Miller RACSWY050N, RACSWY050C, RACDTA-5K/6FT, RACDTA-5K12/6FT, RACSWY2SBA User Instruction Manual

...Page 1

Page 2

Table of Contents

1.0 General Requirements, Warnings and Limitations............................. 3-4

2.0 Purpose................................................................................................4

3.0 Warnings and Limitations...................................................................4-5

3.1 Compatibility Limitations

4.0 Drop Through Anchor............................................................................6

5.0 Zinc Plated Swivel Anchor....................................................................7

6.0 Stainless Steel Swivel Anchors...........................................................10

7.0 Zinc Plated Swivel Anchors.................................................................14

8.0 Hybrid Concrete Anchor......................................................................19

Product Labels................................................................................... 48

Inspection and Maintenance Log....................................................... 51

Table des Matières

1.0 Exigences Générales, Avertissements et Limitations......................... 15-16

2.0 Compatibilité du Système................................................................... 16

2.1 Groupes de Produits Miller Fall Protection

3.0 Installation des Connecteurs D’ancrage............................................. 17-25

3.1 Ancrage à anneau en D (410)

3.2 Ancrage à boulon en D (415, 416/417, 416SS/417SS, 418/419, 418SS/419SS)

3.3 Ancrage à boulon en D pour béton (417C)

4.0 Inspection et Entretien....................................................................... 26

Étiquettes de Produit.......................................................................... 39

Registre D’inspection et D’entretien................................................... 40

Índice

1.0 Requisitos Generales, Advertencias y Limitaciones.......................... 27-28

2.0 Compatibilidad del Sistema............................................................... 28

2.1 Grupos de Productos Anticaídas Miller

3.0 Instalación de los Conectores de Anclaje.......................................... 29-37

3.1 Ancla de argolla “D” montada (410)

3.2 Ancla “D” de perno (415, 416/417, 416SS/417SS, 418/419, 418SS/419SS)

3.3 Ancla “D” de perno (417C)

4.0 Inspección y Mantenimiento.............................................................. 38

Etiquetas del Producto....................................................................... 39

Registro de Inspección y Mantenimiento........................................... 40

2

Page 3

User Instructions - English

Thank You

Thank you for your purchase of Miller fall protection equipment manufactured by Honeywell

Safety Products. Miller brand products are produced to meet the highest standards of quality at

our ISO 9001 certi ed facility. Miller equipment will provide you with years of use when cared for

properly.

WARNING

All persons using this equipment must read, understand and follow

all instructions. Failure to do so may result in serious injury or death.

Do not use this equipment unless you are properly trained.

Questions?

It is crucial that the authorized person/user of this equipment read and understand these instructions. In addition, federal law requires employers to ensure that all users are trained in the

proper installation, use, inspection, and maintenance of fall protection equipment. Fall protection

training should be an integral part of a comprehensive safety program.

Proper use of fall arrest systems can save lives and reduce the potential of serious injuries from

a fall. The user must be aware that forces experienced during the arrest of a fall or prolonged

suspension may cause bodily injury. Consult a physician if there is any question about the

user’s ability to use this product. Pregnant women and minor children must not use this product.

CALL

1.800.873.5242

1.0 General Requirements,

Warnings and Limitations

All warnings and instructions shall be

provided to authorized persons/users.

All authorized persons/users must reference

the regulations governing occupational

safety, as well as applicable ANSI or

CSA standards. Please refer to product

labeling for information on speci c OSHA

regulations, and ANSI and CSA standards

met by product.

Proper precautions should always be taken

to remove any obstructions, debris, material,

or other recognized hazards from the work

area that could cause injuries or interfere with

the operation of the system.

All equipment must be inspected before

each use according to the manufacturer’s

instructions.

All equipment should be inspected by a

quali ed person on a regular basis.

To minimize the potential for accidental

disengagement, a competent person must

ensure system compatibility.

Equipment must not be altered in any

way. Repairs must be performed only by

the manufacturer, or persons or entities

authorized in writing by the manufacturer.

Any product exhibiting deformities, unusual

wear, or deterioration must be immediately

discarded.

Any equipment subject to a fall must be

removed from service.

The authorized person/user shall have

a rescue plan and the means at hand to

implement it when using this equipment.

Never use fall protection equipment for

purposes other than those for which it was

designed. Fall protection equipment should

never be used for towing or hoisting.

Equipment must not be exposed to

environmental hazards and chemicals which

may produce a harmful effect.

Use in a corrosive or caustic environment

dictates a more frequent inspection and

servicing program to ensure the integrity of

the product is maintained.

3

Page 4

User Instructions - English

Do not allow equipment to come in contact

with anything that will damage it including,

but not limited to, sharp, abrasive, rough

or high-temperature surfaces, welding,

heat sources, electrical hazards, or moving

machinery.

Do not expose the equipment to any

hazard which it is not designed to

withstand. Consult the manufacturer in

cases of doubt.

Always check for obstructions below the

work area to make sure potential fall path

is clear.

Allow adequate fall clearance below the

work surface.

Never remove product labels, which include

important warnings and information for the

authorized person/user.

Fall arrest systems used with the

anchorage connector must be rigged in

accordance to regulatory requirements.

2.0 Purpose

The Miller swivel anchorage connectors ar designed to function as an interface between the

anchorage and a fall protection, work positioning, rope access, or rescue system for the purpose

of coupling the system to the anchorage. References to "anchorage connector' in this manual

include and apply to the swivel anchorage connectors, used with either 5,000 lb. or 10,000 lb

anchorage connectors.

3.0 Warnings and Limitations

Compliant fall protection and emergency rescue systems help prevent serious injury during fall

arrest. Users and purchasers of this equipment must read and understand the User Instructions

provided for correct use and care of this product. All users of this equipment must understand

the instructions, operation, limitations and consequences of improper use of this equipment and

be properly trained prior to use per OSHA 29 CFR 1910.66 and 1926.503 or applicable local

standards. Misuse or failure to follow warnings and instructions may result in serious

personal injury or death.

