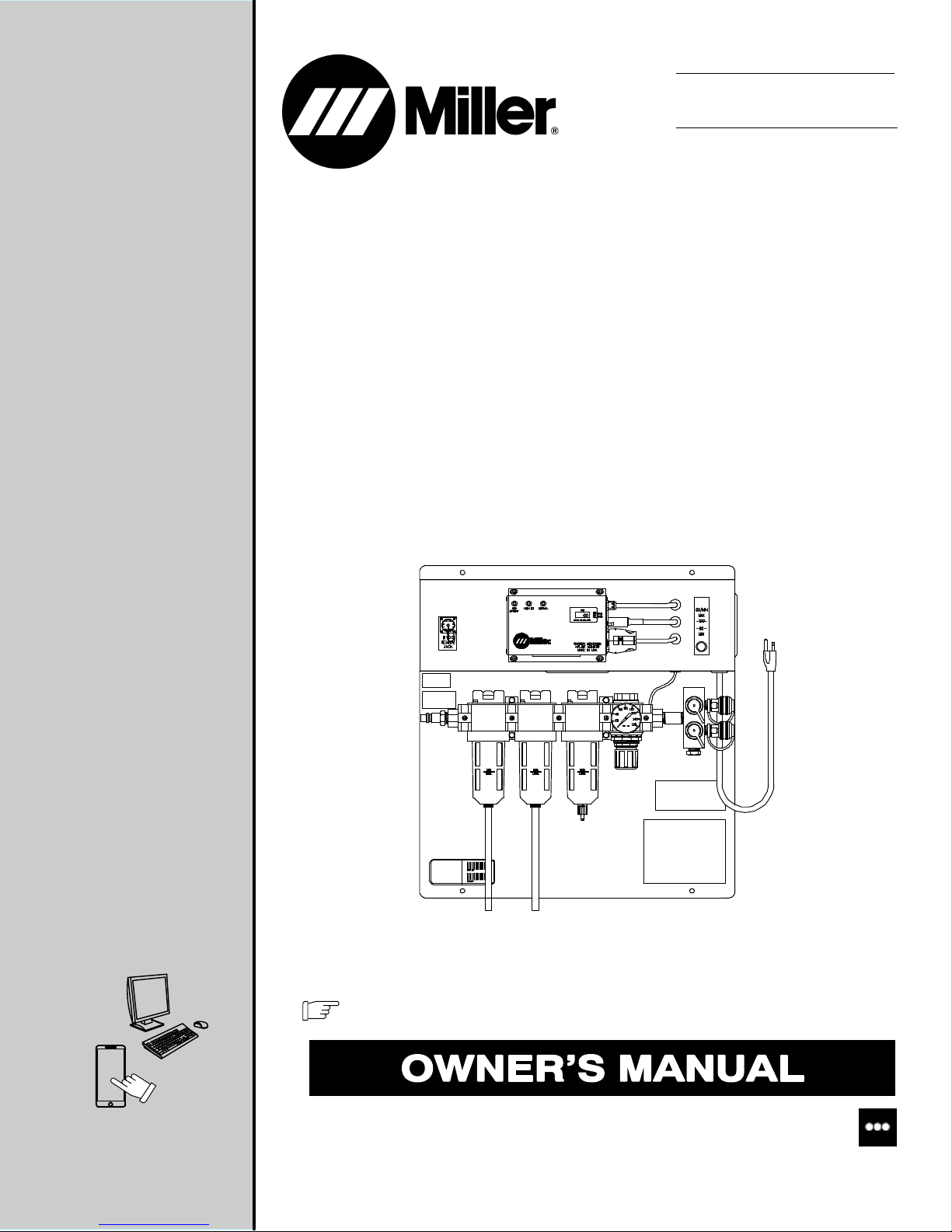

Miller BreatheAir 275961, BreatheAir 275970, BreatheAir 275963, BreatheAir 275981, BreatheAir Owner's Manual

OM-255447 Rev. A 2018−06

Description

Air Filtration Panel

BreatheAirtFiltration Panel

For product information,

Owner’s Manual translations,

and more, visit

www.MillerWelds.com

To help us serve you better, go to www.MillerWelds.Com/Register

File: Accessory

From Miller to You

Thank you and congratulations on choosing Miller. Now you can

get the job done and get it done right. We know you don’t have

time to do it any other way.

