Page 1

compass

Fluid Head

OPERATOR’S

MANUAL

#1036 Compass 20 Fluid Head

20

Page 2

Features and Controls

Sliding Platform Lock

Pan Handle Clamp

Pan Handle

Sliding Platform

Camera Screws

Tilt Lock

Pan Lock

Threaded Stud

Clamp Nut

Fig. 1

1

Page 3

Features and Controls

Camera Plate

Release Knob

Tilt Drag Control

Accessory Mounting

1/4” + Pin Carriage

Quick Release Knob

Safety Tab

Counterbalance Selector

Bubble Level

Pan Drag Control

Fig. 2

2

Page 4

Introduction Safety Instructions

Thank you for purchasing the Compass 20 Fluid Head. The

Compass 20 Fluid Head has been designed to suit payload

capacities from HDV to standard conguration XDCAM and P2HD

cameras.

The robust design and construction of the Compass 20 Fluid Head

offers maximum stability, accuracy and durability and includes

precision ball bearing mounted Fluid Drag Plate system in the Pan

and Tilt assembly to deliver true uid drag performance over the

entire temperature and payload range.

The Fluid Drag and the Counterbalance system were designed to

provide excellent control and repeatability and offer progressive

equal increments of drag and torque.

The Compass 20 Fluid Head also offers Illuminated Bubble level.

The Compass 20 Fluid Head will give best performance when

used on a wide range of Miller tripods, including SOLO DV

(#1501 & 1630) and Lightweight (#440 & 420) tripod. This will

ensure maximum system stability to suit any professional setup. The Compass 20 Fluid Head will suit most industry standard

75 mm tripods as well, please refer to manufactures’ manual for

mounting details.

Attaching/removing the camera.

Please use this manual to familiarise yourself with the operation

of the Compass 20 Fluid Head and observe these instructions

to prevent any damage to your equipment. Ensure that all

equipment is operating correctly and free from defects and

damage, also please ensure that the tripod is steady, secure and

that the bowl is approximately horizontal when attaching the

camera. The operator is responsible for the safe operation of this

piece of equipment.

• Do not exceed the maximum payload capacity of the

Fluid Head.

• Do not leave the camera unattended on the Fluid Head.

• Do not release the SLIDING PLATFORM LOCK whilst the

camera is at an angle.

• Do not adjust the tripod whilst the camera is attached

to the Fluid Head.

• Ensure PAN HANDLE CLAMP and CLAMP NUT is

securely tightened.

• Apply TILT LOCK when adding/removing equipment from the

camera or when attaching/removing the camera from the

Fluid Head.

• Hold camera securely whilst changing Counterbalance, Pan

Drag or Tilt Drag settings.

• Hold the camera securely whilst releasing the

RELEASE KNOB.

• Hold camera securely whilst adjusting the CLAMP NUT to

level the Fluid Head.

