when not in use.

oil-free protective garments such as leather gloves,

fless trousers, high shoes, and a cap.

any combustibles,

your person before doing any welding.

Use equipment outside in open, well-ventilated areas.

from any building air intakes.

away

not add fuel while smoking or

open

flames.

Do not overfill tank – allow room for fuel to expand.

engine.

the work as close to the welding area as

such as a butane lighter or matches,

, bulkhead, or partition

WS F4.1

traveling long, possibly

heavy

if unit is near any sparks or

MOVING PARTS can cause injury.

Moving

parts, such as fans, rotors, and belts can

cut

fingers and hands and catch loose clothing.

1. Keep all doors, panels, covers, and guards closed and

2.

in place.

securely

Stop engine before installing or connecting unit.

SPARKS

can cause BA

TTERY

GASES

TO EXPLODE; BATTERY ACID can

burn eyes and skin.

Batteries contain acid and generate explosive

gases.

STEAM AND PRESSURIZED HOT

COOLANT can burn face, eyes, and

skin.

It is best to check coolant level when engine is

cold

to avoid scalding.

OM-175 104 Page 2

3. Have only qualified people remove guards or covers for

maintenance

4. To prevent accidental starting during servicing, disconnect

negative

5. Keep

parts.

6. Reinstall

finished

1. Always

2. Stop engine before disconnecting or connecting battery

cables.

not allow tools to cause sparks when working on a battery

3. Do

not

4. Do

5. Observe

1. If

the engine is warm and checking

and

3.

2. W

ear safety glasses and gloves and put a rag over cap.

3. Turn cap slightly and let pressure escape slowly before

completely

and troubleshooting as necessary

(–) battery cable from battery

hands, hair

and before starting engine.

wear a face shield when working on a battery

use welder to charge batteries or jump start vehicles.

, loose clothing, and tools away from

panels or

correct polarity (+ and –) on batteries.

guards and close doors when servicing is

removing cap.

.

is needed, follow steps 2

.

moving

.

.

Page 5

1-4. Additional Installation, Operation, And Maintenance Hazards

WARNING

MOVING PARTS can cause injury.

1. Before

2. Block

working

or injectors to keep engine from kicking back or

starting.

flywheel so that it will not

on

generator components.

of generator

, remove spark plugs

turn while working

FLYING PIECES OF METAL or DIRT can

injure eyes.

1. Wear safety glasses with side shields or face

shield.

STATIC ELECTRICITY can damage parts

on circuit boards.

1. Put on grounded wrist strap BEFORE handling

boards

or parts.

2. Use proper static-proof bags and boxes to store,

or ship PC boards.

move,

MAGNETIC FIELDS FROM HIGH

CURRENTS can affect pacemaker

operation.

1. Pacemaker wearers keep away.

earers should consult their doctor before going

2. W

near arc welding, gouging, or spot welding

operations.

HOT PARTS can cause severe burns.

1. .Allow

2. Wear

cooling period before maintaining.

protective gloves and clothing when working

on

a hot engine.

READ INSTRUCTIONS.

1. Use

only genuine MILLER replacement parts.

2. Reinstall injectors and bleed air from fuel system

according to engine manual.

DO NOT LET ENGINE EXHAUST SPARKS

CAUSE FIRE.

1. Use approved engine exhaust spark arrestor in

areas – see applicable codes.

required

LOW VOLTAGE AND FREQUENCY CAN

DAMAGE electrical equipment such as

MOTORS.

1. Turn off or unplug equipment before starting or

stopping

engine.

OVERUSE can cause OVERHEATED

EQUIPMENT.

1. Allow

2. Reduce current or reduce duty cycle before

3.

cooling period.

starting

to weld again.

Follow rated duty cycle.

TILTING OF TRAILER can cause injury.

1. Use

tongue jack or blocks to support weight.

2. Properly install welding generator onto trailer

according

to instructions supplied with trailer

.

FALLING EQUIPMENT can cause serious

personal injury and equipment damage.

1. Use lifting eye to lift unit only, NOT running gear,

gas cylinders, or any other accessories.

Use equipment of adequate capacity to lift unit.

2.

1-5. Principal Safety Standards

Safety

in W

Welding Society, 550 N.W. LeJeune Rd, Miami FL 33126

elding and Cutting

Safety and Health Standards

Superintendent of Documents, U.S. Government Printing Office,

Washington, D.C. 20402.

Recommended Safe Practices for the Preparation for Welding and

Cutting of Containers That Have Held Hazardous Substances

American Welding Society Standard AWS F4.1, from American

Welding Society, 550 N.W. LeJeune Rd, Miami, FL 33126

National Electrical Code

Protection Association, Batterymarch Park, Quincy, MA 02269.

, ANSI Standard

, OSHA 29 CFR 1910, from

, NFPA Standard 70, from National Fire

Z49.1, from American

1-6. EMF Information

Considerations About Welding And The Effects Of Low Frequency

Electric And Magnetic Fields

The

following

the U.S. Congress, Office of Technology Assessment,

Effects

Paper

Office,

findings

with animals and people which clearly establish that low frequency

magnetic

systems.

complex. Current scientific understanding does not yet allow us to

interpret the evidence in a single coherent framework. Even more

frustrating,

questions of possible risk or to offer clear science-based advice on

strategies to minimize or avoid potential risks.”

is a quotation from the General Conclusions Section of

of Power Frequency Electric & Magnetic Fields – Background

, OTA-BP-E-53 (Washington, DC: U.S. Government Printing

May 1989): “. . . there is now a

based on experiments at the cellular level and from studies

fields can

While most of this work is of very high quality

interact with, and produce changes in, biological

it does not yet allow us to draw definite conclusions about

very large volume of scientific

Biological

, the results are

BATTERY ACID can BURN SKIN AND

EYES.

1. Do

not tip.

2.

Replace damaged battery

3.

Flush eyes and skin immediately with water

Safe Handling of Compressed Gases in Cylinders

P-1, from Compressed Gas Association, 1235 Jefferson Davis

Highway, Suite 501, Arlington, VA 22202.

Code

for Safety in W

Canadian Standards Association, Standards Sales, 178 Rexdale

Boulevard, Rexdale, Ontario, Canada M9W 1R3.

S

,

afe Practices For Occupation And Educational Eye And Face

Protection

Institute, 1430 Broadway, New York, NY 10018.

Cutting

Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

To reduce magnetic fields in the workplace, use the following

procedures:

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cables around the body.

4. Keep welding power source and cables as far away as

5. Connect work clamp to workpiece as close to the weld as

About Pacemakers:

The above procedures are also recommended for pacemaker

wearers. Consult your doctor for complete information.

