Page 1

November

1993

Form:

OM-1079A

Millerfi

OWNERS

MANUAL

Effective

With

Style

~

No.

JA-46

''~

covrT(93-ST-071

813-A

and

Read

blocks

safety

Have

only

install,

operate,

Call

your

the

directions.

S

Preflow

S

Uses

S

Equipped

follow

these

carefully.

trained

service

or

distributor

Preflow,

And

115

Volts

With

instructions

and

qualified

if

do

you

Postflow

this

50/60

AC,

Needed

unit.

understand

not

Timer

Interconnecting

and

persons

'

1993

Postflow

For

Hz

MILLER

Use

Input

all

With

Power

Electric

50

Cords

Mfg.

Timer

Series

Co.

Wire

S

Give

For

or:

Appleton,

Feeder

this

help,

MILLER

manual

call

your

Electric

WI

54912

the

to

operator.

distributor

Co.,

Mfg.

414-734-9821

P.O.

Box

1079,

PRIN1EDINUSA

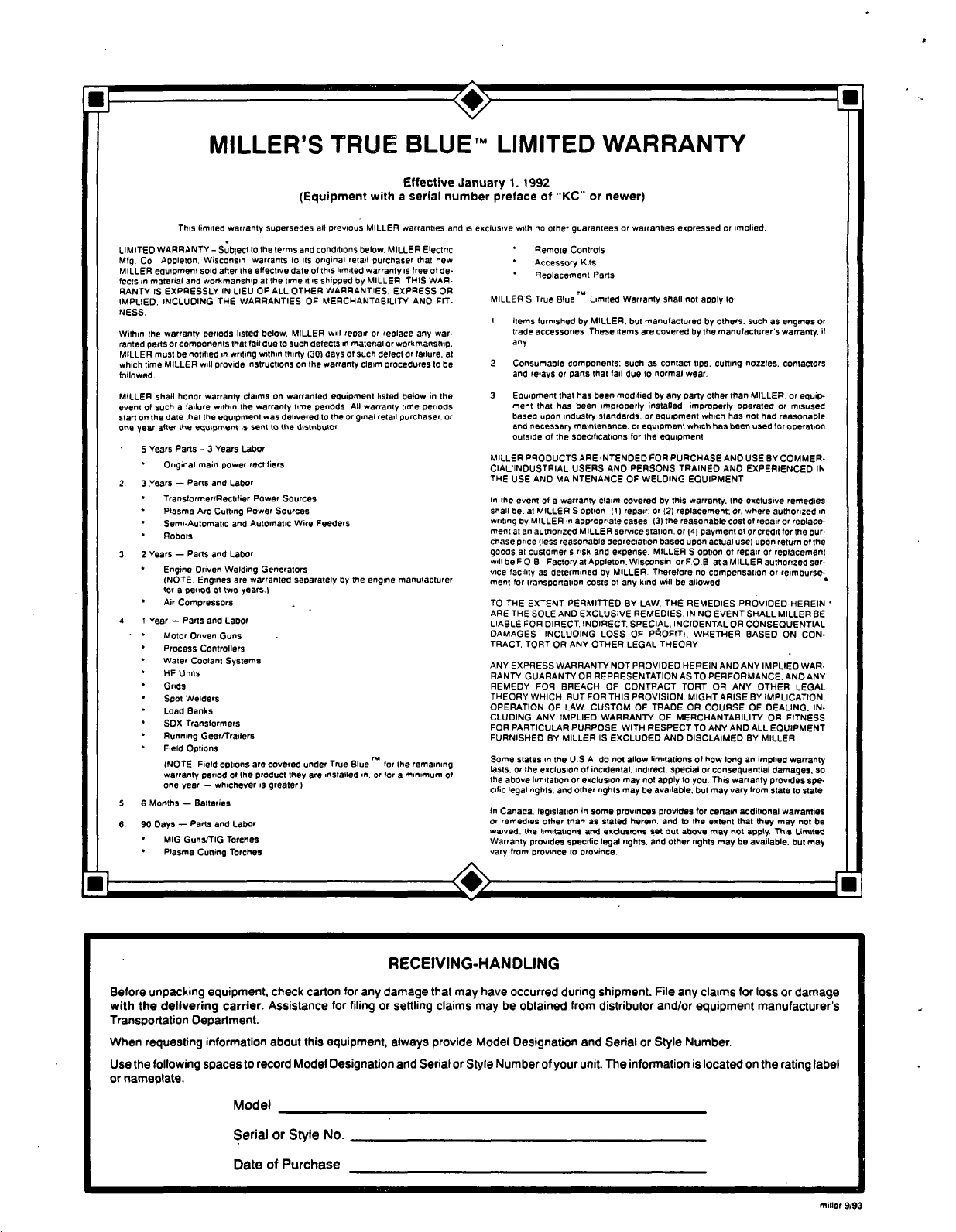

Page 2

MILLERS

TRUE

BLU

ETTM

LIMITED

WARRANTY

LIMITED

Co

Mtg.

MILLER

in

material

tects

RANTY

IMPLtED.

NESS.

Within

the

ranted

parts

MILLER

which

time

followed.

