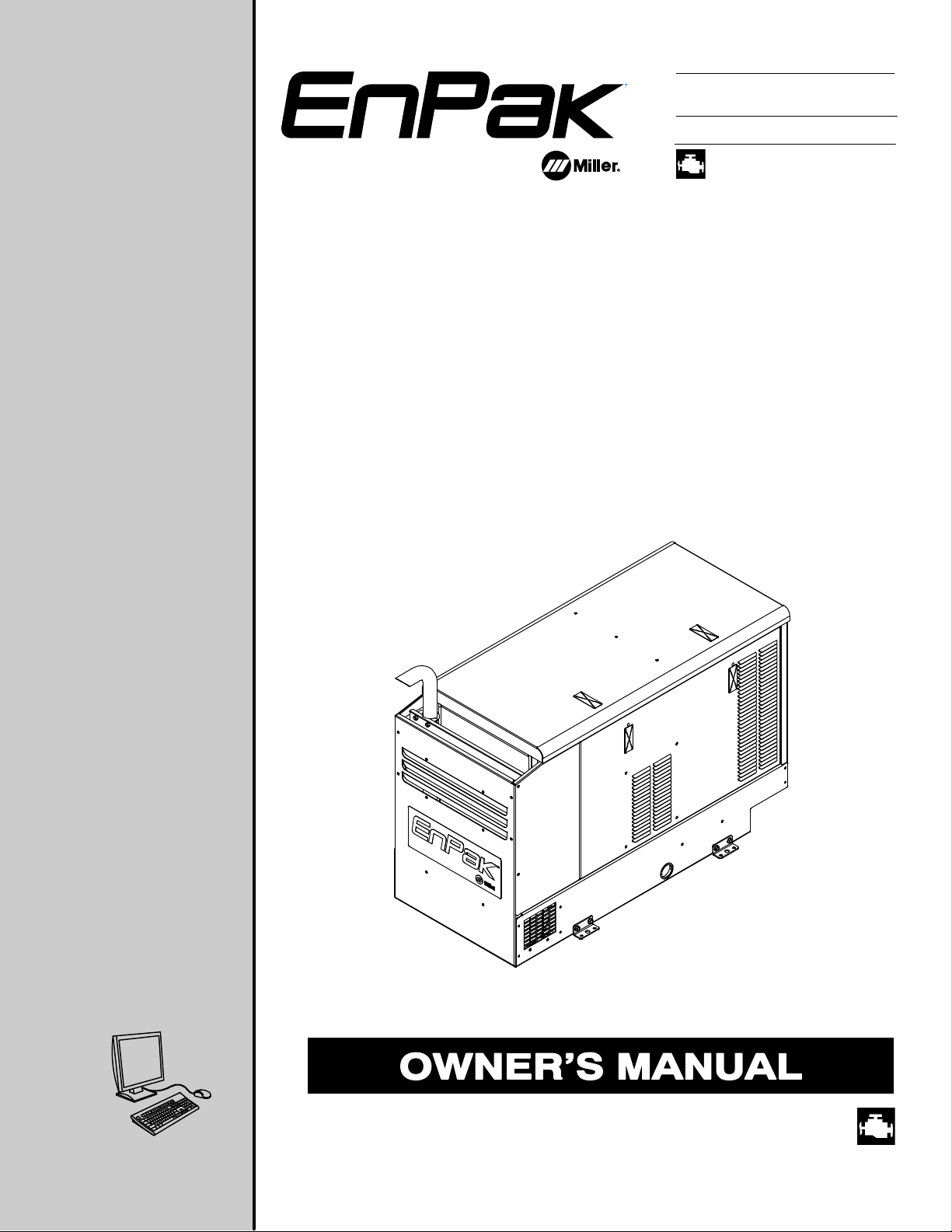

Miller ENPAK Owner's Manual

OM-240 113S

)

2012−10

Description

Mobile Utility Unit With Air Compressor,

Hydraulic Pump, And Auxiliary Power

Capability

)

EnPak

Visit our website at

www.EnPak.com

File: Mobile Utility

From Miller to You

Thank you and congratulations on choosing EnPak® by Miller. Now

you can get the job done and get it done right. We know you don’t have

time to do it any other way.

That’s why when Niels Miller first started building arc welders in 1929,

he made sure his products offered long-lasting value and superior

quality. Like you, his customers couldn’t afford anything less. Miller

products had to be more than the best they could be. They had to be the

best you could buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and service

that meets the high standards of quality and value established in 1929.

This Owner’s Manual is designed to help you get the most out of your

Miller products. Please take time to read the Safety precautions. They

will help you protect yourself against potential hazards on the worksite.

We’ve made installation and operation quick

and easy. With Miller you can count on years

of reliable service with proper maintenance.

And if for some reason the unit needs repair,

there’s a Troubleshooting section that will

help you figure out what the problem is. The

Miller is the first welding

equipment manufacturer in

the U.S.A. to be registered to

the ISO 9001 Quality System

Standard.

parts list will then help you to decide the

exact part you may need to fix the problem.

Warranty and service information for your

particular model are also provided.

Miller Electric manufactures a full line

of welders and welding related equipment.

For information on other quality Miller

products, contact your local Miller distributor to receive the latest full

line catalog or individual specification sheets. To locate your nearest

distributor or service agency call 1-800-4-A-Miller, or visit us at

www.MillerWelds.com on the web.

EnPak_Thank 2011−09

TABLE OF CONTENTS

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING 1................................

1-1. Symbol Usage 1.......................................................................

1-2. Engine Hazards 1.....................................................................

1-3. Hydraulic Hazards 2...................................................................

1-4. Compressed Air Hazards 3..............................................................

1-5. Additional Symbols For Installation, Operation, And Maintenance 4............................

1-6. California Proposition 65 Warnings 5......................................................

1-7. Principal Safety Standards 5............................................................

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION 6..........................

2-1. Signification des symboles 6............................................................

2-2. Dangers existant en relation avec le moteur 6..............................................

2-3. Dangers liés à l’hydraulique 7............................................................

2-4. Dangers liés à l’air comprimé 8..........................................................

2-5. Dangers supplémentaires en relation avec l’installation, le fonctionnement et la maintenance 9.....

2-6. Proposition californienne 65 Avertissements 10..............................................

2-7. Principales normes de sécurité 10.........................................................

SECTION 3 − DEFINITIONS 12.................................................................

3-1. Symbol Definitions 12...................................................................

SECTION 4 − SPECIFICATIONS 12..............................................................

4-1. Auxiliary Power And Engine Specifications 12...............................................

4-2. Air Compressor Specifications 12.........................................................

4-3. Hydraulic Specifications (Models With Hydraulic Power Source) 12.............................

4-4. Sound Level Table 12...................................................................

4-5. Dimensions, Weights, and Operating Angles 13..............................................

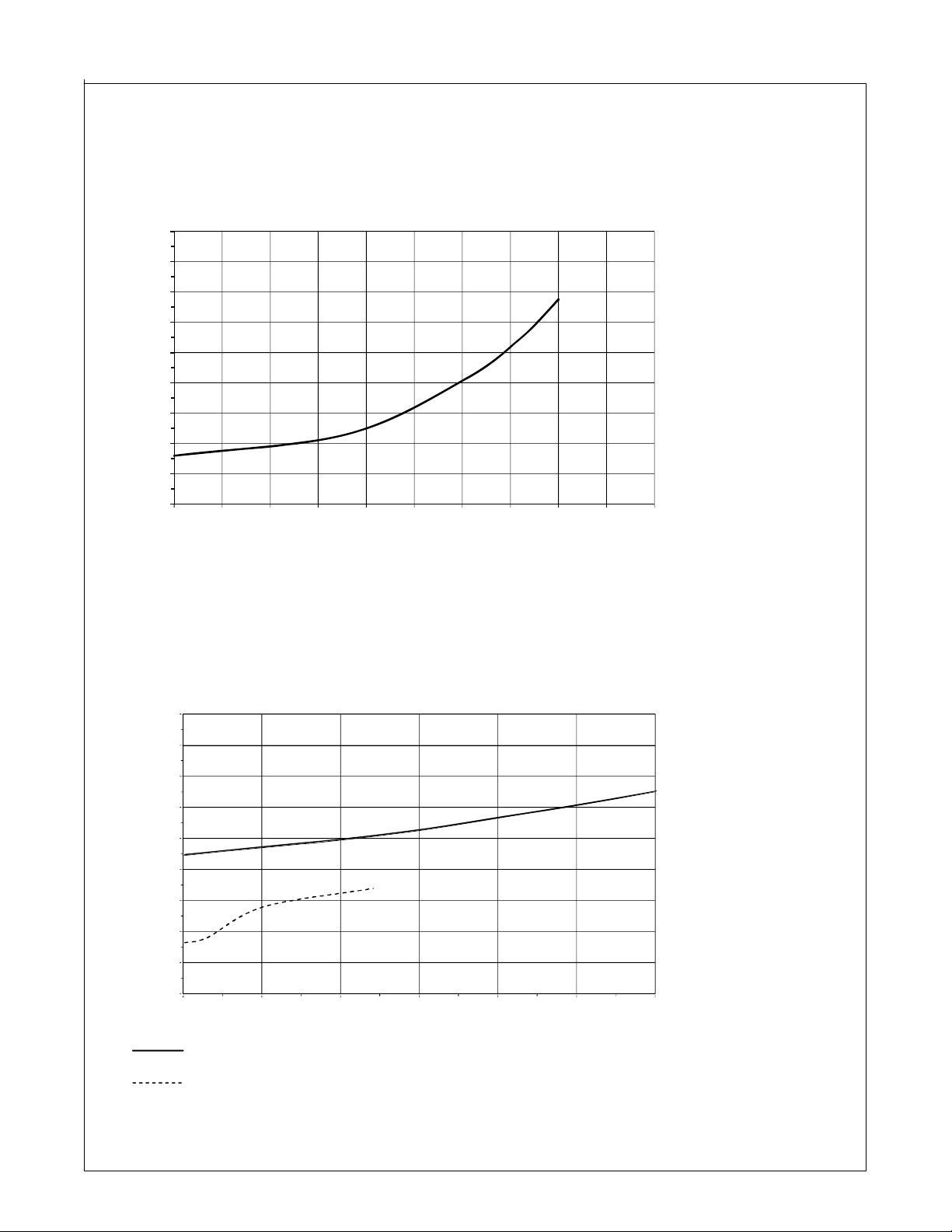

4-6. Fuel Consumption Curves 14.............................................................

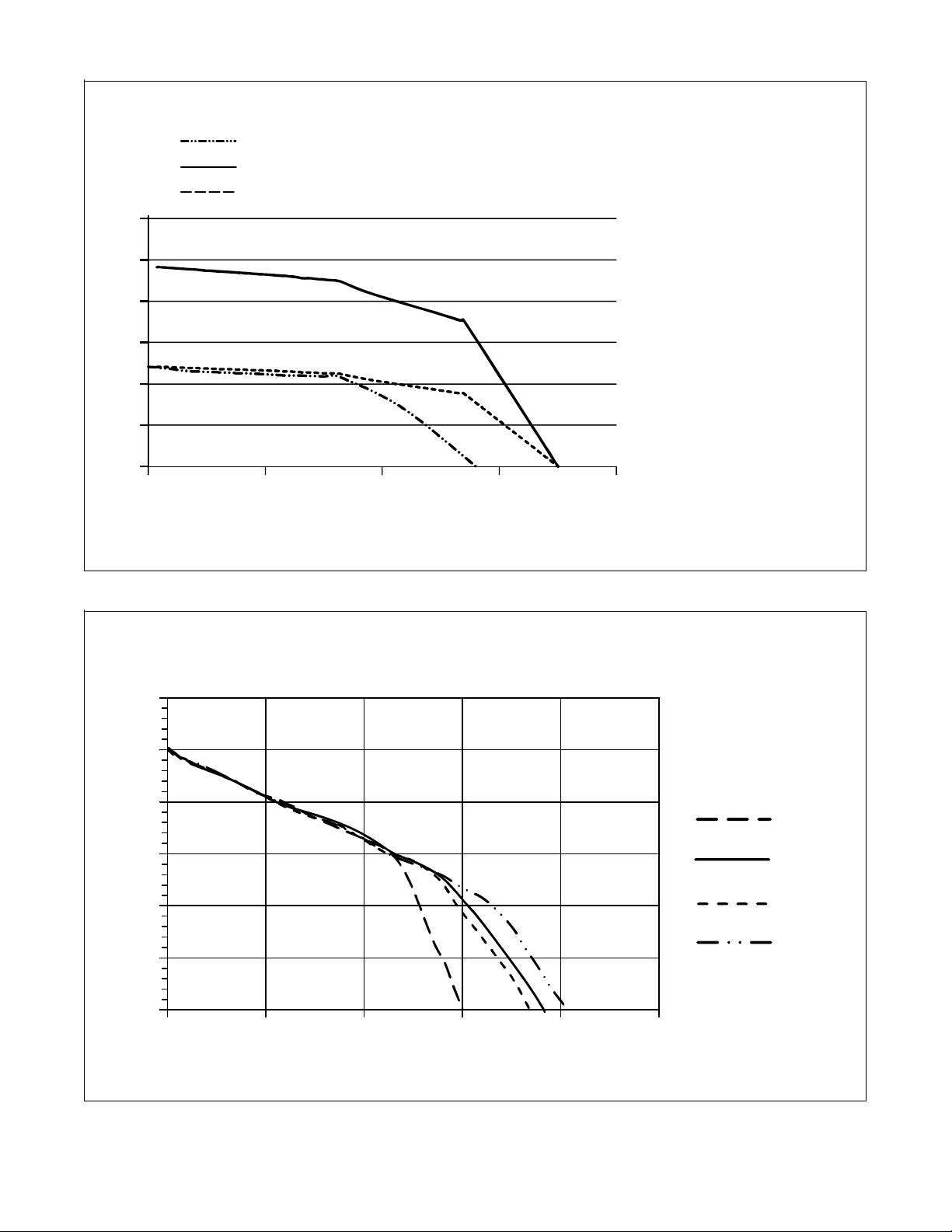

4-7. Auxiliary Power Curves 15...............................................................

