Miller Trailblazer 325 Brochure

Processes (X-Ray Quality)

Stick (SMAW)

MIG (GMAW)

Flux-cored (FCAW)

RMD

®

*

Pulsed MIG (GMAW-P)*

DC TIG (GTAW)

Air carbon arc (CAC-A) cutting and gouging

Rated: 3/16-inch carbons,

Capable: 1/4-inch carbons

Air plasma cutting and gouging with

optional Spectrum

®

models

Rated: 5/8-inch mild steel

Output Range DC stick 30 –325 A

MIG/flux-cored 10–35 V

DC TIG 10–325 A

Generator Power Output Rated at 104°F (40°C)

12,000 watts peak, 10,500 watts continuous

Excel™Power (Recommended option)

2,400 watts (120 V, 20 A) 60 Hz pure sine power**

*Available only on ArcReach models.

**Engine speed rpm may vary while welding.

Industrial

Applications

Fabrication

Maintenance

Repair

Structural steel work

Sheet metal

Pipe

Quick

Specs

Trailblazer®325 Diesel

Diesel Engine-Driven

Welder/AC Generator

Issued July 2018 • Index No. ED/4.8

Welder/generator is warranted for three years, parts and labor.

Engine is warranted separately by the engine manufacturer.

Trailblazer 325 Diesel with optional

ArcReach and Excel power shown.

The Trailblazer exclusive

technologies — Auto-Speed

™

and optional Excel™power —

deliver superior runtimes, increased

fuel efficiency, and improved

welder/generator performance.

No other compact machine in

the 300-amp class delivers more

welding power or more auxiliary

power with better fuel efficiency

and less noise — for productive,

profitable, quieter jobsites.

Remote control of the power source

without a cord.

See page 2.

Trailblazer welder/generators deliver unbeatable arc performance

providing the smoothest, most stable arc in the industry.

Miller Electric Mfg. LLC

An ITW Welding Company

1635 West Spencer Street

P.O. Box 1079

Appleton, WI 54912-1079 USA

MillerWelds.comEquipment Sales US and Canada

Phone: 866-931-9730

FAX: 800-637-2315

International Phone: 920-735-4554

International FAX: 920-735-4125

2

Trailblazer®Technologies

Excel™power (option)

Power at idle — a Miller exclusive. Unlike competitive machines that

provide auxiliary power only at 3,600 rpm (max), Excel power delivers a

full 2,400 watts (20 A) of 120-volt inverter-based, pure sine wave power

at 2,400 rpm while not welding. With Excel power you can operate jobsite

tools like grinders at quiet, fuel-saving speeds.

Refueling time and operating costs are reduced with Excel power, which

means more productivity and profitability. Plus everyone on the jobsite

gets a better working environment because noise levels and exhaust

emissions are lowered. Excel power — available only from Miller.

Dynamic DIG

™

Ultra-adaptive arc control. Unlike conventional DIG

that provides a preset amount of short-clearing

current, Miller’s proprietary Dynamic DIG works on

a time-based algorithm that automatically adjusts

the amount of current required to clear a short. What does this mean?

A smoother more consistent arc that can be tailored to match application,

material, fit-up, and welder technique.

Based on generator-only use for total runtime.

Auto-Speed™technology

Matches engine speed to load — a Miller exclusive. Get the welding

power you need — plus reduced fuel consumption and lower noise

levels for a more-profitable, safer jobsite.

Unlike competitive machines that operate at 3,600 rpm (max) under

any load, Miller-exclusive Auto-Speed technology responds to weld

requirements by automatically adjusting engine speed to one of five rpm

levels so the engine never works harder than necessary. Weld up to 135 amps

while the engine remains at idle (1,800 rpm), saving up to 15 percent

in fuel over competitive units, and drastically reducing jobsite noise.

Unbeatable arc performance

Wide amperage output with better welding deposition rates means you

can get jobs done faster, saving time and money. The Trailblazer also has

precise arc control, which allows you to fine-tune the arc to match your

personal preferences and quickly dial in the perfect parameters to

optimize weld quality and maximize productivity across a variety of

applications and welding processes.

ArcReach®remote control technology (option)

Remote control of the power source

without a control cord. An ArcReach

system allows you to change weld

settings from your ArcReach feeder or remote, saving a trip to the

power supply. ArcReach technology uses the existing weld cable to

communicate welding control information between the feeder or remote

and the power source. This technology eliminates the need for control

cords, and their associated problems and costs.

ArcReach

engine drive

ArcReach feeder

or remote

1,800

RPM

Welding below

135 A

Welding at idle speed

2,400

RPM

2,800

RPM

3,600

RPM

Welding between

136–180 A

Welding above

235 A

Welding between

181–210 A

3,200

RPM

Welding between

211–235 A

Auto-Speed in XX18 and TIG modes.