,

ANSI Standard Z87.1, from American National Standards

And

practical.

possible.

elding and

W

elding Processes

Cutting

, NFP

.

, CGA Pamphlet

, CSA Standard W1

A Standard 51B, from National

.

17.2, from

OM-175 104 Page 3

Page 6

2-1. Symbol Definitions

SECTION 2 – DEFINITIONS

h

Stop

Engine

Start Engine

Engine Oil

Engine Choke

Positive Negative

W

elding Arc

(Electrode)

Hours

(Run, W

Read Operator

Check Valve

Clearance

Gas Metal Arc

elding (GMA

W

Seconds Time

s

Fast

eld/Power)

Manual

Fuel

Wire

W),

Fast/Slow

(Run/Idle)

’s

A

Amperes

Battery (Engine)

Do not switch

while welding

Alternating Current

(AC)

Shielded Metal Arc

W

elding (SMA

W),

Stick

V

Slow (Idle)

Volts

Engine

W

ork Connection

Output

Gas T

ungsten Arc

W

elding (TIG)

Protective Earth

(Ground)

Temperature Circuit Breaker

OM-175 104 Page 4

Page 7

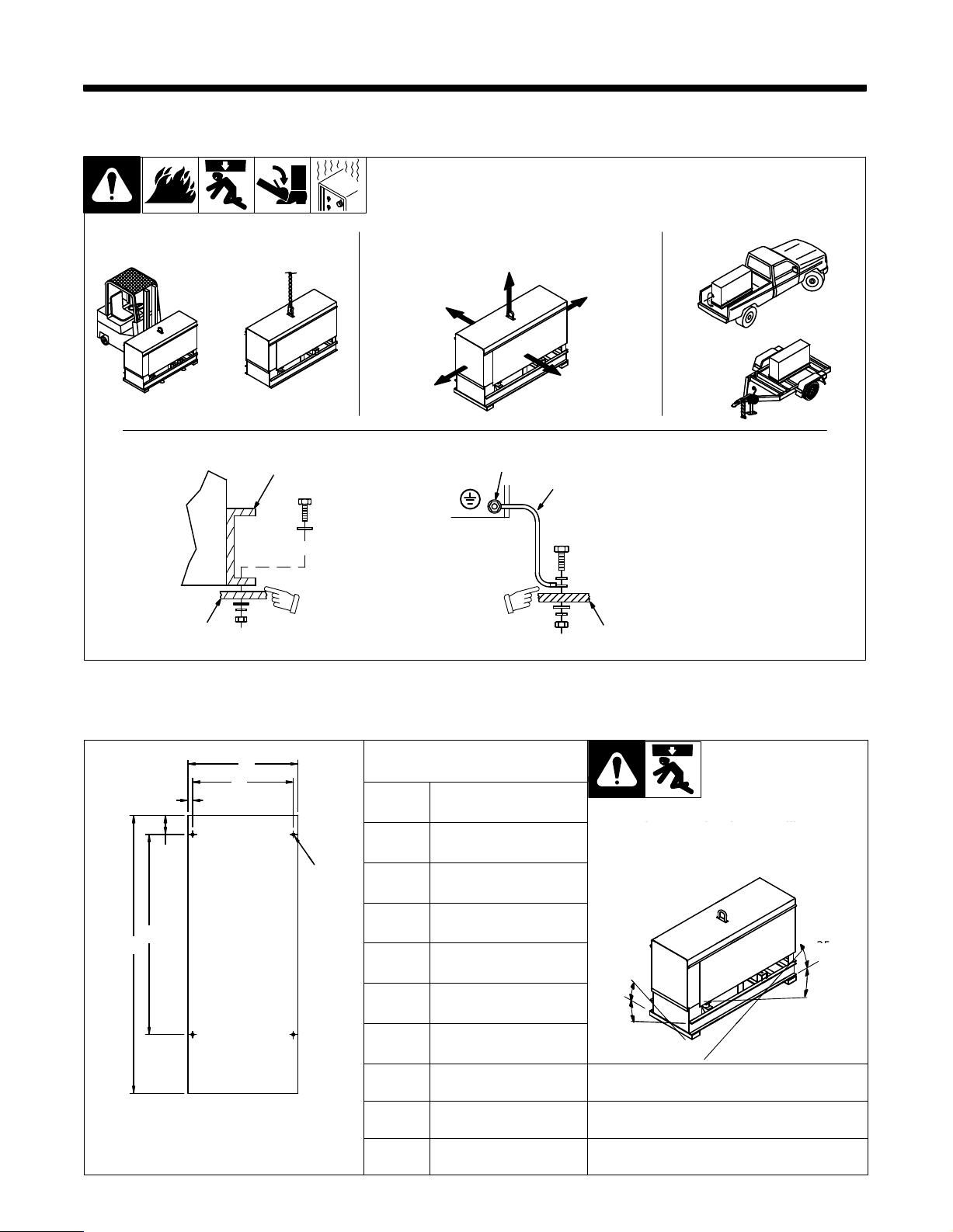

SECTION 3 – INSTALLATION

Do not exceed operating angles while

E

3-1. Installing Welding Generator

Movement Airflow Clearance Location

18 in

OR

(460 mm)

18 in

(460 mm)

18 in

(460 mm)

OR

18 in

(460 mm)

Grounding

1

Electrically

OR

bond

generator frame to

3

GND/PE

vehicle frame by metal-to-metal

2

contact.

3-2. Dimensions, Weights, And Operating Angles

A

B

C

D

G

4 Holes

Height

Width

Depth

Dimensions

31 in (787 mm)

18-3/4 in (476 mm)

46 in (1

164 mm)

18 in

(460 mm)

1 Generator Base

2

Metal V

ehicle Frame

3

4

2

install1* 3/96 – Ref. ST-800 652 / Ref. ST-800 477-A / ST-158 936-A / S-0854

Do not exceed operating angles while

running

Do

not move or operate unit where it could

tip.

Equipment Grounding

Terminal

4

Grounding Cable

Use #10 AWG or larger insulated

wire.

copper

or engine damage will occur

.

E

F

Engine End

ST-800 426

A

B

C

D

E

F

G

18 in (457 mm)

16-1/2 in (419 mm)

3/4 in (19 mm)

3-1/8 in (79 mm)

32-3/4 in (832 mm)

45-1/2 in (1

13/32 in (10 mm) Dia.