MILLER

of

event

the

on

start

one

year

5

Years

2-

3

Years

3.2Years

*

4

I

Year

5

6

Months

6.

90

This

limited

and

EXPRESSLY

warranty

or

components

be

notified

MILLER

honor

failure

a

date

that

the

Parts

Parts

Pans

a

period

Compressors

Pans

Driven

Coolant

Units

Subtect

Wisconsin

sold

aBet

workmanship

THE

periods

will

pronide

warranty

within

the

equipment

equipment

-

3

Years

main

and

Arc

Cutting

and

Driven

Engines

of

and

Controllers

WARRANTY

Appleton.

.

equipment

5

INCLUDING

must

shall

such

aher

Original

TranstormerlRectifier

Plasma

Semi-Automatic

Robots

Engine

(NOTE.

for

Air

Motor

Process

Water

HF

Grids

Welders

Spot

Banks

Load

SDX

Transformers

Gearflraitera

Running

Field

Options

Field

(NOTE

perisd

warranty

one

Days

MIG

Plasma

year

Batteries

Pans

GunsITfG

whichever

and

Cutting

warranty

the

IN

LIEUOFALL

WARRANTIES

listed

that

in

writing

claims

the

is

Labor

power

Labor

and

Labor

Welding

are

two

years.)

Labor

Guns

Systems

options

the

of

Labor

Torches

Torches

supersedes

the

to

terms

warrantstoits

ehective

the

at

time

below.

fail

duetosuch

within

thirty

instructions

on

warranted

warranty

delivered

was

the

sent

to

rectifiers

Power

Sources

Power

Sources

Automatic

Generators

warranted

are

covered

product

they

ia

greater)

(Equipment

all

previous

and

conditions

original

limited

dateofthis

it

is

shipped

WARRANTIES.

OTHER

MERCHANTABILITY

OF

will

MILLER

defects

(30)

days

on

the

warranty

equipment

time

periods

the

to

distributor

Feeders

Wire

separately

True

under

installed

are

retail

by

repair

in

material

of

such

Alt

original

the

by

Blue

with

MILLER

below.

purchaser

warranty

MILLER

or

detect

claim

listed

warranty

retail

engine

rM

in.

or

Effective

serial

a

warranties

MILLER

tree

is

THIS

EXPRESS

AND

replace

or

workmanship.

or

procedures

below

time

purchaser,

manufacturer

for

the

remaining

for

minimum

a

Electric

that

of

WAR

war

any

failure,

to

in

periods

number

new

de

OR

FIT

at

be

the

or

of

and

January

is

enclusive

MILLERS

I

2

3

MILLER

CIALINDUSTRIAL

THE USE

In

shall

writing

ment

chase

goods

wilt

vice

ment

TO

ARE

LIABLE

DAMAGES

TRACt

ANY

RANTY

REMEDY

THEORY

OPERATION

CLUDING

FOR

FURNISHED

Some

lasts.

the

cific

In

or

waived.

Warranty

vary

1992

1.

preface

with

Items

trade

any

Consumable

and

Equipment

ment

based

and

outsideofthe

PRODUCTS

the

event

at

be.

by

at

an

price

at

F

be

0

tacility

for

transportation

THE

THE

FOR

TORT

EXPRESS

GUARANTY

PARTICULAR

states

or

the

above

legal

Canada.

remedies

the

from

KC

of

no

other

Remote

Accessory

Replacement

BtuetM

True

furnished

accessories.

or

relays

that

that

has

upon

necessary

MAINTENANCE

AND

of

a

MILLERS

MILLER

authorized

(less

customers

B

Factory

determined

as

EXTENT

AND

SOLE

DIRECT

IINCLUDING

OR

WARRANTY

FOR

WHICH.

OF

ANY

BY

in

the

euctusion

limitation

and

rights,

legislation

other

limitations

provides

province

or

guarantees

Controls

Kits

Pans

Limited

MILLER.

by

These

components:

that

pans

has

been

been

ntandards,

industry

maintenance,

specifications

ARE

USERS

claim

warranty

option

in

appropriate

MILLER

reasonable

risk

and

at

Appleton.

costs

PERMITTED

EXCLUSIVE

INDIRECT

ANY

OTHER

OR

REPRESENTATION

BREACH

FOR

BUT

CUSTOM

LAW.

IMPLIED

PURPOSE.

MILLER

IS

A

U.S

do

of

incidental,

or

esctusion

other

rights

in

aome

than

as

and

specific

to

province.

newer)

warrantiea

or

Warranty

but

items

such

fail

due

modihed

improperly

or

for

INTENDED

PERSONS

AND

OF

coveredbythis

(1)

repair:

cases.

service

depreciation

espense.

Wisconsin.

MILLER.

by

of

any

BY

REMEDIES.

SPECIAL,

LOSS OF

LEGAL

NOT

PROVIDED

OF

CONTRACT

THIS

PROVISION,

OF

WARRANTY

WITH

EXCLUDED

not

allow

may

may

provinces

herein,

staled

esciusrons

legal

rights,

eapressed

shalt

not

apply

manufactured

covered

are

as

normal

to

by

instalted,

or

equipment

equipment

the

FOR

WELDING

or

13)

station,

MILLERS

Therefore

kind

LAW,

P~OFIT),

TRADE

RESPECT

limitations

indirect,

not

apply

available,

be

providea

set

and

by

the

by

contacn

tips,

wear.

ofher

any

party

improperly

which

which

equipmenf

PURCHASE

TRAINED

EQUIPMENT

warrsnfy.

