Miller Gold Seal Model 420, MW100, Gold Seal 420 Owner's Manual

October 1997 Form: OM-174 470B

Effective With Serial No. KH531011

OWNER’S

MANUAL

CV/DC Welding Power Source/Wire Feeder

For FCAW And GMAW W elding

90 Amperes, 18 Volts At 20% Duty Cycle

Uses 115 Volts AC, Single-Phase Input Power

Overheating, Short-Circuit, And Motor Overload Protection

Usable Range Of 30 To 130 Amperes

Includes Gun, Welding Wire, And Gas V alve

Read and follow these instructions and all

safety blocks carefully.

Have only trained and qualified persons

install, operate, or service this unit.

Call your distributor if you do not understand

the directions.

cover 7/93 – ST-155 507-A PRINTED IN USA

Gold Seal Model 420

Give this manual to the operator.

For help, call your distributor

or: MILLER ELECTRIC Mfg. Co., P.O. Box

1079, Appleton, WI 54912 414-734-9821

1997 MILLER Electric Mfg. Co.

The following safety alert symbol and signal words are used throughout this manual to call attention to and identify

.

t

different levels of hazard and special instructions.

WARNING

WARNING statements identify procedures or practices which must be followed to avoid serious personal

injury or loss of life.

CAUTION

CAUTION statements identify procedures or practices which must be followed to avoid minor personal

injury or damage to this equipment.

ARC WELDING SAFETY PRECAUTIONS

WARNING

ARC WELDING can be hazardous.

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH. KEEP CHILDREN

AWAY. PACEMAKER WEARERS KEEP AWAY UNTIL CONSULTING YOUR DOCTOR.

In welding, as in most jobs, exposure to certain hazards occurs. Welding is safe when precautions are taken. The

safety information given below is only a summary of the more complete safety information that will be found in the

Safety Standards listed on the next page. Read and follow all Safety Standards.

HAVE ALL INSTALLATION, OPERATION, MAINTENANCE, AND REPAIR WORK PERFORMED ONLY BY

QUALIFIED PEOPLE.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks

or severe burns. The electrode and work circuit is

electrically live whenever the output is on. The input

power circuit and machine internal circuits are also

live when power is on. In semiautomatic or automatic

wire welding, the wire, wire reel, drive roll housing, and

all metal parts touching the welding wire are

electrically live. Incorrectly installed or improperly

grounded equipment is a hazard.

1. Do not touch live electrical parts.

2. Wear dry , hole-free insulating gloves and body protection.

3. Insulate yourself from work and ground using dry insulating mats

or covers.

ARC RAYS can burn eyes and skin;

NOISE can damage hearing.

Arc rays from the welding process produce intense

heat and strong ultraviolet rays that can burn eyes and

skin. Noise from some processes can damage

hearing.

4. Disconnect input power or stop engine before installing or

servicing this equipment.

5. Properly install and ground this equipment according to its

Owner’s Manual and national, state, and local codes.

6. Turn off all equipment when not in use.

7. Do not use worn, damaged, undersized, or poorly spliced cables

8. Do not wrap cables around your body.

9. Ground the workpiece to a good electrical (earth) ground.

10. Do not touch electrode while in contact with the work (ground)

circuit.

11. Use only well-maintained equipment. Repair or replace

damaged parts at once.

12. Wear a safety harness to prevent falling if working above floor

level.

13. Keep all panels and covers securely in place.

1. Wear a welding helmet fitted with a proper shade of filter (see

ANSI Z49.1 listed in Safety Standards) to protect your face and

eyes when welding or watching.

2. Wear approved safety glasses. Side shields recommended.

3. Use protective screens or barriers to protect others from flash

and glare; warn others not to watch the arc.

4. Wear protective clothing made from durable, flame-resistan

material (wool and leather) and foot protection.

5. Use approved ear plugs or ear muffs if noise level is high.

FUMES AND GASES can be hazardous

to your health.

Welding produces fumes and gases. Breathing these

fumes and gases can be hazardous to your health.

1. Keep your head out of the fumes. Do not breath the fumes.

2. If inside, ventilate the area and/or use exhaust at the arc to

remove welding fumes and gases.

3. If ventilation is poor, use an approved air-supplied respirator.

4. Read the Material Safety Data Sheets (MSDSs) and the

manufacturer’s instruction for metals, consumables, coatings,

and cleaners.

