Miller DELTAWELD 302, DELTAWELD 402, DELTAWELD 452, DELTAWELD 602, DELTAWELD 652 Owner's Manual

...

July 1996 Form: OM-223H

Model

Welding

Range

OCV

Rati

Effective With Serial No. KG141349

OWNER’S

MANUAL

Deltaweld® 302, 452, 652 (60 Hz)

Deltaweld® 402, 602, 852 (50/60 Hz)

CV/DC Welding Power Sources For GMAW, FCAW, SAW Welding, And CAC-A Cutting And Gouging

Model

300

Amp

450

Amp

650

Amp

*While idling

( ) Indicates specification differences for CE models

cover_om 4/95 − ST-800 453 PRINTED IN USA

Rated

Welding

Output

300 A @ 32

(29) Volts

DC, 100%

Duty Cycle

450 A @ 38

(36.5) Volts

DC, 100%

Duty Cycle

650 A @ 44

Volts DC,

100% Duty

Cycle

Voltage

Range

DC

10 − 32

10 − 38 48 21M

10 − 44 54 21M --

Max

OCV

DC

38

(43)

21M --

Amperes Input at Rated Load Output, 50 or 60 Hz,

IP

ng

200 V 230 V 380 V 400 V 440 V 460 V 575 V KVA KW

42

3.2*271.8*251.7*231.6*211.6*171.3*

72

3.2*632.7*392.6*372.2*332.1*321.4*251.1*

96

3.2*583.3*543.0*502.8*481.6*381.3*

Three-Phase

© 1996 MILLER Electric Mfg. Co.

16.9

1.26*

25.1

1.09*

38.2

1.26*

12.9

0.21*

21.1

0.26*

34.2

0.35*

Declaration of Conformity For

European Community (CE) Products

NOTE

Manufacturer’s Name: Miller Electric Mfg. Co.

Manufacturer’s Address: 1635 W. Spencer Street

This information is provided for units with CE certification (see rating label on unit.)

Appleton, WI 54914 USA

Declares that the product: Deltaweld® 402, 602, And 852

conforms to the following Directives and Standards:

Directives

Electromagnetic compatibility Directives: 89/336/EEC, 92/31/EEC

Low Voltage Directive: 73/23/EEC

Machinery Directives: 89/392/EEC, 91/368/EEC, 93/C 133/04, 93/68/EEC

Standards

Safety Requirements for Arc Welding Equipment part 1: EN 60974-1: 1990

Arc Welding Equipment Part 1: Welding Power Sources: IEC 974-1

(April 1995 − Draft revision)

Degrees of Protection provided by Enclosures (IP code): IEC 529: 1989

Insulation coordination for equipment within low-voltage systems:

Part 1: Principles, requirements and tests: IEC 664-1: 1992

Electromagnetic compatibility (EMC) Product standard for arc welding equipment:

EN50199: August 1995

European Contact: Mr. Luigi Vacchini, Managing Director

MILLER Europe S.P.A.

