Miller GW-55C, GW-55P Owner's Manual

Millerfi

August

1990

FORM:

OM-1541A

Effective

With

Style

No.

JK-48

MODEL:

GW-55C

GW-55P

OWNERS

MANUAL

IMPORTANT:

Read

and

understand

the

entire

contents

of

both

this

manual

and

the

power

source

manual

used

with

this

unit,

with

special

emphasis

on

the

safety

material

throughout

both

manuals,

before

installing,

operating,

or

maintaining

this

equipment.

This

unit

and

these

instructions

are

for

use

only

by

persons

trained

and

experienced

in

the

safe

operation

of

welding

equip

ment.

Do

not

aliow

untrained

persons

to

instaii,

operate,

or

maintain

this

unit.

Contact

your

distributor

if

you

do

not

fuiiy

understand

these

instructions.

MILLER

ELECTRIC

Mfg.

Co.

A

Miller

Group

Ltd..

Company

P.O.

Box

1079

Appleton,

WI

54912

USA

Tel.

414-734-9821

PRINTED

IN

lJ.S.A

u-I-

LIMITED

WARRANTY

EFFECTIVE:

AUGUST

6,

1990

U

This

warranty

supersedes

all

previous

MILLER

warranties

and

is

exclusive

withnoother

guarantees

or

warranties

expressed

or

implied.

LIMITED

WARRANTY

Subject

to

the

terms

and

conditions

hereof,

MILLER

Electric

Mfg.

Co.,

Appleton,

Wisconsin

war

rants

to

its

Distributor/Dealer

that

all

new

and

unused

Equipment

furnished

by

MILLER

is

free

from

defect

in

workmanship

and

materialasof

the

time

and

placeofdelivery

by

MILLER.

No

warranty

is

made

by

MILLER

with

respect

to

engines,

trade

accessoriesorother

items

manufactured

by

others.

Such

engines,

trade

accessories

and

other

items

are

sold

subject

to

the

warrantiesoftheir

respective

manufacturers,

if

any.

All

engines

are

warrantiedbytheir

manufacturer

for

two

years

from

date

of

original

purchase,

except

Deutz

engines

which

have

a

one

year,

2000

hour

warranty.

Exceptas

specified

below,

MILLERs

warranty

does

not

apply

to

components

having

normal

useful

lifeofless

than

one

(1)

year,

such

as

spot

welder

tips,

relay

and

contactor

points,

MILLERMATIC

parts

thatcome

in

contactwith

thewelclingwire

including

nozzles

and

nozzle

insulators

where

failure

does

not

result

from

defect

in

workmanship

or

material.

MILLER

shall

be

required

to

honor

warranty

claims

on

war

ranted

Equipment

in

the

event

of

failure

resulting

from

a

defect

within

the

following

periods

from

the

date

of

delivery

of

Equipment

to

the

original

user:

1.

Arc

welders,

power

sources,

robots,

and

1

year

components

2.

Load

banks

1

year

3.

Original

main

power

rectifiers

3

years

(labor

1

year

only)

4.

All

welding

guns,

feeder/guns

and

torches

.

90

days

5.

All

other

MILLERMATIC

Feeders

1

year

6.

Replacement

or

repair

parts,

exclusiveoflabor

60

days

7.

Batteries

6

months

provided

that

MILLER

is

notified

in

writing

within

thirty

(30)

days

of

the

dateofsuch

failure.

As

a

matter

of

general

policy

only,

MILLER

may

honor

claims

submitted

by

the

original

user

within

the

foregoing

periods.

In

the

case

of

MILLERs

breach

of

warranty

or

any

other

duty

with

respect

to

the

quality

of

any

goods,

the

exclusive

remedies

therefore

shall

be,

at

MILLERs

option

(1)

repair

or

(2)

replace-

mentor,

where

authorized

in

writing

by

MILLER

in

appropriate

cases,

(3)

the

reasonable

cost

of

repair

or

replacement

at

an

authorized

MILLER

service

station

or

(4)

payment

oforcredit

for

the

purchase

price

(less

reasonable

depreciation

based

upon

actual

use)

upon

return

of

the

goods

at

Customers

risk

and

expense.