5. Work in a confined space only if it is well ventilated, or while

wearing an air-supplied respirator. Shielding gases used for

welding can displace air causing injury or death. Be sure the

breathing air is safe.

6. Do not weld in locations near degreasing, cleaning, or spraying

operations. The heat and rays of the arc can react with vapors to

form highly toxic and irritating gases.

7. Do not weld on coated metals, such as galvanized, lead, or

cadmium plated steel, unless the coating is removed from the

weld area, the area is well ventilated, and if necessary, while

wearing a n air-supplied respirator. The coatings and any metals

containing these elements can give off toxic fumes if welded.

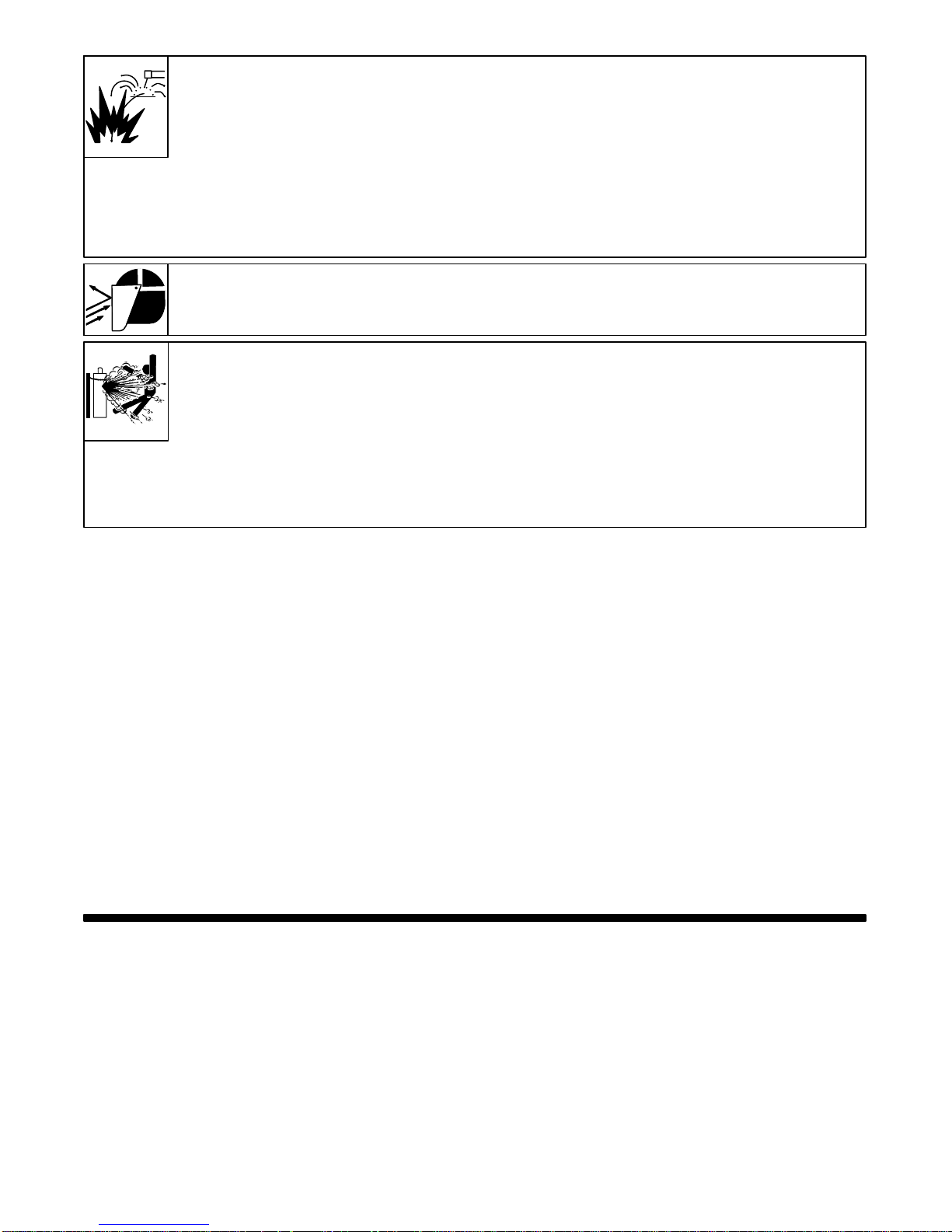

WELDING can cause fire or explosion.

t

.

