Miller Millermatic 251 Technical Manual

TM-1326B 2006−10

Eff. w/Serial Number LB170597

Processes

MIG (GMAW) Welding

Flux Cored (FCAW) Welding

Description

Arc Welding Power Source

and Wire Feeder

R

Millermatic 251

Visit our website at

www.MillerWelds.com

File: MIG (GMAW)

TABLE OF CONTENTS

SECTION 1 − SAFETY PRECAUTIONS FOR SERVICING 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1. Symbol Usage 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2. Servicing Hazards 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3. California Proposition 65 Warnings 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4. EMF Information 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2 − DEFINITIONS 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1. Symbols And Definitions 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 − INSTALLATION 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1. Specifications 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. Welding Power Source Duty Cycle And Overheating 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. Volt-Ampere Curves 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4. Connecting To Weld Output Terminals 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5. Installing Work Cable And Clamp 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6. Connecting Spoolmatic) 15A Or 30A Gun 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7. Setting Gun Polarity For Wire Type 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8. Installing Gas Supply 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-9. Installing Wire Spool And Adjusting Hub Tension 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-10. Positioning Jumper Links 8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-11. Electrical Service Guide 9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

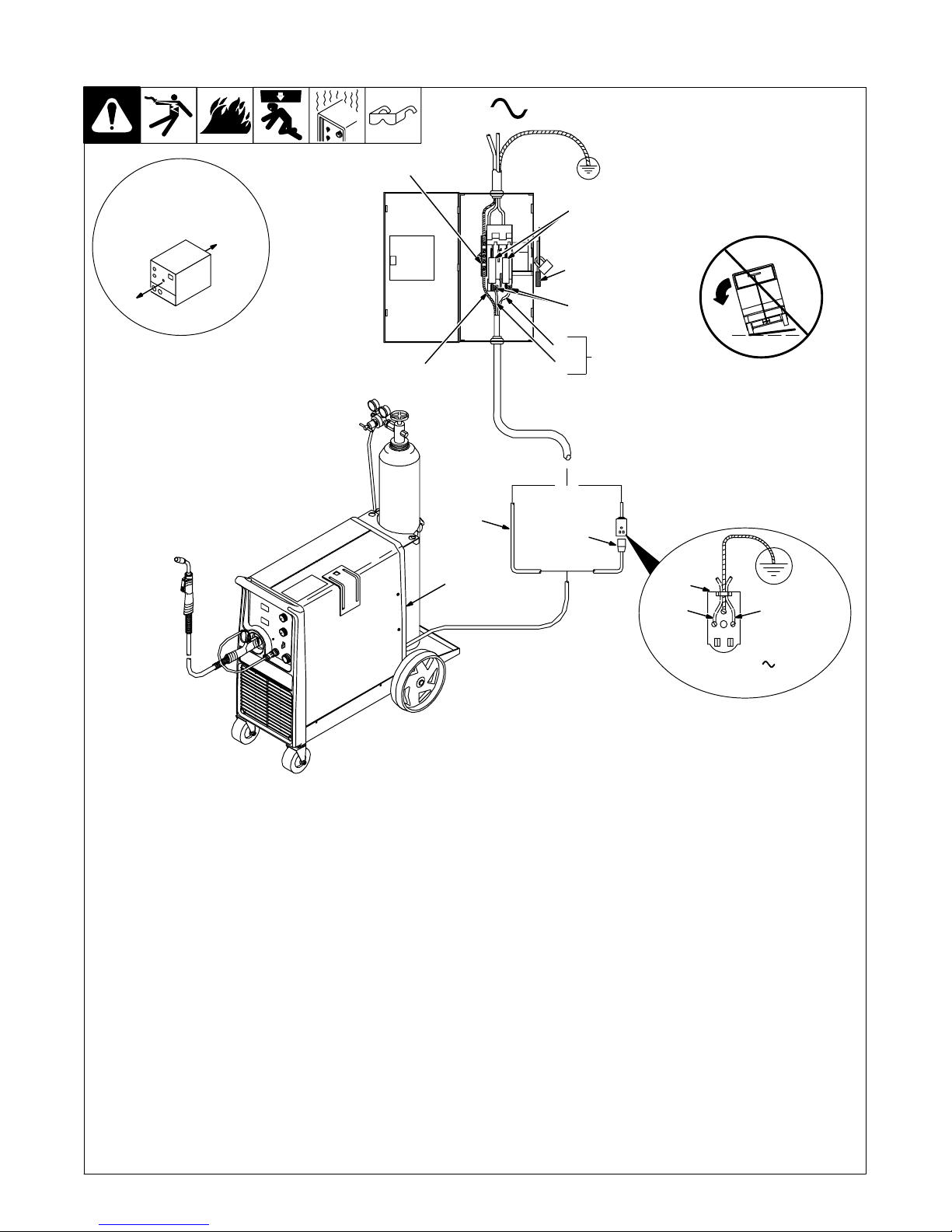

3-12. Selecting A Location And Connecting Input Power 10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

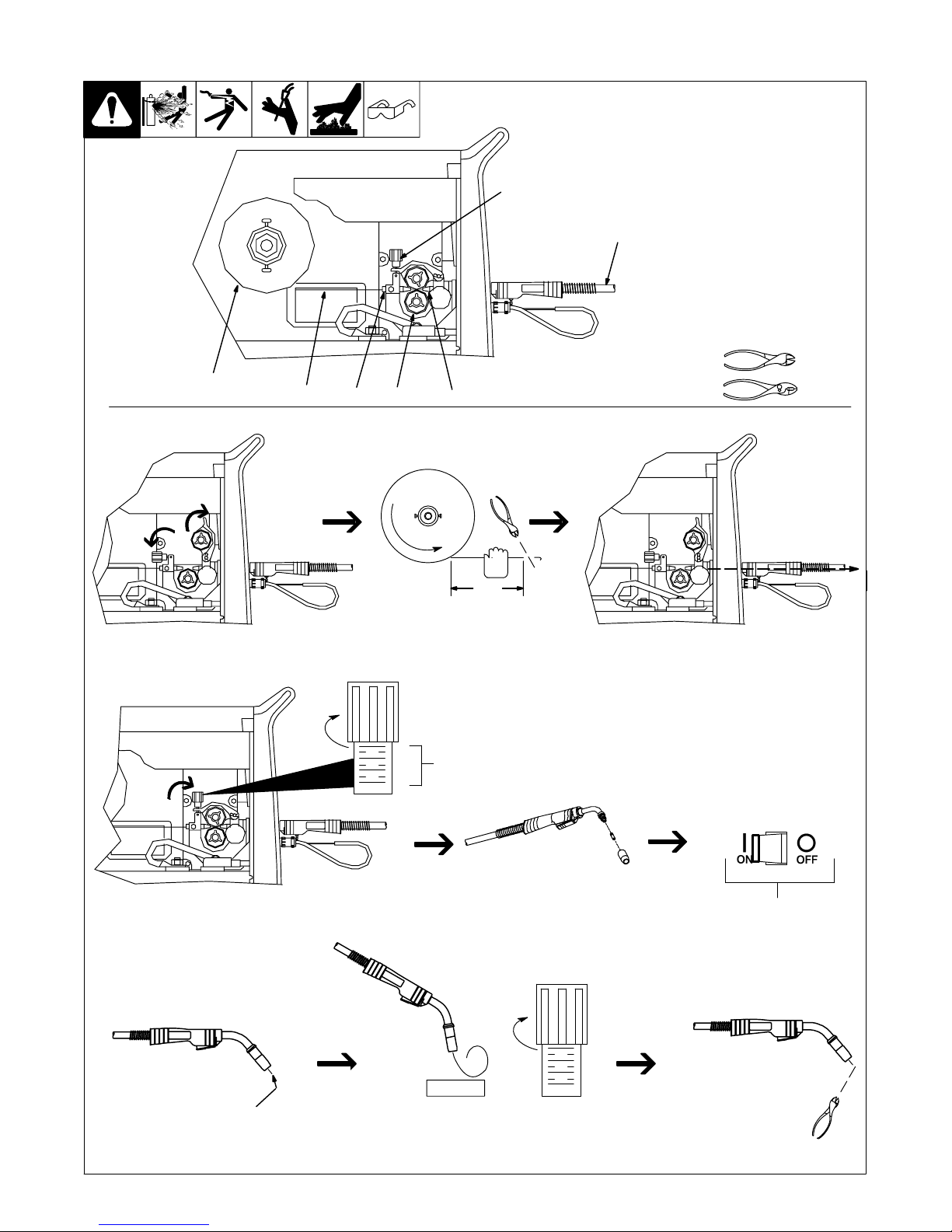

3-13. Threading Welding Wire 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