156 mm)

25°

25°

Weight

Net: 567 lb (258 kg)

Ship: 608 lb (276 kg)

OM-175 104 Page 5

25°

°

25°

angles_1 3/96

Page 8

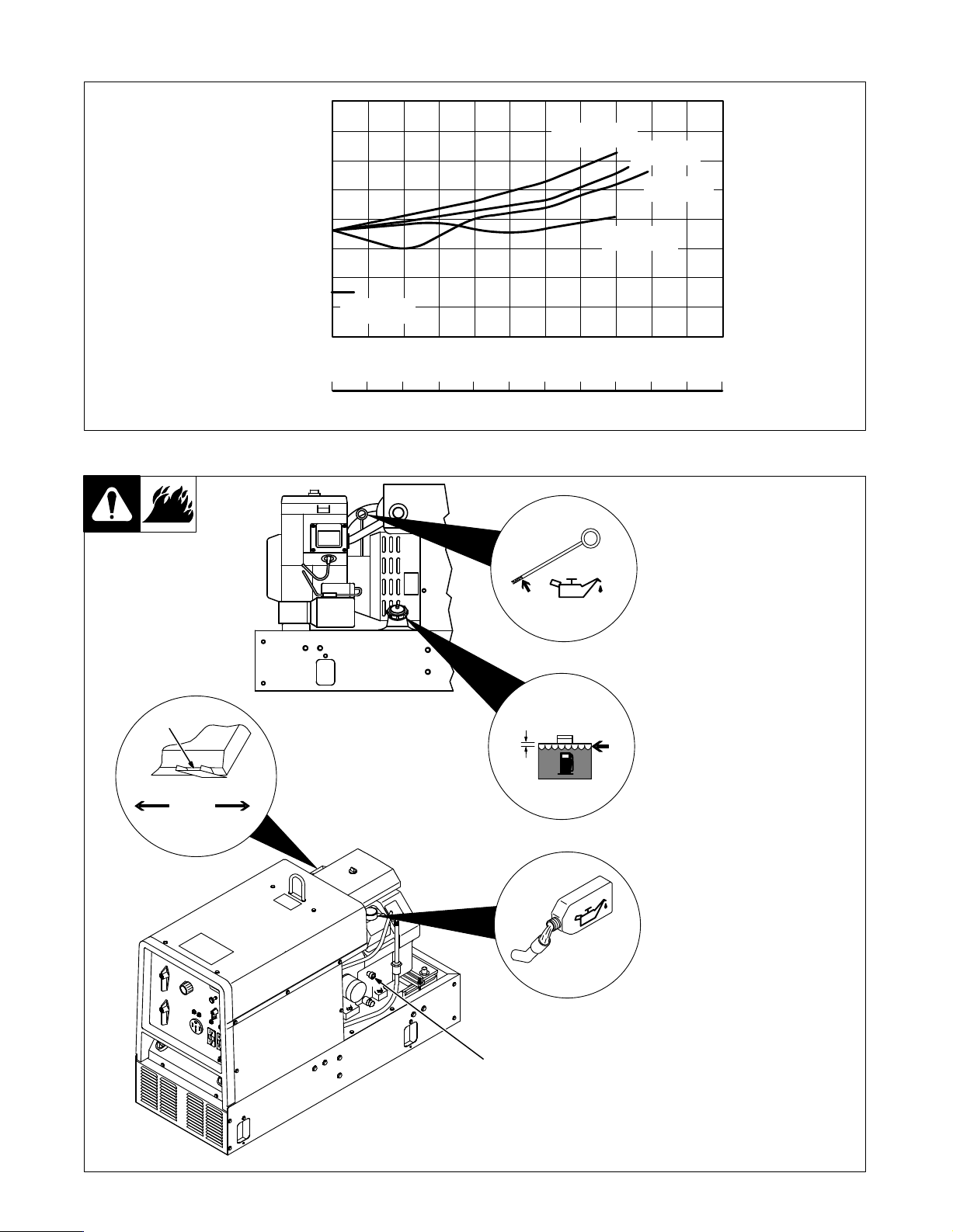

3-3. Fuel Consumption

7.57

6.62

5.67

4.73

3.78

2.84

1.89

0.95

LITERS/HR.

1.67

1.46

1.25

1.04

0.84

0.63

0.42

0.21

IMP. GAS/HR.

2.0

1.8

1.5

1.3

1.0

0.8

0.5

0.3

0.0

0 25 50 75 100 125 150 175 200 225 250 275

U.S. GAL/HR.

0 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 9.0 10.0 11.0

3-4. Engine Prestart Checks

IDLE

2200 RPM

AUX POWER

3750 RPM

3750 RPM

CV WELD

3750 RPM

WELD AMPERES AT 100% DUTY CYCLE

POWER KVA AT 100% DUTY CYCLE

Full

DC WELD

AC WELD

3750 RPM

Ref. SB-179 939

Check

all fluids daily

be

cold and on a level surface. Unit

is

shipped with 10W30 engine oil.

1

Low Oil Pressure Shutdown

Switch

Engine stops if oil pressure gets

low

.

too

2

Anti-Icing Control

Use control to prevent carburetor

in cold weather

icing

. Engine must

.

2

Below Above

45°F

(7°C)

1

1/2 in

(13 mm)

Full

Gasoline

OM-175 104 Page 6

Ref. ST-801 188-A / Ref. ST-801 221

Page 9

3-5. Connecting The Battery

Connect (–) cable last.

T

ools Needed:

3/8,

1/2 in

3-6. Weld Output Terminals And Selecting Cable Sizes

+

–

Ref. ST-800 394-B / Ref. ST-178 079-A / Ref. S-0756-D

ARC

To

floor. Locate welding operation 100 meters from any sensitive electronic equipment. Be sure this welding machine is

installed and grounded according to this manual. If interference still occurs, the user must take extra measures such

as

Weld Output Terminals

WORK ELECTRODE

ST-800 396-A

Weld cable size (A

WG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere.

WELDING can cause Electromagnetic Interference.

reduce possible interference, keep weld cables as short as possible, close together

moving the welding machine, using shielded cables, using line filters, or shielding the work area.

, and down low

Total Cable (Copper) Length In Weld Circuit Not Exceeding

100 ft (30 m) Or Less

Welding

Amperes

100 4 4 4 3 2 1 1/0 1/0

150 3 3 2 1 1/0 2/0 3/0 3/0

200 3 2 1 1/0 2/0 3/0 4/0 4/0

250 2 1 1/0 2/0 3/0 4/0 2-2/0 2-2/0

300 1 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-3/0

350 1/0 2/0 3/0 4/0 2-2/0 2-3/0 2-3/0 2-4/0

10 – 60%

Duty

Cycle

60 – 100%

Duty

Cycle

150 ft

(45 m)

200 ft

(60 m)

250 ft

(70 m)

10 – 100% Duty Cycle

300 ft

(90 m)

(105 m)

, such as on the

350 ft

400 ft

(120 m)

S-0007-D

OM-175 104 Page 7

Page 10

SECTION 4 – OPERATING WELDING GENERATOR

4-1. Front Panel Controls

5 2

1 64

3

1 Engine

Use switch to start engine, select speed,

and stop engine. In Run/Idle position, engine

power speed under load. In Run position,

engine

2

Use control to change engine air-fuel mix.

