Miller Maxstar 152, Maxstar 175 Owner's Manual

June 1993 Form: OM-206C

Effective With Serial No. KD375312

OWNER’S

MANUAL

CC/DC Welding Power Source

For GTA W And SMAW Welding

120 A At 25 V Or 140 A At 25.6 V , 100% Duty Cycle

152 Model: Single-Phase; 175 Model: Three-Phase Input Power

Thermostat Protection Against Overheating

Touch Start For GTAW Welding

14-Pin Remote Control Receptacle

Read and follow these instructions and all

safety blocks carefully.

Have only trained and qualified persons

install, operate, or service this unit.

Call your distributor if you do not understand

the directions.

cover 8/92 – SA-145 666-B PRINTED IN USA

Maxstar 152 And 175

Give this manual to the operator.

For help, call your distributor

or: MILLER ELECTRIC Mfg. Co., P.O. Box

1079, Appleton, WI 54912 414-734-9821

From Miller to You

Thank you and congratulations on choosing Miller. Now you can get

the job done and get it done right. We know you don’t have time to do

it any other way.

That’s why when Niels Miller first started building arc welders in 1929,

he made sure his products offered long-lasting value and superior

quality. Like you, his customers couldn’t afford anything less. Miller

products had to be more than the best they could be. They had to be the

best you could buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and service

that meets the high standards of quality and value established in 1929.

This Owner’s Manual is designed to help you get the most out of your

Miller products. Please take time to read the Safety precautions. They

will help you protect yourself against potential hazards on the worksite.

We’ve made installation and operation quick

and easy. With Miller you can count on years

of reliable service with proper maintenance.

And if for some reason the unit needs repair,

there’s a Troubleshooting section that will

help you figure out what the problem is. The

Miller is the first welding

equipment manufacturer in

the U.S.A. to be registered to

the ISO 9001 Quality System

Standard.

parts list will then help you to decide the

exact part you may need to fix the problem.

Warranty and service information for your

particular model are also provided.

Working as hard as you do

– every power source from

Miller is backed by the most

hassle-free warranty in the

business.

Miller Electric manufactures a full line

of welders and welding related equipment.

For information on other quality Miller

products, contact your local Miller distributor to receive the latest full

line catalog orindividual catalog sheets. To locate your nearest

distributor or service agency call 1-800-4-A-Miller, or visit us at

www.MillerWelds.com on the web.

Miller offers a Technical

Manual which provides

more detailed service and

parts information for your

unit. T o obtain a Technical

Manual, contact your local

distributor. Your distributor

can also supply you with

Welding Process Manuals

such as SMAW, GTAW,

GMAW, and GMA W-P.

EMF INFORMATION

NOTE

The following is a quotation from the General Conclusions Section of

the U.S. Congress, Office of Technology Assessment, Biological

Effects of Power Frequency Electric & Magnetic Fields –

Background Paper, OTA-BP-E-53 (Washington, DC: U.S.

Government Printing Office, May 1989): “. . . there is now a very large

volume of scientific findings based on experiments at the cellular

level and from studies with animals and people which clearly

establish that low frequency magnetic fields can interact with, and

produce changes in, biological systems. While most of this work is

of very high quality, the results are complex. Current scientific

understanding does not yet allow us to interpret the evidence in a

single coherent framework. Even more frustrating, it does not yet

allow us t o draw definite conclusions about questions of possible risk

or to offer clear science-based advice on strategies to minimize or

avoid potential risks.”

Considerations About Welding And The Effects Of Low Frequency Electric And

Magnetic Fields

To reduce magnetic fields in the workplace, use the following

procedures:

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cables around the body.

4. Keep welding power source and cables as far away as practical.

5. Connect work clamp to workpiece as close to the weld as

possible.

About Pacemakers:

The above procedures are among those also normally

recommended for pacemaker wearers. Consult your doctor for

complete information.

TABLE OF CONTENTS

SECTION 1 – SAFETY INFORMATION 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

mod10.1 4/93

SECTION 2 – SPECIFICATIONS

2-1. Volt-Ampere Curves 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2. Duty Cycle 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3 – INSTALLATION

3-1. Typical Process Connections 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2. Selecting A Location And Moving Welding Power Source 3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3. Selecting And Preparing Weld Output Cables 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4. Connecting To Weld Output Receptacles 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5. Remote 14 Receptacle Information And Connections 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6. Connecting Input Power 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4 – OPERATION 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5 – MAINTENANCE & TROUBLESHOOTING

5-1. Routine Maintenance 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2. Overload Protection 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3. Measuring Input Capacitor Voltage 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4. Changing Amperage/Voltage Meter Hold Function 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5. Troubleshooting 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6 – ELECTRICAL DIAGRAMS 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 7 – TUNGSTEN ELECTRODE

7-1. Selecting Tungsten Electrode 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2. Preparing Tungsten 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 8 – PARTS LIST

Figure 8-1. Main Assembly 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8-2. Module, Power & Diode (175 Model Illustrated) 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OM-206C – 6/93

