Miller XMT 304 Technical Manual

TM-180 670B September 2001

Eff. w/Serial Number KG13951 1

Processes

Multiprocess Welding

Description

Arc Welding Power Source

R

XMT 304

(400 Volt Models)

Visit our website at

www.MillerWelds.com

Declaration of Conformity For

European Community (CE) Products

Manufacturer’s Name: Miller Electric Mfg. Co.

Manufacturer’s Address: 1635 W. Spencer Street

Appleton, WI 54914 USA

Declares that the product: XMT 304

conforms to the following Directives and Standards:

Directives

Electromagnetic compatibility Directives: 89/336/EEC, 92/31/EEC

Low Voltage Directive: 73/23/EEC

Machinery Directives: 89/392/EEC, 91/368/EEC, 93/C 133/04, 93/68/EEC

Standards

Electromagnetic compatibility (EMC) Product standard for arc welding equipment:

EN50199: December 1995

Safety Requirements for Arc Welding Equipment part 1: EN 60974-1: 1989

Degrees of Protection provided by Enclosures (IP code): IEC 529: 1989

Insulation coordination for equipment within low-voltage systems:

Part 1: Principles, requirements and tests: IEC 664-1: 1992

European Contact: Danilo Fedolfi, Managing Director

MILLER Europe S.r.l.

Via Privata Iseo

20098 San Giuliano

Milanese, Italy

Telephone: 39(02)98290-1

Fax: 39(02)98281-552

dec_con1 10/95

TABLE OF CONTENTS

SECTION 1 – SAFETY PRECAUTIONS FOR SERVICING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. Symbol Usage 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. Servicing Hazards 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3. EMF Information 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – DEFINITIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. Manufacturer’s Warning Label Definitions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2. Manufacturer’s Rating Labels 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3. Symbols And Definitions 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – INSTALLATION 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. Specifications 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

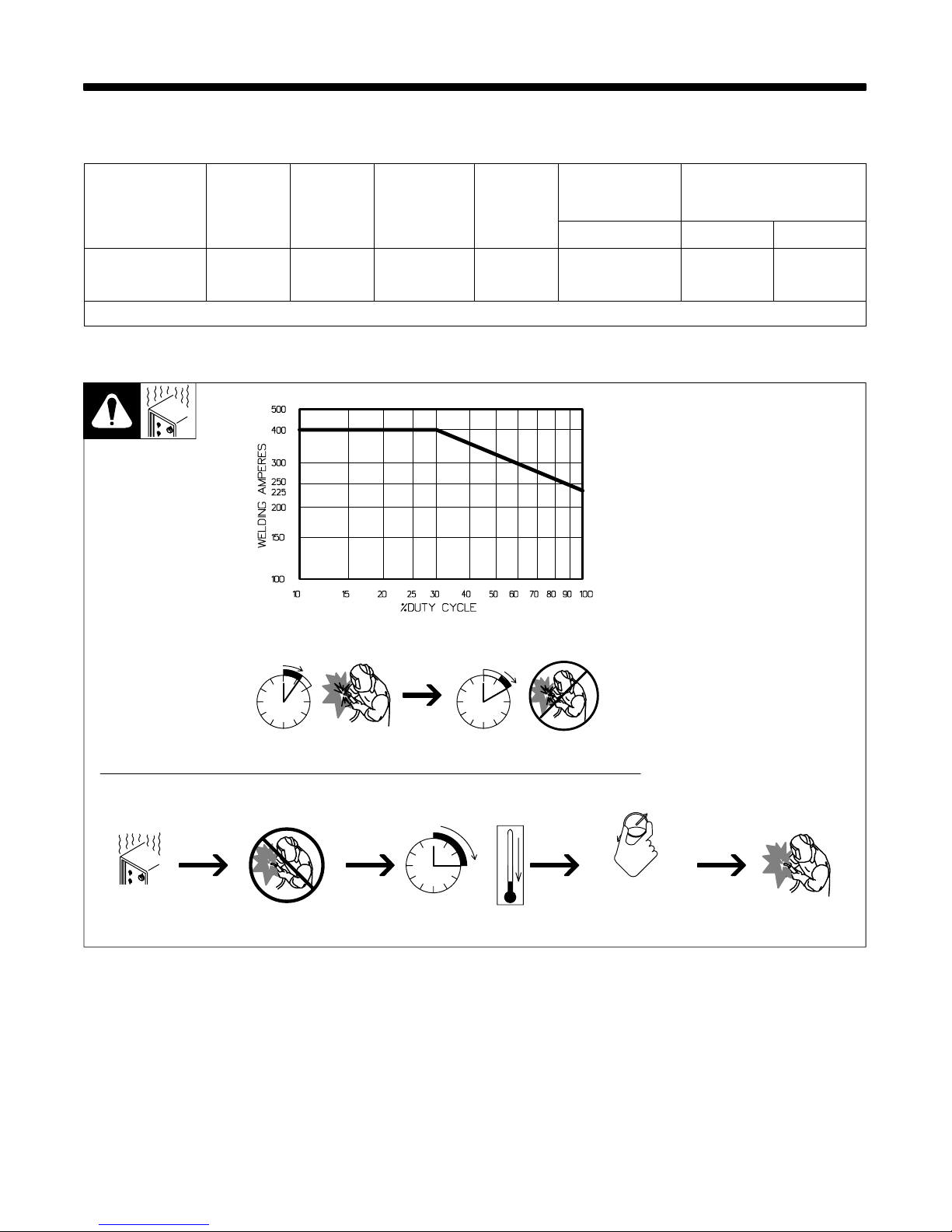

3-2. Duty Cycle And Overheating 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. Volt-Ampere Curves 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4. Selecting A Location 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5. Weld Output Terminals And Selecting Cable Sizes 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

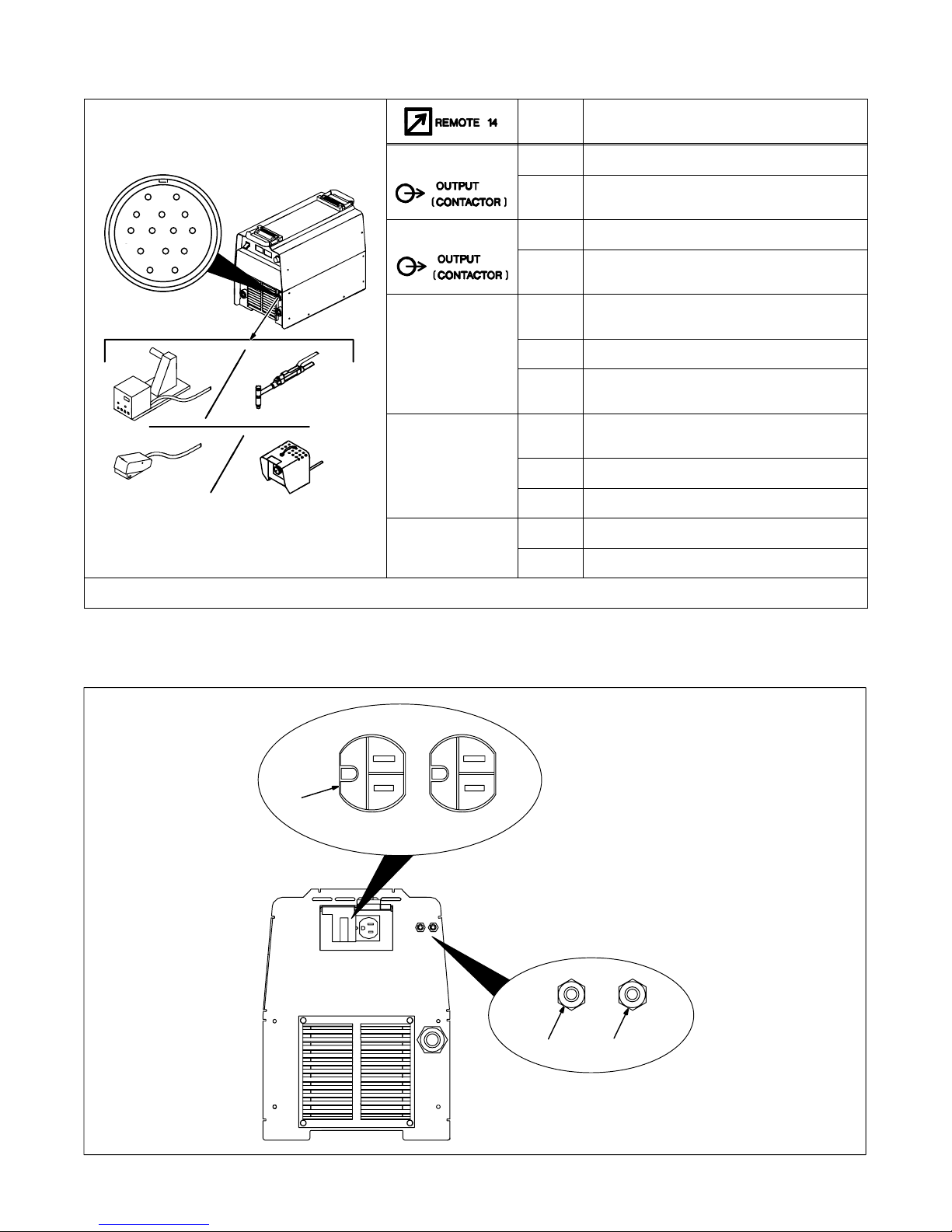

3-6. Remote 14 Receptacle Information 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

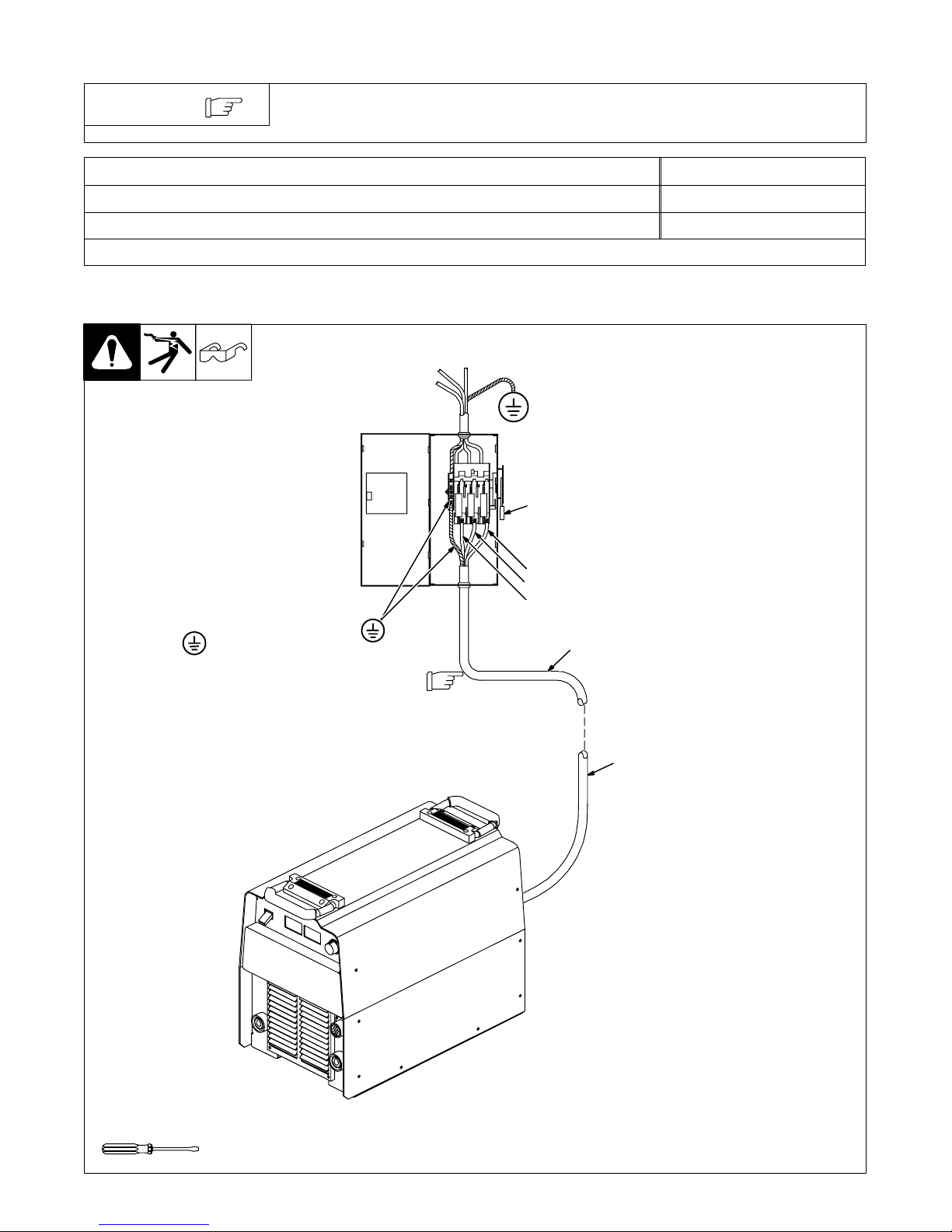

3-7. 110 Volt AC Duplex Receptacle 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8. Electrical Service Guide 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