Via Privata Iseo

20098 San Giuliano

Milanese, Italy

Telephone: 39(02)98290-1

Fax: 39(02)98281-552

dec_con1 10/95

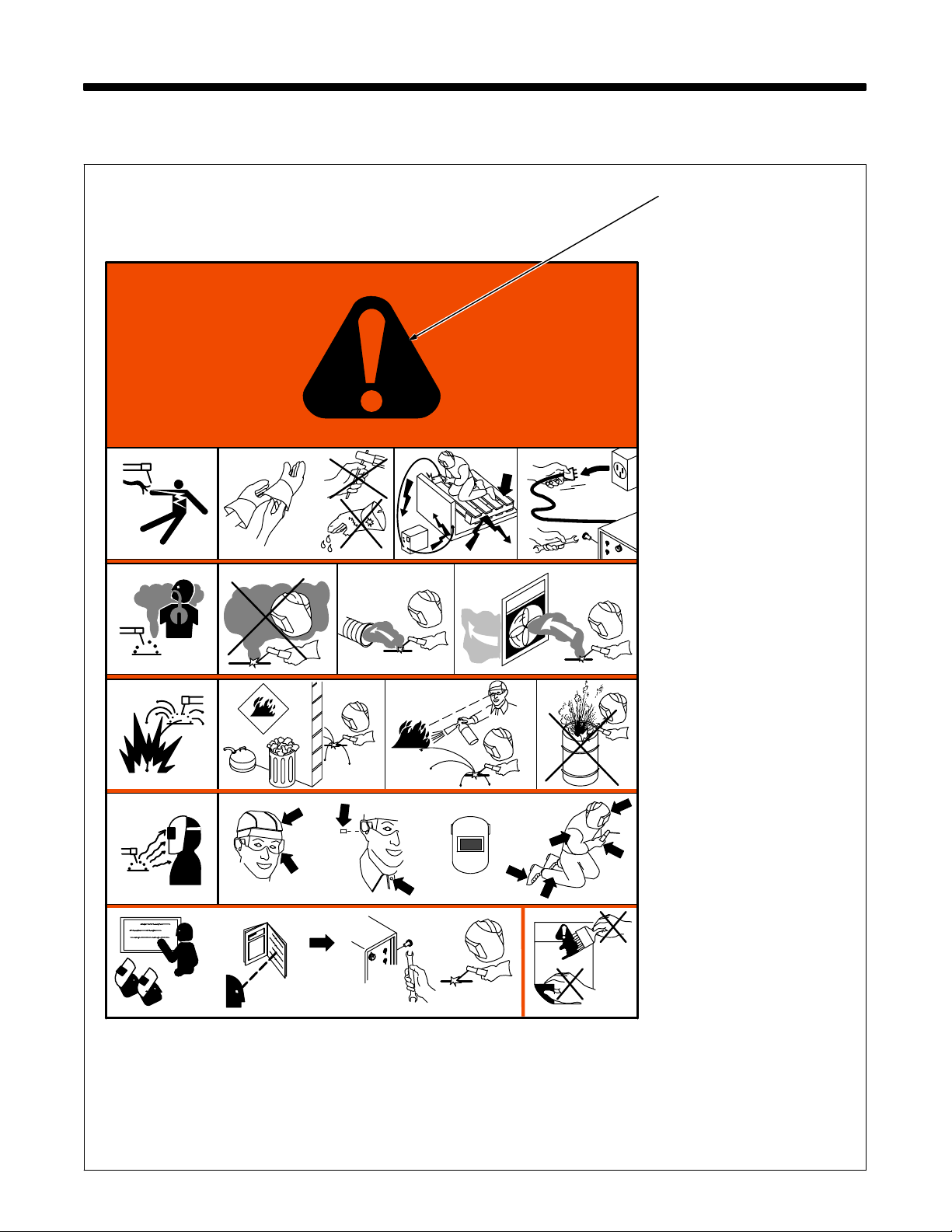

SECTION 1 − DEFINITIONS

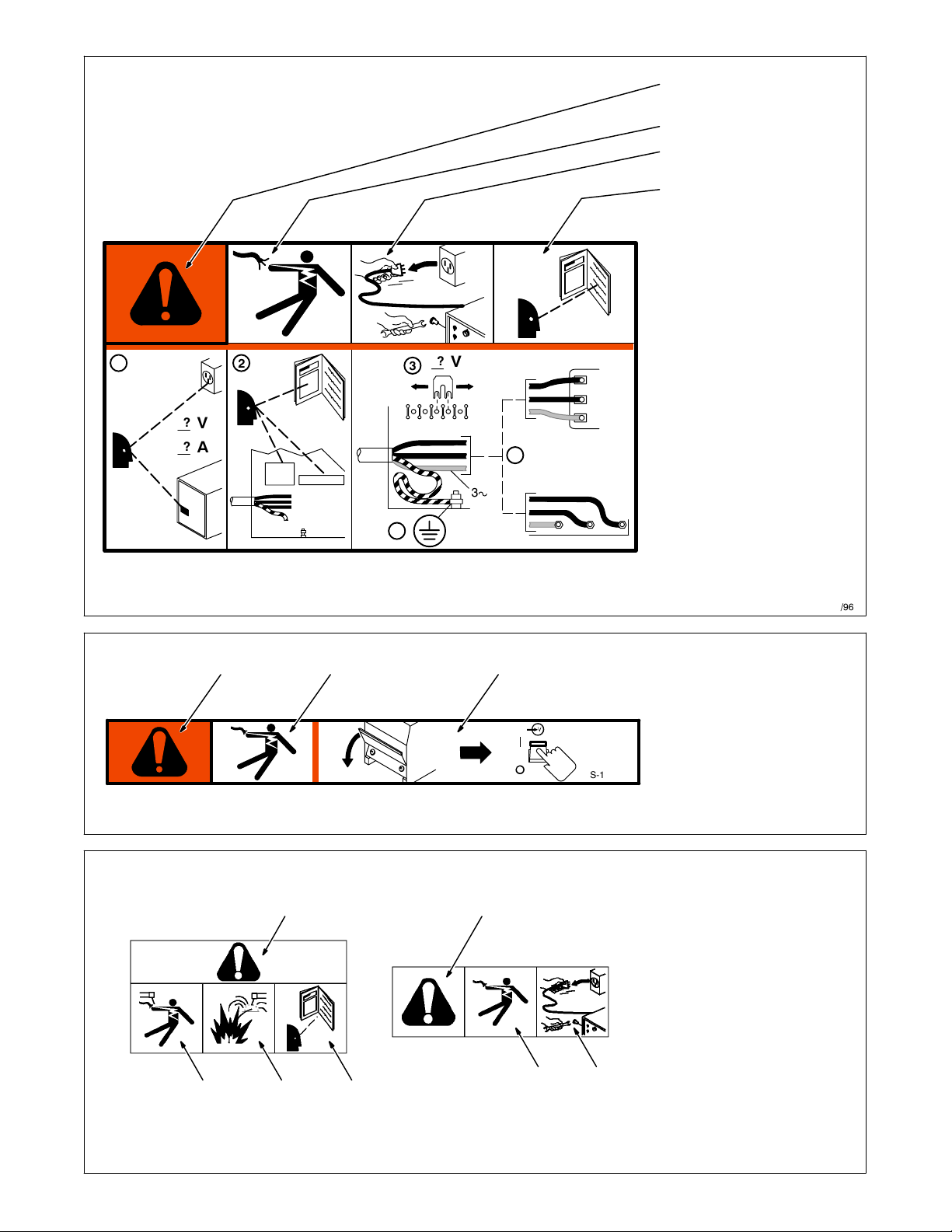

1-1. Warning Label Definitions

1 1.1 1.2

2

3 3.1 3.2 3.3

4 4.1

2.1

+

2.2

2.3

+

+

1.3

Warning! Watch Out! There are

possible hazards as shown by the

symbols.

1 Electric shock from welding

electrode or wiring can kill.

1.1 Wear dry insulating gloves.

Do not touch electrode with

bare hand. Do not wear wet or

damaged gloves.

1.2 Protect yourself from electric

shock by insulating yourself

from work and ground.

1.3 Disconnect input plug or

power before working on

machine.

2 Breathing welding fumes can

be hazardous to your health.

2.1 Keep your head out of the

fumes.

2.2 Use forced ventilation or local

exhaust to remove the fumes.

2.3 Use ventilating fan to remove

fumes.

3 Welding sparks can cause

explosion or fire.

3.1 Keep flammables away from

welding. Do not weld near

flammables.

3.2 Welding sparks can cause

fires. Have a fire extinguisher

nearby, and have a

watchperson ready to use it.

3.3 Do not weld on drums or any

closed containers.

4 Arc rays can burn eyes and

injure skin.