1

5

6

7

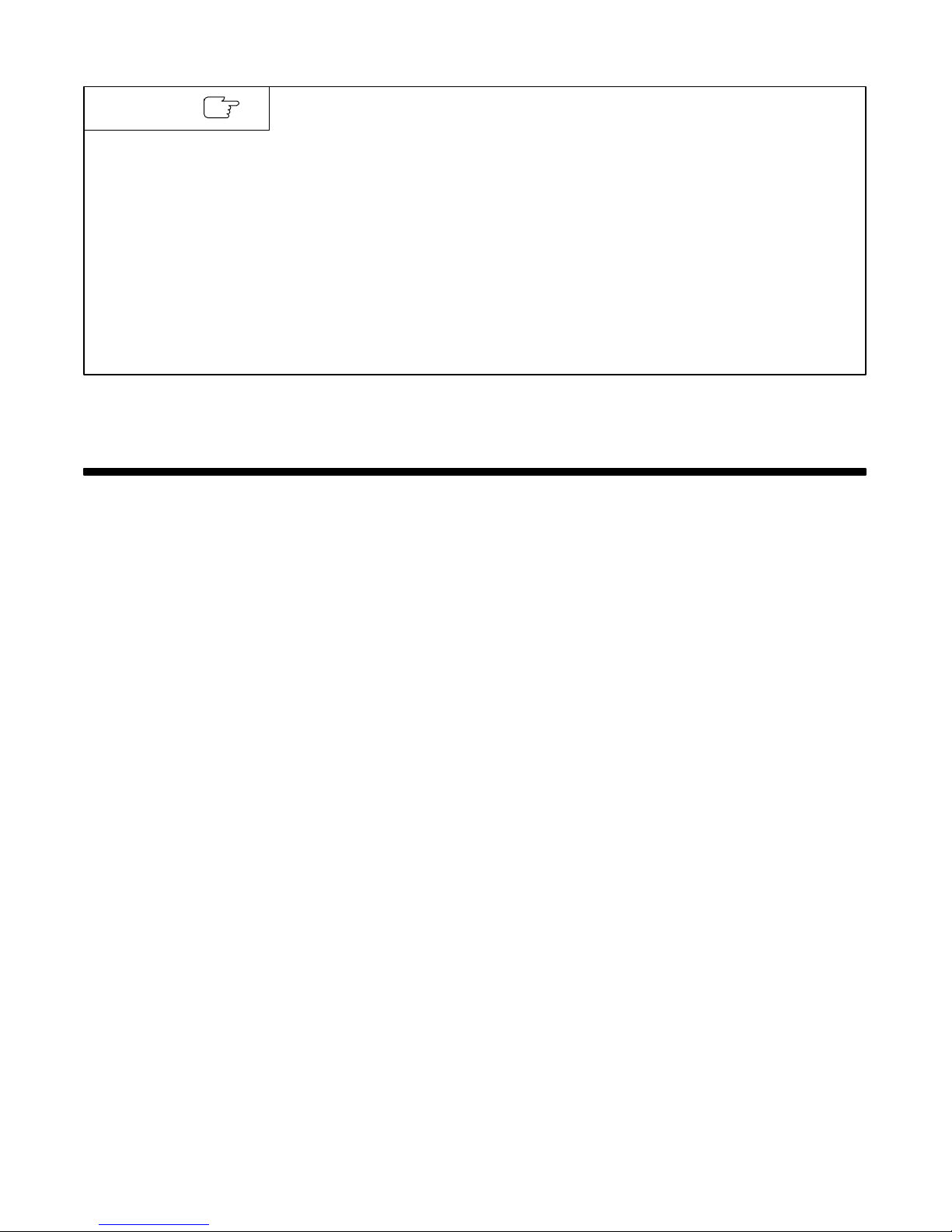

SECTION 1 – SAFETY INFORMATION

Read all safety messages throughout this manual.

Obey all safety messages to avoid injury.

Learn the meaning of WARNING and CAUTION.

2

WARNING

ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Disconnect input power before

installing or servicing.

WARNING

NOTE

Turn Off switch when using high frequency.

3

4

READ SAFETY BLOCKS at start of

Section 3-1 before proceeding.

2

CAUTION

MOVING PARTS can injure.

• Keep away from moving parts.

• Keep all panels and covers closed

when operating.

mod1.1 2/93

1 Safety Alert Symbol

2 Signal Word

WARNING means possible death

or serious injury can happen.

CAUTION means possible minor

injury or equipment damage can

happen.

3 Statement Of Hazard And

Result

4 Safety Instructions To Avoid

Hazard

5 Hazard Symbol (If Available)

6 Safety Banner

Read safety blocks for each sym-

bol shown.

7 NOTE

Special instructions for best oper-

ation – not related to safety.

