Page 1

OM-255503B

2018−12

®

Auto-Darkening Helmets

Model: T94t, T94i Series

T94 T94i

To help us serve you better, go to www.MillerWelds.Com/Register

Page 2

TABLE OF CONTENTS

SECTION 1 − WELDING HELMET SAFETY PRECAUTIONS −

READ BEFORE USING 1........................................................

1-1. Symbol Usage 1............................................................

1-2. Arc Welding Hazards 1.......................................................

1-3. Proposition 65 Warnings 2....................................................

1-4. Lens Shade Selection Table 3.................................................

1-5. Principal Safety Standards 3..................................................

SECTION 2 − CONSIGNES DE SÉCURITÉ POUR

LE CASQUE DE SOUDAGE − LIRE AVANT UTILISATION 4..........................

2-1. Symboles utilisés 4..........................................................

2-2. Dangers relatifs au soudage à l’arc 4...........................................

2-3. Proposition californienne 65 Avertissements 5....................................

2-4. Tableau de sélection d’opacité de lentille 6.......................................

2-5. Principales normes de sécurité 6...............................................

SECTION 3 − SPECIFICATIONS 7.................................................

SECTION 4 − OPERATING INSTRUCTIONS 8......................................

4-1. Helmet Configurations 8......................................................

4-2. Helmet Controls 9...........................................................

4-3. Mode Button And Grind / Low Battery Light 10.....................................

4-4. Mode Control Settings 11......................................................

4-5. Variable Shade Control 12.....................................................

4-6. Lens Delay Control 13.........................................................

4-7. Sensitivity Control 14..........................................................

4-8. Typical Lens Adjustment Procedure 15...........................................

4-9. Info Control Button 16.........................................................

4-10. Clock Control 17.............................................................

4-11. Arc Time And Arc Count Control 18..............................................

SECTION 5 − ADJUSTING HEADGEAR 19..........................................

5-1. Adjusting Headgear On T94 Series Helmets 19....................................

SECTION 6 − REPLACING THE GRINDING SHIELD OR LENS COVERS 20.............

6-1. Replacing Grinding Shield On T94i Helmet 20.....................................

6-2. Replacing Lens Covers On Quick Release Helmets 21.............................

SECTION 7 − REPLACING THE BATTERY 22.......................................

SECTION 8 − INSTALLING OPTIONAL MAGNIFYING LENS 23........................

SECTION 9 − MAINTENANCE 23..................................................

SECTION 10 − TROUBLESHOOTING 24............................................

SECTION 11 − PARTS LISTS 25...................................................

SECTION 12 − LIMITED WARRANTY 28............................................

Page 3

SECTION 1 − WELDING HELMET SAFETY PRECAUTIONS −

READ BEFORE USING

helmet 2018-08

Protect yourself and others from injury — read, follow, and save these important safety

precautions and operating instructions.

1-1. Symbol Usage

DANGER! − Indicates a hazardous

situation which, if not avoided, will

result in death or serious injury. The

possible hazards are shown in the

adjoining symbols or explained in

the text.

Indicates a hazardous situation

which, if not avoided, could result in

death or serious injury. The possible

hazards are shown in the adjoining

symbols or explained in the text.

NOTICE − Indicates statements not related to

personal injury.

Indicates special instructions.

This group of symbols means Warning! Watch

Out! ELECTRIC SHOCK, MOVING PARTS,

and HOT PARTS hazards. Consult symbols

and related instructions below for necessary

actions to avoid the hazards.

1-2. Arc Welding Hazards

Only qualified persons should install, operate, maintain, and repair this equipment. A

qualified person is defined as one who, by possession of a recognized degree, certificate,

or professional standing, or who by extensive knowledge, training and experience, has

successfully demonstrated ability to solve or resolve problems relating to the subject

matter, the work, or the project and has received safety training to recognize and avoid

the hazards involved.

ARC RAYS can burn eyes and skin.

Arc rays from the welding process produce intense visible and invisible (ultraviolet and infrared) rays that can burn eyes and skin. Sparks fly off from the weld.

Wear a welding helmet fitted with a proper shade of filter to protect your face and eyes when

welding or watching (see ANSI Z49.1 and Z87.1 listed in Safety Standards). Refer to Lens

Shade Selection table in Section 1-4.

Wear approved safety glasses with side shields under your helmet.

Use protective screens or barriers to protect others from flash, glare, and sparks; warn

others not to watch the arc.

Wear body protection made from durable, flame−resistant material (leather, heavy cotton,

wool). Body protection includes oil-free clothing such as leather gloves, heavy shirt, cuffless

trousers, high shoes, and a cap.

• Before welding, adjust the auto-darkening lens sensitivity setting to meet the application.

• Stop welding immediately if the auto-darkening lens does not darken when the arc is struck.

NOISE can damage hearing.

Noise from some processes or equipment can damage hearing.

Wear approved ear protection if noise level is high.

OM-255503 Page 1

Page 4

WELDING HELMETS do not provide unlimited eye, ear, and

face protection.

Arc rays from the welding process produce intense visible and invisible (ultraviolet

and infrared) rays that can burn eyes and skin. Sparks fly off from the weld.

Use helmet for welding/cutting applications only. Do not use helmet for laser welding/cutting.

Use impact resistant safety spectacles or goggles and ear protection at all times when using

this welding helmet.

Do not use this helmet while working with or around explosives or corrosive liquids.

This helmet is not rated for overhead welding. Do not weld in the direct overhead position

while using this helmet unless additional precautions are taken to protect yourself from arc

rays, spatter, and other hazards.

Inspect the auto-lens frequently. Immediately replace any scratched, cracked, or pitted cover

lenses or auto-lenses.

Lens and retention components must be installed as instructed in this manual to ensure

compliance with ANSI Z87.1 protection standards.

READ INSTRUCTIONS.

Read and follow all labels and the Owner’s Manual carefully before in-

stalling, operating, or servicing unit. Read the safety information at the beginning of the manual and in each section.

Use only genuine replacement parts from the manufacturer.

Perform installation, maintenance, and service according to the Owner’s Manuals, industry

standards, and national, state, and local codes.

FUMES AND GASES can be hazardous.

Welding produces fumes and gases. Breathing these fumes and gases can be

hazardous to your health.

Keep your head out of the fumes. Do not breathe the fumes.

Ventilate the work area and/or use local forced ventilation at the arc to remove welding fumes

and gases. The recommended way to determine adequate ventilation is to sample for the composition and quantity of fumes and gases to which personnel are exposed.

If ventilation is poor, wear an approved air-supplied respirator.

