Page 1

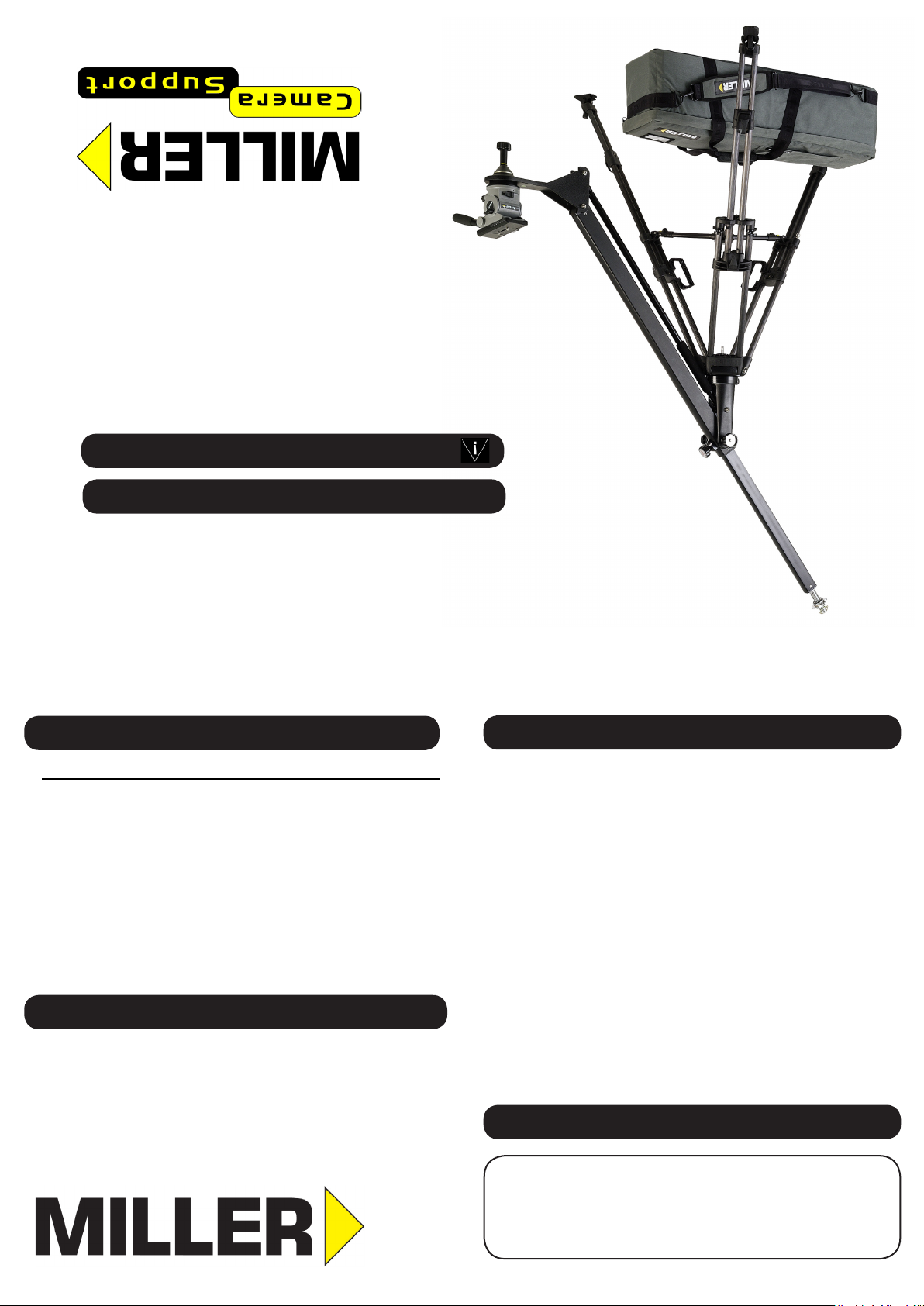

#711 Projib Jib Arm

SAFETY - READ THIS OPERATOR’S MANUAL

O P E R A T O R ’ S M A N U A L

PROJIB

ACCESSORIES & COMPONENTS

Cat # Description

#715 Undermount Kit for Projib

#480 Studio HD Dolly

#483 Studio HD Dolly with Cable Guards and Track Lock

#475 Detachable Rubber Feet (set of 3)

#990 Mid Level Spreader

#974 Softcase for HD 100 & HD 150 2-stage

#309 Hardcase for HD 100 2-stage

#298 Hardcase for HD 150 & Flat Base 1 & 2 Stage

#712 Softcase for Projib

WARRANTY

The Miller Projib is warranteed against any defect in material or

workmanship for a period of 12 calendar months from date of purchase.