Figure 1-1. Safety Information

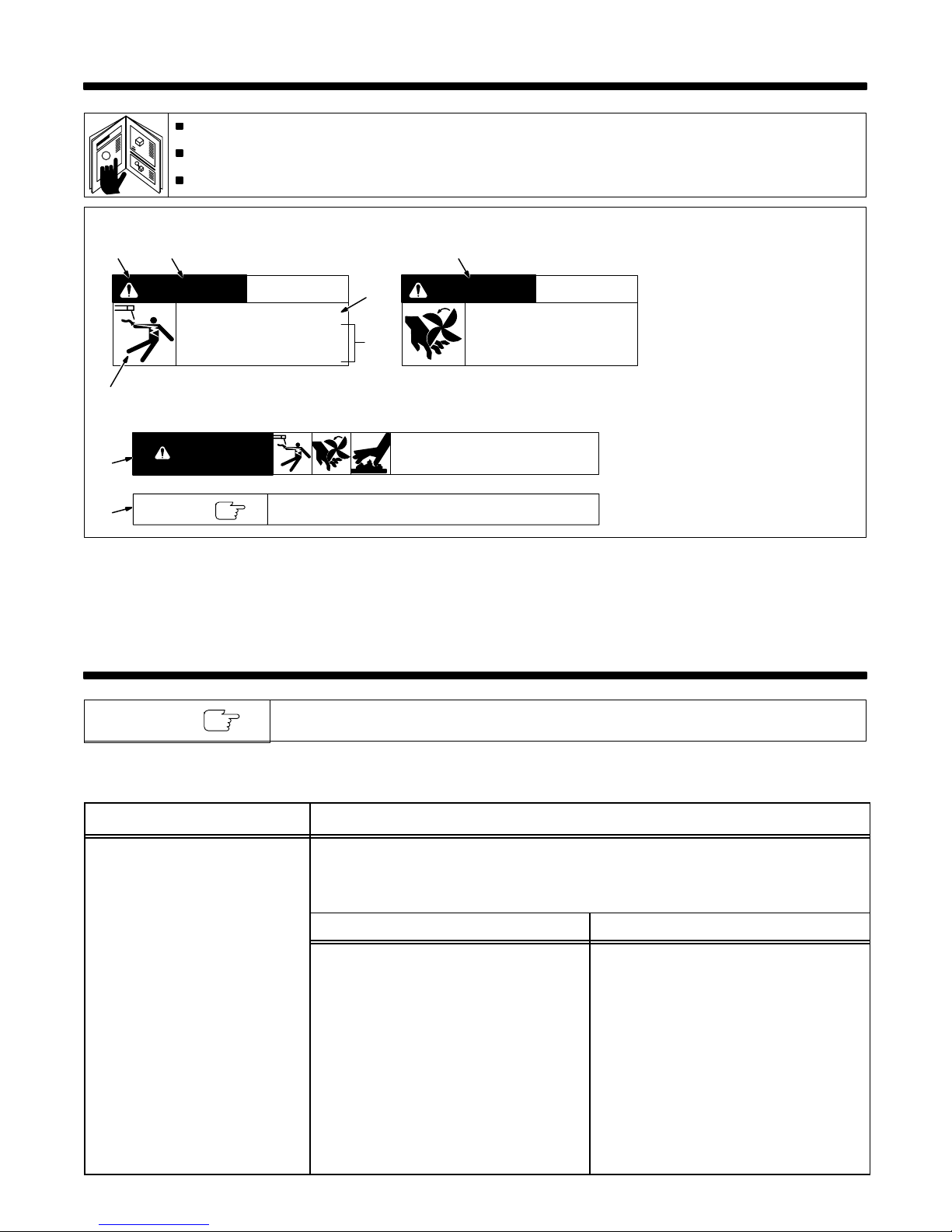

SECTION 2 – SPECIFICATIONS

NOTE

Specification Description

Type Of Output Constant Current (CC), Direct Current (DC)

Welding Process Gas Tungsten Arc (GTAW), Shielded Metal Arc (SMAW) Welding

Options See Rear Cover

Rated Weld Output 120 Amperes, 25 Volts DC At 100% Duty Cycle

Type Of Input Power 230 Volts AC; 50/60 Hz; Single Phase 460 Volts AC; 50/60 Hz; Three-Phase

Input Amperes At Rated Output 25 A 12.5 A

KVA/KW Used At Rated Output 5.85 kVA/3.8 kW 9.56 kVA/5.26 kW

Amperage Range 1-150 A 1-175 A

Max. Open-Circuit Voltage 95 Volts DC 95 Volts DC

Overall Dimensions Length: 16-1/2 in (419 mm); Width: 9-1/2 in (241

Weight Net: 31 lb (14 kg); Ship: 36 lb (16 kg) Net: 39 lb (18 kg); Ship: 42 lb (19 kg)

Unless otherwise noted, the 175 model is shown throughout this manual.

Table 2-1. Welding Power Source

152 Models 175 Models

(See Section 2-2)

mm); Height: 8 in (203 mm)

140 Amperes, 26.5 Volts DC At 100% Duty Cycle

(See Section 2-2)

Length: 16-1/2 in (419 mm); Width: 9-1/2 in (241

mm); Height: 10 in (254 mm)