That’s why when Niels Miller first started building arc welders in

1929, he made sure his products offered long-lasting value and

superior quality. Like you, his customers couldn’t afford anything

less. Miller products had to be more than the best they could be.

They had to be the best you could buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and

service that meets the high standards of quality and value

established in 1929.

This Owner’s Manual is designed to help you get the most out of

your Miller products. Please take time to read the Safety

precautions. They will help you protect yourself against potential

hazards on the worksite. We’ve made installation and operation

quick and easy. With Miller you can count on years of reliable

service with proper maintenance. And if for some reason the unit

needs repair, there’s a Troubleshooting section that will help you

figure out what the problem is. The parts list will then help you to

decide the exact part you may need to fix the problem. Warranty

and service information for your particular model are also provided.

Miller Electric manufactures a full line

of welders and welding related equipment.

For information on other quality Miller

products, contact your local Miller distributor to receive the latest full

line catalog or individual specification sheets. To locate your nearest

distributor or service agency call 1-800-4-A-Miller, or visit us at

www.MillerWelds.com on the web.

Working as hard as you do

− every power source from

Miller is backed by the most

hassle-free warranty in the

business.

Mil_Thank2 2017−07

TABLE OF CONTENTS

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING 1.................................

1-1. Symbol Usage 1.......................................................................

1-2. Breathing Air Hazards 1.................................................................

1-3. Proposition 65 Warnings 2...............................................................

1-4. Principal Safety Standards 2.............................................................

SECTION 2 − SPECIFICATIONS 3..............................................................

2-1. Breathing Air Quality 3..................................................................

2-2. Respirator Air Supply Specifications (Also See Section 2-5) 3.................................

2-3. Filtration Efficiency 3...................................................................

2-4. Equipment Required 4..................................................................

2-5. General Specifications 4................................................................

2-6. CO (Carbon Monoxide) Monitor Specifications 4............................................

SECTION 3 − OPERATION 5...................................................................

3-1. Filtration System Components 5..........................................................

3-2. Connecting And Operating Filtration System 6..............................................

3-3. Wiring Diagram For Remote Alarm Receptacle 8............................................

3-4. Checking The Filtration System Before Use 8...............................................

3-5. Shutting Down The Filtration System 9....................................................

SECTION 4 − MAINTENANCE 10................................................................

4-1. Routine Maintenance 10.................................................................

4-2. Filter And CO Monitor Maintenance 11.....................................................

4-3. Replacing Batteries In CO Monitor 12......................................................

4-4. Replacing CO Sensor In CO Monitor 13....................................................

4-5. Calibrating CO Monitor 14................................................................

4-6. Filtration System Troubleshooting 16.......................................................

SECTION 5 − PARTS LIST 18...................................................................

SECTION 6 − WARRANTY 21...................................................................

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING

AIR FILTER 2018-06

Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions.

1-1. Symbol Usage

DANGER! − Indicates a hazardous situation which, if

not avoided, will result in death or serious injury. The

possible hazards are shown in the adjoining symbols

or explained in the text.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury. The possible

hazards are shown in the adjoining symbols or explained in the text.

NOTICE − Indicates statements not related to personal injury.

1-2. Breathing Air Hazards

The symbols shown below are used throughout this manual

to call attention to and identify possible hazards. When you

see the symbol, watch out, and follow the related instructions

to avoid the hazard. The safety information given below is

only a summary of the more complete safety information

found in the Principal Safety Standards listed in Section 1-4.

Read and follow all Safety Standards.

Only qualified persons should install, operate, maintain, and

repair this equipment. A qualified person is defined as one

who, by possession of a recognized degree, certificate, or

professional standing, or who by extensive knowledge, training and experience, has successfully demonstrated the

ability to solve or resolve problems relating to the subject

matter, the work, or the project and has received safety training to recognize and avoid the hazards involved.

During operation, keep everybody, especially children, away.

BREATHING UNFILTERED AIR can be

hazardous.

Welding produces fumes and gases. Misuse of the air

filtration system may expose you to fumes and gases

hazardous to your health.

D Read and follow these instructions and the safety labels carefully.

The air filtration system helps protect the user from specific airborne contaminants but must be used correctly to be fully effective.

