Page 1

MILLER® FALCON SERIES SELF-RETRACTING LIFELINES

OPERATION AND MAINTENANCE MANUAL

WARNING:

ALL PERSONS USING THIS EQUIPMENT MUST READ AND UNDERSTAND ALL INSTRUCTIONS.

FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY OR DEATH.

FALCON RETRACTABLE LIFELINES

The Miller

by personnel in applications where fall protection in combination with unrestricted worker mobility is

needed.

Proper use of fall arrest systems can save lives and reduce the potential of serious injuries from a

fall. The user must be aware that forces experienced during the arrest of a fall or prolonged

suspension may cause bodily injury. Consult a physician if there is any question about the user’s

ability to use this product. Pregnant women and minors must not use this product.

®

Falcon Series Retractable Lifelines are self-contained retractable lifelines designed to be used

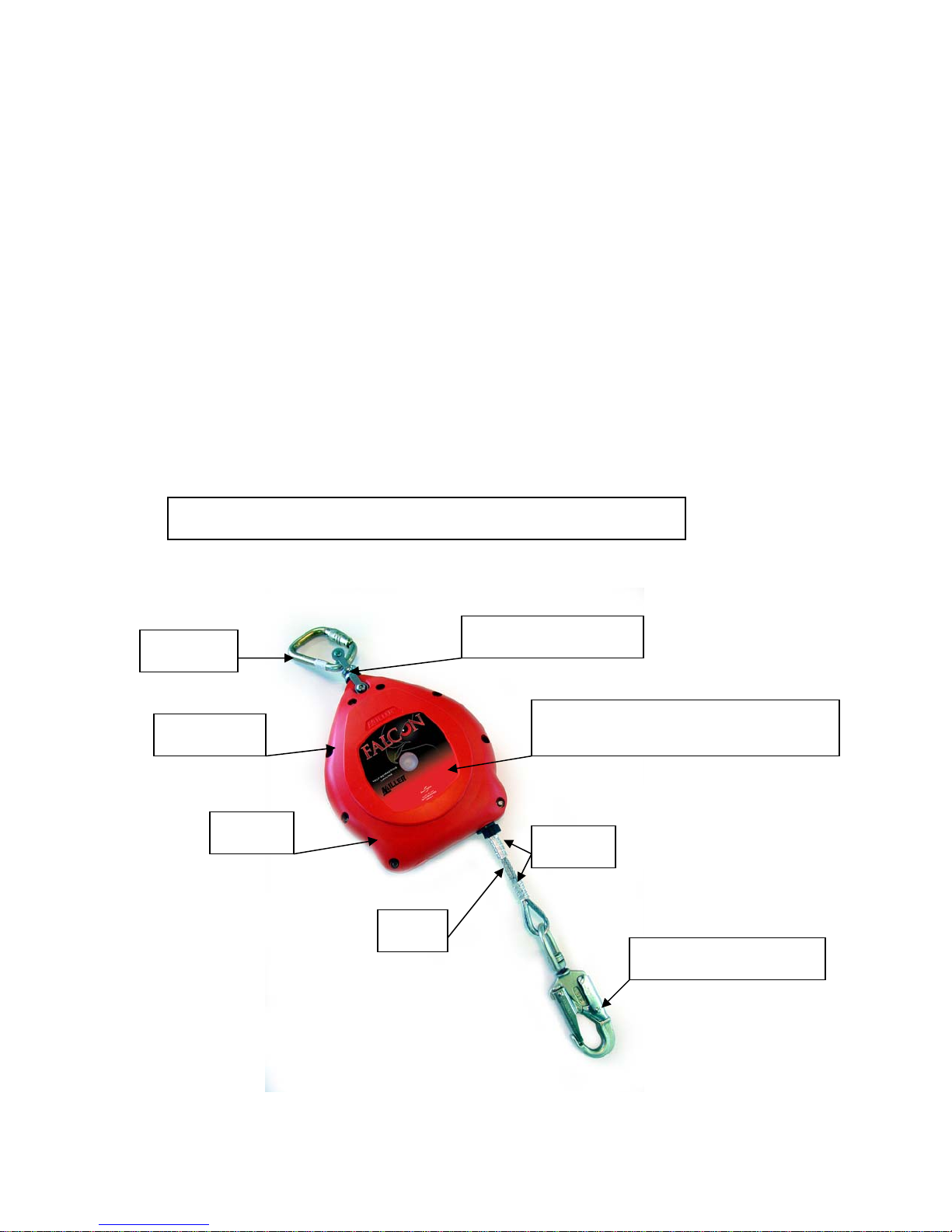

Falcon Series Models MP20 & MP30

Carabiner

Fasteners

Stainless Steel Swivel

Front Label

Back Label w/Identification Insert (back)