OM-206 Page 1

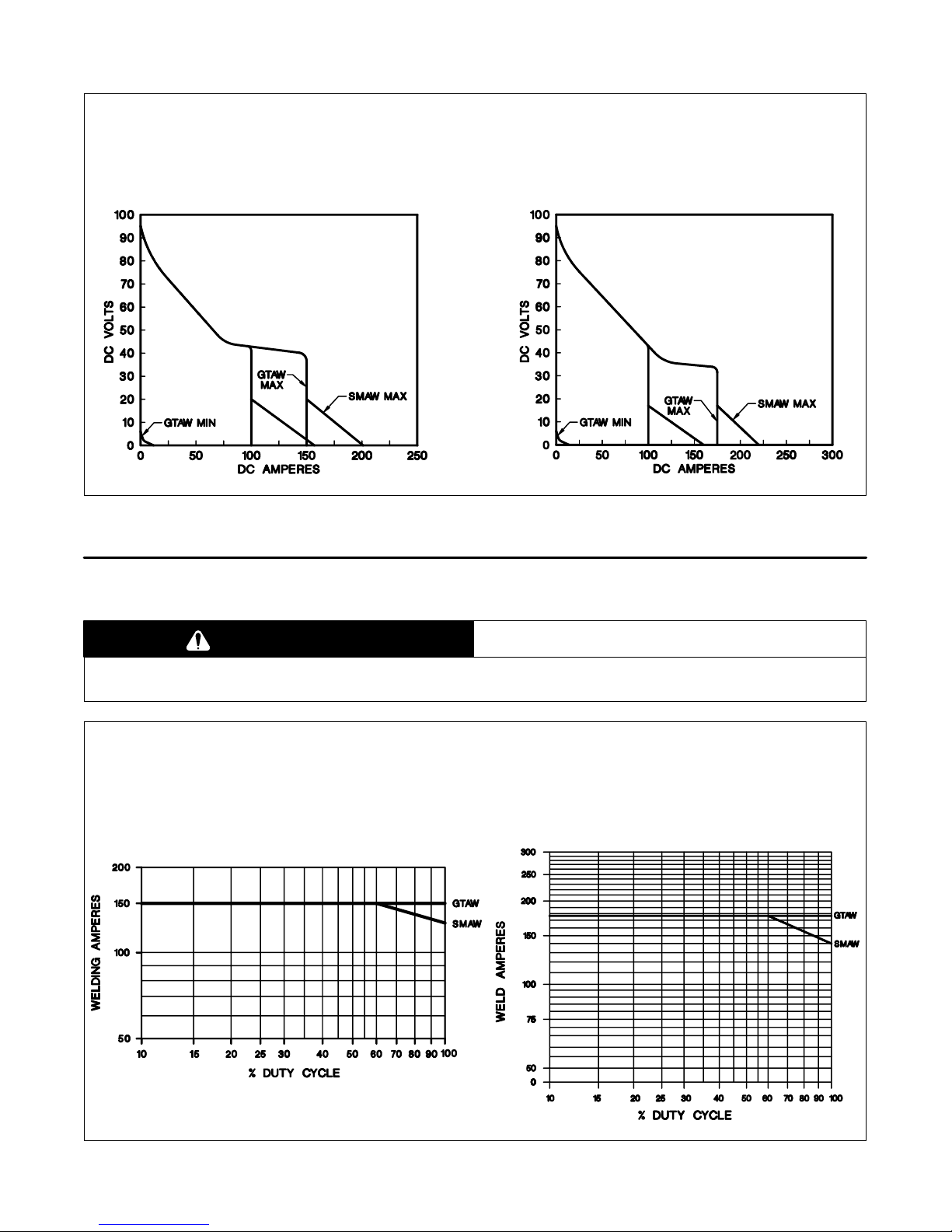

2-1. Volt-Ampere Curves

A. 152 Model B. 175 Model

The volt-ampere curves show the

minimum and maximum voltage

and amperage output capabilities

of the welding power source.

Curves of other settings fall between the curves shown.

ssb1.1 10/91 – SB-151 604 / SB-143 476-B

Figure 2-1. Volt-Ampere Curves

2-2. Duty Cycle

CAUTION

EXCEEDING DUTY CYCLE RATINGS will damage unit.

• Do not exceed indicated duty cycles.

A. 152 Model B. 175 Model

warn7.1 2/92

Duty cycle is how long the unit can

operate within a ten minute period

without causing overheating or

damage.

This unit is rated at 100% duty

cycle allowing continuous operation at rated load.

OM-206 Page 2

sb1.1 2/92 – SB-121 591-B / SB-144 507-B

Figure 2-2. Duty Cycle Chart

SECTION 3 – INSTALLATION

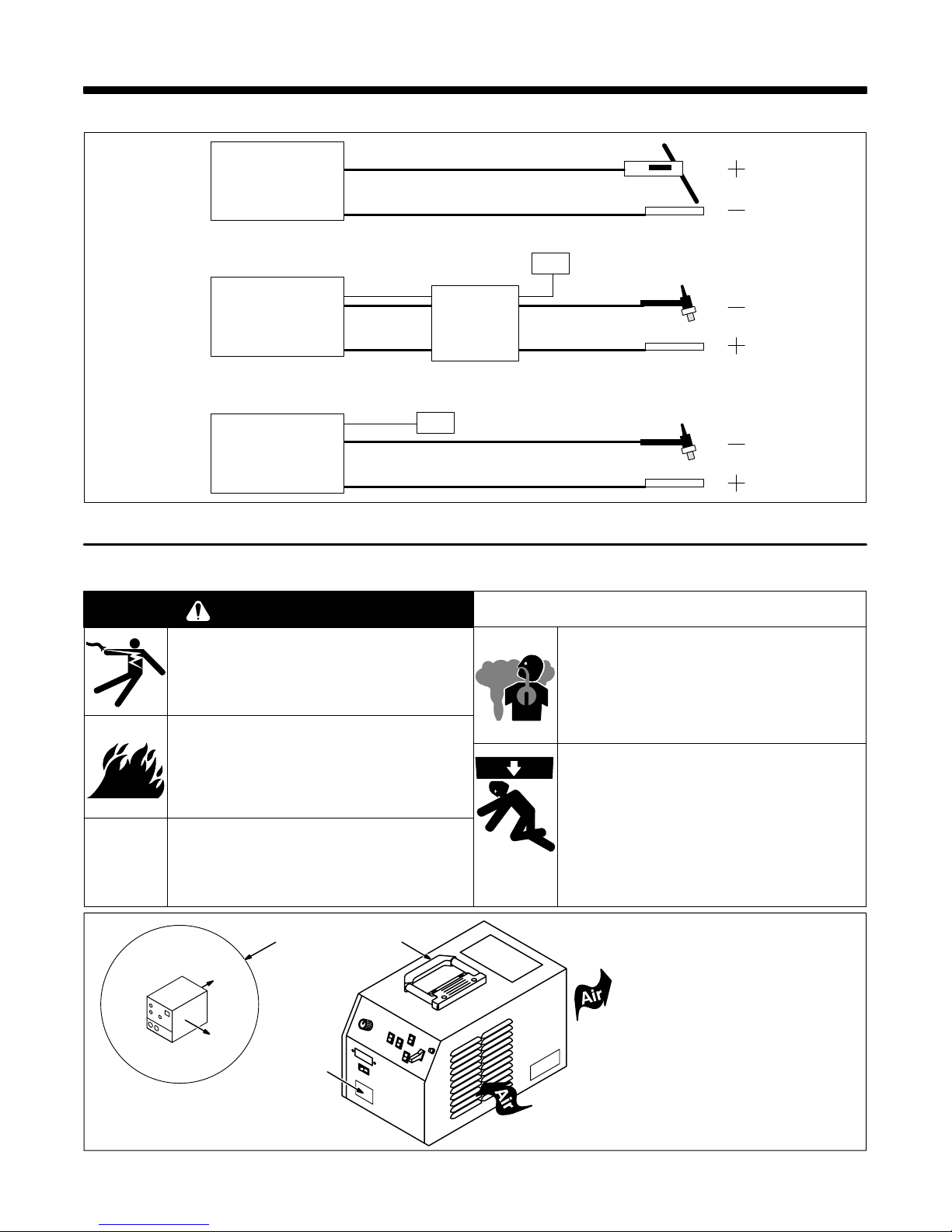

3-1. Typical Process Connections

Welding

Power Source

SMAW

Work

Remote Control

14 Pin

Welding

Power Source

Welding

Power Source

Pulse Control

14 Pin

GTAW

HF Unit

Scratch Start

Pulsed GTAW

Figure 3-1. Typical Process Connections

3-2. Selecting A Location And Moving Welding Power Source

WARNING

ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Disconnect input power conductors from

deenergized supply line BEFORE moving welding

power source.