To Start: pull out choke and turn Engine

Control switch to Start position. Release

switch and slowly push choke in when en-

OM-175 104 Page 8

Control Switch

runs at idle speed at no

runs at weld/power speed.

Place

switch in Run position to operate

most GMA

Engine Choke Control

W equipment.

load, and weld/

starts. Do not crank engine if engine

gine

still

turning. Set anti-icing control (see Sec

3-4).

tion

To Stop: turn Engine Control switch to Off

position.

3 Weld Process Selector Switch

Use switch to select type of weld output.

Use

a positive

Electrode Positive (DCEP) and a negative

(–) position for Direct Current Electrode

Negative

nating

4 Coarse Adjust Switch

(+) position for Direct Current

(DCEN). Use AC position for

current.

alter

is

Use switch to select weld amperage range

-

when Weld Process Selector switch is in

Stick/Tig position, or voltage range when

is in Wire position.

switch

For best arc starts, use lowest amper-

range possible.

age

5

Fine Adjust Control

Use

control to select weld amperage (Stick/

Tig) or voltage (Wire) within the range se-

by the Coarse Adjust switch. Control

lected

may

be adjusted while welding. W

-

would be 110 A DC based on control set-

shown (50% of 70 to 150 A).

tings

6

Engine Hour Meter

Ref. ST-178 079-A

eld output

Page 11

4-2. Duty Cycle

100%

Duty Cycle at 225 Amperes AC, 210 Amperes CC/DC, 200 Amperes CV/DC

Duty

cycle is the percentage of 10

minutes

that unit can weld at

load

without overheating.

Exceeding duty cycle can

damage unit and void warranty.

rated

Continuous Welding

SB-119 454-A

OM-175 104 Page 9

Page 12

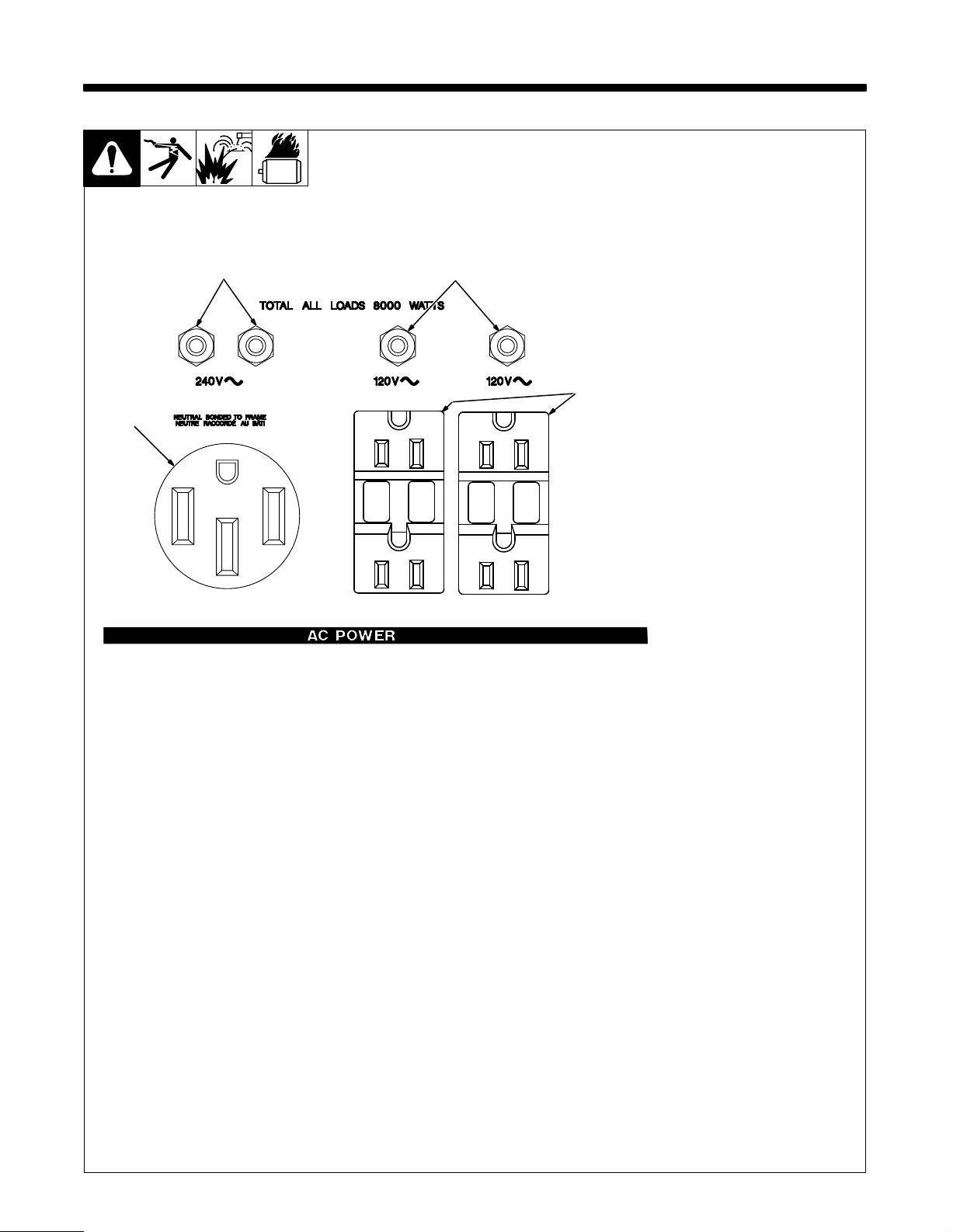

SECTION 5 – OPERATING AUXILIARY EQUIPMENT

5-1. Standard Receptacles

34

2

Auxiliary power decreases as

weld current increases.

Set Fine Adjust control R1 at

for full auxiliary power

10

1

120 V 15 A AC Receptacles

GFCI-2 And GFCI-3

GFCI-2 and GFCI-3 supply 60 Hz

single-phase

speed.

receptacle is 2.4 kVA/kW (CSA:

1.8 kVA/kW).

a ground fault is detected,

If

button pops out and the circuit

opens to disconnect the faulty

1

equipment. Check for faulty tools,

cords,

tacle.

operation.

