Miller Welding System Safety Quick-manual

Safety Quick-Guide

For Arc

Welding

and Cutting

the

Safe Way!

Visit our websites at

www.MillerWelds.com

www.HobartWelders.com

Be sure this guide reaches the operator.

Page 1

Safety Quick-Guide

Thank you for using Miller or Hobart arc welding and cut-

ting equipment.

We ask you to work like a pro and pros weld and cut safely. Please

read and comply with the sample safety procedures outlined in this

guide and the equipment Owner’s Manual.

Always read and follow the Owner’s Manual, the safety labels on the

product, and all applicable safety standards, especially ANSI Z49.1,

Safety in Welding, Cutting, and Allied Processes (we recommend you

get a copy and keep it handy). A list of the safety standards and where

to get them is located in Section 7 of this guide.

Thank you for working safely.

CONTENTS

1. General Safe Practices 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Arc Welding Hazards 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Engine Hazards 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Plasma Arc Cutting Hazards 6. . . . . . . . . . . . . . . . . . . . . . . .

5. Trailer Safety 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Special Situations & Equipment 11. . . . . . . . . . . . . . . . . . . . .

7. Principal Safety Standards 12. . . . . . . . . . . . . . . . . . . . . . . . .

8. Lens Shade Selector Guide 13. . . . . . . . . . . . . . . . . . . . . . . . .

9. Weld Cable Selector Guide 14. . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Safety Quick-Guide

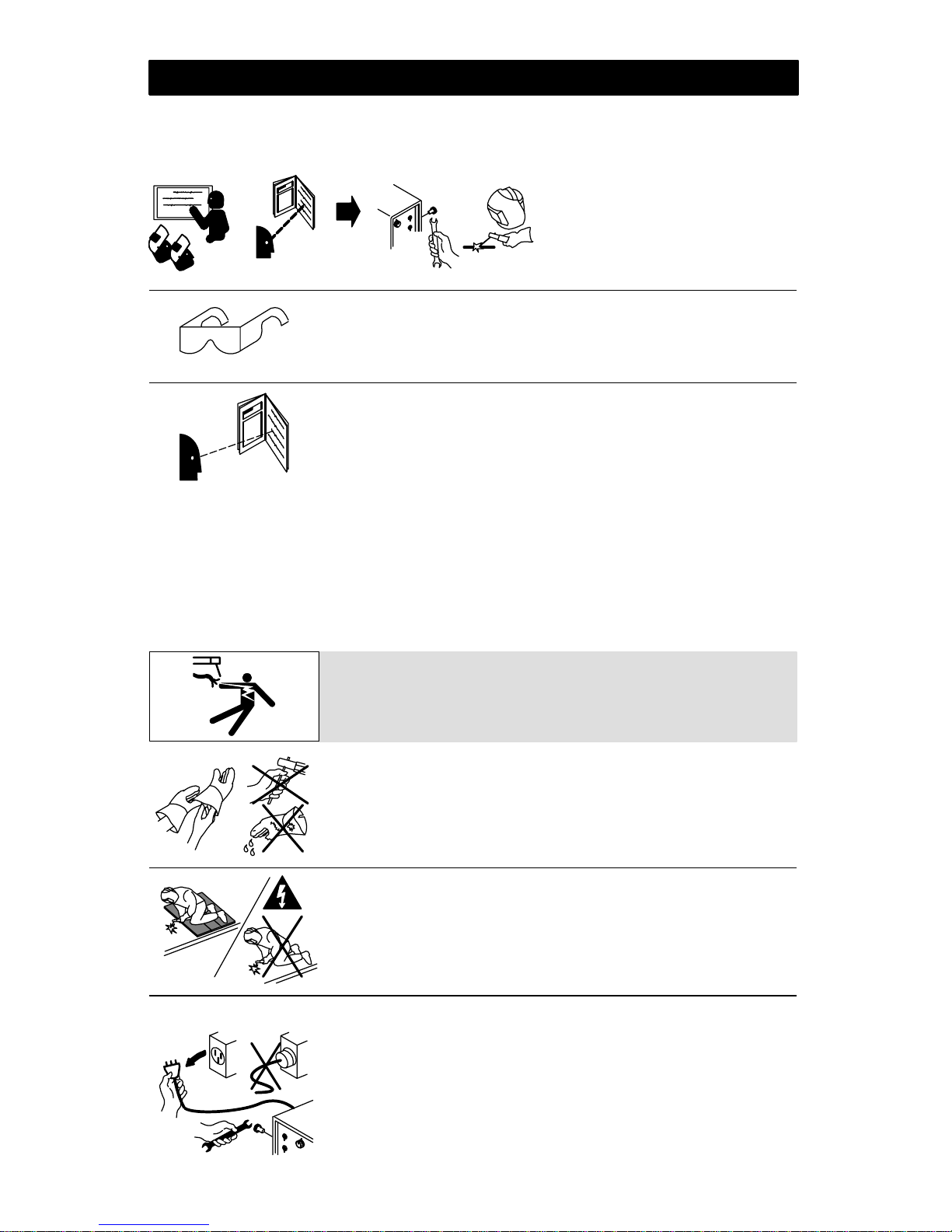

1. General Safe Practices

Become trained and read the