Have an industrial hygienist test the air in your facility to ensure the

air filtration system provides adequate protection from contaminants in your environment. If you have questions about the air

filtration system, see equipment NIOSH label and consult your

Safety Director and a certified Industrial Hygienist. For occupational use applications, employers must implement a written

respiratory protection program meeting the requirements of OSHA

29 CFR 1910.134 (USA) or CSA Z94.4 (Canada), and other substance specific requirements as applicable.

D Do not use the air filtration system until you have been trained in its

proper operation by a qualified person.

D Follow all applicable ANSI, OSHA, CSA, CGA, and other regulato-

ry guidelines pertaining to the use of air filtration systems.

D Do not use the air filtration system where there is danger of fire or

explosion.

D Do not use the air filtration system in applications immediately dan-

gerous to life or health (IDLH).

D Do not enter a hazardous area until you are sure the air filtration

system is assembled correctly, and working properly.

. Indicates special instructions.

This group of symbols means Warning! Watch Out! ELECTRIC

SHOCK, MOVING PARTS, and HOT PARTS hazards. Consult symbols and related instructions below for necessary actions to avoid

these hazards.

D Dangerous contaminants may not smell or be visible. Leave the

area immediately if you notice any of the following:

Breathing becomes difficult....

You experience dizziness, impaired vision, or eye, nose, or ...

mouth irritation.

The air supply smells or tastes unusual....

The air supply equipment alarm sounds....

The equipment is damaged....

Air flow decreases or stops....

If you think the equipment is not supplying adequate protection....

Do not remove the equipment until you are in a safe area.

D Before each use, inspect air filtration system for damage and verify it

operates properly. Before using the air filtration system, test the air

flow to verify the system is receiving an adequate volume of air. Clean

and maintain the air filtration system according to the manufacturer’s

instructions.

D Do not use the air filtration system without all components or with

the air supply turned off because hazardous levels of oxygen and

carbon dioxide can accumulate in the helmet.

D Do not repair, modify, or disassemble the air filtration system or use

with parts or accessories not supplied by the manufacturer. Use only

those components that are part of the NIOSH-approved assembly.

D Breathable air must meet the requirements of Grade D breathing

air as described in Compressed Gas Association Commodity

Specification G.7.1 (United States) or CSA Standard Z180.1

(Canada). Use appropriate filters and carbon monoxide alarms to

ensure breathable air is supplied.

D Have a qualified person test the breathing air to ensure it meets

Grade D requirements. Breathing air testing shall be done in accordance with a written respirator protection program (prepared by a

qualified person) specific to the workplace.

D Locate the compressed air source in a clean environment that is free

from toxic fumes and gases and away from other sources of contamination, such as building exhaust vents and engine-powered vehicles

and equipment (including generators). Be sure inlet on compressed

air source is properly filtered to remove contaminants.

D Use only air line couplings designed for the supplied air system; air

couplings must be incompatible with outlets for other gas systems.

D Operate air filtration system within specified air pressures and air

hose lengths. The air supply system (air supply lines, fittings, filters, couplings, air pump/tanks) must be able to deliver sufficient

air volume within safe limits, 125 psig (862 kPa) maximum. If correct pressure is not maintained, negative air pressure can develop

in the helmet and create a risk of contaminants being inhaled. Also,

unless removed by filters, oil, water, and other contaminants could

flow downstream from the compressed air supply and adversely

affect the supplied air respirator’s performance. While air is flowing, use a reliable pressure gauge to continually monitor air

pressure at the air source connection point.

D To ensure adequate cooling of supply air, follow air compressor manu-

facturer’s recommendations when selecting air hose length. Do not

use an air compressor that supplies air warmer than 160F (71C);

supply air exceeding this temperature will degrade the air hose, which

could adversely affect the supplied air respirator’s performance.

OM-255447 Page 1

D Operate air filtration system only with filters in vertical/upright posi-

tion. Filters must be kept vertical/upright during operation or the

following events may occur:

Auto drains will not function properly, which may result in con-...

tamination of the CO monitor and cause water to pass through

the air supply hose and into the supplied air respirator.

Auto drains may become clogged, requiring that they be ...

cleaned or replaced. See instructions for cleaning or replacing

auto drains.

Moisture and/or contaminants may accumulate in filters. See ...

instructions for filter replacement.

D The air filtration system does not remove toxic fumes and gases, in-

cluding Carbon Monoxide (CO), Carbon Dioxide (CO2), and Nitrogen.