FIRE OR EXPLOSION can result from

placing unit on, over, or near

combustible surfaces.

• Do not locate unit on, over, or near combustible

surfaces.

• Do not install unit near flammables.

BLOCKED AIRFLOW causes

overheating and possible damage to

unit.

• Do not block or filter airflow.

Warranty is void if any type of filter is used.

FUMES can be hazardous; LACK OF

FRESH AIR AND PROPER

VENTILATION can be harmful.

• Do not breathe welding fumes.

• Place unit only where there is a good fresh air

supply and proper ventilation.

FALLING EQUIPMENT can cause

serious personal injury and equipment

damage.

• Use handle to lift unit.

• Have person of adequate physical strength lift unit.

• Move unit with hand cart or similar device.

GTAW

Or

GTAW

Work

Work

swarn11.1* 2/92

1

Rear

Right

3

Figure 3-2. Location And Movement Of Welding Power Source

2

1 10 in (254 mm) Open Space

On Right Side And Rear Of

Unit For Good Airflow

2 Lifting Handle

Use handle to move unit.

3 Rating Label

Locate unit near correct input pow-

er supply.

Ref. SA-145 666-B

OM-206 Page 3

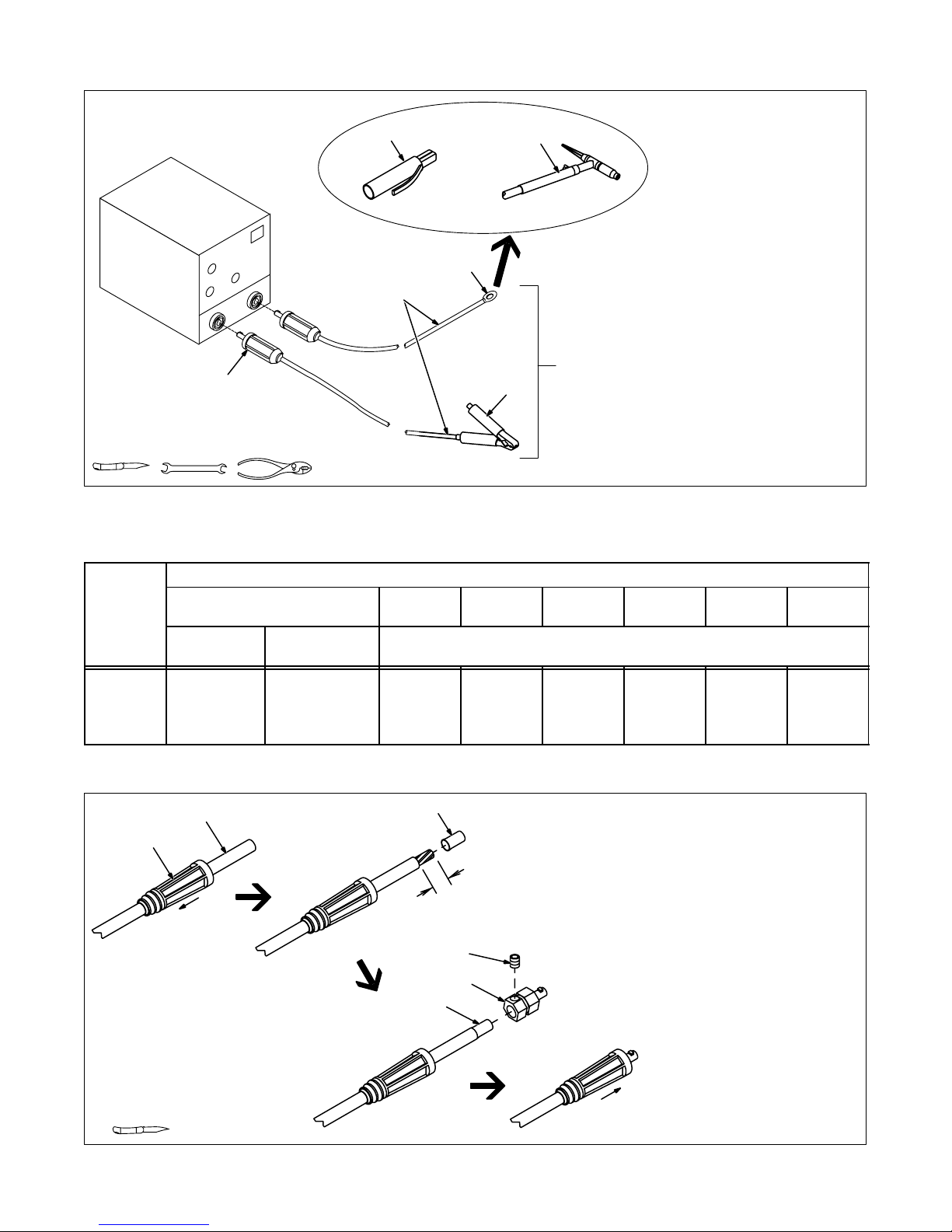

3-3. Selecting And Preparing Weld Output Cables

3

OR

2

1

10 ft (3 m)

Tools Needed:

6

10 ft (3 m)

Figure 3-3. Selecting And Preparing Weld Output Cables

5

4

For Example,

Total Cable

Length In Weld

Circuit = 20 ft (6 m)

1 Weld Output Cable

Determine total cable length in

weld circuit and maximum welding

amperes. Use Table 3-1 to select

proper cable size.

Use shortest cables possible.

Do not use damaged cables.

2 Terminal Lug

Use lugs of proper amperage

capacity and hole size for connecting to work clamp or electrode

holder.

3 Insulated Electrode Holder

4 GTAW Torch

Install according to manufacturer’s

instructions.

5 Work Clamp

Install onto work cable.

