Page 1

Fluid Head

OPERATOR’S

MANUAL

1090

Compass

x

2

Fluid Head

1092

Compass

x

6 Fluid Head

1093

Compass

x

8

Fluid Head

1096

Compass

x

10 Fluid Head

1098

Compass

x

18 Fluid Head

Page 2

2

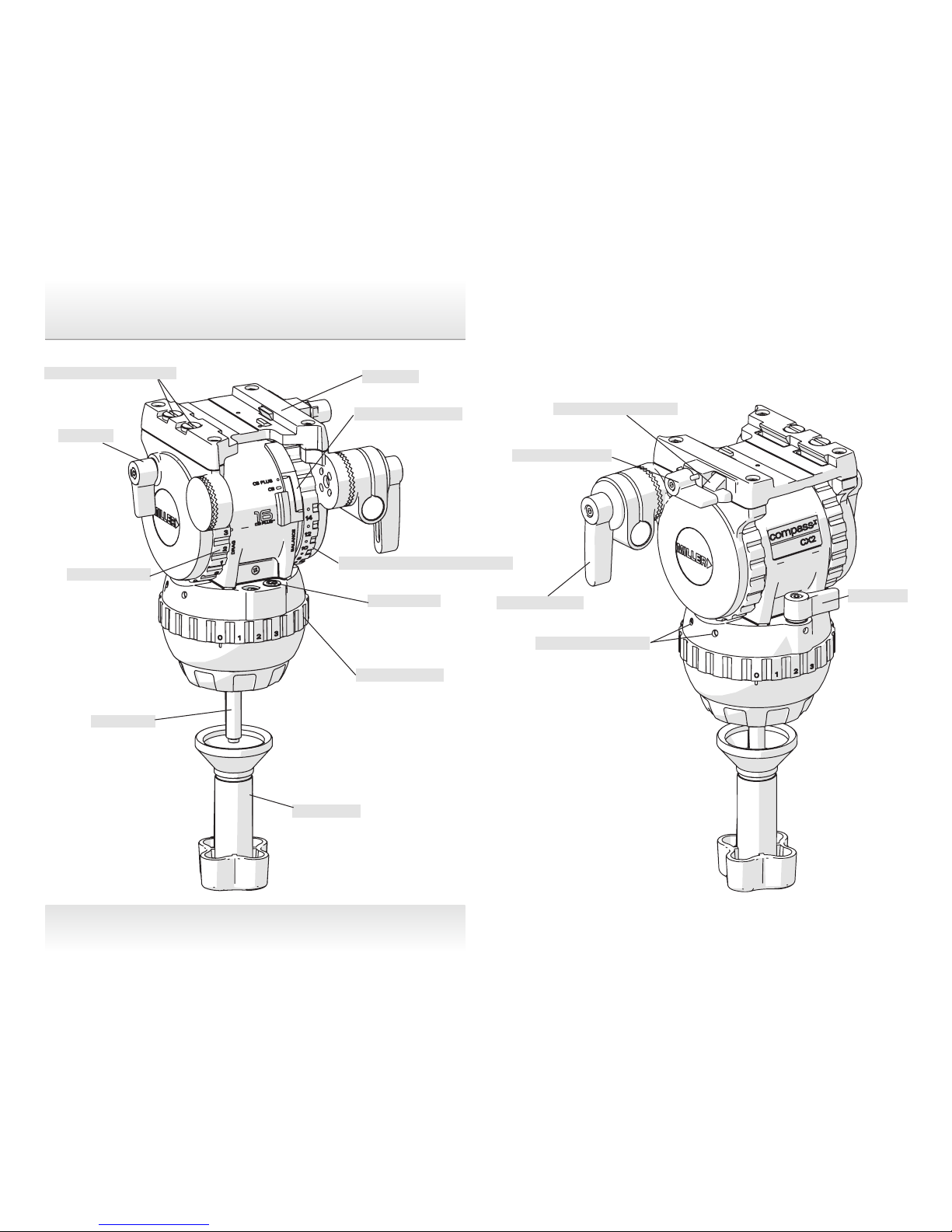

Features and Controls

Fig. 1 Fig. 2

Handle Clamp

LED Button

Pan Lock

Spare Camera Screws

Pan Drag Ring

Tilt Lock

Slide Lock Lever

Counterbalance Selector Ring

Ball Clamp

Tilt Drag Ring

M10 Stud

Accessory Mounts

CB PLUS Selector

Safety Release Lever

Platform

Page 3

3

Thank you for purchasing the Compassx Fluid Head. The

Compassx Fluid Head has been designed to suit a wide range of

cameras, lenses and accessories as demanded by professional

users.