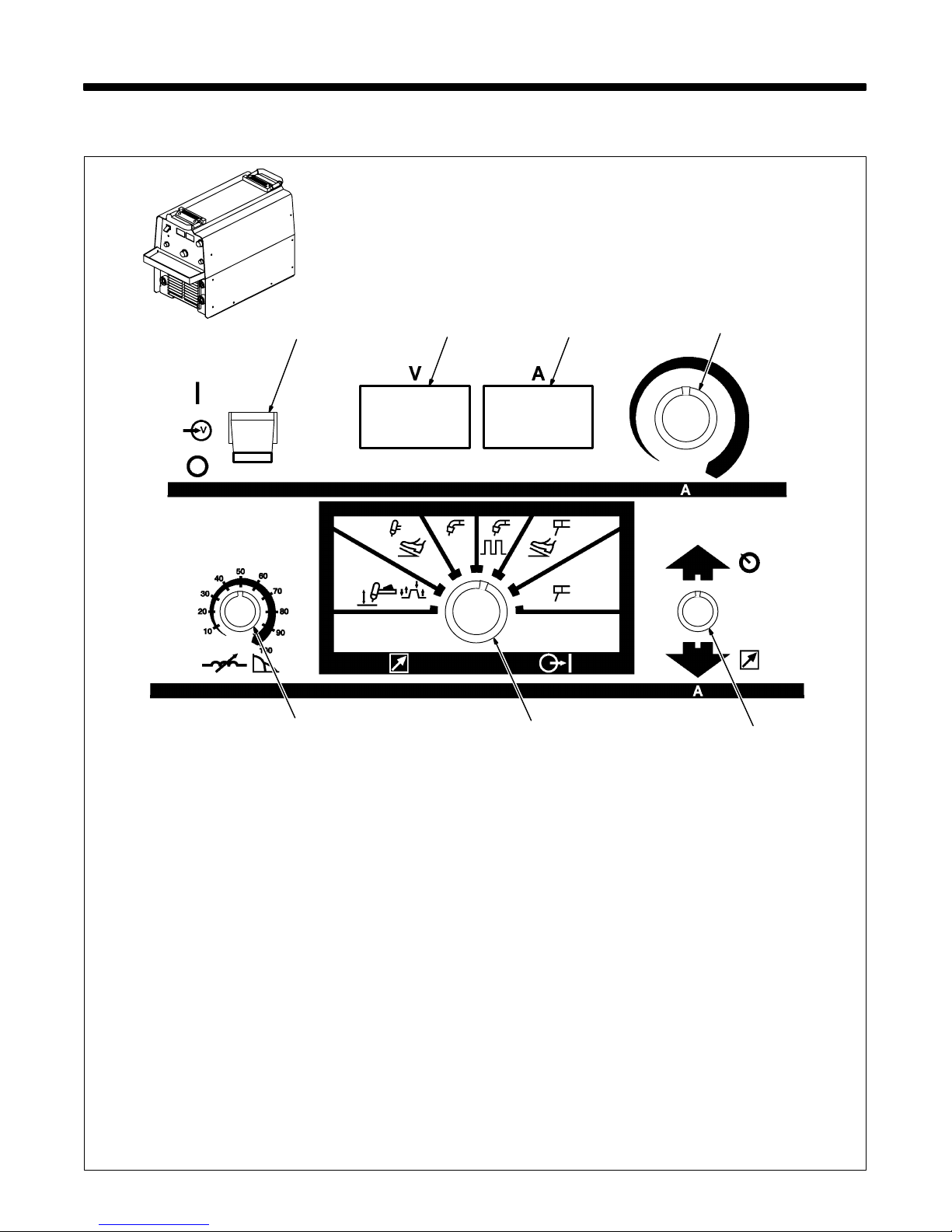

3-9. Connecting Input Power 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 – OPERATION 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

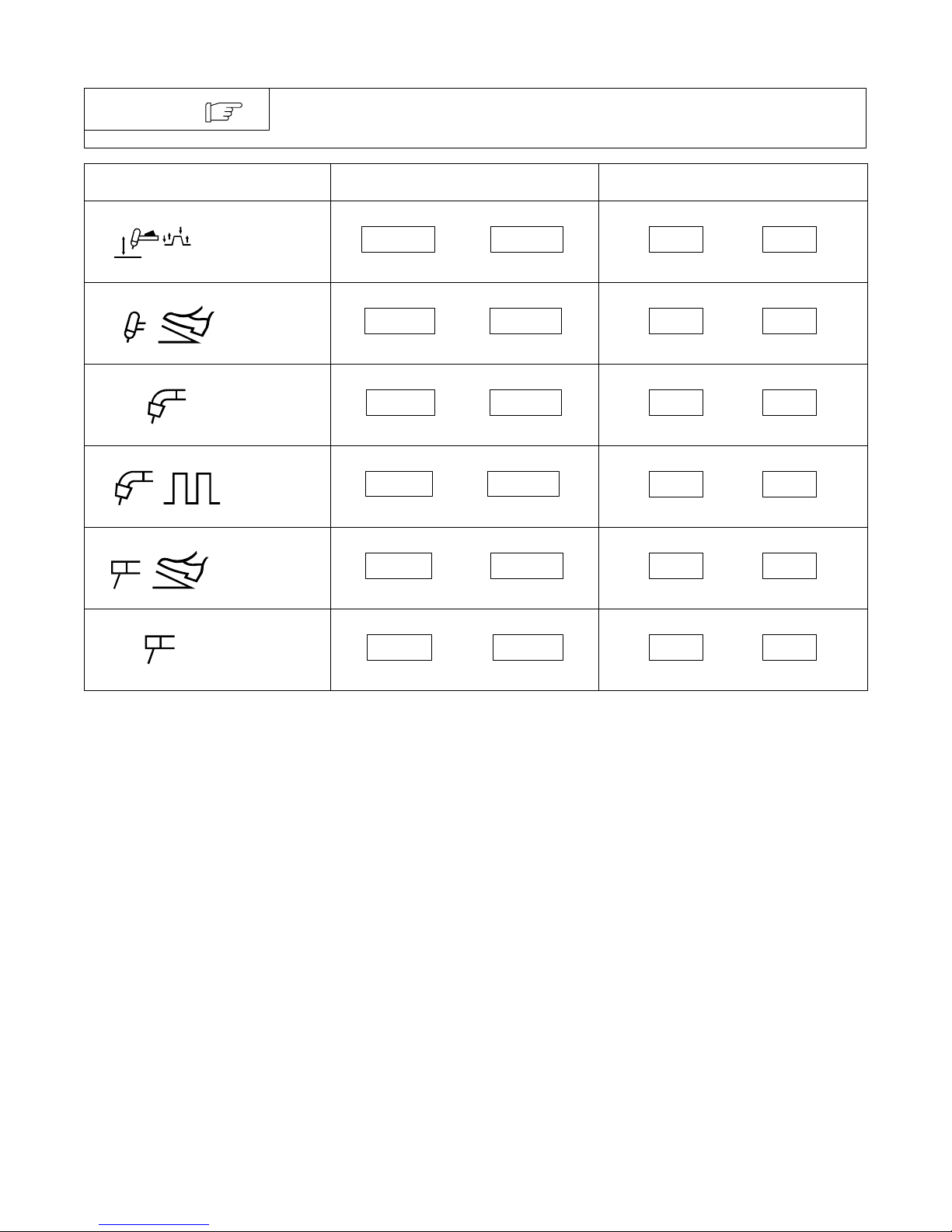

4-1. Front Panel Controls 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2. Meter Functions 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3. Mode Switch Settings 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-4. Lift-Arc Trigger Hold TIG 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 – THEORY OF OPERATION 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – EXPLANATION OF ELECTRICAL PARTS 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7 – PRE-POWER CHECKLIST 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1. Checking Unit Before Applying Power 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2. Output Diodes D1, D2 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3. Input Rectifier SR1 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4. Tank Capacitor C1 and Input Capacitors C3, C4 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5. IGBT Modules PM1, PM2 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-6. Diodes D1, D2, D3, D4 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8 – TROUBLESHOOTING 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-1. Troubleshooting Table 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-2. Voltmeter/Ammeter Help Displays Prior To Serial No. KG150087 30. . . . . . . . . . . . . . . . . . . . . .

8-3. Voltmeter/Ammeter Help Displays Ef fective With KG150087 31. . . . . . . . . . . . . . . . . . . . . . . . .

8-4. Troubleshooting Circuit Diagram For Welding Power Source Prior To KK104771 32. . . . . . . . .

8-5. Troubleshooting Circuit Diagram For Welding Power Source Eff. With KK104771 34. . . . . . . .

8-6. Waveforms For Sections 8-4 And 8-5 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-7. Control Board PC1 Testing Information (All Models – Use With Section 8-8) 37. . . . . . . . . . . . .

8-8. Control Board PC1 Test Point Values (All Models) 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-9. Display Board PC3 Testing Information (All Models – Use With Section 8-10) 40. . . . . . . . . . .

8-10. Display Board PC3 Test Point Values (All Models) 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-11. Interconnecting Board PC2 Testing Information (All Models) 42. . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9 – MAINTENANCE 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-1. Routine Maintenance 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-2. Blowing Out Inside Of Unit 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-3. Measuring Input Capacitor Voltage 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-4. Checking Bus Voltage Imbalance 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 10 – ELECTRICAL DIAGRAMS 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 11 – PARTS LIST FOR KG139511 AND FOLLOWING 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING

This product, when used

for welding or cutting,

produces fumes or

gases which contain

chemicals known to the

State of California to

cause birth defects and,

in some cases, cancer.

(California Health &

Safety Code Section

25249.5 et seq.)