(2)

replacement:

the

reasonable

or

(4)

payment

based

wilt

THEORY

OF

actual

upon

option

FOB

or

no

compensation

be

allowed.

THE

REMEDIES

IN

NO

INCIDENTALORCONSEQUENTIAL

WHETHER

HEREIN

AS

TO

PERFORMANCE.

TORT

MIGHT

DR

COURSE

MERCHANTABILITY

ANY

TO

AND

DISCLAIMED

of

how

specialorconsequential

to

you.

but

may

for

certain

and

the

to

estent

above

out

may

olher

righta

or

implied.

to

others,

manufacturers

nozzles.

cutting

than

operated

has

not

has

been

AND

USE

AND

EXPERIENCED

esclusive

the

where

or,

of

cost

of

or

use)

of

repair

MILLER

at

a

PROVIDED

SHALL

EVENT

BASED

ANY

AND

ANY

DR

ARISE

AND

BY

an

long

This

warranty

vary

additional

that

not

apply.

be

may

such

as

MILLER,

hed

used

BY

repair

credit

upon

or

authorized

or

IMPLfED

OTHER

BY

IMPLICATION.

OF

DEALING.

OR

ALL

EQUIPMENT

MILLER

implied

provides

from

state

they

available,

engines

warranty.

confactors

or

equip

misused

or

reasonable

for

operafion

COMMER

remedies

authorized

or

replace

for

the

of

return

replacement

reimburse

HEREIN

MILLER

ON

CON

WAR

ANY

AND

LEGAL

FITNESS

warranty

damages,

spe

to

state

warranties

not

may

This

UmdeG

but

may

or

if

IN

in

pur

the

ser

-

BE

IN

so

be

.1

Before

with

the

Transportation

When

Use

the

or

nameplate.

Unpacking

delIvering

Department.

requesting

following

equipment,

carrier.

information

to

spaces

Model

Serial

Date

check

Assistance

about

record

__________

or

of

Purchase

carton

this

Model

Style

for

damage

any

for

or

filing

equipment,

Designation

No.

RECEIVING-HANDLING

that

settling

always

Serial

and

provide

claims

or

may

have

may

Model

Style

be

Number

occurred

obtained

during

from

Designation

of

your

shipment.

distributor

and

Serial

The

unit.

File

and/or

or

Style

information

claims

any

equipment

Number,

is

locatedonthe

for

loss

manufacturers

or

damage

rating

label

rrritter

9/93

Page 3

TABLE

OF

CONTENTS

Section

SECTION

SECTION

SECTION

SECTION

SECTION

1-1.

1-2.

2-1.

3-1.

3-2.

3-3.

4-1.

4-2.

No.

-

SAFETY

1

General

Safety

2

SPECIFICATIONS

Descnption

INSTALLATION

3

Installation

Shielding

Welding

4

OPERATOR

Preflow

Postflow

5-

SEQUENCE

PRECAUTIONS

Information

Alert

Symbol

Of

Preflow,

Gas

Control

Gun

Trigger

CONTROLS

Time

Control

Time

Control

OF

And

Safety

And

Signal

Postflow

Connections

Control

OPERATION

AND

SIGNAL

Words

Timer

Connections

WORDS

Page

No.

1

1

1

2

2

3

6

6

SECTION

SECTION

SECTION

Gas

5-1.

5-2.

6-

6-1.

6-2.

6-3.

7-

Diagram

Diagram

8

Figure

Table

Table

Metal

Shutting

MAINTENANCE

Routine

Circuit

Down

Maintenance

Board

Troubleshooting

ELECTRICAL

Circuit

7-1.

7-2.

Wiring

PARTS

8-1.

6-1.

LIST

Complete

Maintenance

6-2.Troubleshooting

Arc

Welding

Handling

DIAGRAMS

Diagram

Diagram

Assembly

LIST

Schedule

(GMAW)

TROUBLESHOOTING

&

Precautions

OF

CHARTS

AND

6

6

7

7

7

8

9

10

TABLES

7

8

OM-1019A

11/93

Page 4

N-i

Page 5

SECTION

1

SAFETY

PRECAUTIONS

AND

SIGNAL

WORDS

1-1.

A.

Information

bels,

design,

troubleshooting

followed

B.

The

shooting

and

safety

stalled,

Sons

codes

of

source

GENERAL

General

presented

and

tags,

installation,

for

the

Safety

installation,

of

arc

procedures

of

others.

operated,

in

accordance

such

as,

Arc

Welding

Owners

plates

which

safe

operation,

welding

which

Therefore,

but

Safety

Manual.

INFORMATION

in

this.manuai

the

on

operation,

should

effective

and

equipment

ensure

and

maintained

with

this

limited

not

Precautions

AND

andonvarious

unit

pertains

maintenance,

be

read,

understood,

of

this

use

maintenance,

requires

personal

this

equipment

onlybyqualified

manual

to,

those

in

and

listedatthe

the

SAFETY

to

equipment

equipment.

and

trouble

practices

and

safety

is

to

all

applicable

welding

power

be

and

and

the

per

end

la

in

1-2.