Read and understand the Safety Data Sheets (SDSs) and the manufacturer’s instructions for

adhesives, coatings, cleaners, consumables, coolants, degreasers, fluxes, and metals.

Work in a confined space only if it is well ventilated, or while wearing an air-supplied respirator.

Always have a trained watchperson nearby. Welding fumes and gases can displace air and

lower the oxygen level causing injury or death. Be sure the breathing air is safe.

Do not weld in locations near degreasing, cleaning, or spraying operations. The heat and rays

of the arc can react with vapors to form highly toxic and irritating gases.

Do not weld on coated metals, such as galvanized, lead, or cadmium plated steel, unless the

coating is removed from the weld area, the area is well ventilated, and while wearing an airsupplied respirator. The coatings and any metals containing these elements can give off toxic

fumes if welded.

1-3. Proposition 65 Warnings

WARNING: Cancer and Reproductive Harm − www.P65Warnings.ca.gov

OM-255503 Page 2

Page 5

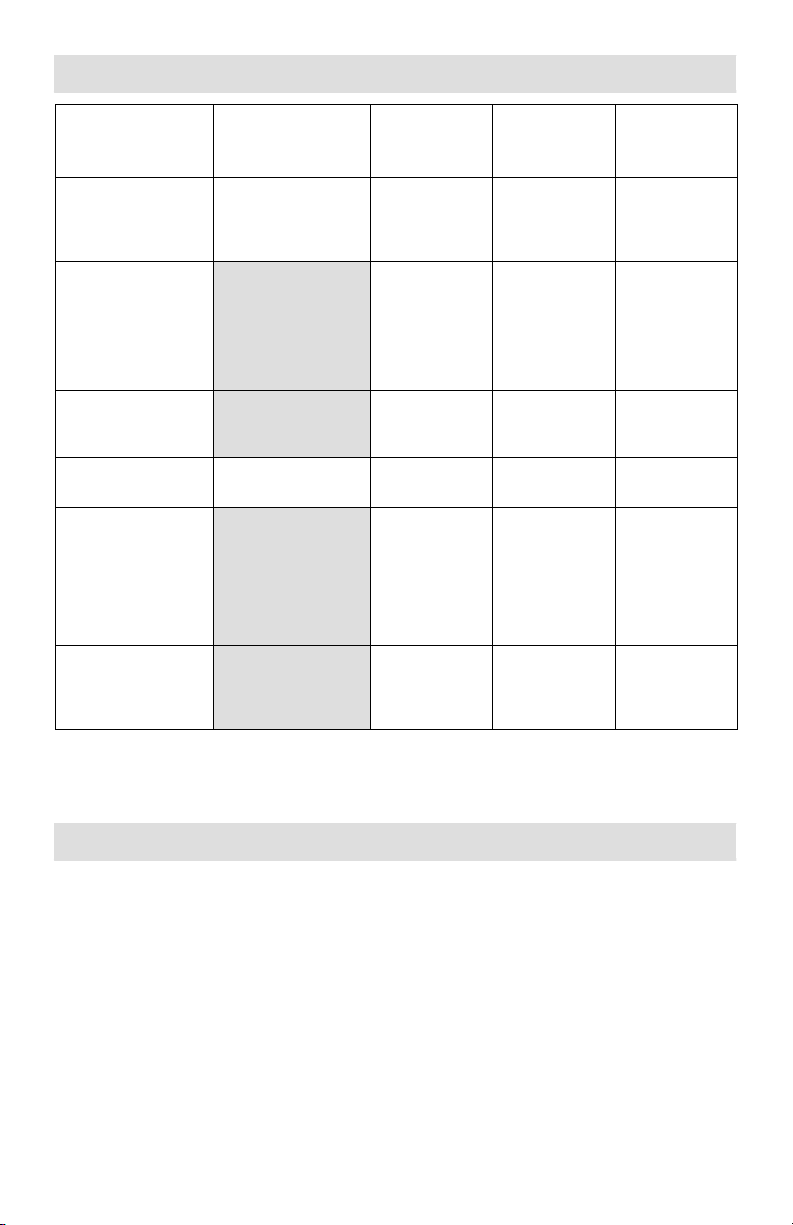

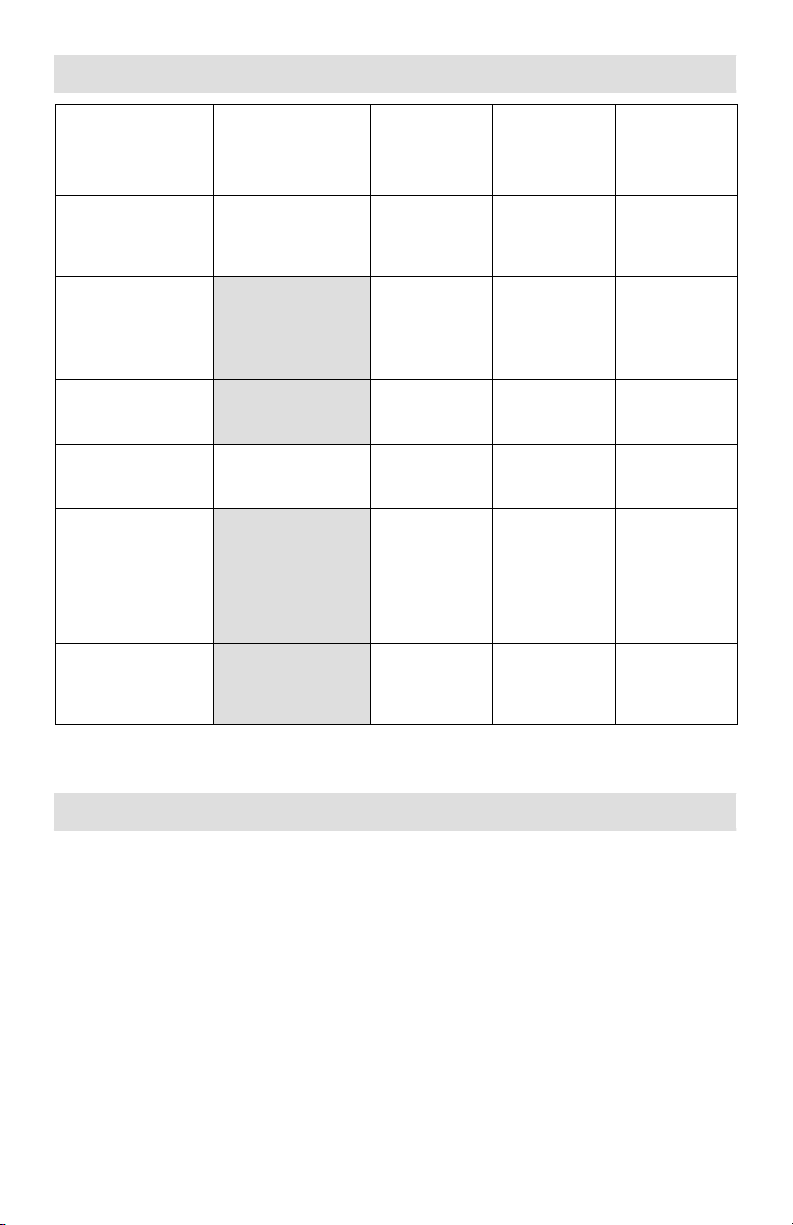

1-4. Lens Shade Selection Table

Process

Shielded Metal Arc

Welding (SMAW)