instructions before working on the

machine or welding or cutting

.

Read Material Safety Data Sheet

s

(MSDSs) for metals, consum

-

ables, and coatings.

+

ANSI Z49.1

OSHA 29CFR 1910

MSDSs

Owner’s Manual

Wear approved safety glasses with side shields under you

r

welding helmet or face shield and at all times in the work area.

Read the equipment Owner’s Manual for more complete safet

y

information.

Wear a safety harness if working above floor level.

Keep children away from all equipment and processes.

Do not install or place machine on or over combustible surfaces

.

Have only qualified persons install, use, or service all equipment

.

2. Arc Welding Haz ards

Electric shock from welding electrode or wiring

can kill.

Wear dry insulating gloves. Do not touch electrode with bare hand.

Do not wear wet or damaged gloves.

Do not touch live electrical parts.

Do not use AC weld output in damp, wet, or confined spaces.

Protect yourself from electric shock by insulating yourself from

work and ground. Use non-flammable, dry insulating material if

possible, or use dry rubber mats, dry wood or plywood, or other dry

insulating material big enough to cover your full area of contact

with the work or ground, and watch for fire.

Disconnect input plug or power before working on machine.

Do not make input connections if color blind.

Frequently inspect input power cord for damage or bare wiring —

repair or replace cord immediately if damaged. Be sure input

ground wire is properly connected to a ground terminal in

disconnect box or receptacle.

Properly install and ground all equipment according to its Owner’s

Manual and national, state, and local codes.