Within this period, we undertake to supply replacements free of charge

for any parts which may prove, on examination, to be defective provided

that such defectiveness is not the result of misuse (including use with

unsuitable ancillary equipment), accident or negligence and further, that

the equipment was purchased from an authorised Miller Fluid Heads’

distributor.

SERVICE, SALES & SUPPORT

Miller Authorised Service Agents must carry out all service and repair work.

Failure to observe this requirement may void warranty. It is advisable to

notify Miller or a MIller Authorised Service Agent if a change of performance is observed as a result of dropping or rough usage. For information

regarding sales and service of Miller products, or for your nearest Miller

representative please contact us via our website or at the following:

MILLER CAMERA SUPPORT EQUIPMENT

30 Hotham Parade, Artarmon, Sydney

NSW 2064 Australia

Tel: +61 2 9439 6377

Fax: +61 2 9438 2819

Email: sales@miller.com.au

MILLER FLUID HEADS (Europe) LTD.

Unit 12A, Shepperton Business Park

Govett Avenue, Shepperton

Middlesex TW17 8BA United Kingdom

Tel: +44 (0)1932 222 888

Fax: +44 (0)1932 222 211

Email: sales@millertripods-europe.com

WEBSITE www.millertripods.com

MILLER CAMERA SUPPORT LLC (USA)

218 Little Falls Road, Cedar Grove,

New Jersey 07009-1231 USA

Tel: (973) 857 8300

Fax: (973) 857 8188

Email: sales@millertripods.us

D5120-4

Page 2

INTRODUCTION

PROJIB SETUP contd.

The Miller Projib is a versatile camera mount; designed to add the

dimension of tracking and elevation to the normal range of movements

afforded by your uid head. It is designed for use in professional lm

and video

production by professional support equipment operators. For safe op-

eration of the Miller Projib, please observe the following precautions:

SAFETY INSTRUCTIONS

The Safe setup and operation of this equipment is the responsibilty

of the operator. This equipment is to be set up and used by qualied

personnel only.

A Miller Projib, when loaded with camera, uid head and counterbalance weights, exerts a considerable amount of leverage on the surface

it is attached to. For this reason, precautions must be taken to prevent

accidental over-balancing. ACCIDENTAL OVER-BALANCING OF

THE PROJIB MAY CAUSE EXPENSIVE EQUIPMENT DAMAGE AND

SERIOUS PERSONAL INJURY. The risk of over-balancing is reduced

by adding suitable ballast, such as sandbags, to the base of the tripod

or dolly to which the Projib is attached. THE USE OF SUITABLE AND

SUFFICIENT BALLAST IS ESSENTIAL TO SAFE PROJIB OPERATION.

The Miller Projib is designed to attach to most professional heavy duty

tripods or hi-hat type dollies. FOR MAXIMUM STABILITY WHEN USING

TWO STAGE TRIPODS, ENSURE THAT THE LOWER TUBE LEGS

ARE COMPLETELY COLLAPSED.

The total payload must not exceed the capacity of the tripod. NOTE:

Make sure all items on the jib, (uid head, camera and counterbalance

weights), as well as the jib itself, are considered in assessing the weight

of the payload. The jib is designed to carry a camera and uid head

weight up to 50 lbs. (22kg) maximum.