MILLERs

option

of

repairorreplacement

will

be

FOB.,

Factory

at

Appleton,

Wisconsin,

or

F.O.B.

at

a

MILLER

authorized

service

facility,

therefore,

no

compensation

for

transportation

costs

of

any

kind

will

be

allowed.

Upon

receipt

of

notice

of

apparent

defect

or

failure,

MILLER

shall

instruct

the

claimant

on

the

warranty

claim

procedures

to

be

followed.

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

AND ANY

IMPLIED

WARRANTY,

GUARANTY

OR

REPRE

SENTATION

AS

TO

PERFORMANCE,

AND

ANY

REMEDY

FOR

BREACH

OF

CONTRACT

WHICH,

BUT

FOR

THIS

PROVISION,

MIGHT

ARISE

BY

IMPLICATION,

OPERATION

OF

LAW,

CUSTOM

OF

TRADE

OR

COURSE

OF

DEALING,

INCLUDING

ANY

IMPLIED

WARRANTY

OF

MERCHAN

TABILITY

OR

OF

FITNESS

FOR

PARTICULAR

PURPOSE,

WITH

RESPECT

TO

ANY

AND

ALL

EQUIPMENT

FURNISHED

BY

MILLERISEXCLUDED

AND

DISCLAIMED

BY

MILLER.

EXCEPT

AS

EXPRESSLY

PROVIDED

BY

MILLER

IN

WRITING,

MILLER

PRODUCTS

ARE

INTENDED

FOR

ULTIMATE

PURCHASE

BY

COMMERCIAL/INDUSTRIAL

USERS

AND

FOR

OPERATION

BY

PERSONS

TRAINED

AND

EXPERIENCED

IN

THE

USE

AND

MAINTENANCE

OF

WELDING

EQUIPMENT

AND

NOT

FOR

CONSUMERS

OR

CONSUMER

USE.

MILLERS

WARRANTIES

DO

NOT

EXTEND

TO,

AND

NO

RESELLER

IS

AUTHORIZED

TO

EXTEND

MILLERS

WARRANTIES

TO,

ANY

CONSUMER.

1.

UI

ERRATA

SHEET

After

this

manual

was

printed,

refinements

in

equipment

design

occurred.

This

sheet

lists

exceptions

to

data

appearing

laterinthis

manual.

AMENDMENT

TO

SECTION

3

INSTALLATION

Add

Section

3-5.

CORROSION

PREVENTION

Prevent

corrosion

in

the

torch

and

cooling

system

by

following

these

guidelines:

a.

Do

not

allow

aluminum,

steel,

cadmium

plate,

soft

(lead)

solder,

or

zinc

materials

to

contact

the

cooling

fluid.

Metal

materials

in

contact

with

the

cooling

fluid

must

be

made

of

brass,

copper,

silver

solder,

or

300

Series

stainless

steel.

b.

Use

only

good

quality

hoses

and

tubing

that

do

not

contain

carbon

or

steel

reinforcing.

c.

Use

only

brass,

plastic,

or

stainless

steel

fittings.

c.

Add

chlorine

bleach

to

the

coolant

system

to

eliminate

algae.

Add

1/2

oz.

(15

ml)

bleach

to

Radiator

and

Watermate

models

1A

and

2A.

Add

1

oz.

(30

ml)

bleach

to

Coolmate

4

models.

Using

more

than

the

specified

amount

of

bleach

in

the

coolant

system

will

increase

corrosion

and

shorten

the

life

of

the

system.

d.

If

operating

the

coolant

system

at

temperatures

below

freezing,

use

a

solution

of

ethylene

glycol

(Miller

Part

No.

128

705)

in

the

system.

Avoid

using

automotive-type

antifreezes

that

contain

anti-leak

compounds

which

could

block

torch

cooling

passages.

e.

Do

not

change

the

coolant

unless

it

becomes

discoloredorcontaminated.

Add

soft,

high

quality

tap

water,

deionized

water,

or

distilled

water

to

the

system

to

maintain

coolant

level.

f.

Make

sure

all

electrical

connections

are

tight.

Do

not

make

electrical

connections

with

connectors

made

of

different

metals.

AMENDMENT

TO

SECTION

6

PARTS

LIST

Amend

Parts

Listasfollows:

Part

Replaced

No.

With

Description

Quant~y

7-35

...

082

366

....

141

936

.