4.1 Wear hat and safety glasses.

Use ear protection and button

shirt collar. Use welding

helmet with correct shade of

filter. Wear complete body

protection.

5 Become trained and read the

instructions before working on

the machine or welding.

6 Do not remove or paint over

(cover) the label.

5 6

+

S-176 254-A

1/96

OM-223 Page 9

Warning! Watch Out! There are

possible hazards as shown by the

symbols.

Electric shock from wiring can kill.

Disconnect input plug or power

before working on machine.

Read the Owner’s Manual before

working on this machine.

1 Consult rating label for input

power requirements, and

check power available at the

job site − they must match.

2 Read Owner’s Manual and

inside labels for connection

points and procedures.

3 Move jumper links as shown

on inside label to match

?

1

2

V

3

voltage at job site.

4 Having a loop of extra length,

connect grounding conductor

first.

?

V

?

A

5

5 Connect line input conductors

as shown on inside label −

double-check all connections,

jumper link positions, and

input voltage before applying

3

power.

4

12 3

1

1

56

234

S-179 290

1/96

1 Warning! Watch Out! There

are possible hazards as

shown by the symbols.

2 Electric shock from wiring and

exposed weld terminals can

kill.

3 Close door before turning on

unit.

S-179 563

1/96

1 Warning! Watch Out! There

are possible hazards as

shown by the symbols.

2 Electric shock from welding

electrode or wiring can kill.

3 Sparks from arcing electrode

can cause explosion or fire −

disconnect cable for process

not in use.

4 Read Owner’s Manual for

connection procedures.

5 Electric shock from wiring can

kill.

6 Disconnect input power

before working on unit or

making terminal strip

connections.

