Miller MTL-20 Owner's Manual

Millerfi

December

1993

Form:

OM-1568B

Effective

With

Style

No.

KB-8

OWNERS

MANUAL

MTL-20

Torches

U

Read

and

follow

these

instructions

and

all

Give

this

manualtothe

operator.

safety

blocks

carefully.

Have

only

trained

and

qualified

persons

install,

operate,

or

service

this

unit.

Call

your

distributor

if

you

do

not

understand

the

directions.

For

help,

call

your

distributor

or:

MILLER

Electric

Mfg.

Co.,

P.O.

Box

1079,

Appleton,

WI

54912

414-734-9821

Water-Cooled

Torches

For

GTAW

Welding

Rated

At

250

Amperes

100%

Duty

Cycle

Using

Argon

Shielding

Gas

.020

Thru

5/32

in

(0.5

Thru

4.0

mm)

Tungsten

Size

Capacity

Includes

12-1/2

Or

25

ft

(3.8

Or

7.6

m)

Cable

Remote

Contactor

And

Current

Control

Available

Tungsten

Electrode

And

Some

Torch

Parts

Needed

cover

7/93ST-141

476-A

'

1993

MILLER

Electric

MIg.

Co.

PRINTED

IN

USA

1F

MILLERS

TRUE

BLU

ETTM

LIMITED

WARRANTY

Effective

January

1,

1992

(Equipment

with

a

serial

number

preface

of

KC

or

newer)

This

limited

warranty

sapersedes

all

previous

MILLER

warranties

and

is

exclusive

with

no

other

gaarantees

or

warranties

expressed

or

implied.

LIMITED

WARRANTY

Subject

to

the

terms

and

conditions

below,

MILLER

Electric

MIg

Co

.

Appleton.

Wisconsin,

warrants

to

its

original

retail

purchaser

that

new

MILLER

equipment

sold

alter

the

effective

date

01

this

limited

warranty

is

tree

ot

de

tects

in

material

and

workmanship

at

the

time

it

is

skipped

by

MILLER

THIS

WAR.

RANTY

IS

EXPRESSLY

IN

LIEU

OP

ALL

OTHER

WARRANTIES,

EXPRESS

OR

IMPLIED,

INCLUDING

THE

WARRANTIES

OF

MERCHANTAPILITY

AND

FIT

NESS

Within

the

warranty

periods

listed

below

MILLER

will

reoair

or

replace

any

war

ranted

parts

or

components

that

tail

dyetosack

detects

in

material

or

workmanship.

MILLER

mast

be

notitied

in

writing

within

thirty

1301

days

01

sack

defect

or

tailare.

at

which

time

MILLER

will

provide

instructionsonthe

warranty

claim

procedures

to

be

toltawed

MILLER

shall

honor

warranty

claims

en

warranted

equipment

listed

belowinthe

eeent

01

sackadilute

within

the

warranty

time

periods

All

warranty

time

periods

start

on

the

date

that

the

equipment

was

delivered

to

the

original

retail

parchaser.

or

one

year

user

the

equipment

is

sent

to

the

distributor

5

Years

Parts

-

3

Yeats Labor

Original

main

power

rectiliers

2 3

YearsParts

and

Labor

Transformer/Rectifier

Power

Searces

*

Plasma

Arc

Catting

Power

Sources

*

Semi-Automatic

and

Automatic

Wire

Feeders

Robots

32YearsParts

and

Labor

Engine

Driven

Welding

Generators

(NOTE

Engines

are

warranted

separately

by

the

engine

manufacturer

for

a

period

01

two

years.(

*

Air

Compressors

1

Year

Parts

and

Labor

Motor

Driven

Guns

*

Process

Controllers

Water

Coolant

Systems

HP

Units

Grids

Spot

Welders

*

Load

Banks

SOX

Transformers

Running

Gearrrrailers

Field

Options

(NOTE

Field

options

are

covered

ander

Trae

BluenM

far

the

remaining

warranty

period

of

the

predact

they

are

installed

in,

or

for

a

minimam

of

one

year

-

whichever

is

greater

I

6

Months

Batreries

90

Days

Parts

and

Labor

MIG

Gsns/TIG

Torches

Plasma

Catting

Torches

Remote

Controls

*

Accessory

Kits

Replacement

Pans

MILLER

S

Trae

Efae

Limited

Watranty

shall

net

apply

to.