,

Sparks and spatter fly off from the welding arc. The

flying sparks and hot metal, weld spatter, hot

workpiece, and hot equipment can cause fires and

burns. Accidental contact of electrode or welding wire

to metal objects can cause sparks, overheating, or

fire.

1. Protect yourself and others from flying sparks and hot metal.

2. Do not weld where flying sparks can strike flammable material.

3. Remove all flammables within 35 ft (10.7 m) of the welding arc. If

this is not possible, tightly cover them with approved covers.

4. Be alert that welding sparks and hot materials from welding can

easily go through small cracks and openings to adjacent areas.

5. Watch for fire, and keep a fire extinguisher nearby .

6. Be aware that welding on a ceiling, floor, bulkhead, or partition

can cause fire on the hidden side.

7. Do not weld on closed containers such as tanks or drums.

8. Connect work cable to the work as close to the welding area as

practical to prevent welding current from traveling long, possibly

unknown paths and causing electric shock and fire hazards.

9. Do not use welder to thaw frozen pipes.

10. Remove stick electrode from holder or cut off welding wire a

contact tip when not in use.

11. Wear oil-free protective garments such as leather gloves, heavy

shirt, cuffless trousers, high shoes, and a cap.

FL YING SPARKS AND HOT METAL can

cause injury.

Chipping and grinding cause flying metal. As welds

cool, they can throw off slag.

CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under high

pressure. If damaged, a cylinder can explode. Since

gas cylinders are normally part of the welding

process, be sure to treat them carefully .

1. Protect compressed gas cylinders from excessive heat,

mechanical shocks, and arcs.

2. Install and secure cylinders in an upright position by chaining

them to a stationary support or equipment cylinder rack to

prevent fa l ling or tipping.

1. Wear approved face shield or safety goggles. Side shields

recommended.

2. Wear proper body protection to protect skin.

3. Keep cylinders away from any welding or other electrical circuits

4. Never allow a welding electrode to touch any cylinder.

5. Use only correct shielding gas cylinders, regulators, hoses, and

fittings designed for the specific application; maintain them and

associated parts in good condition.

6. Turn face away from valve outlet when opening cylinder valve.

7. Keep protective cap in place over valve except when cylinder is

in use or connected for use.

8. Read and follow instructions on compressed gas cylinders

associated equipment, and CGA publication P-1 listed in Safety

Standards.

PRINCIPAL SAFETY STANDARDS

Safety in Welding and Cutting, ANSI Standard Z49.1, from American Welding Society, 550 N.W. LeJeune Rd, Miami FL 33126

Safety and Health Standards, OSHA 29 CFR 1910, from Superintendent of Documents, U.S. Government Printing Of fice, Washington, D.C. 20402.

Recommended Safe Practices for the Preparation for Welding and Cutting of Containers That Have Held Hazardous Substances, American Welding

Society Standard AWS F4.1, from American Welding Society, 550 N.W. LeJeune Rd, Miami, FL 33126

National Electrical Code, NFPA Standard 70, from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet P-1, from Compressed Gas Association, 1235 Jef ferson Davis Highway, Suite 501,

Arlington, VA 22202.

Code for Safety in Welding and Cutting, CSA Standard W1 17.2, from Canadian Standards Association, Standards Sales, 178 Rexdale Boulevard,

Rexdale, Ontario, Canada M9W 1R3.

Safe Practices For Occupation And Educational Eye And Face Protection, ANSI Standard Z87.1, from American National Standards Institute, 1430

Broadway, New York, NY 10018.

Cutting And Welding Processes, NFP A Standard 51B, from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

Ref. sr1 2/92

SECTION 1 – SPECIFICATIONS SECTION 4 – MAINTENANCE & TROUBLESHOOTING

1-1. Volt-Ampere Curve And Duty Cycle Chart 1 4-1. Overload Protection 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 – INSTALLATION 4-3. Gun Maintenance 8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. Installing Work Clamp 2 4-4. Troubleshooting 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2. Installing Gas Supply 2. . . . . . . . . . . . . . . . . . . . . . . .