4-8. Alternator Power Curve 15...............................................................

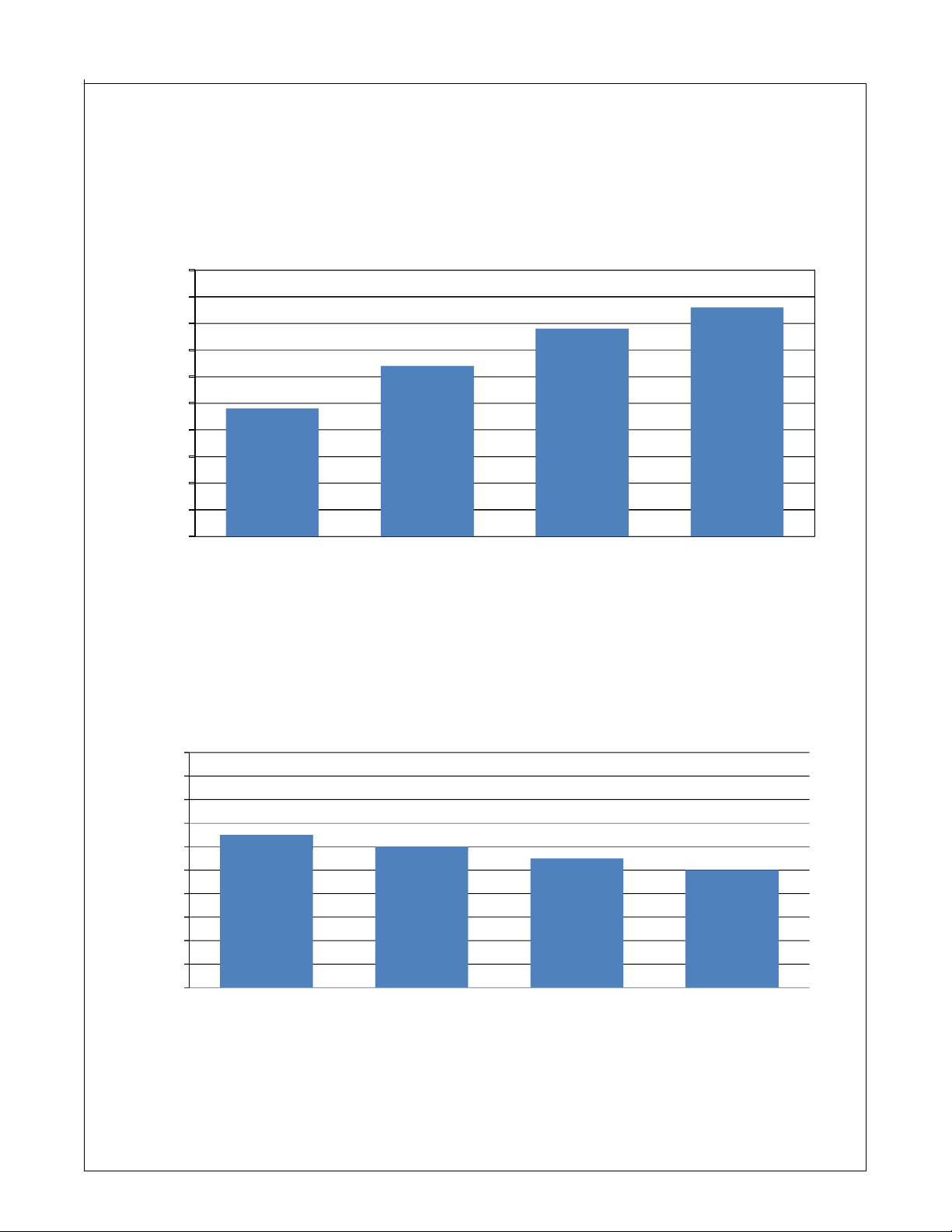

4-9. Air Compressor Curves 16...............................................................

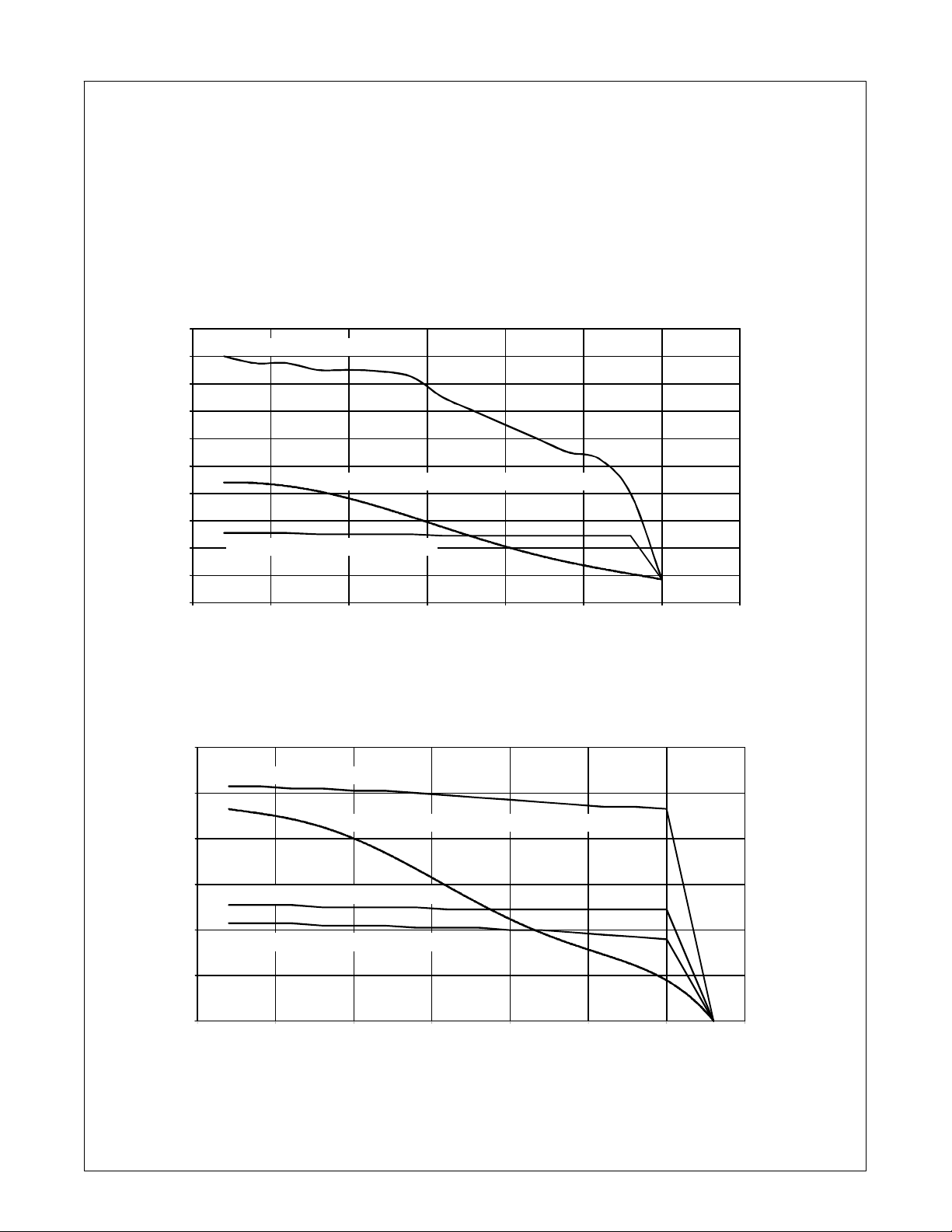

4-10. Hydraulic Pressure Curves (Models With Hydraulic Power Source) 17..........................

SECTION 5 − PRESTART CHECKS 18...........................................................

5-1. Hydraulic System Prestart Checks (Models With Hydraulic Power Source) 18....................

5-2. Engine Prestart Checks 18...............................................................

5-3. Compressor Prestart Checks 19..........................................................

SECTION 6 − OPERATION 20..................................................................

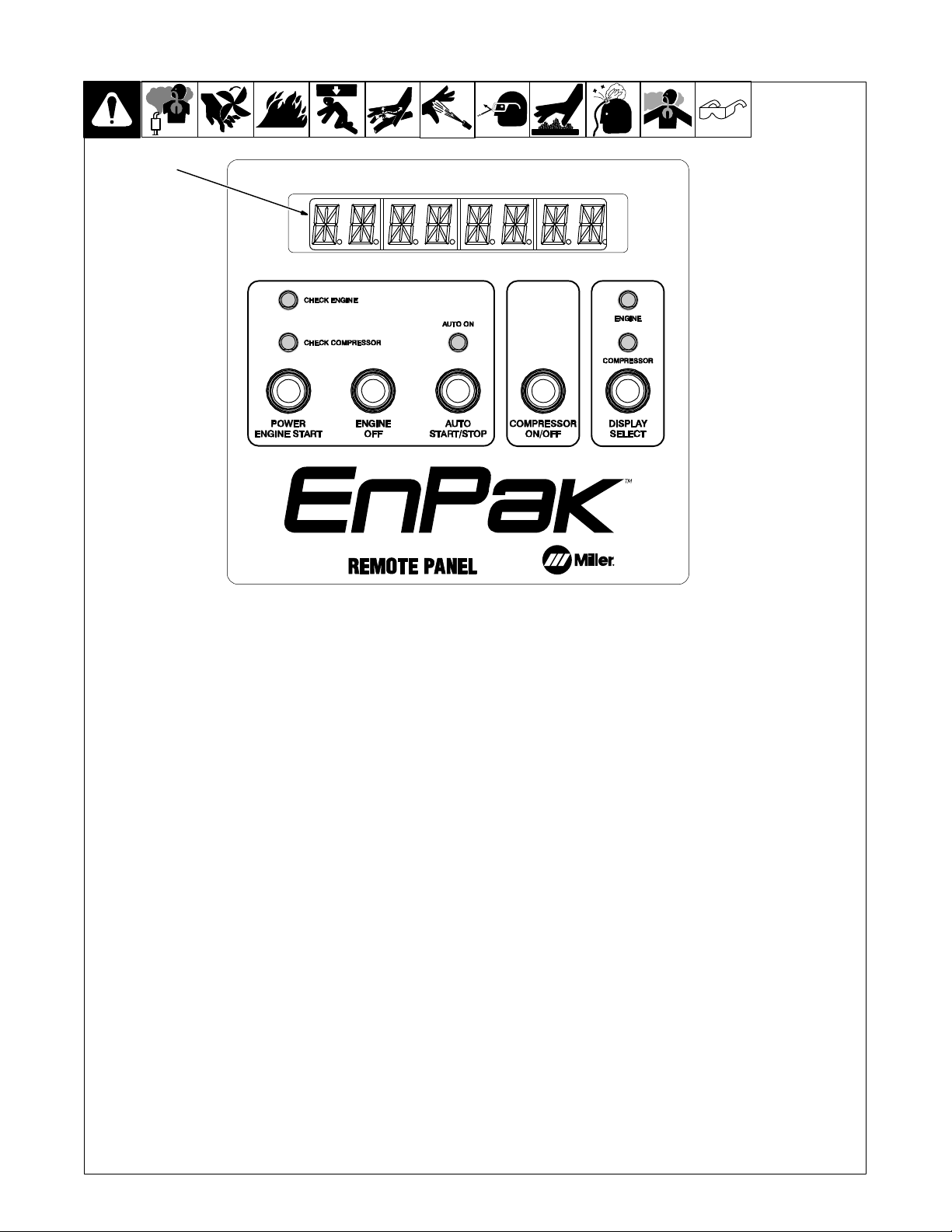

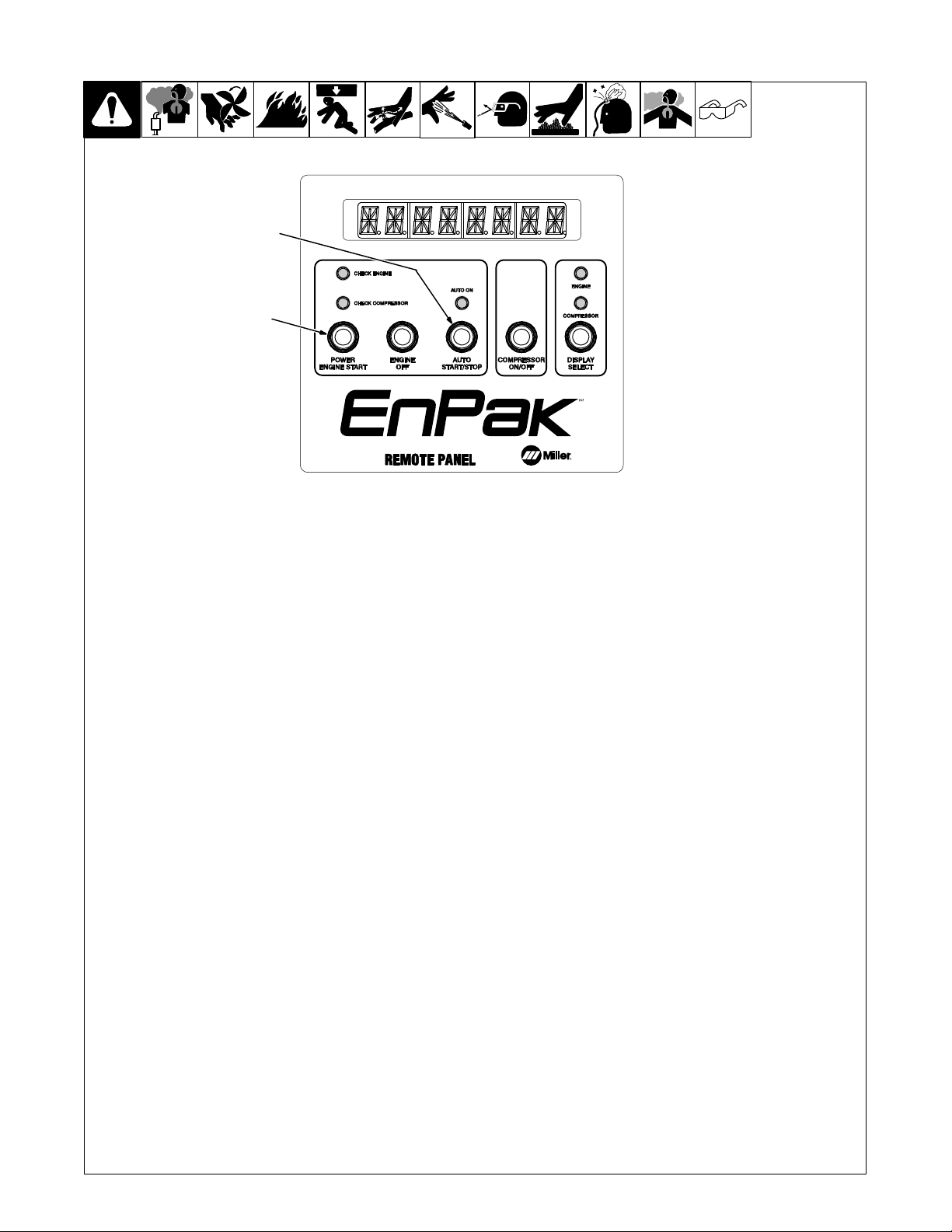

6-1. Remote Panel (Use With Section 6-2) 20...................................................