6 Dinse-Type Connector

Install onto weld cable as shown in

Figure 3-4.

sb6.2* 11/92 – S-0656

Table 3-1. Weld Cable Size*

Total Cable (Copper) Length In Weld Circuit Not Exceeding

100 ft (30 m) Or Less

Welding

Amperes

100 4 4 4 3 2 1 1/0 1/0

150 3 3 2 1 1/0 2/0 3/0 3/0

200 3 2 1 1/0 2/0 3/0 4/0 4/0

250 2 1 1/0 2/0 3/0 4/0 2-2/0 2-2/0

*Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of not more than 300 circular mils per ampere. S-0007-C

2

10 To 60%

Duty Cycle

1

60 Thru 100%

Duty Cycle

150 ft

(45 m)

3

(26 mm)

200 ft

(60 m)

250 ft

(70 m)

300 ft

(90 m)

350 ft

(105 m)

400 ft

(120 m)

10 Thru 100% Duty Cycle

1 Weld Output Cable

2 Handle

3 Sleeve

Slide handle onto cable; strip cable

1 in

5

4

3

and install sleeve.

4 Connector Body

5 Setscrew

Insert cable with sleeve fully into

connector body, tighten setscrew,

and slide handle over connector.

If job requires cable larger than 3/0

AWG, use 2 ft (610 mm) or shorter

piece of 3/0 AWG cable for DinseType connector installation. Connect other end of short cable to the

4/0 or larger weld cable.

Tools Needed:

Figure 3-4. Dinse-Type Connector Assembly

OM-206 Page 4

ST-156 496

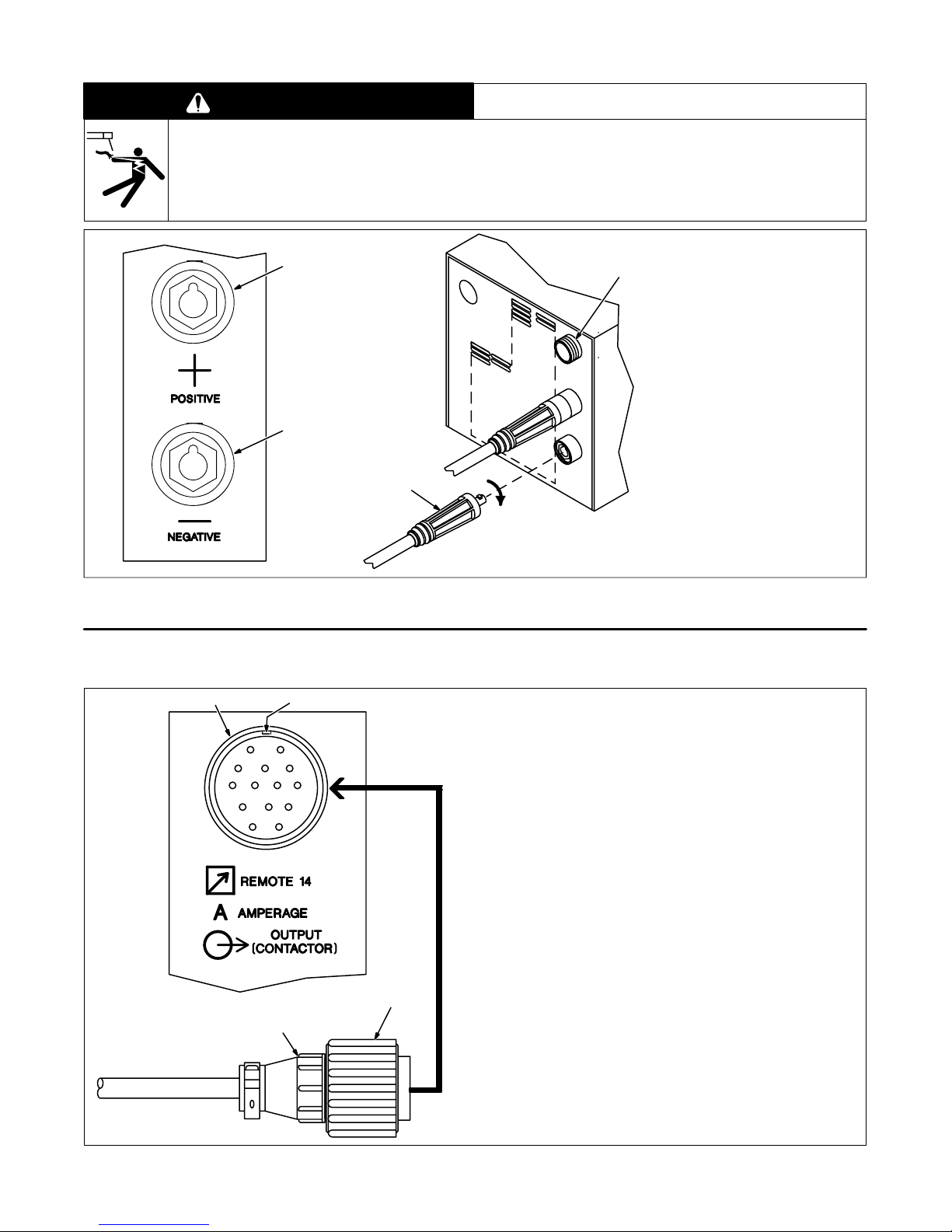

3-4. Connecting To Weld Output Receptacles

WARNING

ELECTRIC SHOCK can kill; ARCING can burn skin or damage electrical equipment.

• Do not touch live electrical parts.

• Turn Off welding power source before making any weld output connections.

• Do not change position of welding cable connectors while welding.

• Be sure connectors are secure in receptacles before welding.

1

2

3

swarn12.2 2/93

1 Positive (+) Weld Output

4

Receptacle

2 Negative (–) Weld Output

Receptacle

3 Connector

For Electrode Positive (DCEP),

connect work cable connector to

negative (–) receptacle and electrode holder cable connector to

positive (+) receptacle.