3

Page 5

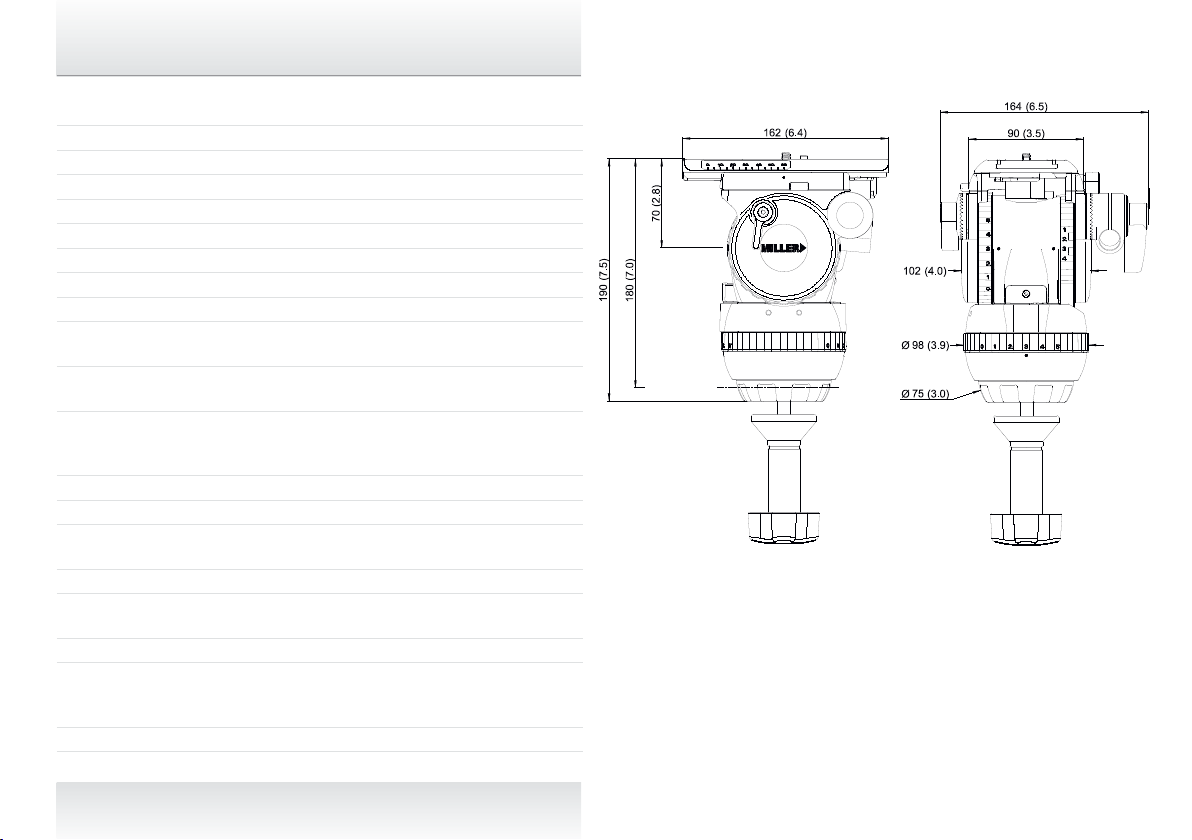

Technical Data

HEIGHT

ABOVE BOWL

Weight 2.7 kg (6.0 lb)

Payload Range 2.0 – 12.0 kg (4.4 - 26.5 lb)

Max. Capacity 20.0 kg (44.0 lb)

Tilt Drag 5 Selectable uid drag positions + 0

Tilt Range + 90˚ / -75˚

Tilt Lock Positive Lock caliper brake system

Pan Drag 5 Selectable uid drag positions + 0

Pan Range 360˚

Pan Lock Positive Lock caliper brake system

Counterbalance System 4 Selectable positions

(see performance graph)

Camera Platform Type Quick release sliding platform

with 60 mm travel.

Camera Plate Quick release mini euro camera plate

and 1/4”, 3/8” and 1/4” + Pin

Carriage

Mounting Base Ø75 mm Ball Levelling

Ball Level Range 10˚

Handle Standard black anodised pan handle

with adjustable angle.

Temperature range -40˚ to +65˚ C (-40° to +149° F)

Construction Lightweight diecast Aluminium alloy,

moulded reinforced plastics

Sealing Water & Dust resistant

Finish Matt black (low sheen) durable

powder coated with anti-corrosive

pre treatment

Warranty 3 Years.

Fig. 3

4

Page 6

Operating Instructions

The operating instructions are described in six steps. Please read

and understand these instructions before using this equipment.

Do not omit any steps.

1 Fluid Head Set-up

1.1 Loosen the PAN HANDLE CLAMP fully then rotate the

PAN HANDLE until it is approximately perpendicular to the

THREADED STUD (g. 4) and tighten the PAN HANDLE

CLAMP - avoid contact wear between the serrations on

the Fluid Head and the PAN HANDLE CLAMP, if this occurs

then unwind the PAN HANDLE CLAMP further.

