Miller ProHeat 35, ProHeat 35 CE, ProHeat 35 Non CE, 907271, 907298 Owner's Manual

...

OM-222166AH 2016−12

Processes

Induction Heating

Description

Induction Heating Power Source

[

ProHeat 35

CE And Non CE Models

(For Stock Nos. 907271, 907298, and 907432)

Visit our website at

www.MillerWelds.com

File: Induction Heating

From Miller to You

Thank you and congratulations on choosing Miller. Now you can get

the job done and get it done right. We know you don’t have time to do

it any other way.

That’s why when Niels Miller first started building arc welders in 1929,

he made sure his products offered long-lasting value and superior

quality. Like you, his customers couldn’t afford anything less. Miller

products had to be more than the best they could be. They had to be the

best you could buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and service

that meets the high standards of quality and value established in 1929.

This Owner’s Manual is designed to help you get the most out of your

Miller products. Please take time to read the Safety precautions. They

will help you protect yourself against potential hazards on the worksite.

We’ve made installation and operation quick

and easy. With Miller you can count on years

of reliable service with proper maintenance.

And if for some reason the unit needs repair,

there’s a Troubleshooting section that will

help you figure out what the problem is. The

Miller is the first welding

equipment manufacturer in

the U.S.A. to be registered to

the ISO 9001 Quality System

Standard.

parts list will then help you to decide the

exact part you may need to fix the problem.

Warranty and service information for your

particular model are also provided.

Working as hard as you do

− every power source from

Miller is backed by the most

hassle-free warranty in the

business.

Miller Electric manufactures a full line

of welders and welding related equipment.

For information on other quality Miller

products, contact your local Miller distributor to receive the latest full

line catalog or individual specification sheets. To locate your nearest

distributor or service agency call 1-800-4-A-Miller, or visit us at

www.MillerWelds.com on the web.

Mil_Thank 2009−09

TABLE OF CONTENTS

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING 1.................................

1-1. Symbol Usage 1.......................................................................

1-2. Induction Heating Hazards 1.............................................................

1-3. Additional Symbols for Installation, Operation, and Maintenance 2..............................

1-4. California Proposition 65 Warnings 3......................................................

1-5. Principal Safety Standards 3.............................................................

1-6. EMF Information 3.....................................................................

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION 4..........................

2-1. Signification des symboles 4.............................................................

2-2. Dangers relatifs au soudage à l’arc 4......................................................

2-3. Dangers supplémentaires en relation avec l’installation, le fonctionnement et la maintenance 5.....

2-4. Proposition californienne 65 Avertissements 6..............................................

2-5. Principales normes de sécurité 6.........................................................

2-6. Informations relatives aux CEM 6.........................................................

SECTION 3 − DEFINITIONS 7..................................................................

3-1. Additional Safety Symbols And Definitions 7................................................

3-2. Miscellaneous Symbols And Definitions 9..................................................

SECTION 4 − SPECIFICATIONS 10..............................................................

4-1. Serial Number and Rating Label Location 10.................................................

4-2. Specifications 10........................................................................

4-3. Environmental Specifications 10...........................................................

SECTION 5 − INSTALLATION 12................................................................

5-1. Selecting A Location 12..................................................................

5-2. Dimensions And Weights 12..............................................................

5-3. Electrical Service Guide 13...............................................................

5-4. Connecting 3-Phase Input Power For 460/575 Volt Models 14..................................

5-5. Connecting 3-Phase Input Power For 400/460 Volt IEC And CE Models 16.......................

5-6. Coolant Jumper Connections 17...........................................................

5-7. Power Source Output Connections 18......................................................

5-8. Remote 14 Receptacle RC14 Information and Connections 19.................................

5-9. Remote 14 Socket Information 19..........................................................

5-10. Temperature Recorder Receptacle RC9 Information And Connections 20........................

5-11. Temperature Recorder Socket Information 20................................................

5-12. Secondary Insulation Protection 21........................................................

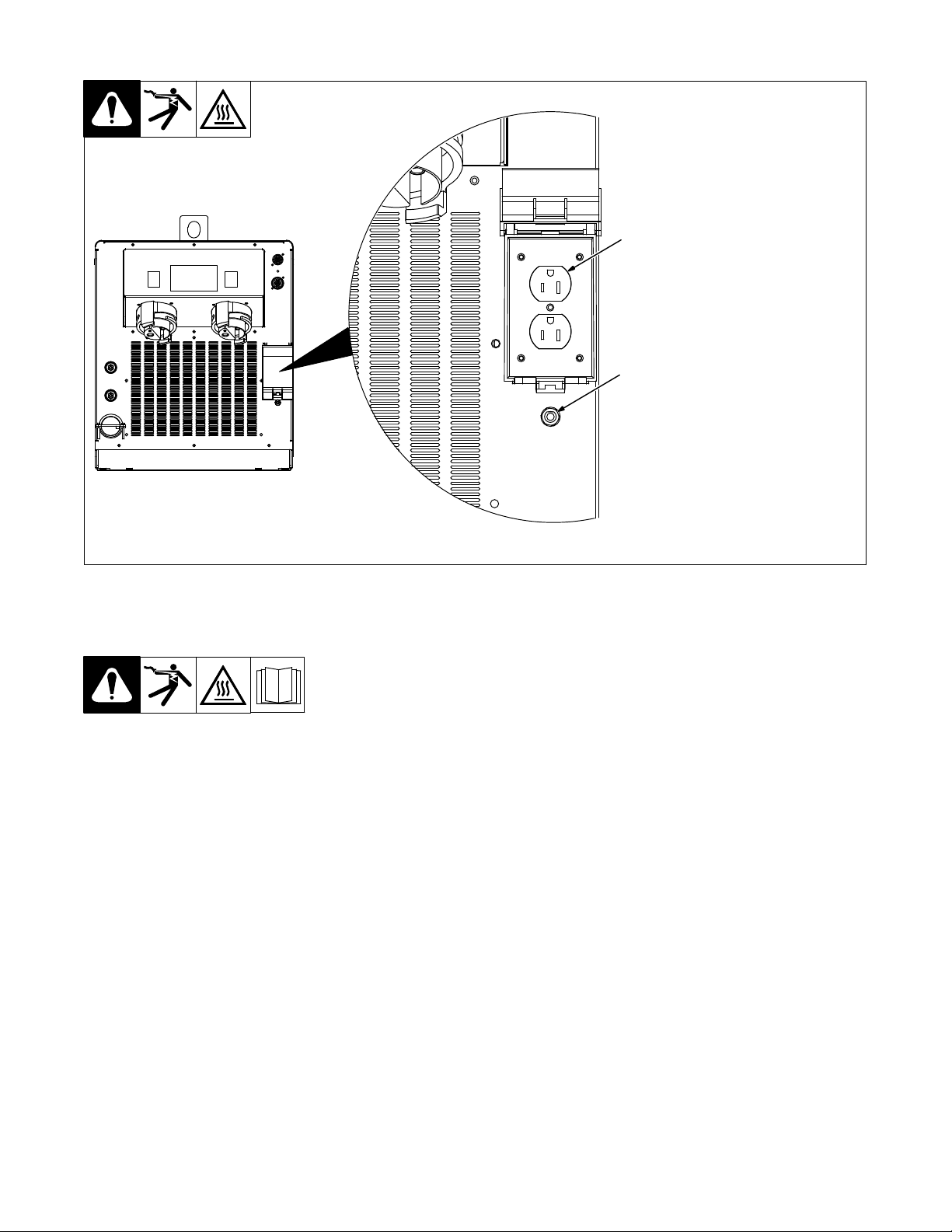

5-13. 115 Volt AC Duplex Receptacle And Supplementary Protector 22...............................

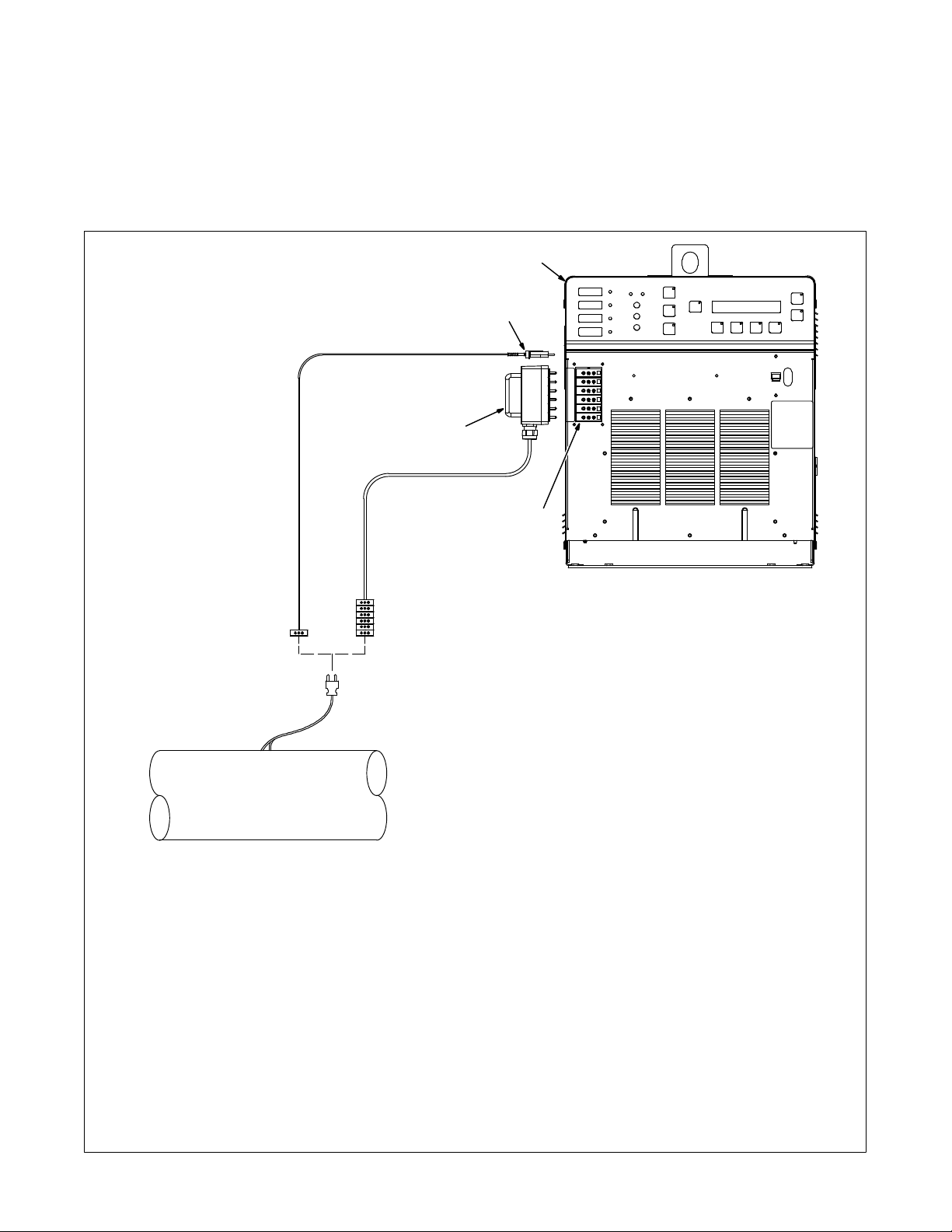

5-14. Locating Thermocouples 22..............................................................

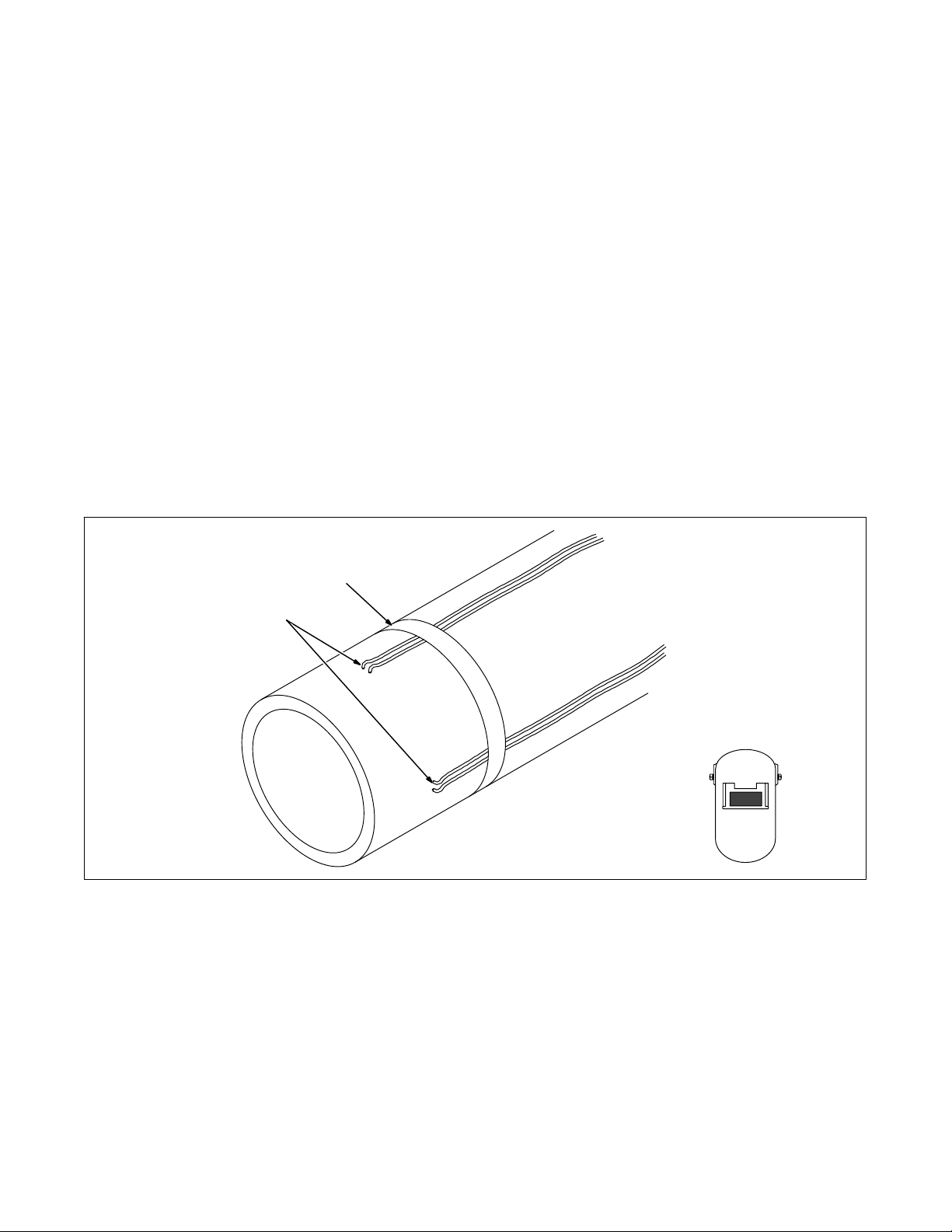

5-15. Attaching Welded Thermocouples 24.......................................................

5-16. Using Contact Thermocouple Sensors 25...................................................

5-17. Using Non−contact Temperature Sensors 25................................................

SECTION 6 − COMPONENTS AND CONTROLS 26................................................

6-1. Controls 26............................................................................

SECTION 7 − SETUP AND OPERATION 27.......................................................

7-1. Safety Equipment 27....................................................................

7-2. System Description 27...................................................................

7-3. Important System Guidelines 27...........................................................

7-4. Power Source/System Setup 27...........................................................

7-4-1.Factory Defaults 29...................................................................

7-5. Programming 29........................................................................

7-5-1.Temperature-Based Control 29..........................................................

TABLE OF CONTENTS (continued)

7-5-1-1. Preheat 29.....................................................................

7-5-1-2. Bake-Out 30....................................................................

7-5-1-3. PWHT (Post-Weld Heat T reat) 31..................................................

7-5-1-4. PWHT Operation 32.............................................................

7-5-1-5. Custom Program 32.............................................................

7-5-2.Remote Control 36....................................................................

7-5-3.Power vs Time Control 36..............................................................

7-5-4.Manual Control 36....................................................................

7-5-5.Rolling Inductor—Manual Or Temperature Control Mode 37..................................

7-6. Run Status 39..........................................................................

7-6-1.Temperature Based Control 39..........................................................

7-6-1-1. Preheat, Bake-Out And PWHT Run Status Screen 39.................................