The robust design and construction of the Compassx Fluid Head

offers maximum stability and durability and includes a precision

drag plate system in the pan and tilt assembly to deliver true uid

drag performance over the entire temperature and payload range.

The uid drag and the counterbalance system were designed to

provide excellent control and repeatability and offer progressive

equal increments of drag and torque through the unique radial

ring design.

The Compassx Fluid Head will give best performance when

used on a wide range of Miller tripods, including SOLO, Toggle,

Sprinter II and HD Tripods (depending on bowl size). This will

ensure maximum system stability to suit any professional setup. The Compassx Fluid Head will suit most industry standard

75mm and 100mm tripods as well, please refer to manufactures’

manual for mounting details.

Introduction Safety Instructions

Please use this manual to familiarise yourself with the operation

of the Compassx Fluid Head and observe these instructions

to prevent any damage to your equipment. Ensure that all

equipment is operating correctly and free from defects and

damage, also please ensure that the tripod is steady, secure and

that the bowl is approximately horizontal when attaching the

camera. The operator is responsible for the safe operation of this

piece of equipment.

• Do not exceed the maximum payload capacity of the Fluid

Head.

• Do not leave the camera unattended on the Fluid Head.

• Do not release the SLIDE LOCK LEVER whilst the camera is at

an angle.

• Do not adjust the tripod whilst the camera is attached to the

Fluid Head.

• Ensure PAN HANDLE CLAMP and CLAMP NUT is securely

tightened.

• Apply TILT LOCK when adding/removing equipment from

the camera or when attaching/removing the camera from the

Fluid Head.

• Hold camera securely whilst changing Counterbalance, Pan

Drag or Tilt Drag settings.

• Hold the camera securely whilst releasing the SAFETY

RELEASE LEVER.

• Hold camera securely whilst adjusting the CLAMP NUT to

level the Fluid Head.

Page 4

4

C of G

2. Mounting Your Camera

2.1 Remove the CAMERA PLATE by lifting the SAFETY

RELEASE LEVER on the PLATFORM (SLIDE LOCK LEVER

must be unwound (clockwise)) (Fig. 3a).

2.2 Attach the CAMERA PLATE to the camera1 such that

the Centre of Gravity (C of G)2 mark on the camera is

approximately in the middle of the camera plate.

2.3 Tighten PAN/TILT LOCKS, mount the CAMERA PLATE

to the PLATFORM non-locking side rst. The side load

lock mechanism will capture camera plate (distinct click

sound will be made when CAMERA PLATE is retained).

CAMERA PLATE will be able to slide freely (60mm) until

SLIDE LOCK LEVER is tightened.

2.4 Untighten TILT LOCK, slide the CAMERA PLATE such

that the camera’s C of G is directly above the centre axis

of the Fluid Head (g. 3b), camera should be balanced (if

not slide camera backward or forward). Once balanced

tighten the SLIDE LOCK LEVER (anti-clockwise)3 and

tighten TILT LOCK.

If this cannot be achieved then reposition the CAMERA

PLATE on the Camera – step 2.2.

NOTES:

1 Refer to the camera’s owners manual for correct method of

attachment to the CAMERA PLATE. Remove the 1⁄4” screw

or 3/8” screw as required.

2 The camera’s C of G can be estimated by placing the

camera on to a round rod and then shifting it backwards

or forwards until a balance point – C of G - is achieved. It is

recommended to identify this point on the camera as it will

be useful in step 2.2.

3 Ensure SLIDE LOCK LEVER is tightened at all times when

you are not nding C of G or mounting/dismounting camera.

Operating Instructions

Fig. 3b

Fig. 3a

Centre Axis

Slide Lock Lever

Pan Lock

Tilt Lock

Platform

Safety Release Lever

Page 5

5

3. Counterbalance Control

The counterbalance system was designed to neutralise the

effect of the camera weight when it is tilted. The Compassx

Fluid Head offers a 16 position counterbalance system which

is operated with the CB SELECTOR RING and the CB PLUS

SELECTOR (Fig. 4). With the Compassx systems it is also

possible to disengage counterbalance (position zero),

NOTE:

Be careful when disengaging counterbalance as you could

damage your equipment with an unwanted tilt drop.

