Miller OBT-600, OBT-1200 Owner's Manual

OM-1596 192 709B

April 2003

Process

Description

Torches For Automatic Welding Systems Using The Submerged Arc Welding (SAW) Process

Torches for

Submerged Arc Welding

(SAW)

Automatic Welding

Automated Applications

Visit our website at

www.MillerWelds.com

OBT-600 And OBT- 1200

From Miller to You

Thank you and congratulations on choosing Miller. Now you can get

the job done and get it done right. We know you don’t have time to do

it any other way.

That’s why when Niels Miller first started building arc welders in 1929,

he made sure his products offered long-lasting value and superior

quality. Like you, his customers couldn’t afford anything less. Miller

products had to be more than the best they could be. They had to be the

best you could buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and service

that meets the high standards of quality and value established in 1929.

This Owner’s Manual is designed to help you get the most out of your

Miller products. Please take time to read the Safety precautions. They

will help you protect yourself against potential hazards on the worksite.

We’ve made installation and operation quick

and easy. With Miller you can count on years

of reliable service with proper maintenance.

And if for some reason the unit needs repair,

there’s a Troubleshooting section that will

help you figure out what the problem is. The

Miller is the first welding

equipment manufacturer in

the U.S.A. to be registered to

the ISO 9001:2000 Quality

System Standard.

parts list will then help you to decide the

exact part you may need to fix the problem.

Warranty and service information for your

particular model are also provided.

Working as hard as you do

– every power source from

Miller is backed by the most

hassle-free warranty in the

business.

Miller Electric manufactures a full line

of welders and welding related equipment.

For information on other quality Miller

products, contact your local Miller distributor to receive the latest full

line catalog orindividual catalog sheets. To locate your nearest

distributor or service agency call 1-800-4-A-Miller, or visit us at

www.MillerWelds.com on the web.

Miller offers a Technical

Manual which provides

more detailed service and

parts information for your

unit. T o obtain a Technical

Manual, contact your local

distributor. Your distributor

can also supply you with

Welding Process Manuals

such as SMAW, GTAW,

GMAW, and GMA W-P .

TABLE OF CONTENTS

SECTION 1 – SAFETY PRECAUTIONS - READ BEFORE USING 1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. Symbol Usage 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. Arc Welding Hazards 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-5. EMF Information 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. Welding Torches 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2. Overall Dimensions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3– INSTALLATION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. Installing Torch Into Drive Assembly (OBT-1200 Shown) 4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. Breakaway Torch Protection (OBT-1200 Models Only) 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. Adding Body Extension (1200 Models Only) 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 – OPERATION 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. Safety Equipment 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 – MAINTENANCE AND TROUBLESHOOTING 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1. Maintenance Schedule 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2. Troubleshooting Table 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – PARTS LIST 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

