Page 1

IMPORTANT

contents

the

of

safety

installing,

ment.

only

operation

trained

unit.

understand

This

by

persons

persons

Contact

of

Read

manual,

this

material

throughout

operating,

unit

and

trained

welding

to

install,

distributor

your

these

instructions.

understand

and

with

or

maintaining

instructions

these

and

experienced

equipment.

operate,

special

the

manual,

Do

or

if

you

the

emphasis

this

for

are

in

the

allow

not

maintain

do

not

entire

on

before

equip

use

safe

un

this

fully

June

Effective

1989

With

Serial

AUTO

sPW1

FORM:

No.

MODEL

ARC

JK585798

MW

113

4150

336B

~Fftr~

,

I

44J

I

~F

OWN

MANUAL

A.rl__

I

II%W~J.

718

ELECTRIC

BOUNDS

S.

APPLETON,

ADDITIONAL

NWSA

PRINTED

WI

COPY

CODE

IN

MILLER

ERS

MFG.

Box

P.O.

ST.

54912

USA

PRICE

$145

NO.

4579

U.S.A.

CO.

1079

Page 2

ONE

YEAR

LIMITED

WARRANTY

COVERAGE

who

purchases

familyorhouseholdpurposes(Consumer)thatthisWelderwill

free

be

one

year

the

original

authorize

other

any

of

the

warranty

ityrelatedtothoWelder,exceptonwarrantyclaimsmadeduring

the

warranty

THIS

EXPRESS

PROHIBITED

ALL

IMPLIED

LIMITED

TABILITYAND

LIMITED

Some

warranty

This

warranty

have

other

Exceptasspecified

components

such

as

in

come

nozzle

workmanship

Miller

Equipment

the

following

the

original

Arc

1.

2.

Original

(labor

All

3.

4.

Replacement

WHAT

Welder

any

warranty

warranty

sonal,

trial

users

Miller

this

defectsinmaterial

from

from

the

purchaser

party,

any

warranty

period,

period,

WARRANTY

WARRANTY;

BY

WARRANTIES,

TO

THE

FITNESS

TO

THE

statesdonot

so

lasts,

gives

which

rights

having

welder

spot

contact

in

IS

NOT

with

material.

or

be

required

the

periods

user:

power

main

1

year

guns,

COVERED

where

event

power

or

insulators

shall

welders,

welding

subjected

repair

by

extends

only

household

or

family

are

given

Electric

Auto

Arc

date

of

purchase.

of

this

including

behalfofMiller

on

Miller

IS

OFFERED

AND,

APPLICABLE

IMPLIED

FORAPARTICULAR

DURATION

allow

the

above

specific

you

vary

below,

normal

useful

tips,

relay

the

welding

failure

to

honorwarranty

of

failure

from

the

sources,

rectifiers

only)

feeder/guns

repair

parts,

to

misuse,

except

anyone

to

those

purposes.

different

a

Co.

Mfg.

Welder

andworkmanship

Welder.

authorized

its

Electric

WARRANTIES

OF

limitationsonhow

limitation

from

Millers

and

does

date

This

purchasing

warrants

(Welder)

This

warranty

Miller

Electric.

shall

havenofurther

LIEUOFANY

IN

EXCEPT

THE

LAW,

INCLUDING

THIS

WARRANTY.

may

rights,

legal

to

state

warranty

life

of less

contactor

wire

including

not

resulting

of

delivery

and

components

and

torches

exclusive

warranty

neglect,

Miller

Electric.

Commercial

result

claims

fromadefect

warranty.

to

the

buyer

for

personal,

fora

period

covers

Electric

does

distributors,

Upon

TO

DURATION

OF

expiration

THE

EXTENT

BUT

MERCI-IAN

to

OTHER

PURPOSE,

an

implied

long

not

and

state.

does

than

points,

of

of

labor

does

accident,

the

apply

you

may

not

apply

one

(1)

parts

nozzles

from

defect

warranted

on

Equipment

...

3

90

60

not

extend

Further,

Welder

for

and

to

within

1

or

indus

of

only

not

offer

liabil-

OF

NOT

IS

you.

also

to

year,

that

and

in

to

year

years

days

days

to

in-

this

per

REMEDY

defective

place

purchase

use),

placement

vided

dure

Welder

the

charges

States

Hawaii

THE

WELDER,

LAW,

WARRANTY:

UNDER

NO

TAL

OF,

BASED

ELECTRICS

THEORY

Some

quential

not

apply

PROCEDURE

ANCE

As

chaser

approved

defect.

period,

dress:

Miller

1635

P.O.

Appleton,

All

Electric

FOR

DEFECTIVE

Miller

Welder,

defective

the

(less

price

reimburse

or

atan

that

for

so

purchaser

(transportation

will

ARE

EVENT

OR

OR

soon

of

The

return

transportation

approved

the

purchaser

obtaining

repaired

of

to

prepaid

be

paid

PURCHASERS

TO

THE

LIMITED

AND,

APPLICABLE

BE

LIABLE

SPECIAL

INABILITY

ON

BREACH

NEGLIGENCE

OF

STRICT

do

states

incidental

or

to

you.

FOR

as

any

the

Welder

Warranty

purchaser

the

Electric

W.

Spencer

Box

1079

Wisconsin

must

be

prepaid.

warranty

the

not

defect

Welder

Mfg.

WELDERUpon

Electric

Welderat

reasonable

the

Consumer

Miller

of

that

used

or

as

defective

destination

any

chargesonshipments

to

the

only

REMEDIES

EXTENT

TO

THE

TO

LAW,

FOR

DAMAGES

TO

USE,

OF

LIABILITY.

allow

the

damages,

OBTAINING

in

a

must,

Station

must

to

Co.

St.

54912

charges

at

will,

its

expense,

depreciation

for

Electric

Welder

performance

a

replacementwill

Welder,

in

nearest

PERMITTED

REMEDY

THE

EXTENT

MILLER

CONSEQUENTIAL,

ARISING

THE

THIS

OR

OTHER

exclusion

the

so

WARRANTY

Welder

becomes

within

thirty

Miller

within

Electric

to

Warranty

Electric

or

then,

Miller

its

option,

refund

basedonactual

the

of

cost

warranty

followed

has

forth

set

with

transportation

continental

the

of

export).

port

FOR

A

BY

APPLICABLE

PROVIDED BY

ENFORCEABLE

ELECTRIC

OF

OUT

WELDER,

WARRANTY,

TORT,

limitation

or

limitations

above

known,

days,

(30)

in

the

one

the

at

Station

of

receipt

or

repair

orcredit

or

repair

station,

the

proce

below.

be

shipped

United

to

Alaska

DEFECTIVE

THIS

SHALL

INCIDEN

THE USE

WHETHER

MILLER

OR

ON

ANY

of

conse

PERFORM

the

notify

of

writing

year

warranty

following

Miller

or

any

re

the

re

pro-

The

may

pur

an

the

ad

to

or

IN

L

Page 3

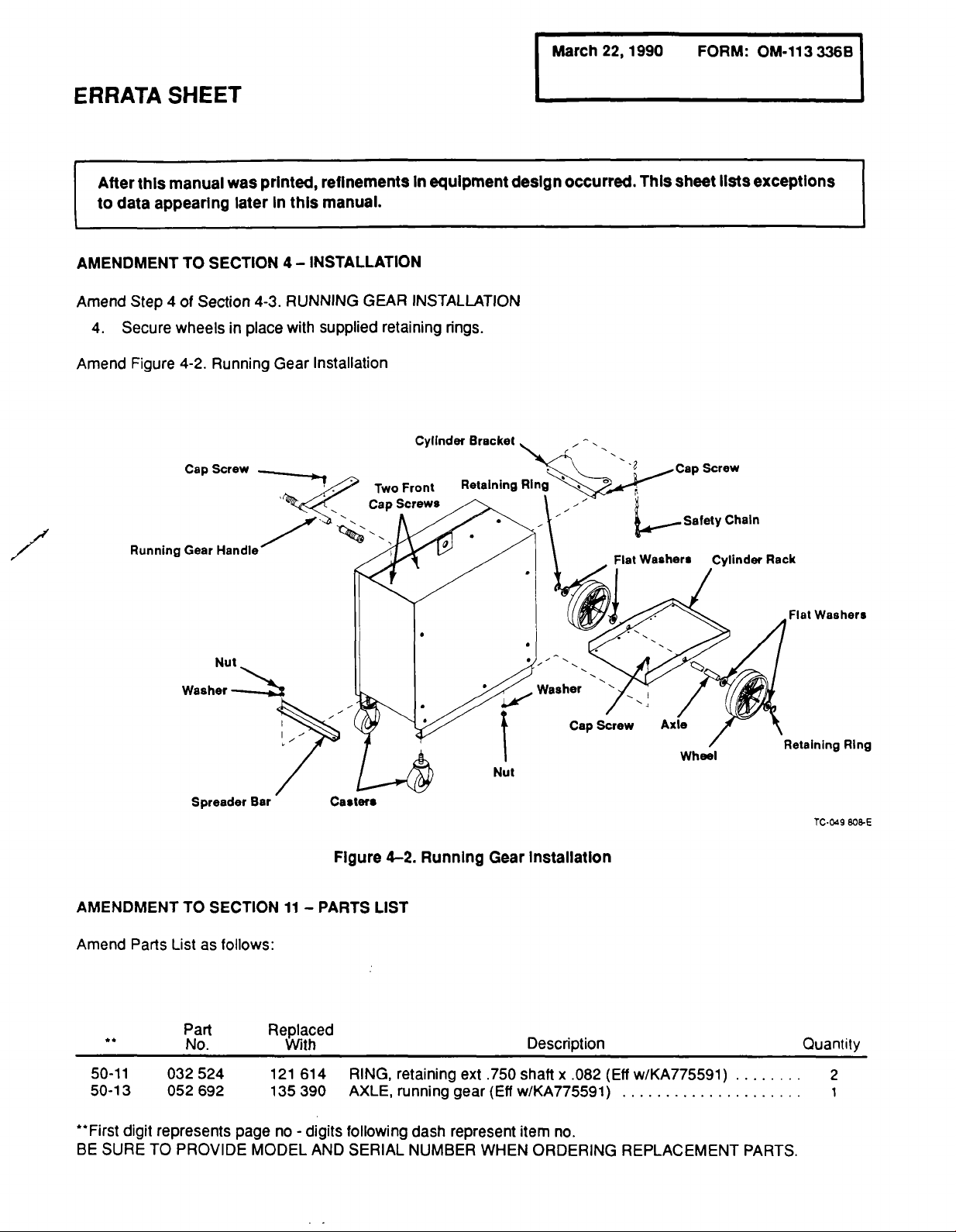

ERRATA

SHEET

After

to

data

AMENDMENT

Amend

Secure

4.