1.2 Ensure that the TRIPOD BOWL is approximately horizontal.

Place the Fluid Head into the TRIPOD BOWL, adjust the

BUBBLE LEVEL (g. 4) such that the bubble is inside the

black circle and tighten the CLAMP NUT.

1.3 Set the initial control settings as follows – see Figure 1 & 2:

• Select Counterbalance to position 4 (top setting).

• Select Pan & Tilt Drag to position 0.

• Tighten the PAN LOCK, TILT LOCK and the SLIDING

PLATFORM LOCK.

Pan Handle Clamp

Pan Handle

Illumination Button

Bubble Level

Threaded Stud

Clamp Nut

Fig. 4

5

Page 7

Operating Instructions

2. Camera Set-up

2.1 Remove the CAMERA PLATE by pulling down the SAFETY

TAB while rotating the QUICK RELEASE KNOB to the left.

The CAMERA PLATE should pop out.

2.2 Refer to the Camera’s owners manual for correct method of

attachment to the CAMERA PLATE. Inspect the CAMERA

PLATE and remove the 1/4” and 3/8” screws (for HDV

mount) or the 1/4” + PIN CARRIAGE (XDCAM/P2HD mount)

as required. The 1/4”and 3/8” screws can be stored

underneath the SLIDING PLATFORM (g. 1).

2.3 Attach camera accessories and the battery to the camera,

it is recommended to estimate the camera’s Centre of

Gravity (C of G) for the purpose of correctly positioning

the camera on the CAMERA PLATE. The camera’s C of G

can be estimated by placing the camera on to a round rod

and then shifting it backwards or forwards until a balance

point – C of G - is achieved. It is recommended to identify

this point on the camera as it will be useful in step 2.5.

2.4 Attach the CAMERA PLATE to the camera or the QUICK

RELEASE TRIPOD ADAPTOR and securely tighten the

screws.

