Miller AugmentedArc Owner's Manual

OM-278680A 2019-08

Processes

Stick (SMAW) Welding

MIG (GMAW) Welding

Flux Cored (FCAW) Welding

TIG (GTAW) Welding

Description

Arc Welding Training System

AugmentedArc

®

Welding Training System

For product information,

Owner’s Manual translations,

and more, visit

www.MillerWelds.com

File: Accessory

From Miller to You

Thank you and congratulations on choosing Miller. Now you can get

the job done and get it done right. We know you don’t have time to do

it any other way.

That’s why when Niels Miller first started building arc welders in 1929,

he made sure his products offered long-lasting value and superior

quality. Like you, his customers couldn’t afford anything less. Miller

products had to be more than the best they could be. They had to be the

best you could buy.

Today, the people that build and sell Miller products continue the

tradition. They’re just as committed to providing equipment and service

that meets the high standards of quality and value established in 1929.

This Owner’s Manual is designed to help you get the most out of your

Miller products. Please take time to read the Safety Precautions. They

will help you protect yourself against potential hazards on the worksite.

We’ve made installation and operation quick

and easy. With Miller, you can count on

years of reliable service with proper

maintenance. And if for some reason the unit

needs repair, there’s a Troubleshooting

section that will help you figure out what the

problem is, and our extensive service

network is there to help fix the problem.

Warranty and maintenance information for

your particular model are also provided.

Miller is the first welding

equipment manufacturer in

the U.S.A. to be registered to

the ISO 9001 Quality System

Standard.

Working as hard as you do

− every power source from

Miller is backed by the most

hassle-free warranty in the

business.

Miller Electric manufactures a full line

of welders and welding-related equipment.

For information on other quality Miller

products, contact your local Miller distributor to receive the latest full

line catalog or individual specification sheets. To locate your nearest

distributor or service agency call 1-800-4-A-Miller, or visit us at

www.MillerWelds.com on the web.

Mil_Thank1

2019−01

TABLE OF CONTENTS

SECTION 1 − SAFETY PRECAUTIONS − READ BEFORE USING 1.................................

1-1. Symbol Usage 1.......................................................................

1-2. Welding Training System Hazards 1.......................................................

1-3. Proposition 65 Warnings 1...............................................................

1-4. Principal Safety Standards 1.............................................................

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION 2...........................

2-1. Symboles utilisés 2.....................................................................

2-2. Dangers liés au système de formation en soudure 2.........................................

2-3. Proposition californienne 65 Avertissements 2..............................................

2-4. Principales normes de sécurité 2.........................................................

SECTION 3 − DEFINITIONS 3..................................................................

3-1. Miscellaneous Symbols And Definitions 3..................................................

SECTION 4 − SPECIFICATIONS 4..............................................................

4-1. Introduction 4.........................................................................

4-2. System Features And Benefits 4.........................................................

4-3. AugmentedArc Complete Package 4......................................................

4-4. Serial Number And Rating Label Location 4................................................

4-5. Unit Specifications 5....................................................................

4-6. Software Licensing Agreement 5.........................................................

4-7. Environmental Specifications 6...........................................................

SECTION 5 − INSTALLATION 6................................................................