The air filtration system does not increase the oxygen content of the

air supply, and the system should not be used if the air entering the

system is oxygen deficient.

READ INSTRUCTIONS.

D Read and follow all labels and the Owner’s

Manual carefully before installing, operating, or

servicing unit. Read the safety information at

the beginning of the manual and in each

section.

D Use only genuine replacement parts from the manufacturer.

D Perform installation, maintenance, and service according to the

Owner’s Manuals, industry standards, and national, state, and

local codes.

TRAPPED AIR PRESSURE AND WHIPPING

HOSES can injure.

D Release air pressure from air filtration system

before servicing

COMPRESSED AIR can injure or kill.

D Before working on compressed air system,

turn off unit, release pressure, and be sure air

pressure cannot be accidentally applied.

D Check compressed air system components

and all connections and hoses for damage,

leaks, and wear before operating unit.

D Do not direct air stream toward self or others.

D Wear protective equipment such as safety

glasses, hearing protection, leather gloves,

heavy shirt and trousers, high shoes, and a cap when working on

compressed air system.

D Use soapy water or an ultrasonic detector to search for

leaks−−never use bare hands. Do not use equipment if leaks are

found.

D Reinstall doors, panels, covers, or guards when servicing is

finished and before starting unit.

D If ANY air is injected into the skin or body seek medical help im-

mediately.

1-3. Proposition 65 Warnings

WARNING: Cancer and Reproductive Harm − www.P65Warnings.ca.gov

1-4. Principal Safety Standards

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks

or severe burns. The input power circuit and machine

internal circuits are live when power is on.

D Do not touch live electrical parts.

D Do not use equipment in damp, wet, or confined spaces, or if there

is a danger of falling.

D Disconnect input power before installing or servicing this

equipment.

D Properly install, ground, and operate this equipment according to

its Owner’s Manual and national, state, and local codes.

D Always verify the supply ground − check and be sure that input

power cord ground wire is properly connected to ground terminal in

disconnect box or that cord plug is connected to a properly grounded receptacle outlet.

D Keep cords dry, free of oil and grease, and protected from hot metal

and sparks.

D Frequently inspect input power cord and ground conductor for

damage or bare wiring – replace immediately if damaged – bare

wiring can kill.

D Turn off all equipment when not in use. Do not leave equipment un-

til it has completely stopped.

Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1,

is available as a free download from the American Welding Society at

http://www.aws.org or purchased from Global Engineering Documents

(phone: 1-877-413-5184, website: www.global.ihs.com).

Safe Practice For Occupational And Educational Eye And Face Protection, ANSI Standard Z87.1, from American National Standards Institute,

25 West 43rd Street, New York, NY 10036 (phone: 212-642-4900, website: www.ansi.org).

NIOSH Approval of Respiratory Devices, CFR Title 42 − Public Health,

Part 84, is available from the Centers for Disease Control, 1600 Clifton

Rd. Atlanta, GA 30329−4027 (phone: 800−232−4636) or as a free

download at www.cdc.gov/niosh.

OSHA, Occupational Safety and Health Standards for General Industry, Title 29, Code of Federal Regulations (CFR), Part 1910.177 Subpart

N, Part 1910 Subpart Q, and Part 1926, Subpart J, from U.S. Government Printing Office, Superintendent of Documents, P.O. Box 371954,

Pittsburgh, PA 15250-7954 (phone: 1-866-512-1800) (there are 10 OSHA Regional Offices—phone for Region 5, Chicago, is 312-353-2220,

website: www.osha.gov).

OM-255447 Page 2

American National Standard for Respiratory Protection, ANSI /ASSE

Standard Z88.2−2015, from American National Standards Institute, 25

West 43rd Street, New York, NY 10036 (phone: 212-642-4900,

website: www.ansi.org).

Selection, Use, and Care of Respirators, CAN/CSA Standard Z94.4,

from Canadian Standards Association, Standards Sales, 5060 Spectrum Way, Suite 100, Mississauga, Ontario, Canada L4W 5NS (phone:

800-463-6727, website: www.csagroup.org).

Commodity Specification for Air, CGA Pamphlet G-7.1, from

Compressed Gas Association, 14501 George Carter Way, Suite 103,

Chantilly, VA 20151 (phone: 703-788-2700, website:www.cganet.com).