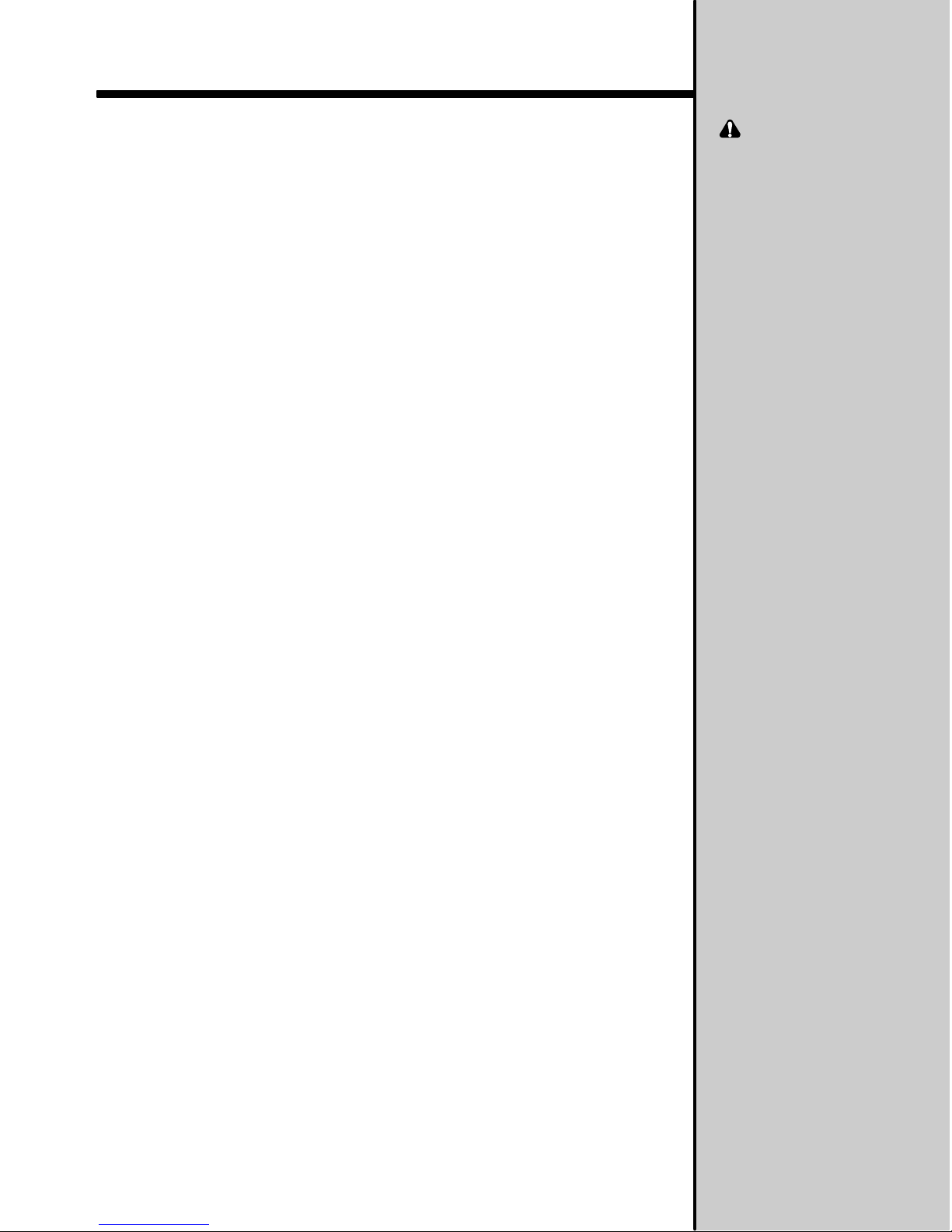

SECTION 1 – SAFETY PRECAUTIONS FOR SERVICING

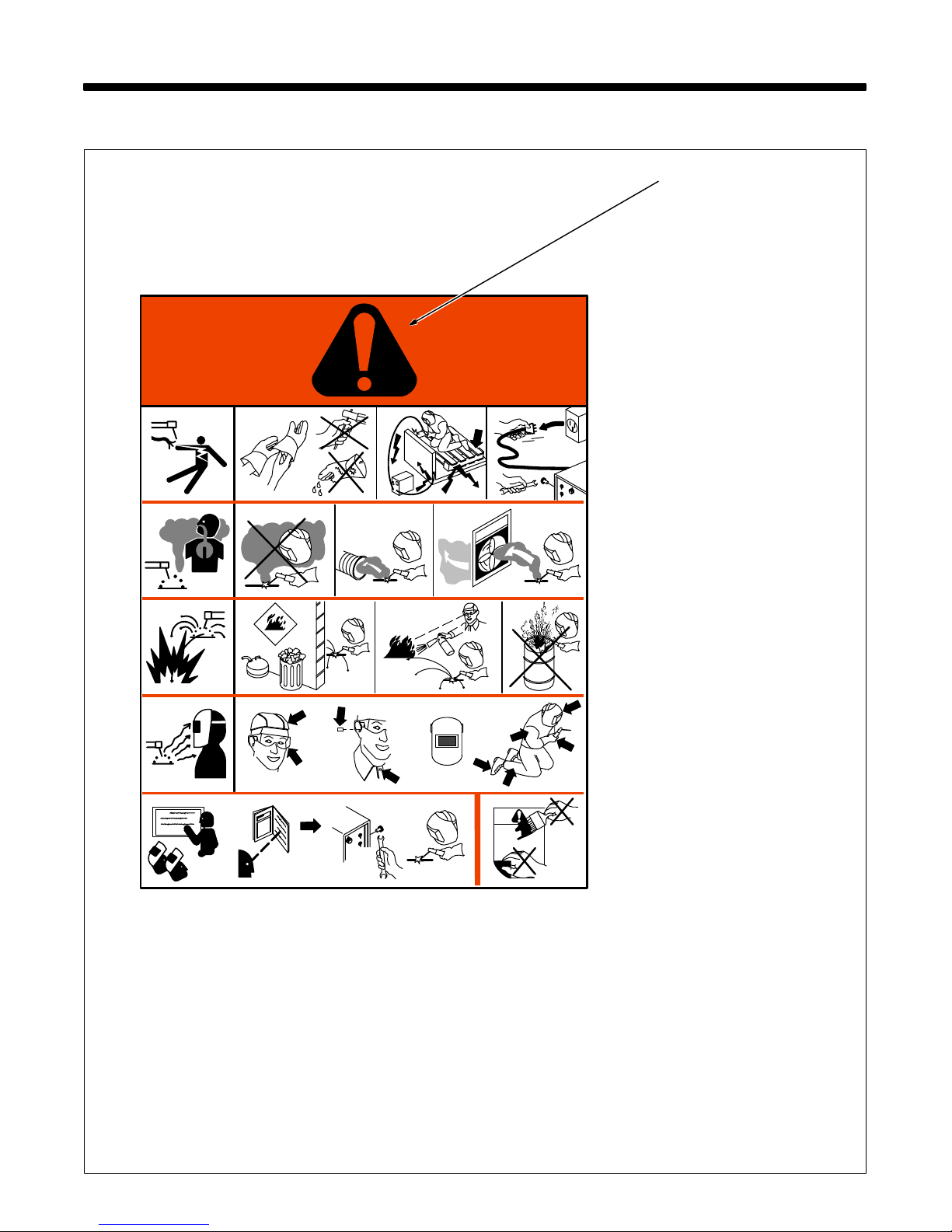

1-1. Symbol Usage

OM-180 670M - 1/00, safety_stm 5/97

Means Warning! Watch Out! There are possible hazards

with this procedure! The possible hazards are shown in

the adjoining symbols.

Y Marks a special safety message.

. Means “Note”; not safety related.

1-2. Servicing Hazards

Y The symbols shown below are used throughout this manual to

call attention to and identify possible hazards. When you see

the symbol, watch out, and follow the related instructions to

avoid the hazard.

Y Only qualified persons should service, test, maintain, and re-

pair this unit.

Y During servicing, keep everybody, especially children, away.

ELECTRIC SHOCK can kill.

D Do not touch live electrical parts.

D Turn Off welding power source an d wi re f ee de r

and disconnect and lockout input power using

line disconnect switch, circuit breakers, or by removing plug from receptacle, o r stop engine before servicing unless the procedure specifically requires an energized unit.

D Insulate yourself from ground by standing or working on dry insulat-

ing mats big enough to prevent contact with the ground.

D Do not leave live unit unattended.

D If this procedure requires an energized unit, have only personnel

familiar with and following standard safety practices do the job.

D When testing a live unit, use the one-hand method. Do not put both

hands inside unit. Keep one hand free.

D Disconnect input power conductors from deenergized supply line

BEFORE moving a welding power source.

SIGNIFICANT DC VOLTAGE exists after removal of

input power on inverters.

D Turn Off inverter, disconnect input power, and discharge input

capacitors according to instructions in Maintenance Section before

touching any parts.

This group of symbols means Warning! Watch Out! possible

ELECTRIC SHOCK, MOVING PARTS, and HOT PARTS hazards.

Consult symbols and related instructions below for necessary actions

to avoid the hazards.

FLYING METAL can injure eyes.

D Wear safety glasses with side shields or face

shield during servicing.

D Be careful not to short metal tools, parts, or

wires together during testing and servicing.

HOT PARTS can cause severe burns.

D Do not touch hot parts bare handed.

D Allow cooling period before working on welding

gun or torch.

EXPLODING PARTS can cause injury.

D Failed parts can explode or cause other parts to

explode when power is applied to inverters.

D Always wear a face shield and long sleeves

when servicing inverters.

SHOCK HAZARD from testing.

D Turn Off welding power source an d wi re f ee de r

or stop engine before making or changing meter lead connections.

D Use at least one meter lead that has a self-

retaining spring clip such as an alligator clip.

D Read instructions for test equipment.

FALLING UNIT can cause injury.

STATIC (ESD) can damage PC boards.

D Put on grounded wrist strap BEFORE handling

boards or parts.

D Use proper static-proof bags and boxes to

store, move, or ship PC boards.

FIRE OR EXPLOSION hazard.

D Do not place unit on, over, or near combustible

surfaces.

D Do not service unit near flammables.

D Use lifting eye to lift unit only, NOT running

gear, gas cylinders, or any other accessories.

D Use equipment of adequate capacity to lift and

support unit.

D If using lift forks to move unit, be sure forks are

long enough to extend beyond opposite side of

unit.

MOVING PARTS can cause injury.

D Keep away from moving parts such as fans.

D Keep all doors, panels, covers, and guards

closed and securely in place.

TM-180 670 Page 1XMT 304

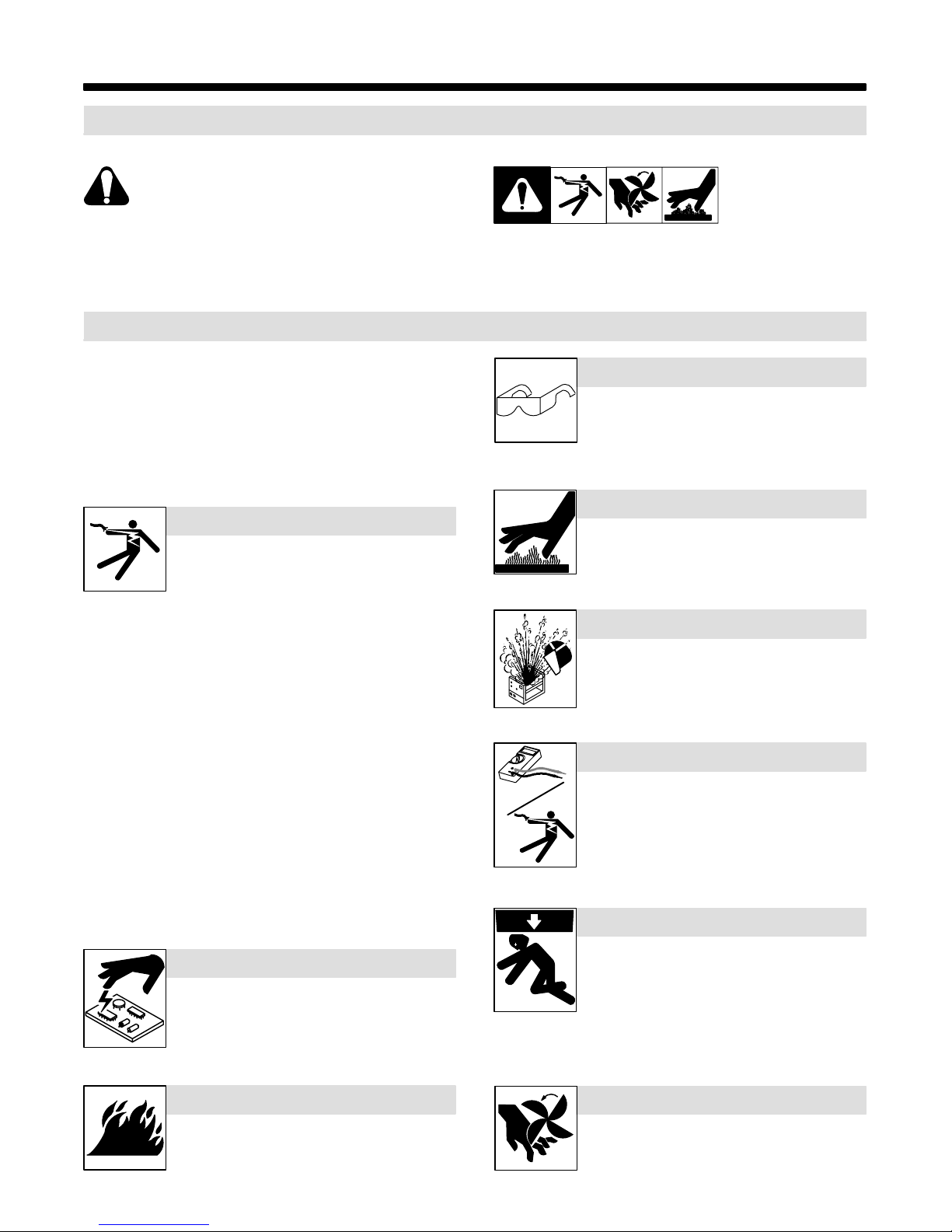

MOVING PARTS can cause injury.

H.F. RADIATION can cause interference.

D Keep away from moving parts.

D Keep away from pinch points such as drive

rolls.

MAGNETIC FIELDS can affect pacemakers.

D Pacemaker wearers keep away from servicing

areas until consulting your doctor.

OVERUSE can cause OVERHEATING.

D Allow cooling period; follow rated duty cycle.

D Reduce current or reduce duty cycle before

starting to weld again.

D Do not block or filter airflow to unit.

1-3. EMF Information

D High-frequency (H.F.) can interfere with radio

navigation, safety services, computers, and

communications equipment.

D Have only qualified persons familiar with

electronic equipment install, test, and service

H.F. producing units.

D The user is responsible for having a qualified electrician prompt-

ly correct any interference problem resulting from the installation.

D If notified by the FCC about interference, stop using the

equipment at once.

D Have the installation regularly checked and maintained.

D Keep high-frequency source doors and panels tightly shut, keep

spark gaps at correct setting, and use grounding and shielding to

minimize the possibility of interference.

READ INSTRUCTIONS.

D Use MILLER Testing Booklet (Part No. 150

853) when servicing this unit.

D Consult the Owner’s Manual for welding safety

precautions.

D Use only genuine MILLER replacement parts.

Considerations About Welding And The Effects Of Low Frequency

Electric And Ma g netic Fields

Welding current, as it flows through welding cables, will cause electromagnetic fields. There has been and still is some concern about such

fields. However, after examining more than 500 studies spanning 17

years of research, a special blue ribbon committee of the National

Research Council concluded that: “The body of evidence, in the

committee’s judgment, has not demonstrated that exposure to power-

frequency electric and magnetic fields is a human-health hazard.”