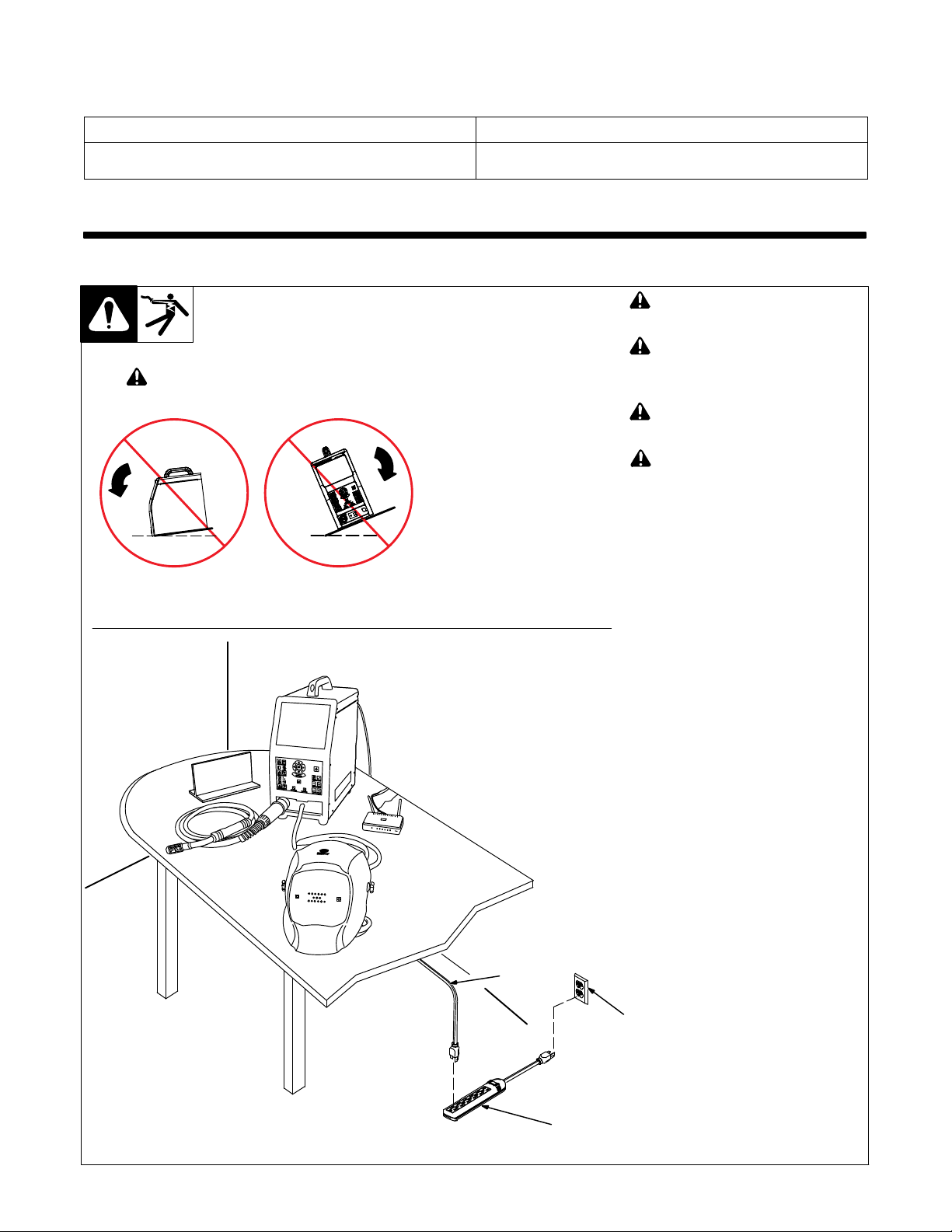

5-1. Selecting A Location 6..................................................................

5-2. Simulator Components 7................................................................

5-3. Installing The Training System − Standalone Configuration 8..................................

5-4. Installing The Training System − Classroom Configuration 9...................................

5-5. Connecting Simulator To An External Monitor 10.............................................

5-6. Assembling AR MIG Gun 10..............................................................

5-7. Assembling AR TIG Torch 11.............................................................

5-8. Assembling AR Stick Electrode 12.........................................................

5-9. AR Stick Electrode, MIG Gun, TIG Torch, And Workpieces 13..................................

5-10. AR Welding Helmet 14...................................................................

5-11. Making Helmet Adjustments 14............................................................

5-12. Connecting Weld Cables 15..............................................................

SECTION 6 − SYSTEM CONTROLS AND COMPONENTS 16.......................................

6-1. Simulator Controls 16....................................................................

SECTION 7 − OPERATION 17...................................................................

7-1. Equipment Setup 17.....................................................................

7-2. Getting Started 17.......................................................................