At

gine

press Test button to verify

GFCI

2

240 V 50 A AC Receptacle

RC1

RC1 supplies 60 Hz single-phase

power

mum

3 Circuit Breakers CB1 And

CB2

CB1 and CB2 protect RC1 from

overload. If CB1 or CB2 opens,

RC1

tacles does not work. 120 volts

still be present at RC1.

may

4 Circuit Breakers CB3 And

CB4

CB3 and CB4 protect GFCI-2 and

GFCI-3 from overload. If CB3 or

CB4 opens, the receptacle does

not work.

If

open, contact a Factory Authorized

Total output of receptacles limited

to 8 kVA/kW. Example: If 20 A is

drawn from GFCI-2 and GFCI-3,

13 A is available at RC1:

only

2

x (120 V x 20

=

7.9 kV

power at

Maximum

etc. connected

Press reset

least

once a month, run en

at weld/power speed and

is working properly

at weld/power speed. Maxi

output is 8 kV

and one of the 120 volt

a circuit breaker continues to

Service Agent.

A/kW

weld/power

output from each

to the recep

button to resume

A/kW.

A) + (240 V x 13 A)

.

Reset

.

recep

-

-

-

-

OM-175 104 Page 10

Ref. ST-178 079-A

Page 13

5-2. Optional Auxiliary Power Receptacles

5

2

Y If unit does not have GFCI

receptacles, use GFCI-pro-

extension cord.

tected

.

Auxiliary power decreases as

weld current increases.

Set Fine Adjust control R1 at

for full auxiliary power

10

1

4

4

Combined

limited to 8 kVA/kW rating of the

generator.

120

1

RC2

phase

Maximum

is

2.4 kV

Circuit breaker protection is the

same

South African And Australian

Receptacle Options

2

3

Receptacles supply 60 Hz singlephase

Maximum

tacle is 3.6 kVA/kW.

4 Circuit Breakers CB1, CB2,

CB1, CB2, and CB3 protect RC1,

RC2, and RC3 from overload. If a

circuit breaker opens, the receptacle does not work. Press button

to

5 Circuit Breaker CB4

CB4 protects all the receptacles

from

of

.

output of all

V

olt Receptacle Option

120 V 15 A AC Receptacles

RC2 And RC3

and RC3 supply

power

at weld/power speed.

output from RC2 or RC3

A/kW (CSA: 1.8 kV

as standard receptacles.

240 V 16 A AC South African

Receptacles RC1, RC2, And

RC3

240 V 15 A AC Australian

Receptacles RC1, RC2, And

RC3

power

at weld/power speed.

output

from each recep

CB3

reset breaker

overload. If CB4 opens,

the receptacles work.

If

a circuit breaker continues to

.

open, contact a Factory Au-

Service Agent.

thorized

.

receptacles

60 Hz single-

A/kW).

-

none

5

3

Ref. ST-172 786-B / Ref. ST-181 714

OM-175 104 Page 1

1

Page 14

5-3. Wiring Optional 240 Volt Plug

Current A

Receptacle*

*One 240 V load or two 120 V loads.

vailable In Amperes

240 V

35

30

25

20

15

V x A = Watts

Each 120 V Duplex

Receptacle

0

5

10

15

20

The

plug

2-wire load or a 120/240V, 3-wire

load.

1

7

1

3

4

120V

120V

240V

4

6

2

3

When wired for 120 V loads, each

duplex receptacle shares a load

with

2

3

4

5

6

7

5

can be wired for a 240 V

See circuit diagram.

Plug Wired For 120/240 V

3-Wire Load

one half of 240 V receptacle.

Plug Wired For 240 V

Load

Neutral (Silver) T

Load 1 (Brass)T

Load 2 (Brass) T

Ground (Green) T

Amperes A

120/240 V Plug

erminal

erminal

erminal

erminal

vailable Using

,

,

, 2-Wire

T

ools Needed:

240V

56

ST-120 813-D

OM-175 104 Page 12

Page 15

SECTION 6 – MAINTENANCE AND TROUBLESHOOTING

6-1. Routine Maintenance

Y

Stop engine before maintaining.

.

See also Engine Manual and mainte-

label. Service engine more

nance

if

used in severe conditions.

8 h

Recycle

fluids.

engine

often

Clean Optional

Spark Arrestor

Screen. See

Section 6-7.

Change

Oil. See

Section 6-4 And

Maintenance

Label.

Wipe

Spills.

Check

Up

And

20 h

50 h

100 h

Check

Spark

Plugs.

Clean

T

ighten W

Terminals.

Check Fluid

Levels.

See Section 3-4.

Service Air

Cleaner Foam

Element. See

Section 6-3.

And

eld

Check Air

Cleaner

Paper

Element. See

Section 6-3.

Change Oil

Filter

. See Section

6-4 And

Maintenance

Label.

Clean Cooling

System.

See Engine

Manual.

OR

200 h

500 h

1000 h

Replace

Filter

Fuel

See Section

Blow Out Or V

.

6-4.

Repair Or Replace

Cracked Cables.

acuum Inside.

During Heavy Service,

Clean Monthly

Clean And

Tighten

Battery

Connections.

Replace

Unreadable

Labels.

.

OM-175 104 Page 13

Page 16

6-2. Maintenance Label

KOHLER CH18 GAS ENGINE

See

Engine Manual for complete engine care. Give

engine Specification and Serial Number when ordering

parts.

Check

daily.

T

o Drain Oil:

Push And

Turn CCW

1/2 in. ID Hose

Pull

Recommended

Oil

Change

Oil

Filter Change

Oil

Filter MILLER 066 698, Kohler 1205001

Oil Capacity

Oil

. .

.

. . . . . . . .

.

. . .

.

. . . . . . . . . . .

.

. . . . . . .

API Service Classification SF-SG/CC-CD.

100 hours

200 hours

1.75 qt (1.7 L) or 2 qt (1.9 L) with filter

change

Fuel Capacity

Fuel

Grade

Fuel

Filter

.

. . . . . .

.

. . . . . . . .

. . . . . . . . .

Gasoline

°C

°F

+100

+30

+20

+10

+32

0

-10

-20

-30

0

8.5 gal (32.2 L)

Unleaded, 87 Octane min.

MILLER 066 1

Kohler

13,.

2505003

5W-20, 5W-30

10W-30, 10W-40

Air Filter Service

100 hours or less – see

.

. . .

Owner’s

Air Filter Element MILLER 067 272,

.

. . .

Kohler

Air Filter W

rapper

MILLER 067 273,

.

. . .

Kohler

12 V

+

Cranking

Engine

Weld/Power 3700.