However, studies are still going forth and evidence continues to be

examined. Until the final conclusions of the research are reached, you

may wish to minimize your exposure to electromagnetic fields when

welding or cutting.

To reduce magnetic fields in the workplace, use the following

procedures:

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cables around your body.

4. Keep welding power source and cables as far away from operator as practical.

5. Connect work clamp to workpiece as close to the weld as possible.

About Pacemakers:

Pacemaker wearers consult your doctor first. If cleared by your doctor,

then following the above procedures is recommended.

TM-180 670 Page 2 XMT 304

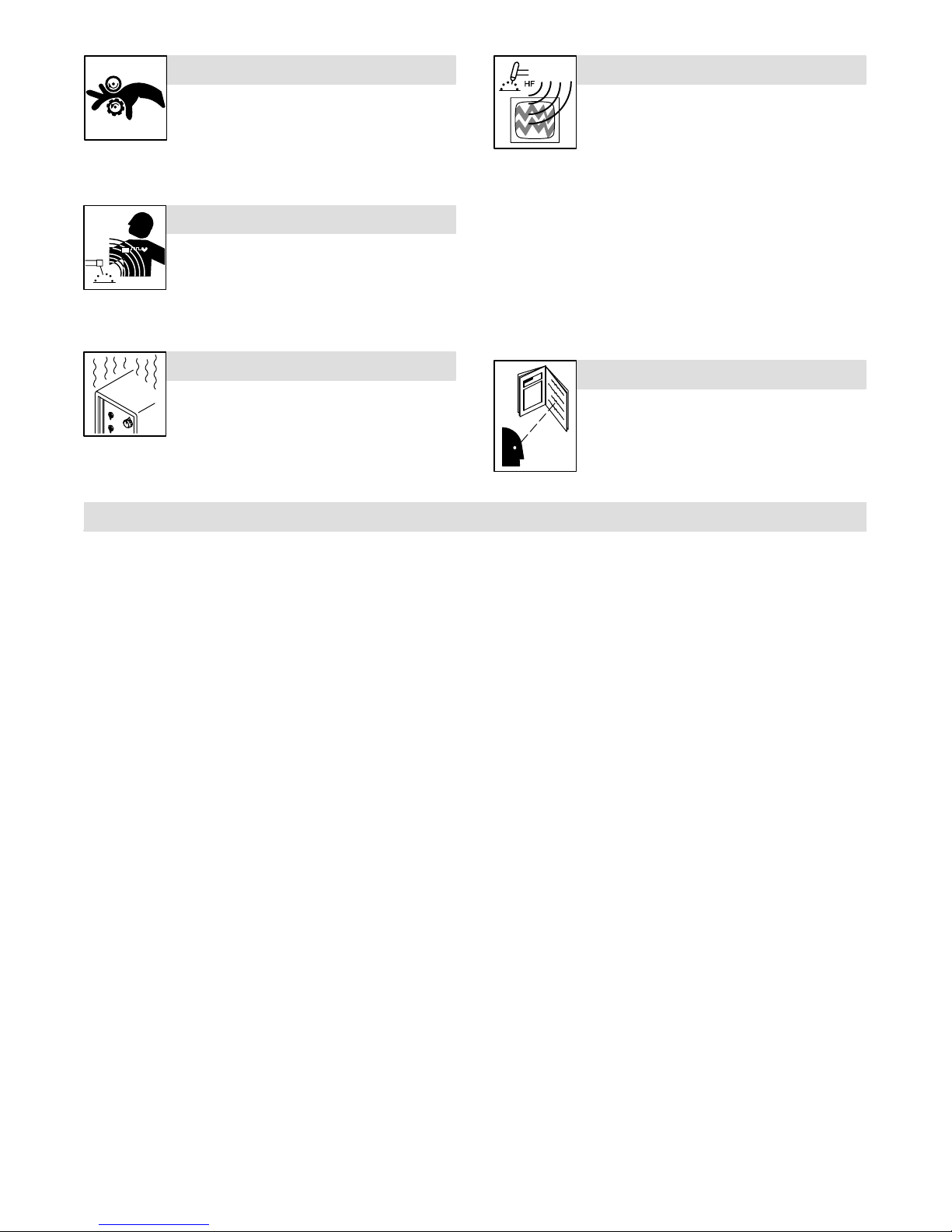

SECTION 2 – DEFINITIONS

2-1. Manufacturer’s Warning Label Definitions

1 1.1 1.2 1.3

2 2.1

3 3.1 3.2 3.3

4 4.1

56

+

2.2

+

2.3

+

+

S-179 310

Warning! Watch Out! There are

possible hazards as shown by the

symbols.

1 Electric shock from welding

electrode or wiring can kill.

1.1 Wear dry insulating gloves.

Do not touch electrode with

bare hand. Do not wear wet or

damaged gloves.

1.2 Protect yourself from electric

shock by insulating yourself

from work and ground.

1.3 Disconnect input plug or

power before working on

machine.

2 Breathing welding fumes can

be hazardous to your health.

2.1 Keep your head out of the

fumes.

2.2 Use forced ventilation or local

exhaust to remove the fumes.

2.3 Use ventilating fan to remove

fumes.

3 Welding sparks can cause

explosion or fire.

3.1 Keep flammables away from

welding. Do not weld near

flammables.

3.2 Welding sparks can cause

fires. Have a fire extinguisher

nearby, and have a

watchperson ready to use it.

3.3 Do not weld on drums or any

closed containers.

4 Arc rays can burn eyes and

injure skin.

4.1 Wear hat and safety glasses.

Use ear protection and button

shirt collar. Use welding

helmet with correct shade of

filter. Wear complete body

protection.

5 Become trained and read the

instructions before working on

the machine or welding.

6 Do not remove or paint over

(cover) the label.

1/96

TM-180 670 Page 3XMT 304

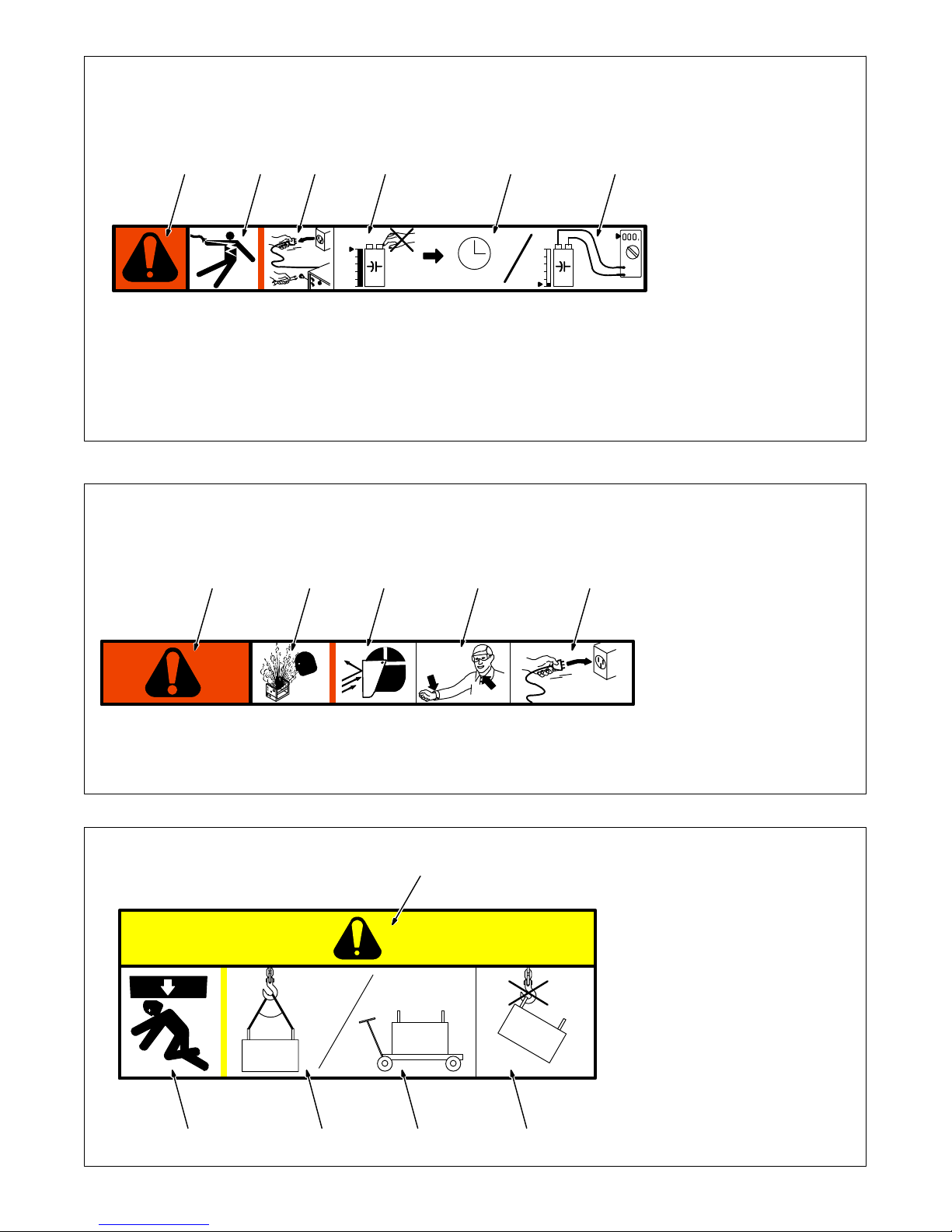

1 Warning! Watch Out! There

2 Electric shock from wiring can

3 Disconnect input plug or

1234 5 6

4 Hazardous voltage remains

V

V

> 60 s

V

S-179 190-A

5 Always wait 60 seconds after

6 Check input capacitor voltage,

1 Warning! Watch Out! There

2 When power is applied failed

1 23 4 5

3 Flying pieces of parts can

4 Always wear long sleeves and

S-179 304-A

5 After taking proper

are possible hazards as

shown by the symbols.

kill.

power before working on

machine.

on input capacitors after

power is turned off. Do not

touch fully charged

capacitors.

power is turned off before

working on unit, OR

and be sure it is near 0 before

touching any parts.

4/96

are possible hazards as

shown by the symbols.

parts can explode or cause

other parts to explode.

cause injury. Always wear a

face shield when servicing

unit.

button your collar when

servicing unit.

precautions as shown,

connect power to unit.

∠= <60

∠

2345

TM-180 670 Page 4 XMT 304

4/96

1 Warning! Watch Out! There

1

are possible hazards as

shown by the symbols.

2 Falling equipment can cause

injury and damage to unit.

3 Always lift and support unit

using both handles. Keep

angle of lifting device less

than 60 degrees.

°

4 Use a proper cart to move

unit.

5 Do not use one handle to lift

or support unit.

