Miller Gold Star 500SSX Owner's Manual

Miller

Apri

1994

Form:

OM-168

256

Effective

With

Serial

No.

KE600689

OWNERS

MANUAL

Read

and

follow

these

instructions

and

all

safety

blocks

carefully.

Have

only

trained

and

qualified

persons

install,

operate,

or

service

this

unit.

Call

your

distributor

if

you

do

not

understand

the

directions.

Gold

Starfi

500SSX

CC/DC

Welding

Power

Source

For

SMAW

and

GTAW

Welding

510

Amperes,

41

Volts

DC,

At

35%

Duty

Cycle

Requires

Three-Phase,

50/60

Hz

Input

Power

Overheating

Protection

Arc

(Dig)

Control

Give

this

manualtothe

operator.

For

help,

call

your

distributor

or:

MILLER

Electric

Mfg.

Co.,

P.O.

Box

1079,

Appleton,

WI

54912

414-734-9821

cover

1/94

ST-cOO

599-H

'

1994

MILLER

Electric

Mfg.

Co.

PRINTEDINUSA

MILLERS

TRUE

BLUETM

LIMITED

WARRANTY

Effective

,Janu

ary

1,

1992

(Equipment

with

a

serial

number

preface

of

KC

or

newer)

This

limited

warranty

supersedes

all

previous

MtLLER

warranties

andisevr:tusive

with

no

other

guarantees

or

warranties

espreasedorimptied.

LtMITED

WARRANTY

Subject

to

the

terms

and

coeditione

betow,

MtLLER

Electric

Mtg.

Co

.

Appleton,

Wisconsin,

warrants

to

its

original

retail

purchaser

that

new

MILLER

equipment

sotd

after

the

effective

dateofthis

limited

warranty

is

tree

of

de

tects

in

materiat

and

workmanship

at

the

time

it

is

shipped

by

MtLLER

THtS

WAR

RANTY

IS

EXPRESSLY

tN

LIEU

OF

ALL

OTHER

WARRANTIES.

EXPRESS

OR

tMPLtED.

INCLUDtNG

THE

WARRANTIES

OF

MERCHANTABILITY

AND

FIT

NESS.

Within

the

warranty

periods

listed

below.

MILLER

will

repair

or

replace

any

war

raeted

parts

or

components

that

fail

due

to

suck

defects

in

material

or

workmanship.

MILLER

must

be

notified

in

writing

within

thirty

(30)

days

of

such

detectorfailure,

at

which

lime

MILLER

will

provide

instructions

on

the

warranty

claim

procedures

to

be

followed.

MILLER

shall

honor

warranty

claims

on

warranted

equipment

listed

belowinthe

event

of

suchafailure

within

the

warranty

time

periods

Alt

warranty

time

periods

start

on

the

date

that

the

equipment

was

delivered

to

the

original

retail

purchaser.

or

one

year

ahei

Ike

equipment

is

sent

to

the

distributor

5

Years

Parts

3

Years Labor

*

Original

main

power

rectihers

2.

3

YearsParts

and

Labor

Transformer/Rectiher

Power

Sources

*

Plasma

Arc

Cuaing

Power

Sources

Semi-Automatic

and

Automatic

Wire

Feeders

*

Robots

3 2

Years

Parts

and

Labor

*

Engine

Driven

Welding

Generators

(NOTE

Engines

are

warranted

separately

by

the

engine

manufacturer

for

a

period

of

Iwo

years.)

*

Air

Compressors

4.

1

YearParts

and

Labor

*

Motor

Driven

Guns

*

Process

Controllers

Water

Coolant

Systems

*

HF

Units

*

Grids

*

Spot

Welders

*

Load

Banks

*

SDX

Transformers

*

Running

Gear/Trailers

Field

Options

(NOTE

Field

options

are

covered

under

True

EluenM

for

the

remaining

warranty

period

of

the

product

they

are

installed

in,

orbra

minimum

of

one

year

whichever

is

greater

I

6

Months

Batteries

90

Days

Parts

and

Labor

*

MIG

Guns/TIG

Torches

Plasma

Cutting

Torches

1

*

Remote

Controls

Accessory

Kits

Replacement

Parts

MILLERS

True

BluerM

Limited

Warranty

shall

not

apply

to:

I

Items

furnished

by

MILLER,

but

manufactured

by

others,

suck

as

ehgines

or

trade

accessories.

These

items

are

coveredbythe

manufacturers

warranty,

if

any

2

Consumable

components:

such

as

contact

rips,

cuEing

nozzles.

confactore

avd

relays

or

parts

Ihet

fail

duels

normal

wear.

3

Equipment

that

has

been

modified

by

any

party

other

than

MILLER.

or

equip

ment

Ihat

has

been

improperly

installed,

improperly

operated

or

misused

based

upon

industry

standards,

or

equipment

which

has

not

had

reasonable

and

necessary

maintenance,

or

equipment

which

has

been

used

for

operation

outside

of

the

specifications

for

the

equipment.

MILLER

PRODUCTS

ARE

INTENDED

FOR

PURCHASE

AND

USEBYCOMMER

CIAL/INDUSTRIAL

USERS

AND

PERSONS

TRAINED

AND

EXPERIENCED

IN

THE

USE

AND

MAINTENANCE

OF

WELDING

EQUIPMENt

In

the

event

of

a

warranty

claim

coveredbythis

warranty,

the

exclusive

remedies

skull

be.

at

MILLERS

option.

11)

repair.

or

(2)

replacement:

or,

where

authorized

in

writing

by

MILLER

in

appropriate

cases,

(3)

the

reasonable

costof

repair

or

replace

ment

alan

authorized

MILLER

service

station:

or

(4)

payment

of

or

credit

for

the

pur

chase

price

(less

reasonable

depreciation

based

upon

actual

use)

upon

return

of

the

goods

at

customers

risk

and

espense.

MtLLERS

option

of

repairorreplacement

will

beFOB

FactoryatAppleton,

Wisconsin.orFOB.

eta

MILLER

authorized

ser

vice

facility

as

determined

by

MILLER

Therefore

no

compensation

or

reimburse

ment

br

Iransportafion

costs

of

any

kind

will

be

allowed.

TO

THE

EXTENT

PERMITTED

BY

LAW.

THE

REMEDIES

PROVIDED

HEREfN

ARE

THE

SOLE

AND

EXCLUSIVE

REMEDIES.INNO

EVENT

SHALL

MILLER

BE

LIABLE

FOR

DIRECT

INDIRECT.

SPECIAL.

INCIDENTAL

OR

CONSEQUENTIAL

DAMAGES

IINCLUDING

LOSS

OF

PROFIT),

WHETHER

BASED

ON

CON

TRACT

TORT

OR

ANY

OTHER

LEGAL

THEORY

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

AND

ANY

IMPLIED

WAR

RANTY.

GUARANTY

OR

REPRESENTATION

ASTO

PERFORMANCE.

ANDANY

REMEDY

FOR

BREACH

OF

CONTRACT

TORT

OR

ANY

OTHER

LEGAL

THEORY

WHICH.

BUT

FOR

THIS

PROVISION.

MIGHT

ARISE

BY

IMPLICATION,

OPERATION

OF

LAW.

CUSTOM

OF

TRADE

OR

COURSE

OF

DEALING.

IN

CLUDING

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

PARTICULAR

PURPOSE,

WITH

RESPECT

TO

ANY

AND

ALL

EQUIPMENT

FURNISHED

BY

MILLER

IS

EXCLUDED

AND

DISCLAIMED

BY

MILLER.

Some

states

in

the

U.S.A

do

not

allow

limitationsofhow

long

an

implied

warranty

lasts.

or

the

euclusiori

of

incidental.

indirect.

special

or

consequential

damages,

so

the

above

limitation

or

evclusion

may

not

apply

to

you.

This

warranty

provides

spe

cilic

legal

rights,

and

other

rights

may

be

available,

but

may

vary

from

state

10

slate.

In

Canada,

legislation

in

some

provinces

provides

for

certain

additional

warranties

or

remedies

other

than

as

staled

herein,

and

10

the

eefenf

that

they

may

not

be

waived,

the

limitations

and

esclusions

set

out

above

may

nor

apply.

This

Limited

Warranty

provides

specific

legal

rights,

and

of

her

rights

maybe

available,

but

may

vary

from

province

to

province.

I

J

7S~>

~.

~-1

S

S

B.

R

EC

EIVI

NG-HAN

D

LING

Before

unpacking

equipment,

check

carton

for

any

damage

that

may

have

occurred

dur)ng

shipment.

File

any

claims

for

loss

or

damage

with

the

delivering

carrier.

Assistance

for

filing

or

settling

claims

may

be

Qbta)ned

trom

distributor

and/or

equ)pment

manufacturers

Transportation

Department.

When

requesting

)nformation

about

this

equipment,

always

provide

Mctdel

Designation

and

Serial

or

Style

Number.

Use

the

following

spaces

to

record

Model

Designation

and

Serial

or

Style

Number

of

your

unit.

The

information

is

located

on

the

ratin9

label

or

nameplate,

Model

__________

Serial

or

Style

No.

DateofPurchase

miller

9/93

ARC

WELDING

SAFETY

PRECAUTIONS

5.

Properly

install

and

ground

this

equipment

according

to

its

Owners

Manual

and

national,

state,

and

local

codes.

6.

When

making

input

connections,

attach

proper

grounding

conductor

first.

7.

Turn

off

all

equipment

when

not

in

use.

8.

Do

not

use

worn,

damaged,

undersized,

or

poorly

spliced

cables.

9.

Do

not

wrap

cables

around

your

body.

10.

Ground

the

workpiece

to

a

good

electrical

(earth)

ground.

11.

Do

not

touch

electrode

if

in

contact

with

the

work

or

ground.

12.

Use

only

well-maintained

equipment.

Repair

or

replace

damaged

parts

at

once.

13.

Wear

a

safety

harness

if

working

above

floor

level.

14.

Keep

all

panels

and

covers

securely

in

place.

a

WARNING

ARC

WELDING

can

be

hazardous.

PROTECT

YOURSELF

AND

OTHERS

FROM

POSSIBLE

SERIOUS

INJURY

OR

DEATH.

KEEP

CHILDREN

AWAY.

PACEMAKER

WEARERS

KEEP

AWAY

UNTIL

CONSULTING

YOUR

DOCTOR.

In

welding,

as

in

most

jobs,

exposure

to

certain

hazards

occurs.

Welding

is

safe

when

precautions

are

taken.

The

safety

information

given

below

is

only

a

summary

of

the

more

complete

safety

information

that

will

be

found

in

the

Safety

Standards

listedonthe

next

page.

Read

and

follow

all

Safety

Standards.

HAVE

ALL

INSTALLATION,

OPERATION,

MAINTENANCE,

AND

REPAIR

WORK

PERFORMED

ONLY

BY

QUALIFIED

PEOPLE.

ELECTRIC

SHOCK

can

kill.