6-2. Remote Panel Operation (Use With Section 6-1) 21..........................................

6-3. Safety Interlock 21......................................................................

6-4. Operation And Error Messages 22.........................................................

6-5. Auto Start/Stop Operation 23.............................................................

6-6. Cold Weather Starting And Operation 24...................................................

6-7. Service Panel 26.......................................................................

6-8. Hydraulic Pump Operation (Models With Hydraulic Power Source) 27...........................

SECTION 7 − COMPRESSOR OPERATION 28....................................................

7-1. Air Compressor Controls 28..............................................................

7-2. Compressor Blow Down 29..............................................................

SECTION 8 − MAINTENANCE 30...............................................................

8-1. Maintenance Label 30...................................................................

8-2. Routine Maintenance 31.................................................................

8-3. Servicing Engine Air Cleaner 33...........................................................

8-4. Safety Interlock Monthly Check (Models With Hydraulic Power Source) 33.......................

TABLE OF CONTENTS

8-5. Changing Engine Oil, Oil Filter, And Fuel Filters 34...........................................

8-6. Engine Sensors And Governor Locations 35................................................

8-7. Changing Compressor Oil, Air Cleaner, And Air/Oil Separator 36...............................

SECTION 9 − TROUBLESHOOTING 37..........................................................

9-1. Generator Power Troubleshooting 37......................................................

9-2. Engine Troubleshooting 37...............................................................

9-3. Compressor Troubleshooting 38..........................................................

9-4. Hydraulic Troubleshooting (Models With Hydraulic Power Source) 39...........................

SECTION 10 − AUTHORIZED DEALER INSTALLATION INFORMATION 41...........................

10-1. Serial Number And Rating Label Location 41................................................

10-2. Installing Unit 41........................................................................

10-3. Mounting Unit 42.......................................................................

SECTION 11 − HYDRAULIC SYSTEM PREPARATION (MODELS WITH HYDRAULIC POWER SOURCE) . . .

43

11-1. Hydraulic System Integration 43...........................................................

11-2. Hydraulic Hose Connections 45...........................................................

11-3. Priming Hydraulic Pump 46...............................................................

11-4. Load Sense Line Bleeding (Closed Center Systems Only) 47..................................

SECTION 12 − ENGINE PREPARATION 48.......................................................

12-1. Connecting the Battery 48................................................................

12-2. Installing Exhaust Pipe 49................................................................

12-3. Fuel Connections 50....................................................................

SECTION 13 − AIR COMPRESSOR SYSTEM PREPARATION 51....................................

13-1. Air Compressor System Integration 51.....................................................

13-2. Compressor Connections 52.............................................................

13-3. Compressor Safety Valve Testing 53.......................................................

SECTION 14 − REMOTE DEVICES CONNECTIONS 54............................................

14-1. Remote Devices Connections 54..........................................................

SECTION 15 − AUXILIARY POWER SYSTEM CONNECTIONS 55...................................

15-1. Grounding Auxiliary Power System To Truck Frame 55.......................................

15-2. Auxiliary Power System Connections And Overload Protection 56..............................

SECTION 16 − DIAGRAMS 58..................................................................

SECTION 17 − GENERATOR POWER GUIDELINES 65............................................

SECTION 18 − PARTS LIST 72.................................................................

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING

Enpak_2011−10

Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions.

1-1. Symbol Usage

DANGER! − Indicates a hazardous situation which, if

not avoided, will result in death or serious injury. The

possible hazards are shown in the adjoining symbols

or explained in the text.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury. The possible

hazards are shown in the adjoining symbols or explained in the text.

NOTICE − Indicates statements not related to personal injury.

1-2. Engine Hazards

The symbols shown below are used throughout this manual

to call attention to and identify possible hazards. When you

see the symbol, watch out, and follow the related instructions

to avoid the hazard. The safety information given below is

only a summary of the more complete safety information

found in the Safety Standards listed in Section 1-7. Read and

follow all Safety Standards.

Only qualified persons should install, operate, maintain, and

repair this unit.

During operation, keep everybody, especially children, away.

BATTERY EXPLOSION can injure.

D Always wear a face shield, rubber gloves, and

protective clothing when working on a battery.

D Stop engine before disconnecting or connect-

ing battery cables, battery charging cables (if

applicable), or servicing battery.

D Do not allow tools to cause sparks when working on a battery.

D Do not use this unit to charge batteries or jump start vehicles un-

less it has a battery charging feature designed for this purpose.

D Observe correct polarity (+ and −) on batteries.

D Disconnect negative (−) cable first and connect it last.

D Keep sparks, flames, cigarettes, and other ignition sources

away from batteries. Batteries produce explosive gases during

normal operation and when being charged.

D Follow battery manufacturer’s instructions when working on or

near a battery.

BATTERY CHARGING OUTPUT can injure.

(Battery charging feature not present on all models.)

D Have only qualified persons do battery charging work.

D Charge lead-acid batteries only. Do not use battery charger to

supply power to an extra-low-voltage electrical system or to

charge dry cell batteries.

D Do not charge a frozen battery.

D Do not use damaged charging cables.

D Do not charge a battery that has loose terminals or one showing

damage such as a cracked case or cover.

D Before charging battery, select correct charger voltage to match

battery voltage.

D Set battery charging controls to the Off position before connect-

ing to battery. Do not allow battery charging clips to touch each

other.

D Keep charging cables away from vehicle hood, door, or moving

parts.

. Indicates special instructions.

This group of symbols means Warning! Watch Out! ELECTRIC

SHOCK, MOVING PARTS, and HOT PARTS hazards. Consult symbols and related instructions below for necessary actions to avoid the

hazards.

FUEL can cause fire or explosion.

D Stop engine and let it cool off before checking or

adding fuel.

D Do not add fuel while smoking or if unit is near

any sparks or open flames.

D Do not overfill tank — allow room for fuel to expand.

D Do not spill fuel. If fuel is spilled, clean up before starting engine.

D Dispose of rags in a fireproof container.

D Always keep nozzle in contact with tank when fueling.

MOVING PARTS can injure.

D Keep away from moving parts such as fans,

belts, and rotors.

D Keep all doors, panels, covers, and guards

closed and securely in place.

D Stop engine before installing or connecting unit.

D Have only qualified persons remove doors, panels, covers, or

guards for maintenance and troubleshooting as necessary.

D To prevent accidental starting during servicing, disconnect

negative (−) battery cable from battery.

D Keep hands, hair, loose clothing, and tools away from moving

parts.

D Reinstall doors, panels, covers, or guards when servicing is

finished and before starting engine.

D Before working on generator, remove spark plugs or injectors to

keep engine from kicking back or starting.

D Block flywheel so that it will not turn while working on generator

components.

EXHAUST SPARKS can cause fire.

D Do not let engine exhaust sparks cause fire.

D Use approved engine exhaust spark arrestor in

required areas — see applicable codes.

HOT PARTS can burn.

D Do not touch hot parts bare handed.

D Allow cooling period before working on equip-

ment.

D To handle hot parts, use proper tools and/or

wear heavy, insulated welding gloves and

clothing to prevent burns.

OM-240 113 Page 1

STEAM AND HOT COOLANT can burn.

D If possible, check coolant level when engine is

cold to avoid scalding.

D Always check coolant level at overflow tank, if

present on unit, instead of radiator (unless told

otherwise in maintenance section or engine

manual).

D If the engine is warm, checking is needed, and there is no over-

flow tank, follow the next two statements.

D Wear safety glasses and gloves and put a rag over radiator cap.

D Turn cap slightly and let pressure escape slowly before

completely removing cap.

BATTERY ACID can BURN SKIN and EYES.

D Do not tip battery.

D Replace damaged battery.

D Flush eyes and skin immediately with water.

1-3. Hydraulic Hazards

Using a generator indoors CAN KILL

YOU IN MINUTES.

D Generator exhaust contains carbon monoxide.

This is a poison you cannot see or smell.

D NEVER use inside a home or garage, EVEN IF

doors and windows are open.

D Only use OUTSIDE and far away from windows, doors, and

vents.

ENGINE HEAT can cause fire.

D Do not locate unit on, over, or near combustible

surfaces or flammables.

D Keep exhaust and exhaust pipes way from

flammables.

HYDRAULIC EQUIPMENT can injure

or kill.

D Incorrect installation or operation of this unit

could result in equipment failure and personal

injury. Only qualified persons should install, operate, and service this unit according to its

Owner’s Manual, industry standards, and national, state, and local codes.

D Do not exceed the rated output or capacity of the hydraulic pump

or any equipment in the hydraulic system. Design hydraulic system so failure of any hydraulic component will not put people or

property at risk.

D Before working on hydraulic system, turn off and lockout/tagout

unit, release pressure, and be sure hydraulic pressure cannot be

accidentally applied.

D Do not work on hydraulic system with unit running unless you are

a qualified person and following the manufacturer’s instructions.

D Do not modify or alter hydraulic pump or manufacturer-supplied

equipment. Do not disconnect, disable, or override any safety

equipment in the hydraulic system.

D Use only components/accessories approved by the manufac-

turer.

D Keep away from potential pinch points or crush points created by

equipment connected to the hydraulic system.

D Do not work under or around any equipment that is supported

only by hydraulic pressure. Properly support equipment by

mechanical means.

MOVING PARTS can injure.

D Keep away from moving parts such as fans,

belts and rotors.

D Keep all doors, panels, covers, and guards

closed and securely in place.

D Keep hands, hair, loose clothing, and tools away from moving

parts.

D Before working on hydraulic system, turn off and lockout/tagout

unit, release pressure, and be sure hydraulic pressure cannot be

accidentally applied.

D Have only qualified people remove guards or covers for maint-

enance and troubleshooting as necessary.

D Reinstall doors, panels, covers, or guards when servicing is

finished and before starting engine.

HYDRAULIC FLUID can injure or kill.

D Before working on hydraulic system, turn off and

lockout/tagout unit, release pressure, and be sure

hydraulic pressure cannot be accidentally applied.

D Relieve pressure before disconnecting or con-

necting hydraulic lines.

D Check hydraulic system components and all con-

nections and hoses for damage, leaks, and wear

before operating unit.

D Wear protective equipment such as safety

glasses, leather gloves, heavy shirt and trousers,

high shoes, and a cap when working on hydraulic

system.

D Use a piece of paper or cardboard to search for leaks−−never use

bare hands. Do not use equipment if leaks are found.

D HYDRAULIC FLUID is FLAMMABLE−−do not work on hydraulics

near sparks or flames; do not smoke near hydraulic fluid.

D Reinstall doors, panels, covers, or guards when servicing is

finished and before starting unit.

D If ANY fluid is injected into the skin, it must be surgically removed

within a few hours by a doctor familiar with this type of injury or gangrene may result.

HOT PARTS AND FLUID can burn.

D Do not touch hot parts bare handed or allow hot

fluid to contact skin.

D Allow cooling period before working on equip-

ment.

D To handle hot parts, use proper tools and/or wear heavy, insu-

lated welding gloves and clothing to prevent burns.

READ INSTRUCTIONS.

D Read and follow all labels and the Owner’s Manu-

al carefully before installing, operating, or servicing unit. Read the safety information at the beginning of the manual and in each section.

D Use only genuine replacement parts from the manufacturer.

D Perform maintenance and service according to the Owner’s

Manuals, industry standards, and national, state, and local

codes.

OM-240 113 Page 2

1-4. Compressed Air Hazards

COMPRESSED AIR EQUIPMENT can

injure or kill.

D Incorrect installation or operation of this unit

could result in equipment failure and personal

injury. Only qualified persons should install, operate, and service this unit according to its

Owner’s Manual, industry standards, and national, state, and local codes.

D Do not exceed the rated output or capacity of the compressor or

any equipment in the compressed air system. Design compressed

air system so failure of any component will not put people or property at risk.

D Before working on compressed air system, turn off and lockout/

tagout unit, release pressure, and be sure air pressure cannot be

accidentally applied.

D Do not work on compressed air system with unit running unless

you are a qualified person and following the manufacturer’s instructions.

D Do not modify or alter compressor or manufacturer-supplied

equipment. Do not disconnect, disable, or override any safety

equipment in the compressed air system.