OM-223 Page 10

Nameplate D-179 389

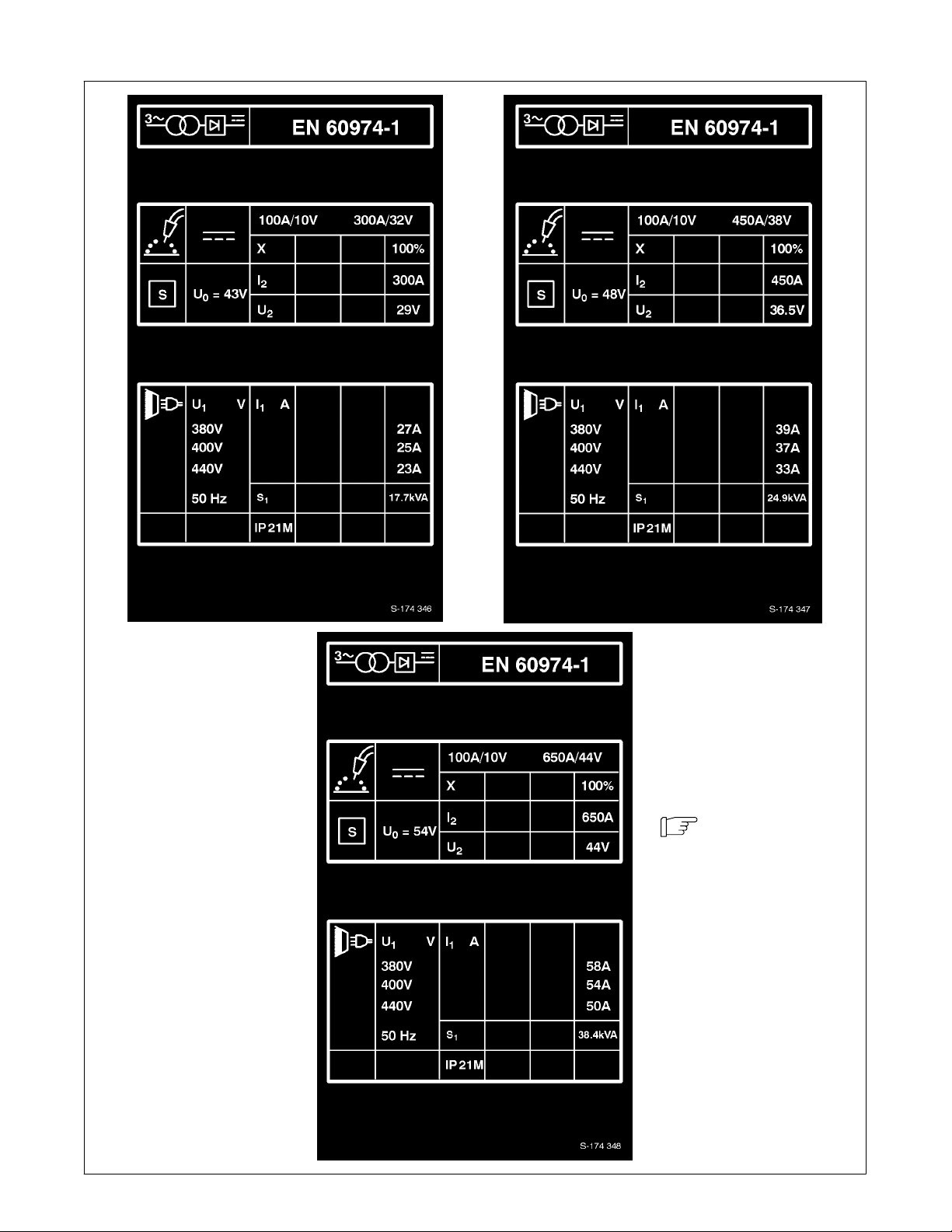

1-2. Manufacturer’s Rating Labels For CE Products

Match label to one on

unit. See Section 2-1.