1. The user shall be equipped with a means of limiting the maximum dynamic forces exerted

on the user during the arrest of a fall to a maximum of 1800 lbf/8kN.

2. Use of this product must be approved by an Engineer or other qualied person to be

compatible with any and all structural & operational characteristics of the selected installation

location and system to be connected to this anchorage connector.

3. The anchorage connector must be inspected prior to each use for wear, damage, and other

deterioration. If defective components are found the anchorage connector must be immediately

removed from service in accordance with the requirements of OSHA 29 CFR 1910.66 and

1926.502.

4. The anchorage connector should be positioned in such a way that minimizes the potential

for falls and the potential fall distance during use. The complete fall protection system must be

planned (including all components, calculating fall clearance, and swing fall) before using.

5. The anchorage connector is designed for single user, with a capacity up to 310 lbs (140

kg) including clothing, tools, etc.

6. The anchorage connector is designed to be used in temperatures ranging from -40ºF to

+130ºF (-40°C to +54°C.

4

Page 5

User Instructions - English

7. This anchorage connector should not be used as part of a horizontal lifeline system that has

not been designed and or approved to be used with 5,000-lbf anchorage connectors.

Always work directly under the anchor point to avoid a swing-fall injury.

Ensure that the anchorage connector is at a height that will not allow a lower level to be

struck should a fall occur. When selecting an anchorage point, always remember that

shock absorbers will elongate when subjected to fall arrest forces. Refer to the labels and

instructions provided with the connecting device to obtain the maximum elongation distance.

Anchorage requirements based on ANSI are as follows:

• For fall arrest systems, anchorages must withstand a static load of 5,000 lbs. (22.2kN) for

non-certied anchorages or two times the maximum arresting force for certied anchorages.

• For positioning systems, anchorages must withstand a static load of 3,000 lbs. (13.3kN) for

non-certied anchorages or two times the foreseeable force for certied anchorages.

• For travel restraint, anchorages must withstand a static load of 1,000 lbs. (4.5kN) for noncertied anchorages or two times the foreseeable force for certied anchorages.

• For rescue systems, anchorages must withstand a static load of 3,000 lbs. (13.3kN) for noncertied anchorages or ve-times the applied load for certied anchorages.

• When more than one personal fall arrest system is attached to an anchorage, the above

anchorage strengths must be multiplied by the number of personal fall arrest systems attached

to the anchorage.

3.1 Compatibility Limitations

COMPATIBILITY LIMITATIONS

All anchorage connectors must only be coupled to compatible connectors. OSHA 29 CFR

1926.502 prohibits snaphooks from being engaged to certain objects unless two requirements

are met: it must be a locking type snaphook, and it must be “designed for” making such a

connection. “Designed for” means that the manufacturer of the snaphook specically designed

the snaphook to be used to connect to the equipment listed. The following connections must be

avoided, because they can result in rollout* when a nonlocking snaphook is used:

• Direct connection of a snaphook to horizontal lifeline.

• Two (or more) snaphooks connected to one D-ring.

• Two snaphooks connected to each other.

• A snaphook connected back on its integral lanyard.

• A snaphook connected to a webbing loop or webbing lanyard.

• Improper dimensions of the D-ring, rebar, or other connection point in relation to

the snaphook dimensions that would allow the snaphook keeper to be depressed by

a turning motion of the snaphook.

*Rollout: A process by which a snaphook or carabiner unintentionally disengages from

another connector or object to which it is coupled. (ANSI Z359.1-2007)

The anchorage connector must be compatible with the snap hook or carabiner of the

connecting device and must not be capable of causing a load to be applied to the gate/

keeper.