The

following

used

throughout

different

tify

a

a

a

IMPORTANT

necessaiy

ment.

SAFETY

WORDS

safety

this

levelsofhazard

This

safety

words

WARNING

tiontothe

WARNING

practices

ous

personal

CAUTION

practices

personal

statements

for

the

ALERT

alert

manual

alert

safety

statements

which

injury

statements

which

or

injury

most

SYMBOL

symbol

call

to

and

symbol

CAUTION

and

statements.

be

must

loss

or

be

must

damage

identify

efficient

-

AND

and

attentiontoand

special

is

used

identify

followedtoavoid

of

life.

identify

followed

this

to

special

operation

words

signal

instructions.

with

the

call

to

procedures

procedures

to

avoid

equipment.

instructions

of

this

SiGNAL

are

iden

signal

atten

or

seri

or

minor

equip

10-1/2

(287

mm)

In.

SECTION

Figure

-

2

SPECIFICATIONS

2-1.

Overall

Dimensions

SB.O71

7

(3

613-A

Weight

Net

lbs.

kg)

Ship

11

(5

lbs.

kg)

2-1.

P

The

ically

DESCRIPTION

reflow,

timed

Postf

preflow

low

Turner

and

is

designed

postflow

add

to

electron

capabilities

to

the

50

Series

can

The

50/60

wire

added

be

Preflow,

Hertz

feeders.

either

to

Postflow

power.

The

side

Turner

preflow,

ofadual

operates

postf

wire

low

capabilities

feeder.

115

on

OM-1079

VAC,

Page

1

Page 6

ELECTRIC

a

Lockout/tagging

ing

removing

red-tagging

ing

Pre

a

digital

1.

2:

INSTALLATION

TIMER

flow,

box.

Loosen

left

Place

wire

the

on

feeder

3-1.

IMPORTANT:

the

control

of

SHOCK

Do

Shut

fee~ier,

ing

specting

touch

not

down

welding

and

disconnect

lockout/tagging

or

installing.

line

disconnect

fuses

from

circuit

device.

(Figure

The

following

Postf!ow

If

desired,

voltage

screws

sidesofthe

the

feeder

same

the

Timer

control

Timer

the

control

(four

wire

Prefiow,

control

direction

align

box.

kill.

can

ilve

electrical

power

procedures

procedures

switch

fuse

box,

breaker

OF

PREFLOW,

3-1)

procedure

on

top

Timer

can

total)

feeder

so

the

the

in

on

both

mounting

(DVC)

Postflow

box

and

with

SECTION

parts.

source

input

consist

in

the

or

other

or

of

the

be

mounted

the

the

control

Timer

front

screws

and

before

of

open

employ

padlock

position,

power

shutting

disconnect

POSTFLOW

for

is

mounting

wire

same

manner.

right

upper

box

wrapper.

on

top

panels

screw

the

on

3-

wire

off

and

feeder

on

top

and

of

the

face

slots

wire

INSTALLATION

3-2.

in

IMPORTANT:

withadual

made

2.

3.

Slide

3.

tighten

SHIELDING

(Figure

to

1.

Disconnect

receptacle

box

side

Connect

1

rear

sert

plugs

rectly),

plug

Connect

the

valve

control

into

keyed

and

snap

the

wire

wire

the

desired

follows:

as

of

plug

the

6-contact

to

of

the

valve

gas

are

and

snap

rear

receptacle

box

gas

so

press

into

Timer

down

feeder

GAS

3-1)

When

using

the

on

and

gas

be

side

gas

the

squeeze

pull

valve

rear

feeder,

the

female

Preflow,

into

plug

so

keyed

press

into

the 6-contact

of

the

as

valve

they

into

they

into

position.

Preflow,

on

follows:

receptacle

will

place

position.

onto

control

CONTROL

the

sure

of

the

valve

of

plug

plug

Postf

6-contact

will

place

male

Postf

the

insert

not

go

until

screws,

box

screws.

CONNECTIONS

Pre

that

wire

plug

the

Postflow

flow,

all

connections

feed

from

wire

retaining

from

receptacle.

disconnected

plug

extending

low

Timer

female

not

together

go

until

retaining

plug

extending

low

Timer

of

rear

the

6-contact

connectors

(the

together

retaining

and

securely

Timer

are

system.

the

feeder

clips

as

gas

control

on

in

from

follows:

plug

clips

the

to

wire

feeder

male

valve

either

Step

the

in

(the

incor

on

from

gas

plug

are

incorrectly),

on

clips

plug

OM-1

079

Page

To

Welding

Trigger

3-1.

Figure

2

Prof

low,

Postflow

Gun

Plug

Timer

To

Gas

Receptacle

Wire

InstallatIon

To

Valve

Feeder

Trigger

On

Wire

On

Receptacle

Feeder

SB.071

613-A

Page 7

3-3.

