Miller hydracool 270 CE Owner's Manual

OM-266 361B 2015−06

Processes

TIG (GTAW) Welding

MIG (GMAW) Welding

Description

Hydracool 270

CE

Visit our website at

www.MillerWelds.com

OWNER’S MANUAL

From Miller to You

Thank you and congratulations on choosing Miller. Now you can get the

job done and get it done right. We know you don’t have time to do it any

other way.

That’s why when Niels Miller first started building arc welders in 1929,

he made sure his products offered long-lasting value and superior quality.

Like you, his customers couldn’t afford anything less. Miller products had

to be more than the best they could be. They had to be the best you could

buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and service

that meets the high standards of quality and value established in 1929.

This Owner’s Manual is designed to help you get the most out of your

Miller products. Please take time to read the Safety precautions. They will

help you protect yourself against potential hazards on the worksite. We’ve

made installation and operation quick and easy. With Miller you can

count on years of reliable service with proper maintenance. And if for

some reason the unit needs repair, there’s a Troubleshooting section that

will help you figure out what the problem is. The parts list will then help

you to decide which exact part you may need to fix the problem.

Warranty and service information for your particular model are also

provided.

Working as hard as you do

− every power source from

Miller is backed by the most

hassle-free warranty in the

business.

Miller Electric manufactures a full line of

welders and welding related equipment. For

information on other quality Miller products, contact your local Miller

distributor to receive the latest full line catalog or individual catalog sheets.

TABLE OF CONTENTS

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING 1.................................

1-1. Symbol Usage 1.......................................................................

1-2. Cooling Equipment Hazards 1............................................................

1-3. Additional Symbols For Installation, Operation, And Maintenance 1.............................

1-4. California Proposition 65 Warnings 2......................................................

1-5. Principal Safety Standards 2.............................................................

SECTION 2 − DEFINITIONS 3..................................................................

2-1. Additional Safety Symbols And Definitions 3................................................

2-2. Miscellaneous Symbols And Definitions 4..................................................

SECTION 3 − SPECIFICATIONS 5..............................................................

3-1. Serial Number And Rating Label Location 5................................................

3-2. Specifications* 5.......................................................................

3-3. Coolant Chart 5........................................................................

3-4. Environmental Specifications 5...........................................................

SECTION 4 − INSTALLATION 6................................................................

4-1. Selecting a Location 6..................................................................

4-2. Installing Unit On A STH 270 Welding Power Source And Connecting 400 V AC Input Power 7......

SECTION 5 − OPERATION 8...................................................................

5-1. Control Panel 8........................................................................

SECTION 6 − MAINTENANCE & TROUBLESHOOTING 9.........................................

6-1. Routine Maintenance 9.................................................................

6-2. Coolant Maintenance 9.................................................................

6-3. Flow Direction 10.......................................................................

6-4. Troubleshooting 10......................................................................

SECTION 7 − ELECTRICAL DIAGRAM 11........................................................

SECTION 8 − PARTS LIST 12...................................................................

WARRANTY

DECLARATION OF CONFORMITY

for European Community (CE marked) products.

ITW Welding Italy S.r.l Via Privata Iseo 6/E, 20098 San Giuliano M.se, (MI) Italy declares that the prod

uct(s) identified in this declaration conform to the essential requirements and provisions of the stat

ed Council Directive(s) and Standard(s).

Product/Apparatus Identification:

Product Stock Number

HYDRACOOL 270 028042107

Council Directives:

·2006/95/EC Low Voltage

·2004/108/EC Electromagnetic Compatibility

·2011/65/EU Restriction of the use of certain hazardous substances in electrical and electronic equipment

Standards:

·IEC 60974-1:2012 Arc Welding Equipment – Part 1: Welding Power Sources

·IEC 60974-2:2013 Arc Welding Equipment – Part 2: Liquid cooling systems

·IEC 60974-10:2007 Arc Welding Equipment – Part 10: Electromagnetic Compatibility Requirements

EU Signatory:

June 30th, 2015

___________________________________________________________________________________

Massimigliano Lavarini Date of Declaration

ITW WELDING ITALY PRODUCTION MANAGER

956 172 232

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING

s

.

-

7

Protect yourself and others from injury — read, follow , and save these important safety precautions and operating instructions.