Touching

live

electrical

parts

can

cause

fatal

shocks

or

severe

burns.

The

electrode

and

work

circuit

is

electrically

live

whenever

the

output

is

on.

The

input

power

circuit

and

machine

internal

circuits

are

also

live

when

power

is

on.

In

semiautomatic

or

automatic

wire

welding,

the

wire,

wire

reel,

drive

roll

housing,

and

all

metal

parts

touching

the

welding

wire

are

electrically

live.

Incorrectly

installed

or

improperly

grounded

equipment

is

a

hazard.

1.

Do

not

touch

live

electrical

parts.

2.

Wear

dry,

hole-free

insulating

gloves

and

body

protection.

3.

Insulate

yourself

from

work

and

ground

using

dry

insulating

mats

or

covers.

4.

Disconnect

input

power

or

stop

engine

before

installing

or

servicing

this

equipment.

ARC

RAYS

can

burn

eyes

and

skin;

ARC

RAYS

~

NOISE

can

damage

hearing.

2.

Wear

a

welding

helmet

fitted

with

a

proper

shade

of

filter

(see

ANSI

Z49.1

listed

in

Safety

Standards)

to

protect

your

face

and

Arc

rays

from

the

welding

process

produce

intense

eyes

when

weldingorwatching.

heat

and

strong

ultraviolet

rays

that

can

burn

eyes

3.

Wear

approved

safety

glasses.

Side

shields

recommended.

and

skin.

Noise

from

some

processes

can

damage

hearing.

4.

Use

protective

screens

or

barriers

to

protect

others

from

flash

and

glare;

warn

others

not

to

watch

the

arc.

NOISE

5.

Wear

protective

clothing

made

from

durable,

fIame-resi~tant

1.

Use

approved

ear

plugs

or

ear

muffs

if

noise

level

is

high.

material

(wool

and

leather)

and

foot

protection.

FUMES

AND

GASES

can

be

hazardous

5.

Work

in

a

confined

space

only

if

it

is

well

ventilated,

or

while

~

to

your

health.

wearing

an

air-supplied

respirator.

Shielding

gases

used

for

Q

Welding

producesfumes

and

gases.

Breathing

these

welding

can

displace

air

causing

injury

or

death.

Be

sure

the

fumes

and

gases

can

be

hazardous

to

your

health.

breathing

airissafe.

6.

Do

not

weldinlocations

near

degreasing,

cleaning,

or

spraying

operations.

The

heat

and

rays

of

the

arc

can

react

with

vapors

to

1.

Keep

your

head

out

of

the

fumes.

Do

not

breathe

the

fumes,

form

highly

toxic

and

irritating

gases.

2.

If

inside,

ventilate

the

area

and/or

use

exhaustatthe

arc

to

remove

welding

fumes

and

gases.

7.

Do

not

weldoncoated

metals,

such

as

galvanized,

lead,

or

3.

If

ventilation

is

poor,

use

an

approved

air-supplied

respirator.

cadmium

plated

steel,

unless

the

coating

is

removed

from

the

4.

Read

the

Material

Safety

Data

Sheets

(MSDS5)

and

the

weld

area,

the

area

is

well

ventilated,

and

if

necessary,

while

manufacturers

instruction

for

metals,

consumables,

coatings.

wearinganair-supplied

respirator.

The

coatings

and

any

metals

and

cleaners,

containing

these

elements

can

give

off

toxic

fumes

if

welded.

WELDING

can

cause

fire

or

explosion.

5.

Watch

for

fire,

and

keep

a

fire

extinguisher

nearby.

Sparks

and

spatter

fly

off

from

the

welding

arc.

The

6.

Be

aware

that

welding

on

a

ceiling,

floor,

bulkhead,

or

partition

flying

sparks

and

hot

metal,

weld

spatter,

hot

can

cause

fireonthe

hidden

side.

workpiece,

and

hot

equipment

can

cause

fires

and

burns.

Accidental

contact

of

electrode

or

welding

wire

7.

Do

not

weldonclosed

containers

such

as

tanks

or

drums.

to

metal

objects

can

cause

sparks,

overheating,

or

fire,

8.

Connect

work

cabletothe

workasclose

to

the

welding

area

as

practical

to

prevent

welding

current

from

traveling

long,

possibly

1.

Protect

yourself

and

others

from

flying

sparks

and

hot

metal.

2.

Do

not

weld

where

flying

sparks

can

strike

flammable

material.

9.

unknown

paths

and

causing

electric

shock

and

fire

hazards.

Do

not

use

weldertothaw

frozen

pipes.

3.

Remove

all

flammables

within

35ff

(10.7

m)

of

the

welding

arc.

If

this

is

not

possible,

tightly

cover

them

with

approved

covers,

10.

Remove

stick

electrode

from

holder

or

cut

off

welding

wire

at

contact

tip

when

not

in

use.

4.

Be

alert

that

welding

sparks

and

hot

materials

from

welding

can

11.

Wear

oil-free

protective

garments

such

as

leather

gloves,

heavy

easilygothrough

small

cracks

and

openingstoadjacent

areas.

shirt,

cuftless

trousers,

high

shoes,

and

a

cap.

FLYING

SPARKS

AND

HOT

METAL

can

cause

injury,

Chipping

and

grinding

cause

flying

metal.

As

welds

cool,

they

can

throw

off

slag.

1.

2.

Wear

approved

face

shield

or

safety

goggles.

Side

shields

recommended.

Wear

proper

body

protection

to

protect

skin.

srI

9/92

a

WARNING

PRINCIPAL

SAFE.:TY

STANDARDS

Safetyin

Welding

and

Cutting,

ANSI

Standard

Z49.i,

from

American

Welding

Society.

550

N.W.

LeJeune

Rd,

Miami

FL

33126

Safety

and

Health

Standards,

OSHA

29

CFR

1910,

from

Superinten

dent

of

Documents,

U.S.

Government

Printing

Office,

Washington,

D.C.

20402.

Recommended

Safe

Practices

for

the

Preparation

for

Welding

and

Cutting

of

Containers

That

Have

Held

Hazardous

Substances,

Ameri

can

Welding

Society

Standard

AWS

F4.1,from

American

Welding

So

ciety,

550

N.W.

LeJeune

Rd,

Miami,

FL

33126

National

Electrical

Code,

NFPA

Standard

70,

from

National

Fire

Pro

tection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

Sri

9/92

Safe

Handling

of

Compressed

Gases

in

Cylinders,

CGA

Pamphlet

P-i,

from

Compressed

Gas

Association,

1235

Jefferson

Davis

High

way,

Suite

501,

Arlington,

VA

22202.

Code

for

Safety

in

Welding

and

Cutting,

GSA

Standard

Wi

17.2,

from

Canadian

Standards

Association,

Standards

Sales,

178

Rexdale

Bou

levard,

Rexdale,

Ontario,

Canada

M9W

I

R3.

Safe

Practices

For

Occupation

And

Educational

EyeAnd

Face

Protec

tion,

ANSI

Standard

Z87.1,

from

American

National

Standards

Institute,

1430

Broadway,

New

York,

NY

10018.

Cutting

And

Welding

Processes,

NFPA

Standard

51

B,

from

National

Fire

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

~

~

~J

.

J

CYLINDERS

can

explodeifdamaged.

Shieldin~

gas

cylinders

contain

gas

under

high

pressure.

If

damaged,

a

cylinder

can

explode.

Since

gas

cylinders

are

normally

part

of

the

welding

process~

be

sure

to

treat

them

carefully,

3.

4.

5.

Keep

cylinders

away

from

any

welding

or

other

electrical

Never

allow

a

welding

electrode

to

touch

any

cylinder.

circuits.

Use

only

correct

shielding

gas

cylinders,

regulators,

hoses,

and

fittings

designed

for

the

specific

application;

maintain

them

and

associated

parts

in

good

condition.

1.

2.

I

Protect

compress~ed

gas

cylinders

from

excessive

heat,

mechanical

shocks,

and

arcs.

Install

and

secure

~ylinders

in

an

upright

position

by

chaining

them

to

a

stationary

support

or

equipment

cylinder

rack

to

prevent

falling

or

ti~ping.

6.

7.

8.

Turn

face

away

from

valve

outlet

when

opening

cylinder

valve.

Keep

protective

cap

in

place

over

valve

except

when

cylinder

is

in

use

or

connected

for

use.

Read

and

follow

instructions

on

compressed

gas

cylinders,

associated

equipment,

and

CGA

publication

P-i

listed

in

Safety

Standards.

I

ENGINES

can

be

hazardous.

ENGINE

EXHAUST

GASES

can

kill.

Engines

produce

harmful

exhaust

gases.

1.

2.

Use

equipment

outside

in

open,

well-ventilated

areas.

If

used

in

a

closed

area,

vent

engine

exhaust

outside

and

away

from

any

building

air

intakes.

E

FUEL

can

cause

fire

or

1.

2.

Stop

engine

before

checkingoradding

fuel.

Do

not

add

fuel

while

smoking

or

if

unit

is

near

any

sparks

or

open

flames.

Engine

fuel

is

highly

flammable.

3.

4.

5.

Allow

engine

to

cool

before

fueling.

If

possible,

check

and add

fuel

to

cold

engine

before

beginning

job.

Do

not

overfill

tankallow

room

for

fuel

to

expand.

Do

not

spill

fuel.Iffuel

is

spilled,

clean

up

before

starting

engine.

MOVING

PARTS

can

cause

injury.

3.

Have

only

qualified

people

remove

guards

or

covers

for

maintenance

and

troubleshooting

as

necessary.

Moving

parts,

such

as

fans,

rotors,

and

belts

can

cut

fingers

and

hands

and

catch

loose

clothing,

4.

To

prevent

accidental

starting

during

servicing,

disconnect

negative

()

battery

cable

from

battery.

I.

Keep

all

doors,

panels,

covers,

and

guards

closed

and

securely

in

place.

5.

6.

Keep

hands,

hair,

loose

clothing,

and

tools

away

from

moving

parts.

Reinstall

panels

or

guards

and

close

doors

when

servicing

is

2.

Stop

engine

before

installing

or

connecting

unit,

finished

and

before

starting

engine.

SPARKS

can

cause

BATTERY

GASES

1.

Always

wear

a

face

shield

when

working

on

a

battery.

TO

EXPLODE;

BATTERY

ACID

can

2.

Stop

engine

before

disconnecting

or

connecting

battery

burn

eyes

and

skin,

cables.

Batteries

contain

acid

and

generate

explosive

iases.

3.

4.

5.

Do

not

allow

tools

to

cause

sparks

when

working

on

a

battery.

Do

not

use

welder

to

charge

batteries

or

jump

start

vehicles.

Observe

correct

polarity

(+

and

)

on

batteries.

r~.

~

.

.~

Y

~

STEAM

AND

COOLANT

can

skin.

The

coolantinthe

r

under

pressure.