The CB SELECTOR RING and the CB PLUS SELECTOR must

be operated when the BASE PLATE is in a horizontal position.

After changing the counterbalance setting it may be

necessary to tilt the camera back and forth to ensure that the

CB spring has engaged.

3.1 For safety it is generally better to start at a higher

counterbalance position (e.g. position 14) and work your

way to the correct setting, this is to reduce any chance of

unwanted tilt drops (Fig. 4).

3.2 Hold the camera and release the TILT LOCK, then gently

tilt the camera from the horizontal position forward

then backward and observe its response. If the camera

‘springs back’ to the horizontal position then a lower

counterbalance setting is required, use the CB SELECTOR

RING to cycle through all even number positions (eight

positions including zero).

3.3 Finer adjustments can be made by engaging the CB PLUS

SELECTOR (upward direction).

3.4 Correct counterbalance setting has been achieved when

the camera does not spring back or drop when pan

handle is released.

Operating Instructions

Fig. 4

CB PLUS on

CB PLUS off

CB PLUS Selector

CB Selector Ring

Page 6

6

Operating Instructions

4. Pan/Tilt Drag Control

The Compass

x

Fluid Head offers selectable positions of

uid drag in the Pan and Tilt (including zero positions). The

settings are equally stepped from lighter drag in position 1

up to heavier drag in position 3 on CX2 and CX6 models and

position 5 on CX8, CX10 and CX18 models, the drag plates

are completely disengaged in position zero.

• Do not pan or tilt the Fluid Head whilst adjusting PAN or

TILT DRAG CONTROL or whilst the PAN and TILT DRAG

CONTROL is between settings.

• The drag setting can be changed at any tilt or pan angle.

5. Pan/Tilt Lock Control

The Compassx Fluid Head offers high capacity caliper disc

brake system to hold the Fluid Head in a xed pan and/or tilt

position. Camera position will not change when applying or

releasing the Pan-tilt locks.

• Do not pan or tilt the Fluid Head whilst the PAN or the TILT

LOCK is partially applied.

6.Illumination

The

Compassx

Fluid Head offers illumination of the BUBBLE

LEVEL when the low ambient light conditions exist.

Illumination can be achieved by pressing the LED BUTTON

once. The light will switch off after 10 seconds.

Fig. 5

Page 7

7

The Compassx Fluid Head offers high quality surface coatings,

dust and moisture seals. Miller recommends keeping the Fluid

Head clean at all times by using soft brushes and lint free cloth

to wipe over the surfaces.

• Do not immerse the Fluid Head in any liquid.

• Do not use stiff brushes, abrasives, harsh detergents and

solvents.

Battery Replacement

T

he

Compassx Fluid Head uses a single 11A type - 6 Volt battery for Illumination. Miller recommends the following batteries

to provide long life performance – GP11A, Duracell MN11 or

Vinnic L1016.

1. Using a Phillips Head #1 screw driver, remove the

RETAINING SCREW and the BATTERY COVER.

2. Using a small at screw driver remove the battery.

3. Align the new battery as shown on the back of the

BATTERY DOOR and place into the BATTERY HOUSING,

then push down the battery into place. A small at screw

driver may be used to push down the battery into the

BATTERY HOUSING.

4. Align the BATTERY DOOR into the body then tighten the

screw lightly.

Maintenance

Fig. 6

Battery

Battery Cover

Page 8

8

Specications

1090 C o m pa s s

x

2

1092 Co m p ass

x

6

1093 C o m p ass

x

8

1096 C o m pa s s

x

10

1098 C o m pas s

x

18

Weight 2.3kg (5.1lbs) 2.3kg (5.1bs) 2.5kg (5.5lbs) 2.5kg (5.5lbs) 2.5kg (5.5lbs)

Payload range 0-8kg (0-17.5lbs) 0-12kg (0-26.4lbs) 0-12kg (0-26.4lbs) 0-12kg (0-26.4lbs) 0-16kg (0-35.2lbs)