2-3. Connecting Input Power 2 SECTION 5 – ELECTRICAL DIAGRAM 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4. Gun Polarity For Wire Type 3. . . . . . . . . . . . . . . . . . .

2-5. Installing Welding Gun 3 SECTION 6 – PARTS LIST. . . . . . . . . . . . . . . . . . . . . . .

2-6. Threading And Feeding Welding Wire 4 Figure 6-1. Main Assembly 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – OPERATION 5. . . . . . . . . . . . . . . . . . . . . . .

TABLE OF CONTENTS

4-2. Drive Assembly Maintenance 7. . . . . . . . . . . . . . . . . .

Figure 6-2. MWG-160M Gun 12. . . . . . . . . . . . . . . . . . . . . . .

SECTION 1 – SPECIFICATIONS

Table 1-1. Welding Power Source

Specifications Description

Type Of Output Direct Current/Constant Voltage (DC/CV)

Rated Weld Output 90 Amperes, 18 Volts DC, 20% Duty Cycle

Type Of Input Power Single-Phase; 60 Hz; At 115 Volts AC

Input Amperes At Rated Output 20 A At 115 V

KVA/KW Used At Rated Output 3 kVA/2.2 kW

Max. Open-Circuit Voltage 30 Volts DC

Control Circuit Voltage At Gun 24 Volts DC

Welding Processes Gas Metal Arc (GMAW) And Flux Cored Arc Welding (FCA W)

Calculated Speed Range At No Load 283 To 716 ipm (7.1 To 17.9 mpm)

Wire Diameter Range .023 To .035 in (0.58 To 0.89 mm)

Overall Dimensions Length: 16-1/2 in (419 mm); Width: 9-1/2 in (241 mm); Height: 17 in (432 mm)

Weight Net: 73 lb (33 kg); Ship: 80 lb (36 kg)

Welding Gun

Rated Output (Air-Cooled) 160 Amperes At 60% Duty Cycle Using CO2 Shielding Gas

Cable Length 10 ft (3 m)

1-1. Volt-Ampere Curve And Duty Cycle Chart

CAUTION

USING GUN BEYOND DUTY CYCLE RATING can damage gun.

• Do not use gun beyond rated amperage when using CO

• Use gun at 30% duty cycle when using mixed shielding gas.

shielding gas.

2

wfwarn8.1 10/91

The volt-ampere curves show the

minimum and maximum voltage

and amperage output capabilities of

the welding power source. Curves

of other settings fall between the

curves shown.

Duty cycle is how long the unit can

operate within a ten minute period

without causing overheating or

damage.

This unit is rated at 20% duty cycle

allowing welding 2 minutes out of

every 10 minutes.

This gun is rated at 60% duty cycle

when using CO2 shielding gas and

30% when using mixed shielding

gas.