4. Attach a 100mm ball levelling uid head to the jib mounting plate.

View the 2nd spirit level, located on the uid head mounting surface of

Projib. If it is not indicating level, rst check to make sure that the central

pivot point is level. Once that is conrmed, loosen the lock ring that is

located at the base of the parallel tube under the jib arm near the central

pivot point at the tripod. CAUTION! DO NOT LOOSEN THE LOCK

RING FOUND NEAR THE FLUID HEAD MOUNTING SURFACE

WHICH IS USED ONLY TO RETURN THE PROJIB TO STORAGE

POSITION. Once the lock ring near the center of Projib is loosened, turn

the entire parallel tube beneath the jib arm in or out until the uid head

mounting surface is indicating level in the #2 bubble level. Tighten the

lock ring in this position. Now level the uid head using the bubble level

on the uid head. Once all three bubble levels are indicating level, the

camera will remain level throughout the jib’s operational range.

5. Mount camera to uid head and add sufcient weights to rear of jib (or

adjust length of jib counterbalance arm) to balance camera. CAUTION:

THE PROJIB COMES EQUIPPED WITH A LARGE PIN WHICH WILL

PREVENT ACCIDENTAL DETACHMENT OF THE WEIGHT RETAINING

NUT DURING JIB OPERATION. BE CERTAIN THAT THIS COTTER

PIN IS IN PLACE DURING JIB OPERATION.

OPERATING CONTROLS

The Projib is tted with pan and tilt drag controls and positive tilt lock for

the jib arm vertical movement. The tilt lock is easily distinguished from

the tilt drag by the large cone shape thrust locker located under the tilt

lock knob. Rotating the drag adjusters inward (clockwise) increases the

amount of drag; counter-clockwise rotation reduces drag. Pan and tilt

drag are adjusted by the operator to personal preference and to achieve

correct motion for shooting requirements.

If the Projib is mounted on a dolly, the dolly should be of a heavy duty

type with sufcient additional payload capacity to accept sandbags or

similar safety ballast to prevent over-balancing as cautioned above.

FAILURE TO OBSERVE THIS PRECAUTION MIGHT CAUSE THE

ASSEMBLY TO OVER-BALANCE IF THE DOLLY IS BROUGHT TO A

SUDDEN STOP AT THE END OF A TRACKING MOVEMENT.

COUNTERWEIGHTS

Miller recommends the use of standard, rubber covered circular barbell weights as suitable counterbalance for the Projib. For the average

camera/uid head payload of between 15kg (30lb) and 20kg (45lb), a

suitable combination of 5kg (10lb), 7.5kg (15lb) and 10kg (20lb) bar-bell

weights is recommended.

PROJIB SETUP

1. Remove the Priojib from the protective carry case and ip over the

uid head mounting plate so that the threaded male and female mount-

ing connectors are aligned. Join the connectors and hand-tighten only.

2. Attach the Projib to the tripod using the clamp nut provided. Note

that the main body of the Projib at the pivot point is tted with a spirit

level. Adjust the legs of the tripod so that the spirit level indicates a level

position for the PROjIB. FAILURE TO LEVEL AT THIS POINT FIRST

WILL PREVENT THE PROJIB FROM MAINTAINING A LEVEL POSITION THROUGHOUT THE RANGE OF MOTION OF THE PROJIB ARM

- REGARDLESS OF OTHER ADJUSTMENTS! Correct levelling of the

tripod bowl or dolly hi-hat is important and should be checked regularly

during operation. Do not adjust the level of the tripod or dolly with the

camera tted.

PROJIB SPECIFICATIONS

Maximum Payload 25kg (50lb)

Typical Payload ENG Camcorders up to 20kg (44lb)

Weight 11.4kg (25lb)

Height Range 2m (78”)

Dimensions (mm) 230W x 505D x 1220L

(folded down) (in) 9”W x 20”D x 48”L

Counterbalance 25mm (1”) centre barbell weights

Attachment 100mm Base, 100mm bowl

Controls Friction pan & tilt locks

Adjustable tilt drag

Levelling Adjustable levelling arm. Dual bubble

levels mounted at tripod base and

uid head mount

Min Tripod Req. HD-style tripod with minimum

24mm (1”) tube diameter.

3. Loosen the lock nut that controls the motion of the sliding counterbalance arm at the rear of the Projib. Slide this arm out so as to achieve a

balance in the Projib over the pivot point at the tripod.

Loading...

Loading...