WELDING

NEC11ONS

IMPORTANT:

with

dual

a

made

to

the

Connect

1.

rear

GER

control

and

GUN

(Figure

When

using

wire

feeder,

desired

the

of

sideofthe

the

4-pin

Preflow,

receptacle

boxasfollows:

threaded

rotate

TRIGGER

the

be

sure

male

Postflow

the

on

collar

3-1)

Pre

that

wire

plug

front

align

CONTROL

Postflow

flow,

all

connections

feed

extending

Timer

of

the

keyways,

clockwise.

fully

system.

from

the

TRIG

to

wire

feeder

insert

CON

Timer

are

the

plug,

Connect

2.

female

flow,

sert

fully

IMPORTANT:

a

plug

the

dual

digital

must

DDSC

ceptacle

female

4-pin

cord.

the

plug

Postflow

trigger

gun

clockwise.

If

the

schedule

be

connected

that

normally

the

on

plug

welding

extending

Timer

plug,

Pre

flow,

control

to

wire

feeder

Pre

the

on

gun

from

follows:

as

and

Pos

the

DDSC

connects

must

flow,

trigger

the

align

rotate

if/ow

Timeris

(DDSC),

and

to

the

be

connectedtothe

low

Postf

to

plug

of

rear

keyways,

threaded

the

gun

the

TRIGGER

Timer

the

the

collar

used

trigger

plug

trigger

4-pin

Pre

in

with

from

re

REMOTE

Welding

14

Receptacle.

FIgure

3-2.

Connection

Diagram

For

Pref

low,

Postflow

Timer

Front

Used

View

With

Single

Prellow,

Timer

Wire

Feeder

Gas

Control

Cord

Wire

Feeder

Posttlow

S~O491

OM-1079

Page

3

Page 8

REMOTE

14

Receptacle

DDSC

additional

Wire

Drive

Current

NP

Power

Drive

Relay

Models

Welding

IMPORTANT:

and

for

infoimation.

And

DVC

See

Owners

connection

Motor

Assembly

Connections

Only

Figure

DVC

the

Manuals

Gun

3-3.

Connection

Diagram

DDSC

Control,

For

Pref

And

Postflow

low,

Digital

Wire

Timer

Feeder

Used

With

DVC

Control,

OM-1

079

Page

4

Page 9

Welding

IMPORTANT:

and

Power

DDSC

for

additional

information.

Source

See

Owners

connection

OVC

the

Manuals

Volta/Contactor

115

Control

Cord

*Cu~nt

MP

DVC

Figure

Relay

Models

3-4.

Connections

Only

ConnectIon

Pra/low

Control

Time

Diagram

trol,

SECTION

For

DDSC

Preflow,

Control,

4-

Voltage

Sensing

Postf

low

And

OPERATOR

Leads

Timer

Digital

Interconnecting

Used

With

Wire

Feeder

CONTROLS

Gas

Valve

Trigger

Cord

Hold

Ga

Control

Cord

Control,

DVC

s-o4~a

Con

Postflow

Control

Time

FIgure

4-1.

Front

Panel

Controls

SB-Oil

813-A

OM-1079

Page

5

Page 10

4-1.

The

lecting

PREFLOW

PREFLOW

the

ginning

tiates

preflow

welding

drive

wire

of

the

power

period

weld

time.

source

motor

TIME

TIME

of

time

cycle.

When

begins

CONTROL

control

provides

shielding

Depressing

the

preflow

contactor

feed

to

the

(Figure

means

a

flows

gas

the

gun

timer

times

is

energized,

wire.

4-1)

of

se

the

be

at

out,

and

ini

the

the

trigger

scale

The

calibratedinincrements

4-2.

The

lecting

gun

The

calibrated

surrounding

POSTFLOW

POSTFLOW

the

period

trigger

scale

is

surrounding

in

TIME

of

released.

increments

TIME

time

PREFLOW

the

to

a

up

CONTROL

control

shielding

POSTFLOW

the

to

a

up

maximum

(Flgure.4-1)

provides

gas

maximum

TIME

of

a

flows

TIME

of

5

means

5

control

seconds.

of

se

after

the

control

seconds.

is

J

is

a

WARNING:

MOVING

IMPROPER

ENVIRONMENT

Do

Keep

not

all

PARTS

touch

covers

erating.

is

of

the

RAYS,

eyes

void

Warranty

portion

ARC

burn

can

hearIng.

Wear

correct

FUMES

AND

yourhealth.

Ventilate

gases.

If

ventilation

to

breathing

HOT

METAL,

fIre

use

and

for

fire

extinguisher

it.

work

cause

Watch

Have

to

Allow

dling.

MAGNETIC

affect

can

Wearers

fore

welding

See

Arc

ing

power

welding

pacemaker

should

going

operations.

Welding

source

safety

ELECTRIC

can

FLOW

AIR

can

live

electrical

and

if

the

enclosure

outer

SPARKS,

and

eye,

GASES

keep

is

inadequate,

device.

SPATrER,

burns.

fire.

and

equipment

FiELDS

consult

near

arc

Safety

Owners

information.

SECTION

SHOCK

AND

serious

EXPOSURE

internal

cause

damage

parts.

panelsinplace

unit

is

operated

removed.