Amend

manual

this

appearing

4

Step

Figure

TO

of

Section

wheels

4-2.

Cap

was

later

SECTION

in

place

Running

Screw

printed,

In

this

4-

RUNNING

4-3.

with

Gear

refinements

manual.

INSTALLATION

GEAR

supplied

retaining

Installation

Two

in

equipment

INSTALLATION

rings.

Cylinder

Front

Bracket

design

occurred.

This

sheet

Screw

lists

exceptions

Rack

AMENDMENT

Amend

**

50-11

50-13

Parts

TO

List

Part

No.

032

052

Nut

Spreader

SECTION

follows:

as

524

692

Bar

11

Replaced

With

121

135

614

390

Casters

Figure

PARTS

LIST

RING,

AXLE,

42.

Running

retaining

running

ext

gear

Nut

Gear

installatIon

Description

.750

shaft

(Eft

w/KA775591)

x

Screw

Cap

.082

(Effw/KA775591)

Wheel

Retaining

TC.049

Quantity

2

I

Ring

808-E

**First

BE

SURE

digit

represents

TO

PROVIDE

page

no

MODEL

-

digits

AND

following

SERIAL

dash

NUMBER

represent

WHEN

item

no.

ORDERING

REPLACEMENT

PARTS.

Page 4

Page 5

RECEIVING-HANDLING

Before

age

claims

Assistance

from

ers

When

ways

unpacking

that

may

for

loss

for

the

distributor

Transportation

requesting

provide

Number.

Section

SECTION

equipment,

have

occurred

or

damage

or

filing

and/or

Department.

information

the

Model

No.

1

1-1.

1-2.

1-3.

1-4.

check

during

with

settling

claims

the

about

Description

SAFETY

Introduction

General

Arc

Welding

Standards

carton

shipment.

the

deliverIng

may

equipment

this

equipment,

and

Serial

RULES

Precautions

Booklet

forany

dam-

File

carrier.

obtained

be

manufactur-

or

Style

TABLE

FOR

OPERATION

Index

any

al

OF

the

Use

tion

mationislocated

Model

Serial

Date

following

Serial

and

________________________________________

or

Style

of

Purchase

CONTENTS

OF

ARC

or

spaces

Style

the

on

to

Number

data

record

card

of

the

your

or

Model

the

unit.

nameplate.

No._____________________________

______________________________

No.

Page

WELDING

POWER

SOURCE

1

1

3

5

Designa

The

infor

SECTION

SECTION

SECTION

2-1.

2-2.

3-1.

3-2.

3-3.

3-4.

3-5.

3-6.

3-7.

4-1.

4-2.

4-3.

4-4.

4-5.

4-6.

4-7.

4-8.

4-9.

4-10.

4-11.

4-12.

4-13.

2-

SAFETY

General

Safety

3

Alert

INTRODUCTION

Volt-Ampere

Duty

Cycle

Description

Supplied

Additional

Optional

Consumable

4

INSTALLATION

Site

Selection

Transporting

Running

Optional

Shielding

Work

Cable

Weld

Polarity

MWG-200

Installation

Welding

Hub

Tension

Electrical

Welding

PRECAUTIONS

Information

Symbol

Curves

Equipment

Required

Equipment

Parts

Methods

Gear

Installation

SPW-1

Gas

Panel

Installation

Assembly

Selection

Welding

Of

Optional

Wire

Spool

Adjustment

Connections

Input

Wire

Threading

AND

And

Safety

And

Signal

Equipment

Installation

Gun

Connections

Spool

Installation

Gun

SIGNAL

Words

WORDS

..

6

6

8

8

8

8

9

10

10

10

10

11

11

12

13

14

14

15

16

16

16

17

Page 6

Section

No.

Page

No.

SECTION

SECTION

SECTION

5-1.

5-2.

5-3.

5-4.

5-5.

6-1.

6-2.

6-3

7-1.

7-2.

7-3.

7-4.

7-5.

7-6.

7-7.

7-8.

7-9.

OPERATOR

5

Power

ThicknessNolts

Fine

Switch

Tuning/Wire

Fan-On-Demand

Optional

SEQUENCE

6

Gas

And

Gas

(Models

Shutting

7-

MAINTENANCE

Routine

Replacing

Drive

Replacing

Inspecting

Overload

Thermal

Printed

Spot

Metal

Gas

Metal

Metal

With

Down

Maintenance

Housing

Hub

Protection

Overload

Circuit

Arc

Arc

Drive

And

Troubleshooting

CONTROLS

And

Pilot

Light

Selector

Speed

Pulse

OF

OPERATION

Welding

Arc

Welding

Optional

&

Roll

Control

Panel

(GMAW)-Continuous

Welding-Pulsed

(GMAW)-Spot

SPW-1

TROUBLESHOOTING

And

Realignment

Assembly

Replacing

Protection

Board

Replacement

Controls

Panel

Wire

Inlet

Motor

Arc

Only)

Guide

Brushes

(GMAW-P)

19

19

19

19

19

20

22

23

23

24

26

26

26

27

27

27

27

SECTION

SECTION

SECTION

8-

Diagram

Diagram

9

9-1.

9-2.

9-3.

9-4.

9-5.

9-6.

10

10-1.

10-2.

10-3.

10-4.

10-5.

10-6.

ELECTRICAL

8-1.

Circuit

8-2.

Circuit

WELDING

Gas

Metal

Gas

Metal

Gas

Metal

Welds

Plug

Skip

Welding

Troubleshooting

AUTO

Pointers

Procedure

Procedures

How

To

Prevent

Procedures

Welding

Diagram

Diagram

TECHNIQUES

Arc

Arc

Arc

BODY

For

Welding

For

For

For

Frames

DIAGRAMS

Welding

Welding

Welding

The

REPAIR

Welding

Welding

Glass

Welding

And

SPW-1

For

&

Panel

TROUBLESHOOTING

(GMAW)Continuous

(GMAW)-Pulsed

(GMAW)-Spot

Gas

Metal

Arc

Welding

APPLICATION

Auto

Mild

Door

Breakage

Fenders

High

Sheet

Body

Steels

Panels

And

And

Strength

(HSS)

Process

Metal

Spatter

Quarter

Steels

Seam

On

Panels

Windows

30

30

31

32

33

34

34

34

37

37

37

38

38

38

Page 7

Section

SECTION

LIST

No.

11

Figure

Figure

Figure

Figure

Figure

Figure

Figure

Figure

OF

CHARTS

Table

Chart

Chart

Table

Table

(GMAW)

Table

Table

Table

PARTS

11-1.

11-2.

11-3.

11-4.

11-5.

11-6.

11-7.

11-8.

3-1.

3-1.

3-2.

3-2.

6-1.

6-2.

7-1.

7-2.

LIST

Main

Assembly

Baffle,

Drive

Assembly,

Panel,

Panel,

SPW

1

Circuit

Running

AND

TABLES

Specifications

Volt-Ampere

Duty

Cycle

Conductor

Input

Suggested

Checking

Maintenance

Troubleshooting

-

Air

W/Components

-

Rear

Front

Card,

W/Components

-

W/Components

Panel

Spot

PC5O

Gear

Curves

And

Parameters

Parameters

Weld

Schedule

Wire

(Optional)

Fuse

For

Size

Continuous

Gas

Metal

Arc

Welding

Page

40

42

44

45

46

48

49

50

21

23

23

28

No.

7

7

7

17

Page 8

Page 9

SECTION

1

SAFETY

RULES

FOR

OPERATION

OF

ARC

WELDING

POWER

SOURCE

1-1.

INTRODUCTION

We

learn

by

experience.

sonal

experience,

harmful,

teach

ers

Safe

practices

welding

search,

evolved

and

tion,

wasteful,

you.

and

development,

reliable

servicing

likeachild

and

developed

cutting

are

equipment

practices.

unwise.

describedinthis

equipmentisimproperly

for

the

son

Some

technical

rules.

Read

tempting

Comply

ticular

personal

Failuretoobserve

ous

injury

equipment

These

1-General

and

ting;

Reference

also

are

cedures

in

the

most

The

National

Health

inspection

ment

1-2.

Different

and

fluxes

radiation

manual,

facturers

specIfic

concerning

A.

Burn

Wear

in

use

shirt

collar

avoid

to

Wear

shields

(protected

safe

practices

based

are

volumes

and

to

with

equipment

safety

safe

on

understand

install,

these

used

and

these

death.

or

be

can

practices

common

to

operate,

procedures

used

Precautions,

2-Arc

Welding

standards:

those

for

given

Index

available

than

Standards

complete.