Gas Metal

Arc Welding

(GMAW)

Flux Cored

Arc Welding

(FCAW)

Gas Tungsten Arc

Welding (TIG)

Air Carbon

Arc Cutting (CAC-A)

Plasma Arc

Cutting (PAC)

Plasma Arc Welding

(PAW)

Electrode Size

in. (mm)

Less than 3/32 (2.4)

3/32−5/32 (2.4−4.0)

5/32−1/4 (4.0−6.4)

More than 1/4 (6.4)

Light

Heavy

Arc Current

in

Amperes

Less than 60

60−160

160−250

250−550

Less than 60

60−160

160−250

250−500

Less than 50

50−150

150−500

Less than 500

500−1000

Less than 20

20−40

40−60

60−80

80−300

300−400

400−800

Less than 20

20−100

100−400

400−800

Minimum

Protective

Shade No.

7

8

10

11

7

10

10

10

8

8

10

10

11

4

5

6

8

8

9

10

6

8

10

11

Suggested

Shade No.

(Comfort)*

−−

10

12

14

−−

11

12

14

10

12

14

12

14

4

5

6

8

9

12

14

6−8

10

12

14

Reference: ANSI Z49.1:2012

* Start with a shade that is too dark to see the weld zone. Then, go to a lighter shade which gives a

sufficient view of the weld zone without going below the minimum.

1-5. Principal Safety Standards

Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, is available as a free download from the American Welding Society at http://www.aws.org or purchased from Global Engineering

Documents (phone: 1-877-413-5184, website: www.global.ihs.com).

Safe Practice For Occupational And Educational Eye And Face Protection, ANSI Standard Z87.1,

from American National Standards Institute, 25 West 43rd Street, New York, NY 10036 (phone:

212-642-4900, website: www.ansi.org).

Industrial Head Protection, ANSI/ISEA Standard Z89.1, from American National Standards Institute,

25 West 43rd Street, New York, NY 10036 (phone: 212-642-4900, website: www.ansi.org).

OM-255503 Page 3

Page 6

SECTION 2 − CONSIGNES DE SÉCURITÉ POUR

LE CASQUE DE SOUDAGE − LIRE AVANT UTILISATION

helmet_2018−08_fre

Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en

lieu sûr ces consignes relatives aux précautions de sécurité et au mode opératoire.

2-1. Symboles utilisés

DANGER! − Indique une situation

dangereuse qui si on l’évite pas peut

donner la mort ou des blessures graves.

Les dangers possibles sont montrés par

les symboles joints ou sont expliqués

dans le texte.

Indique une situation dangereuse qui si

on l’évite pas peut donner la mort ou des

blessures graves. Les dangers

possibles sont montrés par les

symboles joints ou sont expliqués dans

le texte.

AVIS − Indique des déclarations pas en relation avec

des blessures personnelles.

Indique des instructions spécifiques.

Ce groupe de symboles veut dire Avertissement!

Attention! DANGER DE CHOC ELECTRIQUE,

PIECES EN MOUVEMENT, et PIECES

CHAUDES. Consulter les symboles et les

instructions ci-dessous y afférant pour les actions

nécessaires afin d’éviter le danger.

2-2. Dangers relatifs au soudage à l’arc

L’installation, l’utilisation, l’entretien et les réparations ne doivent être confiés qu’à des personnes

qualifiées. Une personne qualifiée est définie comme celle qui, par la possession d’un diplôme reconnu,

d’un certificat ou d’un statut professionnel, ou qui, par une connaissance, une formation et une expérience approfondies, a démontré avec succès sa capacité à résoudre les problèmes liés à la tâche,

le travail ou le projet et a reçu une formation en sécurité afin de reconnaître et d’éviter les risques

inhérents.

LES RAYONS DE L’ARC peuvent provoquer des brûlures

dans les yeux et sur la peau.

Le rayonnement de l’arc du procédé de soudage génère des rayons visibles et invisibles

intenses (ultraviolets et infrarouges) susceptibles de provoquer des brûlures dans les yeux et

sur la peau. Des étincelles sont projetées pendant le soudage.

Porter un casque de soudage muni d’un écran de filtre approprié pour protéger votre visage et vos yeux

pendant le soudage ou pour regarder (voir ANSI Z49.1 et Z87.1 énuméré dans les normes de sécurité).

Se reporter au tableau de sélection des filtres, Section 2-4.

Porter des protections approuvées pour les oreilles si le niveau sonore est trop élevé.

Avoir recours à des écrans protecteurs ou à des rideaux pour protéger les autres contre les rayon-

nements les éblouissements et les étincelles ; prévenir toute personne sur les lieux de ne pas regarder

l’arc.

Porter un équipement de protection pour le corps fait d’un matériau résistant et ignifuge (cuir, coton ro-

buste, laine). La protection du corps comporte des vêtements sans huile comme par ex. des gants de cuir,

une chemise solide, des pantalons sans revers, des chaussures hautes et une casquette.

Avant de souder, régler la sensibilité du verre à obscurcissement automatique en fonction de l’application.

Si le verre ne s’obscurcit pas à l’amorçage de l’arc, cesser immédiatement de souder.

OM-255503 Page 4

Le BRUIT peut endommager l’ouïe.

Le bruit produit par certains procédés ou équipements peut endommager l’ouïe.

Porter des protecteurs antibruit approuvés si le bruit est trop élevé.

Page 7

LES CASQUES DE SOUDAGE ne procurent pas une

protection absolue des yeux, des oreilles ou du visage.

Le rayonnement de l’arc du procédé de soudage génère des rayons visibles et invisibles

intenses (ultraviolets et infrarouges) susceptibles de provoquer des brûlures dans les yeux et

Utilisez uniquement un casque pour les applications de soudage/découpe.

pour le soudage/ découpage laser.