AND

HOT

NOISE

skin,

and

ear,

from

body

can

serIously

breathing

AND

nearby,

cool

to

FROM

HIGH

operation.

with

their

welding,

Precautions

gouging,

Manual

5

SEQUENCE

can

Injury;

parts.

while

with

SURFACES

can

damage

protection.

harm

fumes

use

approved

SLAG

and

know

before

CURRENTS

doctor

or

in

the

weld

for

basic

kill;

TO

op

any

and

can

how

han

be

spot

5-1.

a

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

5-2.

1.

2.

3.

a

OF

OPERATION

GAS

WARNING:

tIon

at

proceedIng.

Install

to

ing

Install

tion3of

Install

Owners

Wear

dry

Connect

piece.

Select

instructed

as

Turn

on

Wear

welding

cording

Rotate

(see

ting

Rotate

setting

Energize

Begin

SHUTTiNG

Stop

welding.

Shut

down

Turn

off

WARNING:

SHIELDING

Shutoff

METAL

ARC

Read

beginning

and

prepare

Owners

its

Preflow,

this

manual.

and

prepare

Manual.

insulating

work

clamp

and

obtain

in

shielding

helmet

to

ANSI

PREFLOW

Section

POSTFLOW

Section

(see

welding

welding.

DOWN

welding

shielding

GAS

gas

WELDING

and

of

welding

Manual.

Postflow

wire

gloves

to

proper

wire

feeder

gas

Z49.1.

TIME

4-1).

TIME

4-2).

power

power

gas

HIGH

can

supply

(GMAW)

follow

entire

Timer

clean,

welding

supply.

with

controltoits

source

at

source.

CONCENTRATION

harm

when

safety

Section5before

power

according

feeder

source

according

and

clothing.

bare

wire,

Owners

proper

control

and

and

health

not

source

metal

filter

to

in

use.

Informa

accord

to

at

and

thread

Manual.

lens

desired

desired

its

feeder.

wire

feeder.

wire

kill.