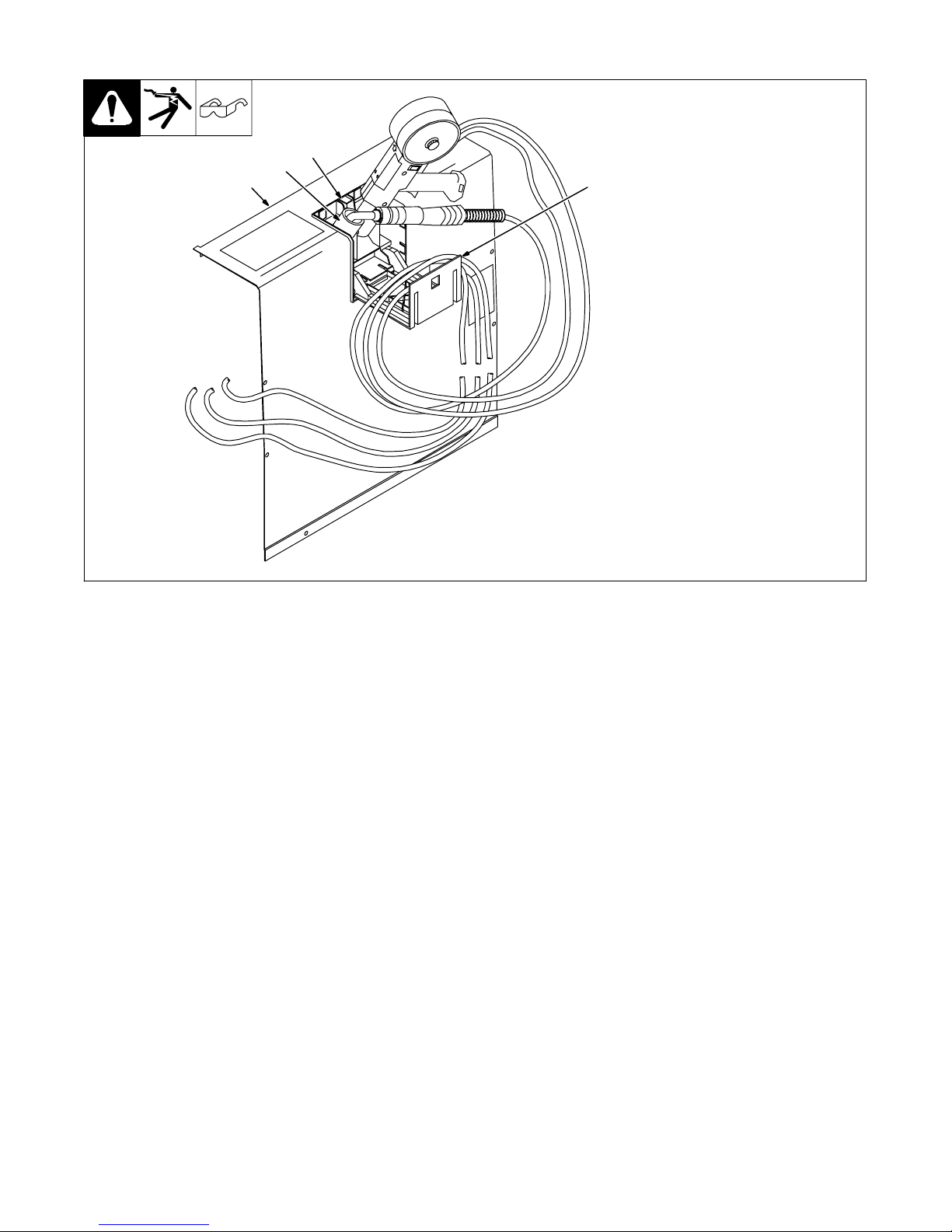

3-14. Using Gun/Cable Holder 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

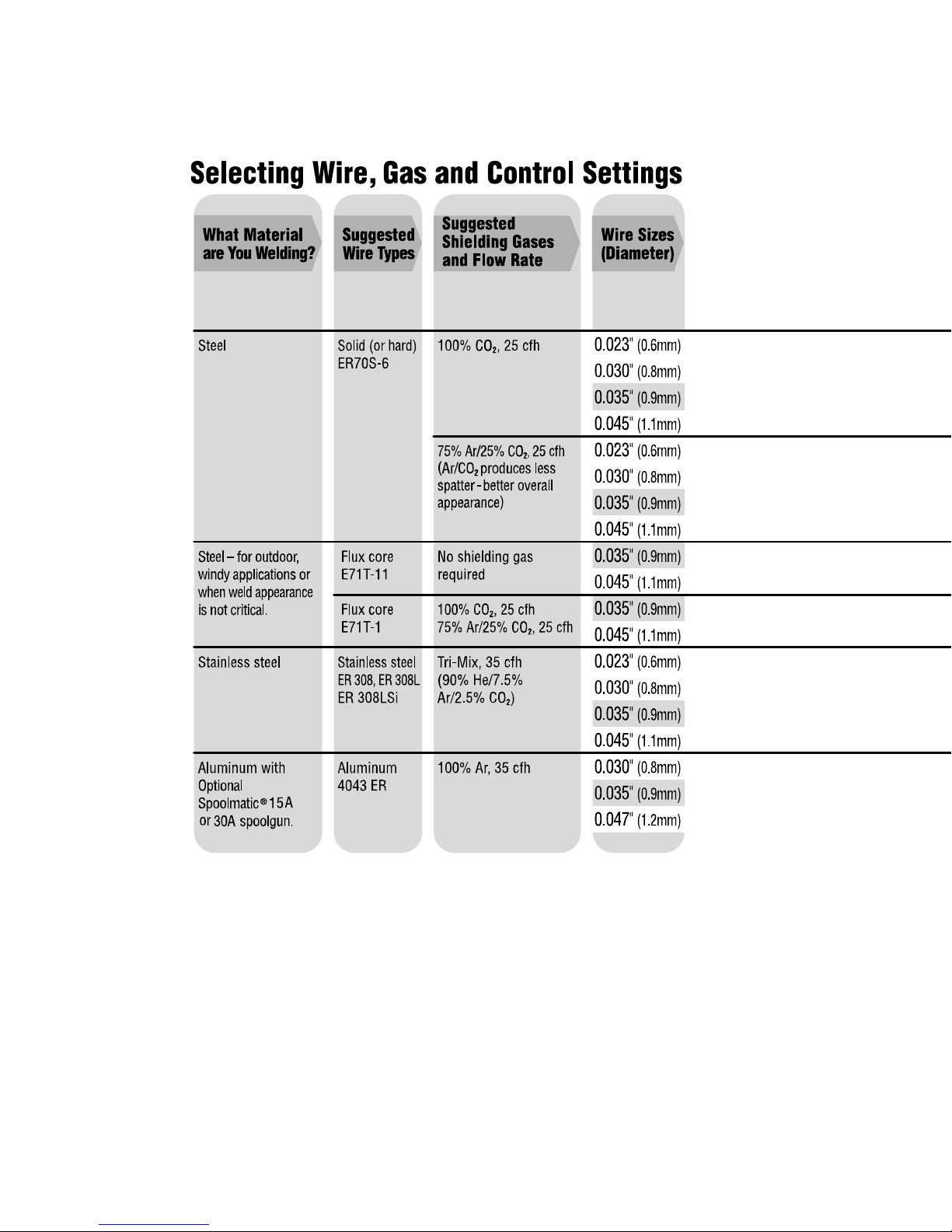

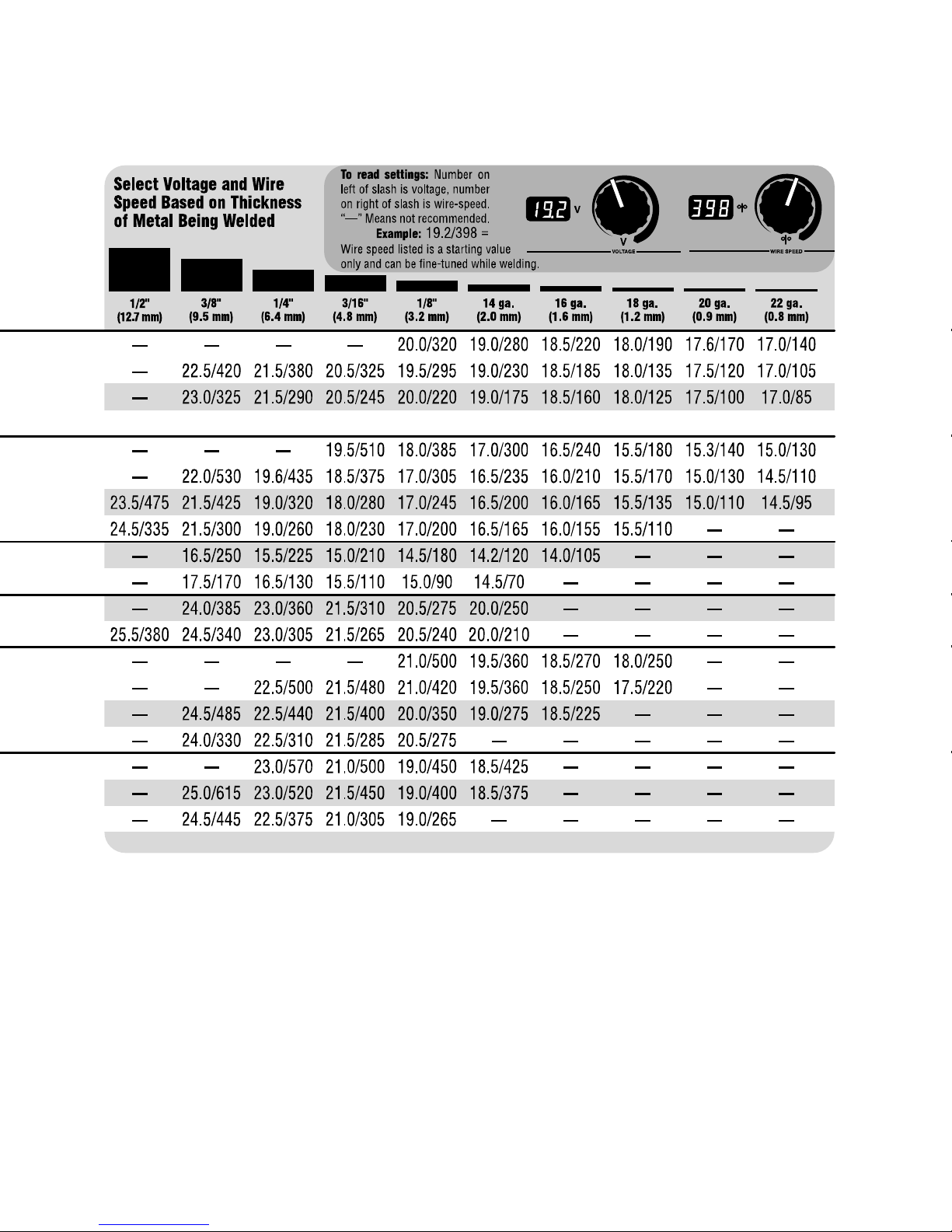

3-15. Weld Parameters 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 − OPERATION 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-1. Controls 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2. Voltmeter And Wire Feed Speed Meter Operation 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 − THEORY OF OPERATION 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 − TROUBLESHOOTING 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1. Troubleshooting Table 22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