3

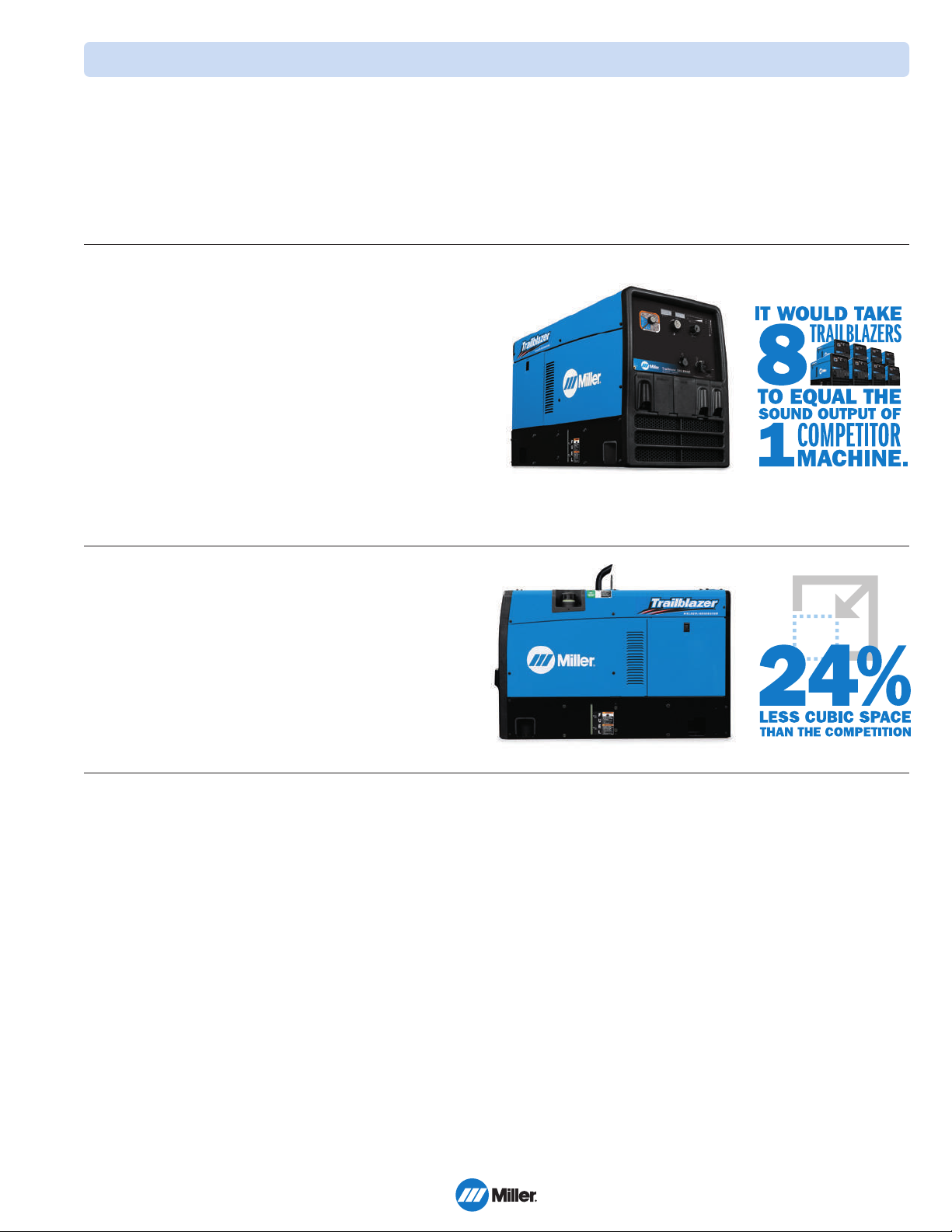

Safer, more productive jobsites

Quieter jobsites are safer and more productive because work crews can

communicate easier, and work can start earlier and end later — even in

noise-sensitive areas. Miller-exclusive Auto-Speed technology makes this

welder/generator the quietest Trailblazer diesel yet — rated at 70 db at

idle (1,800 rpm). If your jobsite needs a welder/generator, it needs a

Trailblazer welder/generator — because no other diesel-fueled choice in

this category is as quiet.

Optional ArcReach®remote control technology eliminates the need to

trace or move heavy secondary weld leads bundled with control cords

on the jobsite. Complete remote control of welding processes and

parameters improves safety by limiting jobsite movement and reducing

slip, trip and fall hazards.

More portable, uses less truck and jobsite space

Trailblazer welder/generators are up to 24 percent smaller and

10 percent lighter then competitive machines — which means moving

them is faster and easier, for maximum productivity. And because

they take up less space, Trailblazer welder/generators let work trucks

carry more equipment and gear — so your work crews can be ready

for anything.

Cleaner and stronger generator power

Combined with a 25-horsepower engine, Trailblazer welder/generators

offer 12,000 watts of clean, truly usable generator power that is

Accu-Rated™, not inflated: tested to deliver uninterrupted peak output for

a minimum of 30 seconds for big loads, so you can get more jobs done.

An independent welder and generator power system ensures no

interaction between jobsite tools and the welding arc, while advanced

generator technology virtually eliminates power spikes and other electrical

imperfections — so welds are cleaner and jobsite tools can run without

interruption, maximizing quality, productivity and profit.

Fewer refueling trips

No other diesel welder/generator in the 300-amp class lets your crews

spend more time working and less time refueling — because only

Trailblazer welder/generators provide Auto-Speed™technology, plus the

Excel™power option, to deliver maximum runtime.

Maximum cost savings

Less money spent on fuel means more profit for you. Every Trailblazer

welder/generator has fuel-saving Auto-Speed technology; add optional

Excel power to save even more on fuel costs and enjoy a combination of

advanced, profit-enhancing features that are only available on a Trailblazer

welder/generator.

Trailblazer®Benefits

Loading...

Loading...