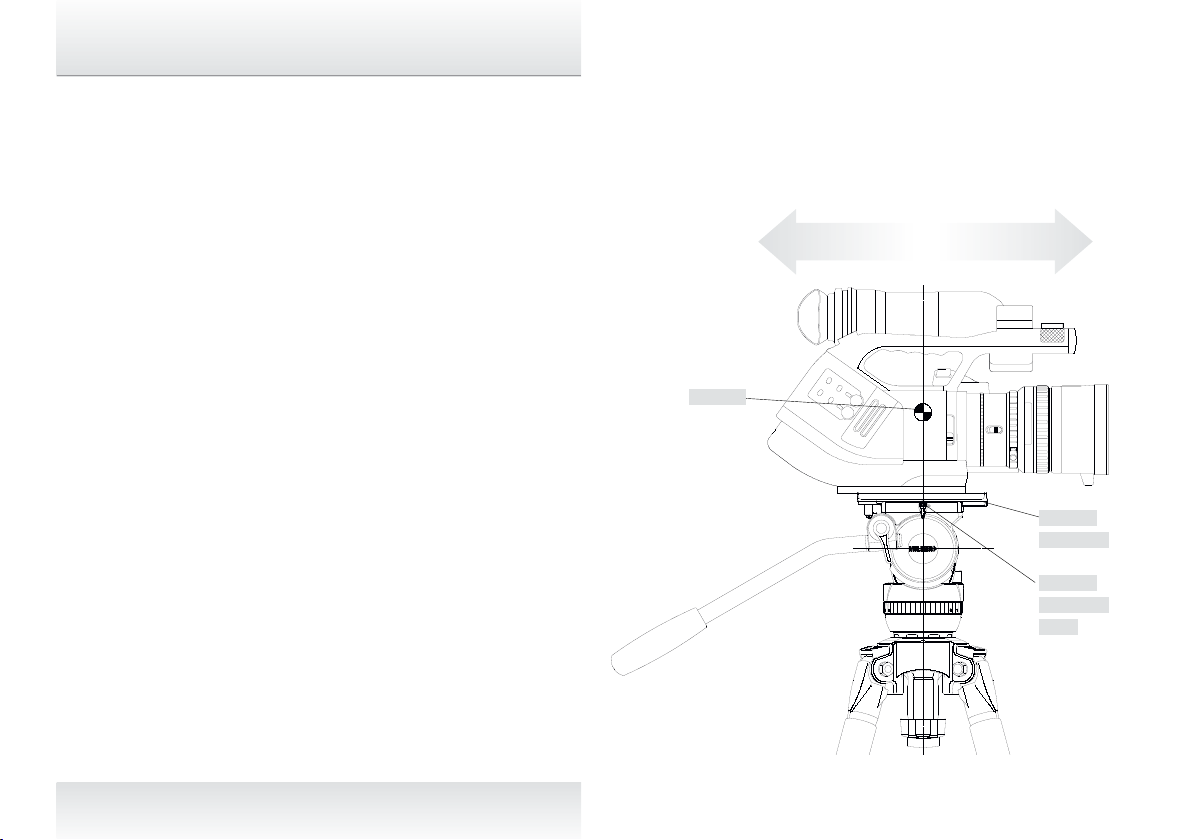

2.5 Align the CAMERA PLATE with the SLIDING PLATFORM

and slide it in until the safety mechanism is engaged.

2.6 Release the SLIDING PLATFORM LOCK and slide the

SLIDING PLATFORM such that the camera’s C of G is

directly above the centre axis of the Fluid Head and tighten

the SLIDING PLATFORM LOCK (g.5). If this can not be

achieved then reposition the CAMERA PLATE on the

Camera or the QUICK RELEASE TRIPOD ADAPTOR – step

` 2.4. This will ensure that the system has maximum stability.

C of G

Sliding

platform

Sliding

platform

lock

Fig. 5

6

Page 8

Operating Instructions

3. Counterbalance Control

The counterbalance system was designed to neutralise the

effect of the camera weight when it is tilted. The Compass 20

Fluid Head offers a 4 position counterbalance system which

can be operated via the COUNTERBALANCE SELECTOR (g.

2). The COUNTERBALANCE SELECTOR must be operated

when the SLIDING PLATFORM is in a horizontal position. After

changing the Counterbalance setting it may be necessary to

tilt the camera back and forth to ensure that the CB spring has

engaged. The camera must be held securely while changing the

Counterbalance setting.

3.1 For safety ensure that Counterbalance position 4

is selected.

3.2 Hold the camera and release the TILT LOCK, then gently tilt

the camera from a horizontal position forward then

backward and observe its response. If the Camera ‘Springs

Back’ to the horizontal position then a lower

Counterbalance setting is required, select Counterbalance

position 3 and recheck, select lower setting again if

necessary. Correct counterbalance setting has been

achieved when minimum effort is required to move the

camera over the entire tilt range.

TIP Fine tuning can be achieved by adjusting the SLIDING

PLATFORM – see step 2.6.

Counterbalance Performance

Fig. 6

7

Page 9

Operating Instructions

4. Pan / Tilt Drag Control.

The Compass 20 Fluid Head offers 5 selectable positions of

uid drag + zero setting in the Pan and Tilt. The settings are

equally stepped from light drag in position 1 up to heavy drag in

position 5, the drag plates are completely disengaged in position

zero.

• Do not Pan or Tilt the Fluid Head whilst adjusting PAN or

TILT DRAG CONTROL or whilst the PAN & TIL DRAG

CONTROL is between settings.

• The drag setting can be changed at any tilt or pan angle.

5. Pan/Tilt Lock Control.

The Compass 20 Fluid Head offers high capacity caliper disc

brake system to hold the Fluid Head in a xed pan and/or tilt

position. Camera position will not change when applying or

releasing the Pan / Tilt locks.