PRESSURIZED

burn

face,

eyes,

adiator

can

be

very

h

HOT

and

ot

and

1.

2.

3.

Donotremoveradiatorcapwhenengineishot.Allowengine

to

cool.

Wear

gloves

and

put

a

rag

over

cap

area

when

removing

cap.

Allow

pressuretoescape

before

completely

removing

cap.

PRECAUTIONS

DE

SECURITE

EN

SOUDAGE

A

LARC

MISE

EN

GARDE

LE

SOUDAGE

A

LARC

est

dangereux.

PROTEGEZ-VOUS,

AINSI

QUE

LES

AUTRES,

CONTRE

LES

BLESSURES

GRAVES

POSSIBLES

OU

LA

MORT.

NE

LAISSEZ

PAS

LES

ENFANTS

SAPPROCHER,

NI

LES

PORTEURS

DE

STIMULATEUR

CARDIAQUE

(A

MOINS

QUILS

NAIENT

CONSULTE

UN

MEDECIN).

DESSAI.

LELECTROCUTION

peut

Œtre

mortelle.

~

Une

dØcharge

Olectrique

peut

vous

tuer

ou

vous

brUler

gravement.

LØlectrodeetle

circuit

de

soudage

sont

sous

tension

au

dØmarrage.

Le

circuit

dentrØe

et

les

circuits

internes

des

matØriels

sont

aussi

sous

__________

tension

des

Ia

mise

en

marche.

En

soudage

automatique

ou

semi-automatique

avec

f

ii,cedernier,

le

support

de

roquette,

le

logement

des

galets

dentrainement

et

toutes

les

piŁces

metalliques

en

contact

avec

le

f

ii

de

soudage

sont

sous

tension.

Des

matŁriels

mal

installØs

ou

mal

misaIa

terre

sont

dangereux.

1.

Ne

touchez

pas

a

des

piŁces

sous

tension.

2.

Portez

des

gants

et

des

vØtements

isolants,

secsetnon

trouØs.

3.

lsolez-vousdeIa

tleasouderetdeIamise

ala

terre

au

moyen

de

petits

tapis

isolants

ou

autres.

4.

DØconnectez

Ia

prise

dentrØe

des

matOrielsouarrŒtez

leur

moteur

avant

de

les

installerouden

faire

lentretien.

~

Le

RAYONNEMENT

DE

LARC

peut

brUler

Ies

yeux

et

Ia

peau;

le

BRUIT

peut

endommager

IouIe.

Larc de

soudage

produit

une

chaleuretdes

rayons

ultraviolets

intenses,

susceptibles

de

brUler

les

yeux

et

Ia

peau.

Le

bruit

cause

par

certains

procØdØs

peut

endommager

louIe.

1.

Portez

un

casque

de

soudeur

avec

Łcran

filtrant

de

teinte

appropriee

(consultez

Ia

norme

ANSI

Z49

indiquee

ci-aprŁs),

pour

vous

protØgerlevisage

et

les

yeux

lorsque

vous

soudez

ou

5.

Veillez

a

installer

ces

matØriels

eta

les

mettre

a

Ia

terre

selon

le

manuel

dutilisationetles

codes

nationaux,

provinciaux

et

locaux

applicables.

6.

ArrØtez

tous

es

matŁriels

aprŁs

utilisation.

7.

Nutilisez

pas

de

cables

uses,

endommages,

mal

Opisses

ou

de

calibre

trop

petits.

8.

Nenroulez

pas

de

cables

autourdevotre

corps.

9.

Mettez

ala

terre

Ia

tle

a

souder

au

moyen

dune

bonne

prise

de

terre.

10.

Ne

touchez

pas

a

lØlectrode

si

vous

Øtes

en

contact

avec

le

circuit

de

soudage

(terre).

11.

Nutilisez

que

des

matØriels

en

bon

Øtat.

RŁparez

ou

remplacez

sur-le-champ

les

piŁces

endommagees.

12.

PortezunharnaisdesØcuritØ

si

vous

travaillez

en

hauteur.

13.

Fermez

solidement

touS

les

panneaux

et

les

capots.

que

vous

observez

lexØcution

dune

soudure.

2.

Portez

des

lunettes

de

sŁcuritØ

approuvØes.

Des

Łcrans

latØraux

sont

recommandØes.

3.

Entourez

laire

de

soudage

de

rideaux

ou

de

cloisons

de

protection

contre

les

coups

darc

ou

lØblouissement;

avertissez

les

observateurs

de

ne

pas

regarder

arc.

4.

Portez

des

vØtements

en

tissus

ignifuge

durable

(lame

et

cuir)

et

des

chaussures

de

sØcuritØ.

5.

Portez

un

casque

antibruitoudes

bouchons

doreille

approuvŁs

sileniveau

de

bruit

est

ØlevŁ.

Les

VAPEURS

ET

LES

FUMEES

sont

dangereuses

pour

Ia

sante.

Le

soudage

dŁgage

des

vapeurs

et

des

fumŁes

quil

~

.

est

dangereuxderespirer.

1.

Ecartez

le

visage

pour

Łviter

de

respirer

les

fumŁes.

2.

A

lintØrieur,

assurez-vous

que

laire

de

soudage

est

bien

ventilØe

ou

que

les

fumŁesetles

vapeurs

sont

aspirØes

a

larc.

3.

SiIaventilation

est

mauvaise,

portez

un

respirateur

a

adduction

dair

approuvØ.

4.

Lisez

es

fiches

signalØtiques

et

es

consignes

du

fabricant

relatives

aux

mØtaux,

aux

produits

consummables,

aux

revŒtements

et

aux

produits

nettoyants.

Le

SOUDAGE

peut

causer

un

incendie

ou

une

explosion.

Larc

produit

des

Øtincelles

et

des

projections.

Avec

Ia

chaleur

intense

degagee

par

a

tleetles

matØriels,

elles

peuvent

causer

un

incendieetdes

brlures.

Le

contact

accidenteldelelectrode

avec

un

objet

mŁtallique

peut

provoquer

des

Øtincelles,

un

Łchauffement

ou un

incendie.

1.

Protegez-vous,

ainsi

que

les

autres,

contre

les

Łtincellesetles

projections.

2.

Ne

soudez

pas

dansunendroitodes

Øtincelles

peuvent

atteindre

des

matŁriELux

inflammables.

3.

Enlevez

toutes

les

rnatiŁres

inflammables

dans

un

rayon

de

10,7

metres

autourdE

larc,

ou

couvrez-Ies

soigneusement

avec

des

bches

approuvØes.

4.

MØfiez-vous

des

Øtincelles

et

des

Øclats

brlants,

susceptibles

de

pØnØtrer

dans

des

aires

adjacentes

par

de

petites

ouvertures

ou

fissures.

5.Netravaillez

dans

un

espace

confine

que

sil

est

bien

ventilØ;

sinon,

portez

un

respirateuraadduction

dair.

Lesgaz

protecteurs

de

soudage

peuvent

dØplacer

IoxygŁne

de

lair

et

causer

des

blessuresouIa

mort.

Assurez-vous

que

lair

est

propre

a

Ia

respiration.

6.

Ne

soudez

pas

a

proximitØ

dopŁrations

de

dŁgraissage,

de

nettoyage

ou

de

pulvØrisation.

La

chaleur

et

les

rayons

de

larc

peuvent

rØagir

avec

des

vapeurs

et

former

des

gaz

hautement

toxiques

et

irritants.

7.Nesoudez

pas

de

tles

galvanisees

ou

plaquŁes

en

p10mb

ou

en

cadmium

sans

les

avoir

grattØes

a

fond,

car

ces

mØtaux,

et

tout

revŒtement

qui

en

contient,

peuvent

alors

dŁgager

des

fumeestoxiques.

Assurez-vousdune

bonneventilation

etportez

un

respirateur

a

adduction

dair

si

cest

nØcessaire.

5.

MŁfiez-vous

des

incendies

et

gardez

un

extincteur

a

poilØe

de

Ia

main.

6.

Noubliez

pas

quune

soudure

sur

un

plafond,unplancher,

une

cloison

ou

une

paroi

peut

en

enflammer

lautre

ctØ.

7.

Ne

soudez

pas

un

recipient

termŁ,

comme

un

reservoir

ou

un

tonneau.

8.

Connectez

le

cable

de

soudageleplus

prŁs

possible

de

Ia

tIe

de

soudage

pour

empŒcher

le

courant

de

suivre

un

parcours

long

et

inconnu,

et

prØvenir

ainsi

les

risques

dØlectrocution

et

dincendie.

9.Nefaites

pas

degeler

des

tuyaux

avec

un

chalumeau.

10.

Videz

votre

carquois

porte-electrodes

ou

coupez

le

fil

au

tube

contact

aprŁs

le

soudage.

11.

Portez

des

vŁtements

protecteurs

non

huileux,

tels

des

gants

en

cuir,

une

chemise

epaisse,

un

pantalon

sans

revers,

des

chaussures

montarites

et

un

casque.

Le

soudage,

comme

Ia

plupart

des

activitØs

industrielles,

expose

a

certains

risques.

Le

soudage

nest

pas

dangereux

lorsquon

prend

des

precautions.

Les

consignes

de

sØcuritØ

suivantesnefont

que

rØsumer

information

contenue

dans

les

normes

ØnumØrØes

ci-aprŁs.

Lisez

et

respectez

toutes

ces

normes.

SEULES

DES

PERSONNES

QUALIFIEES

DOIVENT

FAIRE

DES

IRAVAUX

DINSTALLATION,

DE

REPARATION,

DENTRETIEN

ET

I

Les

BOUTEILLES

endommagees

peuvent

exploser.

Les

bouteilles

contiennent

des

gaz

protecteurs

sous

haute

pression.

Des

bouteilles

endommagees

peuvent

exploser.

C;omme

les

bouteilles

font

normalement

partie

du

procedØ

de

soudage,

traitez-les

avec

soin.

1.

Les

bouteilles

doivent

Œtre

protegees

contre

les

sources

de

chaleur

intense,

es

chocsetles

arcs

de

soudage.

2.

Enchainez

verticalementesbouteilles

a

un

support

ouaun

cadre

fixe

pour

les

empŒcher

de

tomberoudŒtre

renversØes.

3.

Eloignez

les

bouteilles

de

tout

circuit

electrique

ou

de

soudage.

MIS~

EN

GARDE

Le

CARBURANT

peut

causer

un

incendie

ou

une

explosion.

Le

carburarit

est

hautement

inflammable.

1.

ArrŒte:~

le

moteur

avant

de

verifier

le

niveau

de

carburantoude

faire

le

plein.

2.Nefaites

pas

le

plein

en

fumant

ou

proche

dune

source

Des

PI¨CES

EN

MOUVEMENT

peuvent

causer

des

blessures.

Des

piŁces

en

mouvement,

telles

des

ventilateurs,

des

rotors

et

des

courroies

peuvent

couper

les

doigts

et

les

mains,

ou

accrocher

des

vŒtements

amples.