7-6-1-2. Custom Program (Not Applicable With Rolling Inductor) 39.............................

7-6-2.Manual Control 40....................................................................

7-6-3.Remote Control 40....................................................................

7-6-4.Power vs Time Control 40..............................................................

7-7. Parameters 40..........................................................................

7-8. Cooler 41..............................................................................

7-9. Real-Time Operation 41..................................................................

7-10. System Operating Characteristics 44.......................................................

SECTION 8 − MAINTENANCE 46................................................................

8-1. Routine Maintenance 46.................................................................

8-2. Calibration Verification Equipment 47.......................................................

8-3. Calibration Verification Procedure 47.......................................................

8-3-1.Initial Set Up 47......................................................................

8-3-2.TC Input/Output Check 47.............................................................

8-3-3.Finishing Procedure 48................................................................

SECTION 9 − SAFETY PRECAUTIONS FOR SERVICING 51........................................

9-1. Symbol Usage 51.......................................................................

9-2. Servicing Hazards 51....................................................................

9-3. California Proposition 65 Warnings 52......................................................

SECTION 10 − DIAGNOSTICS & TROUBLESHOOTING 53.........................................

10-1. Operator Interface Indicators 53...........................................................

10-2. Limit Conditions 54......................................................................

10-3. Limit Condition Codes 54.................................................................

10-4. Fault Conditions 55......................................................................

10-5. Fault Condition Codes 55.................................................................

10-6. Infrared Sensor Troubleshooting Guide 57..................................................

10-7. System Diagnostic Screens 57............................................................

10-8. ProHeat 35 Firmware Versions And Compatibility 59..........................................

10-9. Removing Wrapper and Measuring Input Capacitor V oltage 60.................................

10-10. Blowing Out Inside Of Unit 61..........................................................

SECTION 11 − ELECTRICAL DIAGRAM 62.......................................................

SECTION 12 − PARTS LIST 64..................................................................

WARRANTY

DECLARATION OF CONFORMITY

for European Community (CE marked) products.

MILLER Electric Mfg. Co., 1635 Spencer Street, Appleton, WI 54914 U.S.A. declares that the

product(s) identified in this declaration conform to the essential requirements and provisions of

the stated Council Directive(s) and Standard(s).

Product/Apparatus Identification:

Product

PROHEAT 35 W/TEMPERATURE CONTROL

Stock Number

907432

400460V, CE

Council Directives:

• 2006/95/EC Low Voltage

• 2004/108/EC Electromagnetic Compatibility

• 2011/65/EU Restriction of the use of certain hazardous substances in electrical and electronic equipment

Standards:

• IEC 609741:2005 Arc welding equipment – Part 1: Welding power sources

• IEC 6097410:2007 Arc Welding Equipment – Part 10: Electromagnetic compatibility (EMC) requirements

• EN 50445:2008 Product family standard to demonstrate compliance of equipment for resistance welding,

arc welding and allied processes with the basic restrictions related to human exposure to electromagnetic

fields (0 Hz – 300Hz)

Signatory:

October 8, 2012

_____________________________________ ___________________________________________

David A. Werba Date of Declaration

240667D

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING

ihom _2015-09

Protect yourself and others from injury — read, follow , and save these important safety precautions and operating instructions.

1-1. Symbol Usage

DANGER! − Indicates a hazardous situation which, if

not avoided, will result in death or serious injury. The

possible hazards are shown in the adjoining symbols

or explained in the text.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury. The possible

hazards are shown in the adjoining symbols or explained in the text.

NOTICE − Indicates statements not related to personal injury .

1-2. Induction Heating Hazards

The symbols shown below are used throughout this manual

to call attention to and identify possible hazards. When you

see the symbol, watch out, and follow the related instructions

to avoid the hazard. The safety information given below is

only a summary of the more complete safety information

found in the Safety Standards listed in Section 1-5. Read and

follow all Safety Standards.

Only qualified persons should install, operate, maintain, and

repair this unit.

During operation, keep everybody, especially children, away.

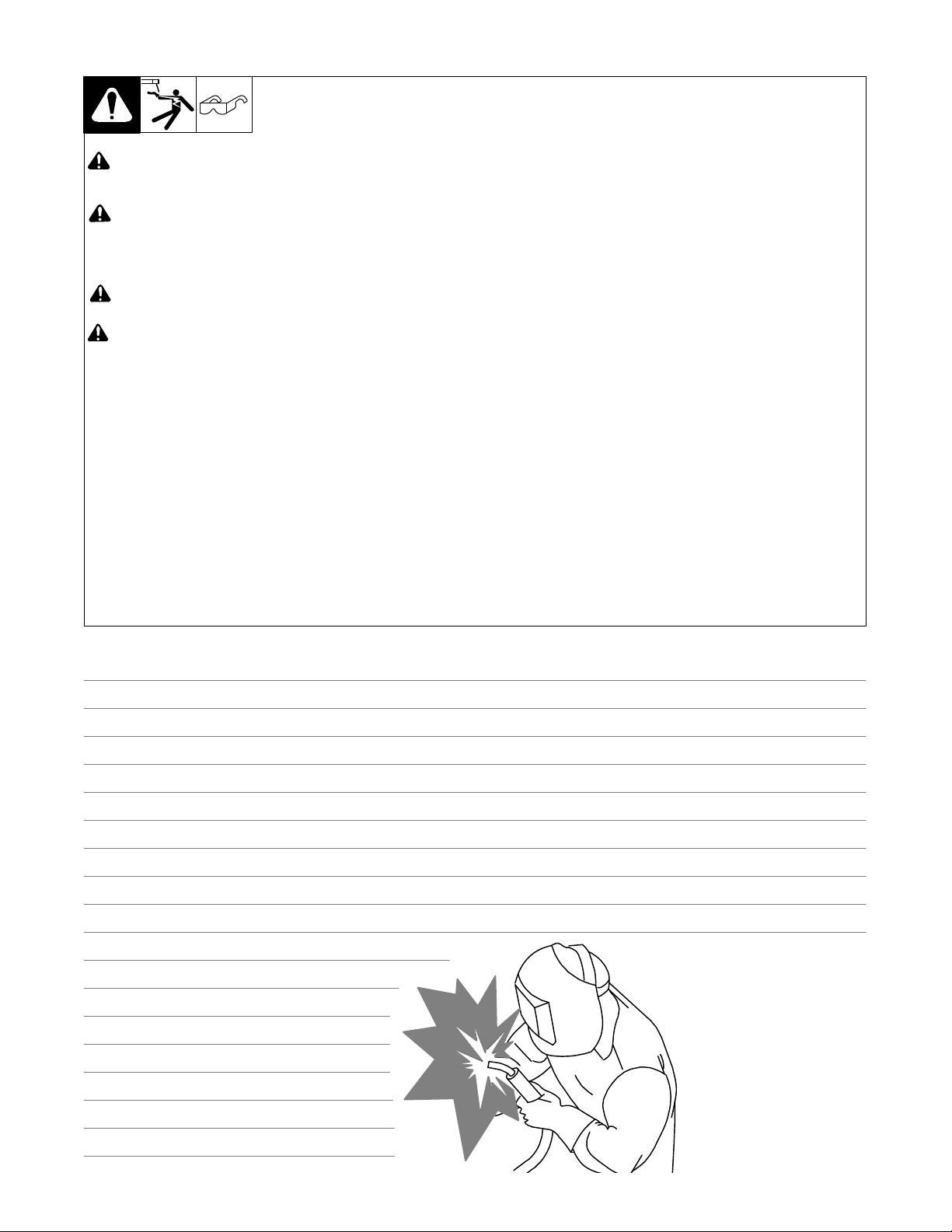

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks

or severe burns. The power circuit and output bus

bars or connections are electrically live whenever

internal circuits are also live when power is on. Incorrectly installed or

improperly grounded equipment is a hazard.

D Do not touch live electrical parts.

D Enclose any connecting bus bars and coolant fittings to prevent

unintentional contact.

D Wear dry , hole-free insulating gloves and body protection.

D Insulate yourself from work and ground using dry insulating mats or

covers big enough to prevent any physical contact with the work or

ground.

D Additional safety precautions are required when any of the following

electrically hazardous conditions are present: in damp locations or

while wearing wet clothing; on metal structures such as floors, gratings, or scaffolds; when in cramped positions such as sitting,

kneeling, o r lying; or when there is a high risk of unavoidable or accidental contact with the workpiece or ground. For these conditions,

see ANSI Z49.1 listed in Safety Standards. And, do not work alone!

D Disconnect input power before installing or servicing this equip-

ment. Lockout/tagout input power according to OSHA 29 CFR

1910.147 (see Safety Standards).

D Use only nonconductive coolant hoses with a minimum length of 18

inches (457 mm) to provide isolation.

D Properly install, ground, and operate this equipment according to its

Owner’s Manual and national, state, and local codes.

D Always verify the supply ground − check and be sure that input pow-

er cord ground wire is properly connected to ground terminal in

disconnect box or that cord plug is connected to a properly grounded

receptacle outlet.

D When making input connections, attach proper grounding

conductor first − double-check connections.

D Keep cords dry, free of oil and grease, and protected from hot metal

and sparks.

the output is on. The input power circuit and machine

. Indicates special instructions.

This group of symbols means Warning! Watch Out! ELECTRIC

SHOCK, MOVING P ARTS, and HOT PARTS hazards. Consult symbols and related instructions below for necessary actions to avoid the

hazards.

D Frequently inspect input power cord and ground conductor for dam-

age or bare wiring – replace immediately if damaged – bare wiring

can kill.

D Turn off all equipment when not in use.

D Do not use worn, damaged, undersized, or repaired cables.

D Do not drape cables over your body.

D Do not touch power circuit if you are in contact with the work, ground,

or another power circuit from a different machine.

D Use only well-maintained equipment. Repair or replace damaged

parts at once. Maintain unit according to manual.

D Wear a safety harness if working above floor level.

D Keep all panels and covers securely in place.

D Use GFCI protection when operating auxiliary equipment in damp or

wet locations.

SIGNIFICANT D C V O LTAGE exists in inverter power

sources AFTER removal of input power.

D Turn Off inverter, disconnect input power, and discharge input

capacitors according to instructions in Maintenance Section before

touching any internal parts.

FUMES AND GASES can be hazardous.

Induction Heating of certain materials, adhesives,

and fluxes can produce fumes and gases. Breathing

these fumes and gases can be hazardous to your

health.

D Keep your head out of the fumes. Do not breathe the fumes.

D If inside, ventilate the area and/or use local forced ventilation to re-

move fumes and gases. The recommended way to determine

adequate ventilation is to sample for the composition and quantity of

fumes and gases to which personnel are exposed.

D If ventilation is poor, wear an approved air-supplied respirator.

D Read and understand the Safety Data Sheets (SDSs) and the man-

ufacturer’s instructions for adhesives, coatings, cleaners,

consumables, coolants, degreasers, fluxes, and metals.

D Work in a confined space only if it is well ventilated, or while wearing

an air-supplied respirator. Always have a trained watchperson nearby. Fumes and gases from heating can displace air and lower the

oxygen level causing injury or death. Be sure the breathing air is

safe.

D Do not heat in locations near degreasing, cleaning, or spraying oper-

ations. The heat can react with vapors to form highly toxic and

irritating gases.

D Do not overheat coated metals, such as galvanized, lead, or

cadmium plated steel, unless the coating is removed from the

heated area, the area is well ventilated, and while wearing an airsupplied respirator. The coatings and any metals containing these

elements can give off toxic fumes if overheated. See coating SDS

for temperature information.

OM-222166 Page 1

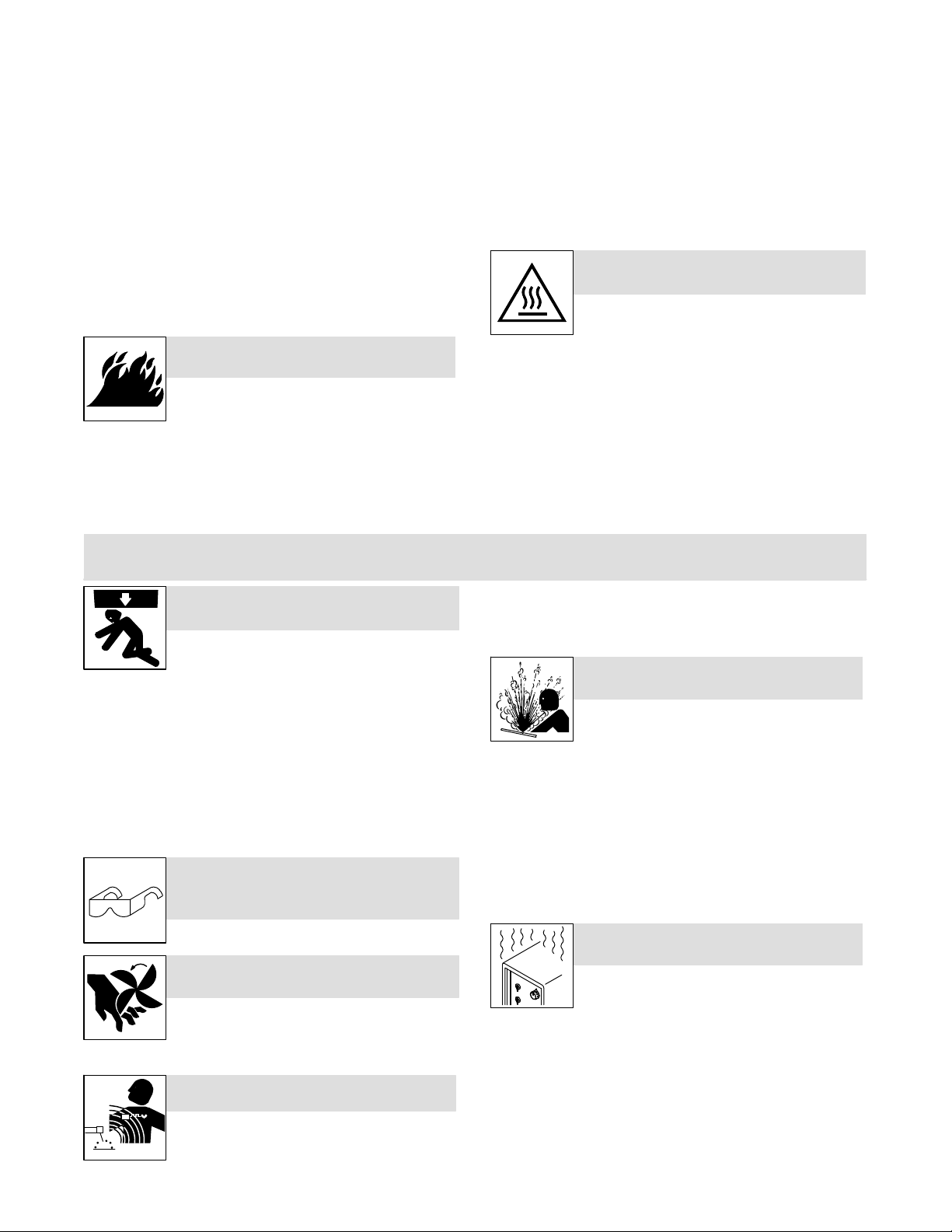

FIRE OR EXPLOSION hazard.

)

r

t

INDUCTION HEATING can burn.

D Do not overheat parts.

D Watch for fire; keep extinguisher nearby.

D Keep flammables away from work area.

D Do not locate unit on, over, or near combustible surfaces.

D Do not install unit near flammables.

D Do not operate where the atmosphere can contain flammable

dust, gas, or liquid vapors (such as gasoline).

D After completion of work, inspect area to ensure it is free of

sparks, glowing embers, and flames.

D Use only correct fuses or circuit breakers. Do not oversize or by-

pass them.

D Read and understand the Safety Data Sheets (SDSs) and the

manufacturer’s instructions for adhesives, coatings, cleaners,

consumables, coolants, degreasers, fluxes, and metals.

D Wear body protection made from durable, flame−resistant material

(leather, heavy cotton, wool). Body protection includes oil-free

clothing such as leather gloves, heavy shirt, cuffless trousers, high

shoes, and a cap.

D Do not touch or handle induction head/coil during operation un-

less the equipment is designed and intended to be used in this

manner as specified in the owner’s manual.

D Keep metal jewelry and other metal personal items away from

head/coil during operation.