D Use only components and accessories approved by the manufac-

turer.

D Keep away from potential pinch points or crush points created by

equipment connected to the compressed air system.

D Do not work under or around any equipment that is supported only

by air pressure. Properly support equipment by mechanical

means.

HOT METAL from air arc cutting and

gouging can cause fire or explosion.

BREATHING COMPRESSED AIR can injure or kill.

D Do not use compressed air for breathing.

D Use only for cutting, gouging, and tools.

TRAPPED AIR PRESSURE AND WHIPPING

HOSES can injure.

D Release air pressure from tools and system be-

fore servicing, adding or changing attachments, or opening compressor oil drain or oil fill

cap.

MOVING PARTS can injure.

D Keep away from moving parts such as fans,

belts and rotors.

D Keep all doors, panels, covers, and guards

closed and securely in place.

D Keep hands, hair, loose clothing, and tools away from moving

parts.

D Before working on compressed air system, turn off and lockout/

tagout unit, release pressure, and be sure air pressure cannot be

accidentally applied.

D Have only qualified people remove guards or covers for maint-

enance and troubleshooting as necessary.

D Reinstall doors, panels, covers, or guards when servicing is

finished and before starting engine.

D Do not cut or gouge near flammables.

D Watch for fire; keep extinguisher nearby.

COMPRESSED AIR can injure or kill.

D Before working on compressed air system,

turn off and lockout/tagout unit, release pressure, and be sure air pressure cannot be accidentally applied.

D Relieve pressure before disconnecting or con-

necting air lines.

D Check compressed air system components

and all connections and hoses for damage,

leaks, and wear before operating unit.

D Do not direct air stream toward self or others.

D Wear protective equipment such as safety glasses, hearing pro-

tection, leather gloves, heavy shirt and trousers, high shoes, and

a cap when working on compressed air system.

D Use soapy water or an ultrasonic detector to search for

leaks−−never use bare hands. Do not use equipment if leaks are

found.

D Reinstall doors, panels, covers, or guards when servicing is

finished and before starting unit.

D If ANY air is injected into the skin or body seek medical help im-

mediately.

HOT PARTS can burn.

D Do not touch hot compressor or air system

parts.

D Allow cooling period before working on equip-

ment.

D To handle hot parts, use proper tools and/or wear heavy, insu-

lated welding gloves and clothing to prevent burns.

READ INSTRUCTIONS.

D Read and follow all labels and the Owner’s

Manual carefully before installing, operating, or

servicing unit. Read the safety information at

the beginning of the manual and in each

section.

D Use only genuine replacement parts from the manufacturer.

D Perform maintenance and service according to the Owner’s

Manuals, industry standards, and national, state, and local

codes.

OM-240 113 Page 3

1-5. Additional Symbols For Installation, Operation, And Maintenance

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks or

severe burns. Machine internal circuits are live when

power is on. Incorrectly installed or improperly

grounded equipment is a hazard.

D Do not touch live electrical parts.

D Do not use AC output in damp areas, if movement is confined, or if

there is a danger of falling.

D Disconnect input power or stop engine before installing or

servicing this equipment. Lockout/tagout input power according to

OSHA 29 CFR 1910.147 (see Safety Standards).

D Properly install, ground, and operate this equipment according to

its Owner’s Manual and national, state, and local codes.

D Turn off all equipment when not in use.

D Use only well-maintained equipment. Repair or replace damaged

parts at once. Maintain unit according to manual.

D Keep all panels and covers securely in place.

FIRE OR EXPLOSION hazard.

D Do not install or place unit on, over, or near

combustible surfaces.

D Do not install unit near flammables.

D Do not overload building wiring − be sure power supply system is

properly sized, rated, and protected to handle this unit.

FALLING EQUIPMENT can injure.

D Use lifting eye to lift unit and properly installed

accessories only, NOT gas cylinders. Do not

exceed maximum lift eye weight rating (see

Specifications).

D Use equipment of adequate capacity to lift and

support unit.

D If using lift forks to move unit, be sure forks are long enough to

extend beyond opposite side of unit.

D Keep equipment (cables and cords) away from moving vehicles

when working from an aerial location.

D Follow the guidelines in the Applications Manual for the Revised

NIOSH Lifting Equation (Publication No. 94−110) when manually lifting heavy parts or equipment.

OVERHEATING can damage motors.

D Turn off or unplug equipment before starting or

stopping engine.

D Do not let low voltage and frequency caused by

low engine speed damage electric motors.

D Do not connect 50 or 60 Hertz motors to the 100 Hertz receptacle

where applicable.

FLYING SPARKS can injure.

D Wear a face shield to protect eyes and face.

D Shape tungsten electrode only on grinder with

proper guards in a safe location wearing proper

face, hand, and body protection.

D Sparks can cause fires — keep flammables away.

MOVING PARTS can injure.

D Keep away from moving parts.

D Keep away from pinch points such as drive

rolls.

OVERUSE can cause OVERHEATING.

D Allow cooling period; follow rated duty cycle.

D Do not block or filter airflow to unit.

STATIC (ESD) can damage PC boards.

D Put on grounded wrist strap BEFORE handling

boards or parts.

D Use proper static-proof bags and boxes to

store, move, or ship PC boards.

TILTING OF TRAILER can injure.

D Use tongue jack or blocks to support weight.

D Properly install welding generator onto trailer

according to instructions supplied with trailer.

READ INSTRUCTIONS.

D Read and follow all labels and the Owner’s

Manual carefully before installing, operating, or

servicing unit. Read the safety information at

the beginning of the manual and in each

section.

D Use only genuine replacement parts from the manufacturer.

D Perform maintenance and service according to the Owner’s

Manuals, industry standards, and national, state, and local

codes.

OM-240 113 Page 4

1-6. California Proposition 65 Warnings

Welding or cutting equipment produces fumes or gases

which contain chemicals known to the State of California to

cause birth defects and, in some cases, cancer. (California

Health & Safety Code Section 25249.5 et seq.)

Battery posts, terminals and related accessories contain lead

and lead compounds, chemicals known to the State of

California to cause cancer and birth defects or other

reproductive harm. Wash hands after handling.

This product contains chemicals, including lead, known to

the state of California to cause cancer, birth defects, or other

reproductive harm. Wash hands after use.

1-7. Principal Safety Standards

For Gasoline Engines:

Engine exhaust contains chemicals known to the State of

California to cause cancer, birth defects, or other reproductive harm.

For Diesel Engines:

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

National Electrical Code, NFPA Standard 70, from National Fire Protection Association, Quincy, MA 02269 (phone: 1-800-344-3555, website:

www.nfpa.org and www. sparky.org).

Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet P-1,

from Compressed Gas Association, 14501 George Carter Way, Suite

103, Chantilly, VA 20151 (phone: 703-788-2700, website:

www.cganet.com).

Battery Chargers, CSA Standard C22.2 NO 107.2−01, from Canadian

Standards Association, Standards Sales, 5060 Spectrum Way, Suite

100, Ontario, Canada L4W 5NS (phone: 800-463-6727, website:

www.csa-international.org).

Safe Practice For Occupational And Educational Eye And Face Protection, ANSI Standard Z87.1, from American National Standards Institute,

25 West 43rd Street, New York, NY 10036 (phone: 212-642-4900, website: www.ansi.org).

For Standards about hydraulic systems, contact the National Fluid

Power Association, Publications Department, 3333 North Mayfair

Road, Suite 211, Milwaukee, WI 53222-3219 (phone: (414) 778-3344,

website: www.nfpa.com).

OSHA, Occupational Safety and Health Standards for General Industry, Title 29, Code of Federal Regulations (CFR), Part 1910, Subpart Q,

and Part 1926, Subpart J, from U.S. Government Printing Office, Superintendent of Documents, P.O. Box 371954, Pittsburgh, PA 15250-7954

(phone: 1-866-512-1800) (there are 10 OSHA Regional Offices—

phone for Region 5, Chicago, is 312-353-2220, website:

www.osha.gov).

Portable Generators Safety Alert, U.S. Consumer Product Safety Commission (CPSC), 4330 East West Highway, Bethesda, MD 20814

(phone: 301-504-7923, website: www.cpsc.gov/cpscpub/pubs/portgen.pdf

Applications Manual for the Revised NIOSH Lifting Equation, The National Institute for Occupational Safety and Health (NIOSH), 1600

Clifton Rd, Atlanta, GA 30333 (phone: 1-800-232-4636, website:

www.cdc.gov/NIOSH).

OM-240 113 Page 5

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT

UTILISATION

Enpak_2011−10_fre

Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives

aux précautions de sécurité et au mode opératoire.

2-1. Signification des symboles

DANGER! − Indique une situation dangereuse qui si on

l’évite pas peut donner la mort ou des blessures graves.

Les dangers possibles sont montrés par les symboles

joints ou sont expliqués dans le texte.

Indique une situation dangereuse qui si on l’évite pas

peut donner la mort ou des blessures graves. Les dangers possibles sont montrés par les symboles joints ou

sont expliqués dans le texte.

NOTE − Indique des déclarations pas en relation avec des blessures

personnelles.

. Indique des instructions spécifiques.

Ce groupe de symboles veut dire Avertissement! Attention! DANGER

DE CHOC ELECTRIQUE, PIECES EN MOUVEMENT, et PIECES

CHAUDES. Consulter les symboles et les instructions ci-dessous y

afférant pour les actions nécessaires afin d’éviter le danger.

2-2. Dangers existant en relation avec le moteur

Les symboles présentés ci-après sont utilisés tout au long du

présent manuel pour attirer votre attention et identifier les risques de danger. Lorsque vous voyez un symbole, soyez

vigilant et suivez les directives mentionnées afin d’éviter tout

danger. Les consignes de sécurité présentées ci-après ne

font que résumer l’information contenue dans les normes de

sécurité énumérées à la section 2-7. Veuillez lire et respecter

toutes ces normes de sécurité.

L’installation, l’utilisation, l’entretien et les réparations ne

doivent être confiés qu’à des personnes qualifiées.

Au cours de l’utilisation, tenir toute personne à l’écart et plus

particulièrement les enfants.

L’EXPLOSION DE LA BATTERIE

peut provoquer des blessures.

D Toujours porter une protection faciale, des

gants en caoutchouc et vêtements de protection lors d’une intervention sur la batterie.

D Arrêter le moteur avant de débrancher ou de brancher des câbles

de batterie, des câbles de chargeur de batterie (le cas échéant) ou

de batterie d’entretien.

D Eviter de provoquer des étincelles avec les outils en travaillant sur

la batterie.

D Ne pas utiliser l’appareil pour charger des batteries ou faire dé-

marrer des véhicules à l’aide de câbles de démarrage, sauf si

l’appareil dispose d’une fonctionnalité de charge de batterie destinée à cet usage.

D Observer la polarité correcte (+ et −) sur les batteries.

D Débrancher le câble négatif (–) en premier lieu. Le rebrancher en

dernier lieu.

D Les sources d’étincelles, flammes nues, cigarettes et autres

sources d’inflammation doivent être maintenues à l’écart des

batteries. Ces dernières produisent des gaz explosifs en

fonctionnement normal et en cours de charge.

D Respecter les consignes du fabricant de la batterie pour

travailler sur une batterie ou à proximité.

Le COURANT DE CHARGE DE BATTERIE peut

provoquer des blessures

batterie n’est pas disponible sur tous les modèles).

D Les opérations de charge de batterie ne doivent être effectuées

que par des personnes qualifiées.

D Ne charger que des batteries plomb−acide. Ne pas utiliser le

chargeur de batterie pour alimenter un autre circuit électrique

basse tension ou pour charger des batteries sèches.

D Ne pas charger une batterie gelée.

D Ne pas utiliser de câbles de charge endommagés.

(la fonctionnalité de charge de

D Ne pas charger une batterie dont les bornes sont desserrées ou

D Avant de charger une batterie, sélectionner la tension de charge

D Régler les commandes de charge de batterie sur la position d’arrêt

D Ranger les câbles de charge à distance du capot, des portes et

D Ne pas faire le plein en fumant ou proche d’une source d’étincel-

D Ne pas faire le plein de carburant à ras bord; prévoir de l’espace

D Faire attention de ne pas renverser de carburant. Nettoyer tout

D Jeter les chiffons dans un récipient ignifuge.

D Toujours garder le pistolet en contact avec le réservoir lors du

D Maintenir fermés et verrouillés les portes, panneaux,

D Arrêter le moteur avant d’installer ou brancher l’appareil.

D Lorsque cela est nécessaire pour des travaux d entretien et de

D Pour empêcher tout démarrage accidentel pendant les travaux

D Ne pas approcher les mains, cheveux, vêtements lâches et outils

D Remettre en place les portes, panneaux, recouvrements ou

D Avant d’intervenir, déposer les bougies ou injecteurs pour éviter la

D Bloquer le volant moteur pour éviter sa rotation lors d’une

présentant une détérioration comme par exemple un boîtier ou un

couvercle fissuré.

correspondant à la tension de la batterie.

avant de brancher la batterie. Veiller à ce que les pinces de charge

ne se touchent pas.

des pièces mobiles du véhicule.

LE CARBURANT MOTEUR peut provoquer un incendie ou une explosion.

D Arrêter le moteur avant de vérifier le niveau de

carburant ou de faire le plein.

les ou d’une flamme nue.

pour son expansion.

carburant renversé avant de faire démarrer le moteur.

remplissage.

Les PIÈCES MOBILES peuvent causer

des blessures.

D S’abstenir de toucher des parties mobiles telles

que des ventilateurs, courroies et rotors.

recouvrements et dispositifs de protection.

dépannage, faire retirer les portes, panneaux, recouvrements ou

dispositifs de protection uniquement par du personnel qualifié.

d’entretien, débrancher le câble négatif (−) de batterie de la borne.

des organes mobiles.

dispositifs de protection à la fin des travaux d’entretien et avant de

mettre le moteur en marche.

mise en route accidentelle du moteur.

intervention sur le générateur.