Idle 2200

Spark

Spark

Use

olt Battery

Performance at 0°F (-18

RPM – No Load

. . . . . . . . .

Plug Gap

Plug

.

. . . . . . . .

only resistor spark plugs and wires.

.

. . . . .

.

BCI Group 58

0.040 in. (1.02 mm)

. . . .

Champion RC-12YC

Spark Arrestor Inspection And Service .

20

operating hours - see Owner’s Manual

Manual

4708303

2408302

°C)

430 Amps

.

. . .

min.

. . . . . . . . . .

S-173 088

6-3. Servicing Air Cleaner

oil

1

Stop

Do not run engine without

engine.

air cleaner or with dirty ele-

2

ment.

1 Precleaner

Wash precleaner with soap and

solution.

water

air

dry completely

Allow precleaner to

.

Spread 1 tablespoon SAE 30 oil

evenly into precleaner. Squeeze

out excess oil.

2 Element

Replace element if dirty or oily

.

OM-175 104 Page 14

aircleaner3 6/96 – ST-156 852 / Ref. ST-178 079-A / S-0759

Page 17

6-4. Changing Engine Oil, Oil Filter, And Fuel Filter

Stop

1

2

3

4

5 Oil Dipstick

Change engine oil and filter ac-

cording

Close valve and valve cap

Fill crankcase with new oil to full

mark

4

6

7

6 Fuel

7

Replace line if cracked or worn.

Install new filter. Wipe up any

spilled

Start engine, and check for fuel

leaks.

Stop engine, tighten con-

engine and let cool.

Oil Drain V

1/2 ID x 12 in Hose

Oil Filter

Oil Fill Cap

before adding oil and running

on dipstick

Fuel Line

nections as necessary, and

wipe

alve

to engine owner’s manual.

engine.

(see Section 6-2).

Filter

fuel.

up fuel.

5

T

ools Needed:

3

2

1

Ref. ST-801 188-A / Ref. ST-801 221 / Ref. ST-178 079-A / ST-800 395 / S-0842

OM-175 104 Page 15

Page 18

6-5. Adjusting Engine Speed

5

4

3

After tuning engine, check engine

speeds with a tachometer (see

If necessary

table).

as

2200

± 50

rpm

3700

± 50

rpm

1

2

follows:

Start engine and run until warm.

Fine Adjust control to 10.

Turn

Idle Speed Adjustment

Move Engine Control switch to

position.

Run/Idle

1

Throttle Solenoid

2

Mounting Screws

3

Idle Speed Screw

Loosen mounting screws. Adjust

position so engine runs at

solenoid

idle speed. If necessary, back out

idle speed screw so solenoid can

be moved to correct position.

mounting screws. Be sure

Tighten

solenoid

linkage works smoothly

Turn idle speed screw for fine adjustments.

Weld/Power

Move

Engine Control

position.

4 Weld/Power

ment Nut

5 Lock Nut

Loosen lock nut. Turn adjustment

until engine runs at

nut

speed. Tighten lock nut.

Stop engine.

, adjust speeds

Speed Adjustment

switch to Run

Speed Adjust

-

weld/power

.

T

ools Needed:

1/4, 3/8 in

T

op V

iew

Ref. ST-801 188-A / ST-801 209-A

OM-175 104 Page 16

Page 19

6-6. Overload Protection

Y Stop

1

F1 protects the generator excita-

tion circuit. If F1 opens, there will

be

1

output.

2 Fuse

F6 protects the engine wiring har-

ness.

not crank.

Replace

panel

.

2

engine.

Fuse F1 (See Parts List)

no/low weld and auxiliary power

F6 (See Parts List)

If F6 opens, the engine does

any open fuses. Reinstall

before operating unit.

If any fuse continues to open,

contact Factory Authorized

Agent.

Service

T

ools Needed:

3/8 in

6-7. Inspecting And Cleaning Optional Spark Arrestor

ST-801 226-A / Ref. ST-801 221

Y Stop

1 Spark Arrestor Screen

Clean and inspect screen. Re-

place

are

engine and let cool.

spark arrestor if screen wires

broken or missing.

T

ools Needed:

1

1/4 in

ST-801 206 / Ref. ST-801 221 / Ref. ST-172 782-A

OM-175 104 Page 17

Page 20

6-8. Troubleshooting

A. Welding

Trouble Remedy

No weld output.

Low weld output.

High weld output.

Erratic weld output.

Check control settings.

Check weld connections.

Check fuse F1 and replace if open (see Section 6-6).

Be sure all equipment is disconnected from receptacles when starting unit.

Have Factory Authorized Service Agent check brushes, slip rings, and integrated rectifier SR2.

Check plug PLG6 connection.

Check fuse F1 and replace if open (see Section 6-6).

Check control settings.

Check and adjust engine speed (see Section 6-5).

Service air cleaner according to engine manual.

Have Factory Authorized Service Agent check brushes and slip rings.

Check control settings.

Check and adjust engine speed (see Section 6-5).

Check control settings.

T

ighten and clean connections to electrode and workpiece.

Use dry

, properly-stored electrodes for SMA

Remove excessive coils from weld cables.

T

ighten and clean connections both inside and outside welding generator

Check and adjust engine speed (see Section 6-5).

Have Factory Authorized Service Agent check brushes and slip rings.

W and GT

AW.

.

B. Auxiliary Power

Trouble Remedy

No

output at auxiliary power recep

tacles.

High power output.

Low power output.

Erratic power output.

OM-175 104 Page 18

-

Reset circuit breakers (see Sections 5-1 and 5-2).

Press receptacle Reset button (see Section 5-1).

Check fuse F1 and replace if open (see Section 6-6).

Check plug PLG6 connection.

Have Factory Authorized Service Agent check brushes, slip rings, and integrated rectifier SR2.

Check and adjust engine speed (see Section 6-5).

Check fuse F1 and replace if open (see Section 6-6).

Increase Fine Adjust control R1 setting.

Check fuel level.

Check and adjust engine speed (see Section 6-5).

Check receptacle wiring and connections.

Have Factory Authorized Service Agent check brushes and slip rings.

Page 21

C. Engine

Trouble Remedy

Engine will not crank.

Check fuse F6, and replace if open (see Section 6-6).

Check battery voltage.

Engine will not start.

Engine starts but stops when Engine

Control switch returns to Run position.

Engine stopped during normal opera

tion.

Battery Discharges between uses.

Check battery connections and tighten if necessary

Check plug PLG4 and plug PLG8 connections.

Have Factory Authorized Service Agent check Engine Control switch S2.

Check fuel level.

Check battery voltage.