D To handle hot parts, use proper tools and/or wear heavy, insu-

lated welding gloves and clothing to prevent burns.

D Do not touch hot parts bare-handed.

D Allow cooling period before handling parts or

equipment.

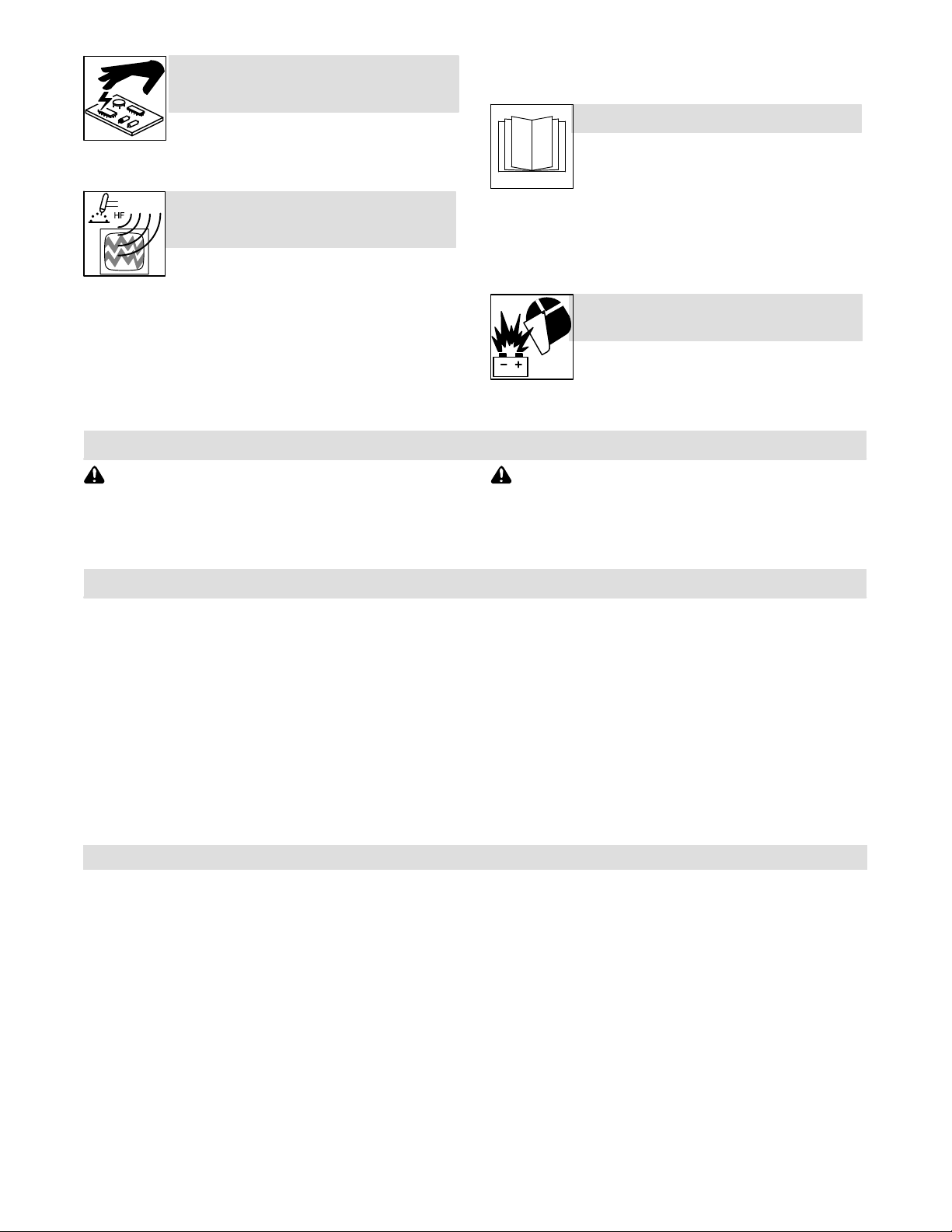

1-3. Additional Symbols for Installation, Operation, and Maintenance

FALLING EQUIPMENT can injure.

D Use handle and have person of adequate

physical strength lift unit.

D Move unit with hand cart or similar device.

D For units without a handle, use equipment of adequate capacity to

lift and support unit.

D Keep equipment (cables and cords) away from moving vehicles

when working from an aerial location.

D If using lift forks to move unit, be sure forks are long enough to

extend beyond opposite side of unit.

D Follow the guidelines in the Applications Manual for the Revised

NIOSH Lifting Equation (Publication No. 94−1 10) when manually

lifting heavy parts or equipment.

FLYING METAL OR DIRT can injure eyes.

D Wear approved safety glasses with side

shields or wear face shield.

D If coolant flow stops, leave one end of hose connected to allow

coolant to return to cooler and relieve pressure.

D Remove hose from hot workpiece to prevent damage.

D Visually inspect condition of hoses, cords, and cables before

each use. Do not use damaged hoses, cords, or cables.

STEAM AND HO T C O OLANT can burn.

Hose may rupture if coolant overheats.

D Never disconnect both ends of hose when in-

stalled on hot workpiece.

OVERUSE can cause OVERHEATING

D Allow cooling period.

D Reduce output or reduce duty cycle before

starting to heat again.

D Follow rated duty cycle.

STATIC (ESD) can damage PC boards.

MOVING PARTS can injure.

D Keep away from moving parts such as fans.

D Keep all doors, panels, covers, and guards

closed and securely in place.

D Have only qualified persons remove doors, panels, covers, or

guards for maintenance and troubleshooting as necessary.

D Reinstall doors, panels, covers, or guards when maintenance is

finished and before reconnecting input power.

ELECTRIC AND MAGNETIC FIELDS (EMF

can affect Implanted Medical Devices.

D Wearers of Pacemakers and other Implanted

Medical Devices should keep away.

D Implanted Medical Device wearers should consult their docto

and the device manufacturer before going near arc welding, spo

welding, gouging, plasma arc cutting, or induction heating

operations.

OM-222166 Page 2

D Put on grounded wrist strap BEFORE handling

boards or parts.

D Use proper static-proof bags and boxes to

store, move, or ship PC boards.

H.F. RADIATION can cause interference.

D High-frequency (H.F.) can interfere with radio

navigation, safety services, computers, and

communications equipment.

D Have only qualified person familiar with elec-

tronic equipment perform this installation.

D The user is responsible for having a qualified electrician promptly

correct any interference problem resulting from the installation.

D If notified by the FCC about interference, stop using the equip-

ment at once.

D Have the installation regularly checked and maintained.

D Keep high-frequency source doors and panels tightly shut.

READ INSTRUCTIONS.

BATTERY EXPLOSION can injure.

D Read and follow all labels and the Owner’s

Manual c a r e f u l l y b e f ore installing, operating, or

servicing unit. Read the safety information at

the beginning of the manual and in each

section.

D Use only genuine replacement parts from the manufacturer.

D Perform installation, maintenance, and service according to the

Owner’s Manuals, industry standards, and national, state, and

local codes.

1-4. California Proposition 65 Warnings

Welding or cutting equipment produces fumes or gases

which contain chemicals known to the State of California to

cause birth defects and, in some cases, cancer. (California

Health & Safety Code Section 25249.5 et seq.)

1-5. Principal Safety Standards

Safety i n W elding, Cutting, and Allied Processes, ANSI Standard Z49.1,

is available as a free download from the American Welding Society at

http://www.aws.org or purchased from Global Engineering Documents

(phone: 1-877-413-5184, website: www.global.ihs.com).

Safety in Welding, Cutting, and Allied Processes, CSA Standard

W117.2, from Canadian Standards Association, Standards Sales, 5060

Spectrum Way, Suite 100, Mississauga, Ontario, Canada L4W 5NS

(phone: 800-463-6727, website: www.csa-international.org).

OSHA, Occupational Safety and Health Standards for General Industry ,

Title 29, Code of Federal Regulations (CFR), Part 1910, Subpart Q, and

Part 1926, Subpart J, from U.S. Government Printing Of fice, Superintendent of Documents, P.O. Box 371954, Pittsburgh, PA 15250-7954

(phone: 1-866-512-1800) (there are 10 OSHA Regional Offices—phone

for Region 5, Chicago, is 312-353-2220, website: www .osha.gov).

D Do not use induction equipment to charge bat-

teries or jump start vehicles unless it has a battery charging feature designed for this purpose.

This product contains chemicals, including lead, known to the

state of California to cause cancer, birth defects, or other reproductive harm. Wash hands after use.

National Electrical Code, NFPA Standard 70, from National Fire Protection Association, Quincy, MA 02269 (phone: 1-800-344-3555, website:

www.nfpa.org and www. sparky.org).

Canadian Electrical Code Part 1, CSA Standard C22.1, from Canadian

Standards Association, Standards Sales, 5060 Spectrum Way, Suite

100, Mississauga, Ontario, Canada L4W 5NS (phone: 800-463-6727,

website: www.csagroup.org).

Safe Practice For Occupational And Educational Eye And Face Protection, ANSI Standard Z87.1, from American National Standards Institute,

25 West 43rd Street, New York, NY 10036 (phone: 212-642-4900, website: www.ansi.org).

Applications Manual for the Revised NIOSH Lifting Equation, The National Institute for Occupational Safety and Health (NIOSH), 1600 Clifton

Rd, Atlanta, GA 30329-4027 (phone: 1-800-232-4636, website:

www.cdc.gov/NIOSH).

1-6. EMF Information

Electric current flowing through any conductor causes localized electric

and magnetic fields (EMF). The current from arc welding (and allied processes including spot welding, gouging, plasma arc cutting, and

induction heating operations) creates an EMF field around the welding

circuit. EMF fields can interfere with some medical implants, e.g. pacemakers. Protective measures for persons wearing medical implants

have to be taken. For example, restrict access for passers−by or conduct individual risk assessment for welders. All welders should use the

following procedures in order to minimize exposure to EMF fields from

the welding circuit:

1. Keep cables close together by twisting or taping them, or using a

cable cover.

2. Do not place your body between welding cables. Arrange cables

to one side and away from the operator.

3. Do not coil or drape cables around your body.

4. Keep head and trunk as far away from the equipment in the welding circuit as possible.

5. Connect work clamp to workpiece as close to the weld as

possible.

6. Do not work next to, sit or lean on the welding power source.

7. Do not weld whilst carrying the welding power source or wire

feeder.

About Implanted Medical Devices:

Implanted Medical Device wearers should consult their doctor and the

device manufacturer before performing or going near arc welding, spot

welding, gouging, plasma arc cutting, or induction heating operations. If

cleared by your doctor, then following the above procedures is recommended.

OM-222166 Page 3

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT

,

UTILISATION

ihom 2015−09fre

Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives

aux précautions de sécurité et au mode opératoire.

2-1. Signification des symboles

DANGER! − Indique une situation dangereuse qui si on

l’évite pas peut donner la mort ou des blessures graves.

Les dangers possibles sont montrés par les symboles

joints ou sont expliqués dans le texte.

Indique une situation dangereuse qui si on l’évite pas

peut donner la mort ou des blessures graves. Les

dangers possibles sont montrés par les symboles

joints ou sont expliqués dans le texte.

AVIS − Indique des déclarations pas en relation avec des blessures personnelles.

2-2. Dangers relatifs au soudage à l’arc

Les symboles présentés ci-après sont utilisés tout au long du

présent manuel pour attirer votre attention et identifier les risques de danger. Lorsque vous voyez un symbole, soyez

vigilant e t suivez les directives mentionnées afin d’éviter tout

danger. Les consignes de sécurité présentées ci-après ne font

que résumer l’information contenue dans les normes de sécurité énumérées à la section 2-5. Veuillez lire et respecter toutes

ces normes de sécurité.

L’installation, l’utilisation, l’entretien et les réparations ne

doivent être confiés qu’à des personnes qualifiées.

Au cours de l’utilisation, tenir toute personne à l’écart et plus

particulièrement les enfants.

UNE DÉCHARGE ÉLECTRIQUE peut

entraîner la mort.

Le contact de composants électriques peut

provoquer des accidents mortels ou des brûlures

graves. Le circuit électrique et les barres collectrices

lorsque l’appareil fonctionne. Le circuit d’alimentation et les circuits

internes de la machine sont également sous tension lorsque

l’alimentation est sur marche. Des équipements installés ou reliés à la

borne de terre de manière incorrecte sont dangereux.

D Ne pas toucher aux pièces électriques sous tension.

D Protéger toutes les barres collectrices et les raccords de refroidis-

sement pour éviter de les toucher par inadvertance.

D Porter des gants isolants et des vêtements de protection secs et

sans trous.

D S’isoler de la pièce à couper et du sol en utilisant des housses ou

des tapis assez grands afin d’éviter tout contact physique avec la

pièce à couper ou le sol.

D D’autres consignes de sécurité sont nécessaires dans les condi-

tions suivantes : risques électriques dans un environnement

humide o u s i l’on porte des vêtements mouillés ; sur des structures

métalliques telles que sols, grilles ou échafaudages ; en position

coincée comme assise, à genoux ou couchée ; ou s’il y a un risque

élevé de contact inévitable ou accidentel avec la pièce à souder ou

le sol. Dans ces conditions, voir ANSI Z49.1 énuméré dans les normes de sécurité. En outre, ne pas travailler seul !

D Couper l’alimentation d’entrée avant d’installer l’appareil ou d’effec-

tuer l’entretien. Verrouiller ou étiqueter la sortie d’alimentation selon

la norme OSHA 29 CFR 1910.147(se reporter aux Principales normes de sécurité).

D N’utiliser que des tuyaux de refroidissement non conducteurs ayant

une longueur minimale de 457 mm pour garantir l’isolation.

D Installer le poste correctement et le mettre à la terre convenable-

ment selon les consignes du manuel de l’opérateur et les normes

nationales, provinciales et locales.

D Toujours vérifier la terre du cordon d’alimentation. Vérifier et s’assu-

rer que le fil de terre du cordon d’alimentation est bien raccordé à la

OM-222166 Page 4

ou les connexions de sortie sont sous tension

. Indique des instructions spécifiques.

Ce groupe de symboles veut dire Avertissement! Attention! DANGER

DE CHOC ELECTRIQUE, PIECES EN MOUVEMENT, et PIECES

CHAUDES. Consulter les symboles et les instructions ci-dessous y

afférant pour les actions nécessaires afin d’éviter le danger.

borne de terre du sectionneur ou que la fiche du cordon est raccordée à une prise correctement mise à la terre.

D En effectuant les raccordements d’entrée, fixer d’abord le conduc-

teur de mise à la terre approprié et revérifier les connexions.

D Les câbles doivent être exempts d’humidité, d’huile et de graisse;

protégez−les contre les étincelles et les pièces métalliques chaudes.

D Vérifier fréquemment le cordon d’alimentation et le conducteur de

mise à la terre afin de s’assurer qu’il n’est pas altéré ou dénudé. Le

remplacer immédiatement s’il l’est. Un fil dénudé peut entraîner la

mort.

D L’équipement doit être hors tension lorsqu’il n’est pas utilisé.

D Ne pas utiliser des câbles usés, endommagés, de grosseur insuffi-

sante ou mal épissés.

D Ne pas enrouler les câbles autour du corps.

D Ne pas toucher le circuit électrique si l’on est en contact avec la piè-

ce, la terre ou le circuit électrique d’une autre machine.

D N’utiliser qu’un matériel en bon état. Réparer ou remplacer sur-le-

champ les pièces endommagées. Entretenir l’appareil conformément à c e manuel.

D Porter un harnais de sécurité si l’on doit travailler au-dessus du sol.

D S’assurer que tous les panneaux et couvercles sont correctement

en place.

D Utiliser une protection différentielle lors de l’utilisation d’un équi-

pement auxiliaire dans des endroits humides ou mouillés.

Il reste une TENSION DC NON NÉGLIGEABLE dans

les sources de soudage onduleur UNE FOIS le

moteur coupé.

D Avant de toucher des organes internes, couper l’onduleur,

débrancher l’alimentation et décharger les condensateurs

d’alimentation conformément aux instructions indiquées dans la

partie maintenance.

LES FUMÉES ET LES GAZ peuvent

être dangereux.

Le chauffage à induction de certains matériaux

adhésifs e t flux génère des fumées et des gaz. Leur

inhalation peut être dangereuse pour votre santé.