Porter des lunettes de sécurité et des protecteurs antibruit résistants aux chocs en tout temps pendant

l’utilisation de ce casque de soudage.

Ne pas utiliser ce casque de soudage pendant la manutention ou le travail à proximité de liquides

explosifs ou corrosifs.

Ce casque n’est pas évalué pour le soudage à la verticale. Ne pas souder dans une position directement à la

verticale tout en utilisant ce casque à moins d’avoir pris des précautions supplémentaires au préalable afin de

se protéger contre les rayonnements de l’arc, des projections et d’autres risques.

Vérifier fréquemment l’état de la cellule à obscurcissement automatique. Remplacer immédiatement

toute loupe ou cellule égratignée, fissurée ou piquée.

La lentille et les composants de retention doivent être installés comme indiqué dans ce manuel pour

assurer la conformité avec les normes de protection ANSI Z87.1.

sur la peau. Des étincelles sont projetées pendant le soudage.

Ne pas utiliser de casque

LIRE LES INSTRUCTIONS.

Lire et appliquer les instructions sur les étiquettes et le Mode d’emploi avant l’instal-

lation, l’utilisation ou l’entretien de l’appareil. Lire les informations de sécurité au début

du manuel et dans chaque section.

N’utiliser que les pièces de rechange recommandées par le constructeur.

Effectuer l’installation, l’entretien et toute intervention selon les manuels d’utilisateurs, les normes

nationales, provinciales et de l’industrie, ainsi que les codes municipaux.

LES FUMÉES ET LES GAZ peuvent être dangereux.

Le soudage génère des fumées et des gaz. Leur inhalation peut être dangereux pour votre

santé.

Eloigner votre tête des fumées. Ne pas respirer les fumées.

À l’intérieur, ventiler la zone et/ou utiliser une ventilation forcée au niveau de l’arc pour l’À l’intérieur, ventiler

la zone et/ou utiliser une ventilation forcée au niveau de l’arc pour l’évacuation des fumées et des gaz de

soudage. Pour déterminer la bonne ventilation, il est recommandé de procéder à un prélèvement pour la

composition et la quantité de fumées et de gaz auxquelles est exposé le personnel.

Si la ventilation est médiocre, porter un respirateur anti-vapeurs approuvé.

Lire et comprendre les fiches de données de sécurité et les instructions du fabricant concernant les

adhésifs, les revêtements, les nettoyants, les consommables, les produits de refroidissement, les dégraisseurs, les flux et les métaux.

Travailler dans un espace fermé seulement s’il est bien ventilé ou en portant un respirateur à alimentation

d’air. Demander toujours à un surveillant dûment formé de se tenir à proximité. Des fumées et des gaz de

soudage peuvent déplacer l’air et abaisser le niveau d’oxygène provoquant des blessures ou des

accidents mortels. S’assurer que l’air de respiration ne présente aucun danger.

Ne pas souder dans des endroits situés à proximité d’opérations de dégraissage, de nettoyage ou de pul-

vérisation. La chaleur et les rayons de l’arc peuvent réagir en présence de vapeurs et former des gaz hautement toxiques et irritants.

Ne pas souder des métaux munis d’un revêtement, tels que l’acier galvanisé, plaqué en plomb ou au

cadmium à moins que le revêtement n’ait été enlevé dans la zone de soudure, que l’endroit soit bien ventilé,

et en portant un respirateur à alimentation d’air. Les revêtements et tous les métaux renfermant ces

éléments peuvent dégager des fumées toxiques en cas de soudage.

2-3. Proposition californienne 65 Avertissements

AVERTISSEMENT : cancer et troubles de la reproduction − www.P65Warnings.ca.gov

OM-255503 Page 5

Page 8

2-4. Tableau de sélection d’opacité de lentille

Procédé Taille

Soudage à l’arc avec

électrode enrobée

(SMAW)

Soudage à l’arc sous

gaz avec fil plein

(GMAW)

Soudage à l’arc avec fil

fourré (FCAW)

Soudage à l’arc sous

gaz avec électrode au

tungstène (TIG)

Coupage à l’arc avec

électrode au carbone et

jet d’air (AAC)

Coupage au plasma

(PAC)

Soudage au plasma

(PAW)

d’électrode

po. (mm)

Moins que 3/32 (2,4)

3/32−5/32 (2,4−4,0)

5/32−1/4 (4,0−6,4)

Plus que 1/4 (6,4)

Légère

Lourde

Courant

d’arc en

ampères

Moins que 60

60−160

160−250

250−550

Moins que 60

60−160

160−250

250−500

Moins que 50

50−150

150−500

Moins que 500

500−1000

Moins que 20

20−40

40−60

60−80

80−300

300−400

400−800

Moins que 20

20−100

100−400

400−800

Opacité de

protection

minimum

No.

7

8

10

11

7

10

10

10

8

8

10

10

11

4

5

6

8

8

9

10

6

8

10

11

Opacité

suggérée

No.

(Confort)*

−−

10

12

14

−−

11

12

14

10

12

14

12

14

4

5

6

8

9

12

14

6−8

10

12

14

Référence : ANSI Z49.1:2012

* Commencer avec une opacité plus élevée pour voir la zone de soudage puis utiliser une lentille plus claire

permettant de voir suffisamment la zone de soudage, sans aller au dessous du minimum.

2-5. Principales normes de sécurité

Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, is available as a free download from the

American Welding Society at http://www.aws.org or purchased from Global Engineering Documents (phone:

1-877-413-5184, website: www.global.ihs.com).

Safe Practice For Occupational And Educational Eye And Face Protection, ANSI Standard Z87.1, from American

National Standards Institute, 25 West 43rd Street, New York, NY 10036 (phone: 212-642-4900, website: www.ansi.org).

OM-255503 Page 6

Page 9

SECTION 3 − SPECIFICATIONS

Specification

Viewing Field 3.81 x 2.62 in

Reaction Time 0.0000500 sec (1/20,000)

Available Shades

All Shades Provide

Continuous

UV And IR

Protection.

Sensitivity Control Adjustable For Varying Ambient Light And Welding Arc

Delay Control Slows Lens Dark-To-Light State Between 0.1 And 1.0 Seconds

Automatic Power Off Shuts Lens Off 45 Minutes After Last Arc Is Struck

Low Battery Light Red LED Illuminates To Indicate 2−3 Days Remaining Battery Life

Power Supply Panasonic CR2450 Lithium Battery

Sensors Independent/Redundant (Four)

Operating

Temperature

Storage

Temperature

Total Weight T94: 21 oz (595 g)

Standards Meets ANSI Z87.1+, CSA Z94.3

Warranty Three Years From Date Of Purchase (Section 12)

When Stored In Extremely Cold Temperatures, Warm Helmet To

Ambient Temperature Before Welding.