5

Page 6

User Instructions - English

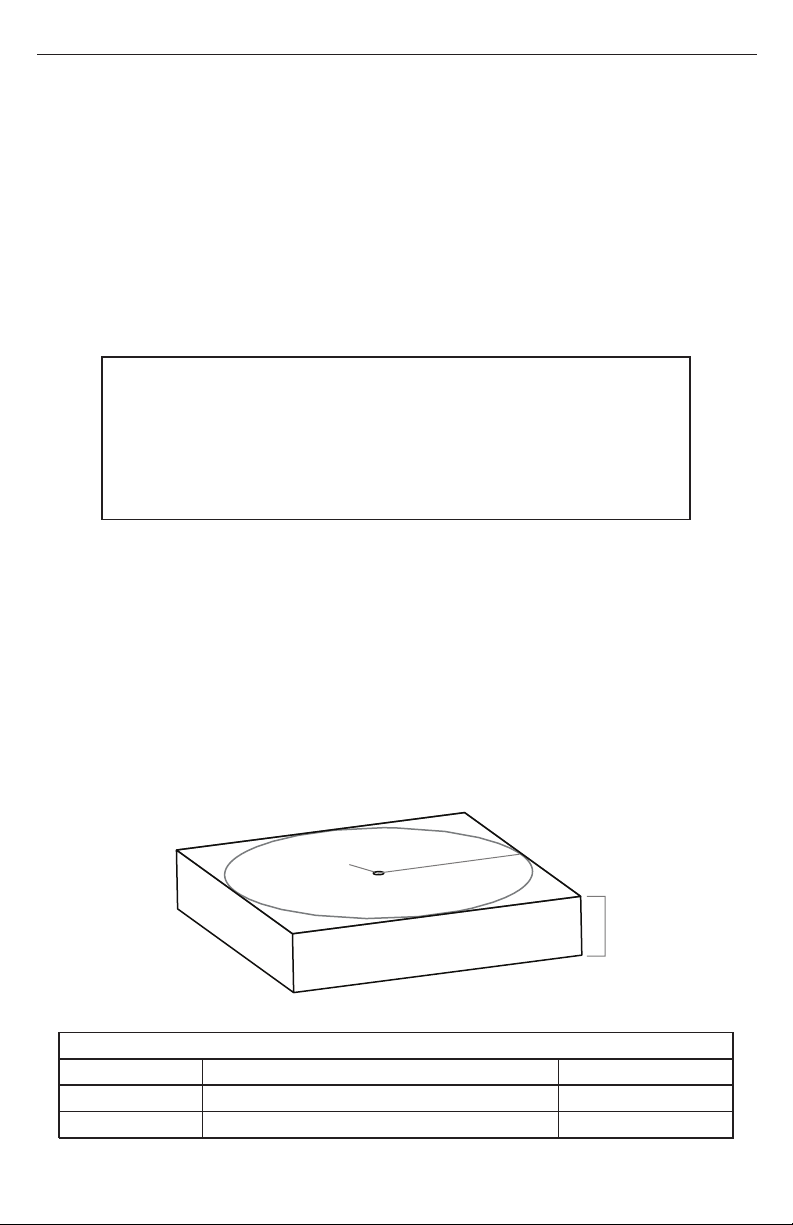

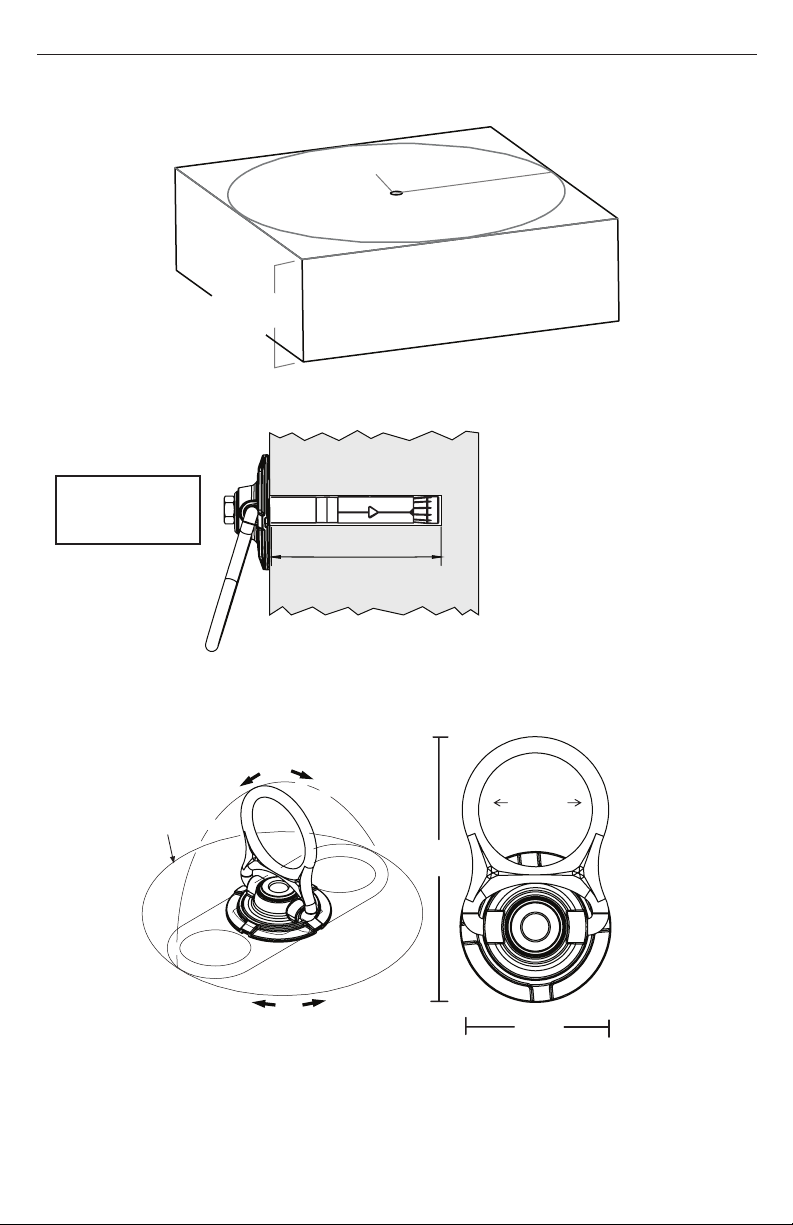

4.0 Drop Through Anchor

5,000 lbf./22kN

Model Numbers RACDTA-5K/6FT (Drop though anchor with 4 in. (10 cm) round plate and

swivel), RACDTA-5K6/6FT (Drop through anchor with 6 in. (15 cm) square plate and swivel),

and RACDTA-5K12/6FT (Drop through anchor with 12 in. (30cm) square plate and swivel).

Warnings and Limitations

• Use only with Honeywell-approved personal fall arrest or restraint systems. The anchorage

must have the strength capable of supporting a static load, applied in the directions

permitted by the system, of at least 5,000-lbf (22kN) in the absence of certication.

Tensile Strength (UTS): 5,000-lbf (22kN)

Working Load (WLL): 1,000 lbs (454kg)

Maximum Capacity: One worker, 310 lbs (140 kg)

Weight: Varies by cable length

Regulatory Compliance

ANSI Z359.1-2007, ANSI Z359.7-2011, OSHA 1910.66 , 1926.502

Installation:

1. The drop through anchor-5k drop through anchor can only be used on a horizontal

surface that is above the users location.

2. Locate or create a through hole in concrete, steel or metal grating capable of

withstanding a 5,000-lbf. Static load or meeting OSHA 1926.502 requirements for a

safety factor of two. (Reference gure 1-A below for dimentional requirements.)

3. Place cable through the hole from top side. The label on plate should be facing up.

Plate must rest at and ush on the mounting surface.