D Ne pas mettre sa tête au-dessus des vapeurs. Ne pas respirer ces

vapeurs.

D À l’intérieur, ventiler la zone et/ou utiliser une ventilation forcée au

niveau de l’arc pour l’évacuation des fumées et des gaz. Pour déterminer la bonne ventilation, il est recommandé de procéder à un

prélèvement pour la composition et la quantité de fumées et de gaz

auxquels est exposé le personnel.

D Si la ventilation est médiocre, porter un respirateur anti-vapeurs ap-

prouvé.

D Lire et comprendre les fiches de données de sécurité et les instructions

du fabricant concernant les adhésifs, les revêtements, les nettoyants,

les consommables, les produits de refroidissement, les dégraisseurs,

a

les flux et les métaux.

D Travailler dans u n espace fermé seulement s’il est bien ventilé ou en

portant un respirateur. Demander toujours à un surveillant dûment

formé de s e tenir à proximité. Des fumées et des gaz provenant du

chauffage peuvent déplacer l’air, abaisser le niveau d’oxygène et

provoquer des lésions ou des accidents mortels. S’assurer que l’air

ambiant ne présente aucun danger .

D Ne pas chauffer dans des endroits se trouvant à proximité d’opéra-

tions de dégraissage, de nettoyage ou de pulvérisation. La chaleur

peut réagir en présence de vapeurs et former des gaz hautement

toxiques et irritants.

D Ne pas surchauffer des métaux munis d ’un revêtement tels que l’acier

galvanisé, p laqué a u p lomb ou a u cadmium, à moins que l e r evêtement

ne soit enlevé de la zone chauffée, que la zone soit bien ventilée et, si

nécessaire, en portant un respirateur. Les revêtements et tous les métaux c ontenant ces é léments peuv ent dégager des fumées tox iques

s’ils sont surchauffés. Voir les informations concernant la température

dans les spécifications de revêtement SDS.

Risque D’INCENDIE OU

D’EXPLOSION.

D Ne pas surchauffer les composants .

D Attention aux risques d’incendie: tenir un ex-

tincteur à proximité.

D Stocker des produits inflammables hors de la zone de travail.

D Ne pas placer l’appareil sur, au-dessus ou à proximité de surfaces

inflammables.

D Ne pas installer l’appareil à proximité de produits inflammables.

D Ne pas souder là où l’air ambiant pourrait contenir des poussières,

gaz ou émanations inflammables (vapeur d’essence, par exemple).

D Une fois le travail achevé, assurez−vous qu’il ne reste aucune trace

d’étincelles incandescentes ni de flammes.

D Utiliser exclusivement des fusibles ou coupe−circuits appropriés.

Ne pas augmenter leur puissance; ne pas les ponter.

D Lire et comprendre les fiches de données de sécurité et les instruc-

tions du fabricant concernant les adhésifs, les revêtements, les

nettoyants, les consommables, les produits de refroidissement, les

dégraisseurs, les flux et les métaux.

D Porter un équipement de protection pour le corps fait d’un matériau

résistant et ignifuge (cuir, coton robuste, laine). La protection du

corps comporte des vêtements sans huile comme par ex. des gants

de cuir, une chemise solide, des pantalons sans revers, des

chaussures hautes et une casquette.

LE CHAUFFAGE PAR INDUCTIO N peut

provoquer des brûlures.

D Ne pas toucher des parties chaudes à mains

nues.

D Laisser refroidir les composants ou équipe-

ments avant de les manipuler.

D Ne pas toucher ou manipuler les câbles/enroulements d’induc-

tion durant l’opération à moins que l’équipement soit conçu à cet

effet comme indiqué dans le manuel d’utilisateur .

D Tenir les bijoux et autres objets personnels en métal éloignés de la

tête/de l’enroulement pendant le fonctionnement.

D Ne pas toucher aux pièces chaudes, utiliser les outils recom-

mandés et porter des gants de soudage et des vêtements épais

pour éviter les brûlures.

2-3. Dangers supplémentaires en relation avec l’installation, le fonctionnement et l

maintenance

LA CHUTE DE L’ÉQUIPEMENT peut

provoquer des blessures.

D Utiliser la poignée et demander à une personne

ayant la force physique nécessaire pour soulever l’appareil.

D Déplacer l’appareil à l’aide d’un chariot ou d’un engin similaire.

D Pour les unités sans poignée, utiliser un équipement de levage de

capacité suffisante pour lever l’appareil.

D Tenir l’équipement (câbles et cordons) à distance des véhicules

mobiles lors de toute opération en hauteur.

D En utilisant des fourches de levage pour déplacer l’unité, s’assu-

rer que les fourches sont suffisamment longues pour dépasser du

côté opposé de l’appareil.

D Suivre les consignes du Manuel des applications pour l’équation

de levage NIOSH révisée (Publication Nº94−110) lors du levage

manuelle de pièces ou équipements lourds.

DES PIECES DE METAL ou DES

SALETES peuvent provoquer des

blessures dans les yeux.

D Porter des lunettes de sécurité à coques latéra-

les ou un écran facial.

DES ORGANES MOBILES peuvent

provoquer des blessures.

D S’abstenir d e toucher des organes mobiles tels

que des ventilateurs.

D Maintenir fermés et verrouillés les portes, panneaux, recouvre-

ments et dispositifs de protection.

Les CHAMPS ÉLECTROMAGNÉTIQUES (CEM)

peuvent affecter les implants médicaux.

D Les porteurs de stimulateurs cardiaques et autres

implants médicaux doivent rester à distance.

D Les porteurs d’implants médicaux doivent consulter leur médecin

et le fabricant du dispositif avant de s’approcher de la zone où se

déroule du soudage à l’arc, du soudage par points, du gougeage,

de la découpe plasma ou une opération de chauffage par induction.

LE LIQUIDE DE REFROIDISSEMENT CHAUD ET

LA VAPEUR peuvent causer des brûlures.

Si le liquide de refroidissement est en surchauffe, un

boyau pourrait se sectionner.

D Ne jamais débrancher les deux extrémités du

tuyau lorsque l’appareil est installé sur une

pièce de travail chaude.

D Si le liquide de refroidissement cesse de s’écouler, laisser une

extrémité du tuyau branchée pour permettre au liquide de

refroidissement chaud de revenir au refroidisseur et

dépressuriser.

D Pour éviter tout risque de dommage, retirer le tuyau de la pièce de

travail chaude.

D Effectuer une inspection visuelle des boyaux, cordons et câbles

avant chaque utilisation. Ne pas utiliser des boyaux, cordons ou

câbles endommagés.

L’EMPLOI EXCESSIF peut SURCHAUFFER L’ÉQUIPEMENT.

D Prévoir une période de refroidissement

D Réduire le courant de sortie ou le facteur de mar-

che avant de recommencer le chauffage.

D Respecter le cycle opératoire nominal.

OM-222166 Page 5

LES CHARGES ÉLECTROSTATIQUES

ut

r

s

f

e

peuvent endommager les circuits imprimés.

D Établir la connexion avec la barrette de terre

AV ANT de manipuler des cartes ou des pièces.

D Utiliser des pochettes et des boîtes antistatiques pour stocker, dé-

placer ou expédier des cartes PC.

D Effectuer régulièrement le contrôle et l’entretien de l’installation.

D Maintenir soigneusement fermés les portes et les panneaux des

sources de haut e fréquence.

LE RAYONNEMENT HAUTE FRÉQUENCE (HF) risque de provoquer

des interférences.

D Le rayonnement haute fréquence (HF) peut

provoquer des interférences avec les équipements de radio-navigation et de communication,

les servic es de sécurité et les ordinateurs.

D Demander seulement à des pers onnes qualifiées familiaris ées a vec

des équipements électroniques de faire fonctionner l’installation.

D L’utilisateur est tenu de faire corriger rapidement par un électricien

qualifié les interférences résultant de l’installation.

D Si le FCC signale des interférences, arrêter immédiatement l’appa-

reil.

D N’utiliser que les pièces de rechange recommandées par le

constructeur.

D Effectuer l’installation, l’entretien et toute intervention selon les

manuels d’utilisateurs, les normes nationales, provinciales et de

l’industrie, ainsi que les codes municipaux.

2-4. Proposition californienne 65 Avertissements

LIRE LES INSTRUCTIONS.

D Lire et appliquer les instructions sur les

étiquettes et le Mode d’emploi avant

l’installation, l’utilisation ou l’entretien de

l’appareil. Lire les informations de sécurité au

début du manuel et dans chaque section.

L’EXPLOSION DE LA BATTERIE pe

provoquer des blessures.

D Ne pas utiliser l’appareil de soudage pou

charger des batteries ou faire démarrer de

véhicules à l’aide de câbles de démarrage, sau

si l’appareil dispose d’une fonctionnalité d

charge de batterie destinée à cet usage.

Les équipements de soudage et de coupage produisent des

fumées et des gaz qui contiennent des produits chimiques

dont l’État de Californie reconnaît qu’ils provoquent des

malformations congénitales et, dans certains cas, des cancers.

(Code de santé et de sécurité de Californie, chapitre 25249.5

et suivants).

2-5. Principales normes de sécurité

Safety i n W elding, Cutting, and Allied Processes, ANSI Standard Z49.1,

from Global Engineering Documents (phone: 1-877-413-5184, website:

www.global.ihs.com).

Safety in Welding, Cutting, and Allied Processes, CSA Standard

W117.2, from Canadian Standards Association, Standards Sales, 5060

Spectrum Way, Suite 100, Mississauga, Ontario, Canada L4W 5NS

(phone: 800-463-6727, website: www.csagroup.org).

OSHA, Occupational Safety and Health Standards for General Industry ,

Title 29, Code of Federal Regulations (CFR), Part 1910, Subpart Q, and

Part 1926, Subpart J, from U.S. Government Printing Of fice, Superintendent of Documents, P.O. Box 371954, Pittsburgh, PA 15250-7954

(phone: 1-866-512-1800) (there are 10 OSHA Regional Offices—phone

for Region 5, Chicago, is 312-353-2220, website: www .osha.gov).

National Electrical Code, NFPA Standard 70, from National Fire Protection Association, Quincy, MA 02269 (phone: 1-800-344-3555, website:

www.nfpa.org and www. sparky.org).

2-6. Informations relatives aux CEM

Le courant électrique qui traverse tout conducteur génère des champs

électromagnétiques (CEM) à certains endroits. Le courant issu d’un

soudage à l’arc (et de procédés connexes, y compris le soudage par

points, le gougeage, le découpage plasma et les opérations de

chauffage par induction) crée un champ électromagnétique (CEM)

autour d u circuit de soudage. Les champs électromagnétiques produits

peuvent causer interférence à certains implants médicaux, p. ex. les

stimulateurs cardiaques. Des mesures de protection pour les porteurs

d’implants médicaux doivent être prises: Limiter par exemple tout accès

aux passants ou procéder à une évaluation des risques individuels pour

les soudeurs. Tous les soudeurs doivent appliquer les procédures

suivantes pour minimiser l’exposition aux CEM provenant du circuit de

soudage:

1. Rassembler les câbles en les torsadant ou en les attachant avec

du ruban adhésif ou avec une housse.

2. Ne pas se tenir au milieu des câbles de soudage. Disposer les

câbles d’un côté et à distance de l’opérateur.

Ce produit contient des éléments chimiques, dont le plomb,

reconnus par l’État de Californie pour leur caractère

cancérogène ainsi que provoquant des malformations

congénitales ou autres problèmes de procréation. Se laver les

mains après toute manipulation.

Canadian Electrical Code Part 1, CSA Standard C22.1, from Canadian

Standards Association, Standards Sales, 5060 Spectrum Way, Suite

100, Mississauga, Ontario, Canada L4W 5NS (phone: 800-463-6727,

website: www.csagroup.org).

Safe Practice For Occupational And Educational Eye And Face Protection, ANSI Standard Z87.1, from American National Standards Institute,

25 West 43rd Street, New York, NY 10036 (phone: 212-642-4900, website: www.ansi.org).

Applications Manual for the Revised NIOSH Lifting Equation, The National Institute for Occupational Safety and Health (NIOSH), 1600 Clifton

Rd, Atlanta, GA 30329-4027 (phone: 1-800-232-4636, website:

www.cdc.gov/NIOSH).

3. Ne pas courber et ne pas entourer les câbles autour de votre

corps.

4. Maintenir la tête et le torse aussi loin que possible du matériel du

circuit de soudage.

5. Connecter la pince sur la pièce aussi près que possible de la

soudure.

6. Ne pas travailler à proximité d’une source de soudage, ni

s’asseoir ou se pencher dessus.

7. Ne pas souder tout en portant la source de soudage ou le

dévidoir.

En ce qui concerne les implants médicaux :

Les porteurs d’implants doivent d’abord consulter leur médecin avant de

s’approcher des opérations de soudage à l’arc, de soudage par points,

de gougeage, du coupage plasma ou de chauffage par induction. Si le

médecin approuve, il est recommandé de suivre les procédures précédentes.

OM-222166 Page 6

SECTION 3 − DEFINITIONS

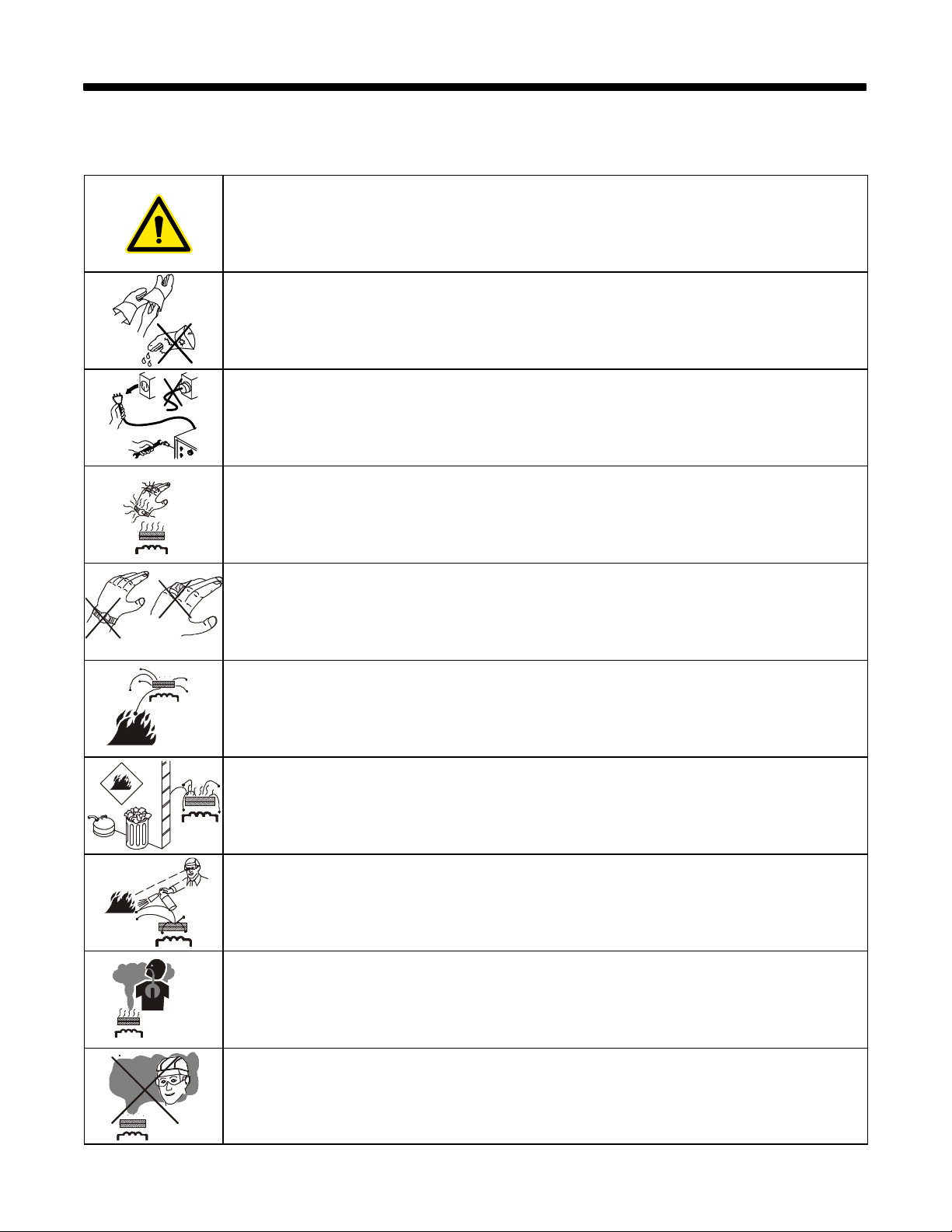

3-1. Additional Safety Symbols And Definitions

. Some symbols are found only on CE products.