Electrical

Administration,

requirements

installation,

GENERAL

arc

levels.

be

MaterIal

technical

Prevention

protective

welding,

and

entry

helmet

use,

PRECAUTIONS

welding

can

produce

In

to

sure

data

their

material.

clothing-gauntlet

hat,

pocket

of

sparks

with

safety

underneath,

clear

by

explain.

these

and

for

the

When

with

are

common

(and

Published

additional

in

Code,

local

and

processes,

addition

consult

Safety

and

and

flaps,

and

appropriate

cover

Learning

from

and

and

usedormaintained.

may

theirinstruction

safety

safe

safety

divided

safety

touching

Let

the

experience

experience

field

experience

safe

installation,

Accidents

not

always

sense,

or

others

Itiswiser

safe

practices

service

as

applicable

of

others.

practices

becomes

confidence.

into

to

arc

Cutting)

through

a

in

manual.

occur

to

the

may

two

welding

(only).

Standards

and

more

in

this

this

manual.

manual.

complete

They

ANSI

Occupational

industrial

also

provide

service.

different

to

flux

Data

electrode

fumes,

the

Information

and

Sheets

codes,

basis

a

electrode

(MSDSs)

precautionary

high

safety-toe

and

gloves

wear

designed

shoes.

cuffless

slag.

goggles

and

filter

glass).

glasses

This

lenses

isaMUST

hot

stove

oth

of

the

use

Re

have

opera

per

when

The

rea

be

given.

require

may

follow

before

the

at

equipment.

the

to

par

manuals,

cause

a

Z49.1is

Safety

for

seri

the

habit,

Sections:

and

cut

on

safety

pro

listed

are

the

and

and

local

for

equip

alloys,

In

manu

measures

Button

trousers

with

or

plates

and

this

for

for

side

for

gases,

is

of

welding

from

glass

Avoid

Hot

should

Medical

a

shift

treatment

Ear

in

others

or

radiant

when

or

oily

metal

never

first

unless

of

should

plugs

confined

work

first

qualified

a

Flammable

sons

intending

B.

Severe

fumes,

that

adequate

Z49.1

oxygen.

Lead

ing

duce

local

the

plied

Metals

fumes

from

Fume

Toxic

discomfort,

vapors,

welding

ventilationasdescribed

listedinStandards

-,cadmium-,

and

similar

harmful

exhaust

area as

respirator.

coated

should

the

work

necessary,

in

Work

and,

tor.

Gas

Leaked

centration

confined

Leaving

to

prevent

downstream

left

a

if

necessary,

leaks

gas

confined

open.

confined

dangerously.

space.

possible

Check

re-entering

the

The

from

heat

toxic

ultraviolet

Vapors

by

highly

ucts.

decompose

form

vapors

solvent

to

vapors

atmosphere

(and

cutting,

energy

broken,

greasy

such

as

be

handled

and

aid

aid

medical

flash

burnsofthe

be

space.

overhead.

hair

preparations

weld

to

Prevention

heat,

(orcutting)

materials,

concentrationsoftoxic

ventilation

well

as

For

with

be

not

surface,

while

wearinganair-supplied

while

in

confined

a

in

large

space,

valves

to

it.

chlorinated

of

the

and

gas,

chipping)

and

flying

pitted,orspattered.

clothing.

electrode

eye

person

facilities

worn

A

illnessordeath

or

zinc-,

the

beryllium,

A

without

treatment.

should

are

eyes

when

hard

hat

should

cut.

or

oxygen

produce.

may

Index.

mercury-,

when

be

must

operator

both

orcontaining

heated

space

unless

the

area

onlywhile

wearing

space

Do

not

OFF

shut

been

that

solvents

flame)

lung

energy

can

bring

quantities

accumulation

have

be

sure

arc

(or

other

(radiant)

trichloroethylene

DO

phosgene.

be

can

or

where

drawn

the

NOT

into

radiant

to

protect

metal.

spark

stubs

Replace

See

Ignite

may

and

workpleces

1-3A.2.

gloves.

First

aid

facilities

available

be

close

working

should

enrichment

NEVER

welded

used,

must

materials

is

for

immediate

by

and

skin

overhead

on

be

worn

be

used

not

result

can

or

Prevent

in

ANSI

ventilate

and

beryllium-bear

(or

cut)

fumes.

each

or

wear

an

be

must

used.

that

coating

well

is

ventilated

respirator.

it

is

being

an

air-supplied

should

change

gas

of

gases

accidentally

the

space

can

form

to

and

and

WELD

the

energy

be

oxygen

cylinders

gas

supply

in

the

opened

is

safe

be

decomposed

PHOSGENE,

irritating

eye

of

the

arc

perchloroethylene

or

welding

can

113336

the

eyes

cover

them.

and

for

each

burns.

or,

when

by

per

from

depletion

them

with

Standard

with

may

pro

Adequate

person

in

air-sup

emittoxic

removed

if

and,

ventilated

respira

avoided.

con

into

a

at

source

if

space

or

before

a

prod

also

can

cut

where

or

cutting

penetrate

1

Page

Page 10

to

atmospheres

trichloroethylene

C.

Fire

and

Causes

bythe

rial;

short

BE

through

and

goggled

To

Keep

and

cause

If

the

Avoid

lators.

at

protect

fire-resistant

Walls

not

work

shields.

Fire

guishing

ing

of

fire

flame,

arc,

misuse

circuits.

AWARE

cracks,

through

operator.

prevent

equipment

electrical

(in

short

combustibles

if

work

nt

pai

If

the

least

35

against

touching

be

welded

should

watcher

equipment

or

cutting

a.

appreciable

containing

or

Explosion

and

explosion

flying

of

compressed

THAT

flying

along

wall

or

Sparks

fires

and

clean

parts)

circuits.

are

practicable,

rooms,

spray

work

cannot

feet

away

ignition

covers

combustibles

on

(or

be

protected

must

be

if:

construction)

b.

appreciable

feet

but

can

c.

openings

within

(concealed

35

feet

sparks

d.

combustibles

metal

Hot

work

ensure

have

been

After

work

glowing

An

empty

produce

be

never

been

cleaned

7

in

Standards

This

includes:

solvent

bles

solubility)

trogen

113

336

Page

or

conducted

permit

supervisors

embers,

container

flammable

welded

water

or

carbon

or

partitions

should

taken.

is

done,

and

on

describedinAWS

as

Index.

a

thorough

washing,

followed

dioxide,

2

heat.

minute

even

perchloroethylene.

Prevention

combustibles

are:

sparks,

gases

hot

slag

and

or

sparksorfalling

slag

windows

out

can

fly

pipes,

floor

through

openings,

and

explosion:

and

operable,

metallic

of

in

out

or

cut).

do

area,

to

an

tanks,

dip

be

moved,

of

reach

with

shields.

Walls,

area

suitable

on

by

standing

and

during

combustibles

within

are

combustibles

be

ignited

orvisible)

may

expose

adjacent

can

be

obtained

approvalthat

check

that

or

flames.

held

toxic

or

cut,

steam

that

combustibles,

vapors

unless

depending

by

purging

and

free

particles

NOT

weld

free

of

storage

move

of

sparks

and

opposite

ceilings,

heat-resistant

with

some

suitable

time

by

for

(including

35

feet

further

are

by

sparks

in

combustibles

to

walls,

be

ceilings,

ignited

before

adequate

is

area

orcaustic

using

free

when

container

Standard

on

and

inerting

protective

amounts

reached

heated

cylinders;

slag

of

of

combustibles.

can

or

sight

35

feet.

oil,

cut.

or

areas,

mate

pass

doors,

of

grease,

that

Move

venti

and

the

can

combustibles

and

heat;

snug-fitting,

sides

should

and

floor

near

covers

fire

extin

afterweld

building

than

35

floors

orwalls

roofs,

radiant

by

operation

precautions

of

sparks,

that

or

heated,

A6.O,

cleaning

the

must

has

listed

(or

combusti

with

can

first

ni

equip-

or

to

or

to

of

or

a

ment

working

A

container

(see

smell

Hollow

welding

Explosive

may

as

D.

Standard

manual,

HANDLING

DERS,

1.

Regulator

regulator

any

with

Never

other

Remove

pair

indicate

Leaks-if

Excessive

with

Faulty

when

release.

Repair.

for

where

recommended

as

level

with

preceding

or

sight

castings

or

cutting.

atmospheres.

contain

gasoline).

Compressed

precautions.

andthose

listed

Pressure

relief

from

downstream

one

or

connect

than

more

that

faulty

close

(first

a

faulty

gas

Creep-if

downstream

Gauge-if

pressurized,

Do

NOT

repair

to

special

personnel.

2.

Cylinders

Cylinders

and

Avoid

third

produce

dent.

ICC

assurance

dled.

Identifying

gas

content.

alter

or

is

illegal

Empties:

mark

must

damage

electrical

electrical

rails,

short

(See

DOT

or

marked

Notify

name,

and

Keep

MT;

keep

1-3C.)

of

gas

on

promptly.

in

A6.O.

Waterfilling

substitute

may

unknown

paragraph).

determineifitissafetoweld

to

containers

or

They

flammable

Gas

detailedinCGA

COMPRESSED

OF

in

11

Standards

for

contents

NOT

Do

must

can

explode.