Page 3

Safety Quick-Guide

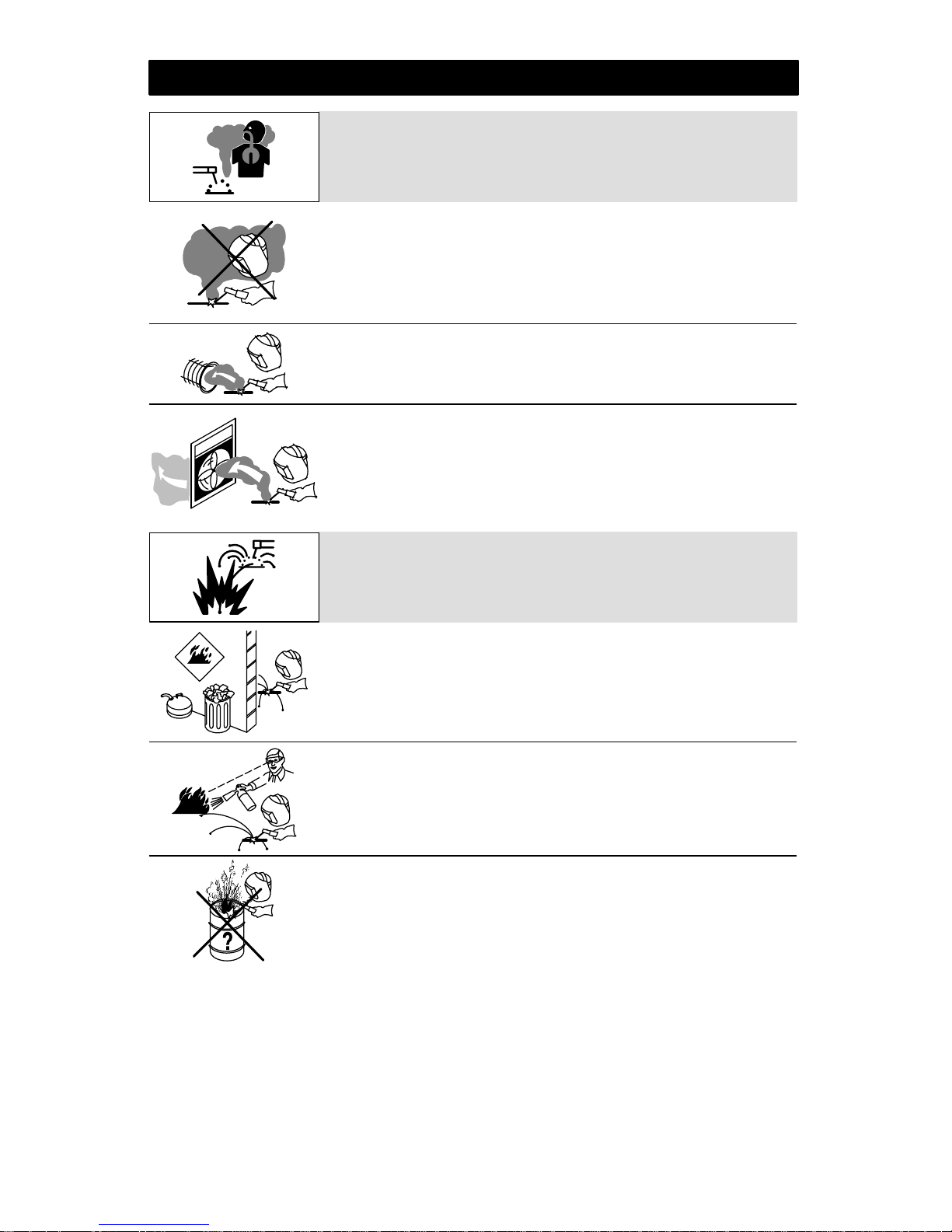

Use a ventilating fan to remove fumes from the breathing zone and

welding area.

If adequacy of ventilation or exhaust is uncertain, have your

exposure measured and compared to the Threshold Limit Values

(TLV) in the Material Safety Data Sheet (MSDS).

Keep your head out of the fumes. Do not breathe the fumes. Use

enough ventilation, exhaust at the arc, or both, to keep fumes and

gases from your breathing zone and the general area.

Read Material Safety Data Sheets (MSDSs) for metals, consumables, and coatings.

Use enough forced ventilation or local exhaust (forced suction) at

the arc to remove the fumes from your breathing area.

Breathing welding fumes can be hazardous to

your health.

Do not weld on drums, tanks, or any closed containers unless a

qualified person has tested it and declared it or prepared it to be

safe (see AWS F4.1 listed in Section 7).

Do not weld near flammable material. Move flammables at least 35

feet (1 1 meters) away or protect them with flame-proof covers (see

NFPA 51B listed in Section 7).

Welding sparks can cause fires. Have a fire extinguisher nearby,

and have a trained fire watch ready to use it.

Welding can cause fire or explosion.