A. Login Screens 17.......................................................................

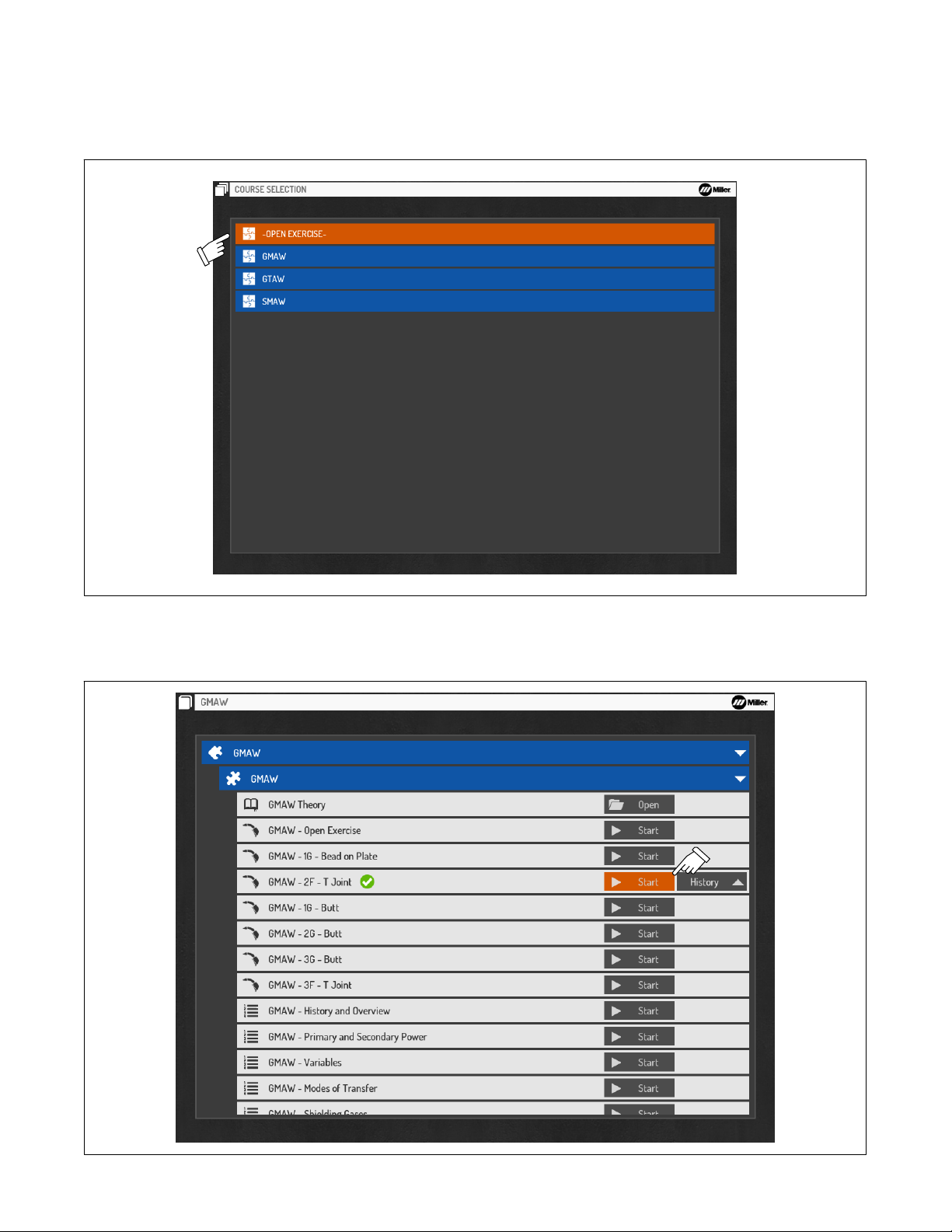

B. Course Selection 18.....................................................................

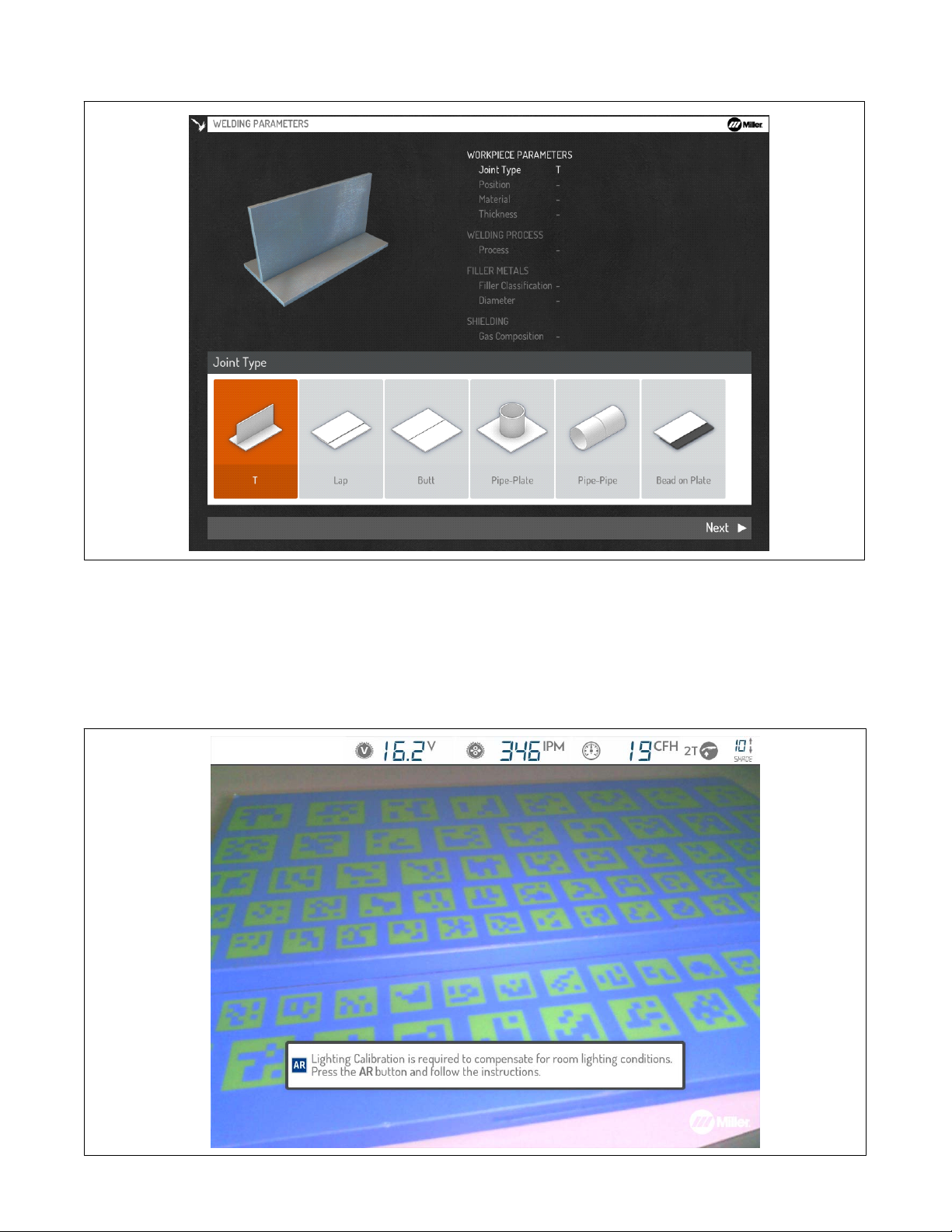

C. Lighting Calibration 19...................................................................

D. Correcting Improper Weld Setting 21.......................................................

E. Determining Correct Position Of MIG Gun/Electrode And AR Helmet 23..........................

F. Course Analysis 26.....................................................................

SECTION 8 − SYSTEM SETTINGS 27............................................................

8-1. Accessing Administrator Home Screen 27..................................................

8-2. Changing System Configuration 27........................................................

A. Changing System Language Setting 27.....................................................

B. Changing System Units And Standards 27..................................................

TABLE OF CONTENTS

SECTION 8 − SYSTEM SETTINGS (Continued) 27.................................................

C. Changing System Date And Time 28.......................................................

D. Changing System Mode 28...............................................................

E. Changing Simulation Settings 28..........................................................

F. Changing Lighting Calibration Options 28...................................................

G. Change WiFi Access Point Settings 28.....................................................

H. Restoring Factory Configuration 28........................................................

8-3. Software Updates 29....................................................................

A. Software Updates − Standalone Mode 29...................................................

B. Software Updates − Classroom Mode 29....................................................

8-4. T

roubleshooting

8-5. Check Components 31...................................................................