Neverweld

dust,

gas,

Equipment

Comply

with

Index.

inerting.

or

Standard

Regulators

valve

is

designed

it

is

overpressure;

equipment.

relief

devices.

a

regulator

for

which

the

regulatorfrom

cylinder

valve).

not

Provide

to

a

cylinder

regulator

service

The

regulator:

leaks

externally.

delivery

valve

gauge

nor

attempt

manufacturers

techniques

be

handled

their

to

walls,

circuit

wires,

circuit

arcs

them;

must

when

do

marking

safety

content.

supplier

number,

hazardous.

valves

them

separate

pressure

closed.

pointer

returns

to

repair.

and

carefully

valves,

contact

or

welding

that

be

the

Use

only

not

rely

if

unmarked.

other

or

closed,

does

to

stop

Send

designated

tools

with

lead

may

each

on

cylinder

cylinders

on

markings

replace

from

below

just

shouldbecleaned

on

vented

where

vapors

sense

or

cut.

before

the

(such

in

depend

be

orcut

liquid

precautions

P-1,SAFE

GASES

to

intended

IN

protect

to

such

protection

CYLIN

only

protect

containing

was

designed.

immediatelyfor

following

not

pin

are

or

safety

cylinders

circuits.

color

NEVER

FULLS

symptoms

continues

off

move

after

pressure

faulty

regulators

repair

used

by

to

prevent

devices:

including

They

to

serious

a

cylinder.

is

properly

with

name

to

identify

DEFACE

on

a

cylinder.

caps

securely;

and

to

stop

center,

trained

leaks

It

return

this

the

gas

re

rise

pin

can

acci

is

an

han

gas

of

air

of

It

Page 11

Prohibited

other

than

roller.

Locate

over.

or

Passageways

where

areas

Transporting

such

port

the

ground

or

magnets.

NOT

Do

and

stag,

contents

low

supplier.

Mixing

Never

such

cylinders

objects,

moving

valve.

valve

gases.

refill

where

Protect

falling

when

Stuck

cylinder

your

Cylinderfittings

Hose

3.

Prohibited

for

the

specified

is:

red

for

gases.

Use

ferrules

wireorother

nary

hoses

to

No

copper

to

tings

Avoid

hose

on,

splice

long

off

otherwise

or

Never

use.

intended

its

secure

cylinders

and

they

cylinders.

a

as

platform

their

by

expose

flame,

etc.

exceed

to

exposure

and

cylinders.

NOT

Do

that

Never

cylinder.

any

should

Never

use.

gas.

fuel

gas,

or

clamps

fittings.

tubing

hose.

to

runs

ground

to

damaged.

a

use

cylinder

NEVER

use,

so

they

work

areas.

struck.

be

may

With

a

crane,

orcradle.

valves

cylinders

particularly

can

green

or

that

may

130F.

exists.

weather.

use

a

not

to

try

never

hose

use

A

general

for

caps,

excessive

to

cause

valves

hammer

be

mix

be

oxygen,

designed

it

as

Use

kinks

from

substitute)

splices.

prevent

keep

or

as

cannot

Keep

cylinders

use

NOT

Do

or

by

rupture.

with

Cool

from

Replace

wrench

or

opened

gases

any

modified

otherthan

hose

identification

and

for

the

a

binding

standard

only

and

run

being

its

contents

a

support

be

a

secure

lift

cylinders

chains,

heat,

water

bumps,

caps

hand.

by

in

a

or

exchanged.

that

black

hose

to

abuse.

over,

for

or

knocked

of

clear

sup

off

slings,

sparks,

Do

al

not

spray

falls,

securely

to

open

Notify

cylinder.

designed

rule

inert

for

ordi

(not

connect

brass

fit

Suspend

stepped

outlet

with

a

Match

the

that

thatthe

CONNECT

gases

Tighten

nections,

Tighten.

retighten

Adapters.

plier)

two

use

LEFT

Regulatoroutlet

by

right

(with

5.

a

Pressurizing

Drain

fore

opening

justing

sive

compression

seat

engaged

Stand

Open

creases

reaches

lowing

seal

to

less

Use

safe

regulators.

Check

there-after.

uid*

leak.

bustible.

from

away

clean

lintless

regulator

regulator

regulator

a

to

a

cylinder

connections.

clean

If

connection

using

Use

between

wrenches

HAND

threads.

hand

grooved

regulator

cylinder

screw

to

open

slightly

side

to

cylinder

slowly.

regulator

position:

stem

against

than

one

pressure

and

efficient,

for

leaks

Brush

or

equivalent

Clean

off

people

to

label

inlet

regulator

and

cloth.

cylinder.

and

and

cylinderoutlet

designed

containing

When

smooth

and

leaks,

adapter

and

to

tighten

hose)

for

nut

on

fitting

connections

oxygen

or

properly

CGA

a

cylinder

(or

threads

hex

Steps:

of

residual

in

(clockwise).

heat

on

pressurization.

on

of

regulator

valve

When

gas

manifold

(or

at

high

single-stage

while

so

slowly

gauge

maximum)

For

oxygen,

possible

turn

to

permit

charts

soapy

(available

recommended

first

on

with

per

pressurization

soap

gallon

water

sources

Before

cylinder

any

of

connecting,

marking

for

a

particular

other

assembling

where

seats

disassemble,

wrench.

(available

and

if

marked

may

left

for

regulator,

adapter

shank)

through

valve)byturning

Draining

pressure

Leave

regulators.

opening

that

regulator

is

pressurized

leave

cylinder

and

inert

leak.

For

quick

emergency

from

your

pressure

solution

of

after

(capfull

water).

dried

test;

ignition.

area,

match.

NEVER

gas.

threaded

necessary.

clean,

from

your

is

one

required.

RIGHT

be

identified

hand

threads

fuel

gas.

suitable

vent

prevents

seat

by

allowing

adjusting

cylinder

pressure

valveinfol

gases,

fuel

open

gas,

shutoff.

supplier)

settings

and

regularly

of

Ivory

Bubbles

soap

Wipe

check

and

or

gas

con

and

sup

and

be

ad

exces

screw

valve.

in

(gauge

fully

to

open

for

on

Liq

indicate

is

com

Coil

excess

Protect

sparks,

Examine

nections.

dicate

leaks.

Repair

ing

(1-2D3).

4.

Proper

Clean

cylinder

orifices

Except

hose

hose

and

slag,

hose

Immerse

or

leaky

Do

Connections

and

damage

for

hydrogen,

to

prevent

from

damage

open

regularly

pressured

hose

worn

NOT

tape.

valve

outlet

seats

crack

flame.

for

leaks,

by

before

valve

kinks

and

by

sharp

wear,

in

hose

cutting

of

impurities

connecting

momentarily,

tangles.

edges,

and

water;

out

area

that

and

by

loose

con

bubbles

and

may

in

splic

clog

regulator.

pointing

E.

User

Responsibilities

Remove

mediately

in

F.

Close

G.

Rope

cutting

leaky

for

equipment

Leaving

supply

gas

Rope

Staging-Support

staging-support

operation;

*Trademark

1-3.

ARC

WELDING

defective

or

repair.

See

manual.

EquIpment

at

source

rope

of

Proctor

User

Unattended

should

may

&

Gamble.

equipment

from

Responsibility

and

drain

gas.

be

not

used

burn.

service

statement

for

welding

113

336

Page

im

or

3

Page 12

Comply

Arc

careless

high

bright

frared

pressed

unnecessary

accidents.

dards

A.

Comply

The

can

from

Skin

shielded

BURNED;

1.

Wear

arc)

essary,

Ieatherjacket

sistant

ton.

Bare

Button

ets

2.

Protect

electric

Welding

no.

face

Protect

Cracked

worn;

Cracked,

IMMEDIATELY.

pitted,

Flash

the

helmet

struck.

eyes

cause

area

3.

Enclosed

rate

round

ble

ticularly

113

with

precautions

Welding,

properly

operator

currents

and

hot.

energy

gases

risks

Precautions

referenced

Burn

Protection

with

precautions

welding

damage

arc

eyes,

light-colored

burns

resemble

are

arcs

COMPLY

Protective

long-sleeve

in

addition

additional

use

or

leggings.

skin

protection.

collar

to

to

prevent

Head

and

Eye

from

eyes

without

arc

helmet

12

denser

or

before

striking

filter

plate

broken

or

radiation

broken,

or

spattered.

goggles

helmet

not

to

give

be

Looking

(particularly

retinal

a

in

the

fieldofvision.

Protection

welding

or

the

operation

or

floor

at

4

Page

enclosed

room

screens

336

done,

invites

at

significant

Sparks

fly,

radiates,

be

and

in

index.

intense

used.

protects

are

may

is

penetrate

surfaces,

acute

more

severe

WITH

Clothing

clothing

to

gloves,

sleeves,

Avoid

outer

Wear

protect

entry

chest

of

sparks.

Protection

exposure

protection.

shield

or

must

be

arc.

with

a

helmet

can

pass

loose

or

Replace

with

side

some

lowered

at

burn

of

protection

an

arc

a

high

that

Nearby

area.

bay

with

panels.

Allow

level.

in

1-1,

is

trouble.

1-2,

safe

a

The

equipment

and

voltages.

fumes

weidments

The

described

1-2.

in

and

visibly

rise,

are

wise

himself

bright.

ultraviolet

here

lightweight

and

burn

the

sunburn,

and

PRECAUTIONS.

those

painful.

(particularly

and

hat,

protective

flame-proof

shoes

clothing

apron,

garments

substantial

dark,

and

to

containing

used

when

clear

cover

or

through

filter

plates

clear

cover

shields

the

over

momentarily

intensity

leave

may

Personnel

For

production

is

best.

and

neck

NEVER

arc.

filter

a

welding.

plate.

shield

to

cause

must

plate

MUST

the

to

face

with

gas-shielded

a

In

open

low-reflective,

for

free

air

this

section.

arc

and

others

and

Its

radiation

and

from

DONT

such

and

but

carries

is

very

and

com

avoids

from

in

stan

reflect

eyes.

gas-

GET

As

nec

fire-re

process,

The

hot,

operator

and

clothing,

skin

for

gas-shielded

(1-2A).

of

untreated

clothing.

button

pock

look

at

shade

plate

Pace

over

should

eyes

before

when

be

NOT

burns.

be

replaced

broken,

worn

should

an

under

arc

unprotected

arc)

a

areas,

dark

sepa

permanent

welding,

non-combusti

circulation,

in

cot

the

can

sur

par

as

an

be

is

Viewing

who

a

Others

flash

Before

bay

B.