1.

Assurez-vous

que

les

portes,

les

panneaux,

les

capots

et

les

protecteurs

sont

bien

lermØs.

2.

Avant

dinstaller

ou

de

connecter

un

systŁme,

arrŒtez-en

le

moteur.

3.

Seules

des

personries

qualifiees

doivent

dØmonter

des

4.

EmpŒchez

tout

contact

entre

une

bouteille

et

une

electrode.

5.

Nutilisez

que

des

bouteilles

de

gaz

protecteur,

des

dØtendeurs,

des

flexibles

et

des

raccords

conus

pour

chaque

application

specifique;

ces

matØriels

et

les

piŁces

connexes

doivent

Œtre

en

bon

Øtat.

6.

Ne

mettez

pas

le

visage

devant

le

robinet

de

bouteille

en

louvrant.

7.

Remettez

le

chapeau

de

bouteille

aprŁs

utilisation.

8.

Lisez

et

respectez

les

consignes

relatives

aux

bouteilles

de

gaz

comprime

et

aux

matØriels

connexes,

ainsi

que

Ia

publication

P-i

de

Ia

CGA,

ØnumØrŁes

dans

les

normes

ci-dessous.

Les

MOTEURS

peuvent

Œtre

dangereux.

1.

Utilisez

des

machines

a

lextØrieur

dans

des

aires

ouvertes

et

bien

ventilØes.

2.

Si

vous

utilisez

des

machines

dansunendroit

confine,

les

fumØes

dØchappement

doivent

Œtre

envoyees

a

lextØrieur,

loin

des

prises

dair

du

btiment.

dØtincelles

ou

dune

flamme

nue.

3.

Si

cest

possible,

laissez

le

moteur

refroidir

avant

de

faire

le

plein

de

carburantouden

verifier

le

niveauaudebut

du

soudage.

4.

Ne

faites

pas

le

plein

de

carburant

a

ras

bord

:

prØvoyez

de

lespace

pour

son

expansion.

5.

Faites

attention

de

ne

pas

renverser

de

carburant.

Nettoyez

tout

carburant

renversØ

avant

de

faire

dØmarrer

le

moteur.

protecteurs

ou

des

capots

pour

faire

lentretienoule

depannage

nØcessaire.

4.

Pour

empŒcher

un

demarrage

accidentel

dun

systŁme

pendant

lentretien,

dØbranchez

le

cable

daccumulateur

a

Ia

borne

negative.

5.

Napprochez

pas

les

mains

ou

es

cheveux

de

piŁces

en

mouvement;

elles

peuvent

aussi

accrocher

des

vŒtements

amples

et

des

outils.

6.

RØinstallez

les

capots

ou

les

protecteurs

et

fermez

les

portes

aprŁs

des

travaux

dentretien

et

avant

de

faire

dŁmarrer

le

moteur.

Le

liquide

do

refroidissement

dun

radiateur

peut

Œtre

brlant

et

sous

pression.

PRINCIPALES

NORMES

DE

SECURITE

Safety

in

Welding

and

Cutting

norme

ANSI

Z49.1,American

Welding

Society,

550,

N.W.

LeJeun~

Rd.,

MiamiFL33128.

Safety

and

Health

Standarc~

OSHA

29

CFR

1910,

Superintendent

of

Documents,

U.S.

Government

Printing

Office,

Washington

D.C.

20402.

Recommended

Safe

Practices

For

the

Preparation

For

Welding

and

GuthnQof

Containers

That

F~ave

Held

Hazardous

Substances,

norme

AWS

F4.i,

American

Welding

Society,

550,

N.W.

LeJeune

Rd.,

Miami

FL

33128.

Safe

Handling

of

Com~ressed

Gases

in

Cylinders

document

P-i,

Compressed

Gas

Association,

1235

Jefferson

Davis

Highway,

Suite

501,

Arlington,

Va

22202.

Code

for

Safety

in

Welding

and

Cutting

norme

CSA

Wi

17.2,

Asso

ciation

canadienne

de

normalisation,

Standards

Sales,

176

Rexdale

Boulevard,

Rexdale,

Ontario,

Canada

M9W1R3.

Safe

Practices

for

Occupation

and

Educational

Eve

and

Face

Protec

ILQI:1,

norme

ANSI

Z87.i

,American

National

Standards

Institute,

1430

Broadway,

New

York,

NY

10018.

National

Electrical

Code

norme

70

NFPA,

National

Fire

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

srlf

9/91

Cutting

and

Welding

PrOcesses

norme

SiB

NFPA,

National

Fire

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

LES

ETINCELLES

ET

LES

metal.

En

refroidissant,

Ia

soudure

peut

projeter

du

laitier.

PROJECTIONS

BRULANTES

peuvent

causer

des

blessures.

Le

piquage

et

le

meulage

produisent

des

Øclats

de

1.

2.

PortezunØcran

facialoudes

lunettes

a

coques

approuvØes.

Des

Øcrans

latØraux

sont

recommandØs.

Portez

des

vŒtements

de

protection

individuelle

appropriØs.

Les

GAZ

DECHAPPEMENT

DES

MOTEURS

PEUVENT

ETRE

MORTELS.

Les

moteurs

produisent

des

gaz

dechappement

nocifs.

Des

ETINCELLES

peuvent

FAIRE

EXPLOSER

un

accumulateur.

UNACCUMULATEUR;LELECTROLYTEDUN

2.

ArrŒtez

le

moteur

avantdeconnecter

ou

de

dØconnecter

des

cables

daccumulateur.

ACCUMUI.ATEUR

peut

brUler

Ia

peau

et

les

~

Nutilisez

que

des

outils

anti-Øtincelles

pour

travailler

sur

un

yeux.

accumulateur.

Les

accumjlateurs

contiennent

de

lelectrolyte

et

4.

Nutilisezpasunpostedesoudagepourchargerunaccumulateur

degagent

d~s

vapeurs

explosives.

ou

connecter

provisoirement

un

vØhicule.

1.

Portez

toujours

un

Øcran

facialentravaillant

sur

5.

Utilisez

Ia

polaritØ

correcte

(+

et

-)

de

laccumulateur.

La

VAPEU

R

ET

LE

LIQUI

DE DE

1.

Ntez

pas

le

bouchon

de

radiateur

tant

que

le

moteur

na

pas

REFROIDISSEMENT

BRULANT

SOUS

refroidi.

PRESSIONI

peuvent

brUler

Ia

peau

et

les

2.

Mettez

des

gants

et

posez

un

torchon

sur

le

bouchon

pour

lter.

e

3.

Laissez

Ia

pression

sechapper

avant

dter

completement

le

~

U

.

bouchon.