Housing

Ferrules

Cable

Self-Locking Snaphook

1

Page 2

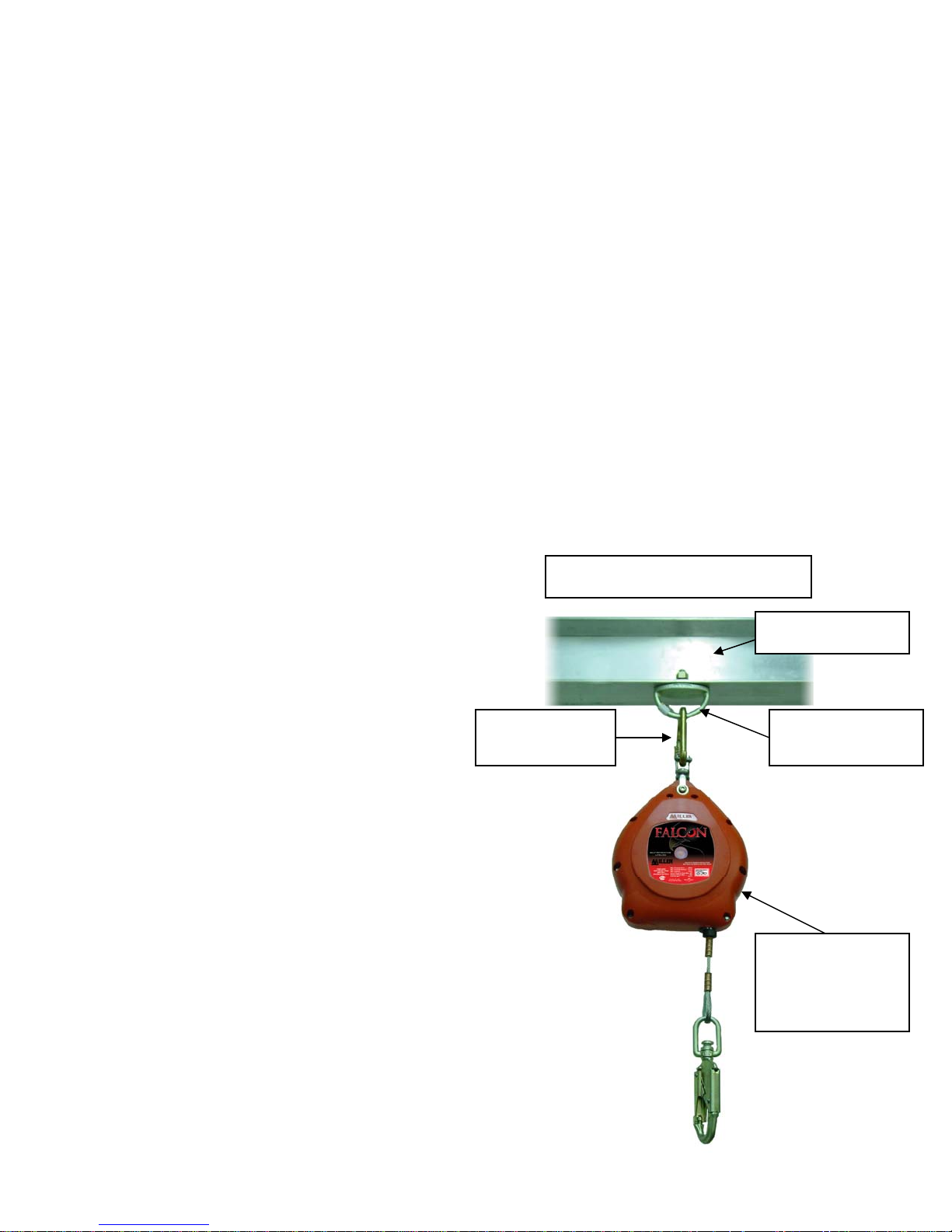

Carabiner

Fasteners

Carry Handle

(Never use for attachment.)

Falcon Series Models MP50 & MP65

Stainless Steel Swivel

Front Label

Back Label w/Identification Insert (back)

Housing

Ferrules

Self-Locking Snaphook

Cable

I. REQUIREMENTS

A. WARNINGS AND LIMITATIONS

Proper precautions should always be taken to remove any obstructions, debris and other material

from the work area that could cause injuries or interfere with the operation of the unit. Caution

should also be taken to insure that all equipment will be clear of all other recognized hazards and

that proper precautions have been taken to address all safety issues in the work area.

Note: Users should be familiar with pertinent regulations governing this equipment. All individuals who use this

product must be correctly instructed on how to use the system, and must read and understand the following

instructions before using the unit.

• For use by one person only. The design working load is 310 pounds (140.6 kg) — DO NOT

EXCEED THIS WEIGHT.

• Only trained personnel should use this device.

• Do not use the unit if the lifeline doesn’t retract.

• Do not use the unit if the lifeline brakes do not engage. Refer to inspection procedures for more

details.

• Do not use the unit if any part of the system appears to be damaged.

• Never use the Carry Handle (MP50 & 65) as an attachment point.

• Do not use the unit if it has been subject to fall arresting forces. Return the unit to Miller Fall

Protection or an authorized service center.

• Do not use the unit if the load impact indicator has been activated.

2

Page 3

• Do not attempt to service this device; if it does not operate satisfactorily or requires repairs,

return the unit to Miller Fall Protection or an authorized service center for repairs.

• Do not lubricate this device.