Pan-tilt drag

3 selectable fluid drag

positions + 0

3 selectable fluid drag

positions + 0

5 selectable fluid drag

positions + 0

5 selectable fluid drag

positions + 0

5 selectable fluid drag

positions + 0

Pan range 360° 360° 360° 360° 360°

Pan-tilt locks

Positive lock calliper

brake system

Positive lock calliper

brake system

Positive lock calliper

brake system

Positive lock calliper

brake system

Positive lock calliper

brake system

Tilt angle +90˚/-75˚ +90°/-75° +90°/-75° +90˚/-75˚ +90°/-75°

Counterbalance

16 selectable positions

(15 + zero position)

16 selectable positions

(15 + zero position)

16 selectable positions

(15 + zero position)

16 selectable positions (15

+ zero position)

16 selectable positions (15 +

zero position)

Camera platform

Side loading, 60mm

balance travel camera

plate with 1/4” and 3/8”

screws

Side loading, 60mm

balance travel camera

plate with 1/4” and 3/8”

screws

Side loading, 60mm

balance travel camera

plate with 1/4” and 3/8”

screws

Side loading, 60mm balance

travel camera plate with 1/4”

and 3/8” screws

Side loading, 60mm balance

travel camera plate with 1/4”

and 3/8” screws

Sliding range 60mm (4.7”) 60mm (4.7”) 60mm (4.7”) 60mm (4.7”) 60mm (4.7”)

Height above bowl 167mm (6.6”) 167mm (6.6”) 167mm (6.6”) 150mm (6.0”) 150mm (6.0”)

Mounting base 75mm (2.9”) ball levelling 75mm (2.9”) ball levelling 75mm (2.9”) ball levelling 100mm (3.9”) ball levelling 100mm (3.9”) ball levelling

Illuminated controls Bubble Level Bubble Level Bubble Level Bubble Level Bubble Level

Temperature range

-40° to +65°C

(-40° to +149°F)

-40° to +65°C

(-40° to +149°F)

-40° to +65°C

(-40° to +149°F)

-40° to +65°C

(-40° to +149°F)

-40° to +65°C

(-40° to +149°F)

Pan handle Fixed 390mm (15.4”) Fixed 390mm (15.4”) Fixed 390mm (15.4”) Fixed 390mm (15.4”) Fixed 390mm (15.4”)