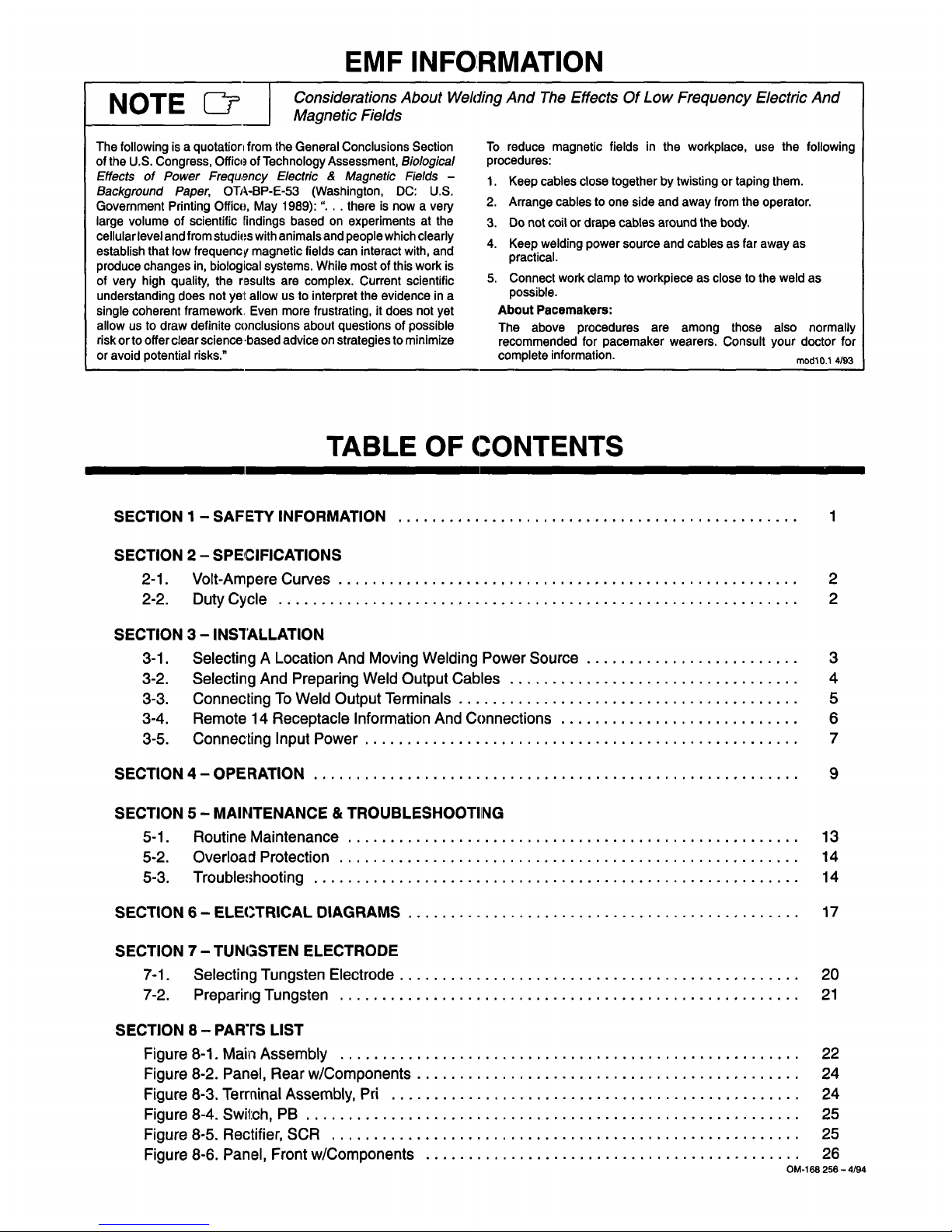

EMF

INFORMATION

TABLE

OF

CONTENTS

SECTION

1

-

SAFETY

INFORMATION

SECTION

2

SPECIFICATIONS

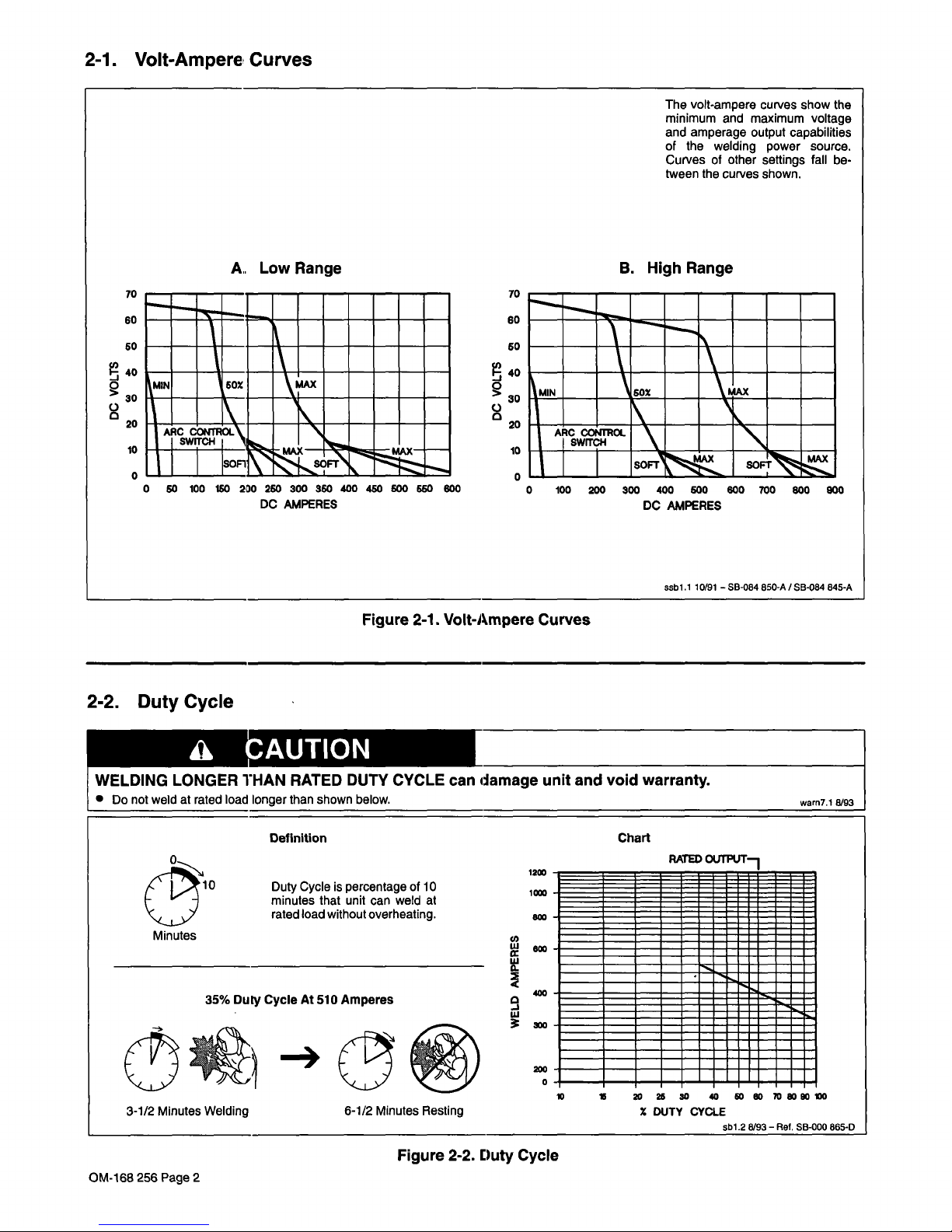

2-1.

Volt-Ampere

Curves

2-2.

Duty

Cycle

SECTION

3

INSTALLATION

3-1.

Selecting

A

Location

And

Moving

Welding

Power

Source

3-2.

Selecting

And

Preparing

Weld

Output

Cables

3-3.

Connecting

To

Weld

Output

Terminals

3-4.

Remote

14

Receptacle

Information

And

Connections

3-5.

Connecting

Input

Power

SECTION

4-

OPERATION

9

SECTION

6-

ELECTRICAL

DIAGRAMS

17

SECTION

7

TUNGSTEN

ELECTRODE

7-1.

Selecting

Tungsten

Electrode

7-2.

Preparing

Tungsten

SECTION

8

PARTS

LIST

Figure

8-1.

Main

Assembly

Figure

8-2.

Panel,

Rear

w/Components

Figure

8-3.

Terminal

Assembly,

Pri

Figure

8-4.

Swil:ch,

PB

Figure

8-5.

Rectifier,

SCR

NOTE

~

Considerations

About

Welding

And

The

Effects

Of

Low

Frequency

Electric

And

-~

Magnetic

Fields

The

following

is

a

quotation

from

the

General

Conclusions

Section

of

the

U.S.

Congress,

Office

of

Technology

Assessment,

Biological

Effects

of

Power

Frequ9ncy

Electric

&

Magnetic

Fields

Background

Paper,

OTA-BP-E-53

(Washington,

DC:

U.S.

Government

Printing

Office,

May

1989):

.

.

.

there

is

now

a

very

large

volumeofscientific

findings

based

on

experiments

at

the

cellular

level

and

from

studies

with

animals

and

people

which

clearly

establish

that

low

frequency

magnetic

fields

can

interact

with,

and

produce

changes

in,

biological

systems.

While

most

of

this

work

is

of

very

high

quality,

the

results

are

complex.

Current

scientific

understanding

does

not

yet

allow

us

to

interpret

the

evidence

in

a

single

coherent

framework,

Even

more

frustrating,

it

does

not

yet

allow

us

to

draw

definite

conclusions

about

questionsofpossible

risk

or

to

offer

clear

science

~based

advice

on

strategies

to

minimize

or

avoid

potential

risks.

To

reduce

magnetic

fieldsinthe

workplace,

use

the

following

procedures:

1.

Keep

cables

close

together

by

twistingortaping

them.

2.

Arrange

cables

to

one

side

and

away

from

the

operator.

3.

Do

not

coil

or

drape

cables

around

the

body.

4.

Keep

welding

power

source

and

cables

as

far

away

as

practical.

5.

Connect

work

clamp

to

workpiece

as

close

to

the

weld

as

possible.

About

Pacemakers:

The

above

procedures

are

among

those

also

normally

recommended

for

pacemaker

wearers.

Consult

your

doctor

for

complete

information.

modlO

1

4/93

2

2

3

4

5

6

7

SECTION

5

MAINTENANCE

&

TROUBLESHOOTING

5-1.

Routine

Maintenance

5-2.

Overlo&J

Protection

5-3.

Troubleshooting

13

14

14

20

21

22

24

24

25

25

Figure

8-6.

Panel,

Front

w/Components

26

OM.168

256

4/94

SECTION

1

-

SAFE~TY

INFORMATION

Read

all

safety

messages

throughout

this

manual.

Obey

all

safety

messages

to

avoid

injury.

Learn

thi?

meaning

of

WARNING

and

CAUTION.

modl.1

2/93

iIIi1~I

Figure

1-1.

Safety

Information

SECTION

2

SPECIFICATIONS

Table

2-1.

Welding

Power

Source

1

2

!

:

2

ELECTRIC

SHOCK

can

kIII.~

Do

not

touch

live

electrical

parts.

~fl

Disconnect

input

power

before

-~_________

installingorservicing.

CA~

/

5

~

w~OVING

PARTS

can

Injure.

)~

S

Keep

away

from

moving

parts.

S

Keep

all

panels

and

covers

closed

wtten

operating.

1

Safety

Alert

Symbol

2

Signal

Word

WARNING

means

possible

death

or

serious

injury

can

happen.

CAUTION

means

possible

minor

injury

or

equipment

damage

can

happen.

3

StatementOfHazard

And

Result

6

a

WARNIF~

7-H

NOTE

D~

READ

SAFETY

BLOCKS

at

start

of

I

_____

SectIon

3-1

berore

proceeding.

Turn

Off

switch

when

using

high

frequency.

4

Safety

InstructionsToAvoid

Hazard

5

Hazard

Symbol

(If

Available)

6

Safety

Banner

Read

safety

blocks

for

each

sym

bol

shown.

7

NOTE

Special

instructions

for

best

oper

ation

not

related

to

safety.

Specifications

Description

Type

Of

Output

Welding

Process

Max

Open-Circuit

Voltage

TypeOfInput

Power

Overall

Dimensions

Input

Amperes

At

Rated

Output

Constant

Current/Direct

Currerlt

(CC/DC)

Shielded

Metal

Arc

(SMAW)

And

Gas

Tungsten

Arc

(GTAW)

Welding

70

Volts

DC

Three-Phase;

220,

380,

400,

Or

415

Volts

AC,

50/60

Hz

See

Figure

3-2

102

A

At

220

V,

59

AAt380

V,

56

A

At

400

V,

54

AAt415

V

510

Amperes,

41

VoltsDCAt

~I5%

Duty

Cycle

(see

Section

2-2)

38.8

kVN25.6

kW

Low:

20-270

A;

High:

37-510

A

Net:

543

lb

(246

kg);

Ship:

568

lb

(258

kg)

Rated

Weld

Output

KVAJKW

UsedAtRated

Output

Amperage Range

Weight

OM-168

256

Page

1

2-1.

Volt-Ampere

Curves

Figure

2-1.

Volt-Ampere

Curves

2-2.

Duty

Cycle

L

~AUTION

WELDING

LONGER

THAN

RATED

DUTY

CYCLE

can

damage

unit

and

void

warranty.

Do

not

weldatrated

load

longer

than

shown

below.

warn7.1

8/93

A~.

Low

Range

The

volt-ampere

curves

show

the

minimum

and

maximum

voltage

and

amperage

output

capabilities

of

the

welding

power

source.

Curvesofother

settings

fall

be

tween

the

curves

shown.

B.

High

Range

70

60

50

40

0

>

30

C.)

20

10

0

70

60

50

40

0

>

30

C.)

20

10

0

0

50

100

150

2D0

250

300

350

400

450

500

650

600

DC

AMPERES

0

100

200

300

400

600

600

700

800

900

DC

AMPERES

ssbl

.110/91SB-084

850-A/SB-084

845-A

Definition

Chart

1200

Duty

Cycle

is

percentage

of

10

minutes

that

unit

can

weld

at

rated

load

without

overheating.

(1)

~O00

35%

Duly

Cycle

At

510

Amperes

ii~

~

3-1/2

Minutes

Welding

6-1/2

Minutes

Resting

Z

DUTY

CYCLE

sbl

.2

8/93Aol.

SB-000

865-D

Figure

2-2.