Compressed Breathing Air and Systems, CSA Standard Z180.1, from

Canadian Standards Association, Standards Sales, 5060 Spectrum

Way, Suite 100, Mississauga, Ontario, Canada L4W 5NS (phone:

800-463-6727, website: www.csagroup.org).

SECTION 2 − SPECIFICATIONS

This equipment helps protect the user from certain contaminants. All users must read and understand these instructions and be

trained in the proper use of this equipment before using. Use this equipment according to all applicable health and safety standards.

If you have questions about the type of respiratory equipment required, consult your safety director and an Industrial Hygienist.

Do not enter a hazardous area until you are sure the supplied air respirator and air filtration system are assembled correctly, working

properly, and the respirator is worn properly.

Operate filtration system only with filters in vertical/upright position. Filters must be kept vertical/upright or auto drains may not function properly. Malfunctioning auto drains may allow contamination of the CO (carbon monoxide) monitor or moisture/contaminants

to accumulate in filters.

. See Owner’s Manual 269676 for information on the supplied air respirator (SAR).

2-1. Breathing Air Quality

The responsibility for the quality of breathing air rests with the user. Compliance with federal, state, or local regulations is the responsibility of the

user and this recommendation does not supersede any existing rules, regulations, or laws which may apply. Miller filtration systems meet or

exceed CGA Grade−D specifications for air quality as adopted by Federal OSHA. When the components are used in accordance with the

manufacturer’s instructions and recommendations, Miller filtration systems meet or exceeds federal regulations presently in force. It is incumbent

upon the user to comply with any changes in the regulations or law which may occur in future situations.

The air supply compressor should be located in a safe, clean ambient air environment. This safe location should be tested periodically using proper

instruments to ensure clean ambient air quality on a consistent basis. Total system Grade−D air quality should be tested at the time of initial setup.

If the compressor is moved, retesting air quality is recommended. Should the location or environment significantly change, the air quality should be

retested.

This series of filtration system products should be used according to the recommendations specified in the manual. The standard filtration system

package is not explosion-proof and should be located in a non-explosive environment. The CO (carbon monoxide) monitor should be calibrated monthly or if the accuracy of the CO monitor is in question. System air quality should be tested for, but not limited to, the following Grade−D air components:

CO − Carbon Monoxide

O2 − Oxygen

CO2 − Carbon Dioxide

H2O − Water (Moisture Content)

Hydrocarbons (Oil Mist)

Total Particulates

Miller filtration systems meet all of the following federal specifications for Grade-D air when used and serviced in accordance with these instructions:

Compressed Gas Association

CGA G.7.1 Commodity Specification for Air

Army Corps of Engineers EM385−1−1,

paragraph 07b−11−4,

Compressed Breathing Air

2-2. Respirator Air Supply Specifications (Also See Section 2-5)

Breathable air must be supplied to the supplied air respirator and meet the requirements of Grade D breathing air as described in Compressed Gas

Association Commodity Specification G.7.1 (United States) or CSA Standard Z180.1 (Canada). The air supply must be able to deliver 6−15 SCFM

(170−425 lpm) to operate the air regulator at the recommended pressures.

2-3. Filtration Efficiency

Stage Filtration Type Filter Drain / Indicator Efficiency

First Particulate/Bulk Liquid Separation Auto Drain And Filter Change Indicator Removes

Second Oil Coalescing And

Ultra Fine Particulate

Third Activated Charcoal Manual Drain And

95% Bulk Particulate And

Liquids At 5 Microns

Auto Drain And Filter Change Indicator Removes Oil And Particulate To

Filter Change Indicator

99.9998% At 0.01 Microns

Removes Organic Vapors, Odors,

And Tastes. Less Than 0.003

Pp/Wt Remaining Oil Content

OM-255447 Page 3

2-4. Equipment Required

The filtration system is designed for use with the Miller Type C supplied air respirator (SAR) for respiratory protection during entry into and escape

from atmospheres not immediately dangerous to life or health. When used with the equipment intended for use with this product, the respirator system

generates a positive air pressure to help prevent contaminants from entering the hood. The filtration system must be connected to a source of respirable

breathing air and be used with the equipment listed below:

D Helmet assembly

D C50 Air regulator and adapter

D Breathing tube assembly

D Belt assembly

D Airline hose

D Detachable couplings

2-5. General Specifications

Stock Number 275961 275963 275970 275981

Type

Dimensions

(L x W x H)

Weight

Inlet Size

Number of Outlets

Maximum Air Flow

Remote Alarm Signal

Maximum Inlet Pressure

Relief Valve

Monitoring Capability

CO Monitor Alarm Setting

Input Power

Operating Temp. Range

Storage Temp. Range

Two Person Two Person Four Person Four Person

32 x 27 x 15 in.