Page 9

9

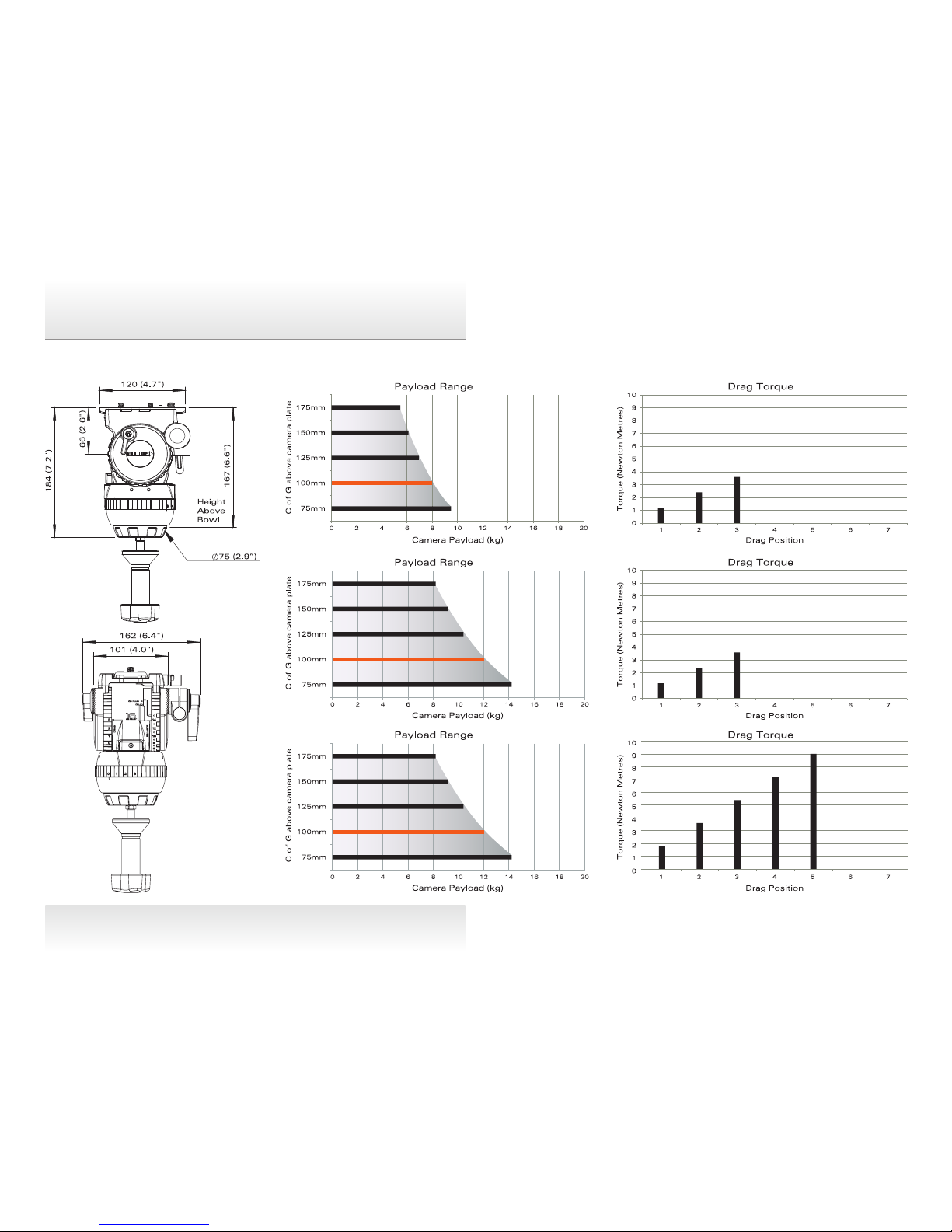

Specications

75mm

CX2

CX6

CX8

Page 10

10

Specications

CX10

CX18

100mm

Page 11

11

The Compassx Fluid Head can be stored for extended periods;

Miller recommends storage in a Miller case and the following:

• Clean the external surfaces.

• Keep in a dry place away from direct sunlight.

• Loosen off PAN & TILT LOCK.

Spare Parts and Accessories

Storage Service, Sales and Support

Miller Authorised Service Agents must carry out all service

and repair work. Failure to observe this requirement may void

warranty.

It is advisable to notify Miller or a Miller Authorised Service Agent

if a change of performance is observed as a result of dropping

or rough usage. For information regarding sales and service of

Miller products or for your nearest Miller representative please

contact us via our website or at the following:

MILLER CAMERA SUPPORT EQUIPMENT

30 Hotham Parade

Artarmon, Sydney, NSW 2064 Australia

P +61 2 9439 6377

F +61 2 9438 2819

sales@miller.com.au

MILLER Camera Support (LLC) USA

216 Little Falls Road (Unit 15 & 16),

Cedar Grove, New Jersey 07009 USA

P +1 (973) 857 8300

F +1 (973) 857 8188

sales@millertripods.us

MILLER FLUID HEADS (EUROPE) LTD.

12A, Shepperton Business Park

Govett Avenue, Shepperton

Middlesex, TW17 8BA

United Kingdom

P +44 (0) 1932 222 888

F +44 (0) 1932 222 211

sales@millertripods-europe.com

millertripods.com

ITEM ITEM NO.

Battery P3798

Camera screw 3/8”

P0037

Camera screw 1/4” P0036

Serrated washer PN12501

Pan handle - xed with clamp 679

Pan handle - telescopic with clamp 696

Accessory mounting adaptor 1/4” and 3/8” 1217

Accessory mounting bracket 1218

Sliding Plate Assembly (Euro)* 1210X

Sliding Plate Assembly (Mini Euro)* 1206X

1/4” screw and pin carriage 493

*1206 & 1210 are not compatible with CompassX,

use 1206X & 1210X only.

Warranty

Please refer to warranty card for complete details.

Page 12

millertripods.com

MILLER CAMERA SUPPORT EQUIPMENT

30 Hotham Parade

Artarmon, Sydney

NSW 2064 Australia

Tel: +61 2 9439 6377

Fax: +61 2 9438 2819

Email: sales@miller.com.au

D12728-2

Loading...

Loading...