When Stored In Extremely Cold Temperatures, Warm Helmet To

Ambient Temperature Before Welding.

Darkened State: No. 8 − No. 13

Darkened State: No. 5 − No. 8

Darkened State: No. 8 − No. 13

(Miller Part No. 217043)

14F to 131F / −10C to +55C

−4F to 158F / −20C to +70C

T94

T94i

(97 x 60mm)

Weld Mode

Light State: No. 3

Cut Mode

Light State: No. 3

Grind Mode

Light State: No. 3

X-Mode

Light State: No. 3

T94i: 25.7 oz (729 g)

OM-255503 Page 7

Page 10

SECTION 4 − OPERATING INSTRUCTIONS

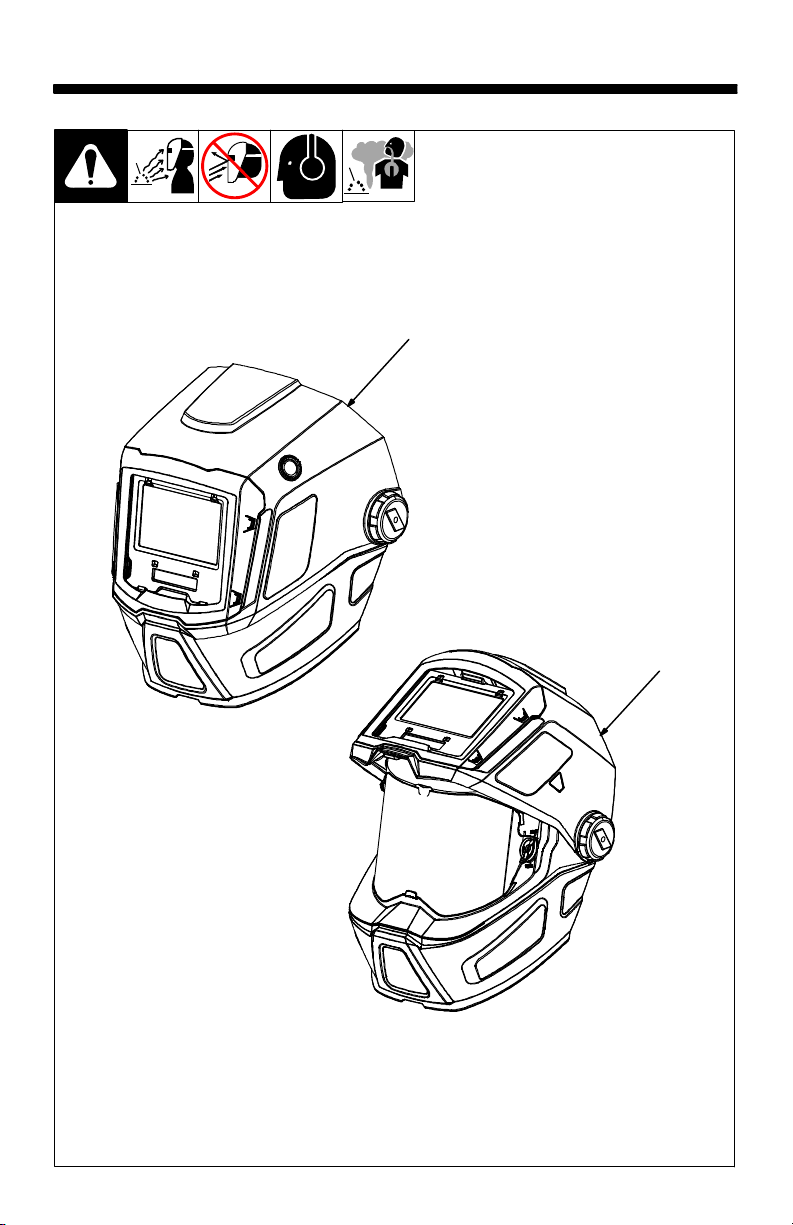

4-1. Helmet Configurations

1 T94 Helmet

The T94 helmet features a fixed posi-

tion, auto-darkening lens and is

designed for standard welding applications.

2 T94i Helmet

The T94i helmet features a flip-up

auto-darkening lens and a separate,

1

clear grinding shield. Flip the lens up

when grinding and performing other

non-welding work. Flip the lens down

when welding or cutting.

OM-255503 Page 8

2

260482-2 / 260483-7

Page 11

4-2. Helmet Controls

7

2

4

1 3

The lens on T94 Series Helmets turns on (darkens)

automatically when welding

begins and turns off when

welding stops.

1 Mode Button (On/Off)

(See Sections 4-3 and

4-4)

2 Grind Mode / Low

Battery Light

(Section 4-3)

6

3 Adjust Button

4 Increase (+) Button

5 Decrease (-) Button

6 Info Control Button

(See Section 4-9)

7 External Grinding

Mode Button (Section

4-4)

5

260482-2 / 260482-4

The External Grinding

Mode button is not

available on the T94i

helmet.

The lens assembly

saves the shade, sensitivity, and delay

settings.

OM-255503 Page 9

Page 12

4-3. Mode Button And Grind / Low Battery Light

1

The auto-darkening lens

on T94 Series Helmets

turns on (darkens) automatically when welding

begins and turns off

when welding stops.

1 Mode Button

Press Mode button to check

if the lens is working properly

OM-255503 Page 10

and to begin Mode and Info

adjustments.

When the Mode button is

pressed, the helmet control

display will appear. Do not

use the helmet if the lens

does not function as described. (See Section 10,

Troubleshooting.)

2 Grind / Low Battery Light

2

260482-4

The Grind / Low Battery light

blinks when the lens is in the

Grind mode. Light stays on

when 2−3 days of battery life

remain.

If battery power is low, replace with CR2450 lithium

battery (1 required − Miller

Part No. 217043). See Section 7.

Page 13

4-4. Mode Control Settings

2

1

1 Mode Button

2 External Grind Mode

Button

Press Mode button to select

the mode appropriate for the

work activity:

Weld Mode − used for most

welding applications. In this

mode the lens turns on

when it optically senses a

welding arc. Adjust shade,

sensitivity, and delay settings as needed.

Cut Mode − used for cutting

applications. In this mode

the lens turns on when it optically senses a cutting arc.

Adjust shade, sensitivity,

and delay settings as needed.

! If nearby objects may

inadvertently contact

the external Grind

Mode button while

you are welding, unplug the Grind Mode

button to prevent accidental activation of

the Grind mode.