Warning! Watch Out! There are possible hazards as shown by the symbols.

Wear dry insulating gloves. Do not wear wet or damaged gloves.

Disconnect input plug or power before working on machine.

Induction heating can cause injury or burns from hot items such as rings, watches, or parts.

Safe1 2012−05

Safe56 2012−05

Safe5 2012−05

Do not wear metal jewelry and other metal personal items such as rings and watches during operation.

Induction heating sparks can cause fire. Do not overheat parts and adhesives.

Keep flammables away from heating operation. Do not heat near flammables.

Heating sparks can cause fires. Have a fire extinguisher nearby and have a watchperson ready to use it.

Breathing heating fumes can be hazardous to your health. Read Material Safety Data Sheets (MSDSs) and

manufacturer’s instructions for material used.

Safe74 2012−07

Safe75 2012−07

Safe76 2012−07

Safe77 2012−07

Safe78 2012−07

Safe79 2012−07

Keep your head out of the fumes.

Safe80 2012−07

OM-222166 Page 7

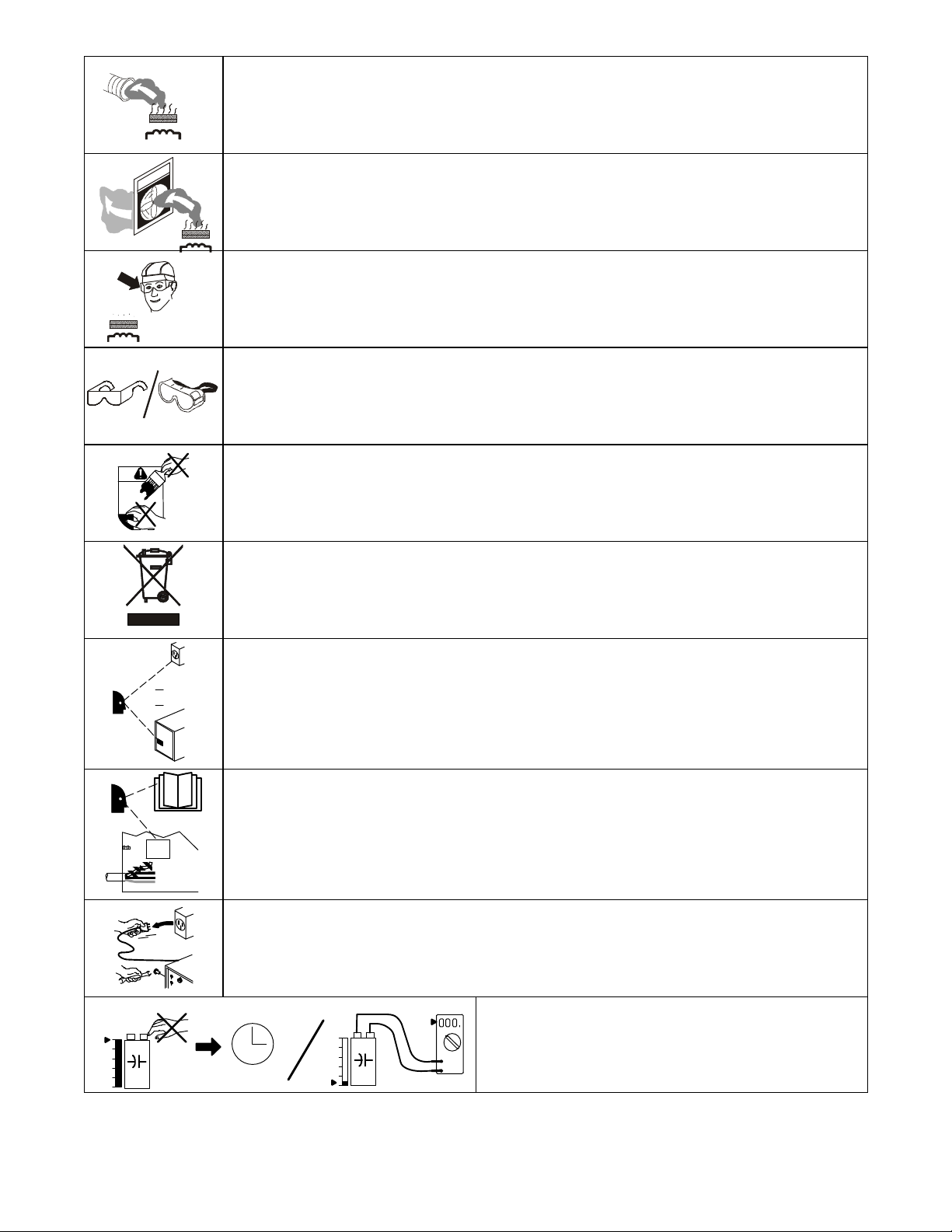

Use forced ventilation or local exhaust to remove the fumes.

Use ventilating fan to remove fumes.

Always wear safety glasses or goggles during and around heating operations to prevent possible injury.

Wear either safety glasses or full goggles depending on type of operation and nearby processes.

Do not remove or paint over (cover) the label.

Safe81 2012−07

Safe82 2012−07

Safe83 2012−07

Safe84 2012−07

Safe20 2012−05

Do not discard product (where applicable) with general waste.

Reuse or recycle Waste Electrical and Electronic Equipment (WEEE) by disposing at a designated collection

facility.

Contact your local recycling office or your local distributor for further information.

?

V

?

A

Consult rating label for input power requirements.

Safe37 2012−05

Safe34 2012−05

Become trained and read the instructions and labels before working on machine.

Safe35 2012−05

Disconnect input plug or power before working on machine.

Safe30 2012−05

Hazardous voltage remains on input capacitors after power is turned

V

V

off. Do not touch fully charged capacitors. Always wait after power is

turned off before working on unit, OR check input capacitor voltage,

and be sure it is near 0 before touching any parts.

OM-222166 Page 8

V

Safe42 2012−05

3-2. Miscellaneous Symbols And Definitions

A

V

X

IP

Hz

I

I

U

U

I

. Some symbols are found only on CE products.

Connect green or green/yellow grounding conductor to ground

terminal.

Connect input conductors (L1, L2 And L3) to line terminals.

Safe86 2012−06

Become trained and read the instructions before working on the

machine or heating.

Safe85 2012−06

Amperage

Volts

Alternating

Current

Duty Cycle

Degree Of

Protection

Hertz

Circuit Protection

Output

Increase

1

2

1max

P

1max

Line Connection

Primary Current

Rated Current

Primary Voltage

Three Phase

Percent

Remote

Panel/Local

1

Load Voltage

High Temperature

2

Read Instructions

Three Phase

Static Frequency

Converter-Transfo

rmer-Frequency

Converter

Rated Maximum

Supply Current

Maximum Power

Consumption

Voltage Input

Off

On

Induction Heating

OM-222166 Page 9

SECTION 4 − SPECIFICATIONS

e

4-1. Serial Number and Rating Label Location

The serial number and rating information for the power source is located on the front of the machine. Use the rating labels to determine input power

requirements and/or rated output. For future reference, write serial number in space provided on back cover of this manual.

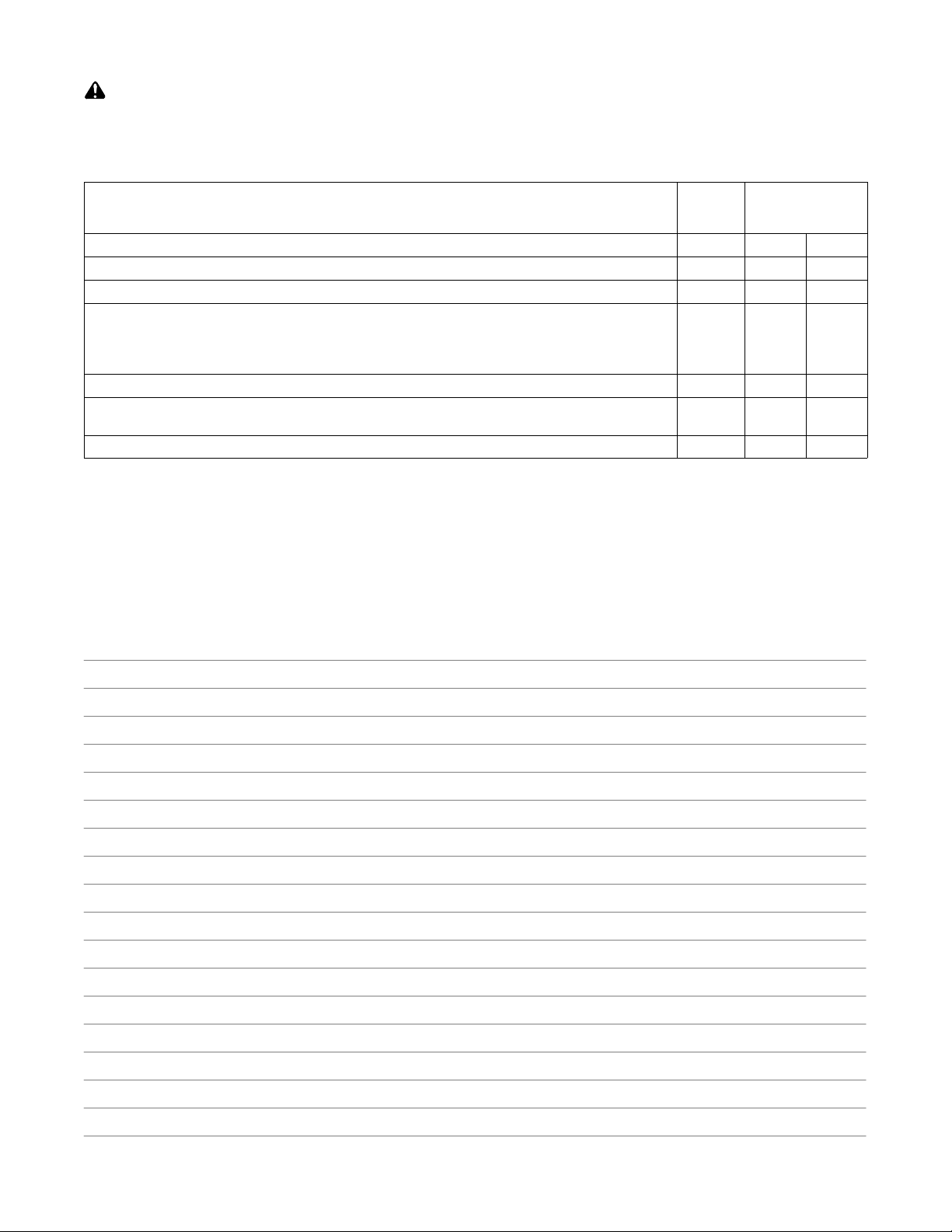

4-2. Specifications

. This equipment will deliver rated output at an ambient air temperature up to 104F ( 40C).

. Do not use information in unit specifications table to determine electrical service requirements. See Sections 5-3, 5-4 and 5-5 for information on

connecting input power.

Amperes Input at

Output

Frequency

5 To 30 kHz

Rated Output

Single Output Dual Output 400 V 460 V 575 V

35 kW At 100% Duty Cycle

350 A (RMS), 700 V (RMS)

35 kW At 100% Duty Cycle

700 A (RMS),

700 V (RMS)

Required

Reflective

Inductanc

2.5 To 50

μh

Rated Load Output

50 or 60 Hz,

Three-Phase

kVA kW

60 A 50 A 40 A 39 37

4-3. Environmental Specifications

A. IP Rating

IP Rating

IP23C

This equipment is designed for outdoor use. It may be stored, but is not intended to be used for welding (heating) outside during precipitation

B. Information On Electromagnetic Compatibility (EMC)

! This Class A equipment is not intended for use in residential locations where the electrical power is provided by the public low−

voltage supply system. There may be potential difficulties in ensuring electromagnetic compatibility in those locations, due to

conducted as well as radiated disturbances.

This equipment complies with IEC61000-3-11 and IEC 61000−3−12 and can be connected to public low-voltage systems provided that the public

low-voltage system impedance Z

4,795,346 VA). It is the responsibility of the installer or user of the equipment to ensure, by consultation with the distribution network operator

if necessary, that the system impedance complies with the impedance restrictions.

at the point of common coupling is less than 33.37mW (or the short−circuit power Ssc is greater than

max

unless sheltered.

Ref. IP23 2014−06

ce-emc 1 2014-07

OM-222166 Page 10

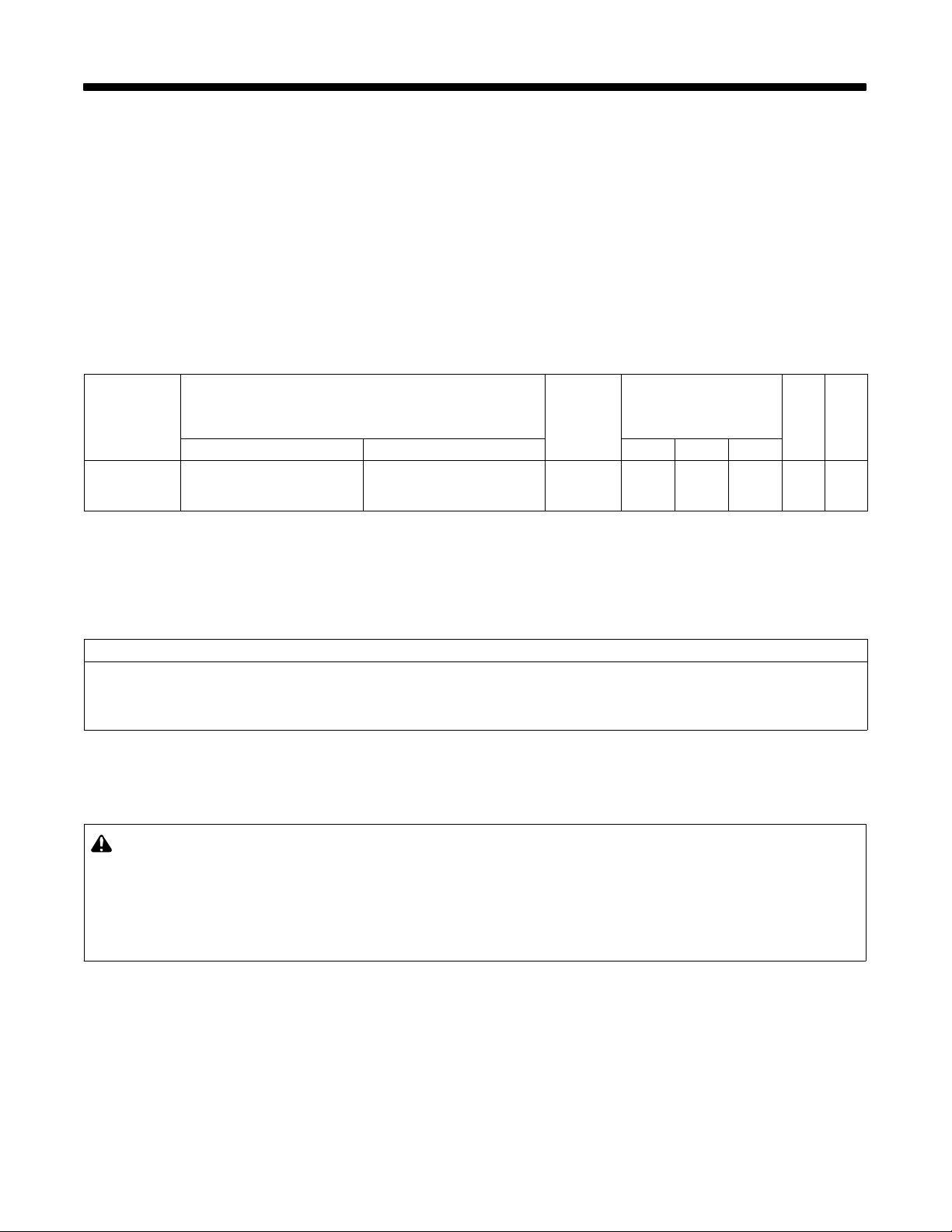

C. Temperature Specifications For Miller ProHeat 35 Rolling Inductor Cold Climate Operation

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ÇÇÇÇ

ProHeat Cooler Rolling Inductor Heating Cables

°C °F

60 140

55 131

50 122

45 113

40 104

35 95

30 86

25 77

20 68

15 59

10 50

5 41

0 32

−5 23

−10 14

−15 5

−20 -4

−25 -13

−30 -22

−35 -31

−40 -40

Storage Operation Storage Operation Storage Operation Storage Operation

Reduced

efficiencies

above 40°C

Store dry Store dry Store dry

Reduced

efficiencies

above 40°C

Energize

system

frequently to

maintain

coolant

temperature

above 14°F

(−10°C).