A. Checking Front Panel Functions 31........................................................

B. Checking Audio 31......................................................................

C. Checking Displays 31....................................................................

D. Checking Camera Set 31.................................................................

E. Calibrating Electrode Retraction 32........................................................

F. Configuring TIG Foot Pedal 32............................................................

8-6. Cameras 33............................................................................

A. Configure Camera Set 33................................................................

B. Restore Factory Camera Calibration 38.....................................................

8-7. Video Device Settings 39.................................................................

A. Lighting Calibration 39...................................................................

B. Temperature Setting (Figure 8-24) 39.......................................................

C. Intensity Setting (Figure 8-25) 40..........................................................

D. Custom Settings 40.....................................................................

SECTION 9 − USING THE TEACHER SOFTWARE 42..............................................

9-1. Installing The Teacher Software Program 42.................................................

9-2. Using The Teacher Software 45...........................................................

A. Student Home Page (Figure 9-11) 46.......................................................

B. Adding A Student (Figure 9-12) 48.........................................................

C. Editing Student Information 49............................................................

D. Deleting A Student (Figure 9-14) 50........................................................

9-3. Module Management 50..................................................................

A. Task Information 51.....................................................................

B. Adding A Module (Figure 9-17 And Figure 9-19) 51...........................................

C. Designing The Welding Exercise (Figure 9-22) 53............................................

D. Scoring 55.............................................................................

E. Copy Module 55........................................................................

9-4. Course Management 57..................................................................

A. Adding Courses 57......................................................................

B. Editing A Course 58.....................................................................

C. Course History 59.......................................................................

9-5. Reviewing Student Activity And Results 59..................................................

A. Student Information (Figure 9-35) 59.......................................................

B. Virtual Classroom 62....................................................................

C. Creating Reports 62.....................................................................

9-6. Account And Settings 63.................................................................

A. Manage Accounts 63....................................................................

B. Settings 63.............................................................................

SECTION 10 − INSTALLING OPTIONAL MAGNIFYING LENS 65....................................

SECTION 11 − MAINTENANCE AND STORAGE 66................................................

11-1. Routine Maintenance 66.................................................................

SECTION 12 − TROUBLESHOOTING 66.........................................................

12-1. Troubleshooting Table 66.................................................................

SECTION 13 − RECONFIGURING STANDALONE ROUTER FOR CLASSROOM MODE 67.............

SECTION 14 − PARTS LIST 68..................................................................

WARRANTY

30......................................................................

SECTION 1 − SAFETY PRECAUTIONS −

READ BEFORE USING

Protect yourself and others from injury — read, follow, and save these important safety precautions and operating instructions.

1-1. Symbol Usage

AugArc 2018-01

DANGER! − Indicates a hazardous situation which, if

not avoided, will result in death or serious injury. The

possible hazards are shown in the adjoining symbols

or explained in the text.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury. The possible

hazards are shown in the adjoining symbols or explained in the text.

NOTICE − Indicates statements not related to personal injury.

1-2. Welding Training System Hazards

The symbols shown below are used throughout this manual

to call attention to and identify possible hazards. When you

see the symbol, watch out, and follow the related instructions

to avoid the hazard. The safety information given below is

only a summary of the more complete safety information

found in the Safety Standards listed in Section 1-4. Read and

follow all Safety Standards.

Only qualified persons should install, operate, maintain, and

repair this equipment. A qualified person is defined as one

who, by possession of a recognized degree, certificate, or

professional standing, or who by extensive knowledge, training and experience, has successfully demonstrated ability to

solve or resolve problems relating to the subject matter, the

work, or the project and has received safety training to recognize and avoid the hazards involved.

READ INSTRUCTIONS.

Read and follow all labels and the Owner’s

Manual carefully before installing, operating, or

servicing unit. Read the safety information at

the beginning of the manual and in each

section.

Use only genuine replacement parts from the manufacturer.

Perform installation, maintenance, and service according to the

Owner’s Manuals, industry standards, and national, state, and

local codes.

Do not repair, modify, or disassemble the training system or use

with parts or accessories not supplied by the manufacturer. Use

only approved components and accessories from the

manufacturer.

Be sure all hardware is properly tightened.

Indicates special instructions.

This group of symbols means Warning! Watch Out! ELECTRIC

SHOCK, MOVING PARTS, and HOT PARTS hazards. Consult symbols and related instructions below for necessary actions to avoid the

hazards.

Do not use the training system until you are sure it is correctly as-

sembled and working properly.

Before each use, inspect the training system for damage and verify

it is secure and installed properly.

Use the training system only as specified in the manual.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks

or severe burns.

Do not touch live electrical parts.

Disconnect input power before installing or servicing this

equipment.

Keep cords dry, free of oil and grease, and protected from hot

metal and sparks.

Frequently inspect input power cord and ground conductor for

damage or bare wiring – replace immediately if damaged – bare

wiring can kill.

Use only well-maintained equipment. Repair or replace dam-

aged parts at once. Maintain unit according to the manual.

Keep all panels and covers securely in place.

Do not use the training system during an electrical storm. Turn

off equipment and disconnect input power until risk of lightning

has passed.

Always verify the supply ground − check and be sure that cord

plug is connected to a properly grounded receptacle outlet.

Do not use equipment in damp or wet conditions.

1-3. Proposition 65 Warnings

WARNING: Cancer and Reproductive Harm − www.P65W

arnings.ca.gov

1-4. Principal Safety Standards

Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use — Part 1: General requirements, CAN/CSA

Standard C22.2 No. 61010−1−12, from Canadian Standards Association, Standards Sales, 5060 Spectrum Way, Suite 100, Mississauga,

Ontario, Canada L4W 5NS (phone: 800-463-6727,

website: www.csagroup.org).