S-174 346 / S-174 347 / S-174 348

OM-223 Page 11

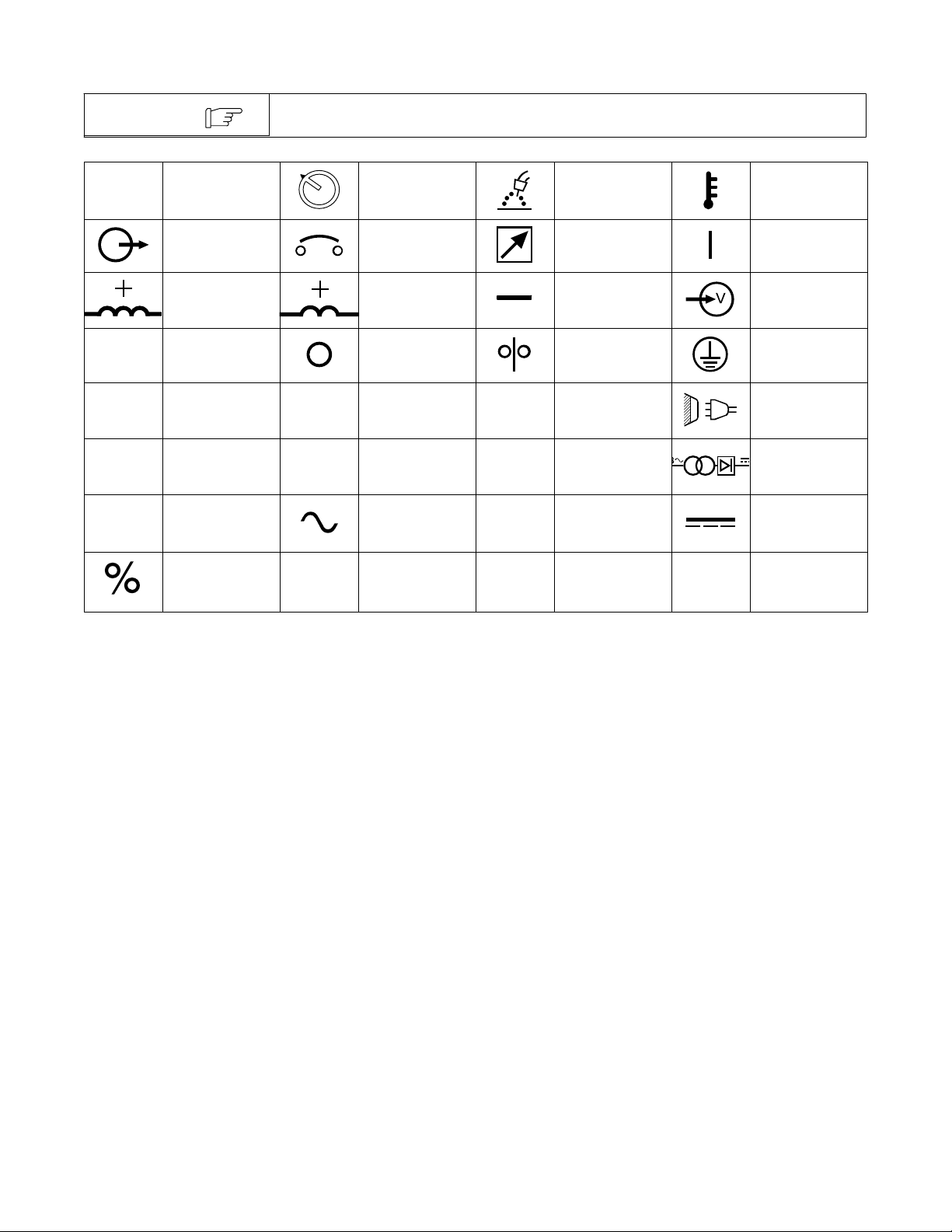

1-3. Symbols And Definitions

NOTE

A

V

U

0

I

1

IP

Some symbols are found only on CE products.

1

Voltage Control/

Panel

Positive Low

Inductance Weld

Output Terminal

Primary Voltage

Rated Welding

Current

Alternating

Current

U

X

S

2

1

Amperes

Output Circuit Breaker Remote On

Positive High

Inductance Weld

Output Terminal

Volts Off Wire Feed

Rated No Load

Voltage (Average)

Primary Current

Degree Of

Protection

U

I

2

Gas Metal Arc

Welding (GMAW)

Negative Weld

Output Terminal

Conventional

Load Voltage

Duty Cycle

KVA Direct Current

Temperature

Input

Protective Earth

(Ground)