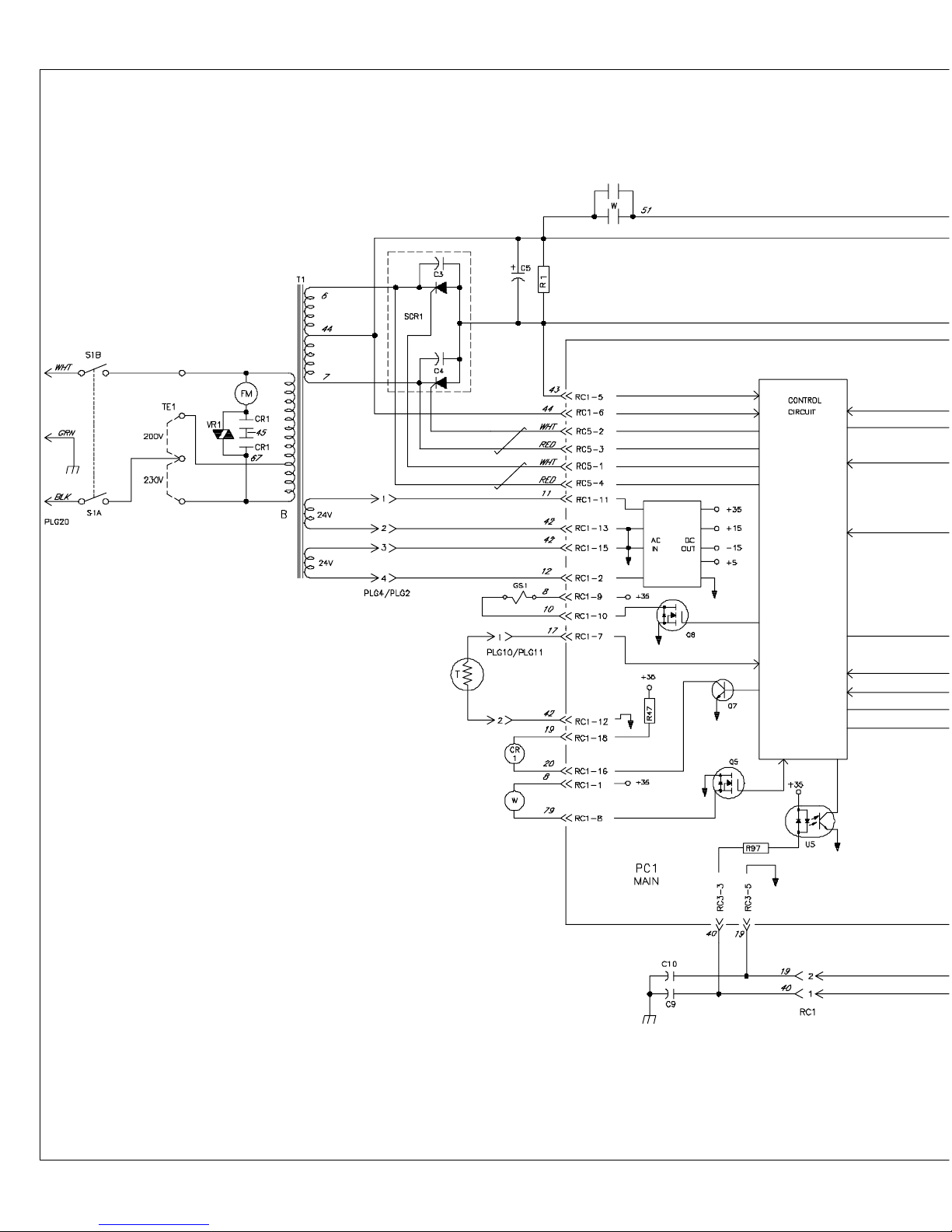

6-2. Troubleshooting Circuit Diagram For Welding Power Source 24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-3. Waveforms For Section 6-2 26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-4. Main Control Board PC1 Testing Information (Use With Section 6-5) 28 . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-5. Main Control Board PC1 Test Point Values 29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-6. Pre-Operational Check 31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7 − MAINTENANCE 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-1. Routine Maintenance 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2. Unit Overload 32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-3. Changing Drive Roll and Wire Inlet Guide 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-4. Aligning Drive Rolls and Wire Guide 33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-5. Removing Knob From Front Panel 34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8 − ELECTRICAL DIAGRAMS 35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 9 − PARTS LIST 56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1 − SAFETY PRECAUTIONS FOR SERVICING

Y Warning: Protect yourself and others from injury — read and follow these precautions.

1-1. Symbol Usage

OM-___ - Date, safety_stm 3/06

Means Warning! Watch Out! There are possible hazards

with this procedure! The possible hazards are shown in

the adjoining symbols.

Y Marks a special safety message.

. Means “Note”; not safety related.

1-2. Servicing Hazards

Y The symbols shown below are used throughout this manual to

call attention to and identify possible hazards. When you see

the symbol, watch out, and follow the related instructions to

avoid the hazard.

Y Only qualified persons should service, test, maintain, and re-

pair this unit.

Y During servicing, keep everybody, especially children, away.

ELECTRIC SHOCK can kill.

D Do not touch live electrical parts.

D Turn Off welding power source and wire feeder

and disconnect and lockout input power using

line disconnect switch, circuit breakers, or by removing plug from receptacle, or stop engine before servicing unless the procedure specifically requires an energized unit.

D Insulate yourself from ground by standing or working on dry insulat-

ing mats big enough to prevent contact with the ground.

D Do not leave live unit unattended.

D If this procedure requires an energized unit, have only personnel

familiar with and following standard safety practices do the job.

D When testing a live unit, use the one-hand method. Do not put both

hands inside unit. Keep one hand free.

D Disconnect input power conductors from deenergized supply line

BEFORE moving a welding power source.

This group of symbols means Warning! Watch Out! possible

ELECTRIC SHOCK, MOVING PARTS, and HOT PARTS hazards.

Consult symbols and related instructions below for necessary actions

to avoid the hazards.

FLYING METAL or DIRT can injure eyes.

D Wear safety glasses with side shields or face

shield during servicing.

D Be careful not to short metal tools, parts, or

wires together during testing and servicing.

HOT PARTS can cause severe burns.

D Do not touch hot parts bare handed.

D Allow cooling period before working on

equipment.

D To handle hot parts, use proper tools and/or

wear heavy, insulated welding gloves and

clothing to prevent burns.

EXPLODING PARTS can cause injury.

D Failed parts can explode or cause other parts to

explode when power is applied to inverters.

D Always wear a face shield and long sleeves

when servicing inverters.

SIGNIFICANT DC VOLTAGE exists after removal of

input power on inverters.

D Turn Off inverter, disconnect input power, and discharge input

capacitors according to instructions in Troubleshooting Section before touching any parts.

STATIC (ESD) can damage PC boards.

D Put on grounded wrist strap BEFORE handling

boards or parts.

D Use proper static-proof bags and boxes to

store, move, or ship PC boards.

FIRE OR EXPLOSION hazard.

D Do not place unit on, over, or near combustible

surfaces.

D Do not service unit near flammables.

SHOCK HAZARD from testing.

D Turn Off welding power source and wire feeder

or stop engine before making or changing meter lead connections.

D Use at least one meter lead that has a self-

retaining spring clip such as an alligator clip.

D Read instructions for test equipment.

FALLING UNIT can cause injury.

D Use lifting eye to lift unit only, NOT running

gear, gas cylinders, or any other accessories.

D Use equipment of adequate capacity to lift and

support unit.

D If using lift forks to move unit, be sure forks are

long enough to extend beyond opposite side of

unit.

TM-1326 Page 1Millermatic 251

MOVING PARTS can cause injury.

H.F. RADIATION can cause interference.

D Keep away from moving parts such as fans.

D Keep away from pinch points such as drive

rolls.

D Have only qualified persons remove doors,

panels, covers, or guards for maintenance as

necessary.

D Keep hands, hair, loose clothing, and tools

away from moving parts.

D Reinstall doors, panels, covers, or guards

when maintenance is finished and before re-

connecting input power.

MAGNETIC FIELDS can affect pacemakers.

D Pacemaker wearers keep away from servicing

areas until consulting your doctor.

OVERUSE can cause OVERHEATING.

D Allow cooling period; follow rated duty cycle.

D Reduce current or reduce duty cycle before

starting to weld again.

D Do not block or filter airflow to unit.

D High-frequency (H.F.) can interfere with radio

navigation, safety services, computers, and

communications equipment.

D Have only qualified persons familiar with

electronic equipment install, test, and service

H.F. producing units.

D The user is responsible for having a qualified electrician prompt-

ly correct any interference problem resulting from the installation.

D If notified by the FCC about interference, stop using the

equipment at once.

D Have the installation regularly checked and maintained.