I

Items

tarnishedbyMILLER.

bat

manafactared

by

others.

sack

as

engines

er

trade

accessories

These

items

are

covered

by

the

manafecturers

warranty,

it

any

2

Consumable

components,

sack

as

contact

tips.

catting

nozzles,

centacters

and

relays

or

parts

that

tail

dye

to

normal

wear

3

Equipment

that

has

been

modrfied

by

any

party

ether

than

MILLER.

or

equip

ment

that

has

been

improperly

installed,

improperly

operated

or

misased

based

apon

indastry

standards.

or

eqaipment

which

has

net

had

reasonable

and

necessary

maintenance.

or

equipment

whick

has

been

axed

tsr

operation

outsideofthe

specifications

br

the

equipment

MILLER

PRODUCTS

ARE

INTENDED

FOR

PURCHASE

AND

USE

BY

COMMER

CIALINDUSTRIAL

USERS

AND

PERSONS

TRAINED

AND

EXPERIENCED

IN

THE

USE

AND

MAINTENANCE

OP

WELDING

EQUIPMENT.

In

the

event

of

a

warranty

claim

coveredbythis

warranty,

the

exclusixe

remedies

shall

be.atMILLER

S

option

(11

repair.

or

(2(

replacement,

or,

where

authorized

in

writing

by

MtLLER

in

appropriate

cases.

(3)

the

reasonable

cost

of

repairer

replace

ment

at

an

authorized

MILLER

sernrce

station.

or

(4)

payment

of

or

credit

br

the

pur

chase

price

(less

reasonable

deprecrutrOn

based

upon

actual

ase(

apes

return

eb

the

goods

at

customers

risk

and

espense.

MILLERS

option

01

repair

or

replacement

will

be

P0

B

Factory

at

Appleton,

Wisconsin,

or

F

0

B

at

a

MILLgR

authorized

ser

vice

facility

us

determined

by

MILLER.

Therefore

no

compensation

or

reimburse

ment

for

trunsportatiee

costs

of

any

kind

will

be

allowed,

TO

THE

EXTENT

PERMITTED

BY

LAW.

THE

REMEDIES

PROVIDED

HEREIN

ARE

THE

SOLE

AND

EXCLUSIVE

REMEDIES

IN

NO

EVENT

SHALL

MILLER

BE

LIABLE

FOR

DIRECT

INDIRECT,

SPECIAL.

INCIDENTAL

OR

CONSEQUENTIAL

DAMAGES

INCLUDING

LOSS

OF

PROFIT),

WHETHER

BASED

ON

CON

TRACT TORT

OR

ANY

OTHER

LEGAL

THEORY

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

ANO

ANY

IMPLIED

WAR

RANTY

GUARANTY

OR

REPRESENTATION

AS

TO

PERFORMANCE

AND

ANY

REMEDY

FOR

BREACH

OF

CONTRACT

TORT

OR

ANY

OTHER

LEGAL

THEORY

WHICH.

BUT

FOR

THIS

PROVISION.

MIGHT

ARISE

BY

IMPLICATION.

OPERATION

OF

LAW,

CUSTOM

OF

TRADE

OR

COURSE

OP

DEALING.

IN

CLUDING

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

PITNESS

FOR

PARTICULAR

PURPOSE,

WITH

RESPECT

TO

ANY

AND

ALL

EQUIPMENT

FURNISHED

BY

MILLER

IS

EXCLUDED

AND

DISCLAIMED

BY

MILLER

Some

states

in

the

U

S

A

do

not

allow

limitations

01

how

long

an

implied

warranty

lasts,

or

the

exclusion

of

incidental,

indirect,

special

or

consequential

damages,

so

the

above

limitationorexclusion

may

not

apply

10

you

This

warranty

pronides

spe

citic

legal

rights,

and

sther

rights

may

be

aeuilable,

but

may

eury

trem

statetostate.

In

Canada.

legislation

in

some

proxinces

proeides

or

certain

additional

warranties

or

remedies

other

thanasstaled

herein,

and

to

the

extent

that

they

may

not

be

waived,

the

limitations

and

exclusions

set

out

aboxe

may

net

apply.

This

Limited

Warranty

pieuides

specific

legal

rights.

and

other

rights

may

be

uxailuble.

but

map

vary

Irom

province

to

proxince.