OM-240 113 Page 6

LES ÉTINCELLES À L’ÉCHAPPEMENT

s

e

r

peuvent provoquer un incendie.

D Empêcher les étincelles d’échappement du

moteur de provoquer un incendie.

D Utiliser uniquement un pare-étincelles

approuvé − voir codes en vigueur.

LES PIÈCES CHAUDES peuvent

provoquer des brûlures.

D Ne pas toucher des parties chaudes à main

nues.

D Prévoir une période de refroidissement avant d

travailler à l’équipement.

D Ne pas toucher aux pièces chaudes, utiliser les outils recomman

dés et porter des gants de soudage et des vêtements épais pou

éviter les brûlures.

LA VAPEUR ET LE LIQUIDE DE

REFROIDISSEMENT CHAUD peuvent

provoquer des brûlures.

D Il est préférable de vérifier le liquide de refroi-

dissement une fois le moteur refroidi pour éviter

de se brûler.

D Toujours vérifier le niveau de liquide de refroidissement dans le

vase d’expansion (si présent), et non dans le radiateur (sauf si précisé autrement dans la section maintenance du manuel du

moteur).

D Si le moteur est chaud et que le liquide doit être vérifié, opérer com-

me suivant.

D Mettre des lunettes de sécurité et des gants, placer un torchon sur

le bouchon du radiateur.

D Dévisser le bouchon légèrement et laisser la vapeur s’échapper

avant d’enlever le bouchon.

L’ACIDE DE LA BATTERIE peut provoquer des brûlures dans les YEUX et

sur la PEAU.

D Ne pas renverser la batterie.

D Remplacer une batterie endommagée.

D Rincer immédiatement les yeux et la peau à l’eau.

L’utilisation d’un groupe autonome

à l’intérieur PEUT VOUS TUER EN

QUELQUES MINUTES.

D Les fumées d’un groupe autonome contient du

monoxyde de carbone. C’est un poison invisible et inodore.

D JAMAIS utiliser dans une maison ou garage, même avec les por-

tes et fenêtres ouvertes.

D Uniquement utiliser à l’EXTERIEUR, loin des portes, fenêtres et

bouches aération.

LA CHALEUR DU MOTEUR peut provoquer un incendie.

D Ne pas placer l’appareil sur, au-dessus ou à

proximité de surfaces inflammables.

D Tenir à distance les produits inflammables de l’échappement.

2-3. Dangers liés à l’hydraulique

Les ÉQUIPEMENTS HYDRAULIQUES

peuvent provoquer des blessures ou

même la mort.

D Une installation ou une utilisation incorrecte

de cet appareil pourrait conduire à des dégâts

matériels ou corporels. Seul un personnel

qualifié est autorisé à installer, faire fonctionner

et réparer cet appareil conformément à son

manuel d’utilisation, aux normes industrielles

et aux codes nationaux, d’état ou locaux.

D Ne pas dépasser le débit nominal ou la capacité de la pompe

hydraulique ou de tout équipement du circuit hydraulique.

Concevoir le circuit hydraulique de telle sorte que la défaillance

d’un composant hydraulique ne risque pas de provoquer

un accident matériel ou corporel.

D Avant d’intervenir sur le circuit hydraulique, couper l’alimentation

électrique, verrouiller et étiqueter l’appareil, détendre la pression

et s’assurer que le circuit hydraulique ne peut être remis sous

pression par inadvertance.

D Ne pas intervenir sur le circuit hydraulique lorsque l’appareil

fonctionne. Seul un personnel qualifié et appliquant les consignes

du fabricant est autorisé le faire.

D Ne pas modifier ou altérer la pompe hydraulique ou

les équipements fournis par le fabricant. Ne pas débrancher,

désactiver ou neutraliser les équipements de sécurité du circuit

hydraulique.

D Utiliser uniquement des composants et accessoires homologués

par le fabricant.

D Se tenir à l’écart de tout point présentant un danger de pincement

ou d’écrasement créé par l’équipement raccordé au circuit

hydraulique.

D Ne pas intervenir sous ou autour d’un équipement qui n’est

soutenu que par la pression hydraulique. Soutenir l’équipement

de façon appropriée par un moyen mécanique.

Les PIÈCES MOBILES peuvent causer

des blessures.

D S’abstenir de toucher des parties mobiles telles

que des ventilateurs, courroies et rotors.

D Maintenir fermés et verrouillés les portes,

panneaux, recouvrements et dispositifs

de protection.

D Ne pas approcher les mains, cheveux, vêtements lâches et outils

des organes mobiles.

D Avant d’intervenir sur le circuit hydraulique, couper l’alimentation

électrique, verrouiller et étiqueter l’appareil, détendre la pression

et s’assurer que le circuit hydraulique ne peut être remis sous

pression par inadvertance.

D Demander seulement à un personnel qualifié d’enlever

les dispositifs de sécurité ou les recouvrements pour effectuer,

s’il y a lieu, des travaux d’entretien et de dépannage.

D Remettre en place les portes, panneaux, recouvrements ou

dispositifs de protection à la fin des travaux d’entretien et avant

de mettre le moteur en marche.

OM-240 113 Page 7

Le LIQUIDE HYDRAULIQUE risque de

provoquer des blessures ou même la mort.

D Avant d’intervenir sur le circuit hydraulique,

couper l’alimentation électrique, verrouiller

et étiqueter l’appareil, détendre la pression

et s’assurer que le circuit hydraulique ne peut

être remis sous pression par inadvertance.

D Détendre la pression avant de débrancher ou

de brancher des canalisations hydrauliques.

D Avant d’utiliser l’appareil, contrôler

les composants du circuit hydraulique,

les branchements et les flexibles en recherchant

tout signe de détérioration, de fuite et d’usure.

D Pour intervenir sur un circuit hydraulique, porter un équipement

de protection tel que des lunettes de sécurité, des gants de cuir,

une chemise et un pantalon en tissu résistant, des chaussures

montantes et une coiffe.

D Pour rechercher des fuites, utiliser un morceau de papier ou

de carton, jamais les mains nues. En cas de détection de fuite,

ne pas utiliser l’équipement.

D Le LIQUIDE HYDRAULIQUE est INFLAMMABLE. Ne pas

intervenir sur des composants hydrauliques à proximité

d’étincelles ou de flammes; ne pas fumer à proximité de liquide

hydraulique.

D Remettre les portes, panneaux, recouvrements ou dispositifs

de protection quand l’entretien est terminé et avant de mettre

en marche l’appareil.

D En cas de pénétration d’un QUELCONQUE liquide dans la peau,

celui−ci doit être retiré chirurgicalement sous quelques heures par

un médecin familiarisé avec ce type de blessure, faute de quoi

la gangrène pourrait apparaître.

LES PIÈCES ET LIQUIDES CHAUDS

peuvent provoquer des brûlures.

D Ne pas toucher les pièces chaudes à main nue

ni laisser des liquides chauds entrer en contact

avec la peau.

D Prévoir une période de refroidissement avant d’intervenir

sur l’équipement.

D Ne pas toucher aux pièces chaudes, utiliser les outils

recommandés et porter des gants de soudage et des vêtements

épais pour éviter les brûlures.

LIRE LES INSTRUCTIONS.

D Lire et appliquer les instructions sur les

étiquettes et le Mode d’emploi avant

l’installation, l’utilisation ou l’entretien de

l’appareil. Lire les informations de sécurité au

début du manuel et dans chaque section.

D N’utiliser que les pièces de rechange recommandées par le

constructeur.

D Effectuer l’entretien en respectant les manuels d’utilisation,

les normes industrielles et les codes nationaux, d’état et locaux.

2-4. Dangers liés à l’air comprimé

Un ÉQUIPEMENT PNEUMATIQUE risque

de provoquer des blessures ou même

la mort.

D Une installation ou une utilisation incorrecte de

cet appareil pourrait conduire à des dégâts

matériels ou corporels. Seul un personnel

qualifié est autorisé à installer, utiliser et

entretenir cet appareil conformément à son

manuel d’utilisation, aux normes industrielles et

aux codes nationaux, d’état ou locaux.

D Ne pas dépasser le débit nominal ou la capacité du compresseur

ou de tout équipement du circuit d’air comprimé. Concevoir

le circuit d’air comprimé de telle sorte que la défaillance

d’un composant ne risque pas de provoquer un accident matériel

ou corporel.

D Avant d’intervenir sur le circuit d’air comprimé, couper

l’alimentation électrique, verrouiller et étiqueter l’appareil,

détendre la pression et s’assurer que le circuit d’air ne peut être

mis sous pression par inadvertance.

D Ne pas intervenir sur le circuit d’air comprimé lorsque l’appareil

fonctionne. Seul un personnel qualifié est autorisé, et appliquant

les consignes du fabricant.

D Ne pas modifier ou altérer le compresseur ou les équipements

fournis par le fabricant. Ne pas débrancher, désactiver ou

neutraliser les équipements de sécurité du circuit d’air comprimé.

D Utiliser uniquement des composants et accessoires homologués

par le fabricant.

D Se tenir à l’écart de tout point présentant un danger de pincement

ou d’écrasement créé par l’équipement raccordé au circuit d’air

comprimé.

D Ne pas intervenir sous ou autour d’un équipement qui n’est

soutenu que par la pression pneumatique. Soutenir l’équipement

de façon appropriée par un moyen mécanique.

MÉTAL CHAUD provenant du découpage ou du gougeage à l’arc risque de

provoquer un incendie ou une explosion.

D Ne pas découper ou gouger à proximité de

produits inflammables.

D Attention aux risques d’incendie: tenir un extincteur à proximité.

L’AIR COMPRIMÉ risque de provoquer

des blessures ou même la mort.

D Avant d’intervenir sur le circuit d’air comprimé,

couper l’alimentation électrique, verrouiller

et étiqueter l’appareil, détendre la pression

et s’assurer que le circuit d’air ne peut être mis

sous pression par inadvertance.

D Détendre la pression avant de débrancher ou

de brancher des canalisations d’air.

D Avant d’utiliser l’appareil, contrôler

les composants du circuit d’air comprimé,

les branchements et les flexibles en

recherchant tout signe de détérioration, de fuite

et d’usure.

D Ne pas diriger un jet d’air vers soi−même ou vers autrui.

D Pour intervenir sur un circuit d’air comprimé, porter un équipement

de protection tel que des lunettes de sécurité, des gants de cuir,

une chemise et un pantalon en tissu résistant, des chaussures

montantes et une coiffe.

D Pour rechercher des fuites, utiliser de l’eau savonneuse ou

un détecteur à ultrasons, jamais les mains nues. En cas

de détection de fuite, ne pas utiliser l’équipement.

OM-240 113 Page 8

D Remettre les portes, panneaux, recouvrements ou dispositifs

de protection quand l’entretien est terminé et avant de mettre

en marche l’appareil.

D En cas d’injection d’air dans la peau ou le corps, demander

immédiatement une assistance médicale.

L’INHALATION D’AIR COMPRIMÉ risque

de provoquer des blessures ou même

la mort.

D Ne pas inhaler d’air comprimé.

D Utiliser l’air comprimé uniquement pour

découper ou gouger ainsi que pour l’outillage

pneumatique.

Une PRESSION D’AIR RÉSIDUELLE

ET DES FLEXIBLES QUI FOUETTENT

risquent de provoquer des blessures.

D Détendre la pression pneumatique des outils et

circuits avant d’entretenir, ajouter ou changer

des accessoires et avant d’ouvrir le bouchon

de vidange ou de remplissage d’huile

du compresseur.

D Avant d’intervenir sur le circuit d’air comprimé, couper

l’alimentation électrique, verrouiller et étiqueter l’appareil,

détendre la pression et s’assurer que le circuit d’air ne peut être

mis sous pression par inadvertance.

D Demander seulement à un personnel qualifié d’enlever

les dispositifs de sécurité ou les recouvrements pour effectuer,

s’il y a lieu, des travaux d’entretien et de dépannage.

D Remettre en place les portes, panneaux, recouvrements ou

dispositifs de protection à la fin des travaux d’entretien et avant

de mettre le moteur en marche.

DES PIÈCES CHAUDES peuvent

provoquer des brûlures graves.

D Ne pas toucher de pièces chaudes

du compresseur ou du circuit d’air.

D Prévoir une période de refroidissement

avant d’intervenir sur l’équipement.

D Ne pas toucher aux pièces chaudes, utiliser les outils

recommandés et porter des gants de soudage et

des vêtements épais pour éviter les brûlures.

LIRE LES INSTRUCTIONS.

Les PIÈCES MOBILES peuvent causer

des blessures.

D S’abstenir de toucher des parties mobiles telles

que des ventilateurs, courroies et rotors.

D Maintenir fermés et verrouillés les portes,

panneaux, recouvrements et dispositifs

de protection.

D Ne pas approcher les mains, cheveux, vêtements lâches et outils

des organes mobiles.

D N’utiliser que les pièces de rechange recommandées par le

constructeur.

D Effectuer l’entretien en respectant les manuels d’utilisation,

les normes industrielles et les codes nationaux, d’état et locaux.

D Lire et appliquer les instructions sur les

étiquettes et le Mode d’emploi avant

l’installation, l’utilisation ou l’entretien de

l’appareil. Lire les informations de sécurité au

début du manuel et dans chaque section.

2-5. Dangers supplémentaires en relation avec l’installation, le fonctionnement et la maintenance

UN CHOC ÉLECTRIQUE peut tuer.

Un simple contact avec des pièces électriques peut

provoquer une électrocution ou des blessures graves.

Les circuits internes de l’appareil sont sous tension à

ce moment-là. Des matériels mal installés ou mal mis à

la terre présentent un danger.

D Ne jamais toucher les pièces électriques sous tension.

D Ne pas se servir de source électrique à courant électrique dans les

zones humides, dans les endroits confinés ou là où on risque de

tomber.