STRAIN

RELIEF,

cable

flexible

(Eff

w/KB1

9)

1

~First

digit

represents

page

no

digits

following

dash

represent

item

no.

BE

SURE

TO

PROVIDE

MODEL

AND

SERIAL

NUMBER

WHEN

ORDERING

REPLACEMENT

PARTS.

SECTION

1

-

SAFETY

PRECAUTIONS

AND

SIGNAL

WORDS

1-1.

GENERAL

INFORMATION

AND

SAFETY

1-2.

SAFETY

ALERT

SYMBOL

AND

SIGNAL

WORDS

A.

General

The

following

safety

alert

symbol

and

signal

words

are

Information

presented

in

this

manual

andonvarious

Ia-

usedthroughoutthismanualtocallattentiontoandiden

bets,

tags,

and

plates

on

the

unit

pertains

to

equipment

tify

different

levels

of

hazard

and

special

instructions.

design,

installation,

operation,

maintenance,

and

troubleshooting

which

should

be

read,

understood,

and

This

safety

alert

symbol

is

used

with

the

signal

followed

forthe

safe

and

effective

use

of

this

equipment.

words

WARNING

and

CAUTION

to

call

atten

tion

to

the

safety

statements.

B.

Safety

The

installation,

operation,

maintenance,

and

trouble-

WARNING

statements

identify

procedures

or

shooting

of

arc

welding

equipment

requires

practices

practices

which

must

be

followedtoavoid

seri

ous

personal

injury

or

toss

of

life.

and

procedures

which

ensure

personal

safety

and

the

safety

of

others.

Therefore,

this

equipment

is

to

be

in-

CAUTION

statements

identify

procedures

or

stalled,

operated,

and

maintained

onlybyqualified

per-

practices

which

must

be

followed

to

avoid

minor

sons

in

accordance

with

this

manual

and

all

applicable

personal

injuryordamage

to

this

equipment.

codes

such

as,

but

not

limited

to,

those

listed

at

the

end

of

Section

1

Safety

Rules

For

Operation

Of

Arc

Weld-

IMPORTANT

statements

identify

special

instructions

ing

Power

Source

in

the

welding

power

source

Owners

necessary

for

the

most

efficient

operation

of

this

equip

Manual.

ment.