Check battery connections and tighten if necessary

Check oil level. Check low oil pressure shutdown switch (see Section 3-4).

Have Factory Authorized Service Agent check fuel shutof

Check oil level. Check low oil pressure shutdown switch (see parts list for location).

Check and refill crankcase with proper viscosity oil for operating temperature, if necessary

-

Check fuel level.

Check oil level. Check low oil pressure shutdown switch (see Section 3-4).

Periodically recharge battery (approximately every 3 months).

Replace battery

Check voltage regulator and connections according to engine manual.

Have Factory Authorized Service Agent check fuel shutof

Clean battery

.

, terminals, and posts with baking soda and water solution; rinse with clear water

.

.

f solenoid FS1.

f solenoid FS1.

.

.

Engine idles but does not come up to

weld speed.

Unstable or sluggish engine speeds.

Engine does not return to idle speed.

Periodically recharge battery (approximately every 3 months).

Replace battery

Check voltage regulator and connections according to engine manual.

Have Factory Authorized Service Agent check auto idle module PC1, and current transformer CT1.

Readjust throttle linkage if necessary

T

une-up engine according to engine manual.

Remove weld and auxiliary power loads.

Check throttle linkage for smooth, non-binding operation.

Have

Factory Authorized Service Agent

switch S2, and throttle solenoid TS1.

trol

.

. Check throttle solenoid TS1 for smooth operation.

check idle module PC1, current transformer CT1, Engine Con

-

OM-175 104 Page 19

Page 22

SECTION 7 – ELECTRICAL DIAGRAM

OM-175 104 Page 20

SB-180 690-B

Figure 7-1. Circuit Diagram For Welding Generator

Page 23

SECTION 8 – PARTS LIST

12

11

13

14

10

9

15

16

Fig 8-3

17

18

23

24

19

20

21

22

8

7

3

2

1

456

42

43

35

36

37

38

39

40

41

34

25

26

33

32

27

Fig 8-2

31

30

28

29

OM-175 104 Page 22

ST-801 432-B

Figure 8-1. Main Assembly

Page 24

Item

No.

Dia.

Mkgs.

Part

No.

Description

Figure 8-1. Main Assembly

Quantity

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 +159 907

1 ♦+169 441

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 108 487 LABEL, warning: falling equipment can cause serious injury 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 169 329 P

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 ♦169 442 P

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 159 914 UPRIGHT, base 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 168 640 SEAL, tank fuel filler neck 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 164 928 SEAL, barrel 11.78 ID x .378thk 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 178 497 PANEL, rear lower 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 147 601 CAP, tank screw-on w/vent 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 178 498 TANK, fuel 8.5gal (consisting of) 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 178 632 FITTING, stand pipe hose .250 x 7.325 lg 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 121 652 FILTER KIT, fuel w/clamps 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 173 088 LABEL, engine maintenance 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 173 065 MUFFLER, exhaust engine w/heat shield (Included w/engine) 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . .

14 +173 042 ENGINE, gas elec start (consisting of) 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 165 271 VALVE, oil drain 3/8-18NPTF 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

TS1 SOLENOID, 14VDC .53A (see engine parts list) 1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

16 Fig 8-3 GENERATOR 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24 182 361 KIT, holddown battery 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 168 385 LABEL, warning battery explosion can blind 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 +159 917 DOOR, access battery 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 173 921 CABLE, bat pos (included w/engine) 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21 168 037 BATTERY, stor 12V 430crk 75rsv GP58 dry 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22 082 319 CABLE, bat neg 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

23 173 043 BRACKET, mtg engine 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24 165 660 BRACKET, mtg generator 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

25 DC-Z 165 578 STABILIZER 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

26 AC-Z 176 301 REACTOR 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27 164 920 BRACKET, mtg stab/reactor 2.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28 159 906 PAN, base 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

29 160 844 COVER, base 4.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30 +180 628 PANEL, front lower 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31 Fig 8-2 PANEL, front w/components 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32 SR1 142 503 RECTIFIER, si 1 ph 300A 400PIV 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

33 173 734 LINK, jumper 2.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34 1T 172 661 BLOCK, stud connection 6 position 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35 D4 135 184

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

36 SR2 035 704 RECTIFIER, integ 40A 800V 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37 172 731 HOLDER, fuse mintr 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

38 F1 *169 296 FUSE, mintr gl 25A 125V 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

39 C1 176 719 CAPACITOR, elctlt 1000uf 75VDC 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40 177 136 CLAMP, capacitor 2.500dia clip 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41 CT1 179 494 TRANSFORMER, current sensing 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42 R2 165 599 RESISTOR, WW adj 225W 0-6 ohm 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . .

. . . . . . . .

. . . . . . . . .

43 134 792 LABEL, warning general precautionary 1.

. .

RC4 116 045 CONNECT

PLG6 136 810 CONNECT

PLG4 CONNECTOR, (see engine parts list) 1.

RC6 168 844 CONNECTOR, rect 4 pin/skt rcpt 1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

180 096 TUNE-UP & FILTER KIT, (consisting of) 1.

066 698 OIL FILTER 1.

121 652 FILTER/CLAMPS, fuel 1.

067 272 ELEMENT, air cleaner 1.

067 273 AIR FILTER, wrapper 1.

067 007 SP

172 669 CABLE, bat neg 1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COVER, top

COVER, top

ANEL, side

ANEL, side

BRACKET, mtg solenoid (see engine parts list) 1.

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ARK PLUG

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIODE BOARD

OR & PINS

OR & PINS

+When ordering a component originally displaying a precautionary label, the label should also be ordered.

♦ Part of Optional 043 051 Stainless Steel kit.

*Recommended Spare Parts.

BE SURE T

O PROVIDE MODEL AND SERIAL NUMBER WHEN ORDERING REPLACEMENT P

ARTS.

OM-175 104 Page 23

1.

1.

2.

2.

2.

1.

1.

1.

Page 25

Item

No.

Dia.

Mkgs.

Part

No.

Description

Figure 8-2. Panel, Front w/Components (Fig 8-1 Item 44)

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 S1 162 671 SWITCH, polarity 5 position 1.