S-179 309-A

1/96

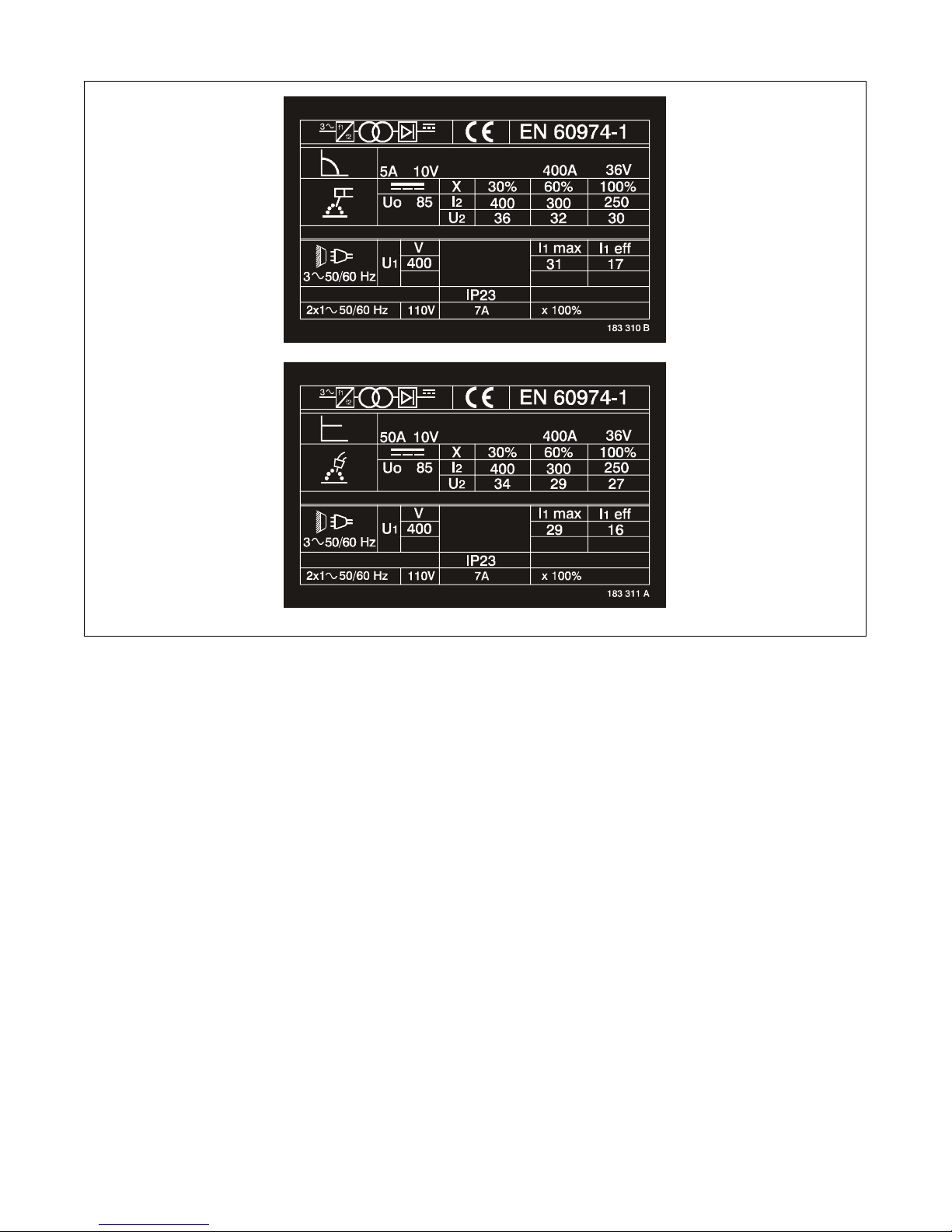

2-2. Manufacturer’s Rating Labels

TM-180 670 Page 5XMT 304

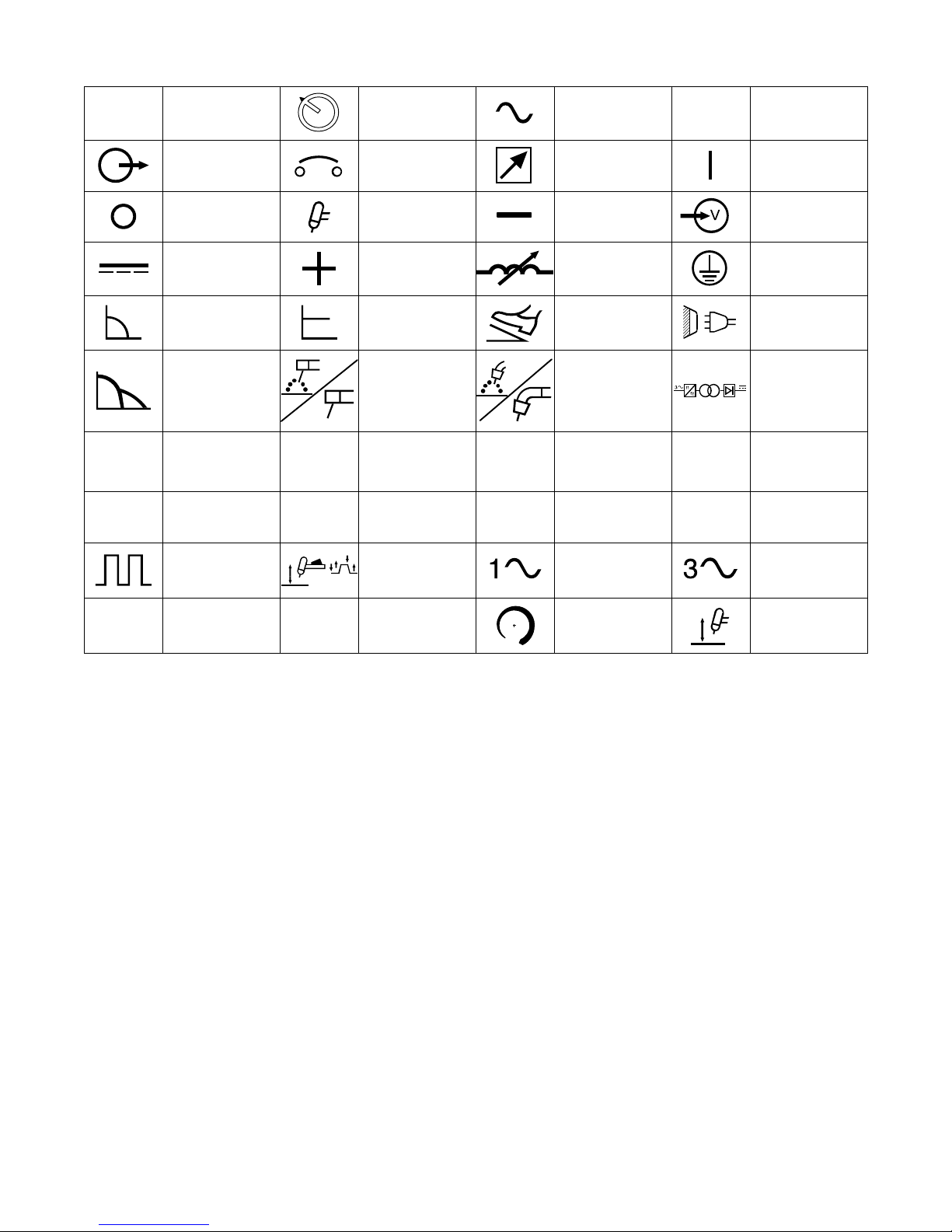

2-3. Symbols And Definitions

A

U

0

Hz

Amperage Panel

Output Circuit Breaker Remote On

Off

Direct Current

(DC)

Constant Current Constant Voltage Foot Control Line Connection

Arc Force

Rated No Load

Voltage (A verage) U

Hertz

Pulsed

IP

Gas Tungsten Arc

Shielded Metal Arc

Welding (SMAW)

Primary Voltage

1

Lift-Arc Trigger

Hold Operation

Welding

Positive Inductance

U

2

Degree Of

Protection

(GTAW)

I

2

Alternating

Current (AC)

Negative Voltage Input

Gas Metal Arc

Welding (GMAW)

Conventional

Load Voltage

Rated Welding

Current

Single Phase Three Phase

V

X

%

Voltage

Protective Earth

(Ground)

Three Phase Static

Frequency Con-

verter-

Transformer-

Rectifier

Duty Cycle

Percent

I

1max

Rated Maximum

Supply Current

I

1eff

Maximum Effective

Supply Current

Increase

Lift-Arc Operation

(GTAW)

TM-180 670 Page 6 XMT 304

3-1. Specifications

SECTION 3 – INSTALLATION

Rated Welding

Output Range Range

Output

300 A @

32 Volts DC,

60% Duty Cycle

*While idling

Voltage

Range

10 – 35 5 – 400 90 23

Amperage

Range

3-2. Duty Cycle And Overheating

Maximum

Open-Circuit

Voltage DC

IP Rating

Amperes Input

at Rated Load

Output 50/60 Hz

400 V KVA KW

17.0

(0.15*)

Duty Cycle is percentage of 10 mi n utes that unit can weld at rated load

without overheating.

If unit overheats, output stops, a

Help message is displayed (see

Section 8-3), and cooling fan runs.

Wait fifteen minutes for unit to cool.

Reduce amperage or duty cycle before welding.

Y Exceeding duty cycle can

12.4

(0.09*)

damage unit and void warranty.

11.5

(0.04*)

Overheating

60% Duty Cycle

6 Minutes Welding 4 Minutes Resting

0

15

Minutes

A

OR

Reduce Duty Cycle

Ref. SA-178 651

TM-180 670 Page 7XMT 304

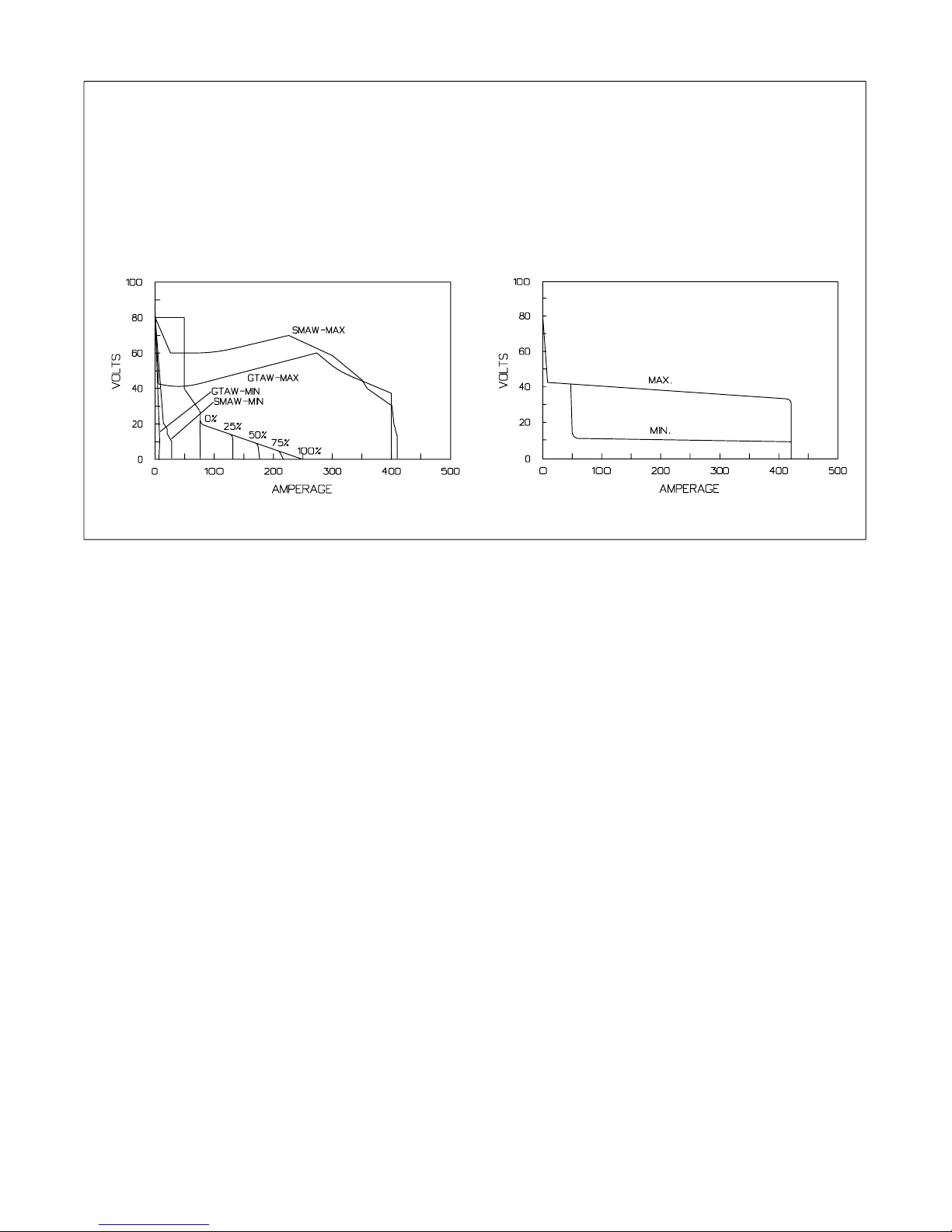

3-3. Volt-Ampere Curves

Volt-ampere curves show minimum

and maximum voltage and amperage output capabilities of unit.

Curves of other settings fall between curves shown.