Energize

system

frequently to

maintain

coolant

temperature

above 14°F

(−10°C).

Energize

system

frequently to

maintain

coolant

temperature

above 14°F

(−10°C).

277088-A

Not Recommended

With Qualifications

Normal Operation With Coolant

NOTICE − The Miller ProHeat 35 Rolling Inductor is rated for operation between 14° F and 140° F (−10° C to 60° C). For operation at -40°F to

14° F (−40° C to -10° C), take the following precautions to prevent equipment damage:

• Connect coolant lines to Rolling Inductor when dry, or when ambient temperature is above −4° F (−20° C).

• Operate ProHeat 35 Heavy Duty Induction Cooler only in temperatures between 14° F and 104° F (−10° C to 40° C) while operating Rolling Inductor/

Liquid Cooled Cables.

• Always use Miller Coolant (Miller Part Number 043810).

• Coolant must flow continuously through the Rolling Inductor/liquid cooled cables, and power must be applied to the Rolling Inductor /liquid cooled

cables at regular intervals to maintain a coolant temperature of at least 14° F (−10° C).

• Store Rolling Inductor/liquid cooled cables dry. Dry unit by using compressed air at 40 psi (2.75 bar) max to blow coolant out of the Rolling Inductor

and power cable.

• Store ProHeat 35 Heavy Duty Induction Cooler at a temperature between−4° F and 131° F(−20° C to 55° C).

. Coolant will not begin to flow until it is 14° F (−10° C).

NOTICE − For colder storage, the cooler must be stored dry. Dry unit by using compressed air at 40 psi (2.75 bar) max to blow coolant out of coolant

lines, filter bowls, pump, flow indicator, and heat exchanger.

OM-222166 Page 11

SECTION 5 − INSTALLATION

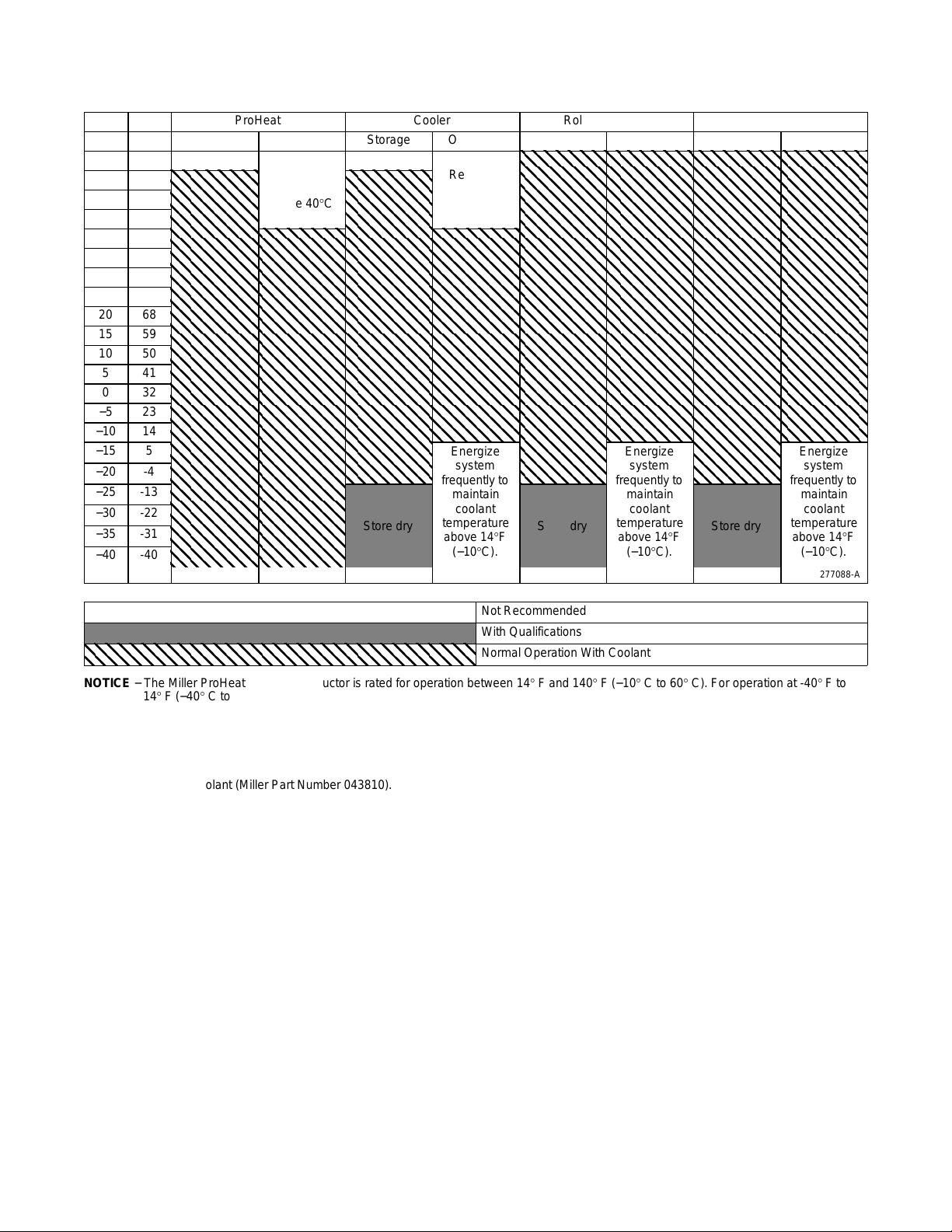

5-1. Selecting A Location

Movement

Location And Airflow

18 in.

(460 mm)

(460 mm)

1

18 in.

OR

2

3

18 in.

(460 mm)

18 in.

(460 mm)

! Do not move or operate unit

where it could tip.

! Special installation may be

required where gasoline or

volatile liquids are present −

see NEC Article 511 or CEC

Section 2 0 .

1 Lifting Eye

2 Lifting Forks

Use lifting eye or lifting forks to

move unit.

If using lifting forks, extend forks

beyond opposite side of unit.

3 Line Disconnect Device

Locate unit near correct input

power supply.

803992-B

loc_large 2015-04

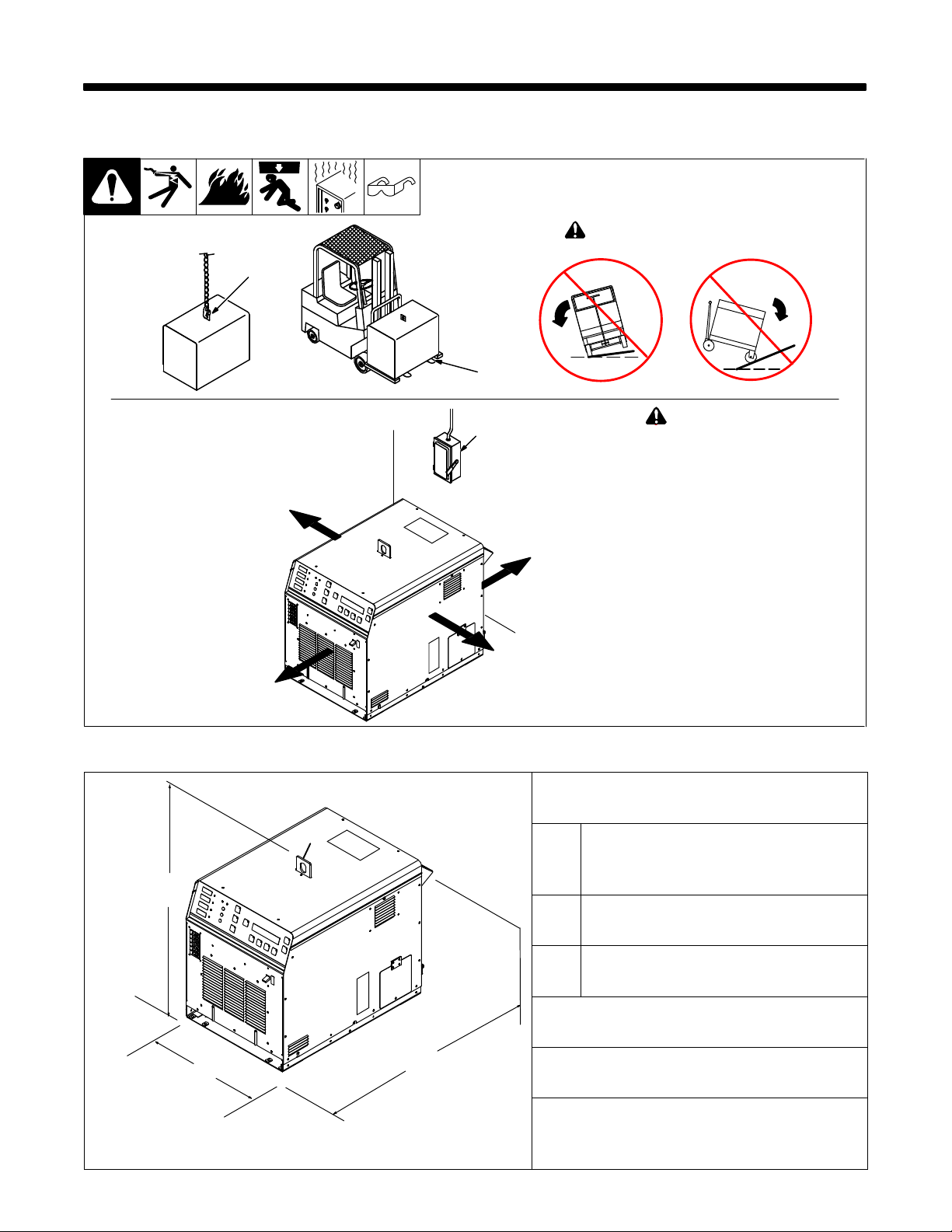

5-2. Dimensions And Weights

*

A

B

OM-222166 Page 12

C

803 992-B

Dimensions

A

B 21.75 in. (553 mm)

C 36.75 in. (933 mm)

* Lifting Eye Weight Rating

27.5 in. (699 mm)

Weight

227 lb (103 Kg)

600 lb (272 kg) Maximum

5-3. Electrical Service Guide

Elec Serv 2014−01

Notes

Failure to f o llow these electrical service guide recommendations could create an electric shock or fire hazard. These recommendations are for a dedicated circuit sized for the rated output and duty cycle of the welding power source.

In dedicated circuit installations, the National Electrical Code (NEC) allows the receptacle or conductor rating to be less than the rating

of the circuit protection device. All components of the circuit must be physically compatible. See NEC articles 210.21, 630.11, and

630.12.

50 Hz

Three

Phase

Input Voltage (V) 400 460 575

Input Amperes (A) At Rated Output 60 50 40

Input Amperes (A) At Rated Output 60 50 40

Max Recommended Standard Fuse Or Circuit Breaker Rating In Amperes

Circuit Breaker 1, Time-Delay Fuses

Normal Operating Fuses

Min Input Conductor Size In AWG

Max Recommended Input Conductor Length In Feet (Meters)

Min Grounding Conductor Size In AWG

Reference: 2014 National Electrical Code (NEC) (including article 630)

1 If a circuit breaker is used in place of a fuse, choose a circuit breaker with time-current curves comparable to the recommended fuse.

2 “Time-Delay” fuses are UL class “RK5” . See UL 248.

3 “Normal Operating” (general purpose - no intentional delay) fuses are UL class “K5” (up to and including 60 amps), and UL class “H” ( 65 amps and

above).

4 Conductor data in this section specifies conductor size (excluding flexible cord or cable) between the panelboard and the equipment per NEC Table

310.15(B)(16). If a flexible cord or cable is used, minimum conductor size may increase. See NEC Table 400.5(A) for flexible cord and cable

requirements.

4

4

3

1

2

70 61 45

80 70 60

254

(77)

60 Hz Three Phase

6 8 8

214

(65)

8 8 10

334

(102)

OM-222166 Page 13

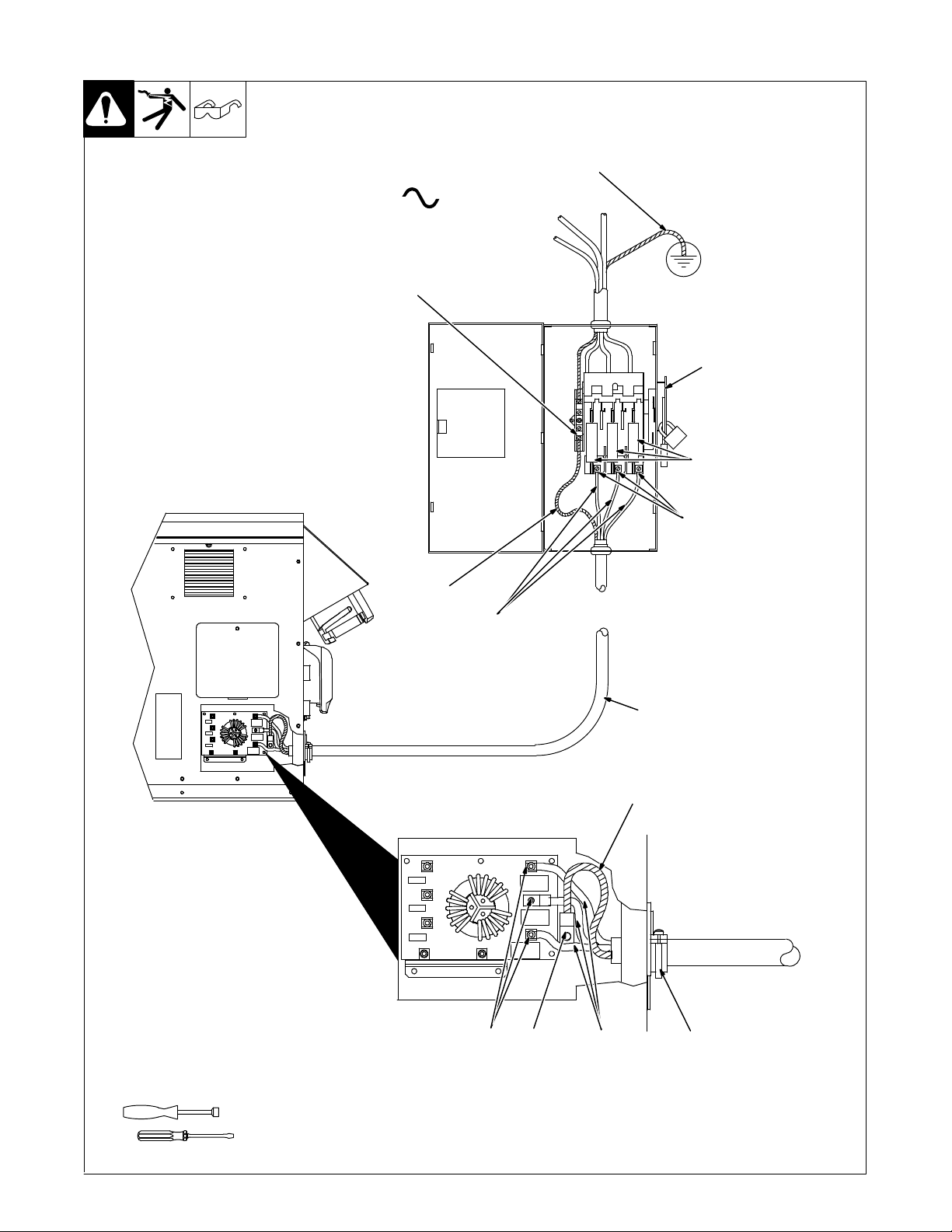

5-4. Connecting 3-Phase Input Power For 460/575 Volt Models

GND/PE Earth Ground

3

8

4

6

7

10

9

1

4

2

365

Tools Needed:

OM-222166 Page 14

3/8 in.

input3 2015−01 / 803 994-D

5-4. Connecting 3-Phase Input Power For 460/575 Volt Models (continued)

Notes

! Installation must meet all National

and Local Codes − have only qualified

persons make this installation.