SECTION

2-

INTRODUCTION

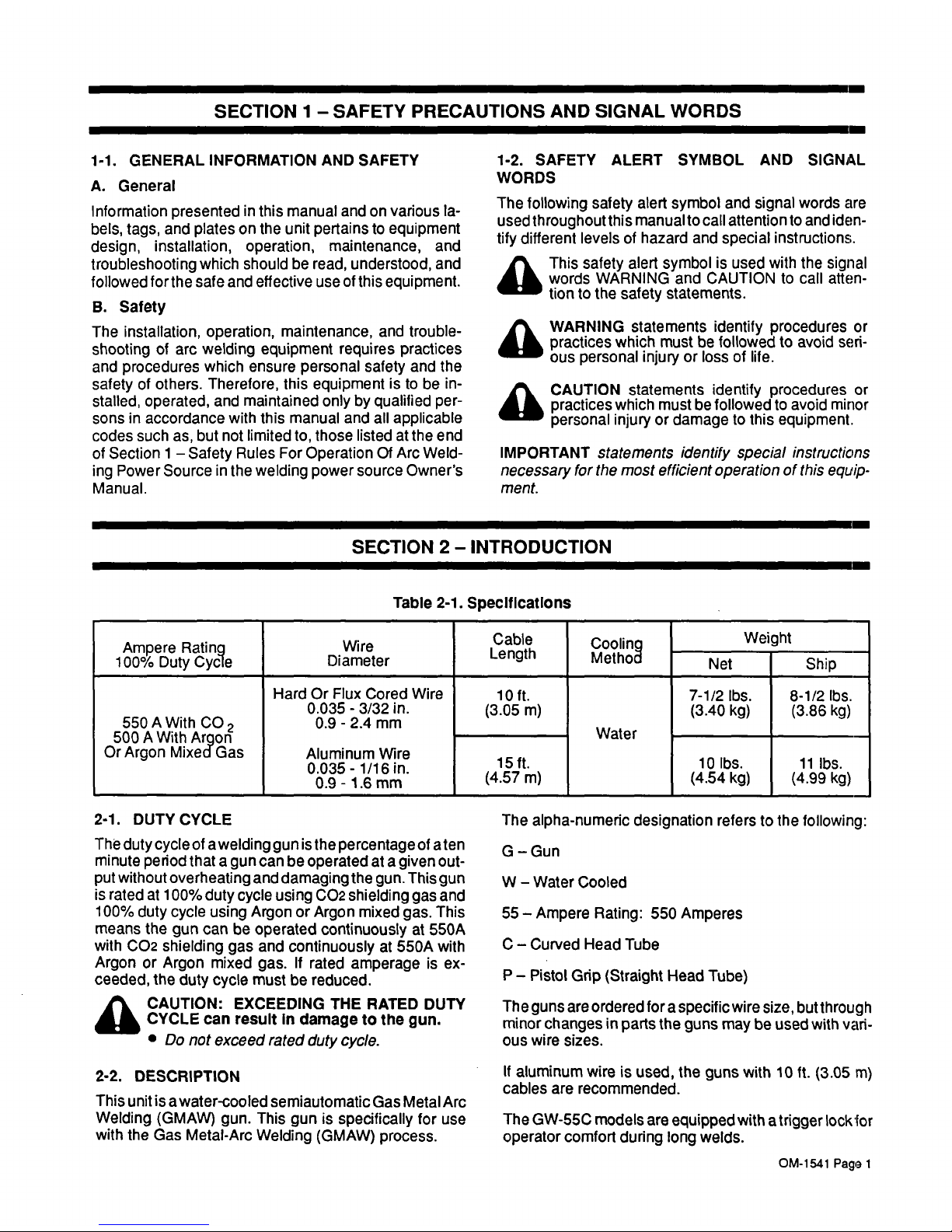

Table

2-1.

SpecifIcations

Ampere

Ratina

100%

Duty

Cycle

Wire

Diameter

Cable

Length

Cooling

Method

Weight

Net

Ship

55OAWithCO2

500

A

With

Aroon

Or

Argon

MixedGas

Hard

Or

Flux

Cored

Wire

0.035

-

3/32

in.

0.9-2.4mm

Aluminum

Wire

0.035-1/16

in.

0.9

-

1.6

mm

10

ft.

(3.05

m)

15

ft.

(4.57

m)

Water

7-1/2

lbs.

(3.40

kg)

8-1/2

lbs.

(3.86

kg)

10

lbs.

(4.54

kg)

11

lbs.

(4.99

kg)

2-1.

DUTY

CYCLE

The

alpha-numeric

designation

refers

to

the

following:

The

duty

cycle

of

awelding

gun

is

the

percentage

of

aten

GGun

minute

penod

that

a

gun

can

be

operated

at

a

given

out

put

without

overheating

and

damaging

the

gun.

This

gun

W

Water

Cooled

is

rated

at

100%

duty

cycle

using

C02

shielding

gas

and

100%

duty

cycle

using

Argon

or

Argon

mixed

gas.

This

55

Ampere

Rating:

550

Amperes

means

the

gun

can

be

operated

continuously

at

550A

with

C02

shielding

gas

and

continuously

at

550A

with

C

Curved

Head

Tube

Argon

or

Argon

mixed

gas.

If

rated

amperage

is

ex-

.

ceeded,

the

duty

cycle

must

be

reduced.

P

Pistol

Grip

(Straight

Head

Tube)

a

CAUTION:

EXCEEDING

THE

RATED

DUTY

The

guns

are

ordered

for

a

specific

wire

size,

but

through

CYCLE

can

result

In

damage

to

the

gun.

minor

changes

in

parts

the

guns

may

be used

with

van-

Do

not

exceed

rated

duty

cycle.

ous

wire

sizes.

2-2.

DESCRIPTION

If

aluminum

wire

is

used,

the

guns

with10ft.

(3.05

m)

cables

are

recommended.

This

unit

is

a

water-cooled

semiautomatic

Gas

Metal

Arc

Welding

(GMAW)

gun.

This

gun

is

specifically

for

use

TheGW-55C

models

are

equippedwithatrigger

locklor

with

the

Gas

Metal-Arc

Welding

(GMAW)

process.

operator

comfort

during

tong

welds.

OM-1541

Page

1

Loading...

Loading...