• Do not pan or tilt the Fluid Head whilst the PAN or the TILT

LOCK is partially applied.

6. Illumination.

The Compass 20 Fluid Head offers illumination of the BUBBLE

LEVEL when the low ambient light conditions exist. Illumination

can be achieved by pressing the ILLUMINATION BUTTON once.

The light will switch off after 10 seconds.

Tilt Drag Control

Fig. 7

Counterbalance Selector

Illumination Button

Bubble Level

Pan Drag Control

8

Page 10

Maintenance

The Compass 20 Fluid Head offers high quality surface coatings.

Miller recommends keeping the Fluid Head clean at all times by

using soft brushes and lint free cloth to wipe over the surfaces.

• Do not immerse the Fluid Head in any liquid.

• Do not use stiff brushes, abrasives, harsh detergents

and solvents.

Battery Replacement

The Compass 20 Fluid Head uses a single 11A type - 6 Volt battery

for Illumination. Miller recommends the following batteries to

provide long life performance – GP11A, Duracell MN11 or Vinnic

L1016.

1 Using a Phillips Head #1 screw driver, remove the

RETAINING SCREW and the BATTERY DOOR.

2 Using a small at screw driver remove the battery.

3 Align the new battery as shown on the back of the

BATTERY DOOR and place into the BATTERY HOUSING,

then push down the battery into place. A small at screw

driver may be used to push down the battery into the

BATTERY HOUSING.

4 Align the BATTERY DOOR into the body then tighten the

screw lightly.

Battery Housing

Illumination Button

9

Retaining Screw

Fig. 8

Battery Door

Battery

Page 11

Storage Service, Sales and Support

The Compass 20 Fluid Head can be stored for extended periods;

Miller recommends storage in a Miller Soft Case and the

following:

• Remove battery.

• Clean the external surfaces.

• Keep in a dry place away from direct sunlight.

• Loosen off PAN & TILT LOCK.

Spare Parts and Accessories

ITEM ITEM NO.

Battery P7715

Camera plate Assembly (Including 1/4” + Pin Carriage)

Camera screw 3/8” P0037

Camera screw 1/4” P0036

1/4” + pin carriage #493

Standard Pan Handle assembly (incl. Handle Clamp) # 680

Standard Pan Handle # 689

Soft Case # 876

Clamp nut P7850

#1208

Warranty

Please refer to warranty card for complete details.

Miller Authorised Service Agents must carry out all service and

repair work. Failure to observe this requirement may void warranty.

It is advisable to notify Miller or a Miller Authorised Service Agent

if a change of performance is observed as a result of dropping or

rough usage. For information regarding sales and service of Miller

products or for your nearest Miller representative please contact

us via our website or at the following:

MILLER CAMERA SUPPORT EQUIPMENT

30 Hotham Parade, Artarmon, Sydney, NSW 2064 Australia

Tel: +61 2 9439 6377 Fax: +61 2 9438 2819

Email: sales@miller.com.au

MILLER CAMERA SUPPORT (LLC) USA

218 Little Falls Road, Cedar Grove, New Jersey 07009-1231 USA

Tel: (973) 857 8300 Fax: (973) 857 8188

Email: sales@millertripods.us

MILLER FLUID HEADS (EUROPE) LTD.

Unit A2, Ford Lane Industrial Estate

Ford Lane, Ford, West Sussex BN18 0DF, United Kingdom

Tel: +44 (0)1243 555255 Fax: +44 (0)1243 555 001

Email: sales@millertripods-europe.com

Website - www.millertripods.com

10

Page 12

www.millertripods.com

MILLER CAMERA SUPPORT EQUIPMENT

30 Hotham Parade

Artarmon, Sydney

NSW 2064 Australia

Tel: +61 2 9439 6377

Fax: +61 2 9438 2819

Email: sales@miller.com.au

D 7881-1 07/09

Loading...

Loading...