:JU

B,

IF

RECEIVING-HANDLING

Before

unpacking

equipment,

check

carton

for

any

damage

that

may

have

occurred

duhng

shipment.

File

any

claims

for

loss

or

damage

with

the

delivering

carrier.

Asststance

for

filing

or

settling

claims

may

be

obtained

from

distributor

and/or

equipment

manufacturers

Transportation

Department.

When

requesting

information

about

this

equipment,

always

provide

Model

Designation

and

Serial

or

Style

Number

Use

the

following

spaces

to

record

Model

Designation

and

Serial

or

Style

Number

of

your

unit.

The

information

is

located

on

the

rating

label

or

nameplate.

Model

__________

Serial

or

Style

No.

DateofPurchase

miller

9/93

SAFETY

PRECAUTIONS

FOR

GTAW

TORCHES

Always

wear

dry

insulating

gloves.

Insulate

yourself

from

work

and

ground.

Do

not

touch

live

electrode

or

electrical

parts.

Repair

or

replace

worn,

damaged,

or

cracked

torchorcable

insulation.

Turn

off

welding

power

source

before

changing

tungsten

electrodeortorch

parts.

Keep

all

covers

and

handle

securely

in

ARC

RAYS

can

burn

eyes

and

skin.

Wear

welding

helmet

with

correct

shade

of

filter.

Wear

correct

eye

and

body

protection.

Cover

exposed

skin.

FUMES

AND

GASES

can

be

hazardous

to

your

health.

Keep

your

head

out

of

the

fumes.

Ventilate

area,

or

use

breathing

device.

Read

Material

Safety

Data

Sheets

(MSDSs)

and

manufacturers

instructions

for

material

used.

WELDING

can

cause

fire

or

explosion.

1.

Do

not

weld

near

flammable

material.

2.

Do

not

weldonclosed

containers.

3.

Watch

for

fire;

keep

extinguisher

nearby.

HOT

SURFACES

can

burn

skin.

1.

Allow

torch

to

cool

before

touching.

2.

Do

not

touch

hot

metal.

3.

Protect

hot

metal

from

contact

by

others.

NOISE

can

damage

hearing;

SOME

APPLICATIONS,

SUCH

AS

PULSING,

are

noisy.

1.

Check

for

noise

level

limits

exceeding

those

specified

by

OSHA.

2.

Use

approved

ear

plugs

or

ear

muffsifnoise

level

is

high.

3.

Warn

others

nearby

about

noise

hazard.

EMF

INFORMATION

a

WARNING

GTAW

WELDING

can

be

hazardous.

PROTECT

YOURSELF

AND

OTHERS

FROM

POSSIBLE

SERIOUS

INJURY

OR

DEATH.

KEEP

CHILDREN

AWAY.

PACEMAKER

WEARERS

KEEP

AWAY

UNTIL

CONSULTING

YOUR

DOCTOR.

In

welding,

as

in

most

jobs,

exposure

to

certain

hazards

occurs.

Welding

is

safe

when

precautions

are

taken.

The

safety

information

given

below

is

only

a

summary

of

the

more

complete

safety

information

found

in

the

welding

power

source

Owners

Manual.

Read

and

follow

all

safety

precautions.

HAVE

ALL

INSTALLATION,

OPERATION,

MAINTENANCE,

AND

QUALIFIED

PEOPLE.

ELECTRIC

SHOCK

can

kill.

REPAIR

WORK

PERFORMED

ONLY

BY

A

NOTE

D~

Considerations

About

Welding

And

The

EffectsOfLow

Frequency

Electric

And

Magnetic

Fields

The

following

is

a

quotation

from

the

General

Conclusions

Section

of

the

U.S.

Congress,

Office

of

Technology

Assessment,

Biological

Effects of

Power

Frequency

Electric

&

Magnetic

Fields

Backg

round

Paper,

OTA-BP-E-53

(Washington,

DC:

U.S.

Government

Printing

Office,

May

1989):

...

there

is

now

a

very

large

volume

of scientific

findings

based

on

experiments

at

the

cellular

level

and

from

studies

with

animals

and

people

which

clearly

establish

that

low

frequency

magnetic

fields

can

interact

with,

and

produce

changes

in,

biological

systems.