(813 x 686 x 381 mm)

45 lb (20.4 kg) 45 lb (20.4 kg) 47 lb (21.3 kg) 47 lb (21.3 kg)

2 2 4 4

49 CFM At 110 psi

1388 lpm At 758 kPa

Yes Yes Yes Yes

10 ppm 5 ppm 10 ppm 5 ppm

32 x 27 x 15 in.

(813 x 686 x 381 mm)

1/2 in. Industrial Interchange

49 CFM At 110 psi

1388 lpm At 758 kPa

150 psi (034 kPa)

125 psi (862 kPa)

Inline Continuous Monitoring Of Carbon Monoxide (CO)

9–16 VDC Or 115 VAC 50/60 Hz

32 to 125F (0 to 51C)

32 to 125F (0 to 51C)

32 x 27 x 15 in.

(813 x 686 x 381 mm)

123 CFM At 110 psi

3483 lpm At 758 kPa

32 x 27 x 15 in.

(813 x 686 x 381 mm)

123 CFM At 110 psi

3483 lpm At 758 kPa

2-6. CO (Carbon Monoxide) Monitor Specifications

The carbon monoxide monitor continuously analyzes air samples and displays the CO concentration in parts per million (ppm). If the CO level is

within acceptable limits (below 10 ppm U.S. or 5 ppm Canada) the system’s green (Normal) light goes on and the red (High CO) light flickers

once per second. If the CO concentration level exceeds the alarm set point, the green (Normal) light goes out, the red (High CO) light goes on,

the audible alarm sounds, and the remote alarm connections energize. After the CO concentration levels drop below the alarm set point, all alarm

indicators deactivate and the unit returns to normal operation.

Dimensions

(L x W x H)

Weight

Case Material

Input Voltage

Shielding

Circuit

Protection

Operating

Temperature

Humidity Range

Flow

Requirements

Display

7.25 x 5.25 x 7.25 in.

(184 x 133 x 184 mm)

2.2 lb (1 kg)

Extruded Aluminum − Anodized Black

115 VAC and/or 9–16 VDC

Internal RFI/EMI Filters

1 Amp / 250 VAC

Fast Acting Fuse

4–113F

(−15.5 − 45C)

10–90% Relative Humidity

50–100 cc/min

3-Digit LCD Indicates

Carbon Monoxide (CO) Concentration

Test Circuit

Sensor Type

Accuracy

Response Time

Detectable Range

Calibration

Alarm Setting

Warning Signals

Warranty

Manual CO Zero And Span Adjustments

10 ppm Carbon Monoxide (CO) U.S.

High CO − Red Light And Audible Alarm

Manually Activated

Sealed Electrochemical sensor for

Carbon Monoxide (CO)

+/− 1% Full Scale

90% In 10–15 Seconds

0–200 ppm Carbon Monoxide (CO)

(5 ppm CO Canada)

Normal Operation − Green Light

Low Battery − Amber Light

Two Years From Original Date Of

Purchase (See Section 6)