or

Sec

to

work-

ac

set

OF

its

OM-1079

Page

6

Page 11

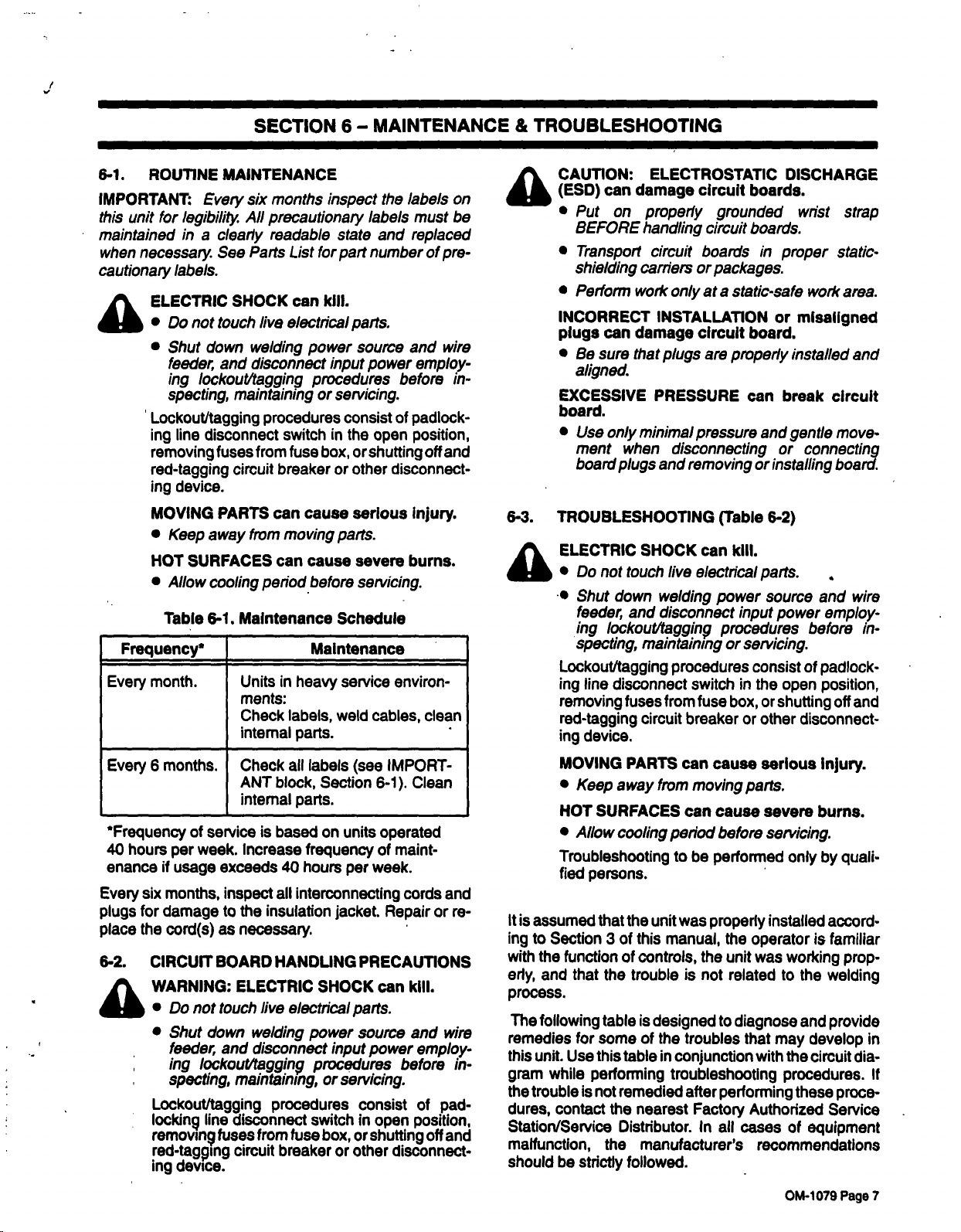

SECTION

MAINTENANCE

6-

&

TROUBLESHOOTING

6-1.

IMPORTANT:

this

maintained

when

ROUTINE

for

unit

necessary.

cautionary

ELECTRIC

a

Lockout/tagging

ing

removing

red-tagging

ing

MOVING

HOT

Table

Frequency*

month.

Every

6

Every

months.

Frequency

40

hours

enance

Every

plugs

place

6-2.

a

if

six

months,

for

damage

the

cord(s)

CIRCUIT

WARNING:

Lockout/tagging

lockin9

removing

red-tagping

ing

MAINTENANCE

six

Every

legibility.

in

labels.

Do

not

Shut

feeder,

ing

lockout/tagging

specting,

line

device.

Keep

SURFACES

Allow

of

week.

per

usage

All

a

clearly

Parts

See

SHOCK

touch

live

down

welding

and

disconnect

maintaining

disconnect

from

fuses

circuit

PARTS

from

away

cooling

6-1.

serviceisbased

period

Maintenance

Units

ments:

Check

internal

Check

ANT

internal

Increase

exceeds

inspect

the

to

as

necessary.

BOARD

ELECTRIC

Do

Shut

feeder,

ing

specting,

not

down

lockout/ta

line

device.

touch

live

welding

and

disconnect

maintaining,

disconnect

from

fuses

circuit

months

inspect

precautionary

can

for

kill.

power

state

part

pans.

source

readable

List

electrical

input

procedures

or

servicing.

procedures

switchinthe

fuse

breaker

can

moving

can

in

heavy

labels,

consist

or

box,

other

or

cause

serious

parts.

cause

severe

be

fore

seivicing.

Schedule

Maintenance

service

weld

parts.

all

labels

(see

Section

block,

parts.

units

on

frequency

40

hours

per

all

interconnecting

insulation

HANDLING

jacket.

SHOCK

electrical

power

PRECAUTIONS

parts.

source

input

ggin9

procedures

or

servicing.

procedures

switch

fuse

box,

breaker

or

consist

in

or

other

labels

the

labels

must

and

replaced

number

power

open

shutting

of

and

employ

before

of

padlock

position,

off

disconnect

injury.

burns.

environ

cables,

6-1).

clean

IMPORT

Clean

operated

of

maint

week.

cords

Repair

kill.

can

and

before

position,

open

disconnect

employ

of

off

power

shutting

pre

wire

or

pad

on

be

in

and

and

re

wire

in

and

CAUTION:

can

a

(ESO)

Put

BEFORE

Transport

shielding

Perform

INCORRECT

can

plugs

Be

sure

aligned.

EXCESSIVE

board.

Use

ment

board

6-3.

a

TROUBLESHOOTING

ELECTRIC

Do

not

Shut

feeder,

ing

specting,

Lockout/tagging

line

ing

removing

red-tagging

device.

ing

MOVING

Keep

HOT

SURFACES

Allow

Troubleshooting

fled

persons.

It

is

assumed

Section

to

ing

with

the

and

erly,

process.

The

following

remedies

this

unit.

while

gram

the

trouble

dures,

Station/Service

malfunction,

should

function

that

for

Use

this

performing

is

not

contact

be

strictly

that

the

table

some

the

ELECTROSTATIC

damage

on

properly

handling

circuit

carriers

work

INSTALLATION

damage

that

plugs

PRESSURE

minimal

only

when

and

plugs

SHOCK

touch

down

welding

and

lockout/ta

disconnect

maintaining

disconnect

from

fuses

circuit

PARTS

from

away

cooling

the

unit

of

this

3

the

manual,

of

controls,

trouble

is

designed

of

the

in

table

remedied

nearest

Distributor.

manufacturers

followed.

circuit

grounded

circuit

boards

or

packages.

static-safe

at

only

a

circuit

are

properly

pressure

disconnecting

boards.

boards.

in

proper

or

board.

break

can

and

or

DISCHARGE

wrist

work

misaligned

installed

gentle

connecting

removingorinstalling

(Table

can

live

electrical

power

ggin9

procedures

procedures

switchinthe

fuse

breaker

can

cause

moving

can

cause

to

be

was

properly

the

is

not

troubles

before

performed

to

period

conjunction

troubleshooting

after

performing

Factory

In

all

6-2)

kill.

parts.

source

input

power

or

servicing.

consist

open

or

box,

or

other

serious

shutting

parts.

severe

servicing.

only

installed

the

operator

unit

was

related

working

to

diagnose

that

may

with

the

procedures.