D Keep high-frequency source doors and panels tightly shut, keep

spark gaps at correct setting, and use grounding and shielding to

minimize the possibility of interference.

READ INSTRUCTIONS.

D Use Testing Booklet (Part No. 150 853) when

servicing this unit.

D Consult the Owner’s Manual for welding safety

precautions.

D Use only genuine replacement parts from the

manufacturer.

1-3. California Proposition 65 Warnings

Y Welding or cutting equipment produces fumes or gases which

contain chemicals known to the State of California to cause

birth defects and, in some cases, cancer. (California Health &

Safety Code Section 25249.5 et seq.)

Y Battery posts, terminals and related accessories contain lead

and lead compounds, chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

1-4. EMF Information

Considerations About Welding And The Effects Of Low Frequency

Electric And Magnetic Fields

Welding current, as it flows through welding cables, will cause electromagnetic fields. There has been and still is some concern about such

fields. However, after examining more than 500 studies spanning 17

years of research, a special blue ribbon committee of the National

Research Council concluded that: “The body of evidence, in the

committee’s judgment, has not demonstrated that exposure to powerfrequency electric and magnetic fields is a human-health hazard.”

However, studies are still going forth and evidence continues to be

examined. Until the final conclusions of the research are reached, you

may wish to minimize your exposure to electromagnetic fields when

welding or cutting.

To reduce magnetic fields in the workplace, use the following

procedures:

For Gasoline Engines:

Y Engine exhaust contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive

harm.

For Diesel Engines:

Y Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cables around your body.

4. Keep welding power source and cables as far away from operator as practical.

5. Connect work clamp to workpiece as close to the weld as possible.

About Pacemakers:

Pacemaker wearers consult your doctor before welding or going near

welding operations. If cleared by your doctor, then following the above

procedures is recommended.

TM-1326 Page 2 Millermatic 251

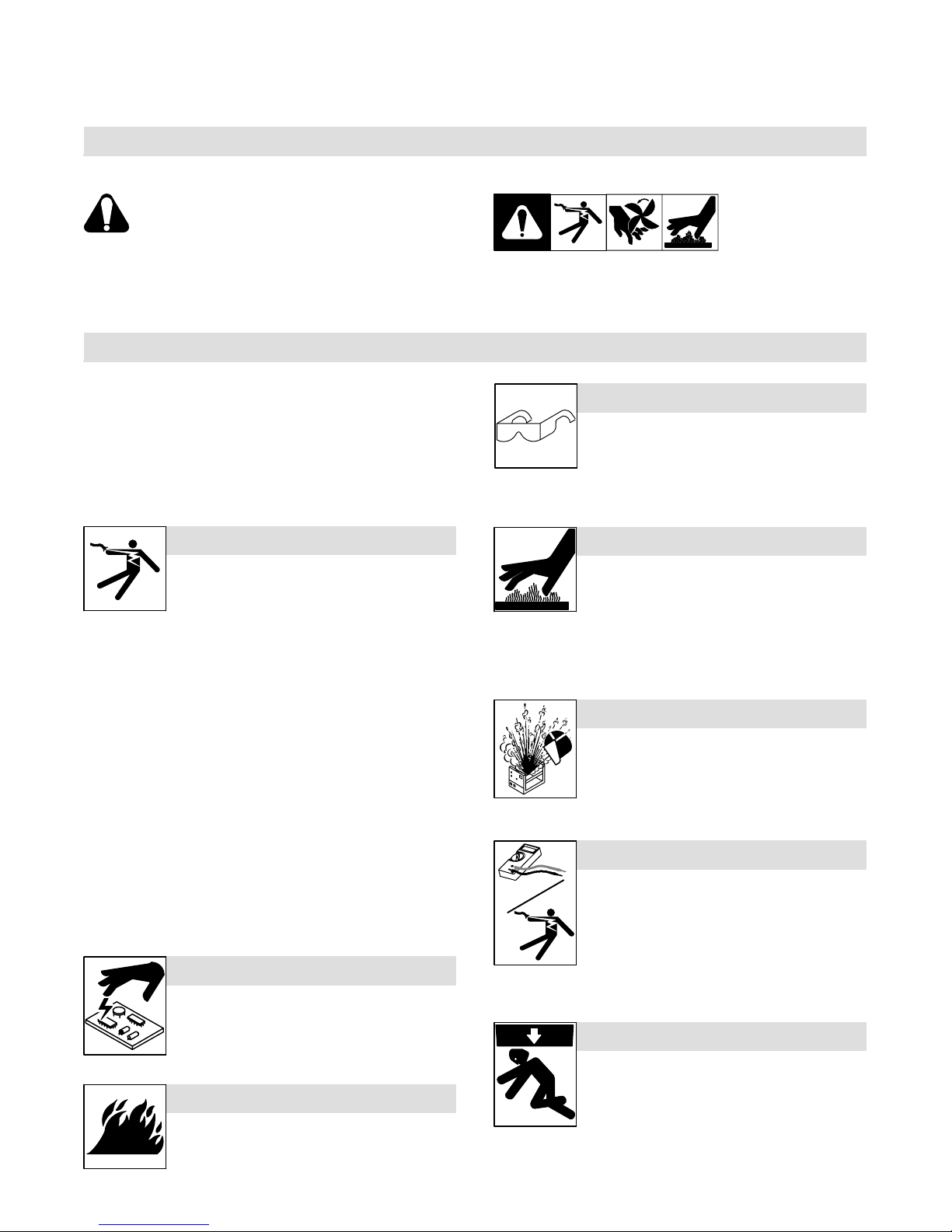

SECTION 2 − DEFINITIONS

Rated Output

2-1. Symbols And Definitions

V

Wire Feed Output

Volts Increase On Off

Gas Metal Arc

Welding (GMAW)

Gun

Voltage Input Press To Reset

Wire Feed Spool

Gun

X

U

0

Duty Cycle

Gas Input Gas Output

Rated No-Load

Voltage (Average)

SECTION 3 − INSTALLATION

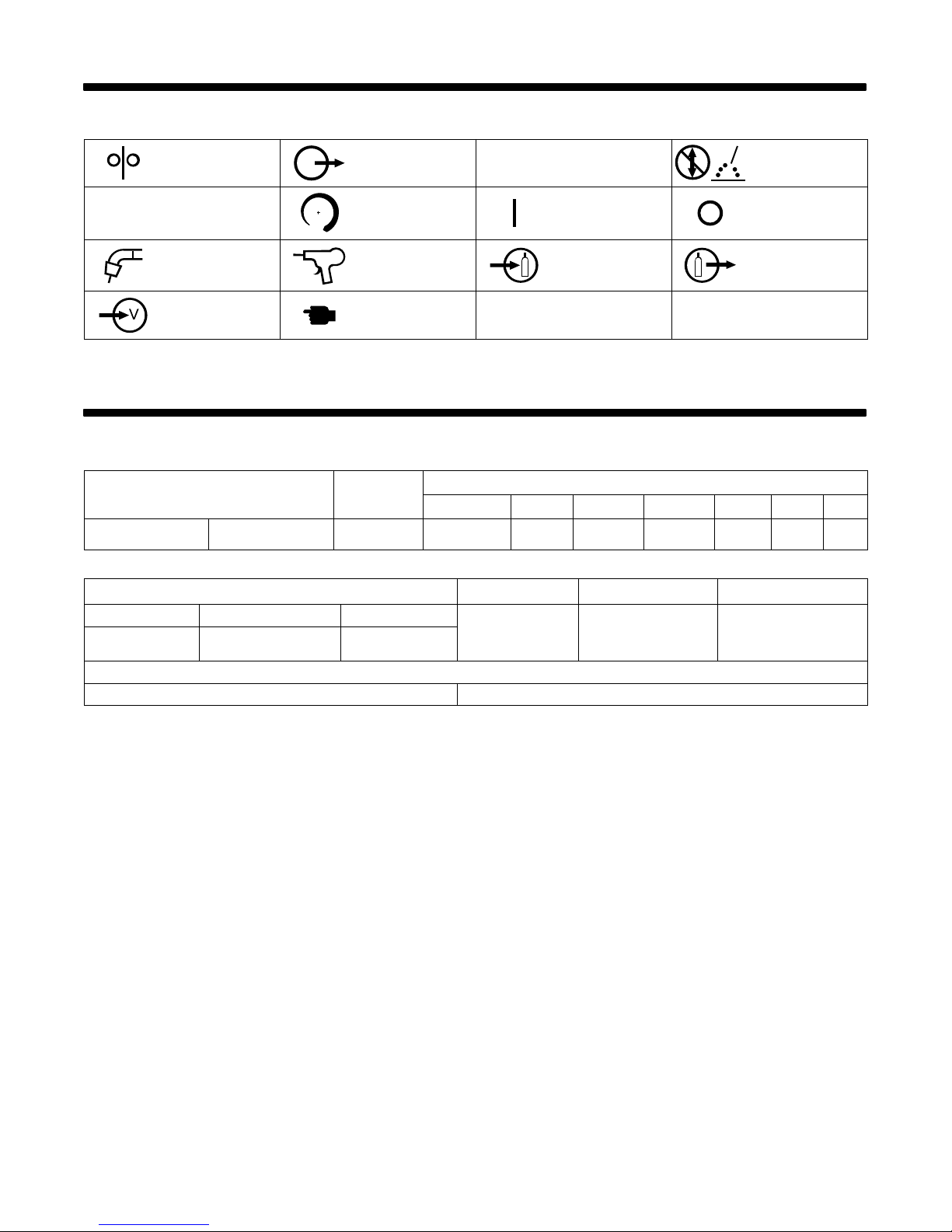

3-1. Specifications

Max. Open

Circuit

Voltage

250 A at 28 VDC,

40% Duty Cycle

Solid Steel Stainless Steel Flux Cored 25−700 IPM

.023 − .045 in

(0.6 − 1.2 mm)