1-3/4” to 2”Ø

Hole size

(4.1cm to 4.4cm)

(A)

e

g

d

e

ny

a

m

ro

f

in

m

(B)

min

Fig. 1-A

HOLE REQUIRMENT CHART

Material: (A)” Minimum distance from edge/corner (B)” thickness

Concrete

Steel

12” in. (30.5 cm)

4” in. (10 cm)

6

4” in. (10 cm)

1/4” in. (.635 cm)

Page 7

User Instructions - English

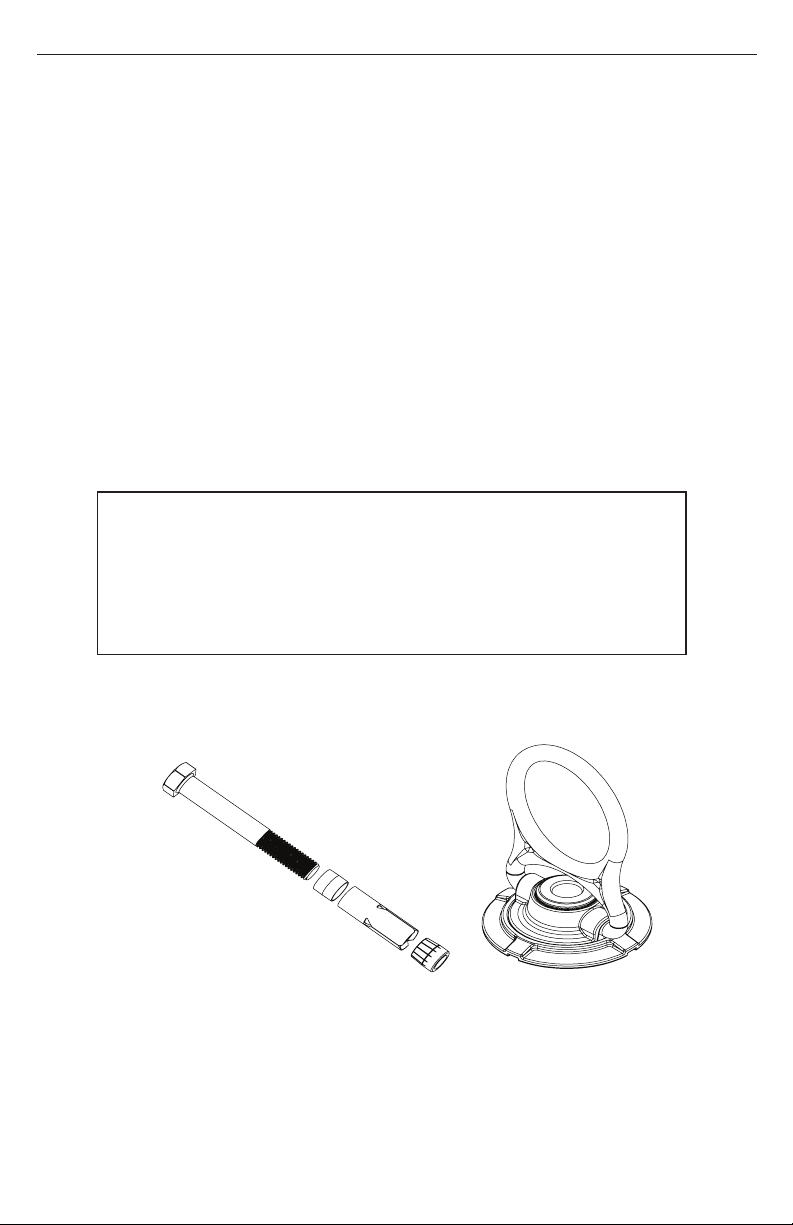

5.0 Zinc-Plated Swivel Anchor

5,000 lbf./22kN

Model Numbers RACSWY050N (swivel only), RACSWY050S (swivel anchor with steel mounting hardware), and RACSWY050C (swivel anchor with concrete mounting hardware), RACSWY2SBA (Steel mounting hardware only) and RACSWY2CSA (Concrete mounting hardware

only).

Warnings and Limitations

• Use only with Honeywell-approved personal fall arrest or restraint systems. The

anchorage must have the strength capable of supporting a static load, applied in

the directions permitted by the system, of at least 5,000-lbf (22kN) in the absence of

certication.

• The anchorage connector may be pulled in any direction shown in the LOADING

CONDITIONS DIAGRAM (pg. 9).

Tensile Strength (UTS): 5,000-lbf (22kN)

Working Load (WLL): 1,000 lbs (454kg)

Maximum Capacity: One worker, 310 lbs (140 kg)

Weight: 1.2 lbs (544.31g)

Regulatory Compliance

ANSI Z359.1-2007, ANSI Z359.7-2011, OSHA 1910.66 , 1926.502

CONCRETE MOUNTING RACSWY050C:

+

- Use a proper drill & bit for concrete. (SDS drill bit)

- Drill a 5/8” (16mm) hole no less than 4” (102mm) deep an 8” (203mm) away from

any edge.

- Hole must be straight & perpendicular to surface.

- Hole must be free of debris

- Concrete strength must be at least 3000psi (20.7MPa) and no less than 7”

(178mm) thick.

7

Page 8

User Instructions - English

Torque:

60ft-lbs

7”

(178mm)

min

drill 5/8” (16mm)Ø

4” min (102mm)

8” (203mm)

min from any edge

8.0”ø

(203.2mm)

180˚

360˚

8

5.5”

(139.7mm)

2.25”ø

(57.15mm)

3.0”

(76.2mm)