While

most

of

this

work

is

of

very

high

quality,

the

results

are

complex.

Current

scientific

understanding

does

not

yet

allow

us

to

interpret

the

evidence

in

a

single

coherent

framework.

Even

more

frustrating,

it

does

not

yet

allow

us

to

draw

definite

conclusions

about

questions

of

possible

risk

or

to

offer

clear

science-based

advice

on

strategies

to

minimize

or

avoid

potential

risks.

To

reduce

magnetic

fields

in

the

workplace,

use

the

following

procedures:

1.

Keep

cables

close

togetherbytwisting

or

taping

them.

2.

Arrange

cables

to

one

side

and

away

from

the

operator.

3.

Do

not

coil

or

drape

cables

around

the

body.

4.

Keep

welding

power

source

and

cablesasfar

away

as

practical.

5.

Connect

work

clamp

to

workpiece

as

close

to

the

weld

as

possible.

About

Pacemakers:

The

above

procedures

are

among

those

also

normally

recommended

for

pacemaker

wearers.

Consult

your

doctor

for

complete

information.

modlO.1

4/93

sr6

7/93

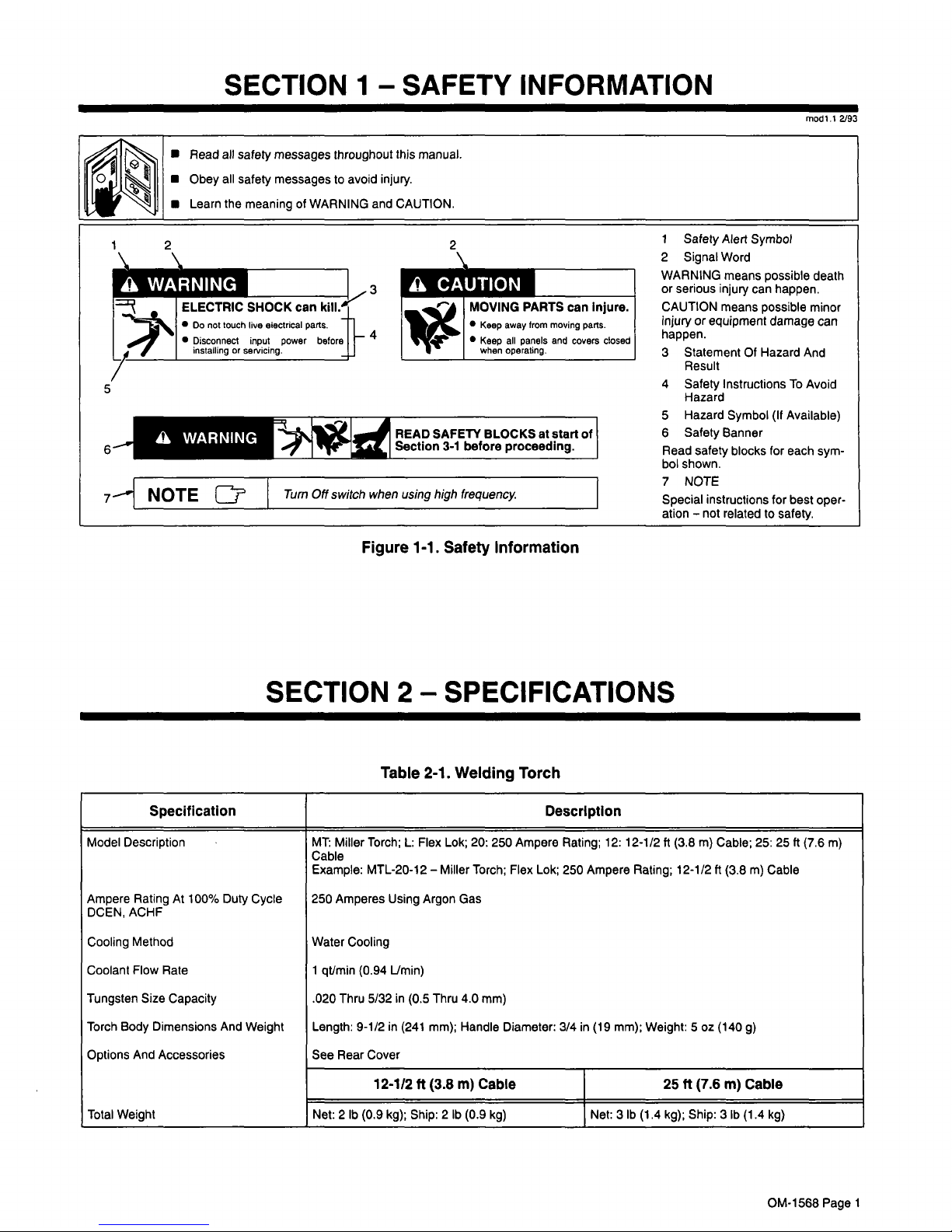

SECTION

1

-

SAFETY

INFORMATION

Read

all

safety

messages

throughout

this

manual.

Obey

all

safety

messages

to

avoid

injury.

Learn

the

meaning

of

WARNING

and

CAUTION.

Ampere

Rating

At

100%

Duty

Cycle

DCEN,

ACHF

Cooling

Method

Coolant

Flow

Rate

Tungsten

Size

Capacity

Torch

Body

Dimensions

And

Weight

Options

And

Accessories