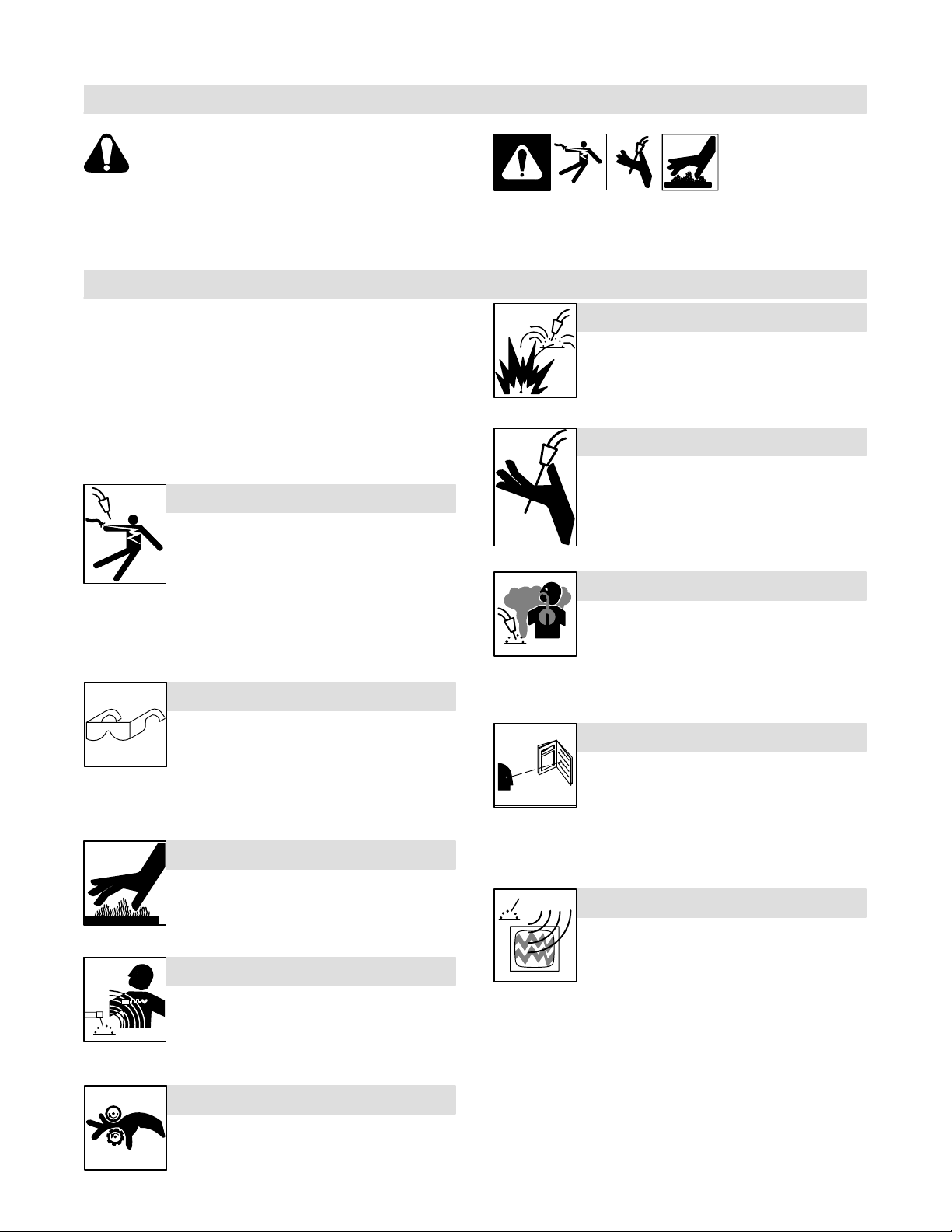

SECTION 1 – SAFETY PRECAUTIONS – READ BEFORE USING

1-1. Symbol Usage

OM-1596 -9/98, safety_saw torch 9/98

Means Warning! Watch Out! There are possible hazards

with this procedure! The possible hazards are shown in

the adjoining symbols.

Y Marks a special safety message.

. Means “Note”; not safety related.

1-2. Arc Welding Hazards

Y The symbols shown below are used throughout this manual to

call attention to and identify possible hazards. When you see

the symbol, watch out, and follow the related instructions to

avoid the hazard. The safety information given below is only

a summary of the more complete safety information found in

the Safety Standards listed in the wire feeder and welding

power source Owner’s Manuals. Read and follow all Safety

Standards.

Y Only qualified persons should install, operate, maintain, and

repair this unit.

Y During operation, keep everybody, especially children, away.

ELECTRIC SHOCK can kill.

D Always wear dry insulating gloves.

D Insulate yourself from work and ground.

D Do not touch live electrode or electrical parts.

D Repair or replace worn, damaged, or cracked

torch or cable insulation.

D Turn off welding power source before changing contact tip or

torch parts.

D Keep all connections tight and secure.

FLYING PARTICLES can injure eyes.

This group of symbols means Warning! Watch Out! possible

ELECTRIC SHOCK, WELDING WIRE, and HOT PARTS hazards.

Consult symbols and related instructions below for necessary actions

to avoid the hazards.

WELDING can cause fire or explosion.

D Do not weld near flammable material.

D Do not weld on closed containers.

D Watch for fire; keep extinguisher nearby.

WELDING WIRE can cause injury.

D Keep hands and body away from torch tip when

welding system is energized.

D Do not put hands or other body parts near the

nozzle when threading welding wire.

FUMES AND GASES can b e h a z a r d o u s .

D Keep your head out of the fumes.

D Ventilate area, or use breathing device.

D Read Material Safety Data Sheets (MSDSs)

and manufacturer’s instructions for material

used.

D Flux granules, slag, welding, chipping, wire

brushing, and grinding cause sparks and flying

flux and metal. As welds cool, they can throw

off slag.

D Wear approved safety glasses with side

shields.

D Wear body protection and cover exposed skin.

HOT PARTS can burn skin.

D Allow gun to cool before touching.

D Do not touch hot metal.

D Protect hot metal from contact by others.

MAGNETIC FIELDS can affect pacemakers.

D Pacemaker wearers keep away.

D Wearers should consult their doctor before

going near arc welding, gouging, or spot

welding operations.

MOVING PARTS can cause injury.

D Keep away from moving parts.

D Keep away from pinch points such as drive

rolls.

READ INSTRUCTIONS.

D Use only genuine MILLER replacement parts.

D Read and follow the safety information in the

wire drive system and welding power source

Owner’s Manuals for more complete welding

safety information.

ARC WELDING can cause interference.

D Electromagnetic energy can interfere with

sensitive electronic equipment such as

computers and computer-driven equipment

such as robots.

D Be sure all equipment in the welding area is

electromagnetically compatible.

D To reduce possible interference, keep weld cables as short as

possible, close together, and down low, such as on the floor.

D Locate welding operation 100 meters from any sensitive elec-

tronic equipment.

D Be sure this torch and welding system are installed and

grounded according to their manuals.

D If interference still occurs, the user must take extra measures

such as moving the welding machine, using shielded cables,

using line filters, or shielding the work area.

OM-1596 Page1

Loading...

Loading...