• The lifeline must be kept clean.

• The equipment should be installed overhead and used in such a manner as to reduce the

potential for a pendulum fall.

• Allow adequate fall clearance below the work surface when using this device.

• Never work above the device.

• Never use the device as a restraint or positioning device.

• Never allow the lifeline to become slack or to pass under or entwine around the user’s arms,

legs, or any other obstacle or person.

• Do not allow cable, rope or webbing lifelines to come in contact with anything that will damage

the lifeline including but not limited to sharp, abrasive, rough or high temperature surfaces,

welding, heat sources, electrical hazards, or moving machinery.

• Use in highly corrosive or caustic environment dictates a more frequent inspection and

servicing program to ensure the integrity of the unit is maintained. Contact Miller Fall Protection

in cases of doubt.

• Employers must provide for prompt rescue in the event of a fall.

• Do not allow lifeline in any application to bend or be subjected to fall arresting forces over

structural members or edges.

• Failure to follow instructions could cause serious injury or death.

• Note: All Miller Falcon models can be coupled with a 928LS Shock-Absorber for users that

weigh between 311 and 400 lbs. (141 and 181 kg.) The 928LS must be mounted between the back

D-ring of the user’s harness and the snaphook of the Falcon.

B. SYSTEM COMPATIBILITY

Miller retractable lifelines are designed for use with

Miller approved components. Substitution or

replacement with non-approved components will

endanger the compatibility within the system and

may affect the reliability and safety of the total

system. It is recommended that the user wear a

Miller full-body harness to distribute the fall

arresting forces over the body and to keep an

unconscious or injured worker in an upright

position.