Page 9

User Instructions - English

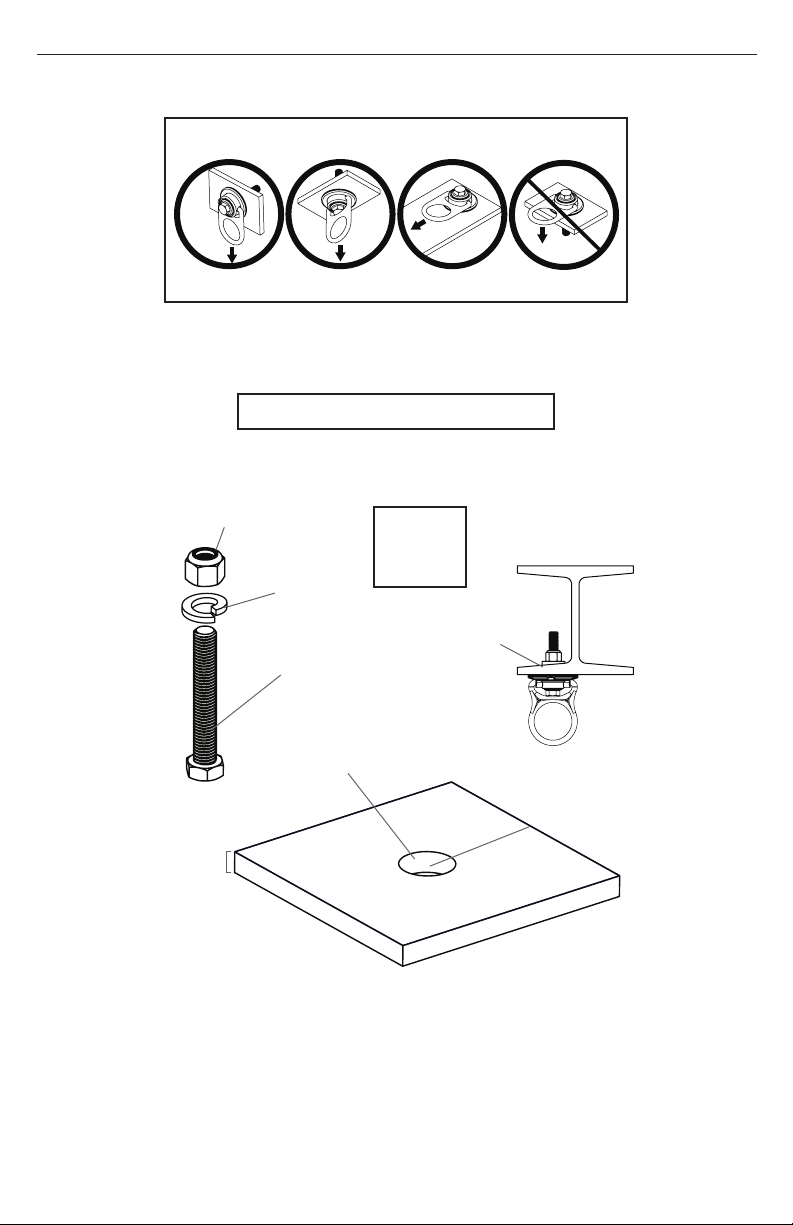

LOADING CONDITIONS DIAGRAM

LOAD

ACCEPTABLE ACCEPTABLE

LOAD

STEEL MOUNTING

1/2”-13 Lock Nut

1/2” Lock

Washer

1/2”-13 x 4”

Hex Bolt *

drill 1/2” (12.7mm)Ø

LOAD

Torque :

45 ft-lbs

(61 Nm)

LOAD

IMPROPERACCEPTABLE

Use

tapered

washer

1/4”

(6mm)

min

3”(76mm)

min from any edge

9

Page 10

User Instructions - English

6.0 Stainless Steel Swivel Anchors

5,000 lbf/22kN

Model Numbers RACSWS100N-316 (swivel only), RACSWS100S-316 (Swivel anchor with

stainless steel mounting hardware), and RACSWS100C-316 (Swivel anchor with concrete

mounting hardware), RACSWS1SBA-316 (Stainless steel mounting hardware only), RACSWS1DNC-316 (Concrete mounting hardware only), RACDNC-TOOL (Concrete bolt assembly tool)

and RACSWP100N-316 (Weld Kit).

Warnings and Limitations

• Use only with Honeywell-approved personal fall arrest or restraint systems. The anchorage

must have the strength capable of supporting a static load, applied in the directions

permitted by the system, of at least 5,000-lbf (22kN) in the absence of certication.

• The anchorage connector may be pulled in any direction shown in the LOADING

CONDITIONS DIAGRAM (below)

180°

8.0”ø

(203.2mm)

5.5”

(139.7mm)

2.25”ø

(57.15mm)

360°

3.0”

(76.2mm)

Tensile Strength (UTS): 10,000-lbf (44kN)

Working Load (WLL): 1,000 lbs (454kg)

Maximum Capacity: One worker, 310 lbs (140 kg)

Weight: 1.2 lbs (544.3g)

Regulatory Compliance

ANSI Z359.1-2007, ANSI Z359.7-2011, OSHA 1910.66 , 1926.502

LOADING CONDITIONS DIAGRAM

LOAD

LOAD

ACCEPTABLE ACCEPTABLE IMPROPER

LOAD

LOAD

ACCEPTABLE

10

1.0”

(25.4mm)

Page 11

User Instructions - English

CONCRETE MOUNTING

- Use a proper drill & bit for concrete. (SDS drill bit)

- Drill a 7/8” (22mm) hole no less than 3” to 3-1/2“ (76mm-89mm) deep 9” (229mm)

away from any edge.

- Hole must be straight & perpendicular to surface.

- Hole must be free of debris

- Concrete strength must be at least 3000psi (20.7MPa) and no less than 7” (178mm)

thick.

-Drop expansion sleeve into hole.

-Use the Setting Tool by placing it in the hole resting on the expansion sleeve. Tap

tool until the blue inner sleeve is at the bottom of the expansion sleeve.

-Now place swivel over the hole and install the bolt provided.

Embedment Depth

3” min 3-1/2” max

(76mm-89mm)

TA

P

drill 3/4” (19mm)Ø

!!!

Setting Tool

(DNC-TOOL)

9” (229mm)

min from any edge

7"

(178mm)

min.

Torque Range:

30-40 ft-lbs

(22-30Nm)

Expansion

Sleeve

11

Page 12

5/8”-11

Lock Nut

User Instructions - English

STEEL MOUNTING

Torque Range:

75 ft-lbs.