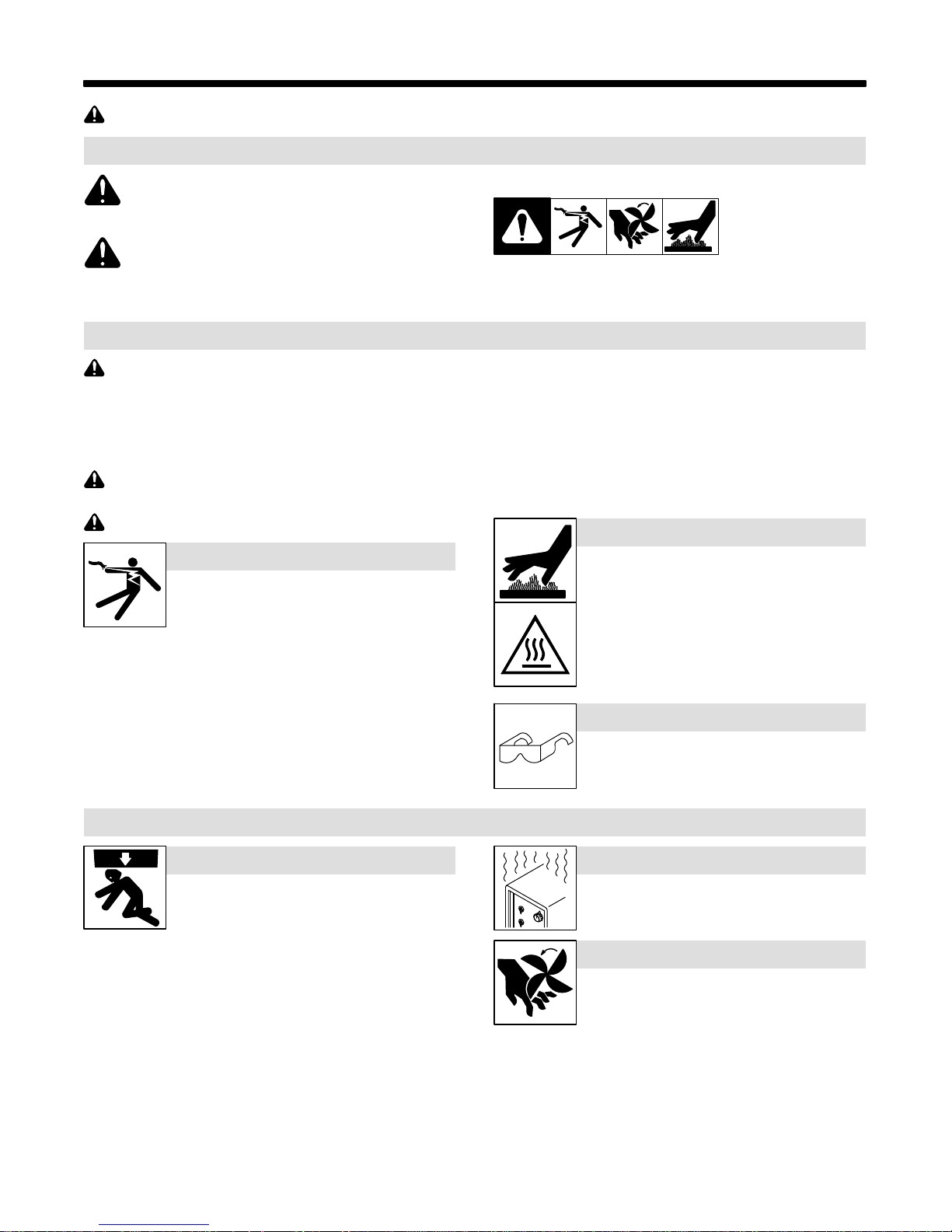

1-1. Symbol Usage

coolers 2013-10

DANGER! − Indicates a hazardous situation which, if

not avoided, will result in death or serious injury. The

possible hazards are shown in the adjoining symbols

or explained in the text.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury. The possible

hazards are shown in the adjoining symbols or explained in the text.

NOTICE − Indicates statements not related to personal injury .

1-2. Cooling Equipment Hazards

The symbols shown below are used throughout this manual

to call attention to and identify possible hazards. When you

see the symbol, watch out, and follow the related instructions

to avoid the hazard. The safety information given below is

only a summary of the more complete safety information

found in the Safety Standards listed in Section 1-5. Read and

follow all Safety Standards.

Only qualified persons should install, operate, maintain, and

repair this unit.

During operation, keep everybody, especially children, away.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shock

or severe burns. The input power circuit and machine

internal circuits are also live when power is on

Incorrectly installed or improperly grounded equip

ment is a hazard.

Do not touch live electrical parts.

Disconnect input power or stop engine before installing or

servicing this equipment. Lockout/tagout input power according to

OSHA 29 CFR 1910.147 (see Safety Standards).

Properly install, ground, and operate this equipment according to

its Owner’s Manual and national, state, and local codes.

Always verify the supply ground − check and be sure that input

power cord ground wire is properly connected to ground terminal in

disconnect box or that cord plug is connected to a properly

grounded receptacle outlet.

Indicates special instructions.

This group of symbols means Warning! Watch Out! ELECTRIC

SHOCK, MOVING P ARTS, and HOT PARTS hazards. Consult symbols and related instructions below for necessary actions to avoid the

hazards.

Keep cords dry, free of oil and grease, and protected from hot metal

and sparks.

Frequently inspect input power cord and ground conductor for

damage or bare wiring – replace immediately if damaged – bare

wiring can kill.

Turn off all equipment when not in use.

Use only well-maintained equipment. Repair or replace damaged

parts at once. Maintain unit according to manual.

Keep all panels and covers securely in place.

HOT PARTS can burn.

HOT PARTS can burn.

Do not touch hot parts bare handed.

Do not touch hot parts bare handed.

Allow cooling period before working on equip-

Allow cooling period before working on equip-

ment.

ment.