* While idling

Operating Temperature Range − −20C to +40C Storage Temperature Range − -30C to + 50C

200 A at 28 VDC,

60% Duty Cycle

Wire Type and Diameter Wire Feed Speed Dimensions Net Weight

.023 − .045 in

(0.6 − 1.2 mm)

38 48

.030 − .045 in

(0.8 − 1.2 mm)

Amps Input at Rated Output (60% Duty Cycle), 50 or 60 Hz, Single-Phase

200 (208) V 230 V 400 V 460 V 575 V KVA KW

2.3*

(.65−17.8 m/min) W: 19 in (483 mm)

42

2*

24

1.2*

H: 32 in (813 mm)

D: 39 in (991 mm)

21

1*

17

0.8*

Do Not Switch

While Welding

9.8

0.46*

215 lb

(98 kg)

0.13*

7.5

TM-1326 Page 3Millermatic 251

3-2. Welding Power Source Duty Cycle And Overheating

500

450

400

350

300

250

200

150

WELD AMPERES

100

50

10 20 30 40 50 60 70 80 90 100

% DUTY CYCLE

Duty Cycle is percentage of 10

minutes that unit can weld at rated

load without overheating.

If unit overheats, Thermistor (T)

opens, output stops, and cooling

fan runs. Wait fifteen minutes for

unit to cool. Reduce amperage or

voltage, or duty cycle before

welding.

Y Exceeding duty cycle can

damage unit and void

warranty.

60% Duty Cycle At 200 Amperes

6 Minutes Welding 4 Minutes Resting

Overheating

3-3. Volt-Ampere Curves

35

30

25

0

Minutes

15

40% Duty Cycle At 250 Amperes

4 Minutes Welding 6 Minutes Resting

A or V

OR

Reduce Duty Cycle

duty1 4/95 − 150 215-A

1

1 Normal Volt-Ampere Curves

The volt-ampere curves show the

normal minimum and maximum

voltage and amperage output

capabilities of the welding power

source. Curves of other settings fall

between the curves shown.

20

VOLTS

15

10

5

0

0 100 200 300 400

TM-1326 Page 4 Millermatic 251

AMPERES

ssb1.1 10/91 − 196 844 / S-0700

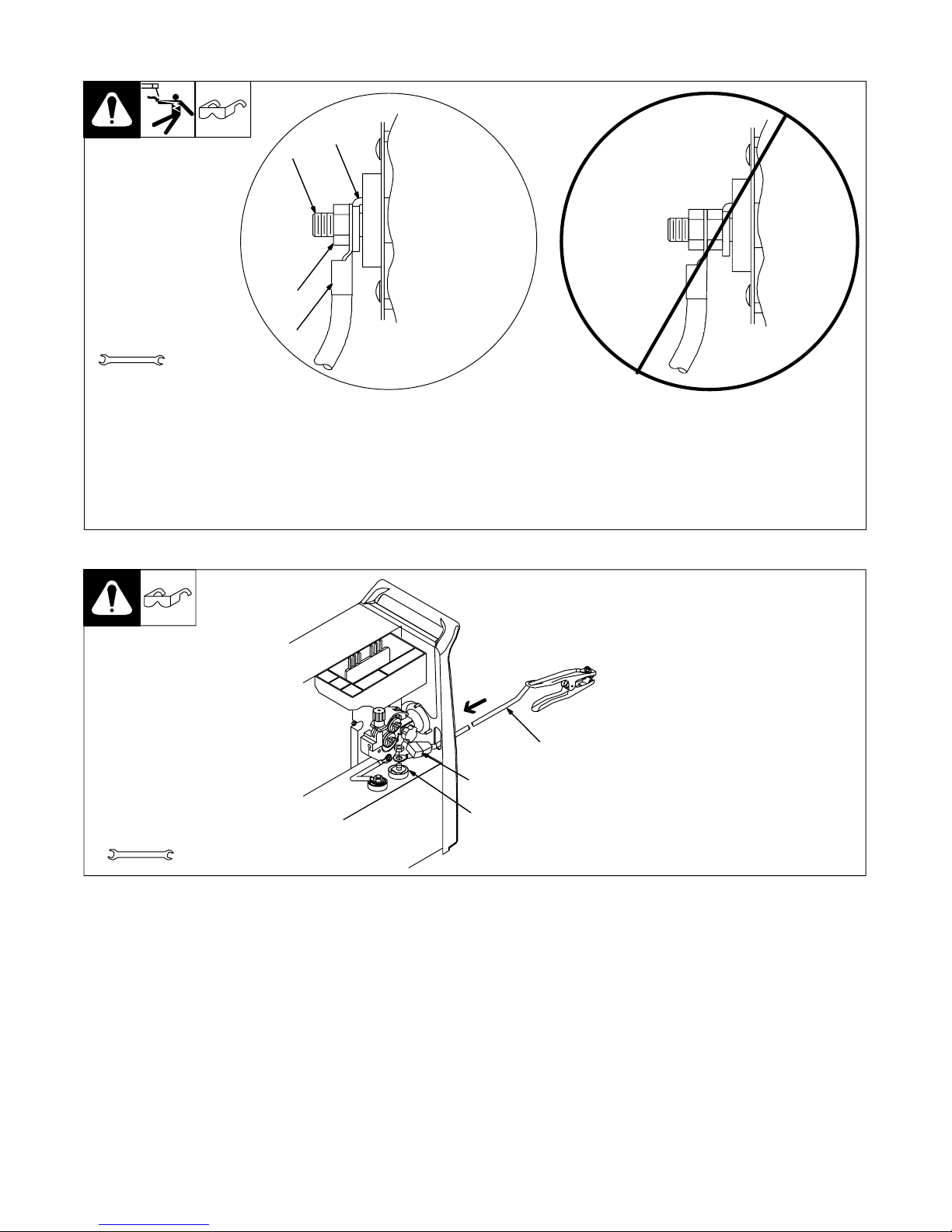

3-4. Connecting To Weld Output Terminals

4

1

Do not place

anything between

weld cable terminal

and copper bar.

2

Tools Needed:

3/4 in (19 mm)

Y Turn off power before connecting to

weld output terminals.

Y Failure to properly connect weld

cables may cause excessive heat

and start a fire, or damage your machine.

3

Correct Installation

1 Weld Output Terminal

2 Supplied Weld Output Terminal Nut

3 Weld Cable Terminal

4 Copper Bar

Remove supplied nut from weld output ter-

3-5. Installing Work Cable And Clamp

803 778-A

Incorrect Installation

minal. Slide weld cable terminal onto weld

output terminal and secure with nut so that

weld cable terminal is tight against copper

bar. Do not place anything between weld

cable terminal and copper bar. Make

sure that the surfaces of the weld cable

terminal and copper bar are clean.

1 Work Cable

2 Boot

Route cable through front panel

opening. Slide boot onto work

cable.

3 Negative (−) Output Terminal

Connect cable to terminal and

cover connection with boot.

Close door.

1

Tools Needed:

3/4 in

2

3

Ref. 802 474-E

TM-1326 Page 5Millermatic 251

3-6. Connecting Spoolmatic) 15A Or 30A Gun

1

2

3

1 Gun Trigger Plug

Insert plug into receptacle, and

tighten threaded collar.

2 Weld Cable

3 Shielding Gas Hose

Route weld cable through opening

in front panel.

Route gas hose along side panel.

4 Positive Weld Output Terminal

Connect weld cable to weld output

terminal.

5 Regulator/Flowmeter

6 Y-Adapter Fitting

Route shielding gas hose up to

regulator/flowmeter. Connect gas

hose to Y-adapter fitting on regulator/flowmeter.

. Two welding guns may be

connected to the welding

power source at the same time,

but only one welding gun may

be in use at any one time. If the

triggers of both welding guns

are pulled at the same time, the

weld output and wirefeed motor

are disabled.

2

Tools Needed:

3/4, 5/8 in

5

6

4

3

804 455-A

TM-1326 Page 6 Millermatic 251

3-7. Setting Gun Polarity For Wire Type

Changing Polarity

1 Polarity Changeover Label

Information

Always read and follow manufacture’s

recommended polarity.

Wire Drive

Assembly Lead

+

Positive Terminal

Shown as shipped − Electrode Positive (DCEP): For

solid steel, stainless steel, aluminum, or flux core with

gas wires (GMAW).

Electrode Negative (DCEN): Reverse lead connections

at terminals from that shown above for gasless flux core

wires (FCAW). Drive assembly becomes negative.