(100Nm)

5/8” Lock

Washer

drill 5/8” (16mm)Ø

5/8”-11x4”

Hex Bolt *

* For steel applications a grade-5, 8 (or equivalent) bolt no shorter than 4” (100mm)

with a locking nut and washer must be used. Swivel anchor must be ush with steel

surface. A 16mm bolt may be used in place of a 5/8”-11 for metric applications.

1/4"

(6mm)

min.

* Use tapered washer with Ibeams that have tapered anges

3”(76mm)

min from any

edge

WELD-ON MOUNTING

316 Stainless Steel 5/8”-

11 x 1-3/4” Bolt

Torque:

85-ft lbs

(115Nm)

Puck

* Weld

* Welding procedure must be approved by a Engineer or other

qualied person to be compatible with any and all structural &

operational characteristics of the selected installation location.

12

Page 13

User Instructions - English

KIT CONTENTS

+

CONCRETE METALACCESSORIES

+

PART NUMBER

RACSWS1SBA-316

(Steel Mounting Hardware Kit)

RACSWS100S-316

(Swivel with Steel Mounting kit)

RACSWS1DNC-316

(Concrete Hardware Kit)

RACSWS100C-316

(Swivel with Concrete Mounting Kit)

+

RACSWP100N-316KIT

(Weld-on Mounting Kit)

RACDNC-TOOL

(Concrete Anchor Tool)

13

Page 14

User Instructions - English

7.0 Zinc Plated Swivel Anchors

10,000 lbf/44kN

Model Numbers RACSWY100N (Swivel only), RACSWY100S (Swivel anchor with steel mounting hardware), and RACSWY100C (Swivel anchor with concrete mounting hardware), RAC-

SWY1SBA (Steel mounting hardware only), RACSWY1CSA (Concrete mounting hardware),

RACSWP100N-KIT (Weld kit) and RACSWX100N (Steel back plate).

Warnings and Limitations

• Use only with Honeywell-approved personal fall arrest or restraint systems. The anchorage

must have the strength capable of supporting a static load, applied in the directions

permitted by the system, of at least 10,000-lbf (22kN) in the absence of certication.

• The anchorage connector may be pulled in any direction shown in the LOADING

CONDITIONS DIAGRAM (Pg. 15)

180°

8.0”ø

(203.2mm)

5.5”

(139.7mm)

2.25”ø

(57.15mm)

360°

(76.2mm)

Tensile Strength (UTS): 10,000-lbf (44kN)

Working Load (WLL): 2,000 lbs (907kg)

Maximum Capacity: One worker, 310 lbs (140 kg)

Weight: 1.2 lbs (544.3g)

Regulatory Compliance

ANSI Z359.1-2007, ANSI Z359.7-2011, OSHA 1910.66,

14

3.0”

1926.502

1.0”

(25.4mm)

Page 15

User Instructions - English

LOADING CONDITIONS DIAGRAM

5/8”-11

Lock Nut

LOAD

LOAD

ACCEPTABLE ACCEPTABLE IMPROPER

LOAD

LOAD

ACCEPTABLE

STEEL MOUNTING

Torque Range:

5/8” Lock

Washer

5/8”-11x4”

Hex Bolt *

75-90 ft-lbs

(100-120 Nm)

drill 5/8” (16mm)Ø

1/4”

(6mm)

min.

* Use tapered washer with I-beams

that have tapered anges

3”(76mm)

min from any edge

* For steel applications a grade-5, 8 (or equivalent) bolt no shorter

than 4” (100mm) with a locking nut and washer must be used.

Swivel anchor must be ush with steel surface. A 16mm bolt may be

used in place of a 5/8”-11 for metric applications.

15

Page 16

User Instructions - English

CONCRETE MOUNTING

- Use a proper drill & bit for concrete. (SDS drill bit)

- Drill a 3/4” (19mm) hole no less than 5” (127mm) deep 9” (229mm) away from any edge.

- Hole must be straight & perpendicular to surface.

- Hole must be free of debris

- Concrete strength must be at least 3000psi (20.7MPa) and no less than 7” (178mm) thick.

drill 3/4” (19mm)Ø

9” (229mm)

min from any edge

Torque:

90ft-lbs

(120Nm)

WELD ON MOUNTING

Grade - 5 or 8 bolt

5/8”-11 x 1-3/4”

Torque:

125-ft-lbs

(169Nm)

15/16” socket required

7"

(178mm)

min.

4” min (102mm)

Embedment Depth

Puck

* Weld

3/8"min.

(9.5mm)

* Welding procedure must be approved by an Engineer or other qualied

person to be compatible with any and all structural & operational characteristics of the selected installation location.

16

Page 17

User Instructions - English

BACK PLATE MOUNTING

Back Plate to be used with 5/8” (16mm)

bolts or all thread. Drill hole perpendicular into surface so bolt can pass freely

through the substrate. Nut must be fully

threaded on the bolt to insure maximum

strength ratings and integrity of anchor.

Torque Range:

to be determined

by an Engineer or

qualied person.

* Bolt or All-thread and nut not included with Back Plate.

17

Page 18

User Instructions - English

KIT CONTENTS

+

CONCRETE METALACCESSORIES

+

PART NUMBER

RACSWY1SBA

(Steel Mounting Hardware Kit)

RACSWY100S

(Swivel with Steel Mounting kit)

RACSWY1CSA

(Concrete Hardware Kit)

RACSWY100C

(Swivel with Concrete Mounting Kit)

+

RACSWP100N-KIT

(Weld-on Mounting Kit)

RACSWX100N

(Backing Plate Only)

18

Page 19

User Instructions - English

8.0 Hybrid Concrete Anchor

Model Number RACSWH100Y

Warnings and Limitations

• Use only with Honeywell-approved personal fall arrest or restraint systems. The anchorage

must have the strength capable of supporting a static load, applied in the directions

permitted by the system, of at least 10,000-lbf (22kN) in the absence of certication.