Duty

Cycle

OM-168

256

Page

2

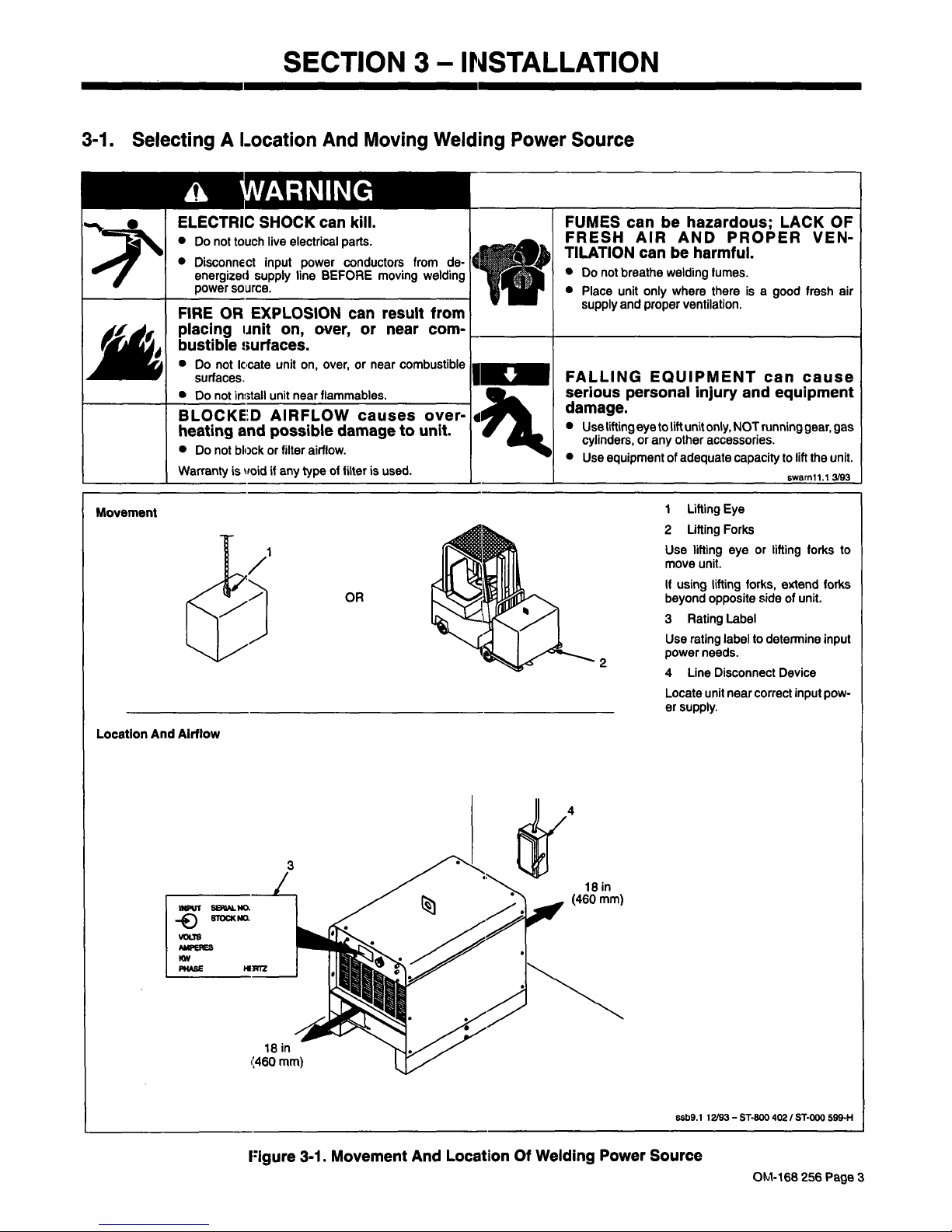

SECTION

3-

INSTALLATION

3-1.

Selecting

A

Location

And

Moving

Welding

Power

Source

£~

~NARNING

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Disconnect

input

power

conductors from

de

energized

supply

line

BEFORE

moving

welding

power

source.

FIRE

OR

EXPLOSION

can

result

from

placing

unit

on,

over,

or

near

com

bustible

t~urfaces.

Do

not

iccate

unit

on,

over,

or

near

combustible

surfaces.

Do

not

install

unit

near

flammables.

BLOCKED

AIRFLOW

causes

over

heating

and

possible

damage

to

unit.

Do

not

block

or

filter

airflow.

Warranty

is

~oid

if

any

type

of

filter

is

used.

I

FALLING

EQUIPMENT

can

cause

serious

personal

Injury

and

equipment

damage.

Use

lifting

eye

to

lift

unit

only,

NOT

running

gear,

gas

cylinders,

or

any

other

accessories.

Use

equipmentofadequate

capacity

to

lift

the

unit.

cwarnhil

3/93

Figure

3-1.

Movement

And

Location

Of

Welding

Power

Source

FUMES

can

be

hazardous;

LACK

OF

FRESH

AIR

AND

PROP

ER

VEN

TILATION

can

be

harmful.

Do

not

breathe

welding

fumes.

Place

unit

only

where

there

is

a

supply

and

proper

ventilation.

good

fresh

air

Movement

OR

Location

And

Airflow

1

Lifting

Eye

2

Lifting

Forks

Use

lifting

eye

or

lifting

forks

to

move

unit.

If

using

lifting

forks,

extend

forks

beyond

opposite

sideofunit.

3

Rating

Label

Use

rating

labeltodetermine

input

power

needs.

4

Line

Disconnect

Device

Locate

unit

near

correct

input

pow

er

supply.

ssb9.1

12193-

ST-BOO

402

I

ST-000

599-H

4

l8in

(460

mm)

18

in

~460

mm)

OM-168

256

Page

3

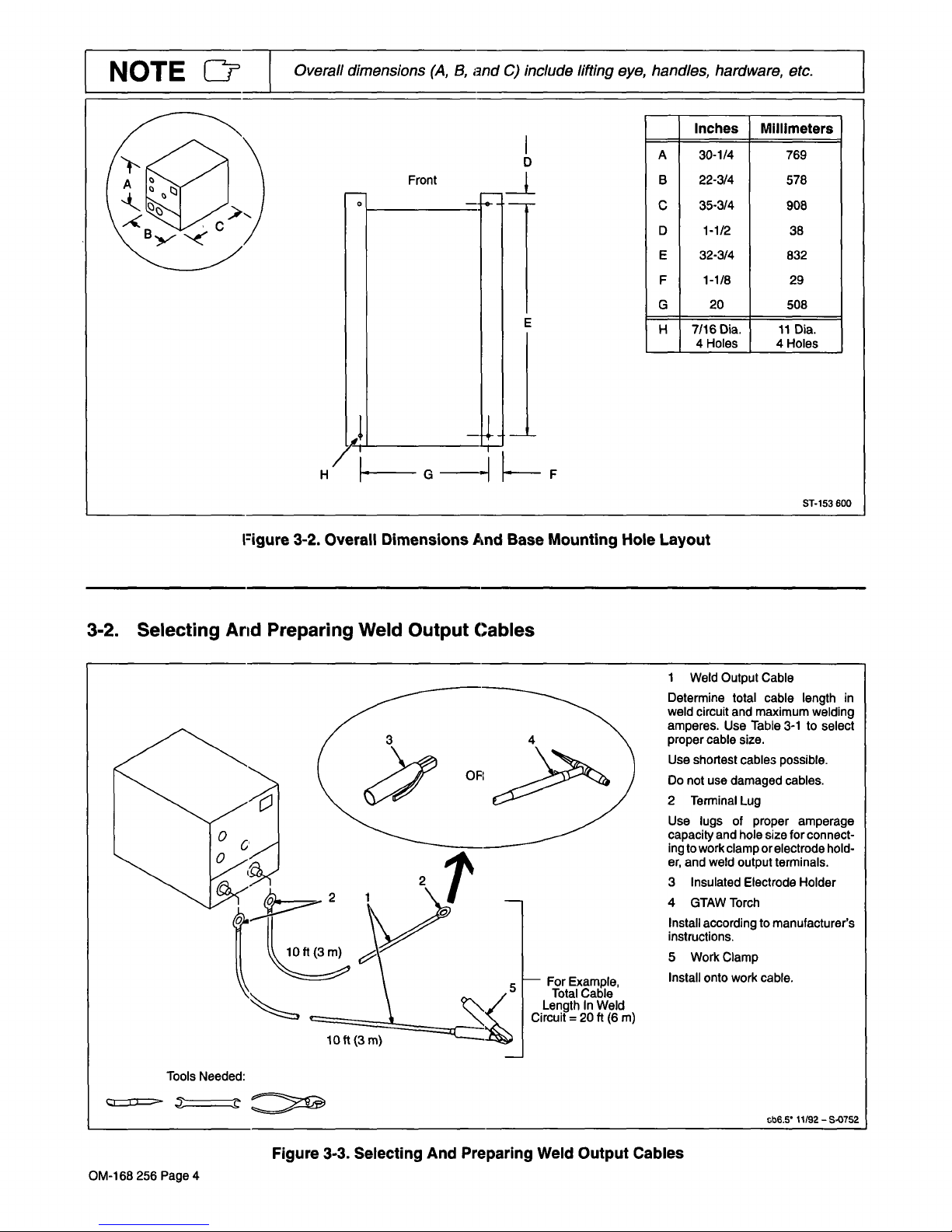

NOTE

LI~ii~

Overall

dimensions

(A,

B,

and

C)

include

lifting

eye,

handles,

hardware,

etc.

I

D

Inches

Millimeters

A

30-1/4

769

Front

B

22-3/4

578

D

1-1/2

38

E

32-3/4

832

~-

C

35-3/4

908

F

1-1/8

29

G

20

508

E

H

7/l6Dia.

11

D~a.

/

4

Holes

4

Holes

1~

H

G

F

ST-153

600

:igure

3-2.