Comply

Generator

air.

C.

Comply

the

will

be

working

goggles.

starting

doors

are

Toxic

Fume

with

engine

Carbon

Fire

and

with

looking

monoxide

Equipments

equipment.

Loose

cause

Never

sel.

ture

D.

Comply

E.

Exposed

ing

ment

conductor.

TOUCH

cable

fire.

a

strike

It

creates

lead

or

Compressed

with

can

Prevention

hot

or

fatally

DO

wet

a

Shock

circuit,

Provide

weld.

directly

in

area.

to

weld,

closed.

PreventIon

precautions

exhaust

Explosion

precautions

rated

capacity.

It

overheat

may

connections

on

an

arc

brittle

a

such

to

Gas

precautions

conductorsorother

in

ungrounded,

shock

NOT

surface

See

make

in1-2B.

must

kill.

can

Prevention

in

a

cylinder

area

a

rupture

Equipment

in1-2D.

a

person

STAND,

when

face

shields

weld.

the

at

all

that

may

that

sure

be

1

-2C.

Do

not

cables

can

under

persons

that

vented

overload

and

overheat

other

or

cause

rough

bare

electrically-HOT

whose

SIT,

LIE,

welding,

for

screen

to

cause

or

pressure

a

metal

body

LEAN

without

all

persons

are

wearing

or

flaps

the

outside

arc

welding

fire.

a

flash

and

ves

violent

rup

handling.

the

in

weld

equip

becomes

OR

ON,

suitable

a

protection.

To

protect

Wear

body

adequate

duckboard,

dry

can

tween

metal

able

through

A

voltage

ducting

ing

objects

trical

against

dry

insulating

and

clothing

insulation

be

not

avoided.

body

reduces

dangerous

the

will

object

include,

work

tools,

workpieces,

metal

object

1.

Grounding

Arc

welding

the

National

grounded

And

When

welding

culatorto

quate

according

Cutting.

installing,

power

the

to

carry

shock:

gloves

dry.

against

rubber

or

Sweat,

and

an

electrically

the

electrical

and

body.

exist

between

in

the

work

but

benches,

Never

etc.

unless

the

Equipment

the

equipment

Electrical

to

connect

source,

building

ground.

ground

and

Never

work

electrical

when

mat

sea

resistance,

possibly

the

circuit.

limited

not

are

welding

touch

welding

must

be

Code,

ANSI

Z49.1

the

frames

control,

currents

worktable,

Conductors

body

in

damp

dampness

water,

HOT

part

lethal

electrode

Examples

to,

power

the

electrode

power

grounded

and

the

Safety

of

each

safely.

Equipment

protection.

area

shock.

moisture

or

or

and

currents

and

buildings,

source

source

Keep

without

Stay

or

sweat

grounded

could

to

any

of

conduct

elec

cases,

and

is

according

work

must

In

Welding

unit

such

andwater

be

must

made

on

be

en

flow

con

any

off.

cir

ade

a

to

be

as

Page 13

electrically

tally.

carrying

HOT

NOTGROUNDto

Do

ANY

Three-phase

equipment

available,

wires

ment

ment

tion

that

Before

conductors

frames

If

line

a

equipment

ground

plug

ceptacle,

ground

prong

Never

plug

2.

Electrode

Fully

NOT

3.

Connectors

Fully

join

welding

4.

Cables

Frequently

IMMEDIATELY

or

damaged

from

taped

Keep

from

5.

Terminals

Terminals

should

6.

a.

before

connect

of

the

ground

will

become

can

welding,

connections.

at

cord

for

leadtothe

is

added

the

prong

plug,

remove

broken

with

a

insulated

holders

use

insulated

inspect

bared

cable.

to

give

cable

hot

metal

and

have

Electrode

Equipment

3-phase

are

connect

cable

dry,

insulating

Welding

metal

welding

mally

off

control

equipped

cally

and

touch

ject

the

welding

b.

Equipment

contactor)

stray

current

by

electrical

flammable

or

gas

connection.

Check

installing.

single-phase

Do

line.

lead

to

the

third

electrically

shock,

possibly

check

touching

with

a

ground

connection

grounded

for

connection

ground

If

only.

Holders

the

to

the

ground

off

electrode

with

lock-type

ground

bare

to

switchbox.

must

lead

line

a

grounded

prong

ground

holders

protruding

connectors

lengths.

cables

REPLACE

insulationtoavoid

Cables

resistance

free

and

And

other

power

arc

welding

(GTAW)

are

equipped

of

the

HOT

when

the

welding

the

electrode

in

contact

forwear,

those

with

equivalenttooriginal

of

oil

and

sparks.

Other

Exposed

exposed

covers

with

output

sources

(GMAW),

and

with

the

welding

electrode

the

power

gun

wire

with

the

power

without

source

shock,

may

conduit,

such

liquid

phase

requirements

If

only

3-phase

equipment

NOT

connect

or

wire,

(live)

HOT-a

dangerous

fatally.

for

continuity.

metal

lead

a

switchbox,

to

a

be

cord

of

is

provided

If

a

grounded

connected

comes

mating

from

a

plug,

prong.

should

screws.

shouldbeused

cracks

with

excessively

possibly-lethal

Parts

of

electrical

before

control

use

gas

processes

that

output.

becomes

source

is

conducting

any

is

off.

on/off

areas

and

closed.

damaged

grease,

parts

secured

on/off

for

similar

devices

power

wire

switch

or

electrode

output

possiblyfa

orto

a

pipe

oil

fuel.

or

as

of

equip

equip

condi

Be

is

two

sure

to

the

the

power

only

equipment

with

the

connect

the

three-prong

to

re

the

mating

withathree-

receptacle.

or

use

be

used.

Do

to

and

damage.

worn

shock

be

may

cable.

protected

units

operation.

(contactor)

with

the

gas

When

electri

is

Never

unless

arc

nor

on

so

ON

ob

(no

tungsten

permit

switch

circuit

control

a

Welding

metal

esses

output

ment

power

electrode

off.

7.

Safety

Safety

should

Before

shut

switches)

tag

Disconnect

all

pull

Do

not

ing.

against

Leaving

disconnect

Power

welding

F.

port

Magnetic

Devices

devices

be

not

installation,

OFF

all

115

volts

open

in

an

It,

shock

equipment

all

disconnect

power

Protection

Devices

fields

operation.

equipment

before

(pacemaker)

going

operations.

1-4.

STANDARDS

For

more

information,

their

latest

revisions

1.

ANSI

Standard

CUTTING

Society,

2.

NIOSH,

AND

GAS

from

the

ernment

3.

OSHA,

29CFR

Documents,

Washington,

4.

ANSI

Standard

OCCUPATION

FACE

PROTECTION

National

NY

York,

5.

ANSI

Standard

SAFETY-TOE

American

New

way,

6.

ANSI

Standard

USE

OF

power

arc

may

on-off

electrode

the

switchisturned

suchasinterlocks

disconnectedorshunted

power

to

prevent

cables

alt

line-cord

power

emergency,

burns,

power

source.

For

sources

welding

not

unless

be

equipped

control

the

(SMAW)

devices.

is

electrically

welding

inspection,

and

remove

accidental

from

welding

plugs.

circuit

or

change

it

must

from

flash

or

unattended.

to

equipment.

switch

must

Wearers

or

line

be

of

(Pacemakers)

from

Persons

near

obtainable

N.W.

550

SAFETY

WELDING

Superintendent

Printing

SAFETY

obtainable

1910,

D.C.

Standards

10018.

National

York,

CUTTING

high

wearing

arc

welding,

BOOKLET

refer

and

Z49.1,

LeJeune

AND

Office,

U.S.

20402.

Z87.1,

AND

Z41.1,

FOOTWEAR

NY

Z49.2,

currents

electronic

should

consult

gouging,

the

to

comply

SAFETY

from

HEALTH

AND

of

Washington,

AND

HEALTH

from

Government

SAFE

EDUCATIONAL

obtainable

Institute,

STANDARD

Standards

10018.

FIRE

AND

WELDING

with

used

similar

and

with

welding

With

such

HOT

ON.

Never

power

and

circuit

out.

service,

of

fuses

(or

turning

power

polarity

equipment,

lock

ON

source,

while

disconnected,

switch

Always

be

Electronic

can

INDEX

following

as

the

Rd,

arcing.

shut

available

affect

pacemaker

life

with

their

or

spot

standards

applicable:

IN

WELDING

American

Miami,

IN

ARC

CUTTING

Documents,

D.C.

STANDARDS,

the

Superintendent

Printing

PRACTICES

from

the

1430

Broadway,

FOR

obtainable

Institute,

PREVENTION

1430

PROCESSES

shielded

proc

power

equip

when

the

touch

the

source

breakers

red-

or

of

power.

and

weld

guard

OFF

and

the

near

Life

Sup

support

doctor

welding

AND

Welding

FL

33126.

WELDING

obtainable

U.S.

Gov

20402.

Office,

FOR

EYE

AND

American

New

MENS

from

the

Broad

IN

THE

is

or

of

113

336

Page

5

Page 14

obtainable

Institute,

AWS

7.

CONTAINERS

TIBLES

ciety,

NFPA

8.

TEMS

PROCESSES

Protection

MA

NFPA

9.

CODE

Association,

02269.

10.

NFPA

PROCESSES

Protection

MA

11.

CGA

PRESSED

1430

Standard

obtainable

N.W.

550

Standard

FOR

Association,

02269.

Standard

obtainable

Standard

Association,

02269.