2 NAMEPLATE, (order by model and serial number) 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 165 602 PANEL, front 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 S3 165 487 SWITCH, selector 4 position 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 R1 117 243 RHEOSTAT, WW 100W 10 ohm 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 PC1 142 724 MODULE, pull to idle 5 pin 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 S2 176 606 SWITCH, ignition 4 position w/out handle 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 GFCI2,3 147 939 RECEPTACLE, str dx grd 2P3W 15A 125V 2.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 CB1,2 117 501 CIRCUIT BREAKER, man reset 1P 40A 250VAC 2.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 CB3,4 093 996 CIRCUIT BREAKER, man reset 1P 20A 250VAC 2.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 HM 145 247 METER, hour 12-24VDC 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 175 010 CONTROL, push/pull 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 119 014

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 R3,VR1 046 819 SUPPRESSOR 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 Work,

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 RC1 164 704 RECEPTACLE, str 3P4W 50A 125/250V 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17 083 030 STUD, brs .250-20 x 1.750 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 010 915 WASHER, flat .250 ID brs 3.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19 601 836 NUT, .250-20 brs 3.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20 159 921 BEZEL 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21 147 195 NUT, .375-27 nyl 4.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22 148 956

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23 097 924 KNOB, pointer 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Elect

099 255 TERMINAL, pwr output neutral 2.

LEVER, switch

HANDLE, switch

Quantity

1.

2.

24

23

22

123 45

21

17

18

20

19

6

7

8

9

10

11121314

BE SURE T

OM-175 104 Page 24

O PROVIDE MODEL AND SERIAL NUMBER WHEN ORDERING REPLACEMENT P

16

15

Figure 8-2. Panel, Front w/Components

ST-800 816-A

ARTS.

Page 26

Item

No.

Part

No.

Description

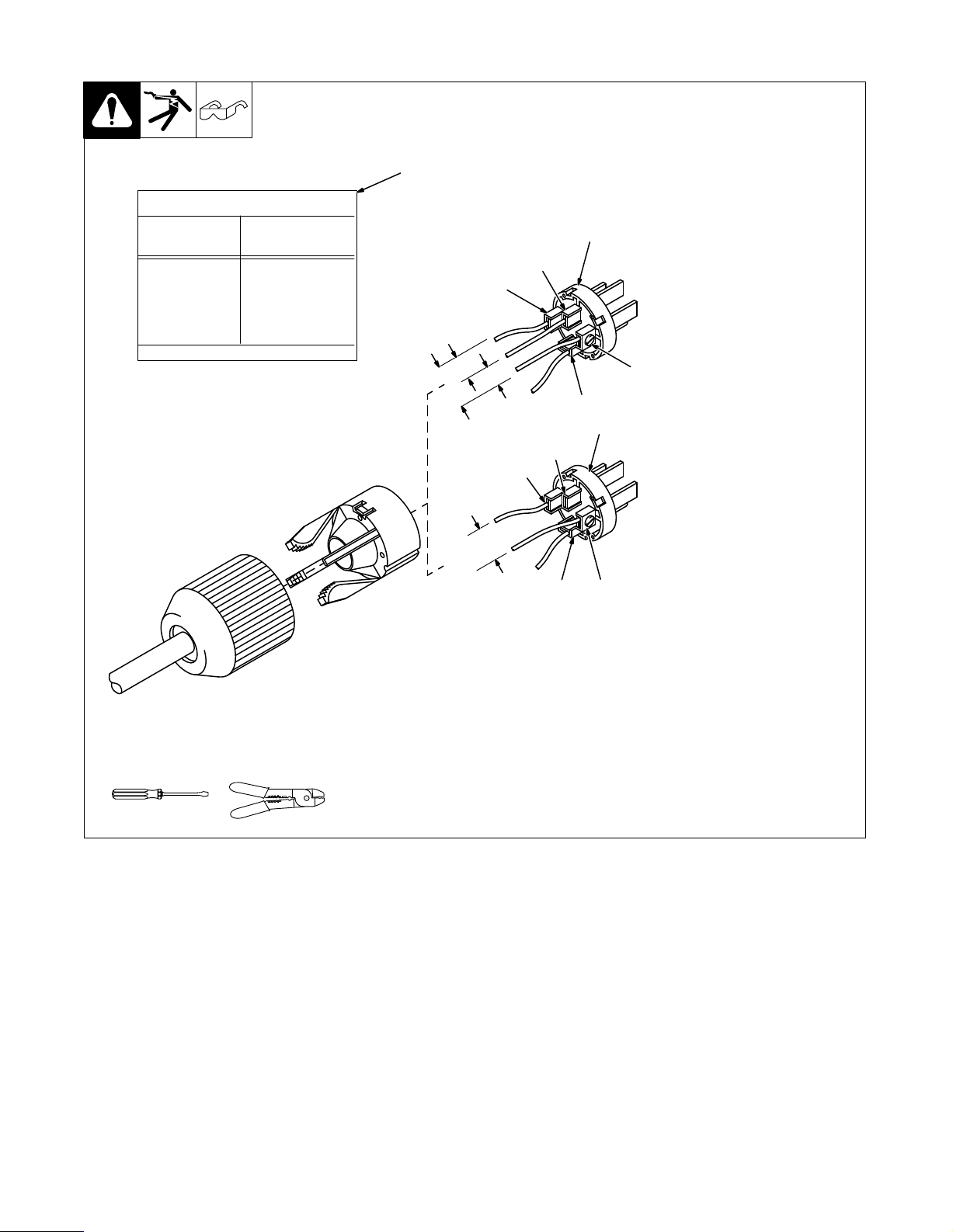

Figure 8-3. Generator (Fig 8-1 Item 21)

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 013 367 LABEL, warning moving parts can cause serious injury 1.

2 165 818 LABEL, warning engine fuel can cause fire 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 +179 500 STATOR, generator 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 159 909 ROTOR, generator (consisting of) 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 053 390 BEARING, ball rdl sgl row 1.370 x 2.830 x .6 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 160 566 FAN, rotor 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 172 683

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 142 156 SCREW, .375-16 x 1.750hexhd 4.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 160 573 STUD, stl .375-16 x 17.125 4.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10 125 548 HOLDER, brush elect 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11 005 614 HOLDER, brush 2.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12 *126 984

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 161 306 CAP, brushholder 2.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14 047 879 BAR, retaining brushholder 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

15 010 910 WASHER, flat .406 ID stl 4.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16 010 909 NUT, .375-16 stl 4.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17 160 943 ENDBELL, (consisting of) 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18 143 220 O-RING, 2.859 ID x .139CS 1.

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADAPTER, engine

BRUSH w/SPRING

Quantity

1.

2.

17

18

16

15

4

5

2

1

3

9

10

11

12

13

14

6

7

8

ST-800 798

Figure 8-3. Generator

+When ordering a component originally displaying a precautionary label, the label should also be ordered.

*Recommended Spare Parts.

BE SURE T

O PROVIDE MODEL AND SERIAL NUMBER WHEN ORDERING REPLACEMENT P

ARTS.

OM-175 104 Page 25

Loading...

Loading...