D Couper l’alimentation ou arrêter le moteur avant de procéder à

l’installation, à la réparation ou à l’entretien de l’appareil.

Déverrouiller l’alimentation selon la norme OSHA 29 CFR

1910.147 (voir normes de sécurité).

D Installez, mettez à la terre et utilisez correctement cet équipement

conformément à son Manuel d’Utilisation et aux réglementations

nationales, gouvernementales et locales.

D Mettre l’appareil hors tension quand on ne l’utilise pas.

D N’utiliser qu’un matériel en bon état. Réparer ou remplacer

sur-le-champ les pièces endommagées. Entretenir l’appareil

conformément à ce manuel.

D Porter un harnais de sécurité quand on travaille en hauteur.

D Ne pas surcharger l’installation électrique − s’assurer que l’ali-

mentation est correctement dimensionnée et protégée avant de

mettre l’appareil en service.

Risque D’INCENDIE OU

D’EXPLOSION.

D Ne pas placer l’appareil sur, au-dessus ou

à proximité de surfaces inflammables.

D Ne pas installer l’appareil à proximité de pro-

duits inflammables.

OM-240 113 Page 9

LA CHUTE DE L’ÉQUIPEMENT

e

-

-

,

peut provoquer des blessures.

D Utiliser l’anneau de levage pour lever l’appareil

et les accessoires correctement installées

seuls, PAS les bouteilles de gaz. Ne pas dépasser le poids nominal maximal de l’œilleton

(voir les spécifications).

D Utiliser un équipement de levage de capacité suffisante pour

lever l’appareil.

D En utilisant des fourches de levage pour déplacer l’unité, s’assu-

rer que les fourches sont suffisamment longues pour dépasser

du côté opposé de l’appareil.

D Tenir l’équipement (câbles et cordons) à distance des véhicules

mobiles lors de toute opération en hauteur.

D Suivre les consignes du Manuel des applications pour l’équation

de levage NIOSH révisée (Publication Nº94−110) lors du levage

manuelle de pièces ou équipements lourds.

LE SURCHAUFFEMENT peut

endommager le moteur électrique.

D Arrêter ou déconnecter l’équipement avant d

démarrer ou d’arrêter le moteur.

D Ne pas laisser tourner le moteur trop lentement sous risque d’en

dommager le moteur électrique à cause d’une tension et d’une fré

quence trop faibles.

D Ne pas brancher de moteur de 50 ou de 60 Hz à la prise de 100 Hz

s’il y a lieu.

LES ÉTINCELLES PROJETÉES

peuvent provoquer des blessures.

D Porter un écran facial pour protéger le visage et

les yeux.

D Affûter l’électrode au tungstène uniquement à

la meuleuse dotée de protecteurs. Cette manœuvre est à exécuter dans un endroit sûr lorsque l’on porte l’équipement homologué de protection du visage, des mains et du corps.

D Les étincelles risquent de causer un incendie − éloigner toute

substance inflammable.

Les PIÈCES MOBILES peuvent

causer des blessures.

D Ne pas s’approcher des organes mobiles.

D Ne pas s’approcher des points de coincement

tels que des rouleaux de commande.

L’EMPLOI EXCESSIF peut

SURCHAUFFER L’ÉQUIPEMENT.

D Laisser l’équipement refroidir ; respecter le fac-

teur de marche nominal.

D Ne pas obstruer les passages d’air du poste.

LES CHARGES ÉLECTROSTATIQUES peuvent endommager les

circuits imprimés.

D Établir la connexion avec la barrette de terre

avant de manipuler des cartes ou des pièces.

D Utiliser des pochettes et des boîtes antistatiques pour stocker,

déplacer ou expédier des cartes de circuits imprimes.

UNE REMORQUE QUI BASCULE peut

provoquer des blessures.

D Utiliser les supports de la remorque ou des

blocs pour soutenir le poids.

D Installer convenablement le poste sur la remor-

que comme indiqué dans le manuel s’y rapportant.

LIRE LES INSTRUCTIONS.

D Lire et appliquer les instructions sur les

étiquettes et le Mode d’emploi avant

l’installation, l’utilisation ou l’entretien de

l’appareil. Lire les informations de sécurité au

début du manuel et dans chaque section.

D N’utiliser que les pièces de rechange recommandées par le

constructeur.

D Effectuer l’entretien en respectant les manuels d’utilisation,

les normes industrielles et les codes nationaux, d’état et locaux.

2-6. Proposition californienne 65 Avertissements

Les équipements de soudage et de coupage produisent des

fumées et des gaz qui contiennent des produits chimiques

dont l’État de Californie reconnaît qu’ils provoquent des malformations congénitales et, dans certains cas, des cancers.

(Code de santé et de sécurité de Californie, chapitre 25249.5

et suivants)

Les batteries, les bornes et autres accessoires contiennent

du plomb et des composés à base de plomb, produits chimiques dont l’État de Californie reconnaît qu’ils provoquent des

cancers et des malformations congénitales ou autres

problèmes de procréation. Se laver les mains après manipu-

lation.

Ce produit contient des produits chimiques, notamment du

plomb, dont l’État de Californie reconnaît qu’ils provoquent

des cancers, des malformations congénitales ou d’autres

problèmes de procréation. Se laver les mains après

utilisation.

2-7. Principales normes de sécurité

National Electrical Code, NFPA Standard 70, from National Fire Protection Association, Quincy, MA 02269 (phone: 1-800-344-3555, website:

www.nfpa.org and www. sparky.org).

Safe Handling of Compressed Gases in Cylinders, CGA Pamphlet P-1,

from Compressed Gas Association, 4221 Walney Road, 5th Floor,

Chantilly, VA 20151 (phone: 703-788-2700, website:www.cganet.com).

Battery Chargers, CSA Standard C22.2 NO 107.2−01, from Canadian

Standards Association, Standards Sales, 5060 Spectrum Way, Suite

OM-240 113 Page 10

Pour les moteurs à essence :

Les gaz d’échappement des moteurs contiennent des produits chimiques dont l’État de Californie reconnaît qu’ils

provoquent des cancers et des malformations congénitales

ou autres problèmes de procréation.

Pour les moteurs diesel :

Les gaz d’échappement des moteurs diesel et certains de

leurs composants sont reconnus par l’État de Californie comme provoquant des cancers et des malformations

congénitales ou autres problèmes de procréation.

100, Ontario, Canada L4W 5NS (phone: 800-463-6727, website:

www.csa-international.org).

Safe Practice For Occupational And Educational Eye And Face Protection, ANSI Standard Z87.1, from American National Standards Institute,

25 West 43rd Street, New York, NY 10036 (phone: 212-642-4900, website: www.ansi.org).

For Standards about hydraulic systems, contact the National Fluid

Power Association, Publications Department, 3333 North Mayfair

Road, Suite 211, Milwaukee, WI 53222-3219 (phone: (414) 778-3344,

website: www.nfpa.com).

OSHA, Occupational Safety and Health Standards for General Industry, Title 29, Code of Federal Regulations (CFR), Part 1910, Subpart Q,

and Part 1926, Subpart J, from U.S. Government Printing Office, Superintendent of Documents, P.O. Box 371954, Pittsburgh, PA 15250-7954

(phone: 1-866-512-1800) (there are 10 OSHA Regional Offices—

phone for Region 5, Chicago, is 312-353-2220, website:

www.osha.gov).

U.S. Consumer Product Safety Commission (CPSC), 4330 East West

Highway, Bethesda, MD 20814 (phone: 301-504-7923, website:

www.cpsc.gov).

Applications Manual for the Revised NIOSH Lifting Equation, The National Institute for Occupational Safety and Health (NIOSH), 1600

Clifton Rd, Atlanta, GA 30333 (phone: 1-800-232-4636, website:

www.cdc.gov/NIOSH).

OM-240 113 Page 11

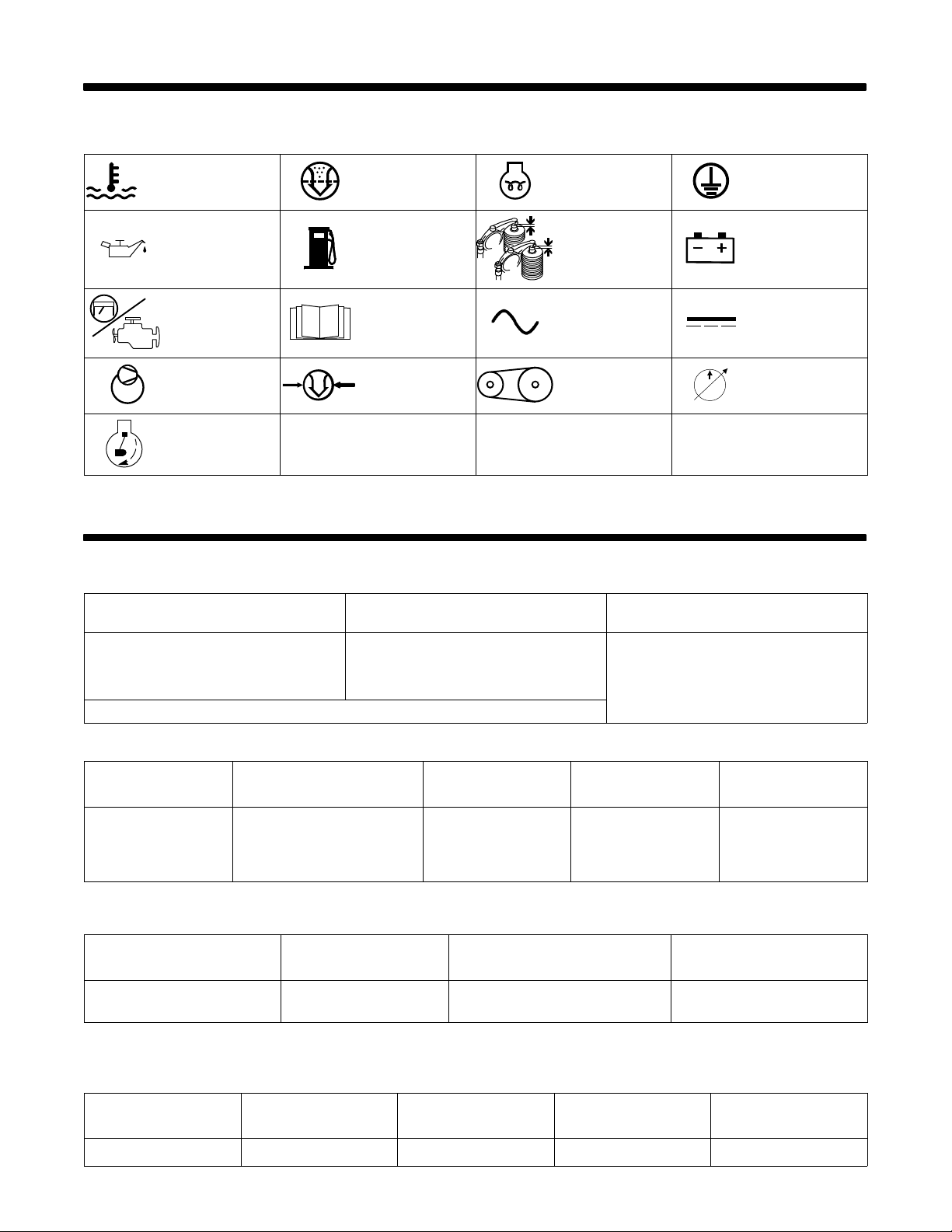

3-1. Symbol Definitions

SECTION 3 − DEFINITIONS

Engine Cooling Engine Air Filter Glow Plugs

Engine Oil Fuel

Engine

Air Compressor Air Pressure Engine Belt Hydraulic Pump

Crank Engine

Read Operator’s

Manual

SECTION 4 − SPECIFICATIONS

4-1. Auxiliary Power And Engine Specifications

Standard Generator Power Rating

Optional EnVertert AC To AC Converter

Power Rating

Check Valve

Clearance

Alternating Current

(AC)

Protective Earth

(Ground)

Battery (Engine)

Direct Current

(DC)

Engine

Single-Phase,

6 kVA/kW at 3600 RPM

120/240 V AC, 50/25 A,

60 Hz, Continuous

Combined Maximum Auxiliary Power Output (Standard Generator And EnVerter) Is 6kVA/kW

2.4 kVa/kW, 20 A at 2600 to 3600 RPM,

300 Watts at 1800 RPM

120 V AC Pure Sine Wave, Continuous

Kubota D1105−E3B, 3−Cylinder, 27.7 HP,

Liquid−Cooled, Diesel Engine w/Electronic

4-2. Air Compressor Specifications

Compressor Type

Rotary Screw

Air Output At Effective

Working Pressure

40 scfm @ 100 psi (1.13 m

−1

min

100% Duty Cycle, 3600 RPM

@ 689 kPa),

3

Range: 90−175 psi

(620−1206 kPa)

Factory set at 120 psi

Pressure

(827 kPa)

Safety Relief

Valve Setting

Auto Shutoff: 200 psi

(1379 kPa)

Pressure Relief: 200 psi

(1379 kPa)

4-3. Hydraulic Specifications (Models With Hydraulic Power Source)

Pump Type

Variable Displacement Piston

*Dependant on system cooling capacity.