II. INSTALLATION

LOCKING

CARABINER

TYPICAL INSTALLATION

ANCHORAGE

ANCHORAGE

CONNECTOR

The Falcon series retractable lifelines must be

mounted to an overhead anchor by the attachment

swivel using a locking carabiner or another Miller

Fall Protection approved mounting device. The

anchorage fixtures must be capable of supporting

a 5,000 lb. (22kN) tensile load or meet OSHA

1926.502 requirements for a safety factor of two.

Review all warnings and instructions when

selecting a mounting location.

The Falcon series retractable lifelines must be

inspected and tested satisfactorily before each use

as described in section III. Operation & Inspection.

Before the user is subject to a fall hazard, connect

the snap hook of the unit onto the back D-ring of

the user’s harness.

MP20 (6.2m)

OR

MP30 (10m)

SHOWN

3

Page 4

III. OPERATION & INSPECTION

A. GENERAL INSPECTION

•Before use, inspect device for loose fasteners, bent, cracked, distorted, worn, malfunctioning, or

damaged parts.

B. GENERAL OPERATION

WARNING: The following operation checkpoints and inspections must be done prior to each use:

1. Anchorage Connection: Make sure the carabiner is properly seated and in the locked position

between the attachment swivel on the unit and the anchor point or make certain the unit is properly

installed in the Miller mounting device. The anchorage connector and anchorage point must be capable

of supporting 5,000 Ibs. (22kN) or meet OSHA 1926.502 requirements for a safety factor of two.

2. Lifeline Retraction: With the device in the mounted position, test the lifeline retraction and tension by

pulling out several feet of the lifeline and allow it to retract back into the unit. Always maintain a light

tension on the lifeline as it retracts. The lifeline should pull out freely and retract all the way back into the

unit.

a. If the lifeline does not pull out smoothly or sticks when retracting, pull all of the lifeline out of the

housing and allow it to retract slowly under tension.

b. The lifeline should be checked regularly for signs of damage. Inspect for cuts, burns, corrosion, kinks,

frays, or worn areas.

c. Do not pull the lifeline out of the housing or let it retract while the unit is laying flat. Always inspect and

operate the unit in a mounted position.

3. Braking Mechanism: The braking mechanism can be tested by graspi ng the lifeline above the load

indicator and applying a sharp steady pull downward which will engage the brakes. There should be no

slippage of the lifeline while the brakes

are engaged. Once tension is released,

the brakes will disengage and the unit will

return to the retractable mode.

4. Snap Hook: Check the snap hook to

be sure that it operates freely, locks, and

the swivel operates smoothly. Inspect the

snap hook for any signs of damage to the

keepers and any bent, cracked, or

distorted components.

5. Snap Hook Load Indicator: A load

indicator is located in the swivel of the

snap hook. The swivel eye will elongate

and expose a red area when subjected to

fall arresting forces as shown.

UNITS THAT DO NOT PASS THIS

INSPECTION OR HAVE BEEN

SUBJECTED TO FALL ARRESTING

FORCES MUST BE REMOVED FROM

SERVICE.

SNAP HOOK ACTIVATION INSPECTION

BEFORE

AFTER- RED WILL

APPEAR HERE WHEN

SUBJECTED TO FALL

ARREST FORCES

4

Page 5

IV.TRAINING

It is the responsibility of the user to assure that they read, understand, and follow all instructions and are

trained in the care and use of this device. Training should be repeated periodically and any time there is

a change of components within the system. Training must be conducted without exposing the trainee to a

fall hazard.

V. MAINTENANCE

A. SERVICING

Servicing must only be carried out by a Miller Fall Protection approved service technician trained in the

repair and service of Miller Fall Protection Falcon Series fall arrest lifeline systems/devices. A record log

of all servicing and inspection dates for this device must be maintained by the company safety officer.