Authorized

cases

of

recommendations

before

of

disconnect

the

and

develop

circuit

these

equipment

strap

static

area.

and

circuit

move

board.

and

wire

employ

in

padlock

position,

off

and

injury.

burns.

quail-

by

accord

familiar

is

prop

welding

provide

in

dia

If

proce

Service

OM-1079

Page

7

Page 12

Table

6-2.Troubleshootlng

J

TROUBLE

Gas

valve

will

not

operate.

Wire

not

feeder

feed

energizes

wire.

.

but

Extremelyshortorinfinitelylong

preflow

and/or

postflow

time.

will

Gas

cure.

Dual

Gun

cure.

Gun

Dual

valve

Timer

trigger

trigger

Timer

SECTION

CAUSE

connections

Board.

connections

switch.

Board.

7-

ELECTRICAL

not

not

Check

Se-

plug

plug

ceptacle.

See

Authorized

Check

Se-

plug

PLG51

tacleonwire

essary.

Check

sary.

See

Authonzed

connections

PLG5O

PLG53

Section

connections

PLG52

from

gun

Section

DIAGRAMS

from

from

Secure

6-2,

Service

from

rear

feeder.

tngger

6-2,

Service

REMEDY

between

rear

rear

of

of

Timer;

Timer

gas

connections

and

contact

Station/Service

between

rear

Timer

of

Secure

switch,

and

of

Timer

contact

gun

and

connections

and

Station/Service

valve

and

and

gas

if

necessary.

nearest

Distributor.

tngger

and

between

TRIGGER

replace

nearest

Distributor.

and

plug

between

valve

re

Factory

and

plug

plug

recep

if

nec

if

neces

Factory

TP

wI~

~G6I

IT

310

OM-1079

0 0

A

2

ASCO

0

SC0

I

000

Page

0

8

TOGAS

VM.~

DIagram

7-1.

CircuIt

DIagram

Circuit

DIagram

No.

SB.072

257-B

Page 13

500

52

SC-i

No.

Diagram

Wiring

Diagram

WIring

7-2.

DIagram

0

Page 14

SECTION

8-

PARTS

LIST

9

23

24~

21

20

Figure

8-1.

Complete

19 18

Assembly

16

17

SG-071

10

11

614-8

OM-1079

Page

10

Page 15

Item

No.

Dia.

Mkgs.

Part

No.

Figure

8-1.

Description

Complete

Quantity

Assembly

..21

3

4

5

6

7

8

9

10

11

12.,

13

14

15

16...

17

18

19...

20

22~..

23

24

25

26...

....

...

...

.

..

...

1,3T

PLG52

PLG51

PLG5O

PLG53

PLG54

RC52...

CR52....

R61

,62

...

..

..

..

..

..

..

+049

134

038042

010476

010217

604571

079531

080328

079534

079878

079535

048

056 265

052246

070654

072128

031251

079

079747

010301

084440

073

097922

080388

048848

080148

048725

028

057359

173

327

842

798

730

770

WRAPPER

..

..

LABEL,

STRIP,

warning

term

BUSHING,

BLANK,

CABLE,

CLAMP,

RECEPTACLE

snap-in

port

cable

TERMINAL,

HOUSING

TERMINAL,

CONNECTOR,

CONNECTOR,

CABLE,

pwr

BUSHING,

CASE

SECTION,

BRACKE1~

HOUSING,

TERMINAL,

BUSHING,

CIRCUIT

TERMINAL,

NAMEPLATE,

KNOB,

RELAY,

pointer

end

SPRING,

SOCKEt

BRACKET,

POTENTIOMETER,

BLANK,

snap-in

4P

strain

No.

PLUG

No.

strain

mtg

term

contact

al

CARD,

hdr

24VAC

hold

relay

mtg

.140

general

relief

metal

18

strain

precautionary

.625

.625mtg

4/c

(orderbyft)

relief

szll

w/SOCKETS,

female

male

(order

.875d1a

down

lskt

18-14

&

PINS,

(consisting

1

18-14

pin

female

male

2Oga

relief

6skt

6cont

5/c

.300

(order

front/bottom/back

connector

hdr

13

pin

hdr24-18

ID

.250

x

dual

timer

22

pin

model

by

.250

x

3PDT

relay

11

pin

relay

Csltd

nyl

.375mtg

ID

x

hole

.453

free

wire

w/cable

73ORMS

1OA

ID

x

posn

wire

00

and

ID

lIT

sft

hole

.57Omtg

max

hanging

wire

of)

clamp

ft)

by

.55Omtg

.312

x

style

2W

1

hole

00

cable

(consisting

hole

number)

ohm

meg

of)

.

1

1

2

2

1

7ft

2

1

4

1

4

1

1

5ft

2

1

2

1

13

1

1

1

1

.2

1

1

1

1

2

1

+When

BE

ordering

SURE

TO

a

component

PROVIDE

originally

MODEL

AND

displaying

STYLE

NUMBER

a

precautionary

WHEN

label,

ORDERING

the

label

REPLACEMENT

should

also

be

ordered.

PARTS.

OM-1079

Page

11

Page 16

Loading...

Loading...