8.5 GPM at 3000 psi at 3200

Rated

Output

RPM, 50% Duty Cycle*

Maximum Pressure Maximum Flow Rate

3500 psi (241.3 bar) 20 GPM (75.7 lpm)

4-4. Sound Level Table

Governor

Air Compressor

Oil Capacity

2 qt (1.9 L)

Idle Speed

1800 rpm

Air Compressor On 63 dB 68 dB 73 dB 75 dB

OM-240 113 Page 12

2600 rpm 3200 rpm 3600 rpm

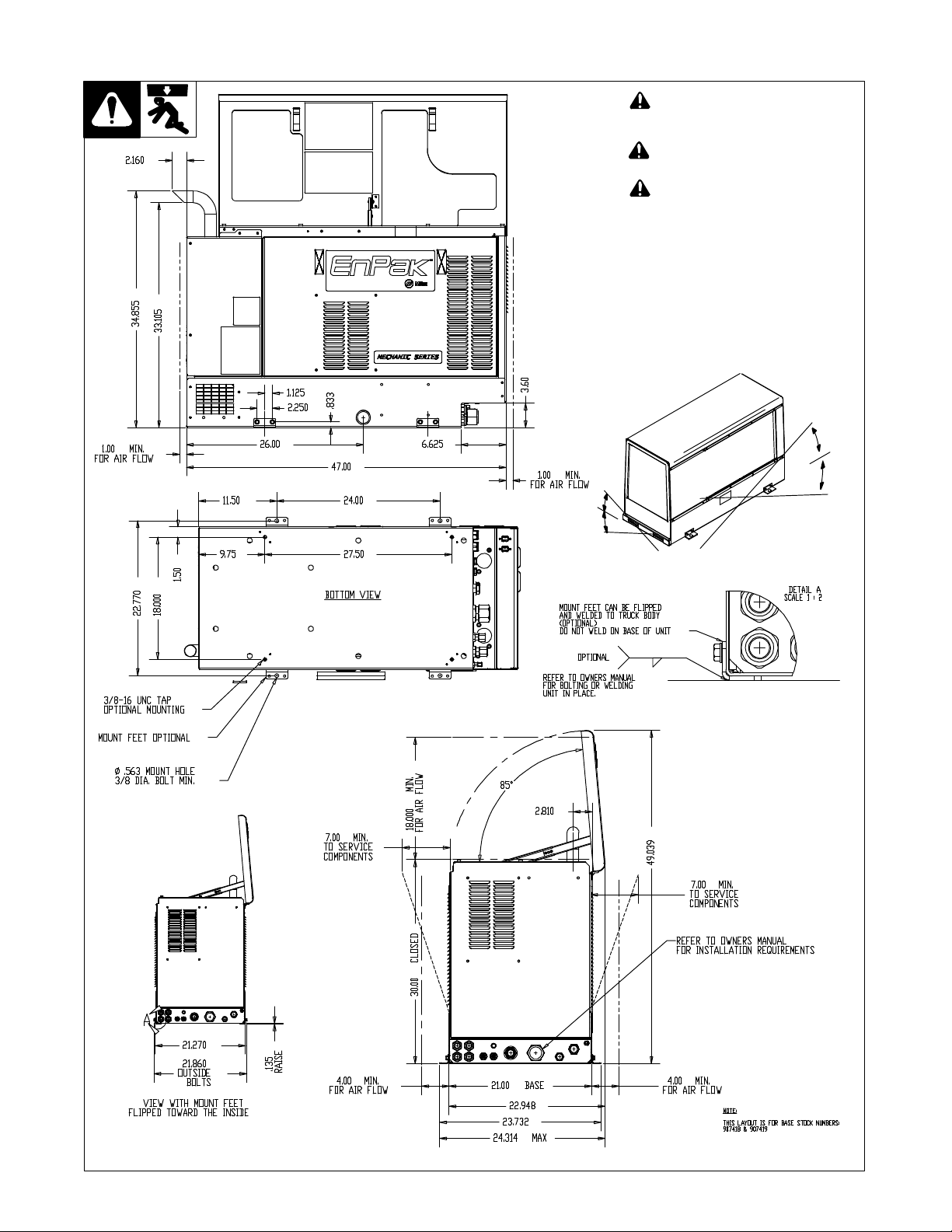

4-5. Dimensions, Weights, and Operating Angles

! Do not exceed tilt angles or engine

could be damaged or unit could

tip.

! Do not move or operate unit where

it could tip.

! Do not operate suspended from

lifting eye.

Weight: 870 lb (390 kg)

767 lb (348 kg) Without

Hydraulic Power Source

925 lb (419 kg) Fully Equipped

W/Packaging

Lifting Eye Weight Rating: 1000 lb (454

kg)

15°

15°

15°

15°

287 139-E

OM-240 113 Page 13

4-6. Fuel Consumption Curves

Compressor

1.80

1.60

1.40

1.20

1.00

0.80

0.60

U. S.. GAL./HR.

0.40

0.20

0.00

0 5 10 15 20 25 30 35 40 45 50

CUBIC FEET PER MINUTE (CFM)

Auxiliary Power

1.80

1.60

1.40

1.20

1.00

0.80

U. S.. GAL./HR.

0.60

0.40

0.20

0.00

0.0 1.0 2.0 3.0 4.0 5.0 6.0

AUXILIARY POWER IN KILOWATTS

Standard Auxiliary Power

Optional EnVertert Auxiliary Power

. Combined maximum auxiliary power output

(standard generator and EnVerter) is 6kVA/kW.

243 168-A / 243 169-A

OM-240 113 Page 14

4-7. Auxiliary Power Curves

EnVertert Power

240 VAC Auxiliary Power

120 VAC Auxiliary Power

300

250

200

150

VOLTS

100

50

0

20 40 60 800

. Combined maximum

auxiliary power output

(standard generator and

EnVerter) is 6kVA/kW.

AMPS

The AC generator power curves

show the generator power available

in amperes.

The EnVertert power curve shows

the power available in amperes.

Tools and motors are designed to

operate within 10% of 120/240

VAC.

. When the EnPak is running at

1800 RPM, the voltage output

of the generator is too low to activate some electric machines

that require the full 120 VAC or

240 VAC for operation. If the

electric machine that you are

using is not recognized as a

load by the EnPak, and does

not turn on, place the EnPak in

high speed. This will bring the

output of the generator up to

the normal 120 VAC or 240

VAC level, and the machine

that is plugged into the generator should work normally. This is

for the standard generator

power only, and does not apply

to the EnVerter power output

which is 120 VAC regardless of

engine RPM.

4-8. Alternator Power Curve

15

14.5

14

13.5

VOLTS

13

12.5

12

0 20 40 60 80 100

242 594-A

The alternator volt−ampere curve

shows the available alternator output at various engine rpm.

1800 RPM

3200 RPM

2600 RPM

3600 RPM

. Combined maximum

auxiliary power output

(standard generator and

EnVerter) is 6kVA/kW.

AMPS

242 595-A

OM-240 113 Page 15

4-9. Air Compressor Curves

50

CFM VS ENGINE RPM

45

40

35

30

25

24

20

15

10

5

CUBIC FEET PER MINUTE (CFM)

0

1800 2600 3200 3600

50

48

46

44

42

43

40

38

36

34

32

CUBIC FEET PER MINUTE (CFM)

30

100 125 150 175

32

ENGINE SPEED (RPM)

CFM VS PSI

42

PRESSURE (PSI)

41

43

39

40

OM-240 113 Page 16

Ref. 220 807−A

4-10. Hydraulic Pressure Curves (Models With Hydraulic Power Source)

. Curves are typical. Output will

vary depending on system

pressure losses to load sense

pressure location.

Fluid: ISO 32 Hydraulic Oil

Fluid Temperature: 49° C (120° F)

Load Sense Pressure:

Closed Center − 400 PSID

(27.6 bar)

Open Center − 200 PSID (13.8

bar)

Closed Center

20.0

18.0

16.0

14.0

12.0

Hydraulic Load Only

10.0

8.0

FLOW (GPM)

6.0

4.0

2.0

0.0

12.0

10.0

8.0

6.0

FLOW (GPM)

4.0

Hydraulic Load Only − Manual Mode

0 500 1000 1500 2000 2500 3000 3500

Hydraulic Load Only

Hydraulic Load Only − Manual Mode

Hydraulic Load Only − 1800 RPM (Outriggers)

Hydraulic +40 CFM @ 100 PSI Compressor Load

PRESSURE (PSI)

Open Center

Hydraulic +40 CFM @ 100 PSI Compressor Load

2.0

0.0

0 500 1000 1500 2000 2500 3000 3500

PRESSURE (PSI)

242 506-A / 242 507-A

OM-240 113 Page 17

SECTION 5 − PRESTART CHECKS

5-1. Hydraulic System Prestart Checks (Models With Hydraulic Power Source)

NOTICE − Ensure hydraulic system is properly connected with valves open before starting unit. Damage will result if unit is run before hydraulic system

is complete. Hydraulic pump does not disengage via clutch.

5-2. Engine Prestart Checks

Check all fluids daily. Engine must be

2

1

3

4

cold and on a level surface. Unit is

shipped with 10W30 engine oil.

. Follow run-in procedure in engine

manual.

. This unit has a low oil pressure

shutdown switch. However, some

conditions may cause engine damage before the engine shuts down.

Check oil level often and do not use

the oil pressure shutdown system

to monitor oil level.

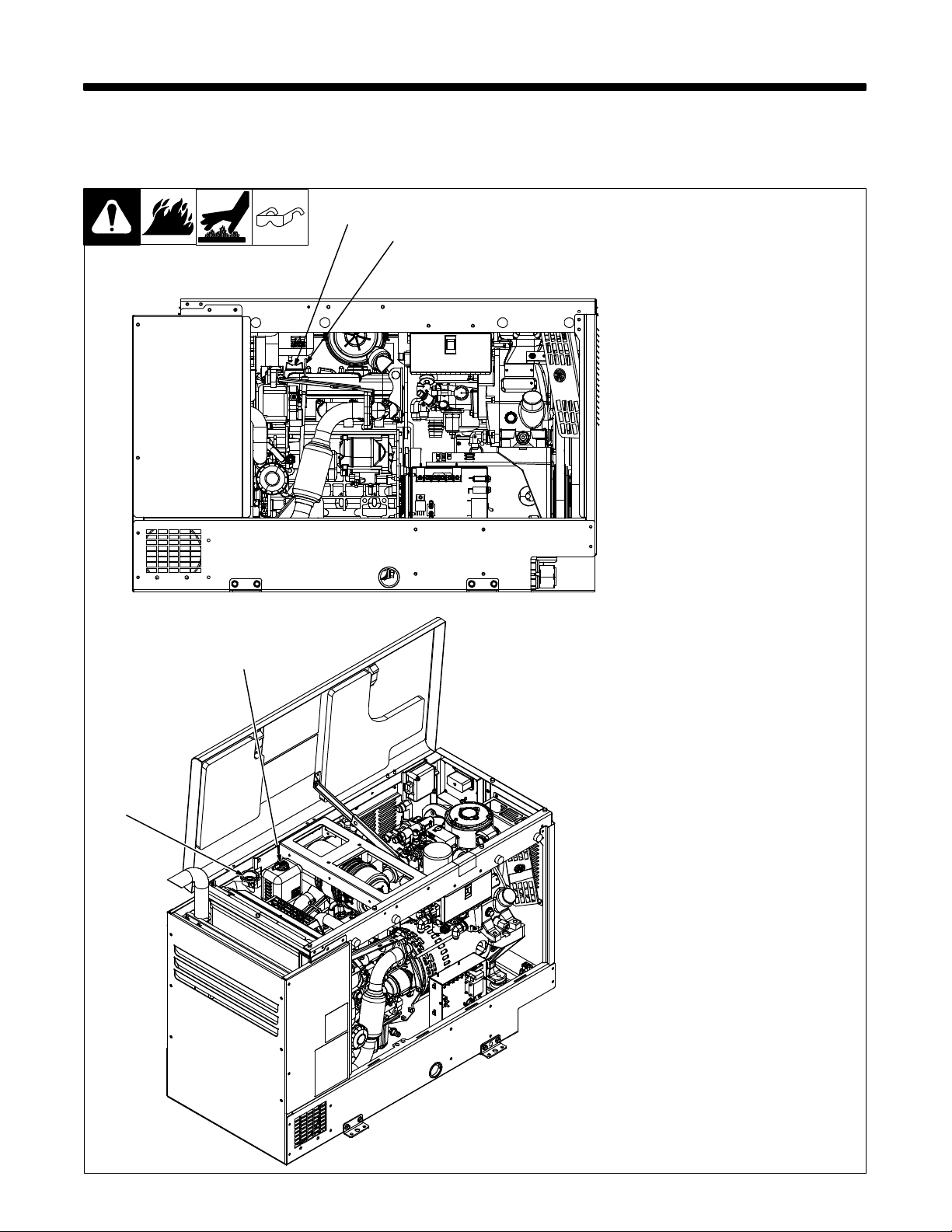

Open top cover and service side door.

1 Oil Dipstick

2 Oil Fill

3 Coolant Overflow Bottle

4 Radiator Cap

Fuel

Be sure fuel connections are made and

tight. Be sure fuel tank utilized for unit

operation is full.

Coolant

Check coolant level in radiator and

overflow bottle. If coolant is below Low

level in overflow bottle, add coolant until

level in bottle is between Low and Full

levels. If overflow bottle coolant level

was low, check coolant level in radiator.

Engine Oil

Check oil with unit on level surface. If oil

is not up to full mark on dipstick, add oil

(see maintenance label).

Use remote panel to determine hours

until next recommended oil change

(see Section 6-1).

. For cold weather starting informa-

tion, see Section 6-6.

Keep battery in good condition.

Store battery in warm area.

Use correct grade oil for cold

weather.

Continue initial system checks, see

Section 5-3.

OM-240 113 Page 18

805 444

5-3. Compressor Prestart Checks

. The compressor is equipped with high

oil temperature shutdown. High oil

temperature can be caused by low oil

or hot air recirculation.

. Do not open oil fill cap until unit has

been off for 10 minutes. Do not open

while running.

NOTICE − Do not mix oil types. Do not

overfill.