For Electrode Negative (DCEN),

reverse cable connections.

Align keyway, insert connector,

and turn clockwise.

4 Remote 14 Receptacle (see

Section 3-5).

Figure 3-5. Connecting To Weld Output Receptacles

3-5. Remote 14 Receptacle Information And Connections

1 2

AJ

K

B

L

C

D

Rear Panel

I

NH

M

G

F

E

3

Socket Information:

Remote Contactor

A +15 volts dc

B Contact closure to pin A completes +15 volts dc con-

tactor control circuit.

Remote Amperage/Voltage Control

C Command reference; +10 volts dc.

4

D Control circuit common.

E Input command signal (potentiometer wiper or 0 to

+10 volts dc).

K Chassis common.

The remaining sockets are not used.

Ref. SC-140 373 / Ref. ST-152 126

1 Remote 14 Receptacle RC7

2 Keyway

3 Plug

4 Threaded Collar

To connect to this receptacle, align

keyway, insert plug, and tighten

threaded collar.

sb7.1* 8/92 – Ref. SC-140 373 / Ref. S-0004-A / S-0750

Figure 3-6. Remote 14 Connections

OM-206 Page 5

3-6. Connecting Input Power

WARNING

ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Turn Off welding power source, and disconnect input power before inspecting or installing.

• Have only qualified persons install unit.

• Installation must meet National Electrical Code and all other codes.

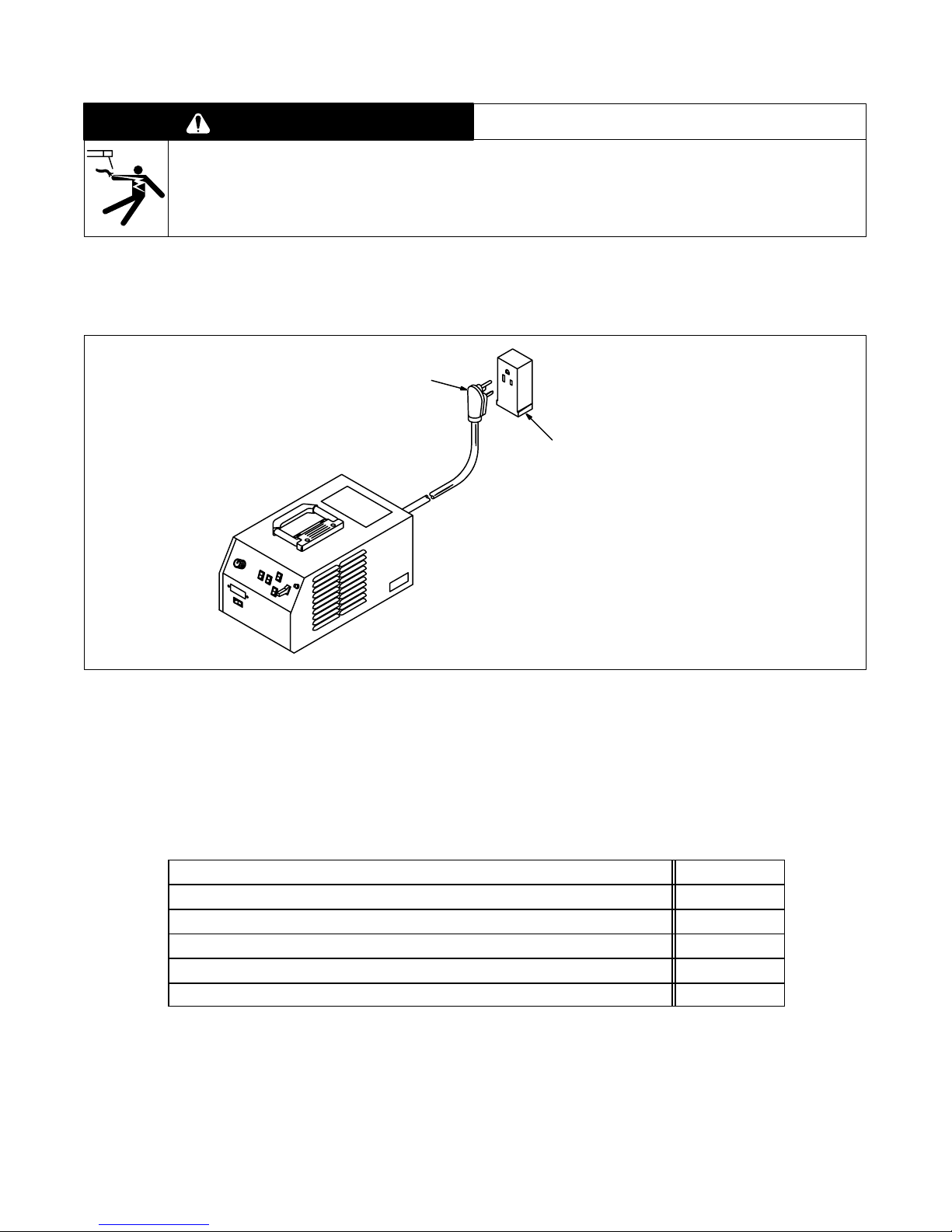

A. Connecting Input Power To 152 Models

swarn3.1 2/93

1 230 VAC Cord/Plug

1

2

2 230 VAC Grounded

Receptacle

An individual branch circuit capa-

ble of carrying 25 amperes, and

including overcurrent protection

such as fuses or circuit breaker is

required. Recommended standard

fuse or circuit breaker rating is 40

amperes.