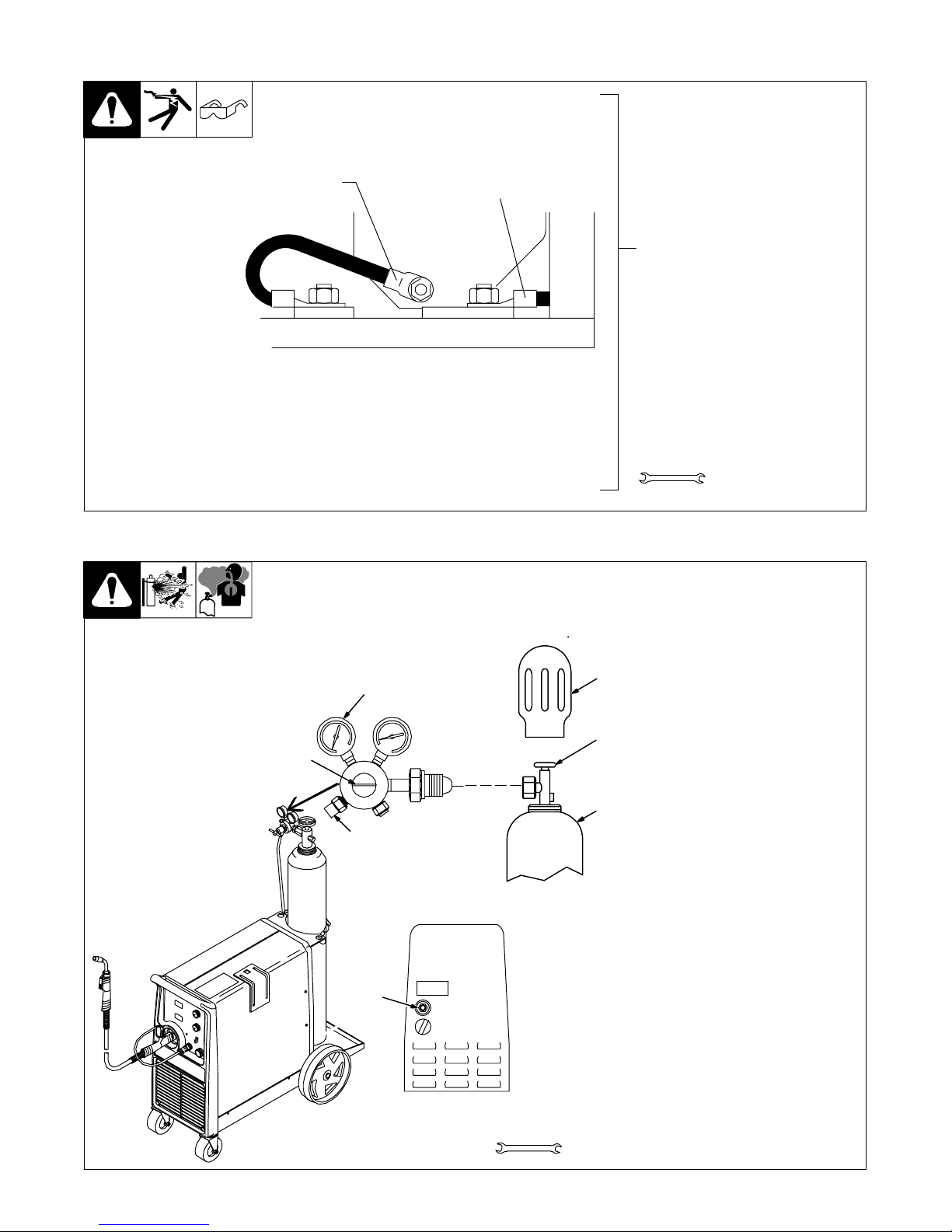

3-8. Installing Gas Supply

. DO NOT use Argon/Mixed gas regulator/flowmeter

with CO2 shielding gas. See Parts List for optional

CO2 gas regulator/flowmeter.

4

7

5

Work Clamp Lead

1

D

D

-

Negative Terminal

3/4, 11/16 in

Ref. 190 821-A

Obtain gas cylinder and chain to

running gear, wall, or other

stationary support so cylinder

cannot fall and break off valve.

1 Cap

2 Cylinder Valve

1

2

3

Argon Gas Or

Mixed Gas

6

Remove cap, stand to side of

valve, and open valve slightly. Gas

flow blows dust and dirt from valve.

Close valve.

3 Cylinder

4 Regulator/Flowmeter

Install so face is vertical.

5 Regulator/Flowmeter Gas

Hose Connection

6 Welding Power Source Gas

Hose Connection

Connect customer supplied gas

hose between regulator/flowmeter

gas hose connection, and fitting on

rear of welding power source.

7 Flow Adjust

Typical flow rate is 20 cfh (cubic

feet per hour). Check wire

manufacturer’s recommended

flow rate.

Rear Panel

Tools Needed:

1-1/8, 5/8 in

802 028-A / Ref. 802 477-B

TM-1326 Page 7Millermatic 251

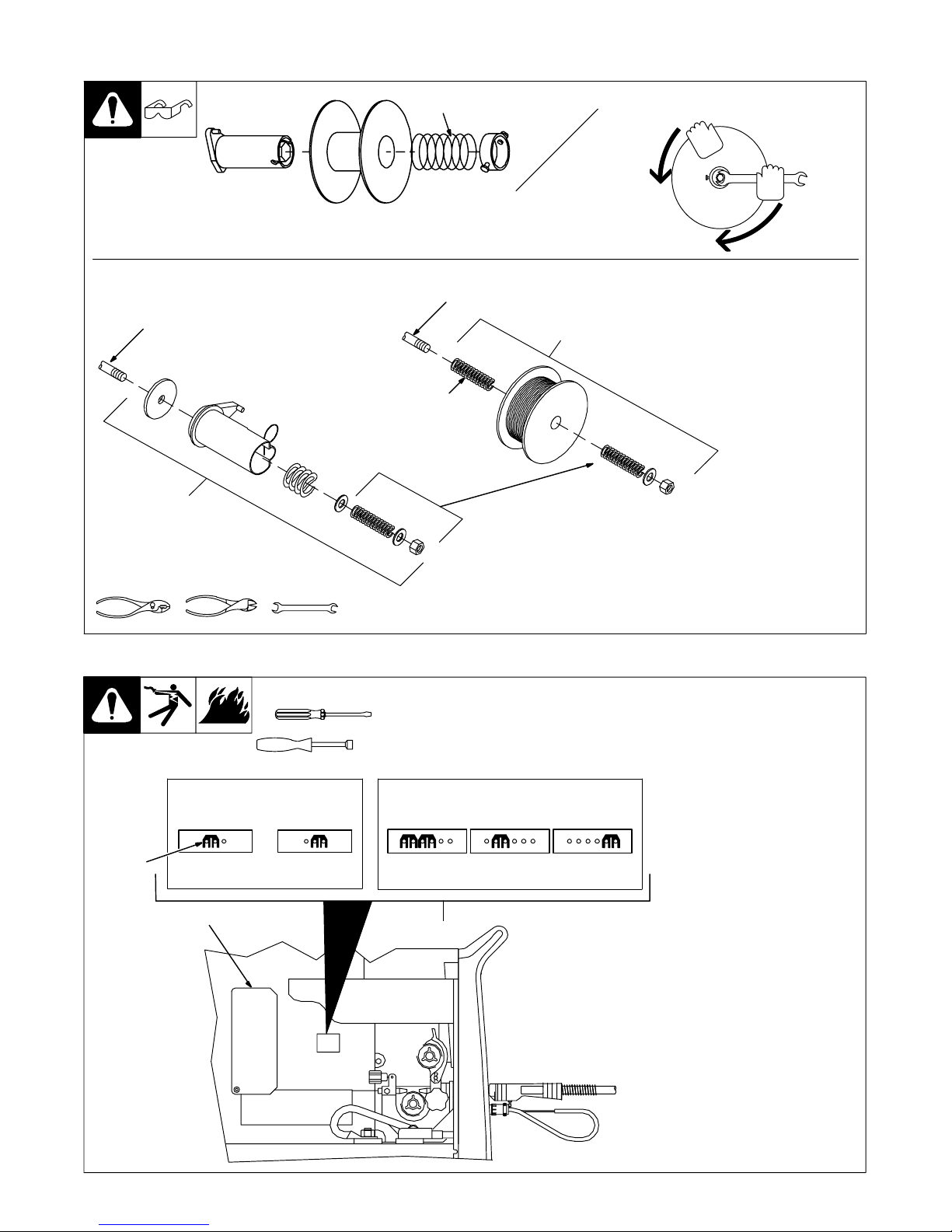

3-9. Installing Wire Spool And Adjusting Hub Tension

Installing 1 Or 2 lb Wire Spool

Spindle

Remove these

components

from spindle.

Use compression spring

with 8 in (200 mm) spools.

Spindle

Order extra spring

Part No. 186 437

Install these

components

onto spindle.

When a slight force is needed

to turn spool, tension is set.

To install either a 1 lb or 2 lb wire

spool, follow the procedure as

shown in the illustration.

Tools Needed:

15/16 in

3-10. Positioning Jumper Links

Tools Needed:

200VOLTS 230VOLTS

3

153 980-C

1

3/8 in

230VOLTS 460VOLTS 575VOLTS

2

072573-B / 802 922

Check input voltage available at

site.

1 Jumper Links Access Door

Open door.

2 Jumper Link Label

Check label − only one is on unit.

3 Input Voltage Jumper Links

Move jumper links to match input

voltage.

Close and secure access door.

144 916-D

TM-1326 Page 8 Millermatic 251

Ref. 802 476-D

3-11. Electrical Service Guide

Input Voltage 200 230 400 460 575

Input Amperes At Rated Output 48 42 24 21 17

Max Recommended Standard Fuse Or Circuit Breaker Rating In Amperes

2

Circuit Breaker 1, Time-Delay

Normal Operating

Min Input Conductor Size In AWG

4

Max Recommended Input Conductor Length In Feet (Meters)

Min Grounding Conductor Size In AWG

4

Reference: 2005 National Electrical Code (NEC) (including article 630)

1 Choose a circuit breaker with time-current curves comparable to a Time Delay Fuse.

2 “Time-Delay” fuses are UL class “RK5” .

3 “Normal Operating” (general purpose − no intentional delay) fuses are UL class “K5” (up to and including 60 amp), and UL class “H” ( 65 amp and

above).