Grind Mode − used for met-

al grinding applications. In

this mode the shade is fixed

shade No. 3. No lens adjustments are possible.

Use external Grind Mode

button to select grinding

mode without raising helmet.

260482-2 / 260482-4

To use Grind mode, press

and hold the external Grind

button for two seconds.

Press Grind Mode button

again to turn off Grind mode.

X-Mode − used for outdoor

or low current welding applications. In this mode the

lens turns on when it senses

weld current. Adjust shade,

sensitivity, and delay settings as needed.

Nearby welding may af-

fect helmet operation

when lens is in X-Mode.

Stay at least 12 ft (3.7

m) away from other

welding activity.

OM-255503 Page 11

Page 14

4-5. Variable Shade Control

21

1 Mode Button

2 Increase (+) And

Decrease (-) Buttons

Use the + and − adjustment

buttons to adjust the lens

shade in the darkened state.

Use the table in Section 1-4

to select proper shade control setting based on your

welding process. The shade

ranges for each mode are as

follows:

Weld − No. 8 − No. 13

Cut − No. 5 − No. 8

OM-255503 Page 12

Grind − No. 3 only

X-Mode − No. 8 − No. 13

Start at the highest setting

and adjust lighter to suit the

application and your personal preference.

Variable Shade Adjustment Procedure

Press Mode (On/Off)

button to turn lens On.

Helmet control display

will appear.

260482-4

Press Mode Button to

select desired function:

Weld, Cut, or X-Mode.

Use + and − adjustment

buttons to select desired

shade.

Begin welding or contin-

ue with other lens adjustments.

Page 15

4-6. Lens Delay Control

1 Mode Button

2 Adjust Button

3 Increase (+) And De-

crease (-) Buttons

Select Delay by pressing the

Adjust button. Use the + / −

buttons to adjust the time for

the lens to switch to the clear

state after welding or cutting.

The delay is particularly useful in eliminating bright

after-rays present in higher

amperage applications

where the molten puddle remains bright momentarily

after welding. Use the + / -

buttons to adjust delay from

0 to 10 (0.1 to 1.0 second).

The delay ranges for each

mode are as follows:

Weld, Cut, X-Modes − 0 −

10

Grind Mode − No delay ad-

justment

There is no lens delay

adjustment in the Grind

mode.

Lens Delay Adjustment

Procedure

Press Mode (On/Off)

2

button to turn lens On.

Helmet control display

will appear.

Press Mode button to

select desired function:

Weld, Cut, or X-Mode.

Use Adjust button to se-

lect delay, and then

adjust to desired delay

using + / − buttons.

Begin welding or contin-

ue with other lens

adjustments.

31

260482-4

OM-255503 Page 13

Page 16

4-7. Sensitivity Control

1 Mode Button

2 Adjust Button

3 Increase (+) And

Decrease (-) Buttons

Use control to make the lens

more responsive to different

light levels in various welding

processes. Use a Mid-

Range or 30−50% sensitiv-

ity setting for most appli-

cations.

It may be necessary to adjust

helmet sensitivity to accommodate different lighting conditions or if lens is flashing

On and Off.

The sensitivity ranges for

each mode are as follows:

Weld, Cut, X-Modes − 0 − 10

Stick Electrode Mid-Range

Short Circuiting (MIG) Low/Mid-Range

Pulsed & Spray (MIG) Mid-Range

Gas Tungsten Arc (TIG) Mid/High-Range

Plasma Arc Cutting/Welding Low/Mid-Range

OM-255503 Page 14

Grind Mode − No sensitivity

adjustment

! Do not weld in the

Grind mode; the lens

will not darken.

Sensitivity Adjustment

Procedure

Adjust helmet sensitivity

in lighting conditions helmet will be used in.

Press Mode (On/Off)

button to turn lens On.

Helmet control display

will appear.

Press Mode button to

select desired function:

Weld, Cut, or X-Mode.

Use the Adjust button to

select sensitivity, then

Recommended Sensitivity Settings

2

use the +/− buttons to

adjust sensitivity to the

lowest setting.

31

Face the helmet in the di-

rection of use, exposing

it to the surrounding light

conditions.

Press + button until the

lens darkens, then press

− button until lens clears.

Helmet is ready for use.

Slight readjustment may be

necessary for certain applications or if lens is flashing

on and off.

Reduce Sensitivity set-

ting if lens stays dark

longer than Delay setting.

260482-4

Page 17

4-8. Typical Lens Adjustment Procedure

Lens assembly displays

prior settings when turned

On. Retained settings are

not shown in example.

In the Grind mode the lens is

a fixed shade No. 3. No lens

adjustments are possible.

Adjusting Lens Assembly:

Turn lens On. Display

screen appears.

Select mode (Weld, Cut,

Grind, X-Mode).

Select shade by pressing

+/− buttons.

Select Delay by pressing

Adjust until Delay appears,

then use the +/− buttons to

set.

Select Sensitivity by

pressing Adjust until Sens

appears, then use the +/−

buttons to set.

Press Adjust until full

screen appears to confirm

settings.

Begin work.

260482-4

OM-255503 Page 15

Page 18

4-9. Info Control Button

1

1 Info Control Button

Press Info Control button to

select from the following

functions:

Clock − displays actual

time of day in 24 hour format. See Section 4-10 to

set clock.

OM-255503 Page 16

Arc Time − records the

amount of time the lens

assembly is in the dark

state (exposed to arc). See

Section 4-11 to reset Arc

Time.

260483-6

Arc Count − records the

number of times the lens

darkens. See Section 4-11

to reset the Arc Count.

Lens automatically

exits the Info function

after 30 seconds of inactivity.

Page 19

4-10. Clock Control

1

1 Mode Button

2 Info Control Button

3 Adjust Button

4 Increase (+) And De-

crease (-) Buttons

Clock Procedure

2

Press Mode (On/Off)

button to turn helmet On.

Helmet control display

will appear.

Press Info Control but-

ton once. Clock is displayed on screen.

Clock displays time in 24

hour format.

Press and hold Adjust

button until only the hour

digits are displayed.

Press + / − buttons to

change hour setting.

3 4

260483-6

Press Adjust button to

switch to minute setting.

Press + / − buttons to

change minute setting.

Press Info Control but-

ton to set.

Press Mode button to re-

turn to main control display.

OM-255503 Page 17

Page 20

4-11. Arc Time And Arc Count Control

1

The arc time function records the amount of time the

lens assembly is dark (exposed to an arc). The arc

count function records the

number of times the lens

darkens.