Pamphlet

the

American

from

Broadway,

A6.0,

WHICH

from

LeJeune

51,

WELDING,

obtainable

70,

from

Batterymarch

51B,

obtainable

P-i,

GASES

National

New

York,

WELDING

HAVE

the

Rd,

OXYGEN-FUEL

HELD

American

Miami,

CUTTING,

the

from

Batterymarch

NATIONAL

National

the

Park,

CUTTING

the

from

Batterymarch

SAFE

IN

HANDLING

CYLINDERS

Standards

NY

AND

CUTTING

COMBUS

Welding

FL

33126.

GAS

AND

National

Park,

ELECTRICAL

Protection

Fire

Quincy,

WELDING

AND

National

Park,

obtainable

10018.

ALLIED

Qui

Qui

OF

COM

SYS

ncy,

So

Fire

MA

Fire

ncy,

fromthe

son

GSA

12.

WELDING

nadian

178

M9W

NWSA

13.

PHY

Association,

19103.

14.

American

RECOMMENDED

PREPARATION

OF CONTAINERS

HAZARDOUS

American

Miami,

ANSI

15.

TORY

can

New

Compressed

Davis

Highway,

Standard

AND

Standards

Rexdale

1R3.

booklet,

obtainable

Welding

Welding

FL

33126.

Standard

PROTECTION,

National

NY

York,

Gas

Suite

W117.2,

CUTTING

Association,

Boulevard,

WELDING

from

the

Arch

1900

Society

SAFE

WELDING

FOR

AND

SUBSTANCES,

Society,

Z88.2,

Standards

10018.

PRACTICE

Association,

501,

Arlington,

CODE

FOR

obtainable

Standards

Rexdale,

SAFETY

National

Street,

Standard

PRACTICES

PIPING

obtainable

THAT HAVE

obtainable

N.W.

550

Institute,

Jeffer

1235

VA

22202.

the

IN

Ca

SAFETY

from

Sales,

Ontario,

Welding

Philadelphia,

Canada

BIBLIOGRA

Supply

PA

AWSF4.i,

FOR

THE

CUTTING

AND

HELD

from

the

LeJeune

FOR

from

1430

RESPIRA

the

Broadway,

Rd,

Ameri

2-1.

GENERAL

A.

General

Information

bels,

design,

troubleshooting

followed

The

nameplate

labeling

pear

B

.

Safety

The

installation,

shooting

and

procedures

safety

stalled,

sons

codes

Section

of

Power

ing

presented

and

tags,

installation,

for

the safe

the

front

the

at

appropriate

of

arc

of

others.

operated,

in

accordance

such

as,

1

Safety

Source.

plates

which

of

operation,

welding

which

Therefore,

but

SECTION

INFORMATION

in

this

the

on

operation,

should

and

effective

this

unit

uses

controls.

panel

section

equipment

ensure

and

maintained

with

this

limited

not

Rules

2-

SAFETY

AND

SAFETY

manual

unit

and

pertains

maintenance,

be

read,

understood,

of

this

use

international

The

symbols

in

the

text.

maintenance,

requires

personal

this

equipment

only

by

manual

to,

For

and

those

listedatthe

Operation

PRECAUTIONS

various

on

to

equipment

equipment.

symbols

also

and

trouble

practices

and

safety

istobe

qualified

all

applicable

Of

Arc

and

and

per

end

Weld

la

for

ap

the

in

2-2.

SAFETY

WORDS

The

following

used

throughout

different

tify

a

a

a

IMPORTANT

necessary

ment.

SIGNAL

AND

ALERT

safety

this

levelsofhazard

This

safety

words

tiontothe

WARNING

WARNING

practices

ous

personal

CAUTION

practices

personal

statements

for

the

WORDS

alert

symbol

manualtocall

alert

symbol

safety

which

statements.

statements

must

injury

statements

which

must

or

injury

most

damage

efficient

SYMBOL

and

attention

and

special

is

and

CAUTION

identify

be

followed

loss

or

identify

be

followed

identify

operation

AND

signal

instructions.

with

used

procedures

of

life.

procedures

to

this

to

equipment.

special

SIGNAL

words

iden

and

to

the

signal

call

to

to

of

alien

seri

avoid

avoid

minor

instructions

this

equip

are

or

or

113336

Page

6

Page 15

SECTION

Table

INTRODUCTION

3-

3-1.

SpecificatIons

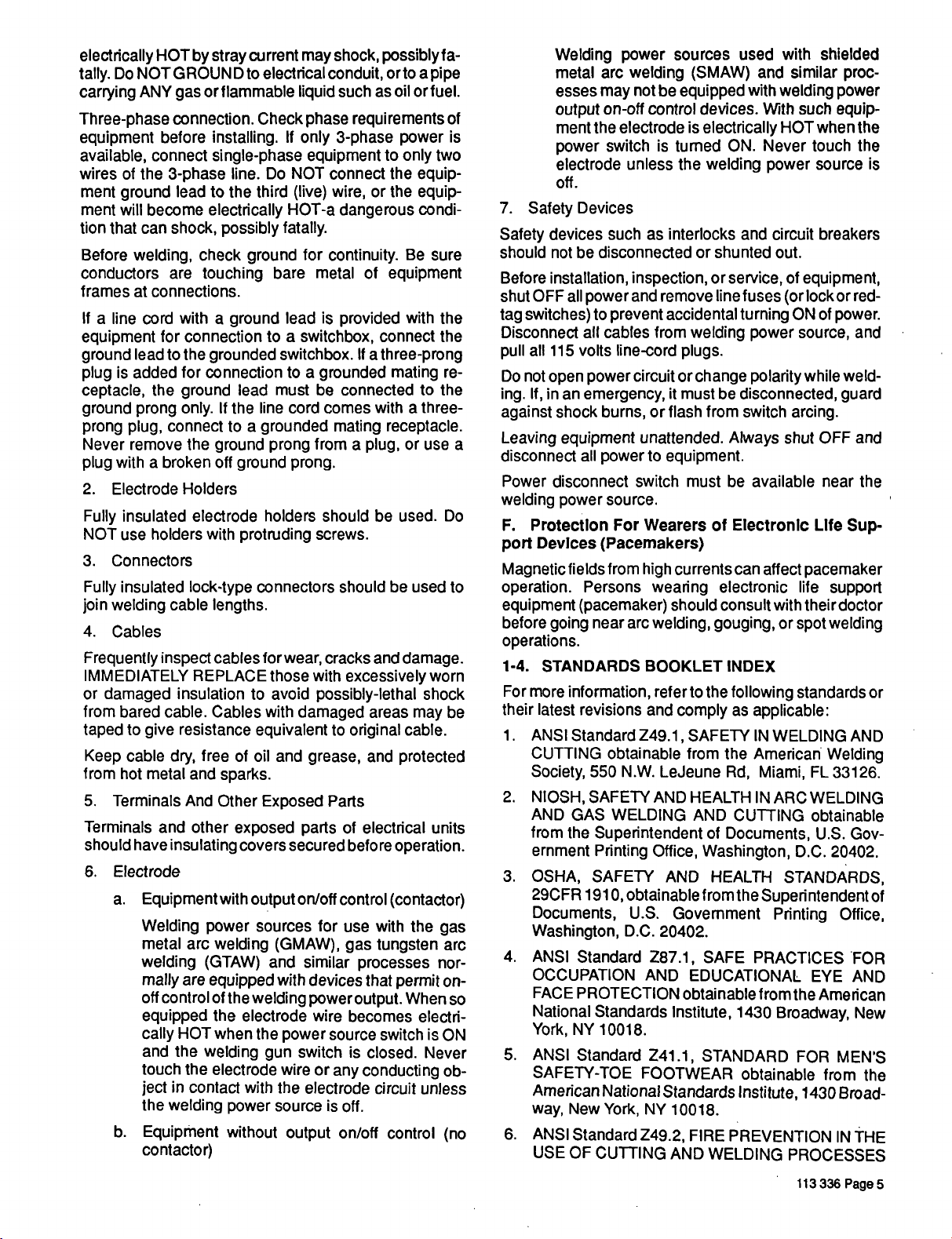

Rated

Weld

Output

At

60%

Duty

Cycle

150

Amperes

At

Volts

23

DC

Max.

Open-

Circuit

Voltage

32

Rated

At

input

Hz

60

Single-Phase

At

200V 230V 460V

26.5

24

12

Load

Output

575V

9.6

kva

5.5

kw

4.8

Control

Circuit

Voltage

Gun

At

24

Volts

DC

*Add

2-3/4

~Add5lbs.

Electrode

Wire

Feed

Speed

60to486

1pm

to

(1.5

mpm)

Dimensions

Width

A:

13-1/2

(343

B:

Length

27

in.

(686

C:

Height

30

in.

(762

lbs.

12.3

in.

mm)

mm)

mm)

(1.25

(2.27

205

(93

kg)

kg)

.023/.025

.030

.035

Weight

Net

lbs.

kg)

for

units

units

for

Electrode

Wire

Diameter

Capability

in.

(0.6

10.~

in.

in.

215

with

with

mm~

mmj

~0.9

.