To handle hot parts, use proper tools and/or

To handle hot parts, use proper tools and/or

wear heavy, insulated welding gloves and

wear heavy, insulated welding gloves and

clothing to prevent burns.

clothing to prevent burns.

FLYING ME TA L o r DIRT can injure eyes.

Wear approved safety glasses with side

shields even under your welding helmet.

1-3. Additional Symbols For Installation, Operation, And Maintenance

FALLING EQUIPMENT can injure.

Use equipment of adequate capacity to lift and

support unit.

If using lift forks to move unit, be sure forks are

long enough to extend beyond opposite side of

unit.

Keep equipment (cables and cords) away from moving vehicles

when working from an aerial location.

Follow the guidelines in the Applications Manual for the Revised

NIOSH Lifting Equation (Publication No. 94−110) when manually lifting heavy parts or equipment.

OVERUSE can cause OVERHEATING

Allow cooling period; follow rated duty cycle.

Do not block or filter airflow to unit.

MOVING PARTS can injure.

Keep away from moving parts such as fans.

Keep all doors, panels, covers, and guards

closed and securely in place.

Have only qualified persons remove doors, panels, covers, or

guards for maintenance and troubleshooting as necessary.

Reinstall doors, panels, covers, or guards when maintenance is

finished and before reconnecting input power.

OM-266 361 Page 1

READ INSTRUCTIONS.

Read and follow all labels and the Owner’s

Manual c a r e f u l l y b e f ore installing, operating, or

servicing unit. Read the safety information at

the beginning of the manual and in each

section.

Use only genuine replacement parts from the manufacturer.

1-4. California Proposition 65 Warnings

Perform maintenance and service according to the Owner’s

Manuals, industry standards, and national, state, and local codes.

Read and understand the Safety Data Sheets (SDSs) and the

manufacturer’s instructions for adhesives, coatings, cleaners,

consumables, coolants, degreasers, fluxes, and metals.

Welding or cutting equipment produces fumes or gases

which contain chemicals known to the State of California to

cause birth defects and, in some cases, cancer. (California

Health & Safety Code Section 25249.5 et seq.)

This product contains or produces a chemical known to the

state of California to cause cancer or birth defects (or other

reproductive harm). (California Health & Safety Code Section

25249.5 et seq.)

1-5. Principal Safety Standards

Safety i n W elding, Cutting, and Allied Processes, ANSI Standard Z49.1,

is available as a free download from the American Welding Society at

http://www.aws.org o r purchased from Global Engineering Documents

(phone: 1-877-413-5184, website: www.global.ihs.com).

Safe Practices for the Preparation of Containers and Piping for W elding

and Cutting, American Welding Society Standard AWS F4.1, from Glob-

al Engineering Documents (phone: 1-877-413-5184, website:

www.global.ihs.com).

Safe Practices for W elding and Cutting Containers that have Held Combustibles, American Welding Society Standard AWS A6.0, from Global

Engineering Documents (phone: 1-877-413-5184,

website: www.global.ihs.com).

National Electrical Code, NFPA Standard 70, from National Fire Protection Association, Quincy, MA 02269 (phone: 1-800-344-3555, website:

www.nfpa.org and w w w. sparky .org).

Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet P-1,

from Compressed Gas Association, 14501 George Carter Way, Suite

103, Chantilly, VA 20151 (phone: 703-788-2700, website:

www.cganet.com).

This product contains chemicals, including lead, known to

the state of California to cause cancer, birth defects, or other

reproductive harm. Wash hands after use.

Safety in Welding, Cutting, and Allied Processes, CSA Standard

W117.2, from Canadian Standards Association, Standards Sales, 5060

Spectrum Way, Suite 100, Ontario, Canada L4W 5NS (phone:

800-463-6727, website: www.csa-international.org).

Safe Practice For Occupational And Educational Eye And Face Protection, ANSI Standard Z87.1, from American National Standards Institute,

25 West 43rd Street, New York, NY 10036 (phone: 212-642-4900, website: www.ansi.org).

Standard for Fire Prevention During Welding, Cutting, and Other Hot

Work, NFP A Standard 51B, from National Fire Protection Association,

Quincy, M A 0 2 2 6 9 ( p h o n e : 1 - 8 0 0 - 3 4 4 - 3 555, website : w w w.nfpa.org.

OSHA, Occupational Safety and Health Standards for General Indus-

try, Title 29, Code of Federal Regulations (CFR), Part 1910, Subpart Q,

and Part 1926, Subpart J, from U.S. Government Printing Office, Superintendent of Documents, P.O. Box 371954, Pittsburgh, PA 15250-7954

(phone: 1-866-512-1800) (there are 10 OSHA Regional Offices—

phone for Region 5, Chicago, is 312-353-2220, website:

www.osha.gov).

Applications Manual for the Revised NIOSH Lifting Equation, The National Institute for Occupational Safety and Health (NIOSH), 1600

Clifton Rd, Atlanta, GA 30333 (phone: 1-800-232-4636, website:

www.cdc.gov/NIOSH).

OM-266 361 Page 2

Loading...

Loading...