1 Mode Button

2 Info Control Button

OM-255503 Page 18

2

3 Adjust Button

Arc Time / Count Procedure

Press Mode (On/Off)

button to turn helmet On.

Helmet control display

will appear.

3

260483-5

Press Info Control but-

ton repeatedly until Time

or Count is displayed on

screen.

Press and hold the Ad-

just button to reset to

zero.

Press the Mode button

when finished.

Page 21

SECTION 5 − ADJUSTING HEADGEAR

5-1. Adjusting Headgear On T94 Series Helmets

1

4

2

There are four headgear

adjustments: headgear

top, tightness, angle adjustment, and distance

adjustment.

1 Headgear Top

Adjusts headgear for proper

depth on the head to ensure

correct balance and stability.

2 Headgear Tightness

To adjust, turn the adjusting

knob located on the back of

the headgear left or right to

desired tightness.

3 Angle Adjustment (Not

Shown)

Seven slots on the right side

of the headband provide adjustment for the forward tilt of

the helmet. To adjust, lift and

reposition the control arm to

the desired position.

4 Distance Adjustment

Adjusts the distance be-

tween the face and the lens.

To adjust, press black tabs

on the top and bottom of the

pivot point and use other

hand to slide headgear forward or backward. Release

tabs. (Both sides must be

equally positioned for proper

vision.)

Numbers on the adjust-

ment slides indicate set

position so both sides

can be adjusted equally.

260482-7

OM-255503 Page 19

Page 22

SECTION 6 − REPLACING THE GRINDING SHIELD OR

LENS COVERS

6-1. Replacing Grinding Shield On T94i Helmet

! Never use the auto-dark-

ening lens without the inside and outside lens

covers properly installed.

Welding spatter will damage the auto-darkening

lens and void the

warranty.

1 Grinding Shield

2 Retaining Clip

3 Tab

Rotate both retaining clips to the

Open position.

Gently push shield toward bot-

tom tab and remove shield from

1

3

helmet.

Remove retaining clips from

shield. Install clips in same location on new shield. (Retaining

clips are not interchangeable.)

Install new shield in helmet and

rotate clips to the Lock position.

Tear-Away Protective Sheets

Tear-away sheets are available

2

to prolong the life of the grinding

shield (see Parts List).

To install tear-away sheets, pull

backing from both sides of the

tear-away, remove white adhesive backing strips, and

place on clear shield.

OM-255503 Page 20

260483-7

Page 23

6-2. Replacing Lens Covers On Quick Release Helmets

2

1

! Never use the

auto-darkening lens

without the inside

and outside lens covers properly

installed. Welding

spatter will damage

the auto-darkening

lens and void the

warranty.

Outside Lens Cover

1 Lens Holder

2 Lens Holder Release

Points

3 Outside Lens Cover

Remove lens holder by

pulling the holder away

from the helmet on either

side of lens holder.

2

4

3

Remove lens cover from

shell by pulling top center of

lens. Replace lens cover in

lens holder by placing one

edge in place, bending lens

cover, and inserting opposite edge into lens holder

channel. Reinstall lens

holder in helmet.

Inside Lens Cover

4 Auto-Darkening Lens

5 Inside Lens Cover

Remove the inside lens

cover by pulling top center

of lens cover from lens

holding channels.

Replace the lens cover by

gently bowing it in the center and inserting it, one end

6

5

260483-8 / 260482-10

at a time, into the lens holding channels.

Be sure the cover lens

is seated properly to

prevent fogging.

Auto-Darkening Lens

6 Lens Release Tab

Remove lens holder and

outside lens cover using instructions above. Press up

on lens release tab and

push auto-darkening lens

assembly from the inside to

remove.

Replace the lens by aligning it on the release tabs

and pressing it in until it

snaps into place.

OM-255503 Page 21

Page 24

SECTION 7 − REPLACING THE BATTERY

+

1

To replace the battery, remove the auto-darkening

lens assembly (see Section 6).

1 Battery Tray

After removing the lens assembly, slide the battery

OM-255503 Page 22

holding tray out and remove the old battery.

Replace with Panasonic

CR2450 lithium type battery (1 required) (Miller Part

No. 217043).

Be sure Positive (+)

Be sure Positive (+)

side of battery

faces up.

260482-11

side of the battery

faces up (toward inside

of helmet).

Reinstall the battery tray.

To test battery, press the

Mode button. The display

screen should turn on. Reinstall the lens assembly.

Page 25

SECTION 8 − INSTALLING OPTIONAL MAGNIFYING LENS

1 Optional Magnifying Lens

Starting at the bottom, slide magni-

fying lens into the helmet retaining

brackets. Align the magnifying lens

with the auto-darkening lens assembly. Reverse procedure to remove magnifying lens.

To prevent lens fogging, install

flat side of magnifying lens toward auto-darkening lens.

1

260482-12

SECTION 9 − MAINTENANCE

NOTICE − Never use solvents or abrasive cleaning detergents.

NOTICE − Do not immerse the lens assembly in water.

The helmet requires little maintenance. However, for best performance clean after each use. Using

a soft cloth dampened with a mild soap and water solution, wipe the cover lenses clean. Allow to air

dry. Occasionally, the filter lens and sensors should be cleaned by gently wiping with a soft, dry cloth.

OM-255503 Page 23

Page 26

SECTION 10 − TROUBLESHOOTING

Trouble Remedy

Auto lens not On – autolens settings do not appear when the Mode button is pressed.

Not switching – auto-lens

stays light and will not

darken when welding.

Not Switching – auto-lens

stays dark after the weld

arc is extinguished, or the

auto-lens stays dark when

no arc is present.

Sections of the auto-lens

are not going dark, distinct

lines separate the light and

dark areas.

Switching or Flickering –

the auto-lens darkens then

lightens while the welding

arc is present.

Check battery and verify it is in good condition and installed properly.

Check battery surfaces and contacts and clean if necessary.

Check battery for proper contact and gently adjust contact points

if necessary. This is particularly important if the helmet has been

dropped.

Stop welding immediately: Press the Mode (On/Off) button.

If power is On, review the sensitivity recommendations and adjust

sensitivity.

Clean lens cover and sensors of any obstructions. Make sure the

sensors are facing the arc. Angles of 45 or more may not allow

the arc light to reach the sensors.

Fine-tune the sensitivity setting in small increments. In extreme

light conditions, it may be necessary to reduce the surrounding

light levels.

Stop welding immediately: The auto-lens may be cracked which

can be caused by the impact of dropping the helmet.

Weld spatter on the auto lens may also cause cracking. (The lens

may need to be replaced; most cracked lenses are not covered by

warranty).