OM-278680 Page 1

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION

7

Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives

aux précautions de sécurité et au mode opératoire.

2-1. Symboles utilisés

AugArc_2018−01_fre

DANGER! − Indique une situation dangereuse qui si on

l’évite pas peut donner la mort ou des blessures graves.

Les dangers possibles sont montrés par les symboles

joints ou sont expliqués dans le texte.

Indique une situation dangereuse qui si on l’évite pas

peut donner la mort ou des blessures graves. Les dangers possibles sont montrés par les symboles joints ou

sont expliqués dans le texte.

AVIS − Indique des déclarations pas en relation avec des blessures

personnelles.

Indique des instructions spécifiques.

Ce groupe de symboles veut dire Avertissement! Attention! DANGER

DE CHOC ELECTRIQUE, PIECES EN MOUVEMENT, et PIECES

CHAUDES. Consulter les symboles et les instructions ci-dessous y

afférant pour les actions nécessaires afin d’éviter le danger.

2-2. Dangers liés au système de formation en soudure

Les symboles représentés ci-dessous sont utilisés dans ce manuel pour attirer l’attention et identifier les dangers possibles. En

présence de l’un de ces symboles, prendre garde et suivre les

instructions afférentes pour éviter tout risque. Les instructions

en matière de sécurité indiquées ci-dessous ne constituent

qu’un sommaire des instructions de sécurité plus complètes

fournies dans les normes de sécurité énumérées dans la Section 2-4. Lire et observer toutes les normes de sécurité.

L

’installation,

doivent être confiés qu’à des personnes qualifiées. Une

personne qualifiée est définie comme celle qui, par la

possession

statut professionnel, ou qui, par une connaissance, une formation et une expérience approfondies, a démontré avec

succès sa capacité à résoudre les problèmes liés à la tâche,

le travail ou le projet et a reçu une formation en sécurité afin

de reconnaître et d’éviter les risques inhérents.

l’utilisation, l’entretien et les réparations ne

d’un diplôme reconnu, d’un certificat ou d’un

LIRE LES INSTRUCTIONS.

Lire et appliquer les instructions sur les

étiquettes

lation, l’utilisation ou l’entretien de l’appareil.

Lire les informations de sécurité au début du

N’utiliser que les pièces de rechange recommandées par le

constructeur.

Effectuer l’installation, l’entretien et toute intervention selon les

manuels d’utilisateurs, les normes nationales, provinciales et de

l’industrie,

Ne pas réparer, modifier ou démonter le système de formation,

et ne pas l’utiliser avec des pièces ou accessoires non fournis

par le fabricant. Utiliser uniquement des composants et

accessoires approuvés par le fabricant.

S’assurer que toute la quincaillerie est bien serrée.

Ne pas utiliser le système de formation avant d’être certain qu’il est

bien monté et qu’il fonctionne correctement.

manuel et dans chaque section.

ainsi que les codes municipaux.

et le Mode d’emploi avant l’instal-

Avant chaque utilisation, inspecter le système de formation pour

déceler tout signe de dommage et s’assurer qu’il est bien installé et

maintenu correctement.

Utiliser le système de formation seulement conformément au

manuel.

Ne pas toucher aux pièces électriques sous tension.

Couper le courant avant d’installer ou de faire l’entretien de cet

équipement.

En effectuant les raccordements d’entrée, fixer d’abord le

conducteur de mise à la terre approprié et contre-vérifier les

connexions.

Les câbles doivent être exempts d’humidité, d’huile et de

graisse; protégez−les contre les étincelles et les pièces

métalliques

N’utiliser qu’un matériel en bon état. Réparer ou remplacer

sur-le-champ les pièces endommagées. Entretenir l’appareil

conformément

Maintenir solidement en place tous les panneaux latéraux et les

capots.

Ne pas utiliser le système de formation pendant un orage

électrique.

l’alimentation

d’éclairs.

Toujours vérifier la terre du cordon d’alimentation − Vérifier et

s’assurer que la fiche du cordon est raccordée à une prise

correctement mise à la terre.

Ne pas utiliser l’équipement en conditions humides ou

mouillées.

UNE DÉCHARGE ÉLECTRIQUE peut

entraîner la mort.

Tout contact avec des pièces électriques sous

tension peut causer un choc mortel ou des brûlures

graves.

chaudes.

à ce manuel.

Mettre l’équipement hors tension et débrancher

électrique jusqu’à ce que soit éliminé le risque

2-3. Proposition californienne 65 Avertissements

AVERTISSEMENT : cancer et troubles de la reproduction − www.P65W

2-4. Principales normes de sécurité

Safety Requirements for Electrical Equipment for Measurement, Control, and Laboratory Use — Part 1: General requirements, CAN/CSA

Standard C22.2 No. 61010−1−12, from Canadian Standards Association, Standards Sales, 5060 Spectrum Way, Suite 100, Mississauga,

Ontario, Canada L4W 5NS (phone: 800-463-6727,

website: www.csagroup.org).

OM-278680 Page 2

arnings.ca.gov

.