A. CC Mode

ARC CONTROL

B. CV Mode

va_curve1 4/95 – SA-178 652 / SA-178 653

TM-180 670 Page 8 XMT 304

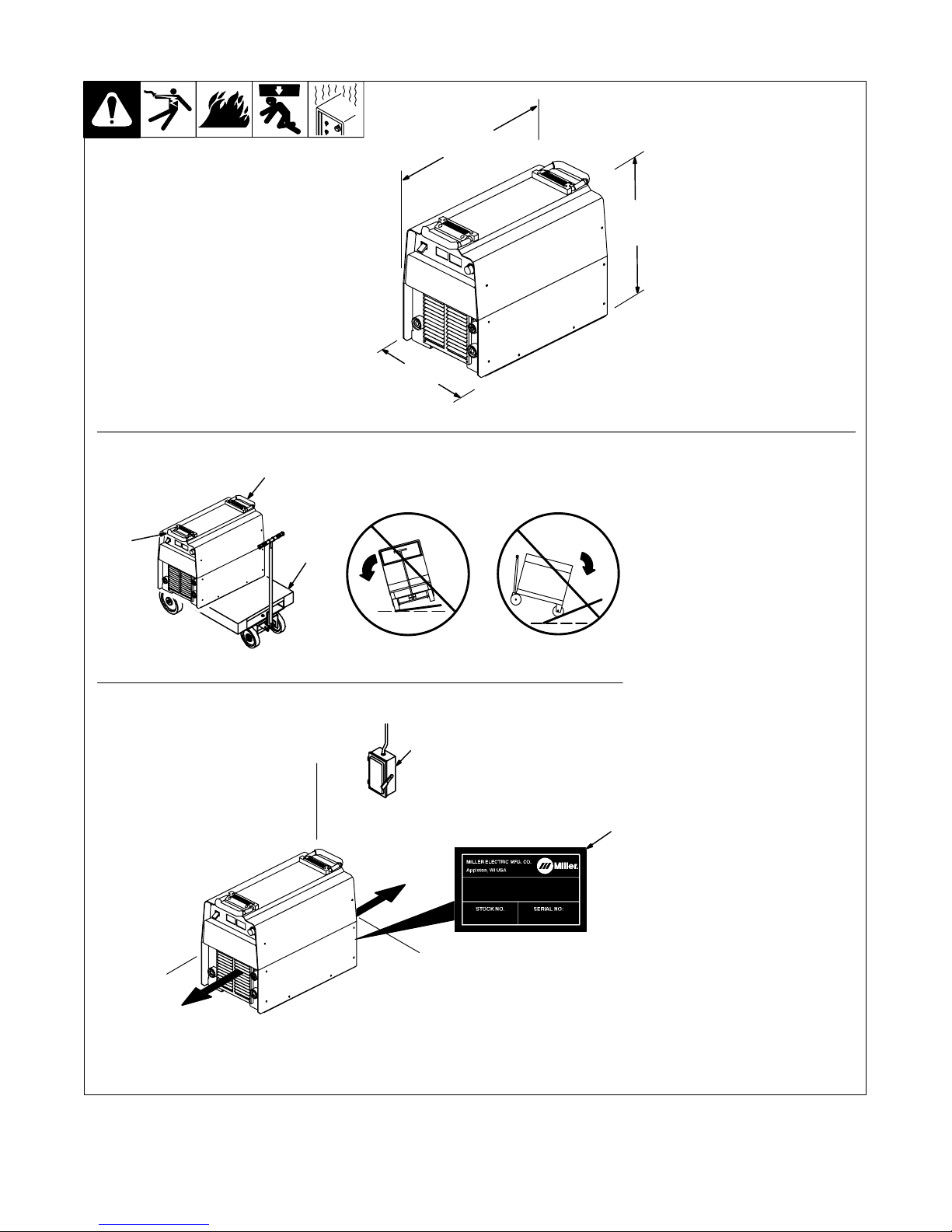

3-4. Selecting A Location

Dimensions And Weight

87 lb (39.5 kg)

24 in

(610 mm)

17 in

(432 mm)

12-1/2 in

(318 mm)

Movement

1

Location

1

2

Y Do not move or operate unit

where it could tip.

4

3

18 in

(460 mm)

1 Lifting Handles

Use handles to lift unit.

2 Hand Cart

Use cart or similar device to move

unit.

3 Plate Label

Use label to determine input power

needs.

4 Line Disconnect Device

Locate unit near correct input

power supply.

Y Special installation may be

required where gasoline or

volatile liquids are present –

see NEC Article 511 or CEC

Section 2 0 .

18 in

(460 mm)

loc_2 3/96 - ST-801 192

TM-180 670 Page 9XMT 304

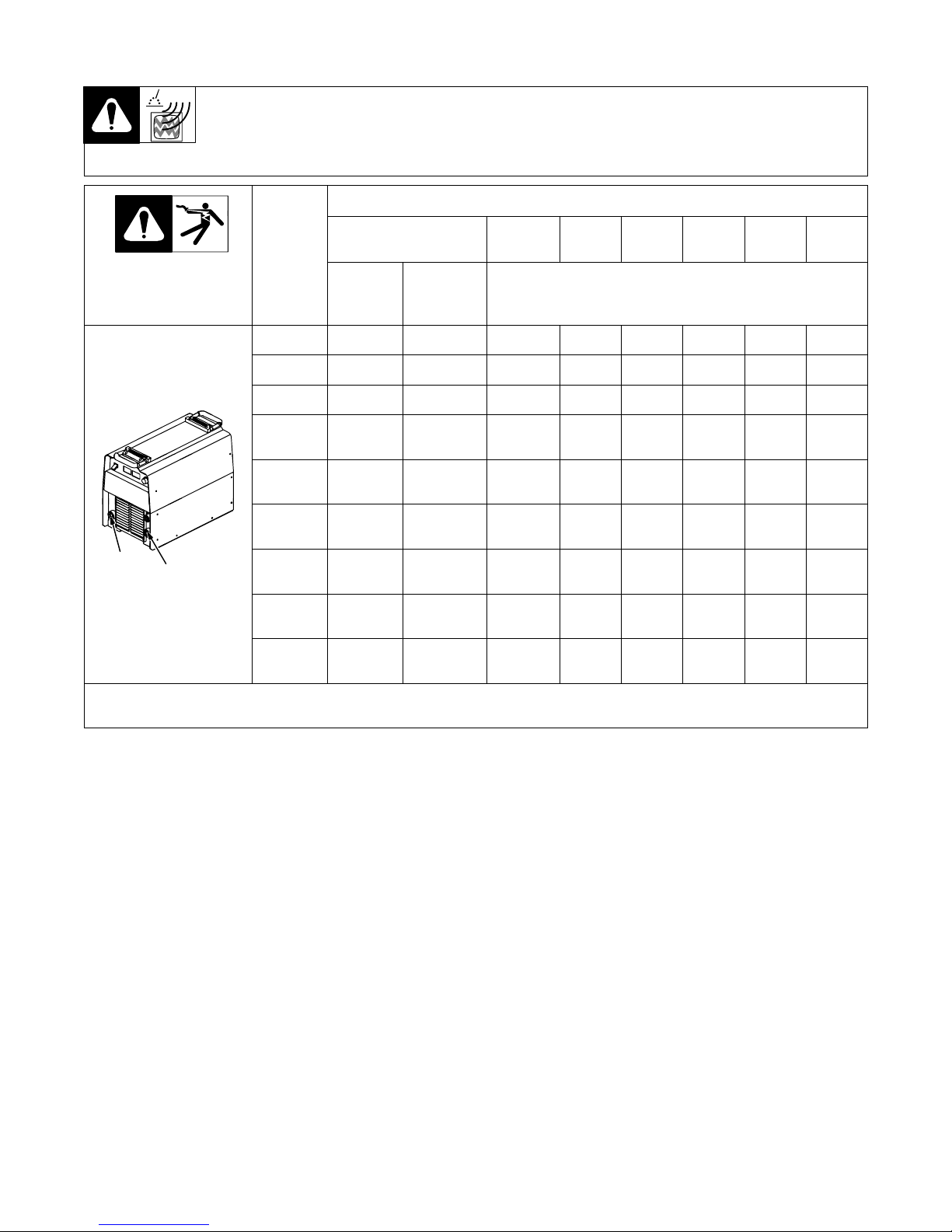

3-5. Weld Output Terminals And Selecting Cable Sizes

Y ARC WELDING can cause Electromagnetic Interference.

To reduce possible interference, keep weld cables as short as possible, close together, and down low, such as on the floor.

Locate welding operation 100 meters from any sensitive electronic equipment. Be sure this welding machine is installed

and grounded according to this manual. If interference still occurs, the user must take extra measures such as moving

the welding machine, using shielded cables, using line filters, or shielding the work area.

Total Cable (Copper) Length In Weld Circuit Not Exceeding*

Weld Output

Terminals

+

Output Receptacles

–

100 ft (30 m)**

Or Less

Welding

Amperes

100 4 (20)** 4 (20) 4 (20) 3 (30) 2 (35) 1 (50) 1/0 (60) 1/0 (60)

150 3 (30)** 3 (30) 2 (35) 1 (50) 1/0 (60) 2/0 (70) 3/0 (95) 3/0 (95)

200 3 (30) 2 (35) 1 (50) 1/0 (60) 2/0 (70) 3/0 (95) 4/0 (120) 4/0 (120)

250 2 (35) 1 (50) 1/0 (60) 2/0 (70) 3/0 (95) 4/0 (120)

300 1 (50) 1/0 (60) 2/0 (70) 3/0 (95) 4/0 (120)

350 1/0 (60) 2/0 (70) 3/0 (95) 4/0 (120)

400 1/0 (60) 2/0 (70) 3/0 (95) 4/0 (120)

500 2/0 (70) 3/0 (95) 4/0 (120)

600 3/0 (95) 4/0 (120)

10 – 60%

Duty

Cycle

60 – 100%

Duty

Cycle

150 ft

(45 m)

2-2/0

(2x70)

200 ft

(60 m)

250 ft

(70 m)

10 – 100% Duty Cycle

2-2/0

(2x70)

2-2/0

(2x70)

2-2/0

(2x70)

2-3/0

(2x95)

2-3/0

(2x95)

2-4/0

(2x120)

300 ft

(90 m)

2-2/0

(2x70)

2-3/0

(2x95)

2-3/0

(2x95)

2-4/0

(2x120)

3-3/0

(3x95)

350 ft

(105 m)

2-2/0

(2x70)

2-3/0

(2x95)

2-3/0

(2x95)

2-4/0

(2x120)

3-3/0

(3x95)

3-4/0

(3x120)

400 ft

(120 m)

2-2/0

(2x70)

2-3/0

(2x95)

2-4/0

(2x120)

2-4/0

(2x120)

3-3/0

(3x95)

3-4/0

(3x120)

*Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere.

**( ) = mm2 for metric use. S-0007-E

TM-180 670 Page 10 XMT 304

3-6. Remote 14 Receptacle Information

C

VOLTAGE

Socket* Socket Information

AJ

K

I

B

L

C

D

*The remaining sockets are not used.

I

NH

M

G

F

E

ST-801 192

24 VOLTS AC

24 VOLTS AC

115 VOLTS AC

115 VOLTS AC

REMOTE

OUTPUT

CONTROL

A/V

A/V

AMPERAGE

VOLTAGE

GND

A 24 volts ac. Protected by circuit breaker CB2.

B Contact closure to A completes 24 volts ac con-

tactor control circuit.

I 115 volts ac. Protected by circuit breaker CB1.

J Contact closure to I completes 115 volts ac con-

tactor control circuit.

C Output to remote control; 0 to +10 volts dc, +10

volts dc in MIG mode.

D Remote control circuit common.

E 0 to +10 volts dc input command signal from re-

mote control.

H V oltage feedback; +1 volt dc per 10 output recep-

tacle volts.

F Current feedback; +1 volt dc per 100 amperes.

M CC/CV select

G Circuit common for 24 a nd 115 volts ac circuits.

K Chassis common.

3-7. 110 Volt AC Duplex Receptacle

1

1 110 V 7 A AC Receptacle

Power is shared between duplex

receptacle and Remote 14 receptacle (see Section 3-6).

2 Circuit Breaker CB1

3 Circuit Breaker CB2

CB1 protects 110 volt ac portion of

duplex receptacle and Remote 14

receptacle from overload.

CB2 protects 24 volt ac portion of

Remote 14 receptacle from

overload.

Press button to reset breaker.

2 3

Ref. ST-801 245-A

TM-180 670 Page 11XMT 304

3-8. Electrical Service Guide

NOTE

Input Voltage

Input Amperes At Rated Output

Max Recommended Standard Fuse Or Circuit Breaker Rating In Amperes

Reference: 1996 National Electrical Code (NEC). S-0092J

Actual input voltage should not exceed ± 10% of indicated required input voltage. If

actual input voltage is outside of this range, output may not be available.

400 (Three Phase Only)

17.0

30

“

3-9. Connecting Input Power

Y Disconnect and lockout/tag-

out input power before connecting input conductors

from unit.

Y Have only qualified persons

make this installtion.

Check input voltage available at

site.

1 Line Disconnect Device

2 Input And Grounding

Conductors

Select type and size of overcurrent

protection using Section 3-8.

Y Always connect green/yel-

low wire to supply grounding terminal, never to a line

terminal.

Y Always connect grounding

conductor first.

1

L1

L2

L3

= GND/PE

Green/Yellow

Install conductors into a deenergized

line dissconnect device.

2

2

Tools Needed:

TM-180 670 Page 12 XMT 304

Input_9_99 / Ref. ST-144 221 / ST-801 192

SECTION 4 – OPERATION

4-1. Front Panel Controls

1

7

2

3

5

4

6

ST-179 275

1 Power On/Off Switch

. The fan motor is thermostatically

controlled and only runs when cooling is

needed.

2 Voltmeter (see Section 4-2)

3 Ammeter (see Section 4-2)

4 Voltage/Amperage Adjustment Control

5 Mode Switch

The Mode switch setting determines both the

process and output On/Off control (see Section 4-3. Source of control (panel or remote)

for the amount of output is selected on the

Voltage/Amperage Control switch.

For Air Carbon Arc (CAC-A) cutting and

gouging, place switch in Stick position. For

best results, place Inductance/Dig control in

the maximum position.

6 Voltage/Amperage Control Switch

For front panel control, place switch in Panel

position.