Review the sensitivity setting recommendations and increase the

sensitivity if possible. Be sure the arc sensors are not being

blocked from direct access to the arc light.

Check the lens cover for dirt and spatter that may be blocking the

arc sensors. Increasing Lens Delay 0.1 − 0.3 second may also

reduce switching.

Inconsistent or lighter

auto-lens shading in the

dark state, noticeable on

the outside edges and corners.

OM-255503 Page 24

Referred to as an angle of view effect, auto-darkening lenses

have an optimum viewing angle.

The optimum viewing angle is perpendicular or 90 to the surface

of the auto-lens. When that angle of view varies in the dark-state,

welders may notice slightly lighter areas at the outside edges and

the corners of the lens. This is normal and does not represent any

health or safety hazard.

This effect may also be more noticeable in applications where

magnifying lenses are used.

Page 27

SECTION 11 − PARTS LISTS

7

8

9

8

1

6

5

10

2

3

Miller

11

4

13

Figure 10-1. T94 Auto-Darkening Welding Helmet

OM-255503 Page 25

12

Ref. 260482

Page 28

Item

No. Quantity

Part

No.

Description

Figure 10-1. T94 Auto-Darkening Welding Helmet

1 258864 Shell, Helmet T94 (Includes Item 6) 1............ ......... .................

2 216327 Lens Cover, Inside 4-1/4 x 2-1/2 in (5 Per Pkg.) 1............ ......... .......

3 260557 Lens Assembly, ADF T94 W/Cable 1............ ......... .................

4 260197 Covers, Side Window 2............ ......... .............................

5 265304 Lens Cover, Front T94 (5 Per Pkg.) 1............ ......... .................

6 265309 Lens Holder, Front T94 1............ ......... ...........................

7 260486 Headgear, Gray (Includes) 1............ ......... ........................

8 *265891 Kit, Headgear Adjust Angle 1........... ........... .....................

9 770249 Headband, Fabric 1............ ........... ..............................

079975 Replacement O-rings For Kit 256178 (5 Per Pkg.) 1.............. ......... .....

10 259574 Tray, Battery 1........... ......... ....................................

217043 Battery, Lithium (CR2450) 1.............. ......... .........................

11 770250 Helmet Bag − Miller 1........... ......... ..............................

♦222003 Adapters, Hard Hat (Not Shown) 1............ ......... ...................

12 256179 Button, Grind Mode 1........... ......... ..............................

13 ♦212235 Lens, 0.75 Magnification 1......... ......... ..........................

13 ♦212236 Lens, 1.00 Magnification 1......... ......... ..........................

13 ♦212237 Lens, 1.25 Magnification 1......... ......... ..........................

13 ♦212238 Lens, 1.50 Magnification 1......... ......... ..........................

13 ♦212239 Lens, 1.75 Magnification 1......... ......... ..........................

13 ♦212240 Lens, 2.00 Magnification 1......... ......... ..........................

13 ♦212241 Lens, 2.25 Magnification 1......... ......... ..........................

13 ♦212242 Lens, 2.50 Magnification 1......... ......... ..........................

* Adjustment Hardware Kit With O-rings.

♦Optional

OM-255503 Page 26

Page 29

12

11

10

14

2

1

2

13

12

5

7

8

9

6

15

4

3

Figure 10-2. T94i Auto-Darkening Welding Helmet

OM-255503 Page 27

Ref. 260483

Page 30

Item

No. Quantity

Part

No.

Description

Figure 10-2. T94i Auto-Darkening Welding Helmet

1 258854 Shell, Helmet T94i (Includes Item 9) 1............ ......... ................

2 245819 Clip, Retaining Grinding Shield 2............ ......... .....................

3 258979 Lens, Grinding Shield (Clear) 1............ ......... ......................

4 ♦258853 Shield, Grinding Tear Away 1.......... ......... ........................

5 216327 Lens Cover, Inside 4−3/16 in x 2−1/2 in 1............ ......... .............

6 259572 Lens Assembly, ADF T94i Without Cable 1............ ......... ............

217043 Battery, Lithium (CR2450) 1.............. ......... .........................

7 259574 Tray, Battery T94i 1............ ......... ................................

8 265304 Lens Cover, Front 1............ ......... ...............................

9 265309 Lens Holder, Front 1............ ......... ...............................

10 260197 Covers, Side Window 2........... ......... .............................

11 260486 Headgear, Gray (Includes) 1........... ......... ........................

12 *265891 Kit, Headgear Adjust Angle 1.......... ........... ......................

13 770249 Headband, Fabric 1........... ........... ..............................

079975 Replacement O-rings For Kit 256178 (5 Per Pkg.) 1.............. ......... .....

14 770250 Bag, Helmet (Miller Logo) 1........... ......... .........................

♦222003 Adapters, Hard Hat (Not Shown) 1............ ......... ...................

15 ♦212235 Lens, 0.75 Magnification 1......... ......... ..........................

15 ♦212236 Lens, 1.00 Magnification 1......... ......... ..........................

15 ♦212237 Lens, 1.25 Magnification 1......... ......... ..........................

15 ♦212238 Lens, 1.50 Magnification 1......... ......... ..........................

15 ♦212239 Lens, 1.75 Magnification 1......... ......... ..........................

15 ♦212240 Lens, 2.00 Magnification 1......... ......... ..........................

15 ♦212241 Lens, 2.25 Magnification 1......... ......... ..........................

15 ♦212242 Lens, 2.50 Magnification 1......... ......... ..........................

* Adjustment Hardware Kit With O-rings.

♦Optional

SECTION 12 − LIMITED WARRANTY

LIMITED WARRANTY – Subject to the terms and conditions below, Miller

Electric Mfg. LLC, Appleton, Wisconsin, warrants to its original retail purchaser that the new Miller equipment sold after the effective date of this

limited warranty is free of defects in material and workmanship at the time

it is shipped by Miller. THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL

OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND FITNESS.

Miller auto-darkening lens helmets are warranted for 3 years from the date

of purchase. Proof of purchase is required for warranty transactions so it

is imperative that a copy of the original invoice or sales receipt be retained.

For warranty transactions, contact your Miller Distributor.

Miller Helmet Warr 2018-01

OM-255503 Page 28

Effective January 1, 2018

Page 31

OM-255503 Page 29

Page 32

For product information,

Owner’s Manual translations,

and more, visit

www.MillerWelds.com

®

Miller Electric Mfg. LLC

An Illinois Tool Works Company

1635 West Spencer Street

Appleton, WI 54914 USA

ORIGINAL INSTRUCTIONS © 2018 Miller Electric Mfg. LLC

Loading...

Loading...