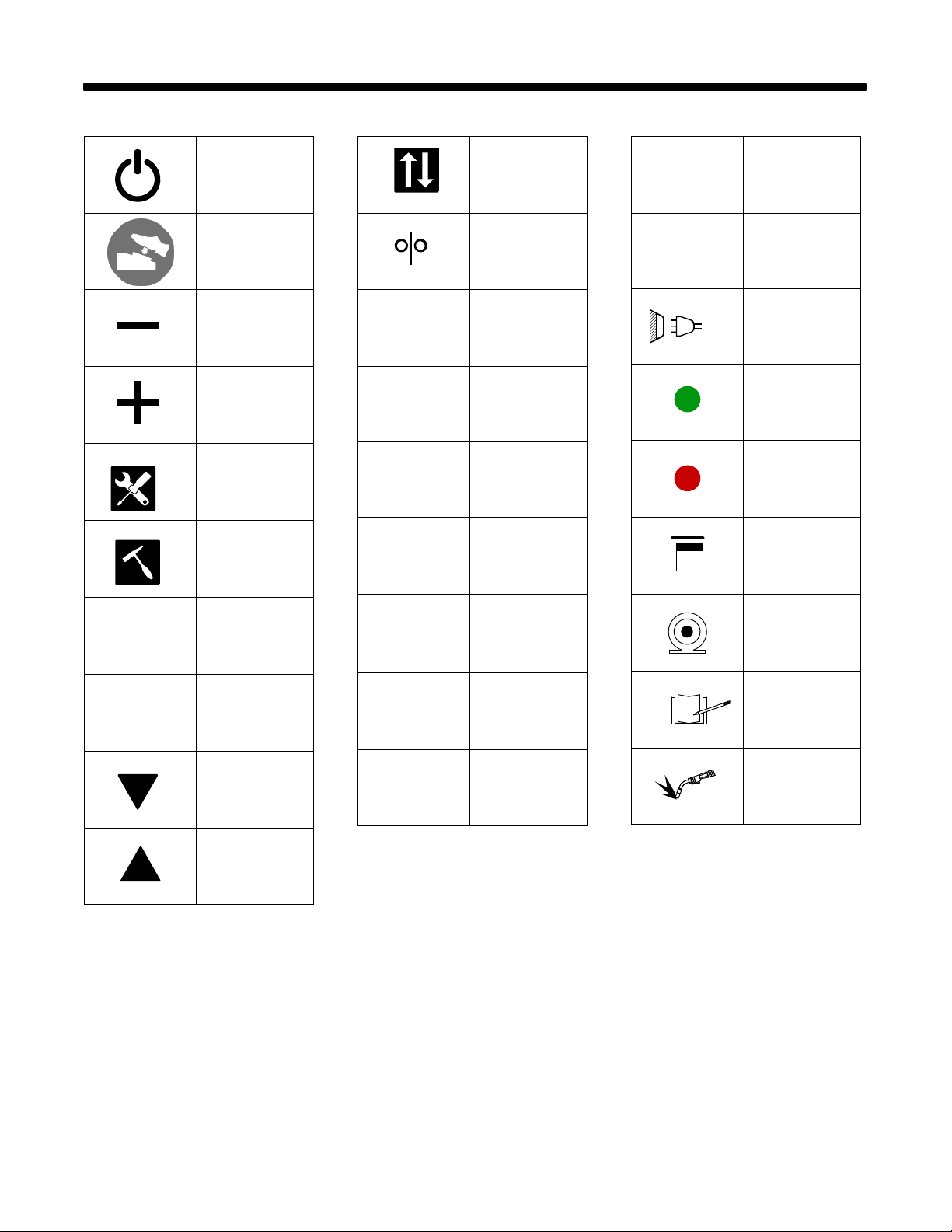

SECTION 3 − DEFINITIONS

3-1. Miscellaneous Symbols And Definitions

Power On/Off

TIG Foot Pedal

Enabled

Decrease

Increase

Settings

Clean Slag

Pass

AR

A

V

2T

4T

Change Transfer

Mode

Wire Feed

Augmented Reality

Amperage

Voltage

Press To Start

Weld; Release To

Stop Weld

Press And

Release To Start

Weld; Press And

Release To Stop

Weld

AC

IP

Alternating Current

Internal Protection

Rating

Input Plug And

Cord

Connected To

Network

Disconnected

From Network

Connected And

Seeing Theory

Connected And

Analyzing An

Exercise

X

Fail

Down

Up

DC+

DC−

DC Electrode

Positive

DC Electrode

Negative

Connected And

Doing A Quiz

Connected And

Performing An

Exercise

OM-278680 Page 3

SECTION 4 − SPECIFICATIONS

4-1. Introduction

The AugmentedArc is an augmented reality (AR) welding training system that provides the new student or the experienced welder the opportunity to

develop, enhance, or verify their welding abilities through an interactive, simulated welding process on a variety of weld joint configurations. This

product is designed to help welding students acquire the necessary welding knowledge, capacities, abilities, welding sensations and skills, thereby

saving the time and money normally spent training in a live welding situation. It is an educational solution to help both students and trainers improve their

learning experience and enhance results and qualifications. The system can be installed as a standalone or classroom configuration.

After the AugmentedArc system is installed, the user turns on the training system, selects the desired welding assignment, puts on the augmented

reality (AR) welding helmet and welding gloves (welding gloves are recommended to simulate a live welding experience), and begins the simulated

welding activity. The cameras and AR markers convey the weld data (gun angles, gun speed, contact tip to work distance [CTWD], aim) to the system

microprocessor, which compares it to the specified weld parameters of the assignment selected. The system evaluates the weld data and grades the

student’s performance.

The AugmentedArc instruction is complementary to training with live welding equipment. To complete their welding training, students should also

practice their acquired skills by welding under the supervision of qualified persons in a safe welding environment.

NOTICE − Do not install or use the Augmented Arc in the same area as live welding equipment.

4-2. System Features And Benefits

S Advanced computer simulation techniques using artificial vision technology create a realistic welding environment.