For remote control, make connections to Re-

mote 14 receptacle, and place switch in

Remote position. In most modes, remote

control is a percent o f the Voltage/Amperage

Adjustment control setting (the value selected on Voltage/Amperage Adjustment

control is maximum available on remote). In

the MIG mode, remote control provides full

range of unit output regardless of V/A Adjust

control setting.

7 Inductance/Dig Control

Control adjusts Dig when a Stick (SMAW)

welding position is selected on mode switch.

When set lower, short-circuit amperage at

low arc voltage is the same as normal welding

amperage.

When set higher, short-circuit amperage is increased at low arc voltage to assist with arc

starts as well as reduce sticking while welding (see volt-ampere curves in Section 3-3).

Select setting best suited for application.

Control adjusts inductance when a MIG

(GMAW) position is selected on the mode

switch. Inductance determines the “wetness”

of the weld puddle. When set higher, “wet-

ness” (puddle fluidity) increases.

When pulsed MIG, or one of the TIG (GTAW)

processes is selected, this control is not functional.

TM-180 670 Page 13XMT 304

4-2. Meter Functions

NOTE

The meters display the actual weld output values for approximately three seconds

after the arc is broken.

Mode Meter Reading At Idle Meter Reading While Welding

VA

10.3 85

Actual Volts Actual Amps

VA

10.3 85

Actual Volts Actual Amps

VA

24.5 250

Actual Volts Actual Amps

VA

24.5 250

Actual Volts Actual Amps

VA

24.5 85

Actual Volts Actual Amps

Lift-Arc T rigger

Hold TIG (GTA W)

TIG (GTAW)

MIG (GMAW)

Pulsed MIG

(GMAW-P)

Remote

Control SMAW

VA

85

Blank Preset Amps

VA

85

Blank Preset Amps

VA

24.5

Preset Volts Blank

VA

PPP PPP

Pulse Display Pulse Display

VA

85

Blank Preset Amps

Panel Control

SMAW

VA

85.0 85

Actual Volts (OCV) Preset Amps

VA

24.5 85

Actual Volts Actual Amps

TM-180 670 Page 14 XMT 304

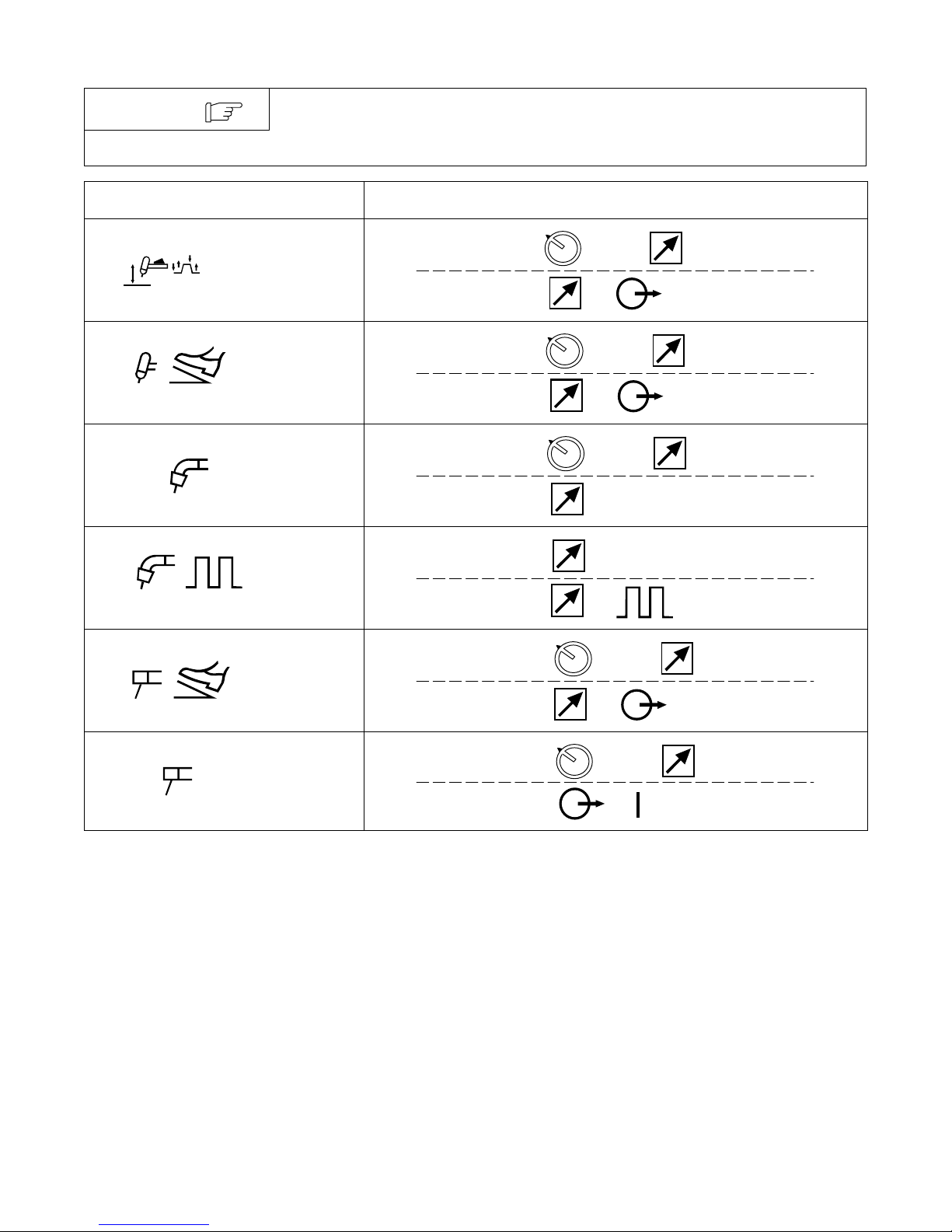

4-3. Mode Switch Settings

NOTE

The SMAW modes provide the Adaptive Hot Start feature, which automatically

increases the output amperage at the start of a weld should the start require it. This

eliminates electrode sticking at arc start.

Mode Output Control

Lift-Arc T rigger

Hold TIG (GTA W)

TIG (GTA W) With

HF Unit,

Pulsing Device,

Or Remote Control

MIG (GMAW)

Pulsed MIG

(GMAW-P)

(Requires an

external

pulsing device.)

Select: or Amp

Requires: Control

Select: or Amp

Requires: Control

Select: or Volt

Requires: Feeder

Select: Volt

Requires: Feeder or Control

Remote

Control SMAW

Panel Control

SMAW

Select: or Amp

Requires: Control

Select: or Amp

Weld

TM-180 670 Page 15XMT 304

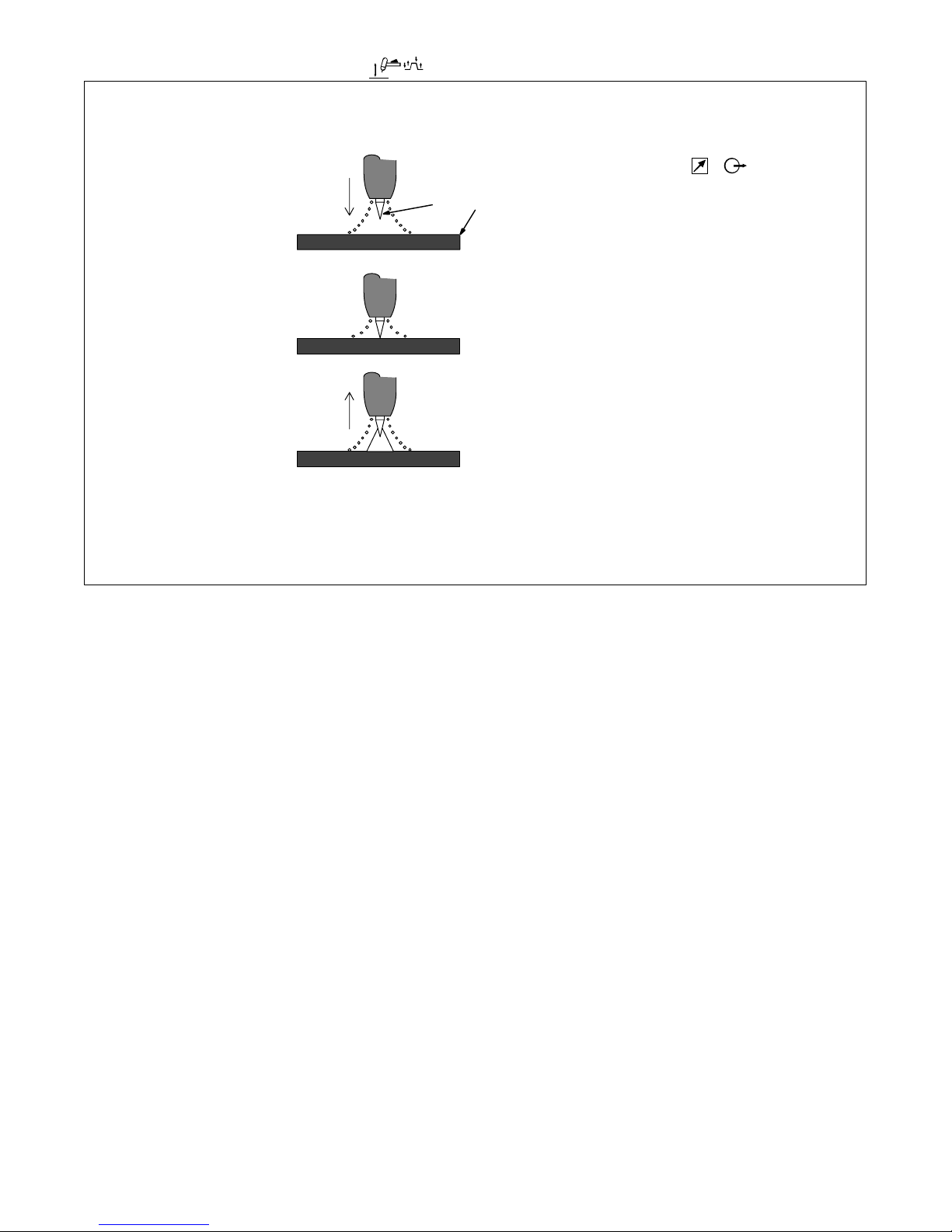

4-4. Lift-Arc Trigger Hold TIG

“Touch”

Do NOT Strike Like A Match!

1

1 – 2

Seconds

1 TIG Electrode

2 Workpiece

. Procedure requires:

control

2

Start sequence:

• Touch tungsten electrode to

workpiece at weld start point.

• Momentarily depress output

switch.

• Slowly lift electrode. An arc will

form when electrode is lifted.

• To stop welding, momentarily

depress output switch and output will shut off.

Note: If output switch is momentarily depressed and tungsten is

not touching workpiece:

Do not touch tungsten to work.

Output will shut off in 3 seconds.

Start sequence over.

Ref. S-156 279

TM-180 670 Page 16 XMT 304

Notes

TM-180 670 Page 17XMT 304

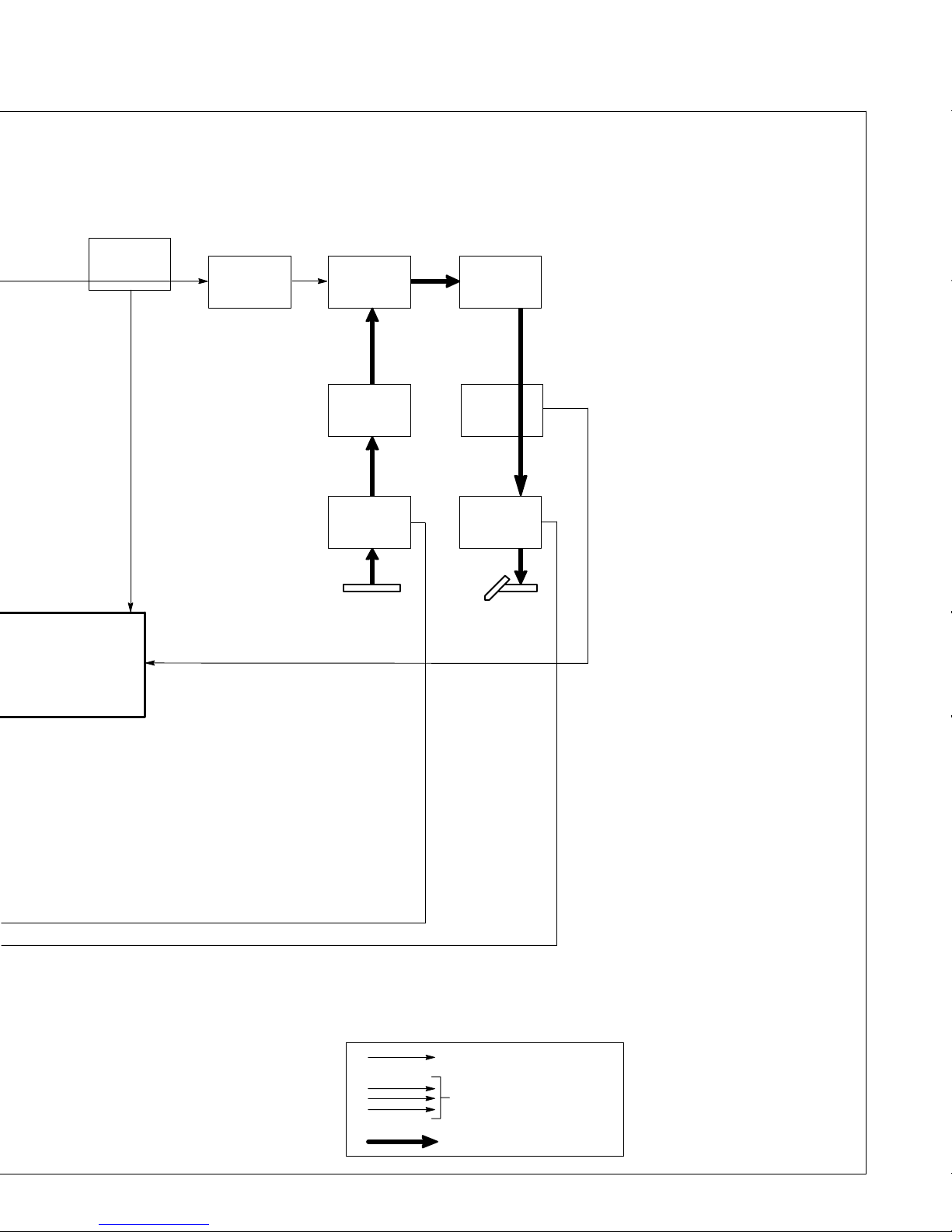

SECTION 5 – THEORY OF OPERATION

1 Power On/Off Switch S1

Provides on/off control of welding

power source.