Overal

Dimensions

And

Base

Mounting

Hole

Layout

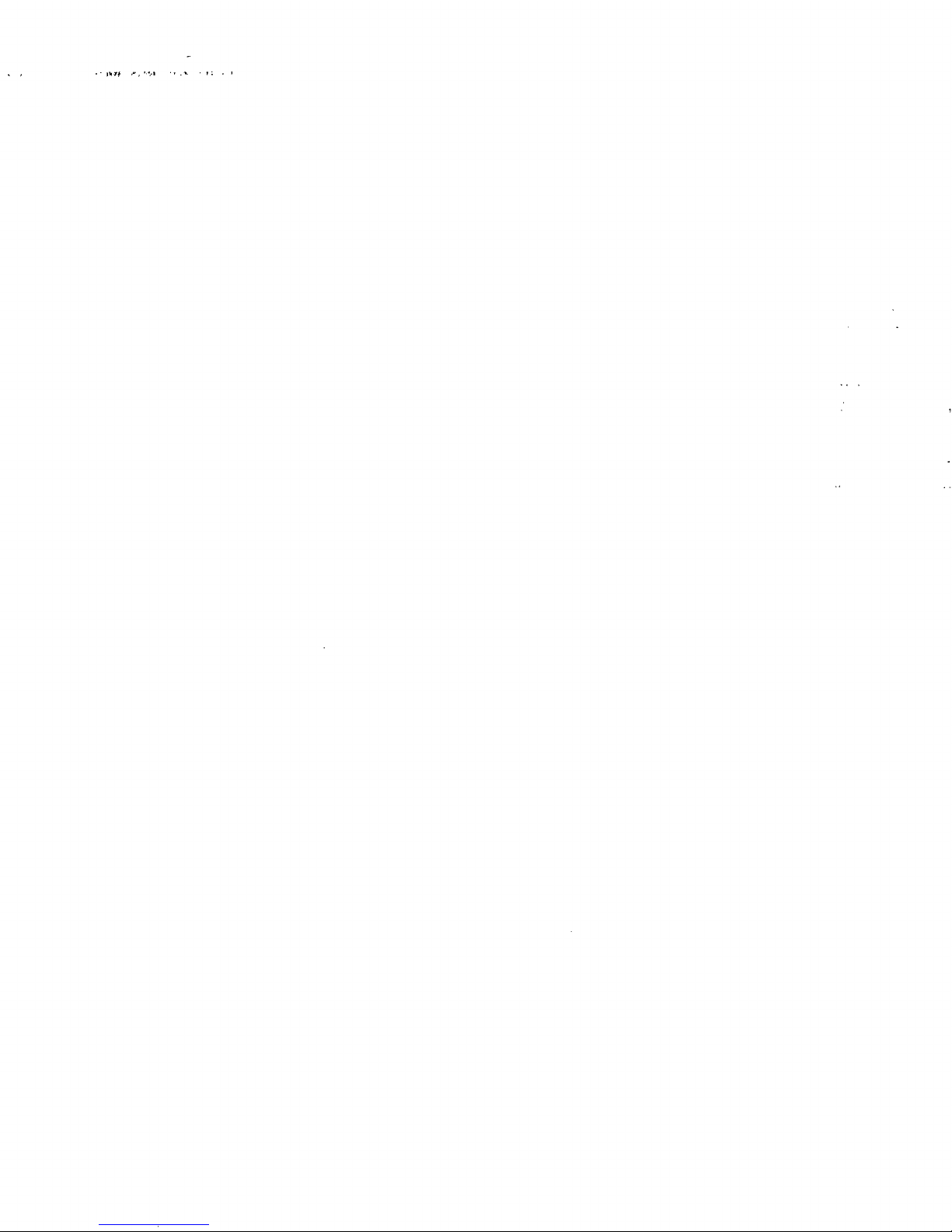

3-2.

Selecting

Arid

Preparing

Weld

Output

Cables

1

Weld

Output

Cable

Determine

total

cable

length

in

weld

circuit

and

maximum

welding

amperes.

Use

Table

3-1toselect

proper

cable

size.

Use

shortest

cables

possible.

Do

not

use

damaged

cables.

~

2

Terminal

Lug

Use

lugs

of

proper

amperage

capacity

and

hole

size

for

connect

ing

to

work

clamp

or

electrode

hold

er,

and

weld

output

terminals.

3

Insulated

Electrode

Holder

4

GTAW

Torch

Install

according

to

manufacturers

instructions.

5

Work

Clamp

For

Example,

Install

onto

work

cable.

Total

Cable

Length

In

Weld

Circuit=20

ft

(6

m)

Tools

Needed:

c,~

th6.5

11/92

S~0752

10

ft

(3m)

Figure

3-3.

Selecting

And

Preparing

Weld

Output

Cables

OM-168

256

Page

4

-

-~-,

-

-

p

-

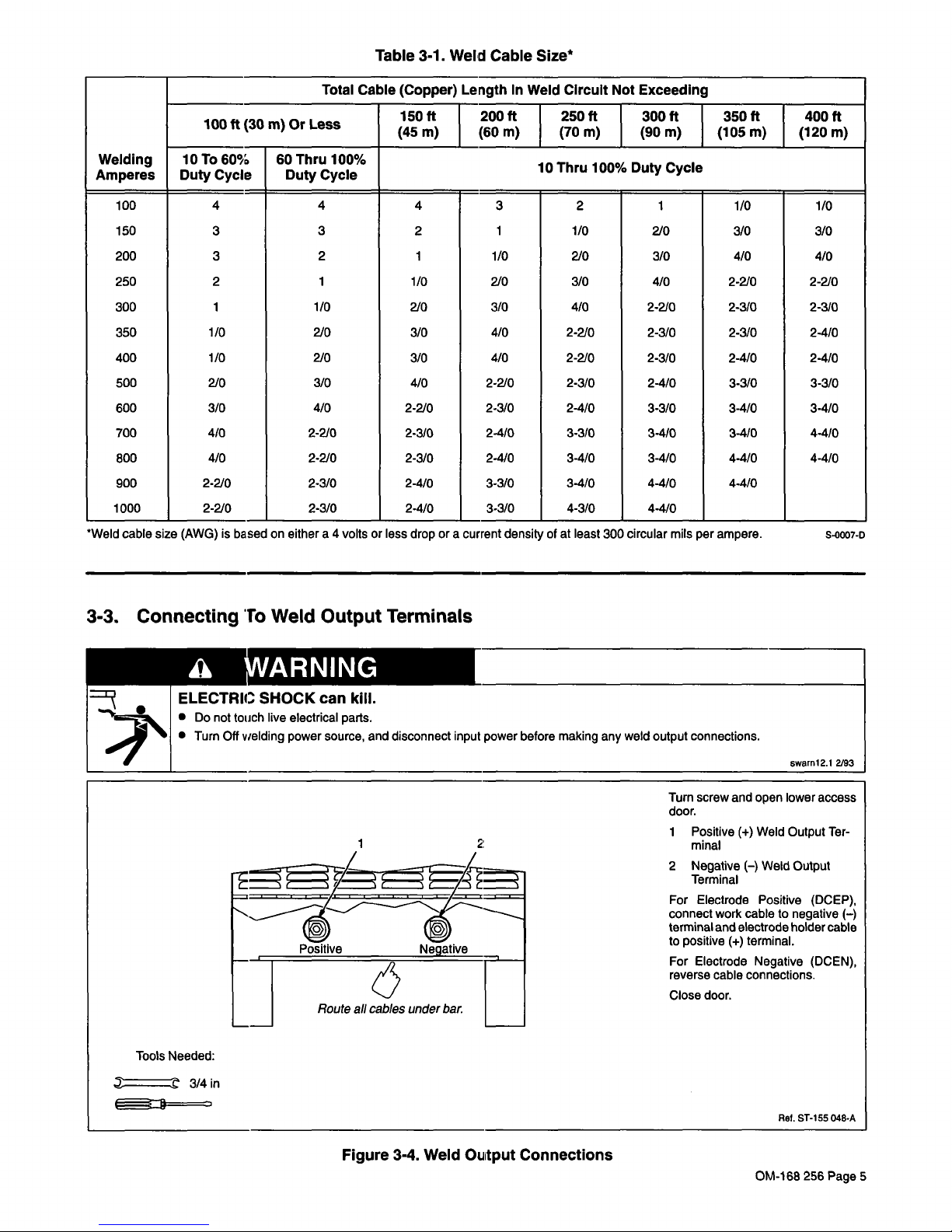

Table

3-1.

Weld

Cable

Size*

4A

~JVARNING

Tools

Needed:

3/4in

~==~

Figure

3-4.

Weld

Oiitput

Connections

Welding

Amperes

Total

Cable

(Copper)

Length

In

Weld

Circuit

Not

Exceeding

100

ft

(30

m)

Or

Less

150ff

I

200ft

I

250ff

I

300ff

I

350ff

I

(45

m)

(60

m)

(70

m)

(90

m)

(105_m)_j~120_m)

400ft

10

To

60%

Duty

Cycle

60

Thru

100%

Duty

Cycle

10

Thru

100%

Duty

Cycle

100

150

200

250

300

350

400

500

600

700

800

900

1000

4

3

3

2

1

1/0

1/0

2/0

3/0

4/0

4/0

2-2/0

2-2/0

4

3

2

1

1/0

2/0

2/0

3/0

4/0

2-2/0

2-2/0

2-3/0

2-3/0

4

2

1

1/0

2/0

3/0

3/0

4/0

2-2/0

2-3/0

2-3/0

2-4/0

2-4/0

3

1

1/0

2/0

3/0

4/0

4/0

2-2/0

2-3/0

2-4/0

2-4/0

3-3/0

3-3/0

2

1/0

2/0

3/0

4/0

2-210

2-2/0

2-3/0

2-4/0

3-3/0

3-4/0

3-4/0

4-3/0

1

210

3/0

4/0

2-2/0

2-3/0

2-3/0

2-4/0

3-3/0

3-4/0

3-4/0

4-4/0

4-4/0

1/0

3/0

4/0

2-2/0

2-3/0

2-3/0

2-4/0

3-3/0

3-4/0

3-4/0

4-4/0

4-4/0

1/0

3/0

4/0

2-2/0

2-3/0

2-4/0

2-4/0

3-3/0

3-4/0

4-4/0

4-4/0

*Weldcable

size

(AWG)

isbased

on

either

a

4

voltsorless

drop

or

a

current

density

ofatleast

300

circular

mils

per

ampere.