! Disconnect and lockout/tagout input

power before connecting input conductors from unit. Follow established

procedures regarding the installation

and removal of lockout/tagout devices.

! Make input power connections to the

welding power source first.

! Always connect green or green/yel-

low conductor to supply grounding

terminal first, and never to a line terminal.

. The circuitry in this unit automatically

adapts the power source to the primary

voltage being applied. Check input voltage available at site. This unit can be

connected t o either 460 or 575 V AC input

power.

See rating label on unit and check input voltage available at site.

1 Input Power Conductors (Customer

Supplied Cord)

Select size and length of conductors using

Section 5-3. Conductors must comply with

national, state, and local electrical codes. If

applicable, use lugs of proper amperage

capacity and correct hole size.

Welding Power Source Input Power Connections

2 Strain Relief (Customer Supplied)

Install strain relief of proper size for unit and

conductors. Route conductors (cord)

through strain relief. Tighten strain relief.

3 Welding Power Source Grounding

Terminal

4 Green Or Green/Yellow Grounding

Conductor

Connect green or green/yellow grounding

conductor to welding power source grounding terminal first.

5 Welding Power Source Line Terminals

6 Input Conductors L1, L2 And L3

Connect input conductors L1, L2 and L3 to

welding power source line terminals.

Close and secure access door on welding

power source.

Disconnect Device Input Power Connections

7 Disconnect Device (switch shown in

OFF position)

8 Disconnect Device (Supply) Grounding

Terminal

9 Disconnect Device Line Terminals

Connect green or green/yellow grounding

conductor to disconnect device grounding

terminal first.

Connect input conductors L1, L2, And L3 to

disconnect device line terminals.

10 Over-Current Protection

Select type and size of over-current protec-

tion using Section 5-3 (fused disconnect

switch shown).

Close and secure door on line disconnect device. Follow established lockout/tagout procedures to put unit in service.

input3 2015−01

Work like a Pro!

Pros weld and cut

safely. Read the

safety rules at

the beginning

of this manual.

OM-222166 Page 15

5

-5. Connecting 3-Phase Input Power For 400/460 Volt IEC And CE Models

GND/PE Earth Ground

3

8

7

10

9

4

6

1

4

Tools Needed:

OM-222166 Page 16

3/8 in.

5

3

6

2

Input3 2015-01 / Ref. 804 430-B

! Installation must meet all National

5-5. Connecting 3-Phase Input Power For 400/460 Volt IEC And CE Models (continued)

and Local Codes − have only qualified

persons make this installation.

! Disconnect and lockout/tagout input

power before connecting input conductors from unit. Follow established

procedures regarding the installation

and removal of lockout/tagout devices.

! Make input power connections to the

welding power source first.

! Always connect green or green/yel-

low conductor to supply grounding

terminal first, and never to a line terminal.

. The circuitry in this unit automatically

adapts the power source to the primary

voltage being applied. Check input voltage available at site. This unit can be

connected t o either 400 or 460 V AC input

power.

See rating label on unit and check input voltage available at site.

1 Input Power Conductors (Customer

Supplied Cord)

Select size and length of conductors using

Section 5-3. Conductors must comply with

national, state, and local electrical codes. If

applicable, use lugs of proper amperage

capacity and correct hole size.

Welding Power Source Input Power Connections

2 Strain Relief (Customer Supplied)

Install strain relief of proper size for unit and

conductors. Route conductors (cord)

through strain relief. Tighten strain relief.

3 Welding Power Source Grounding

Terminal

4 Green Or Green/Yellow Grounding

Conductor

Connect green or green/yellow grounding

conductor to welding power source grounding terminal first.

5 Welding Power Source Line Terminals

6 Input Conductors L1, L2 And L3

Connect input conductors L1, L2 and L3 to

welding power source line terminals.

Close and secure access door on welding

power source.

Disconnect Device Input Power Connections

7 Disconnect Device (switch shown in

OFF position)

8 Disconnect Device (Supply) Grounding

Terminal

9 Disconnect Device Line Terminals

Connect green or green/yellow grounding

conductor to disconnect device grounding

terminal first.

Connect input conductors L1, L2, And L3 to

disconnect device line terminals.

10 Over-Current Protection

Select type and size of over-current protec-

tion using Section 5-3 (fused disconnect

switch shown).

Close and secure door on line disconnect device. Follow established lockout/tagout procedures to put unit in service.

input3 2015−01

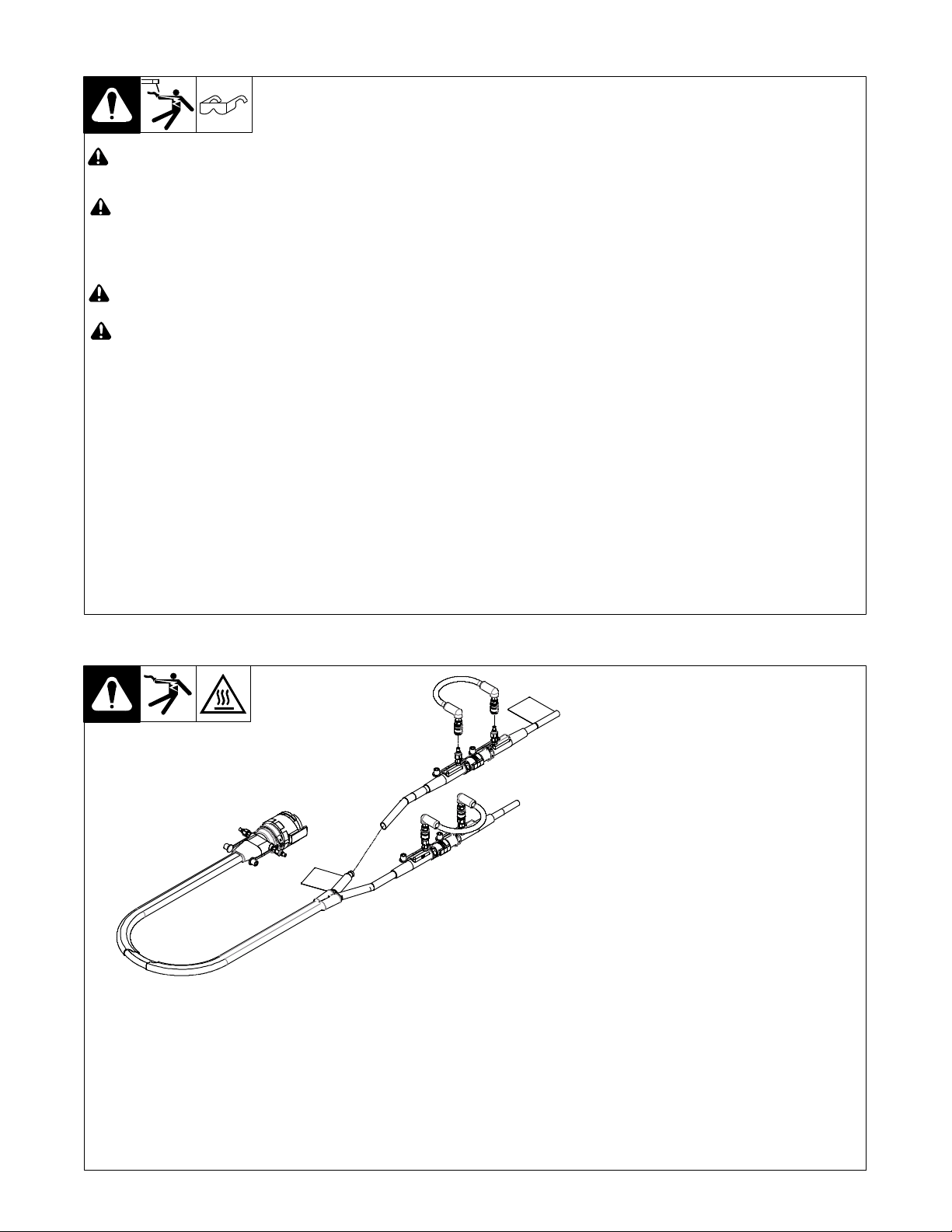

5-6. Coolant Jumper Connections

276861-A

OM-222166 Page 17

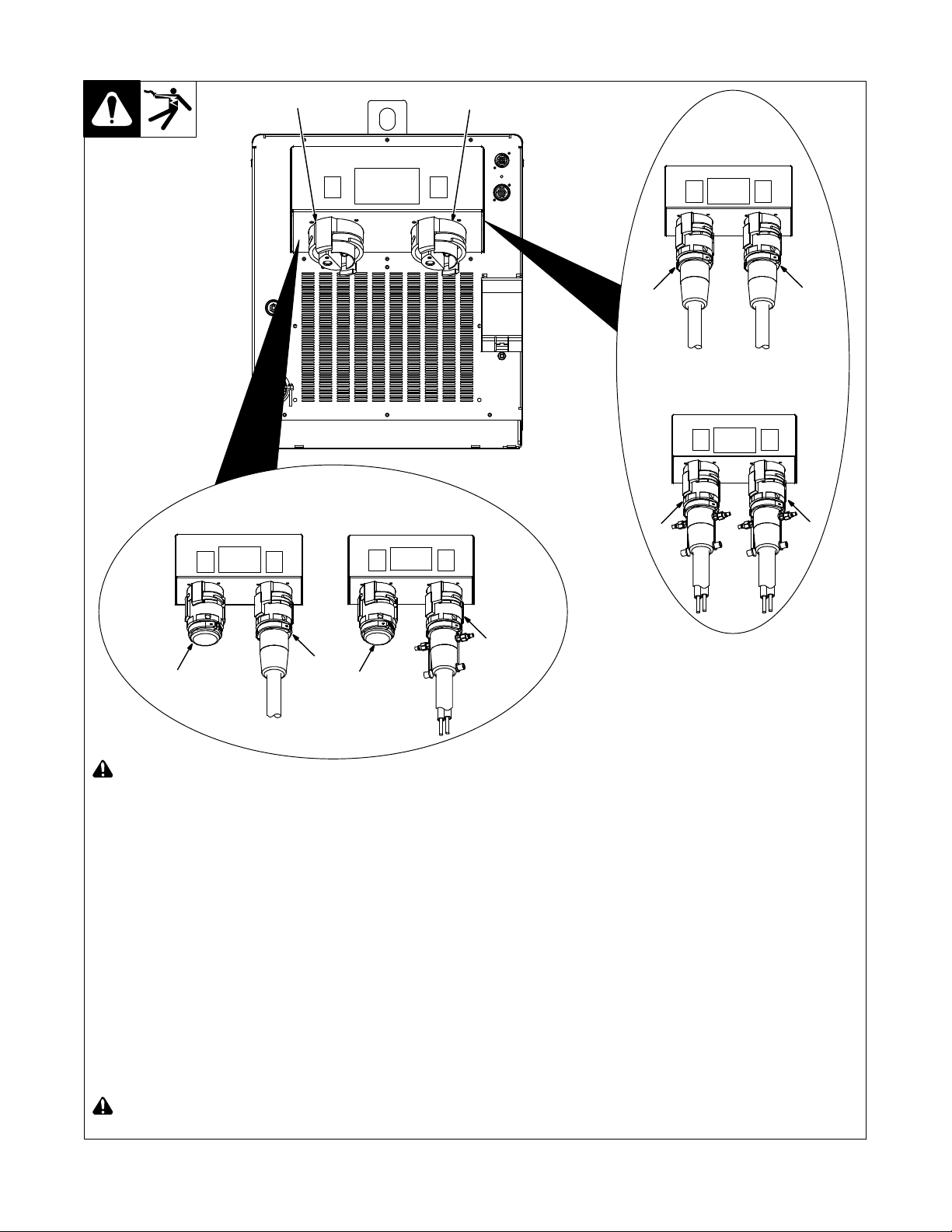

5-7. Power Source Output Connections

12

Dual Air-Cooled

Output Connection

Single Air-Cooled

Output Connection

12

12

Single Liquid-Cooled

Output Connection

12

4

Dual Liquid-Cooled

Output Connection

12

4

12

55

3

! Steam and hot coolant can burn.

Hose may rupture if coolant overheats.

Never disconnect both ends of

hose when installed on hot

workpiece. If coolant flow stops,

leave one end of hose connected to

allow hot coolant to return to cooler

and relieve pressure. Remove hose

from hot workpiece to prevent damage.

1 Output Connector 1

2 Output Connector 2

3 Protective Plug

4 Air-Cooled Extension Cable

5 Liquid-Cooled Extension Cable

The power source is capable of single or

dual output. When connected for single

power output, up to 35 kW is available at

the single output connection. When

connected f o r dual power, output power is

divided between the two output

connections.

! Do not move or disconnect cables

while output is on.

4

3

Single Air-Cooled Output Connection

Connect air-cooled output extension cable

to Output Connector 1 or Output

Connector 2. Connect Protective Plug to

remaining Output Connector.

Single Liquid-Cooled Output Connection

Connect liquid-cooled output extension

cable to Output Connector 1 or Output

Connector 2. Connect Protective Plug to

remaining Output Connector.

Dual Air-Cooled Output Connection

Connect air-cooled output extension

cables to Output Connector 1 and Output

Connector 2.

. Extension cables must be the same

length: 25 ft (7.6 m), 50 ft (15.2 m), or

75 ft (22.8 m).

5

Ref. 803 993-C / Ref. 804 217-A

. Blankets must be the same size.

Dual Liquid-Cooled Output Connection

Connect liquid-cooled output extension

cables to Output Connector 1 and Output

Connector 2.

. Extension cables must be the same

length: 10 ft (3 m), 25 ft (7.6 m), or 50

ft (15.2 m).

. Heating cables must be the same

length: 30ft (9.1 m), 50 ft (15.2 m), 80ft

(24.2 m), or 140 ft (42.7 m).

. Total length of heating and extension

cables must not exceed 360 ft (110 m) .

The extension cable is counted twice

the length because it has a supply and

return hose.

NOTICE − Use only Miller ProHeat accessories with a Miller ProHeat power source.

OM-222166 Page 18

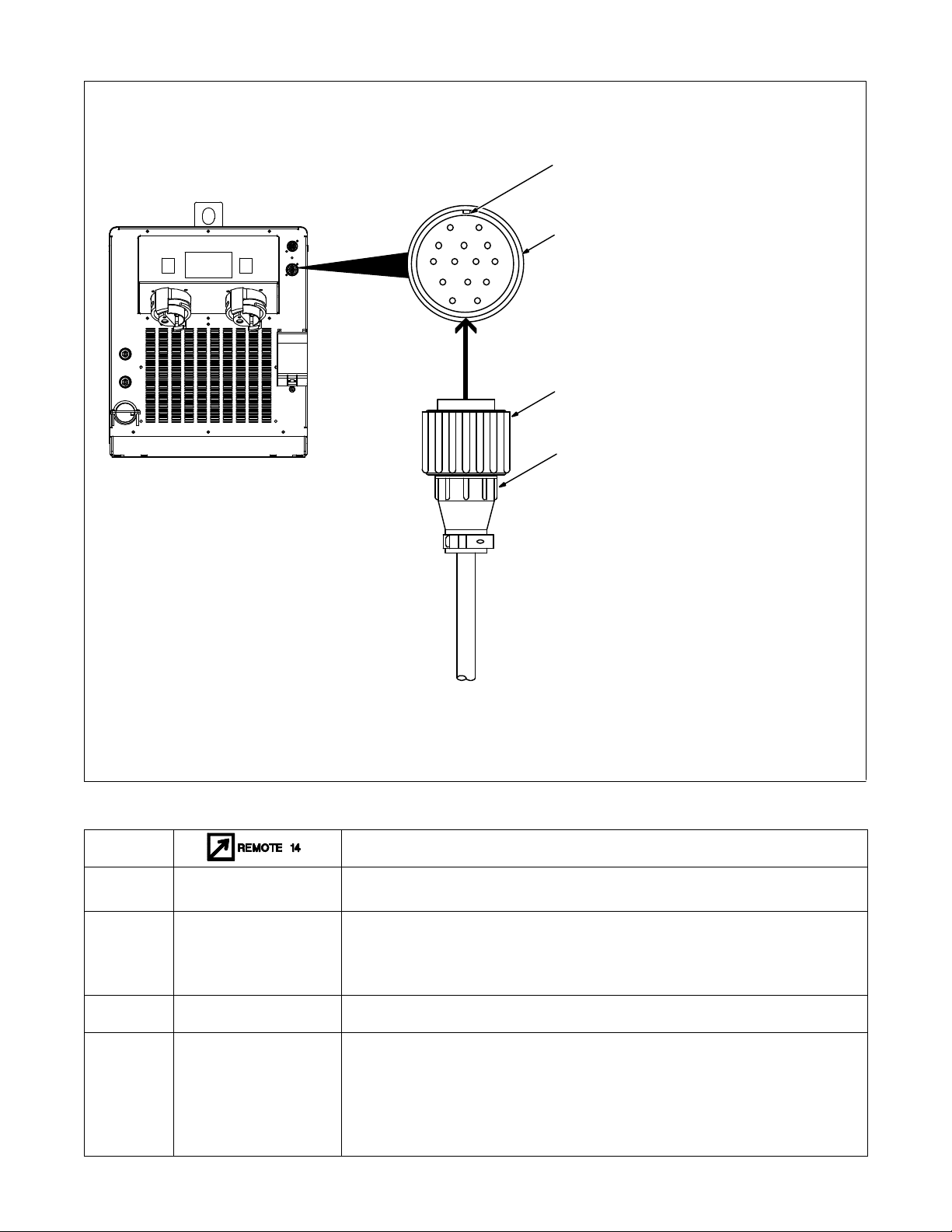

5-8. Remote 14 Receptacle RC14 Information and Connections

3

AJ

K

B

12

L

C

D

I

NH

M

G

F

E

4

2

1

1 Plug

2 Threaded Collar

3 Keyway

4 Remote 14 Receptacle RC14

(See Section 5-9)

To connect to receptacle, align keyway, insert plug and tighten

threaded collar.