This device must be returned to Miller Fall Protection or an approved service center whenever

subjected to fall arresting forces for physical inspection and recertification. Only original Miller

replacement parts are approved for use in this device. Contact your Miller distributor or call Miller Fall

Protection’s Customer Service Department at 1-800-873-5242 for a return goods authorization number.

(The Following Note Applies Only To CSA Approved Products) Note: CSA Z259.2.2 Requires Type

2 and Type 3 devices to be returned to the manufacturer or an approved service agent no more than 2

years after the date of manufacture for inspection and maintenance and annually thereafter.

B. CLEANING

Periodically clean the exterior of the device and wipe the lifeline using a damp cloth and mild detergent.

Towel dry.

C. STORAGE

Store in a clean, dry location when not in use. The lifeline should be fully retracted into the unit when not

in use.

FRONT I.D.LABEL (FIG. A)

FALCON SELF–RETRACTING LIFELINE

WARNING: FAILURE TO OBSERVE INSTRUCTIONS

MAY RESULT IN SERIOUS OR FATAL INJURY

COMPLIANCE:

OSHA 1926.502, OSHA 1910.66, ANSI A10.14,

CSA Z259.2.2-98 (TYPE 2), ANSI Z359.1

MAX ARRESTING FORCE 900 LBS. (4 kN)

MAX ARREST DISTANCE 3' - 6" (1.06 m)

MAX CAPACITY 310 LBS. (140.6 kg)

LOAD-INDICATING SNAPHOOK WARNING:

REMOVE FROM SERVICE IF RED APPEARS

FIG. A

5

Page 6

BACK WARNING LABEL (FIG. B)

FIG. B

INSTALLATION

• SEE INSTRUCTIONS FOR MOUTING

PROCEDURE.

• ANCHORAGE AND MOUNTING HARDWARE

MUST BE CAPABLE OF SUPPORTING A 5,000

LB. (22kN) STATIC LOAD OR MEET OSHA

1926.502 REQUIREMENTS FOR A SAFETY

FACTOR OF TWO.

• INSPECT BEFORE USE FOR ANY SIGNS OF

DAMAGE, WEAR OR MALFUNCTIONING

COMPONENTS.

• DEVICE MUST BE TAKEN OUT OF SERVICE FOR

INSPECTION AND RECERTIFICATION AFTER

ARRESTING A FALL OR LOAD INDICATOR HAS

BEEN ACTIVATED.

BEFORE USING

• CHECK LIFELINE RETRACTION BY PULLING

OUT A MINIMUM OF 4 FT. (1.2M.) OF LIFELINE

AND ALLOW IT TO RETRACT UNDER LIGHT

TENSION.

• CHECK BRAKING ACTION BY GRASPING LIFELINE ABOVE LOAD INDICATOR AND APPLYING

A SHARP PULL TO THE LIFLINE. THE BRAKES MUST ENGAGE.

• RELEASE THE TENSION AND ALLOW LIFLINE TO RETRACT SLOWLY INTO THE UNIT. THE

LIFLINE SHOULD RETRACT COMPLETELY.

• ALLOW ADEQUATE FALL CLEARANCE BELOW THE WORK SURFACE WHEN USING THIS

DEVICE.

WARNING: MANUFACTURER’S INSTRUCTIONS SUPPLIED WITH THIS PRODUCT AT THE TIME

OF SHIPMENT MUST BE FOLLOWED: FAILURE TO DO SO MAY RESULT IN SERIOUS INJURY OR

DEATH. ONLY FOR USE BY ONE PERSON AS A PERSONAL FALL ARRESTER. DEVICE MUST

BE TAKEN OUT OF SERVICE FOR INSPECTION AND RECERTIFICATION

**THIS SELF-RETRACTING LIFLINE SHOULD BE INSPECTED BY THE USER PRIOR TO EACH USE

ACCORDING TO MANUFACTURER’S INSTRUCTIONS.**

IDENTIFICATION LABEL (FIG. C)