Figure 1-1. Volt-Ampere Curve And Duty Cycle Chart

OM-174 470 Page 1

ssb1.1 10/91 – SB-124 646-A / sb1.3 10/91 – SB-124 655-A

SECTION 2 – INSTALLATION

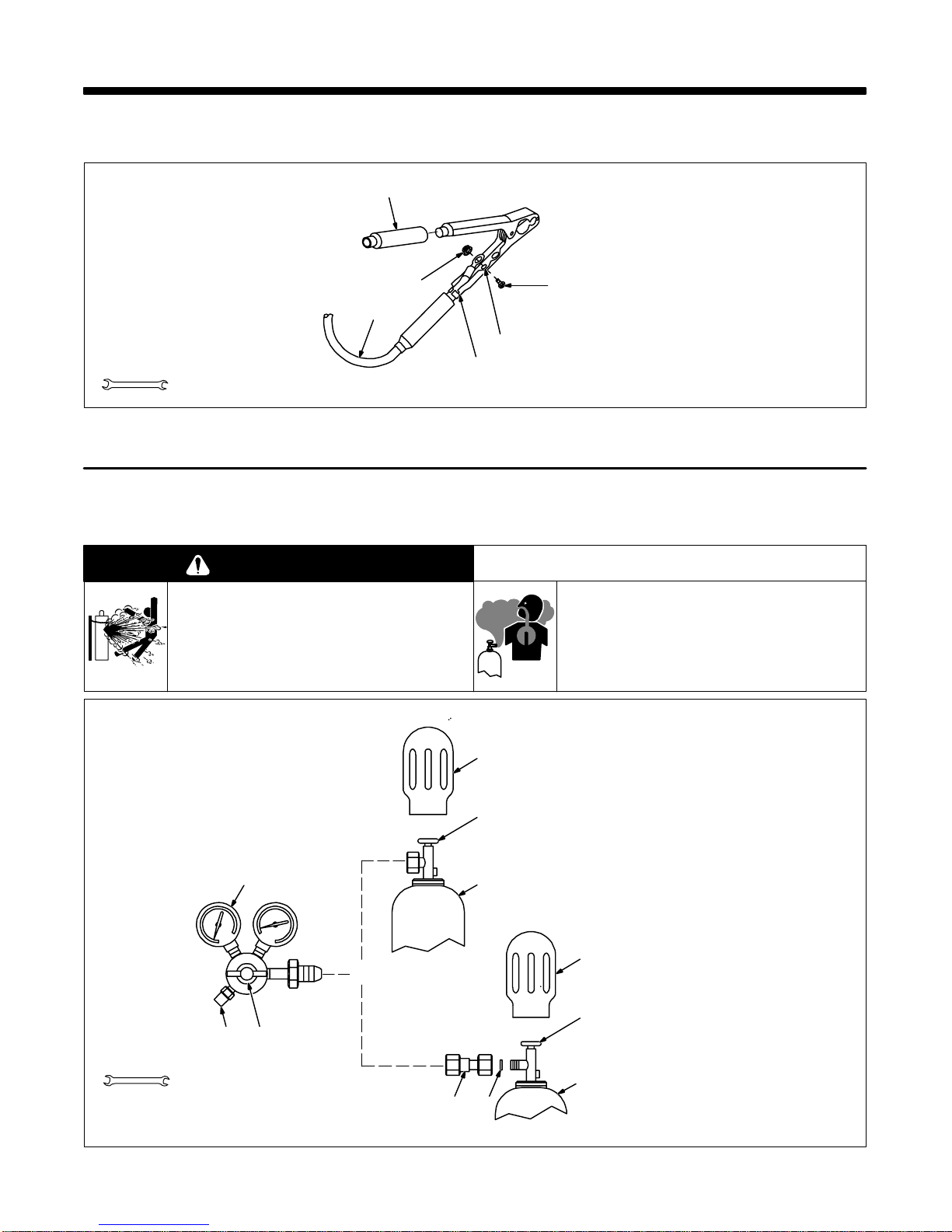

2-1. Installing Work Clamp

Tools Needed:

3/8, 7/16 in

2-2. Installing Gas Supply

WARNING

CYLINDERS can explode if damaged.

• Keep cylinders away from welding and other

electrical circuits.

• Never touch cylinder with welding electrode.

• Always secure cylinder to running gear, wall, or

other stationary support.

1

6

5

3

4

2

Figure 2-1. Installing Work Clamp

BUILDUP OF SHIELDING GAS can harm

health or kill.

• Shut of f shielding gas supply when not in use.

1 Insulator

2 Bolt

3 Smaller Hole

4 Work Clamp Tabs

Bend tabs around work cable.

5 Work Cable From Unit

6 Nut

Ref. ST-025 190-D

warn4.1 9/91

Tools Needed:

1-1/8, 5/8 in

546

OR

Argon Gas Or

Mixed Gases

7 8

Chain gas cylinder to running gear,

wall, or other stationary support so

cylinder cannot fall and break off

1

2

3

1

2

3

valve.

1 Cap

2 Cylinder Valve

3 Cylinder

4 Regulator/Flowmeter

5 Gas Hose Connection

Fitting has 5/8-18 right-hand

threads.

6 Flow Adjust

Typical flow rate is 20 cfh (cubic feet

per hour). Check wire manufacturer’s recommended flow rate.

Make sure flow adjust is closed

when opening cylinder to avoid

damage to the flowmeter.

7CO2 Adapter

8 O-Ring

Install adapter with O-ring between

regulator/flowmeter and CO

cylinder.

ssb3.1* 5/94 – ST-158 697-A / Ref. ST-149 827-B

2

Figure 2-2. Typical CO2 Regulator/Flowmeter Installation

OM-174 470 Page 2

Loading...

Loading...