2 Filter Board PC6

Filters line input power.

3 Input Rectifier SR1

Changes the ac line input power to

full-wave rectified dc.

4 Control Transformer T2

Supplies power to control board

PC1, interconnecting board PC2,

and Remote 14 receptacle RC1.

5 Circuit Breaker CB1

Provides overload protection for

115 volts ac portion of Remote 14

receptacle RC1 and optional 115

volt ac receptacle.

6 Circuit Breaker CB2

Provides overload protection for 24

volts ac portion of Remote 14

receptacle RC1.

7 115 Volt AC Receptacle

Connects auxiliary equipment to

welding power source (optional fo r

CC models).

8 Remote 14 Receptacle RC1

Connects remote amperage or

voltage and contactor controls.

9 Control Board PC1

Controls weld output by changing

gate pulses (frequency of pulses) to

IGBT power modules PM1 and

PM2 after comparing current or

voltage feedback to reference level

set by R2 on PC3.

10 400 V Input Contactor W1

Connects the 190 volts ac secon-

dary voltage from T2 to interconnecting b o ard PC2 to balance voltage on input capacitors C3 and C4.

Effective w/KK104771, this circuit

has been removed.

11 Fan Motor FM

Provides cooling of internal compo-

nents.

12 Display Board PC3

Consists of voltmeter V, ammeter

A, Inductance/Dig control R44,

Voltage/Amperage Adjustment

control R2, Mode switch S3, and

Voltage/Amperage Control switch

S2.

13 Voltmeter V, Ammeter A

See Section 4-2.

14 Inductance/Dig Control R44

(CC/CV Models) Or Dig

Control R44 (CC Models)

In CV mode, R44 functions as an inductance control modifying the response of the arc. In CC mode, R44

functions as a dig control.

Three-Phase

Line Input

Power

8

Remote 14

Receptacle

RC1

1

Power On/

Off Switch

2

Filter Board

PC6

7

115 Volts AC

Receptacle

S1

4

115

VAC24VAC

5

Circuit

Breaker

CB1

6

Circuit

Breaker

CB2

3

SCR/

Integrated

Rectifier SR1

Control

Transformer T2

VAC

CenterTapped

9

12

13

Voltmeter

V

14

Inductance/

Dig Control

R44

16

Mode Switch

S3

18

Input

Capacitors

C3, C4

21

190

10

VAC

Input

Contactor

W1

18

190

VAC

Ribbon

Cable

Display Board PC3

13

Ammeter

15

Amperage

Adjustment

Control R2

17

Amperage

Switch S2

19

Inductor L1,

Choke T3

Interconnecting

Board PC2

23 23

IGBT Power

Module PM1

22

IGBT Board

PC4 PC5

Gating

Signals

Control Board PC1

A

Voltage/

Voltage/

Control

20

Inductors

L3, L4

IGBT Power

Module PM2

22

IGBT Board

11

Fan Motor

FM

Gating

Signals

TM-180 670 Page 18 XMT 304

24

Current

Transformer

CT1

T1 Primary

Current

Feedback

25

Series

Resonant

Capacitor C1

Current Feedback

Voltage Feedback

Voltage Feedback

26 27

Main

Transformer

T1

28

Stabilizer

Z1

30

Negative (–)

Weld Output

Receptacle

Work

29

30

AC Or DC Control Circuits

3φ Power

Weld Current Circuit

Output

Diodes

D1, D2

Hall

Device

HD1

Positive (+)

Weld Output

Receptacle

Electrode

15 Voltage/Amperage Adjustment

Control R2 (CC/CV Models) Or

Amperage Adjustment Control

R2 (CC Models)

Selects weld output voltage or amperage level. Setting defines maximum output when remote voltage

and/or amperage control is used and

Mode switch S3 is in a CC position.

16 Mode Switch S3

Selects type of weld output, meter

function, and remote contactor or

front panel for welding process.

17 Voltage/Amperage Control

Switch S2 (CC/CV Models) Or

Amperage Control Switch S2

(CC Models)

Selects front panel or remote voltage

or amperage control.

18 Input Capacitors C3, C4

Filter the dc output voltage of SR1.

19 Inductor L1, Choke T3

Limit peak current in SR1, C3, and

C4, and filter line input power.

20 Inductors L3, L4

Limit voltage and current in IGBT’s

during turn-on and turn-off.

21 Interconnecting Board PC2

Provides electrical connections for

SR1, T1, C1, C3, C4, L1, L3, L4, T3,

and IGBT’s. Precharge and bleeder

resistors are mounted on PC2.

22 IGBT Boards PC4, PC5

Provide interconnection of gate

pulses from PC1 to PM1 and PM2.

23 IGBT Power Modules PM1,

PM2

Use very fast on/off switching action

to effectively turn the dc into ac.

24 Current Transformer CT1

Provides current feedback to PC1

from the primary of T1 for control circuit timing and to limit primary current.

25 Series Resonant Capacitor C1

Reduces losses in IGBT power mod-

ules PM1 and PM2.

26 Main Transformer T1

Energized b y on/off switching action

of PM1 and PM2, and supplies power to weld output circuit.

27 Output Diodes D1, D2

Rectify output of T1.

28 Stabilizer Z1

Smooths out welding current.

29 Hall Device HD1

Provides weld or secondary current

feedback signal to PC1.

30 Positive (+) And Negative (–)

Weld Output Receptacles

Provide weld output and allow

changing of output polarity.

TM-180 670 Page 19XMT 304

SECTION 6 – EXPLANATION OF ELECTRICAL PARTS

6-1. Safety Precautions – Read Before Using This Guide

Y WARNING: ELECTRIC SHOCK can kill.

D Disconnect input power or stop engine before servicing.

D Do not touch live electrical parts.

D Do not operate machines with covers removed.

D Have only qualified persons install, use, or service equipment.

6-2. Explanation Of Electrical Parts

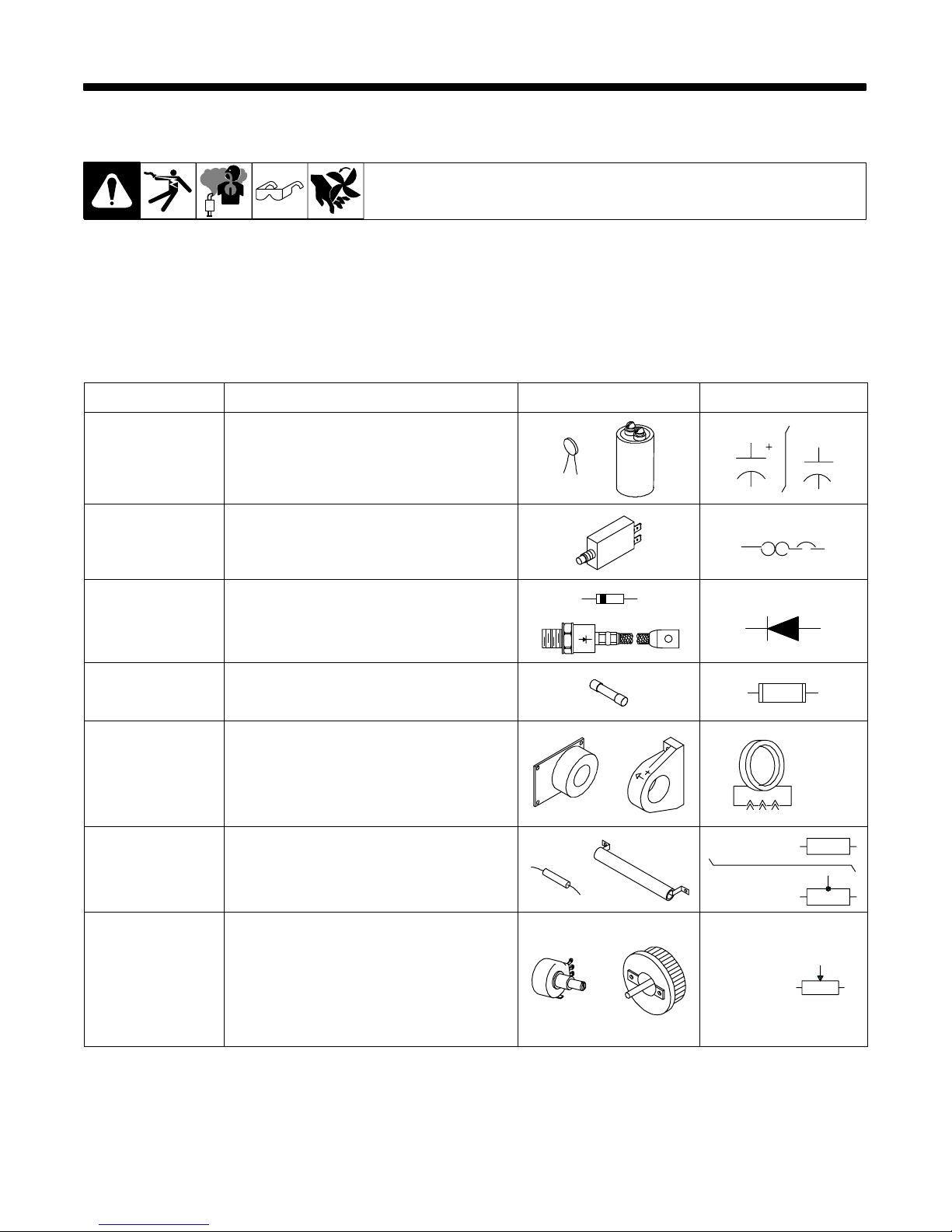

P ART NAME FUNCTION PICTURE CIRCUIT SYMBOL

elect_parts 1/01

CAPACITOR A device that stores electrical energy. Large

capacitors or a “bank” of capacitors can be

used to “smooth out” the DC welding arc in a

MIG welding power source. Smaller “disk”

capacitors can be used for HF protection.

CIRCUIT BREAKER A protection device that breaks a circuit when

current levels exceed its rating. Unlike a fuse

that needs to be replaced when blown, a

circuit breaker can be reset.

DIODE A device that allows current to flow in one

direction only. Most common use is to

change AC to DC.

FUSE A protection device, usually an enclosed

piece of wire that melts and breaks the circuit

when the current exceeds the fuse rating.

HALL DEVICE Produces a small DC voltage proportional to

the current it is sensing (usually welding

current). This feedback signal can be used to

regulate the welding output (line voltage

compensation). It may even be used to drive

an ammeter.

RESISTOR A device which resists the flow of electric

current. Uses include limiting the current for a

motor brake circuit in a wire feeder and for

discharging a capacitor.

POLARIZED NON-POL.

C1 C1

CB1

D1

F1

HD1

FIXED

FIXED TAPPED

R1

R1

POTENTIOMETER

OR

RHEOSTAT

Both devices have a moveable brush that

makes contact along a resistor, allowing you

to easily change the resistance measured at

the brush (sometimes referred to as a wiper).

Their primary purpose is to give the operator

a way to adjust welding parameters such as

wire speed, preflow time, voltage,

inductance, etc.

TM-180 670 Page 20 XMT 304

VARIABLE

R1

Loading...

Loading...