Total

Weight

Figure

1-1.

Safety

Information

SECTION

2-

SPECIFICATIONS

Table

2-1.

Welding

Torch

modl,1

2193

1

2

2

a

CAUTION

!

:

3

__________

_____

=fl~S~9I~,ngPOw&Of0r~11

~

________________________

5

6

a

WARNING

7H

NOTE

~

READ

SAFETY

BLOCKS

at

start

of

Section

3-1

before

proceeding.

1

Safety

Alert

Symbol

2

Signal

Word

WARNING

means

possible

death

or

serious

injury

can

happen.

CAUTION

means

possible

minor

injury

or

equipment

damage

can

happen.

3

Statement

Of

Hazard

And

Result

4

Safety

Instructions

To

Avoid

Hazard

5

Hazard

Symbol

(If

Available)

6

Safety

Banner

Read

safety

blocks

for

each

sym

bol

shown.

7

NOTE

Special

instructions

for

best

oper

ation

not

related

to

safety.

Turn

Off

switch

when

using

high

frequency.

Specification

Model

Description

Description

MT:

Miller

Torch;

L:

Flex

Lok;

20:

250

Ampere

Rating;

12:

12-1/2

ft(3.8

m)

Cable;

25:25

ft(7.6

m)

Cable

Example:

MTL-20-12

Miller

Torch;

Flex

Lok;

250

Ampere

Rating;

12-1/2

ft

(3.8

m)

Cable

250

Amperes

Using

Argon

Gas

Water

Cooling

1

qt/min

(0.94

11mm)

.020

Thru

5/32

in

(0.5

Thru

4.0

mm)

Length:

9-1/2

in

(241

mm);

Handle

Diameter:

3/4

in

(19

mm);

Weight:

5

oz

(140

g)

See

Rear

Cover

12-1/2

ft

(3.8

m)

Cable

25

ft

(7.6

m)

Cable

Net:

2

lb

(0.9

kg);

Ship:

2

lb

(0.9

kg)

Net:

3

lb

(1.4

kg);

Ship:

3

lb

(1.4

kg)