Page 4

Safety Quick-Guide

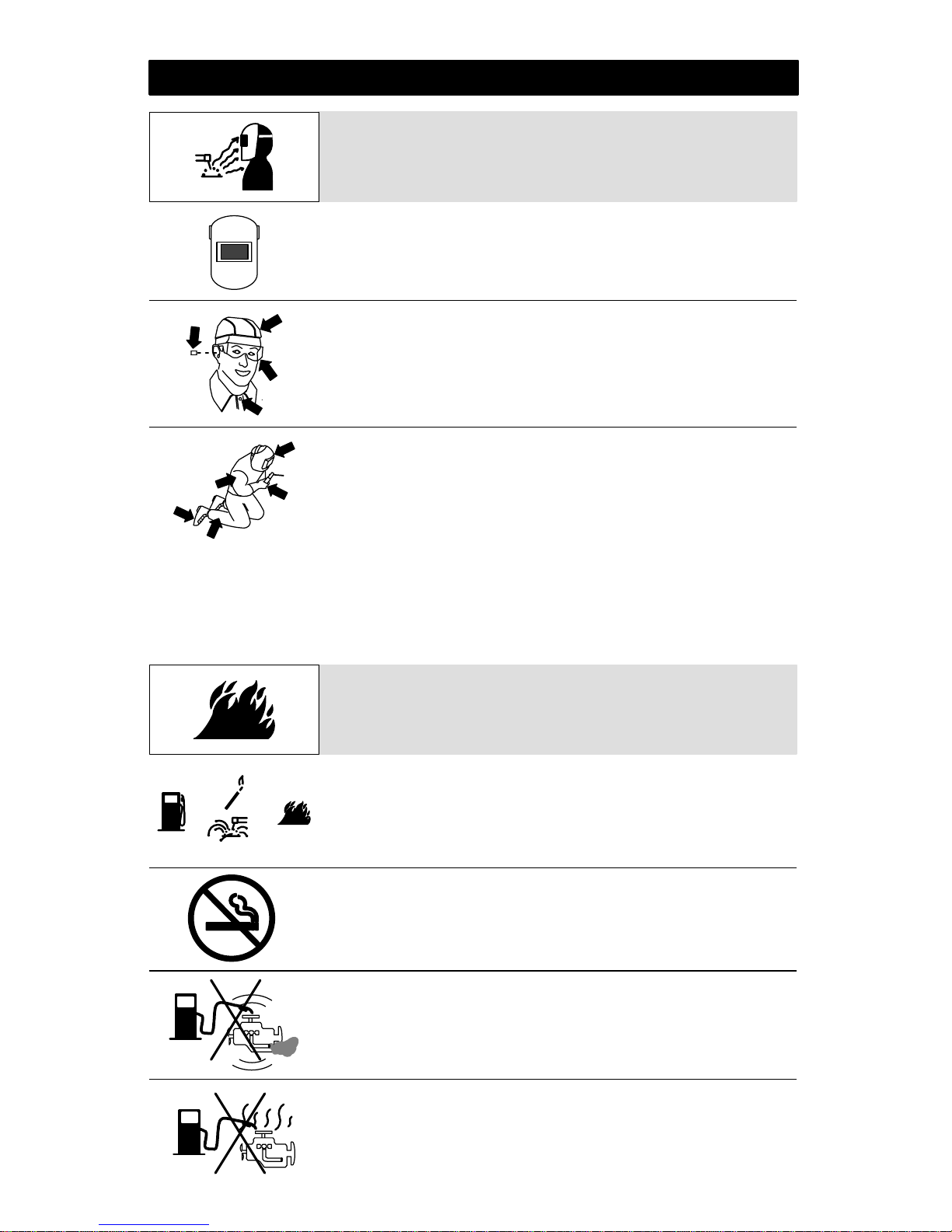

Wear complete body protection. Wear oil-free protective clothing

such as leather gloves, heavy shirt, cuffless pants, and high boots.

Wear welders cap and safety glasses with side shields. Use ear

protection when welding out of position or in confined spaces.

Button shirt collar.

Use welding helmet with correct shade of filter (see Section 8 to

choose the correct shade).

Arc rays can burn eyes and skin.

3. Engine Hazards

Engine fuel plus flames or sparks can cause fire or explosion.

Do not weld near engine fuel.

Do not spill fuel. If fuel is spilled, clean it up and do not start engine

until fumes are gone.

+ =

Do not smoke while fueling or if near fuel or fumes.

Stop engine before fueling.

Do not fuel a hot engine. Stop engine and let it cool off before

checking or adding fuel.

Fuel can cause fire or explosion.

Loading...

Loading...