Ship

lbs.**

(98

kg)

spot

spot

mm)

TB-087

313-C

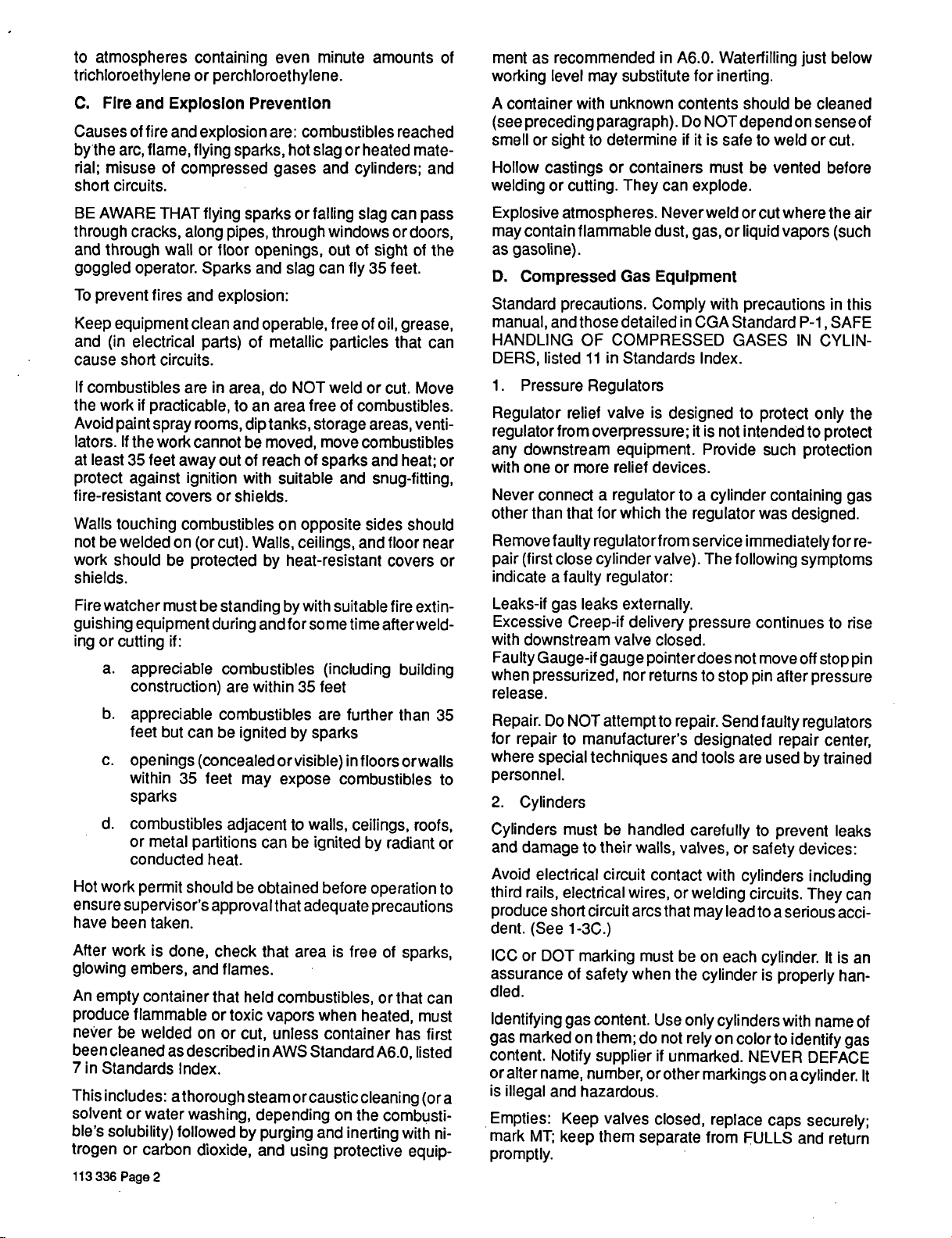

3-1.

6

5

4

3

2

1

Overall

HIGH

LOW

436-lA

Figure

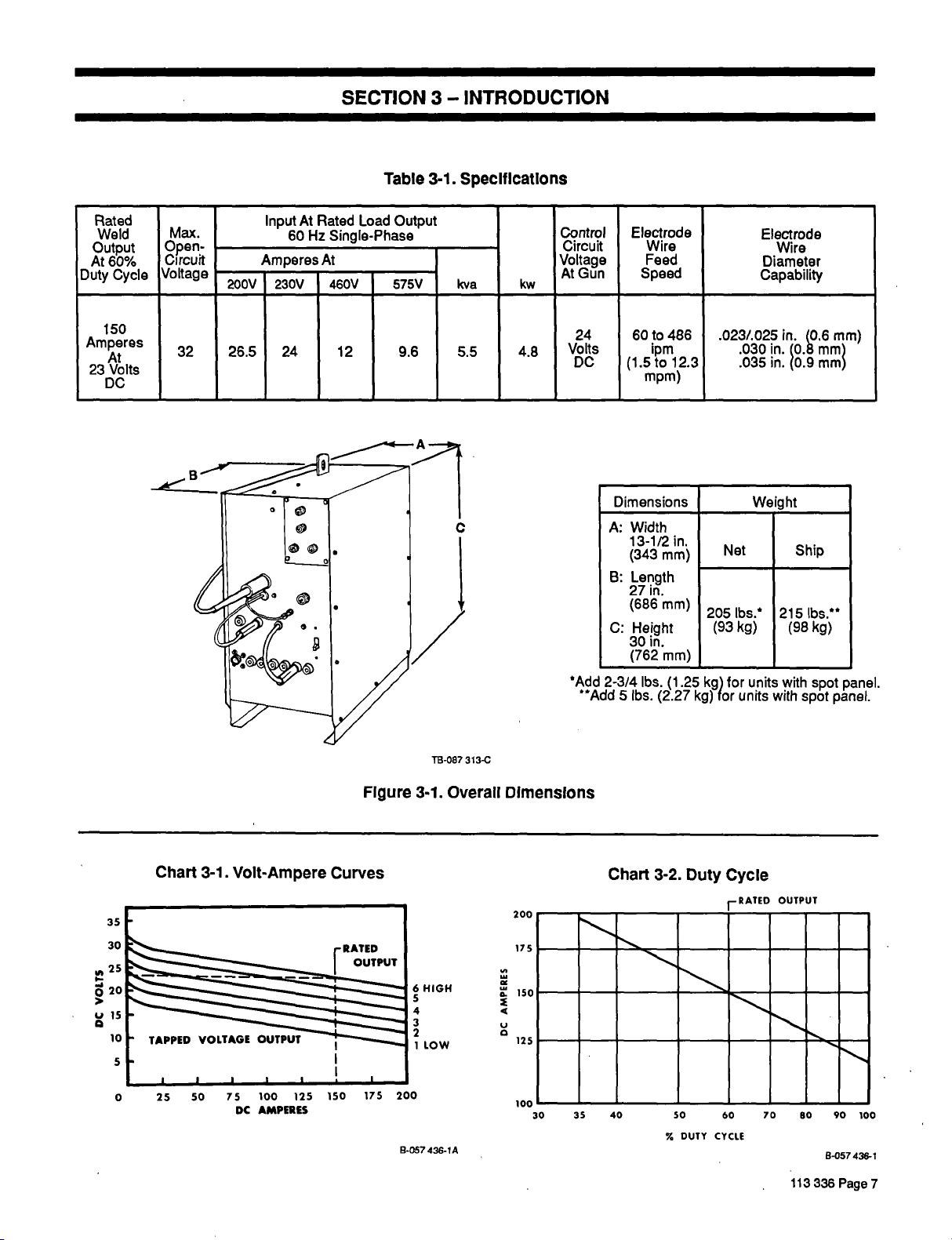

Chart

3-1.

Volt-Ampere

In

.J

0

U

50

25

0

100

75

DC

AMPERES

125

Curves

150

175

200

9-057

Dimensions

Chart

200

-

175

150

@.

4

U

125

100

30

~

40

35

3-2.