Connect input power plug to proper

230 VAC receptacle.

Figure 3-7. Input Power Connections

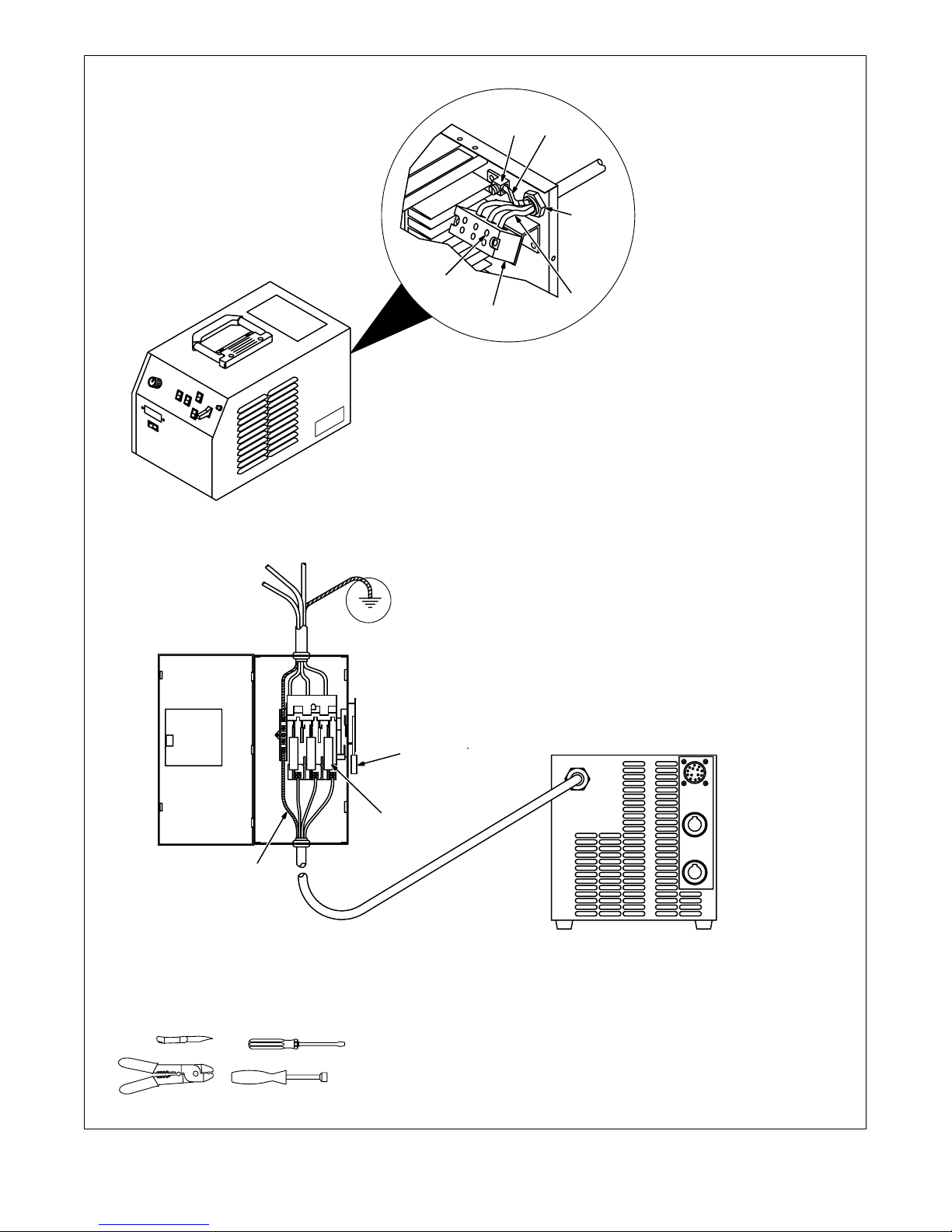

B. Connecting Input Power To 175 Models

Table 3-2. Electrical Service Requirements For 175 Ampere Models*

Input Voltage

Input Amperes At Rated Output

Recommended Standard Fuse Or Circuit Breaker Rating In Amperes

Input Conductor Size In AWG/Kcmil

Max Input Conductor Length In Feet (Meters)

Grounding Conductor Size In AWG/Kcmil

*

These values are calculated from the 1990 edition of the National Electrical Code (NEC).

1 Recommended fuse or circuit breaker size is that closest to 150% of rated input amperage of the welding power

source. Article 630-12(a) of NEC allows fuse or circuit breaker sizing up to 200% of rated input amperage.

2 Input conductor size is for insulated copper wire with 75

conductors in a cable or raceway (Table 310-16 of NEC).

3 Maximum length is to prevent more than a 3% voltage drop between service entrance and input terminals of the

welding power source (Articles 210-19(a) and 215-2(b) of NEC).

4 The grounding conductor shall be colored or identified as specified in the NEC. Grounding conductor size for

copper wire is not required to be larger than input conductor (Article 250-95 of NEC).

OM-206 Page 6

ST-156 250

460

12

1

2

3

4

20

14

326 (99)

14

°C rating with not more than three single current-carrying

S-0092-F

Have only qualified persons make

this installation.

Remove wrapper.

73

4

6

2

5

1 Line Disconnect Device Of

Proper Rating

2 Input Conductors

3 Grounding Conductor

Select size and length using

Table 3-2. Conductor rating must

comply with national, state, and local electrical codes.

Strip 3/8 in (10 mm) insulation off

all conductors.

4 Strain Relief Connector

Insert conductors through strain

relief.

5 Input Terminal Block

6 Line Terminals

7 Ground Terminal

Insert grounding conductor into

grounding terminal and tighten

screw.

Insert each input conductor into

proper screw terminal L1, L2, or L3

on terminal block and tighten

screws.

Install and connect grounding

conductor and input conductors in

conduit or equivalent to deenergized line disconnect device.

Be sure grounding conductor goes

to an earth ground.

Reinstall wrapper.

8 Overcurrent Protection

Select type and size using

Table 3-2. Install into deenergized

line disconnect device (fused

disconnect switch shown)

3

Tools Needed:

1

8

5/16 in

ssb2.4* 3/93 – ST-145 667-B / SA-145 666-B

Figure 3-8. Input Power Connections

OM-206 Page 7

Loading...

Loading...