MODEL/LENGTH

MP20G/20FT (6.2m) · 3/16” (4.8mm) GALVANIZED STEEL CABLE

MP20SS/20FT (6.2m) · 3/16” (4.8mm) STAINLESS STEEL CABLE

MP30G/30FT (10m) · 3/16” (4.8mm) GALVANIZED STEEL CABLE

MP30SS/30FT (10m) · 3/16” (4.8mm) STAINLESS STEEL CABLE

MP50G/50FT (15m) · 3/16” (4.8mm) GALVANIZED STEEL CABLE

MP50SS/50FT (15m) · 3/16” (4.8mm) STAINLESS STEEL CABLE

MP65G/65FT (20m) · 3/16” (4.8mm) GALVANIZED STEEL CABLE

DATE OF MANUFACTURE

DATE DE FABRICIATION

XX/XX

SERIAL NO/NO. DE SERIE

FIG. C

MODEL/LENGTH

MODELE/LONGUEUR

MPXXX/XXFT

LB554 REV. A

MP65SS/65FT (20m) · 3/16” (4.8mm) STAINLESS STEEL CABLE

DATE OF MANUFACTURE: MM\YY

SERIAL NO.: XXXXX

6

Page 7

MILLER FALCON - MP SERIES SELF-RETRACTING LIFELINES MODEL SPECS

Model LifeLine Material Length Weight (lbs.) A (inches) B (inches) C (inches)

MP20G

MP20SS

MP30G

MP30SS

MP50G

MP50SS

MP65G

MP65SS

3/16” (4.8mm)

galvanized cable

3/16” (4.8mm)

stainless steel cable

3/16” (4.8mm)

galvanized cable

3/16” (4.8mm)

stainless steel cable

3/16” (4.8mm)

galvanized cable

3/16” (4.8mm)

stainless steel cable

3/16” (4.8mm)

galvanized cable

3/16” (4.8mm)

stainless steel cable

A

B C

20’ (6.2m) 8.9 (4.0kg) 12.1 (30.8cm) 8.4 (21.3cm) 4.0 (10.2cm)

20’ (6.2m) 8.9 (4.0kg) 12.1 (30.8cm) 8.4 (21.3cm) 4.0 (10.2cm)

30’ (10m) 10.8 (4.9kg) 12.1 (30.8cm) 8.4 (21.3cm) 4.0 (10.2cm)

30’ (10m) 10.8 (4.9kg) 12.1 (30.8cm) 8.4 (21.3cm) 4.0 (10.2cm)

50’ (15m) 14.8 (6.7kg) 15.5 (39.4cm) 9.8 (24.8cm) 4.0 (10.2cm)

50’ (15m) 14.8 (6.7kg) 15.5 (39.4cm) 9.8 (24.8cm) 4.0 (10.2cm)

65’ (20m) 17.2 (7.8kg) 15.5 (39.4cm) 9.8 (24.8cm) 4.0 (10.2cm)

65’ (20m) 17.2 (7.8kg) 15.5 (39.4cm) 9.8 (24.8cm) 4.0 (10.2cm)

7

Page 8

MATERIAL SPECIFICATIONS

Housing: High Impact Nylon

Fasteners: Stainless Steel

Top Swivel: Stainless Steel

Ferrules: Aluminum or Copper

Cable: Galvanized or Stainless Steel

Snaphook: Drop Forged Steel

Brake Pawls: Bronze

Drum: Aluminum

Frame Plates: Aluminum or Stainless Steel

Power Spring: Stainless Steel

Mainshaft: Stainless Steel

TECHNICAL SPECIFICATIONS

Max Working Load: 310 lbs -140.62 kg

Ultimate Strength: 3600 lbs. -16.01kN

Lifeline Tension: 3 to 4 lbs. -13.3/17.8 N

Free Fall Distance: 24” Max. - 609.6 mm

Deceleration Distance: 42” Max – 1.06m

Arresting Force: 900 lbs. (approx.) – 4kN

Strength Test: 300 lbs. 4’ free fall

(1.33 kN @ 1.22m free fall)