%

~

50

DUTY

Duty

Cycle

1RATED

60

CYCLE

OUTPUT

-

--

~-

113

00

9-057436-1

336

90

Page

100

7

70

Page 16

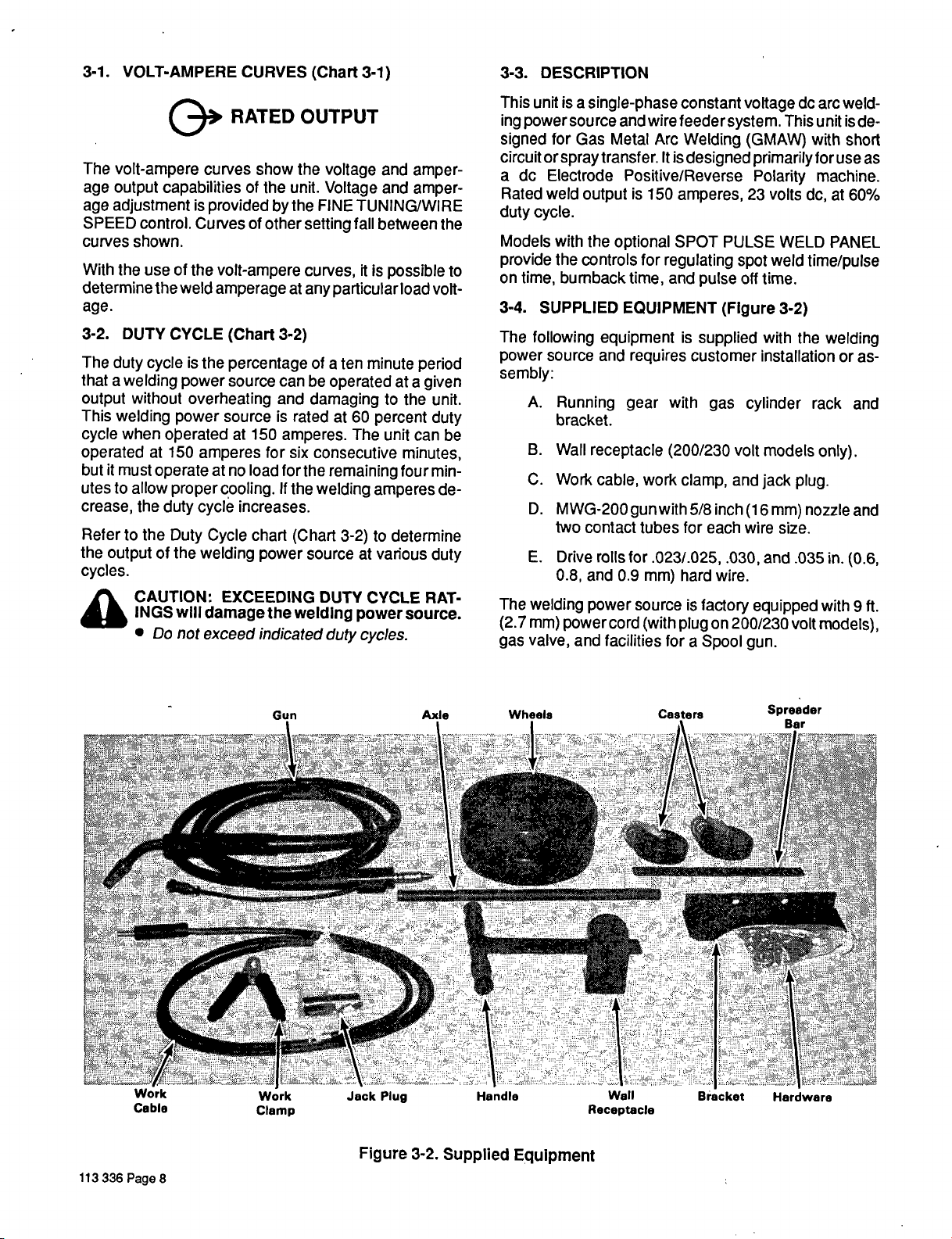

3-1.

VOLT-AMPERE

The

volt-ampere

output

age

adjustment

age

SPEED

curves

With

determine

age.

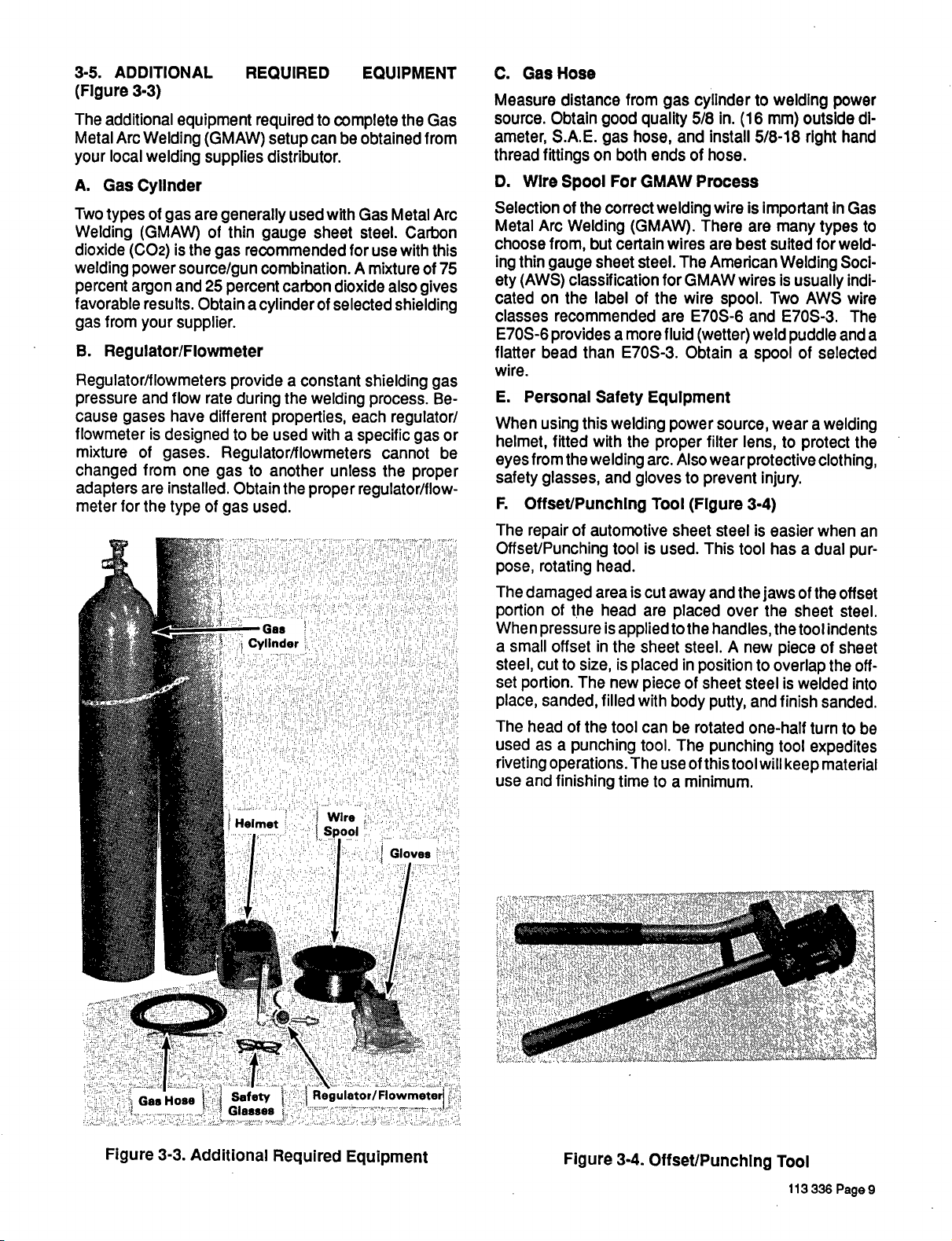

3-2.

The

that

output

This

cycle

shown.

the

DUTY

duty

a

welding

without

welding

when

operated

but

it

must

utes

crease,

Refer

the

allow

to

to

output

cycles.

CAUTION:

a

INGS

curves

capabilities

is

control.

use

cycle

the

of

the

weld

CYCLE

is

power

Curves

the

overheating

power

operated

150

at

amperes

operate

proper

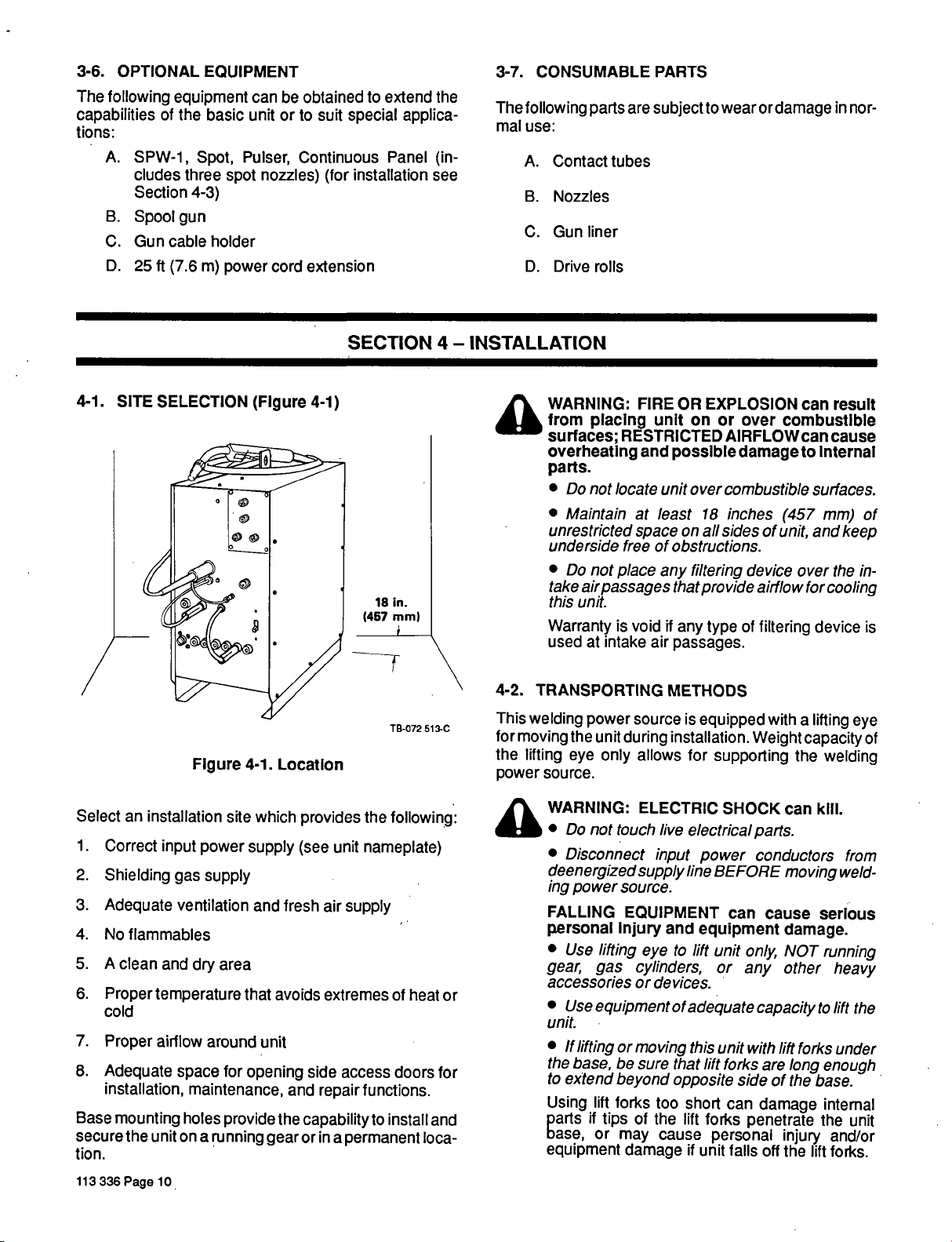

the