5-0007-c

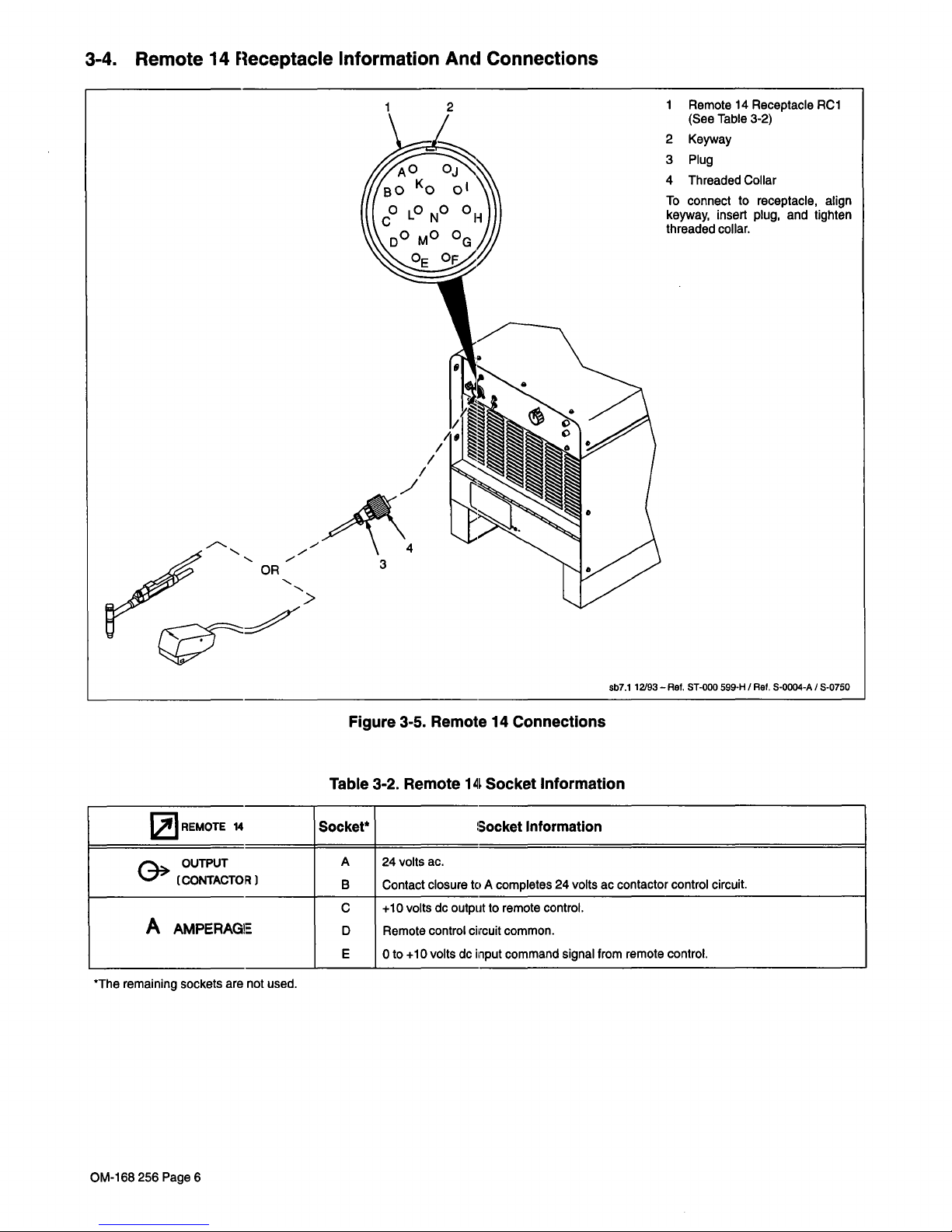

3-3.

Connecting

To

Weld

Output

Terminals

E

LECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

S

Turn

Off

welding

power

source,

and

disconnect

input

power

before

making

any

weld

output

connections.

swarnl2.1

2193

Turn

screw

and

open

lower

access

door.

1

Positive

(+)

Weld

Output

Ter

1

2:

minal

2

Negative

(-)

Weld

Output

For

Electrode

Positive

(DCEP),

connect

work

cable

to

negative

()

terminal

and

electrode

holder

cable

to

positive

(+)

terminal.

For

Electrode

Negative

(DCEN),

reverse

cable

connections.

Close

door.

Rel.

ST-155

048-A

OM-168

256

Page

5

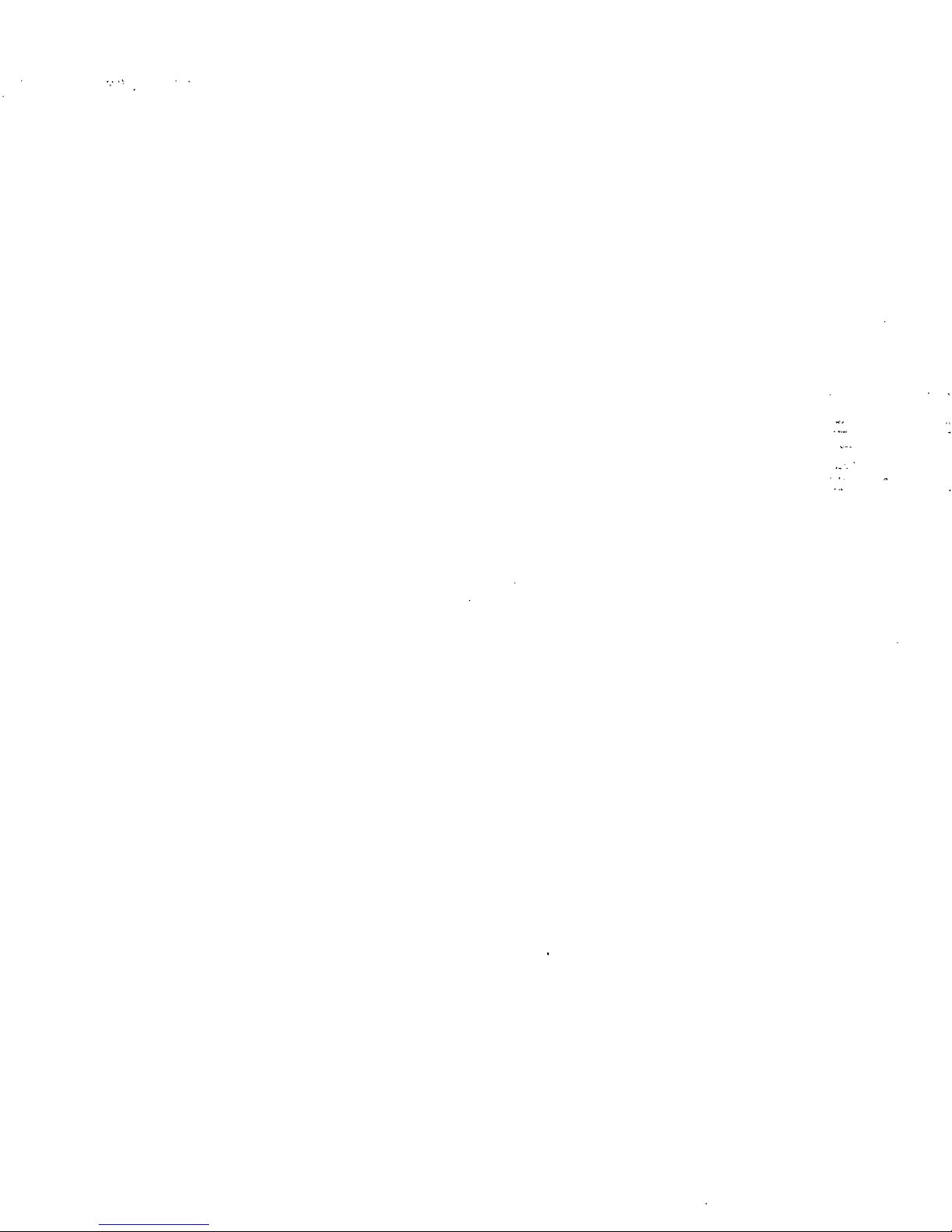

3-4.

Remote

14

Receptacle

Information

And

Connections

Figure

3-5.

Remote

14

Connections

Table

3-2.

Remote

14

Socket

Information

REMOTE

14

Socket*

Socket

Information

OUTPUT

(CONTACTOR)

A

B

24

volts

ac.

Contact

closuretoA

completes

24

volts

ac

contactor

control

circuit.

A

AMPERAGE

C

D

E

+10

volts

dc

output

to

remote

control.

Remote

control

ciircuit

common.

0

to

+10

volts

do

input

command

signal

from

remote

control.

*The

remaining

sockets

are

not

used.

1

Remote

14

Receptacle

Rd

(See

Table

3-2)

2

Keyway

3

Plug

4

Threaded

Collar

To

connect

to

receptacle,

align

keyway,

insert

plug,

and

tighten

threaded

collar.

sbl.1

12193

Ret.

ST-coo

599-H

/

Ret.

5-0004-A

/

5-0750

~

OR

>

3

OM-168

256

Page

6

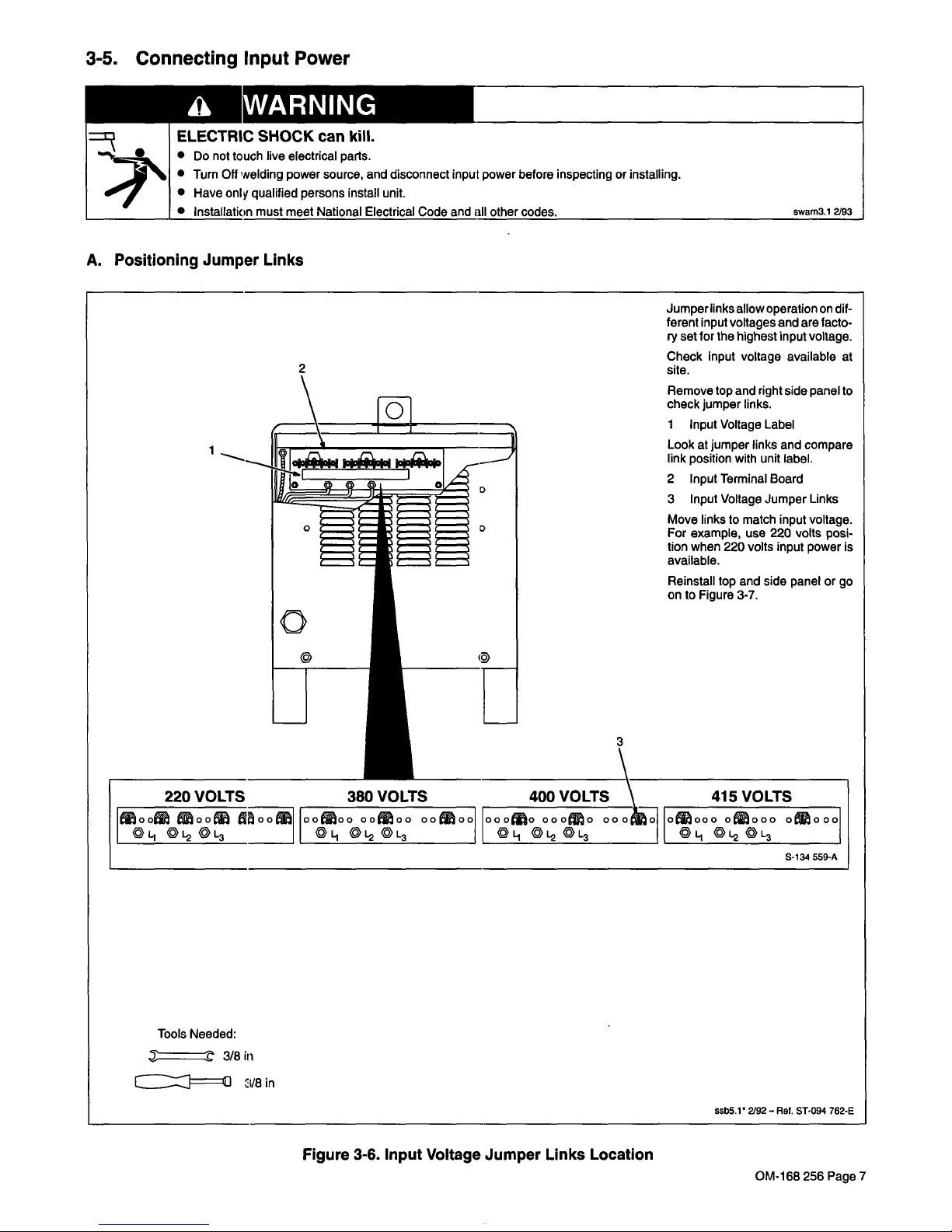

3-5.

Connecting

Input

Power

WARNING

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Turn

Off

welding

power

source,

and

disconnect

input

power

before

inspectingorinstalling.

Have

only

qualified

persons

install

unit.

Installation

must

meet

National