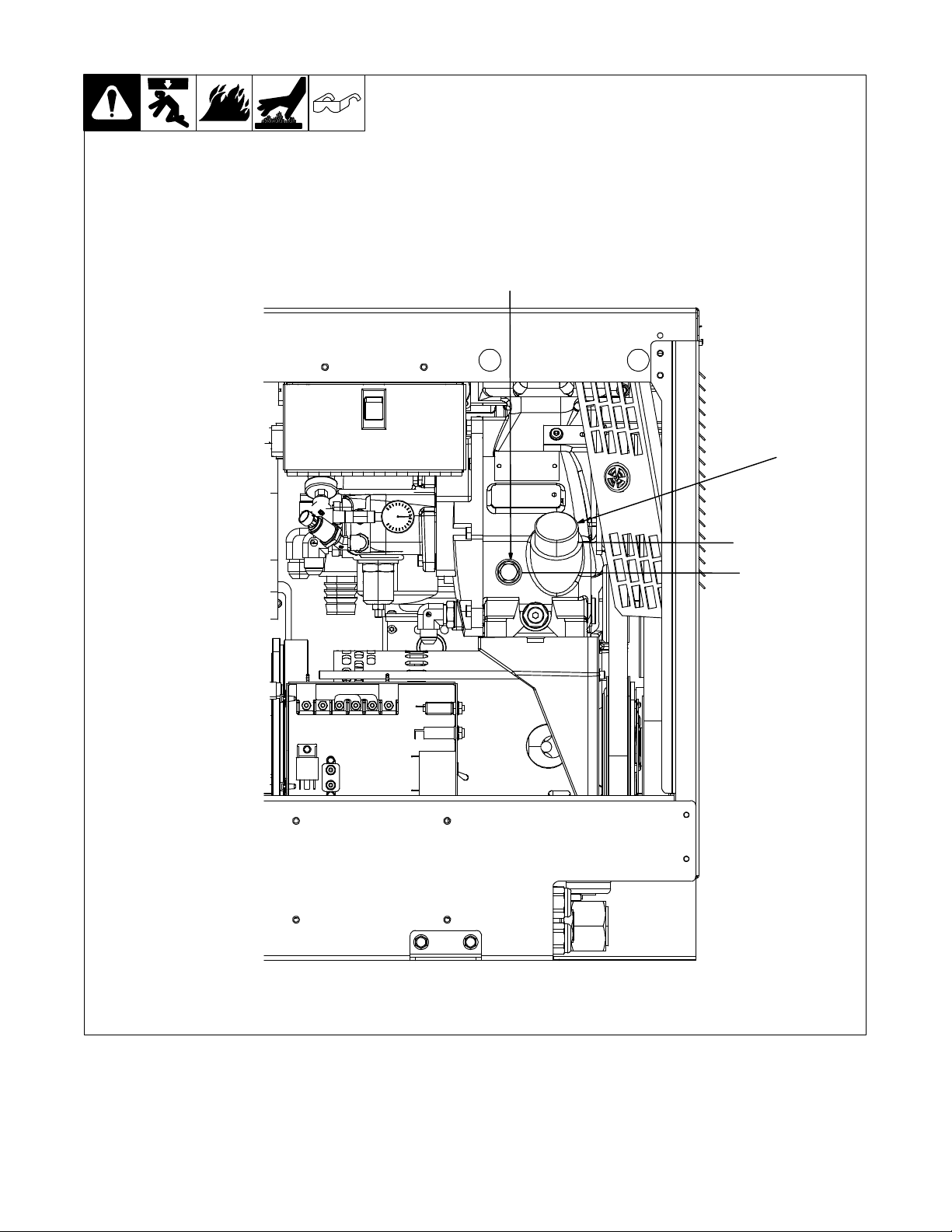

1 Air Compressor Oil Fill Cap

Hand tighten oil fill cap. Using excess

force can damage o−ring.

2 Air Compressor Oil Sight Hole

2

The unit is shipped with oil in the compressor reservoir. Minimum oil level is half

way up the sight hole. Maximum oil level is

in threaded area of oil fill pipe. Check level

frequently. If oil needs to be added, be

sure unit is off for 10 minutes before removing fill cap.

1

. Minimum com-

pressor oil level

is half way up

the sight hole.

Maximum oil

level is in

threaded area

of oil fill pipe.

805 444

OM-240 113 Page 19

SECTION 6 − OPERATION

O

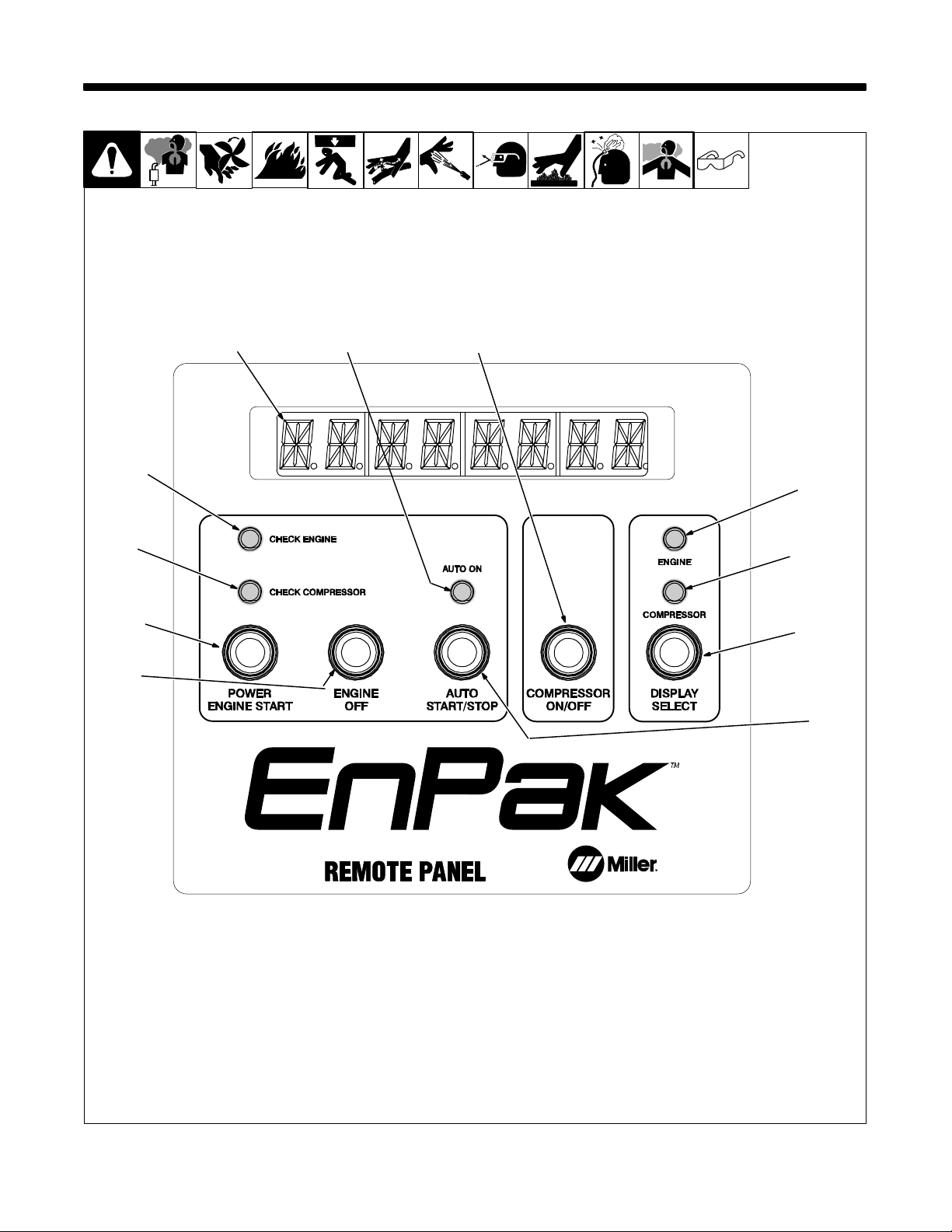

6-1. Remote Panel (Use With Section 6-2)

1

2

3

7

8

4

11

5

6

10

9

OM-240 113 Page 20

248 998

6-2. Remote Panel Operation (Use With Section 6-1)

1 Alpha−Numeric Display

During the Auto Start/Stop mode start se-

quence, the following appears:

SYSTEMon

STARTING

GLOWPLUG

CRANKING

. STARTING and GLOWPLUG may

switch order depending on ambient

temperature.

During the manual mode start sequence,

the following appears:

SYSTEMon

GLOWPLUG

GLOWdone

CRANKING

See Section 6-4 for error messages that

appear.

2 Check Engine LED

Lights when display is showing an engine

error.

If an engine error occurs and the engine

shuts down, the error will be stored in

memory. If the display has already turned

off, press the Power button once to activate

the Remote Panel. If the error is in memory,

the display will read ERROR and after a

few seconds will flash the error code. See

Section 6-4 for error messages that appear.

To erase the error, press and hold the Display Select push button until the display

reads SYSTEMon, and the indicator is off.

The display will now cycle normally when

the Display Select push button is pushed.

3 Check Compressor LED

Lights when display is showing a com-

pressor error.

4 Auto On LED

Lights when Auto Start/Stop mode is se-

lected.

5 Engine LED

Lights when display is showing engine related information.

6 Compressor LED

Lights when display is showing com-

pressor related information.

7 Power Engine Start Push Button

Press and release to turn on power to the

display only. This allows access to the display menu.

When Auto Start/Stop is selected (Auto On

LED is lit). Press and release the Power

Engine Start push button two times. The

first press and release will power up the

control system and the second press and

release will initiate the automatic starting

sequence. The Engine Off push button can

be pressed at any time to stop the sequence.

In manual mode, press and release the

Power Engine Start push button once to

power up the control system, then press

and release the button to start the glow

plug operation. When the display shows

GLOWdONE, press and hold the push button to crank the engine and complete the

starting sequence. The starter will disengage at a predetermined RPM based on

the ambient temperature.

With engine running, press and release to

toggle between low speed and high speed.

The display will flash HIGH SPd when engine is locked in high speed.

8 Engine Off Push Button

Press when engine is running to stop en-

gine, or to stop the automatic start sequence.

9 Auto Start/Stop Push Button

Press and release the Auto Start/Stop

push button to toggle between automatic

and manual control.

When the automatic mode is selected, the

Auto On LED lights and display reads ENAbLEd.

While the display shows ENAbLEd, press

and hold the push button to change the

auto stop timer (range of two to 30

minutes). This time is placed in memory

and is remembered the next time the EnPak is started.

When the system is placed in manual

mode, the display shows dISAbLEd and

the Auto On LED is off.

10 Display Select Push Button

Press and release to cycle through the fol-

lowing displays:

RPM

Battery voltage

Current fuel usage (Gallons Per Hour)

Engine hours

Engine maintenance hours (Counts down

from 400 hours)

Engine temperature

Compressor hours

Compressor maintenance hours (Counts

down from 500 hours)

. Maintenance hours initially count

down from 50 hours. Complete maintenance required after first 50 hours of

operation according to Section 8.

. Current fuel usage is for reference

only. Variables such as ambient temperature, altitude and fuel blend affect

actual usage.

11 Compressor On/Off Push Button

When engine is running, press twice to turn

compressor on or off. When turned on, engine will speed up to 2600 RPM for 5

seconds, and then return to 1800 RPM.

This indicates the compressor is on.

When engine is not running, Press and release to display SET MIN. When SET MIN

is displayed, press and hold to increment

minimum pressure setting.

. Compressor minimum pressure is set

through the control program. Compressor maximum working pressure is

set at the Air Pressure Regulator

(P−PRV). See Section 7-1.

6-3. Safety Interlock

Models With Hydraulic Power Source: The safety interlock system must be engaged before the EnPak engine can be started Contact dealer for

detailed description of supplied system.

Models Without Hydraulic Power Source: The safety interlock system requires 12 volts DC be supplied from the accessory position of the truck

ignition switch to pin 5 of RC13. Splice into supplied plug and wire.

. Test safety interlock monthly, see Section 8-4.

OM-240 113 Page 21

6-4. Operation And Error Messages

1

1 Alpha−Numeric Display

The following operational messages

may appear:

CHNG OIL

Indicates an oil change is needed. This light

flashes after the first 50 hours of operation

and then at normal oil change intervals

thereafter.

If CHECK ENGINE LED is on, engine oil

change time interval has counted down to

zero, indicating it is time to change engine

oil.

To reset display after oil change, see Section 8-5.

If CHECK COMPRESSOR LED is on,

compressor oil change time interval has

counted down to zero, indicating it is time to

change compressor oil.

To reset display after oil change, see Section 8-7.

HIGH SPd

Indicates engine is locked in high speed.

With engine running, press Power/Start

button to toggle speed.

AUTOSTOP

This will flash briefly when unit is in Auto On

mode and the engine stops automatically.

The following error messages may appear:

. If error message appears, consult

troubleshooting section for remedial

actions.

Hi TEMP

Indicates high compressor temperature if

CHECK COMPRESSOR LED is on.

OVErPRES

Indicates the compressor has an over pressure error.

OVErSPEEd

Indicates an engine over speed error.

LOW OIL

Indicates a low oil pressure condition in the

engine.

NoCHARGE

Indicates an alternator problem.

HiTEMP 1

Indicates high engine temperature if

CHECK ENGINE LED is on. The temperature switch has indicated high temperature.

HiTEMP 2

Indicates high engine temperature if

CHECK ENGINE LED is on. The temperature sensor has indicated high temperature.

SPd SENS

Indicates a problem with the engine speed

sensor.

GovCNTRL

Indicates a problem with the engine governor control.

SEN OPEN

Indicates coolant sensor is open.

SENSHORT

Indicates coolant sensor is shorted.

ALTRNATR

Indicates an open condition in the alternator.

248 998

HiVOLTiN

Indicates high input voltage from the battery.

LoVOLTiN

Indicates low input voltage from the battery.

ERROR

If an engine error occurs and the engine

shuts down, the error will be stored in

memory. If the display has already turned

off, press the Power push button once to

activate the Remote Panel. If the error is in

memory, the display will read ERROR and