• The anchorage connector may be pulled in any direction shown in the LOADING

CONDITIONS DIAGRAM (Pg. 20)

6-1/4”

(15.88cm)

2.25”ø

(57.15mm)

5.5”

(139.7mm)

Compression

Bushing

Sleeve

3.0”

(76.2mm)

8.0”ø

(203.2mm)

1.0”

(25.4mm)

180˚

360˚

19

Retaining

Bushing

Cable

Bolt

Spoon

Cone

Page 20

User Instructions - English

LOADING CONDITIONS DIAGRAM

LOAD

LOAD

ACCEPTABLE ACCEPTABLE

LOAD

LOAD

IMPROPERACCEPTABLE

Tensile Strength (UTS): 10,000-lbf (44kN)

Working Load (WLL): 1.000 lbs (454kg)

Maximum Capacity: One worker, 310 lbs (140kg)

Weight: 2.0-lbs (949g)

Regulatory Compliance: ANSI Z359.1-2007, ANSI Z359.7-

2011, OSHA 1910.66 , 1926.502

DRILLING :

1. Use a hammer drill (SDS), drill a 1” (25mm) diameter hole at least 5”

(127mm) deep. The drilled hole must be straight and perpendicular to

the surface. Make sure the hole is of uniform diameter and free of peaks and

valleys on the inner wall. See diagram below.

2. Blow hole clean with compressed air.

3. Refer to the diagram below for hole location and requirements.

4. Always inspect the hole carefully when reusing a previously drilled hole.

Hole to Edge:

Drill 1ӯ

(2.54cm)

10”

(25.4cm)

min from any edge

Section View:

1”min

(2.54cm)

20

6”min

(15.24cm)

5” min

depth

(12.7cm)

Page 21

User Instructions - English

Check for kinked

or frayed cables.

Look for signs

of wear on

spoons.

INSPECT BEFORE USE

Check for deformation

of cone.

INSTALLATION:

1. Before installing make sure the

cone is below the spoons. Insert the

anchor into hole so the base plate rest

at on the concrete surface.

Drop In

Swivel should

move freely.

2. Pull up on the bolt while holding

swivel ush with the concrete. Tighten

the bolt by turning it clockwise by

hand until bolt is fastened ush to

swivel.

Step 1.

3. Use a torque wrench to set the pretension on the bolt for the loading situation

required for the application.

LOAD: BOLT TORQUE:

10,000-lbf

(44 kN)

5,000-lbf

(22 kN)

85-ft-lbs

(9.60 Nm)

30-ft-lbs

(3.38 Nm)

Pull Up

Bolt &

Step 2.

Twist

Clockwise

Step 3.

21

Page 22

User Instructions - English

REMOVAL:

1. Loosen bolt so that at least 3/4”

(1.9cm) of threads are exposed.

Unscrew

min of

3/4”

(1.9cm)

2. Use a hammer to tap down bolt and

disengage cone from the spoons.

Step 1.

TAP!!!

Step 2.

3. Pull the anchor from the hole.

Step 3.

22

Page 23

User Instructions - English

4.0 Inspection and Maintenance

Inspection

Miller Anchorage Connectors are designed for today’s rugged work environments. To maintain

their service life and high performance, all components should be inspected frequently.

Anchorage connectors must be visually inspected by the user before each use and

inspected by a Competent Person on a regular basis.

Inspect product for any of the following: bent, cracked, distorted, worn, malfunctioning or

damaged parts; loose fasteners or missing parts/components; deterioration; deformation;

corrosion; signs that indicate the product has been subjected to a fall arrest; or any other

indications of damage/problems that may affect the integrity and operation of the product. If in

doubt, contact the manufacturer.

Devices that do not pass inspection

or have been subjected to fall arresting forces

must be removed from service.

Cleaning and Storage

Basic care of all Miller Fall Protection equipment will prolong the life of the unit and will contribute toward the performance of its vital safety function. Periodically clean the device to remove

any dirt, paint, corrosives, contaminants, or other materials that may have accumulated. When

not in use, store in a clean, dry area, free of exposure to furmes or corrosive elements.

Servicing

Servicing of Miller fall protection equipment must only be carried out by Honeywell Safety Products or persons or entities authorized in writing by Honeywell. A record log of all servicing and

inspection dates for this device must be maintained. Only original Honeywell replacement parts

are approved for use in this device. Non-repairable devices that do not pass inspection must

be disposed of in a manner to prevent inadvertent further use. Contact Honeywell Technical

Service at 800.873.5242 if you have any questions.

23

Page 24

Étiquettes de Produit

Etiquetas del Producto

5K Swivel AnchorRAC-

SWY050N

User Instructions - English

Product Labels

LABEL LOCATIONS

5K Swivel Anchor

Model: RACSWY050N

5K Stainless Steel

Swivel Anchor

RACSWY100N

WARNING: All persons using this equipment must read,

understand and follow all instructions. Failure to do so may

result in serious injury or death.

COMPLIANCE: OSHA 1910.66 & 1926.502 ANSI Z359.1-07

CE 0321 / EN 795:1996 (US PAT # 8,424,638)

Z359.7-11

(INSPECT BEFORE USE)

24

5k S.S. Swivel Anchor

Zinc Plated Steel

Max Capacity:

(1) person 310-lbs

Working Load 2,000-lbs

Model: RACSWY100N

Page 25

User Instructions - English

5K Drop-Through Swivel Anchor

RACDTA-5K/

Polyurethane Sleeve

4"0 3/16" Plate

(Length Specied by Customer)

Aircraft Cable

25

Page 26

User Instructions - English

10K Zinc-Plated Steel

Swivel Anchor

WARNING: All persons using this equipment must read,

understand and follow all instructions. Failure to do so may

result in serious injury or death.