I227

REV. B

MFP9720108

Sperian Protection

43 Garden Boulevard

Dingley VIC 3172

1300 139 166

FAX: 1300 362 491

www.millerfallprotection.com.au

8

Page 9

p

W

Miller Falcon 16ft and 20ft SRL MILLER FALL PROTECTION

Model: MP16P/16FT or MP20P/20FT

New Product Information/Instruction Manual Insert:

We would like to thank you for your purchase of Miller Fall Protection equipment. Please

carefully read this supplemental Instruction and specification sheet. It contains special

instructions, inspections and maintenance procedures that are unique to the Falcon 16ft/20ft

product line, and should be referenced in addition to the Miller Falcon instruction booklet also

included with this product. Should you have any questions about your Miller Fall Protection

roduct, please contact the Miller Technical Service at 1300 139 166

Load Indicator

Activation Inspection

In addition to the standard inspection

procedures, the load indicator should be

inspected prior to each use to ensure the unit

has not seen fall arresting forces.

Before

After Fall Arrest

arning Labels

Page 10

SP345 REVA

Miller Falcon 16ft and 20ft SRL MILLER FALL PROTECTION

Model: MP16P/16FT or MP20P/20FT

Description

Miller Falcon 16ft (4.9m) and 20ft. (6.1m) web lifelines

with stainless steel swivel, aluminum snaphook and

carabiner.

Nearly indestructible, high impact-resistant

thermoplastic housing withstands the harsh rigors of

the toughest applications. Pound for pound the

strongest, most durable line of self-retracting lifelines

on the market.

Materials

Housing: High-strength thermoplastic

Hub: Aluminum and high-strength

Braking

Mechanism: High-strength steel, yellow zinc

Lifeline: Core: Technora® (aramid fiber)

Snaphook: Aluminum

Carabiner: Aluminum

polypropylene

composite

chromate plating

Outer cover: Chemically-treated

polyester for increased abrasion

resistance

Technical

Maximum

Working Load: 400lbs (181kg)

Working Length

Capacity: 16ft (4.9m) or 20ft (6.1m)

Maximum

Arresting Force: <900lbs/f (4kN) for up to 310lbs.

<1800lbs/f (8kN) for up to 400lbs.

(140kg) Working Load

(181kg) Working Load

Certification

Meets all applicable OSHA, ANSI, CSA and CE

requirements.

www.millerfallprotection.com.au

WARNING!

TO ASSURE THE ACCURACY OF THE DATA. IT DOES NOT PROVIDE IMPORTANT PRODUCT WARNINGS AND INSTRUCTIONS. MILLER FALL PROTECTION RECOMMENDS

ALL USERS OF FALL PROTECTION EQUIPMENT UNDERGO THOROUGH TRAINING, AND THAT ALL WARNINGS AND INSTRUCTIONS PROVIDED WITH THE PRODUCTS BE

THIS DOCUMENT PROVIDES AN OVERVIEW OF FALL PROTECTION PRODUCTS AVAILABLE FROM MILLER FALL PROTECTION AND CARE HAS BEEN TAKEN

THOROUGHLY READ AND UNDERSTOOD PRIOR TO EACH USE. FAILURE TO READ AND FOLLOW ALL PRODUCT WARNINGS AND INSTRUCTIONS COULD RESULT IN

MODEL NUMBER *L - LENGTH WEIGHT WEIGHT

WITHOUT CARABINER WITH CARABINER

MP16P/16FT 16’ (4.9m) 2.90lbs.(1.31kg) 3.32lbs (1.50kg)

MP20P/20FT 20’ (6.1m) 2.98lbs.(1.35kg) 3.40lbs (1.54kg)

SERIOUS INJURY OR DEATH.

Loading...

Loading...