NOTICE − Use only Miller ProHeat

accessories with a Miller ProHeat

power source.

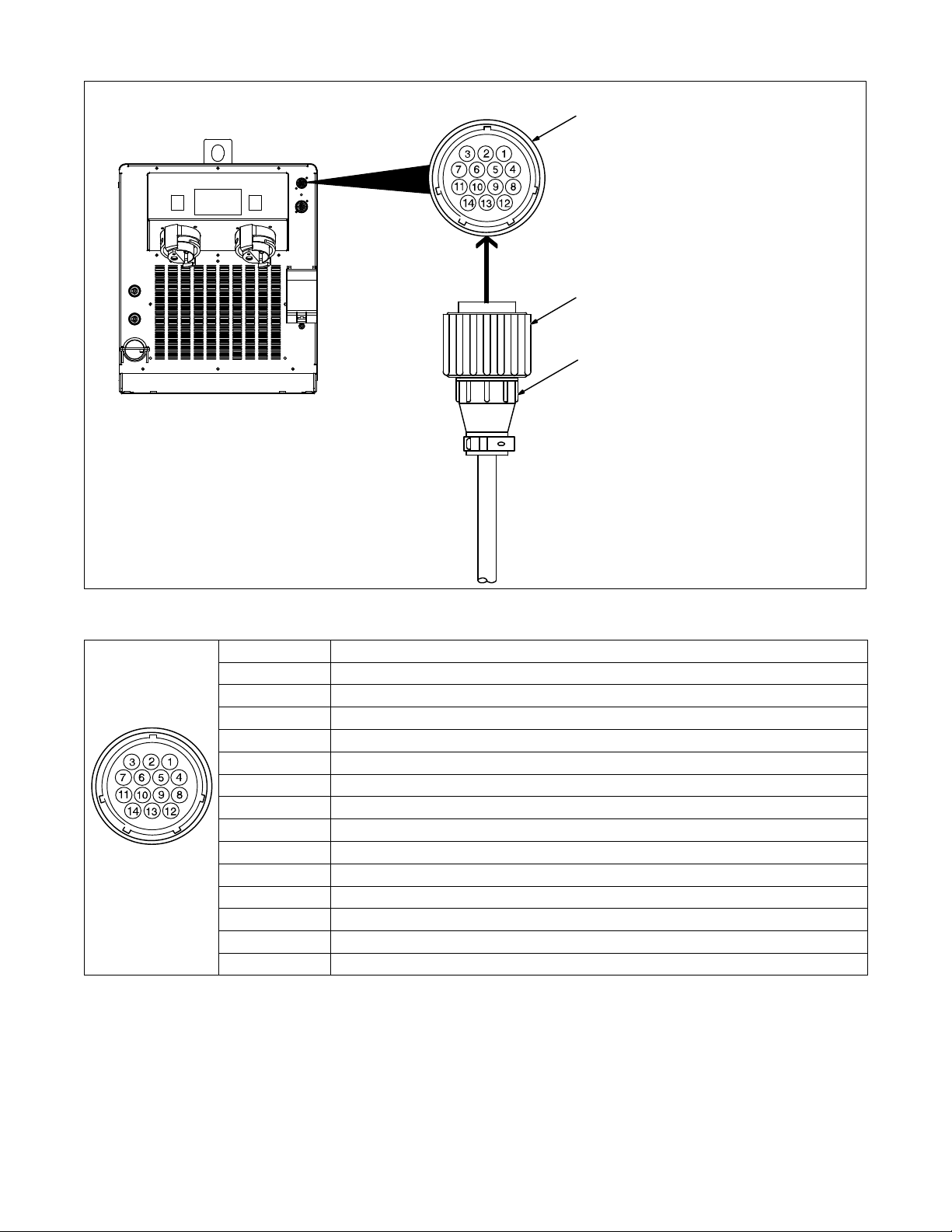

5-9. Remote 14 Socket Information

Socket Socket Information

A

B

C

D

E

G

F, J Power Source Fault

H

I

L

M

N

K

Remote Contactor

Remote Output Control

Remote Metering

+24 volts DC.

Contact closure to A completes 24 volts DC contactor control circuit.

Command reference; +10 volts DC.

Control circuit common.

Input command signal (potentiometer wiper or 0 to +10 volts DC).

Travel sense detect.

Absence of internal contact closure between F and J signals power source fault to remote control device (an external power source must be used).

Tank 2 IRMS (1 volt/10 amperes).

Actual frequency output signal (1 volt/10 kHz).

Average power output signal (1 volt/10 kW).

Voltage output signal RMS (1 volt/100 volts).

Total current output signal RMS (1 volt/100 amperes).

Chassis common.

803 993-D

OM-222166 Page 19

5-10. Temperature Recorder Receptacle RC9 Information And Connections

1 Plug

3

12

2

1

2 Threaded Collar

3 Temperature Recorder

Receptacle RC9 (See Section

5-11)

To connect to receptacle, insert

plug and tighten threaded collar.

5-11. Temperature Recorder Socket Information

Socket No . Socket Information

1 Thermocouple No. 1 (TC1), 0-10 volt DC signal [0V = −50° F (−46° C), 10V = 1500° F (816° C)]

2 Thermocouple No. 2 (TC2), 0-10 volt DC signal [0V = −50° F (−46° C), 10V = 1500° F (816° C)]

3 Thermocouple No. 3 (TC3), 0-10 volt DC signal [0V = −50° F (−46° C), 10V = 1500° F (816° C)]

4 Thermocouple No. 4 (TC4), 0-10 volt DC signal [0V = −50° F (−46° C), 10V = 1500° F (816° C)]

5 Signal Common

6 Thermocouple No. 5 (TC5), 0-10 volt DC signal [0V = −50° F (−46° C), 10V = 1500° F (816° C)]

7 Thermocouple No. 6 (TC6), 0-10 volt DC signal [0V = −50° F (−46° C), 10V = 1500° F (816° C)]

8 Unused

9 Unused

10 Chassis Ground

11 Unused

12 Unused

13 Unused

14 Unused

* The voltage to temperature calculation is:

(DC Volts Out x 155) − 50 = °F

(DC Volts Out x 86.1) − 45.4 = °C

The ProHeat display should read ±6 °F or ±3.3 °C.

803 993-C

OM-222166 Page 20

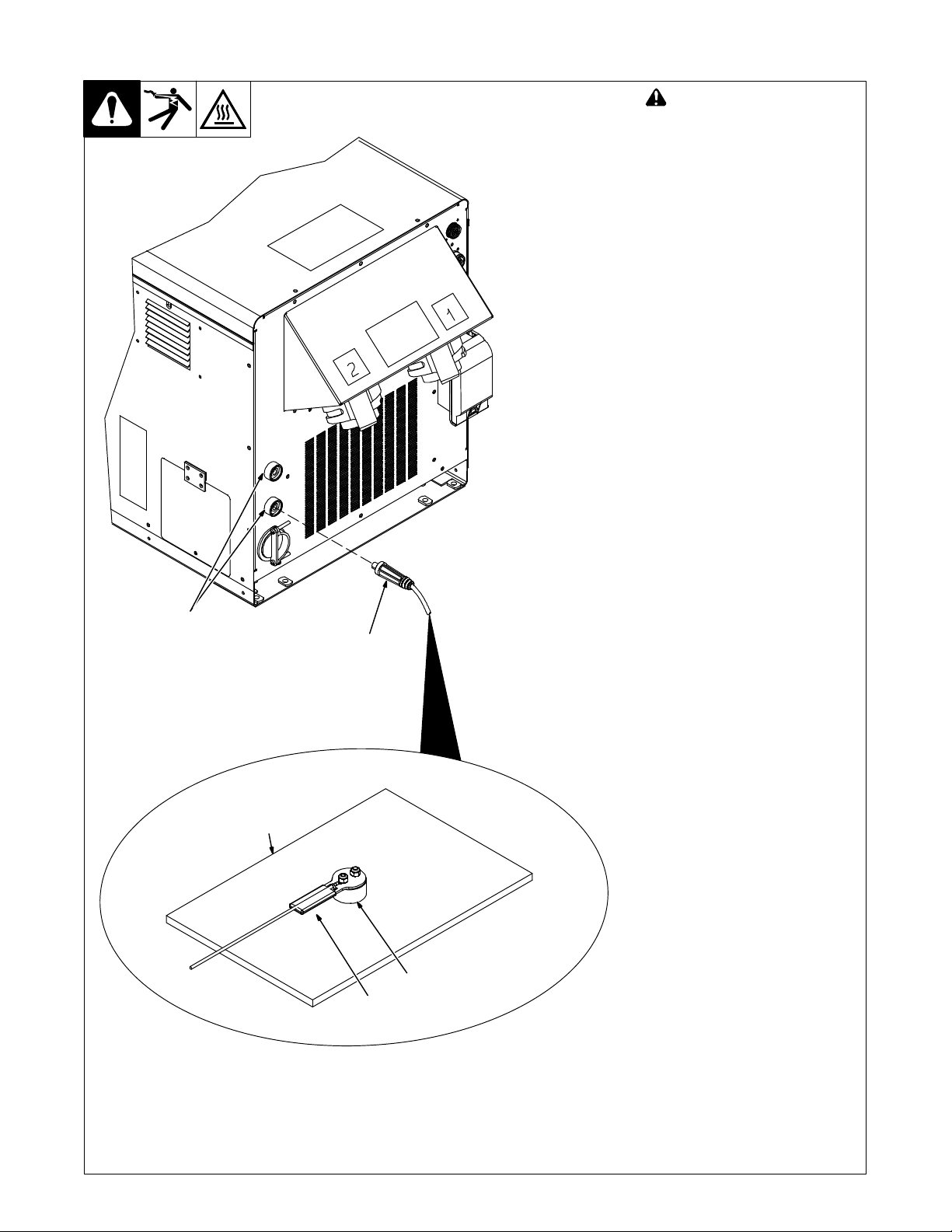

5-12. Secondary Insulation Protection

1

2

! Connect supplied ground

lead(s) between the

workpiece and power source

to provide proper secondary

insulation protection from a

short in the output circuit.

For single output, only one

ground lead is required. For

dual output , use both ground

leads.

Secondary insulation protection

circuitry automatically shuts down

the power source output if a

potentially hazardous condition

exists at the heating device

connected t o the power source (e.g.

insulation has broken down on a

heating blanket causing the

conductor to come into contact with

the workpiece or a heating coil

touches the workpiece causing a

short in the output circuit).

1 Receptacles

2 Plug

To connect plug, align key with key-

way, insert end into receptacle, and

rotate plug until tight.

3 Handle

4 Magnet

. The secondary isolation magnet

must be in contact with bare

metal (free from rust, paint,

grease, etc.).

5 Workpiece

Use handle to place magnet on the

workpiece.

5

4

3

803 994-B / 272 889-A

OM-222166 Page 21

5-13. 115 Volt AC Duplex Receptacle And Supplementary Protector

1 115 VAC 2.5 A Single-Phase

2 Supplementary Protector CB1

The receptacle supplies nominal 115

volts AC auxiliary power for use with

the optional digital recorder. Maximum output from receptacle is 2.5

amperes.

1

CB1 protects 115 volt receptacle

RC1 from overload. If CB1 opens,

2

1

RC1 does not work.

2

AC Receptacle RC1

(2.5 A)

803 993-C

5-14. Locating Thermocouples

Thermocouple location is one of the most critical steps in the Heat Treatment Operation.

Thermocouples shall be located as follows to provide a survey of heating uniformly and enable time and temperature control:

1. Locate thermocouples to ensure that the full area of the heat band is monitored.

S Locate thermocouples to ensure that the full area of the heat band is monitored.

S The code normally specifies the number of thermocouples to be used based on the pipe diameter.

S The control thermocouple is placed in the plane of the weld (center of the heat zone).

S The control thermocouple is placed at the top of the pipe in a standard pipe joint configuration. In other applications, the thermocouple

should be located in the hottest portion of the weldment to be stress relieved.

2. Consider all nozzles and other welded attachments that cause potential heat sinks through metal mass or cold spots due to heat convection or

conduction, and have additional thermocouples applied.

3. Attach a spare thermocouple beside control thermocouples.

4. Attach thermocouples to ensure uniformity of temperature in both thin and thick workpieces.

5. Physically inspect all thermocouples for continuity and mark them by an identification number corresponding to the recorder channel.

6. Match the drawings of the workpiece indicating the numerous thermocouple locations, controlling thermocouple locations, etc. to weld identification information.

7. The system is equipped with 3-pin thermocouple connections at the front of the unit. Six thermocouples can be attached to the power source.

S The system is equipped with 3-pin connectors to accommodate shielded extension cables. The shielded cables protect from electri cal

interference.

8. Type K thermocouple wire has a positive and negative wire. The positive wire is marked as solid yellow or striped yellow. The connector screw

terminals are marked positive and negative. Be sure to attach the wire to the connector with proper polarity.

9. Multiple type K thermocouple devices are supported, such as contact TC probes, welded on TC wire, and IR sensors with type K output. IR

sensors with 4−20 mA outputs are also supported.

OM-222166 Page 22

10. The following describes the thermocouple routing from work to power source.

S Type K thermocouple wire (two wire) is attached directly to the workpiece using a Thermocouple Attachment Unit (see next section for

information on attaching thermocouples).

S The other end is fitted with a 2-pin type K connector.

S The 2-pin connector plugs into the 3-pin composite extension cable. The extension cable has a six-channel block of 3-pin female connec-

tors. The pin size locates the position of the 2-pin connector on the extension.

S The extension cable contains six, 3-wire bundles of shielded cable.

S The 3-pin male extension cable plugs into the 3-pin female connector on the front of the power source.

1

3

4

2

For temperature control mode, the power

source must have (as a minimum) one

thermocouple connected to receptacle

TC1. If multiple thermocouples are desired,

either use individual thermocouple plugs or

the thermocouple extension cable.

To connect thermocouples to the power

source, proceed as follows:

. Do NOT weld thermocouples to work-

piece while thermocouple cable is connected to the power source.

Turn Off power source.

1 Power Source

2 Thermocouple Receptacles

804 320-A

3 Individual Thermocouple Extension

Cable

4 Multiple Thermocouple Extension

Cable

Align plug pin(s) with receptacle socket(s)

and push plug into receptacle.

OM-222166 Page 23

5-15. Attaching Welded Thermocouples

. Do NOT weld thermocouples while connected to power source.

1. Attach thermocouples using a portable Thermocouple Attachment Unit (TAU). This unit spot welds thermocouple wire directly to the

workpiece. Th i s method of thermocouple attachment ensures accurate temperature measurement.