COMPLIANCE: OSHA 1910.66 & 1926.502 ANSI Z359.1-07

(US PAT # 8,424,638)

Z359.7-11

(INSPECT BEFORE USE)

10K Swivel Hybrid Anchor

10k Swivel Anchor

Zinc Plated Steel

Max Capacity:

(1) person 310-lbs

Working Load 2,000-lbs

Model: RACSWY100N

WARNING: All persons using this equipment must read,

understand and follow all instructions. Failure to do so may result in

serious injury or death. (INSPECT BEFORE USE)

COMPLIANCE: OSHA 1910.66 & 1926.502 ANSI Z359.1-07 Z359.7-11

26

10k Hybrid Anchor

Zinc Plated Steel

Max Capacity:

(1) person 310-lbs

Model: RACSWH100Y

Page 27

Inspection and Maintenance Log

Registre D'inspection et D'entretien

Registro de Inspección y Mantenimiento

DATE OF MANUFACTURE:_________________________________________________

DATE DE FABRICATION / FECHA DE FABRICACIÓN

MODEL NUMBER:________________________________________________________

NUMÉRO DE MODÈLE / NÚM. DE MODELO

DATE PURCHASED:______________________________________________________

DATE D’ACHAT / FECHA DE COMPRA

INSPECTION DATE

DATE D’INSPECTION

FECHA DE INSPECCIÓN

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

INSPECTION

ITEMS NOTED

POINTS NOTÉS

LORS DE L’INSPECTION

PUNTOS DE INSPECCIÓN

RELEVANTES

CORRECTIVE

ACTION

ACTION CORRECTIVE

MEDIDA CORRECTIVA

MAINTENANCE

PERFORMED

ENTRETIEN EFFECTUÉ

MANTENIMIENTO

REALIZADO

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

Approved by:

Approuvé par:

Aprobado por:

27

Page 28

MILLER® FALL PROTECTION PRODUCTS

TOTAL SATISFACTION ASSURANCE

At Honeywell Safety Products and its predecessors, we have been providing quality Miller brand

Our products endure rigorous tests to ensure that the fall protection equipment you trust is manufactured

to the highest standards. Miller fall protection products are tested to withstand normal wear and tear,

Our Limited Lifetime Warranty does not apply to normal wear and tear or abusive treatment of the product.

If a replacement is necessary and your product is no longer available, a comparable product will be substituted.

fall protection equipment to millions of workers worldwide since 1945.

LIMITED LIFETIME WARRANTY

BACKED BY OVER 65 YEARS IN THE FALL PROTECTION BUSINESS

We sincerely believe that our fall protection equipment is the best in the world.

but are not indestructible and can be damaged by misuse.

In the unlikely event that you should discover defects in either workmanship or materials,

under our Limited Lifetime Warranty, we will repair or replace the product at our expense.

Should a product issue surface, contact us at 800.873.5242.

Manufacturing specications are subject to change without notice.

PRODUITS MILLER® FALL PROTECTION

ASSURANCE DE SATISFACTION TOTALE

Honeywell Safety Products et ses prédécesseurs offrent les équipements antichute de marque Miller

ASSURÉE GRÂCE À PLUS DE 65 ANS PASSÉS DANS LE DOMAINE DE LA PROTECTION CONTRE LES CHUTES

Nous croyons sincèrement que notre équipement de protection contre les chutes est le meilleur au monde. Nos

Les produits de protection contre les chutes Miller sont soumis à des essais pour vérier qu’ils résistent à une usure

normale; ils ne sont cependant pas indestructibles et peuvent s’endommager en cas de mauvaise utilisation. Notre

de qualité à des millions de travailleurs dans le monde entier depuis 1945.

GARANTIE LIMITÉE À VIE

produits sont soumis à des tests rigoureux, an d’assurer que les équipements de protection contre

les chutes dans lesquels vous avez conance sont fabriqués selon les normes les plus exigeantes.

garantie limitée à vie ne s’applique pas à l’usure normale ou à un usage abusif du produit.

Dans le cas peu probable où vous découvririez des défauts, soit de fabrication, soit de matériau,

dans le cadre de notre garantie à vie, nous réparerons ou remplacerons le produit à nos frais.

En cas de remplacement, si votre produit n’est plus offert, vous recevrez un produit comparable.

En cas de problème sur un produit, nous contacter au 800-873-5242.

Les caractéristiques de fabrication peuvent être modiées sans préavis.

PRODUCTOS ANTICAÍDAS MILLER

®

GARANTÍA DE SATISFACCIÓN TOTAL

En Honeywell Safety Products y sus predecesores, hemos estado brindando la calidad de la marca Miller en

equipos de protección de caída a millones de trabajadores alrededor del mundo desde 1945.

NOS RESPALDAN MÁS DE 65 AÑOS EN LA FABRICACIÓN DE EQUIPO ANTICAÍDAS

Sinceramente creemos que su equipo de protección contra caídas es el mejor del mundo. Nuestros productos resisten

rigurosas pruebas para garantizar que el equipo de protección contra caídas en el que usted confía está fabricado de

conformidad con las normas más elevadas. Los productos anticaídas Miller son sometidos a pruebas para que resistan el

desgaste normal, pero no son indestructibles y su incorrecta utilización puede dañarlos.

Nuestra Garantía limitada de por vida no se aplica al desgaste normal ni al maltrato del producto.

En el poco probable caso de que usted descubriera defectos de mano de obra o materiales, por nuestra Garantía lim-

itada de por vida, repararemos o sustituiremos el producto por cuenta nuestra. Si un reemplazo es necesario y nuestro

producto ya no está disponible, se lo sustituiremos por otro comparable.

En caso de que surja un problema con el producto, contáctenos al 800.873.5242.

Las especicaciones de fabricación están sujetas a modicaciones sin previo aviso.

GARANTÍA LIMITADA DE POR VIDA

28

Page 29

User Instructions - English

29

Page 30

Toll Free: 800.873.5242

Fax: 800.892.4078

Download this manual at: www.millerfallprotection.com

Téléchargez ce manuel à l’adresse: www.millerfallprotection.com

Puede bajar por Internet este manual en: www.millerfallprotection.com

Honeywell Safety Products

P.O. Box 271, 1345 15th Street

Franklin, PA 16323 USA

Loading...

Loading...