Teacher software allows the instructor to adapt their training programs to the AugmentedArc system. The instructor can manage and monitor

student activity and progress from a PC (personal computer) (see Section 9).

Analysis mode allows all of the welding exercises performed in the simulator to be visualized, providing detailed results of all of the welding

parameters.

System allows for remote maintenance and software updates, and is adaptable to meet specific training requirements.

The system configuration can be installed as a standalone or classroom application. The standalone application includes a simulator and a

router, and all of the information is saved on the unit. The classroom application can include multiple simulators, a router, and a controller. All

of the information is saved on the controller.

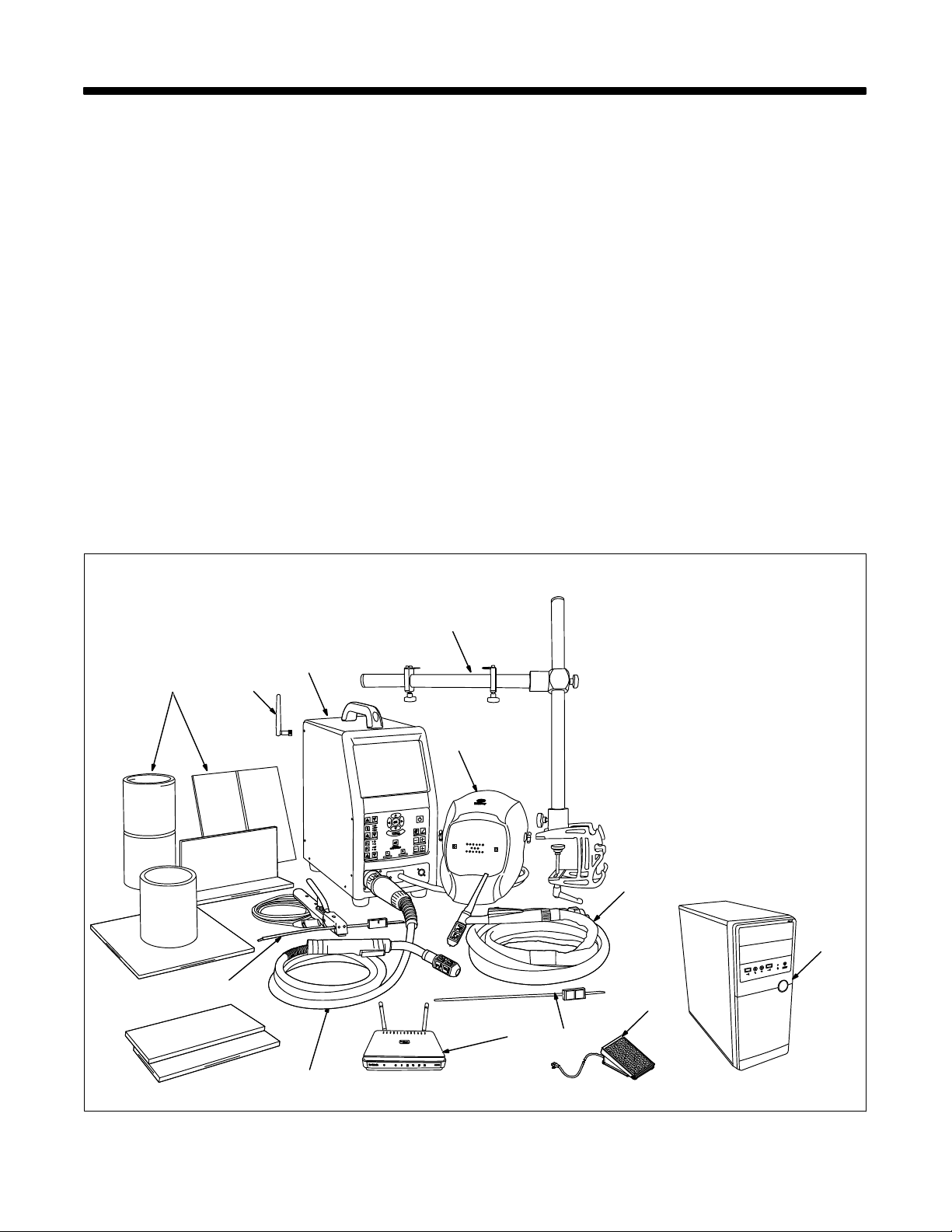

4-3. AugmentedArc Complete Package

1

10

11

Input power and Ethernet cables

are not shown.

3

2

1 Simulator

2 Helmet

3 Workpiece Stand

4 TIG (GTAW) Torch And Cable

5 TIG Filler Rod

6 TIG Foot Pedal And Adapter

Cable (Optional)

7 Router

8 MIG (GMAW) / FCAW Gun

And Cable

9 Stick (SMAW) Electrode

Holder And Cable

10 Workpieces (Five Total)

11 WiFi Antenna (Two Total)

12 Controller (Optional, For

Classroom Configuration Only)

4

12

9

161-93 / 161-97 / 161-100 / Ref. 805 465-A

7

8

5

6

4-4. Serial Number And Rating Label Location

The serial number and rating information for this product is located on the back of the unit. Use rating label to determine input power requirements, and to

register for free software upgrades. For future reference, write serial number in space provided on back cover of this manual.

OM-278680 Page 4

4-5. Unit Specifications

Dimensions (L x W x H) Simulator: 17.25 x 9.38 x 21 in. (438 x 238 x 533 mm)

Weight Simulator: 20.7 lb (9.4 kg) AR Welding Helmet: 1.97 lb (0.89 kg)

Simulator and Helmet (including cables): 23.8 lb (10.8 kg)

Input Power 80 to 264 Volts AC, 0.9A (230 VAC) to 1.8A (115 VAC), 50/60 Hz

External VGA Port Resolution External HDMI Port Resolution: 1024 x 768 Pixels

Display Port Resolution: 1024 x 768 Pixels

Resolution during boot-up is 800 x 600 Pixels.