Line Connection

Three-Phase

Transformer

Rectifier

Percent

OM-223 Page 12

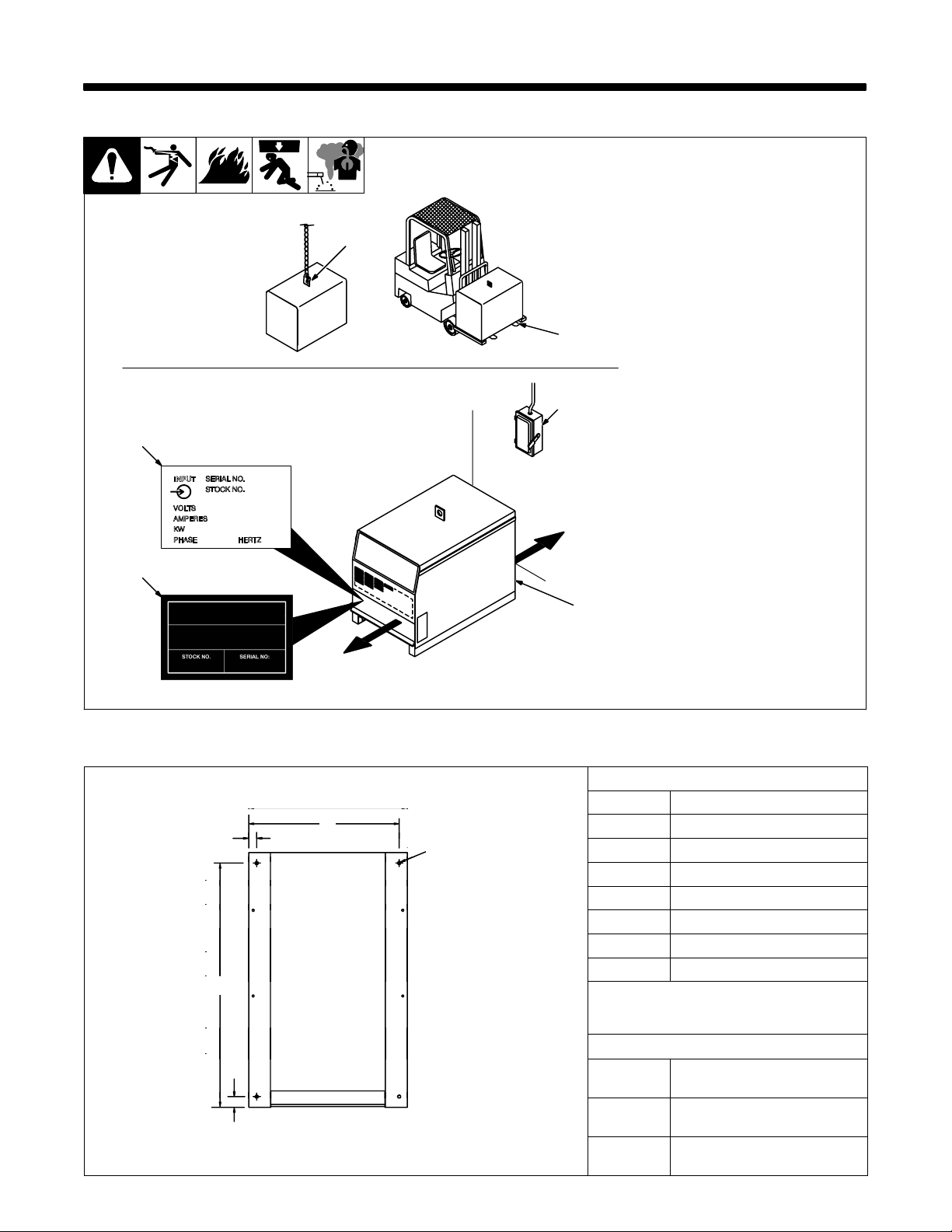

SECTION 2 − INSTALLATION

Di

B

2-1. Selecting A Location

Movement

Location And Airflow

3

4

1 Lifting Eye

2 Lifting Forks

Use lifting eye or lifting forks to

move unit.

If using lifting forks, extend forks

1

OR

2

6

18 in

(460 mm)

beyond opposite side of unit.

3 Rating Label (Non CE Models

Only)

Use rating label to determine input

power needs. Label located under

front access door.

4 Plate Label (CE Models Only)

Label located under front access

door.

5 Rating Label (CE Models

Only)

Use rating label to determine input

power needs. Label located on rear

access door (see Section 1-2).

6 Line Disconnect Device

Locate unit near correct input pow-

er supply.

Y Special installation may be

required where gasoline or

volatile liquids are present −

see NEC Article 511 or CEC

Section 20.

18 in

(460 mm)

2-2. Dimensions And Weights

D

A

C

E

4 Holes

Ref. ST-153 556-A

5

mensions

Height 27-1/4 in (692 mm)

Width 22-1/4 in (565 mm)

Depth* 35-3/4 in (908 mm)

A** 35 in (889 mm)

B*** 1-1/4 in (32 mm)

C 21 in (533 mm)

D 1-3/16 in (30 mm)

E 7/16 in (11 mm) Dia

*300 Amp Model = 28-1/4 in (718 mm)

**300 Amp Model = 25-7/8 in (657 mm)

***300 Amp Model = 3/4 in (19 mm)

Weight

300 Amp

450 Amp

650 Amp

Net: 323 lb (147 kg)

Ship: 340 lb (154 kg)

Net: 384 lb (174 kg)

Ship: 401 lb (182 kg)

Net: 472 lb (214 kg)

Ship: 489 lb (222 kg)

OM-223 Page 13

Loading...

Loading...