OM-1568

Page

1

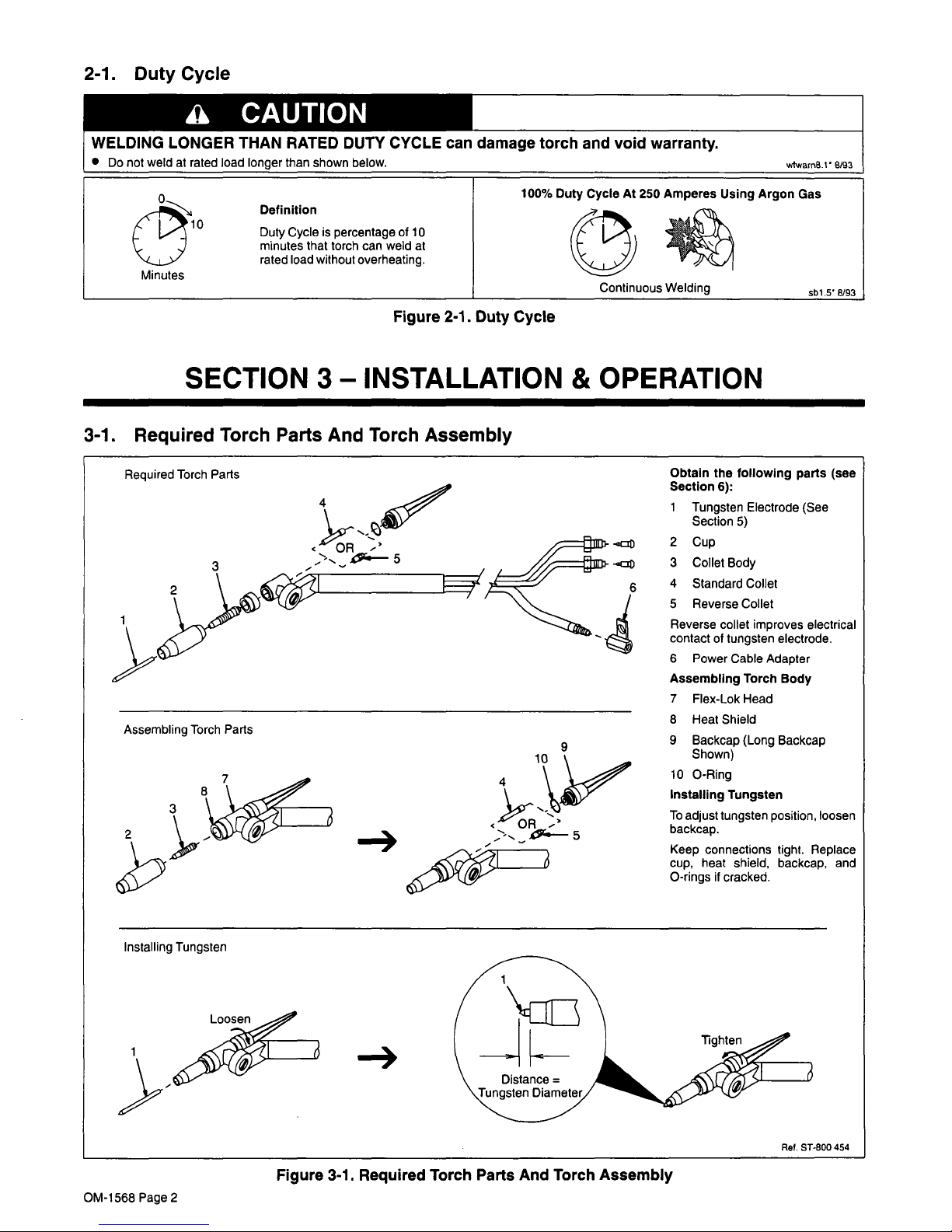

2-1.

Duty

Cycle

a

CAUTION

WELDING

LONGER

THAN

RATED

DUTY

CYCLE

can

damage

torch

and

void

warranty.

Do

not

weld

at

rated

load

longer

than

shown

below.

3-1.

Required

Torch

Parts

And

Torch

Assembly

Installing

Tungsten

Loosen

~ia

Obtain

the

following

parts

(see

Section

6):

1

Tungsten

Electrode

(See

Section

5)

-~

2

Cup

-~

3

Collet

Body

4

Standard

Collet

5

Reverse

Collet

Reverse

collet

improves

electrical

contact

of

tungsten

electrode.

6

Power

Cable

Adapter

Assembling

Torch

Body

7

Flex-Lok

Head

8

Heat

Shield

9

Backcap

(Long

Backcap

Shown)

10

0-Ring

Installing

Tungsten

To

adjust

tungsten

position,

loosen

backcap.

Keep

connections

tight.

Replace

cup,

heat

shield,

backcap,

and

0-rings

if

cracked.

wlwacnB.r

8/93

0

Definition

Duty

Cycle

is

percentage

of

10

10

minutes

that

torch

can

weld

at

rated

load

without

overheating.

Minutes

100%

Duty

Cycle

At

250

Amperes

Using

Argon

Gas

G~

Continuous

Welding

sbl58/93

Figure

2-1.

Duty

Cycle

SECTION

3-INSTALLATION

&

OPERATION

Required

Torch

Parts

Assembling

Torch

Parts

2

-4

5

Tighten

Figure

3-1.

Required

Torch

Parts

And

Torch

Assembly

~ef.

ST-800

454

OM-1568

Page

2

Loading...

Loading...