4 Conductor data in this section specifies conductor size (excluding flexible cord or cable) between the panelboard and the equipment per NEC Table

310.16. If a flexible cord or cable is used, minimum conductor size may increase. See NEC Table 400.5(A) for flexible cord and cable requirements.

Y Caution: Failure to follow these fuse and circuit breaker recommendations could create an electric shock or fire hazard. These

recommendations are for a dedicated branch circuit that applies to the rated output and duty cycle of the welding power source.

60 50 30 25 20

3

70 60 35 30 25

8 8 12 12 14

96

(29)

127

(39)

156

(47)

8 10 12 12 14

206

(63)

209

(64)

TM-1326 Page 9Millermatic 251

3-12. Selecting A Location And Connecting Input Power

1

18 in (457 mm) of

space for airflow

8

6

4

1

L1

=GND/PE Earth Ground

10

7

9

5

L2

2

Y Do not move or operate

unit where it could tip.

3

L1L2

Y Installation must meet all National

and Local Codes − have only qualified

persons make this installation.

Y Disconnect and lockout/tagout input

power before connecting input conductors from unit.

Y Always connect green or green/yel-

low conductor to supply grounding

terminal first, and never to a line terminal.

Y Special installation may be required

where gasoline or volatile liquids are

present − see NEC Article 511 or CEC

Section 20.

1 Rating Label

Supply correct input power.

2 Plug (NEMA Type 6-50P)

3 Receptacle

[NEMA Type 6-50R (Customer

Supplied)]

4 Input Power Cord.

Connect directly to line disconnect device if

hard wiring is required.

5 Black And White Input Conductor (L1

And L2)

6 Green Or Green/Yellow Grounding

Conductor

7 Disconnect Device (switch shown in

the OFF position)

8 Disconnect Device Grounding Terminal

230 VAC, 1

Ref. 802 477-B / 803 766-B

9 Disconnect Device Line Terminals

Connect green or green/yellow grounding

conductor to disconnect device grounding

terminal first.

Connect input conductors L1 and L2 to

disconnect device line terminals.

10 Over-Current Protection

Select type and size of over-current

protection using Section 3-11 (fused

disconnect switch shown).

Connect plug to receptacle if hard wiring

method is not used.

Close and secure door on disconnect device.

Remove lockout/tagout device, and place

switch in the On position.

TM-1326 Page 10 Millermatic 251

3-13. Threading Welding Wire

1 Wire Spool

2 Welding Wire

3 Inlet Wire Guide

4 Pressure Adjustment Knob

5 Drive Roll

4

6 Outlet Wire Guide

7 Gun Conduit Cable

Lay gun cable out straight.

7

Tools Needed:

35

621

. Hold wire tightly to keep it

from unraveling.

6 in

(150 mm)

Open pressure assembly. Pull and hold wire; cut off end. Push wire thru guides into gun;

Tighten

. Use pressure indicator

scale to set a desired

drive roll pressure.

1

2

3

4

Pressure

Indicator

Scale

continue to hold wire.

Close and tighten pressure

assembly, and let go of wire.

Press gun trigger until wire

comes out of gun. Reinstall

contact tip and nozzle

Remove gun nozzle and contact tip. Turn On.

Tighten

1

2

3

WOOD

4

Feed wire to check drive roll pressure.

Tighten knob enough to prevent slipping.

Cut off wire. Close

and latch door.

Ref. 802 064-D / S-0627-A

TM-1326 Page 11Millermatic 251

3-14. Using Gun/Cable Holder

2

4

1

1 Side Panel

2 Latch

3 Cable Holder

Press latch down to release and

open door.

3

4 Holster (2)

Wrap cable around cable holder,

and place gun nozzle into holster.

Ref. 802 726-A

TM-1326 Page 12 Millermatic 251

Notes

TM-1326 Page 13Millermatic 251

3-15. Weld Parameters

TM-1326 Page 14 Millermatic 251

201 202-A

TM-1326 Page 15Millermatic 251

SECTION 4 − OPERATION

4-1. Controls

4

5

3

. This unit has three automatic timers included in its operation to

help save contact tips, gas, and wire:

Tip Saver − Weld output shuts off if tip is shorted to work surface.

Safety shut-off − Weld output will shut off if no arc is detected within 3

seconds after gun trigger is depressed.

Jog mode − When loading a new roll of wire or if the gun trigger is

accidentally pressed, gas will shut off after 1 minute and wire will shut off

after 2 minutes saving wire and gas.

1 Voltage Control

Turn control clockwise to increase

voltage.

2 Wire Speed Control

Turn control clockwise to increase wire

feed speed.

JOG Mode

If the trigger on either gun is held for

more than 3 seconds without striking

1

an arc, the unit will automatically shut

off weld power (and shielding gas

output on MIG gun only), but will feed

wire continuously at the preset wire

feed speed (which may be faster or

slower than Run−in Speed) until trigger

is released.

Run−in Wire Feed Speed Settings

Run−in settings for the MIG and Spool

Guns are independently set and stored

in unit memory. The settings are in

percent of the welding wire feed speed

2

preset. Both settings are adjustable

from 25 to 150 percent.

MIG Gun Run−in is factory set at 100%

which is recommended for most wire

sizes and types.

Spool Gun Run−in is factory set at 50%

which is recommended for .030 & .035

wire. A Run−in setting of 25% is

recommended for .047 wire.

To check Run−in settings, start with

the power switch OFF. Press and hold

the MIG or Spool Gun Trigger while

turning the power switch ON. The unit

will power up with both the displays

reading 888 , then the voltage display

will read −−− and the wire feed display

will read the preset Run−in percentage

from memory for the gun selected. To

return to the weld mode without

making a change, simply release

trigger and pull the trigger again

momentarily (one second).

To change Run−in settings, start with

the power switch OFF. Press and hold

the MIG or Spool Gun Trigger while

turning the power switch ON. The unit

will power up with both the displays

reading 888 , then the voltage display

will read −−− and the wire feed display

will read the preset Run−in percentage

from memory for the gun selected. To

change the Run−in value, release the

trigger and turn the wire feed control

knob (or the wire feed adjustment knob

located on the bottom handle of the

spool gun) to the desired setting for the

selected gun. To return to weld mode

after the Run−in speed change, pull

the trigger momentarily (one second).

3 Power Switch

4 Voltmeter

5 Wire Feed Speed Meter

TM-1326 Page 16 Millermatic 251

Ref. 205 637

4-2. Voltmeter And Wire Feed Speed Meter Operation

1

2

1 Voltmeter

2 Wire Feed Speed Meter

Power Up Status

Both meters display 888 at unit power up.

After one second, preset values appear on

both meters. The MIG gun settings (not

spool gun) are always the default at initial

power up of the unit. If the power is reset to

quickly, characters other than 888 may ap-

pear. To reset, turn power off for at least 3

seconds, then turn power back on.

Welding Status

When either a MIG gun or spool gun trigger

is pressed and a welding arc is established,

the voltmeter displays actual weld voltage.

When the gun trigger is released and

welding arc extinguished, the voltmeter

displays the last actual voltage for 5

seconds and then returns to preset voltage.

If welding resumes before unit displays

preset voltage, actual welding voltage will

appear on the voltmeter.

The wire feed speed meter always displays

preset wire feed speed (IPM).

Gun Selection

The wire feed speed meter will display

preset wire feed speed (IPM) for the

appropriate gun selection either MIG or

spool gun. To preset desired wire feed

speed, connect desired gun, press gun

trigger for one second, and release trigger.

The meter preset will be retained by the

meter board until a different gun is

connected and preset is performed or the

unit is turned off and back on. The MIG gun

settings (not spool gun) are always the

default at initial power up of the unit.

Error Messages

Volt Meter Display (HL.P)

Wire Feed Speed Display (001)

HL.P 001 − Communication Lost between

Control Board PC1 and Display Board PC2

HL.P 002 − Unit over temperature, unit is in-

operative until temperature is reduced inside unit (see Section 6-1)

HL.P 003 − No Open Circuit Voltage (OCV)

detected when either trigger is pulled

HL.P 004 − Gun trigger was engaged for

approximately 2 minutes with no arc

detected, or weld wire is stuck causing a

direct short. If HL.P 004 occurs during

power up, see Section 6-1.

HL.P 005 − Wire feed malfunction. Check

wire feed delivery system (see Section

6-1).

See Section 6-1 for additional information

on all HL.P codes.