OM-255447 Page 4

SECTION 3 − OPERATION

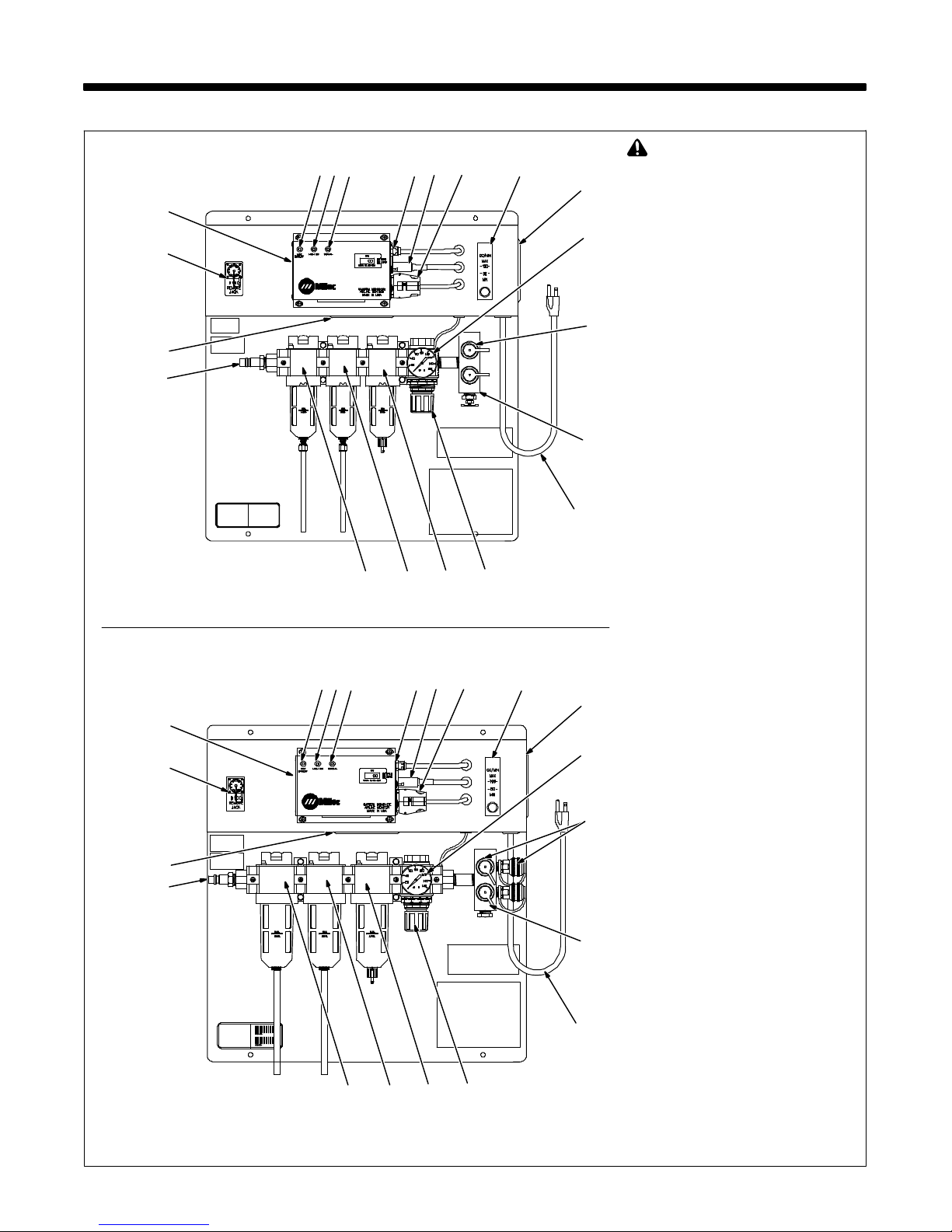

3-1. Filtration System Components

Two-Person Units

1

20

19

18

Four-Person Units

1

20

23467 8

23467 8

5

14151617

5

13

10

! Operate filtration system only

with filters in vertical/upright posi-

9

10

tion. Filters must be kept vertical/

upright or auto drains may not

function properly. Malfunctioning

auto drains may allow contamination of the CO monitor or moisture/contaminants to accumulate

in filters.

. A four-person unit is shown through-

out this manual.

1 CO Monitor

11

2 CO Monitor Low Battery Light (See

Section 4-3)

3 High CO Light (Red)

4 Normal Operation Light (Green)

5 Air Sample Inlet

6 CO Monitor 115 VAC Power

12

7 Remote Signal Connector

8 Flowmeter

9 115 VAC Gang Box

10 Air Pressure Gauge

11 Air Outlet Fitting /Dust Cap

12 Relief Valve (Located Behind Air

Outlet Block)

13 115 VAC Power Cord

14 Air Pressure Regulator

15 Third Stage Filter Assembly

16 Second Stage Filter Assembly

17 First Stage Filter Assembly

18 Air Inlet Fitting

9

19 High CO Audible Alarm

20 Remote Alarm Receptacle

19

18

11

12

13

14151617

OM-255447 Page 5

Loading...

Loading...