TM-1326 Page 17Millermatic 251

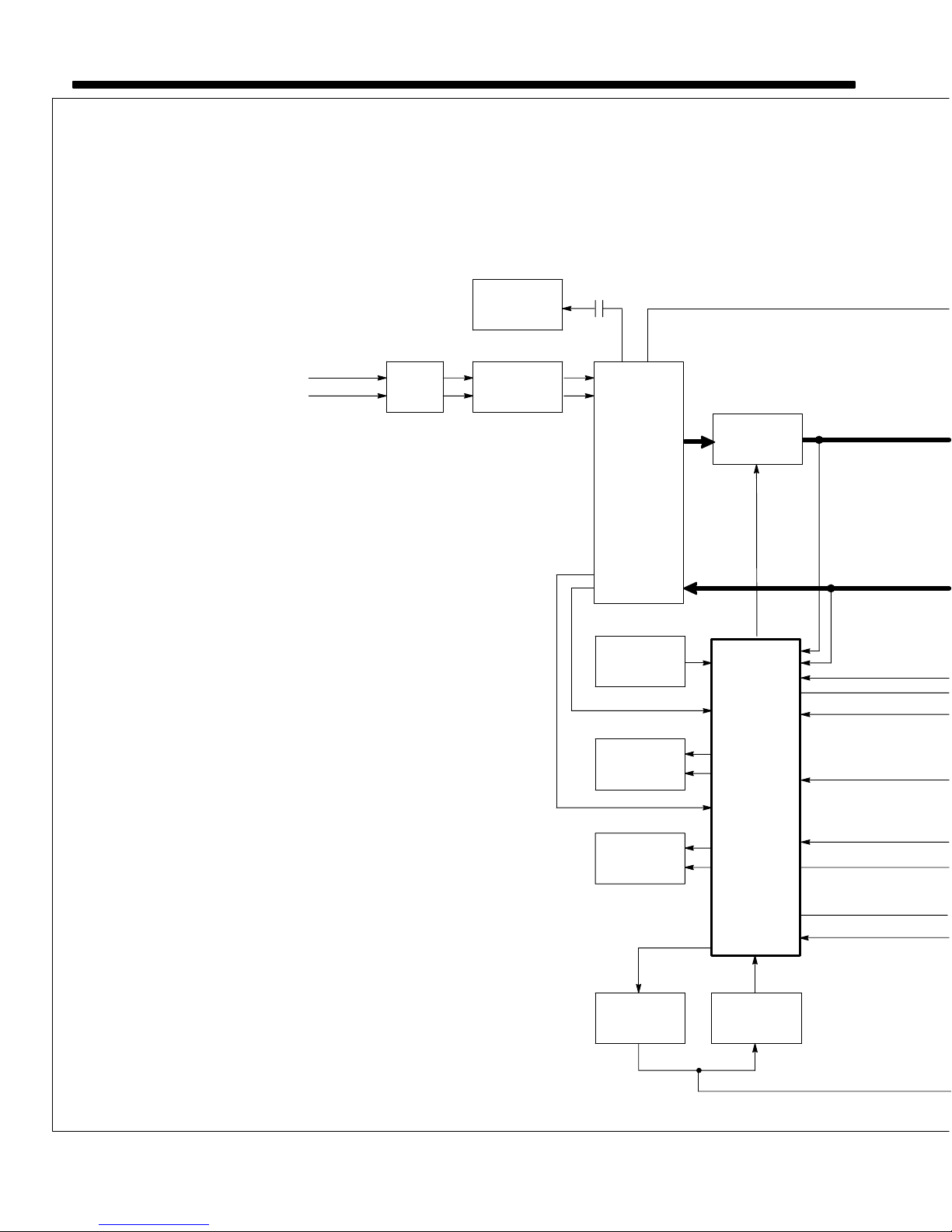

SECTION 5 − THEORY OF OPERATION

1 Power Switch S1

Turns unit on and off.

2 Input Terminal Board TE1

Provides means for operation on

different input voltages.

3 Main Transformer T1

Supplies power to weld output cir-

cuit, main control board PC1, other

control circuits, and fan motor FM.

4 Fan Motor FM

Controlled by thermistor, and fan

control relay CR1.

5 Rectifier SR1

SR1 Changes the ac output from T1

to full-wave rectified dc.

6 Capacitor Bank C5, Burden

Resistor R1

C5 filters the dc output voltage of

SR1; R1 discharges C5 when unit is

not triggered.

7 Stabilizer Z1

Smooths out current to positive (+)

output terminal on wire drive

assembly.

Start winding and contactor W

changes characteristic of stabilizer

Z1 during arc start operation.

8 Positive (+) And Negative (−)

Output Terminals

Provide weld output and allow

changing of output polarity.

9 Main Control Board PC1

Controls weld output by changing

the SCR gate pulses (conduction

times) after comparing voltage

feedback signal to selected voltage

signal.

Monitors unit temperature.

Controls wire speed by changing

the pulse width modulation signal

(wider or narrower pulses meaning

more or less voltage to motor) after

comparing motor speed feedback

voltage signal to selected voltage

signal.

Single-Phase

Line Input Power

A. Block Diagram

4

Fan Motor

FM

12 3

Power

Switch

S1

Input

Terminal

Board TE1

CR1

24 VAC

24 VAC

Main

Transformer

T1

10

Thermistor T

11

Gas Valve

GS1

Contactor W

24 VAC

5

Rectifier

SR1

9

Main

Control

Board PC1

SCR

Gate

Pulses

Voltage

Feedback

TM-1326 Page 18 Millermatic 251

12 13

Circuit

Breaker

CB1

Wire Drive

Motor PM

Pulse Width

Modulation

6

Burden

Resistor

4

Fan

Control

Relay CR1

R1

6

Capacitor

Bank C5

7

Stabilizer Z1

Contactor W

19

And Start

Winding

Reed

Relay

87

Positive (+)

Output

Terminal

8

Negative (−)

Output

Terminal

Wire

Drive

Assembly

Electrode

Work

10 Thermistor T

If unit overheats, PC1 disables unit

stopping all weld output.

11 Gas Valve GS1

Controlled by circuitry on main

control board PC1.

12 Circuit Breaker CB1

CB1 Protects wire drive motor PM

and spool gun motor circuits.

13 Wire Drive Motor PM

Feeds wire at a speed set by R3.

14 Wire Speed Control R3

Selects wire speed.

15 Voltage Control R2

Selects weld output voltage level.

16 Gun Trigger Receptacle RC1

Connects gun trigger circuit to

welding power source.

17 Receptacle RC7

Connects optional Spoolmatic 30A

welding gun.

18 Meter Board PC2

Voltmeter, Wire Feed Speed meter,

and HELP message displays.

19 Reed Relay

Senses weld current and changes

mode from start to weld.

14

Wire Speed

Control R3

16

Gun Trigger

Receptacle

RC1

15

Control R2

Voltage

17

Spool Gun

Receptacle

10-Pin

RC7

18

Meter

Board

PC2

AC Or DC Control Circuits

1φ Power

Weld Current Circuit

TM-1326 Page 19Millermatic 251

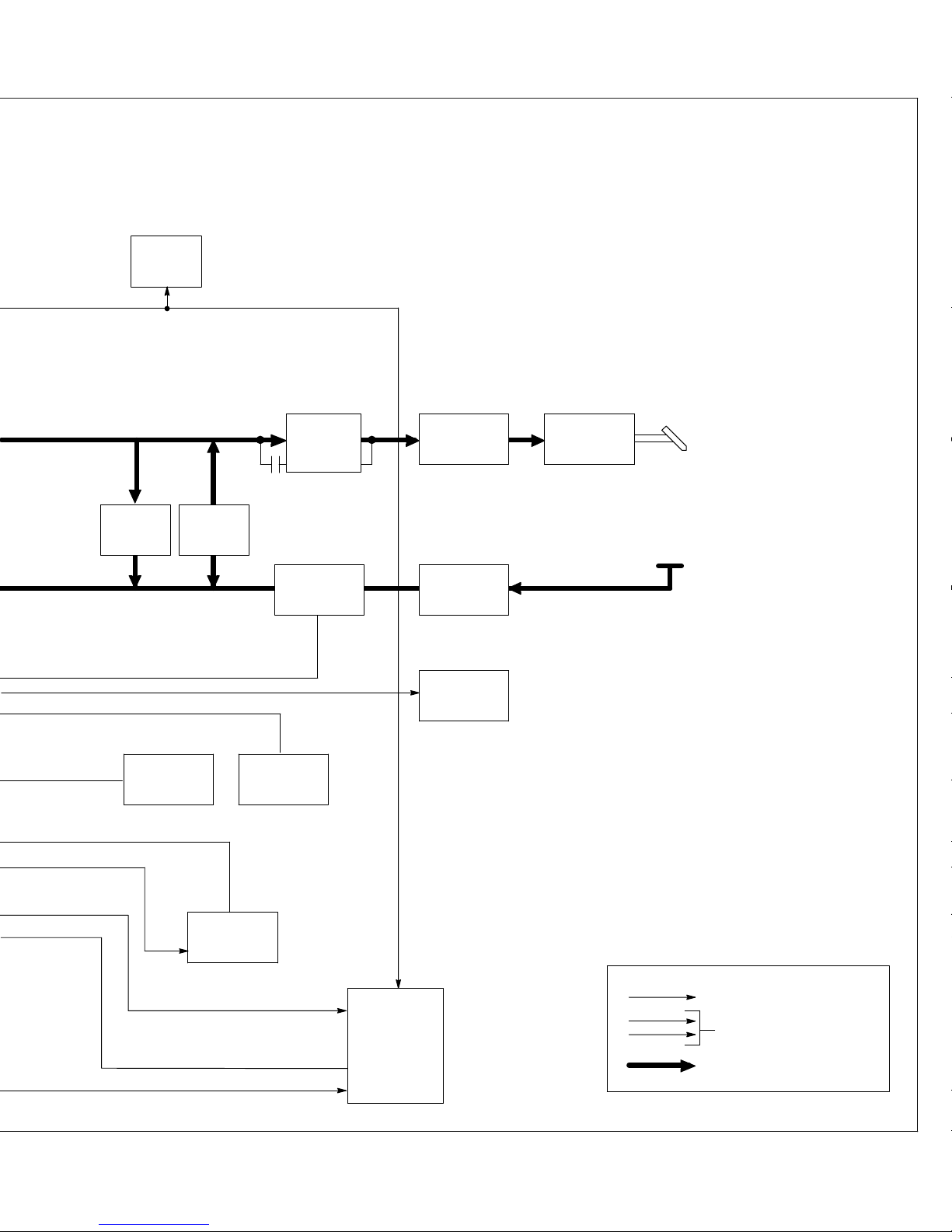

B. Basic Training Circuit

TM-1326 Page 20 Millermatic 251

Loading...

Loading...