Simulation Modes/Processes Stick (SMAW), MIG (GMAW/FCAW), TIG (GTAW)

Software Version Displayed On System Settings Screen.

Register for free software upgrades at MillerWelds.com/register.

Computer OS: Linux

Main Monitor 9.7 in. integrated LCD monitor, 1024 x 768 resolution

PC Requirements For Installation Of Teacher

Software (See Section 9)

Supported Welding Processes Stick (SMAW), MIG (GMAW), FCAW, TIG (GTAW)

Parameters Tracked By Cameras MIG: Work Angle, Travel Angle, Travel Speed, Contact Tip To Work Distance (CTWD), Aim

Supported Joints Bead On Plate, T-Joint, Butt Joint, Lap Joint, Pipe-Plate, Pipe-Pipe

Welding Positions 1F, 2F, 3F, 4F, 1G, 2G, 3G, 4G, 5G, 6G

Workpiece Positions Horizontal, Vertical, Flat, Overhead

Voltage Selection MIG (GMAW and FCAW) 10 − 38 Volts

Amperage (Intensity) Selection Stick (SMAW), MIG (GMAW and FCAW), TIG (GTAW): 50 − 425 Amps

Polarity Selection DCEP, DCEN, AC

Shielding Gas Selection CO2, Argon-O2, Argon-CO2, And Mixtures

Wire Speed Selection MIG (GMAW and FCAW): 50 - 1000 ipm (1.27 − 25.4 m/min)

Base Material Selection Carbon Steel, Stainless Steel, Aluminum

Workpiece Thickness Selection 1/8, 1/4, 3/8 in. (3.2, 6.4, 9.5 mm)

Stick Electrode Selection E7018, E6010, E6013

Stick Electrode Diameter Selection 1/8, 3/32, 5/32 in. (2.50, 3.25, 4.00 mm)

Wire Diameter Selection Solid Wire: 0.030, 0.035, 0.045 in. (0.8, 1.0, 1.2 mm)

Filler Rod Selection 5/64, 3/32 in. (2.0 And 2.4 mm)

Real Time Guide Parameters On-Screen Help Guides Provide Corrective Feedback To User During Simulation

Teacher Software Standalone Application

Helmet Miller Black Infinity Helmet With Premium Headgear. Includes Integrated 4.8 in. LCD dis-

MIG Guns/TIG Torches Miller Brand

Stick Electrode And TIG Filler Rod Markers AR Marker Attachment

Measurements Global Setting Displays Measurements In Standard (Imperial) Or Metric

Languages English, French, Spanish

Processor: i7

RAM: 4GB DDR3L

Graphics Card: NVIDIA GTX 950

60GB Solid State Hard Drive

Operating System: Windows 7 (64 bits), Windows 8 (64 bits), Windows 10 (64 bits)

Processor: 2.2 GHz 3 MB

RAM: 4 GB

Display (min): 1366 x 768

Graphic Board: 2GB VRAM Direct X9 compatible graphics card:

NVidia GeForce: 750 or better, or 900 Mobile Series or better

Radeon: HD 6000 series or better, or HD 7000 Mobile series or better

Hard Drive: 1 GB

Stick: Work Angle, Travel Angle, Travel Speed, Arc Length, Aim

TIG: Rod Work Angle, Rod Filler Angle, Travel Angle, Travel Speed, Arc Length, Aim, Work

Angle

play (1024 x 600), and integrated speakers.

4-6. Software Licensing Agreement

The End User License Agreement and any third-party notices and terms and conditions pertaining to third-party software can be found at

https://www

.millerwelds.com/eula

and are incorporated by reference herein.

OM-278680 Page 5

4-7. Environmental Specifications

A. Temperature Specifications

Operating Temperature Range Storage/Transportation Temperature Range

41 to 113°F (5 to 45°C)

SECTION 5 − INSTALLATION

5-1. Selecting A Location

! Do not move or operate unit

where it could tip.

−4 to 140°F (−20 to 60°C)

! Only qualified persons should in-

stall, operate, maintain, and repair this unit.

! Installation must meet all Nation-

al, State, and Local Codes − have

only qualified persons make this

installation.

! Do not move unit by pulling on

simulator, router, helmet, or cables or equipment may tip.

! Do not use this equipment to sup-

port personnel, large tools, or

other material.

NOTICE − Use training system only in-

doors and away from sources of high frequency (TIG welders) and other types of

electrical interference. It may be necessary to enclose nearby electrical wiring

in conduit if unit is affected by interference.

NOTICE − Do not use training system in

damp or wet locations. Keep training

system components dry.

NOTICE − Do not position training sys-

tem where the cameras are in direct sunlight. High intensity sunlight can interfere

with gun tracking.

NOTICE − Do not install or use the Aug-

mented Arc in the same area as live

welding equipment.

1 120 Volt, 15 Amp AC Grounded

Receptacle

2 Input Power Cord(s)

3 Surge-Protected Power Strip

Position unit near the 120 volt AC receptacle but away from obstructions that

may restrict movement of cables and

gun/electrode

holders.

Temp_2016-07

A 120 volt AC, 15 amp individual

branch circuit protected by time de-

lay fuses or circuit breaker is

required. Use of a surge-protected

2

power strip is recommended.

OM-278680 Page 6

1

3

Loc_AugArc

2016-08 / 161-092

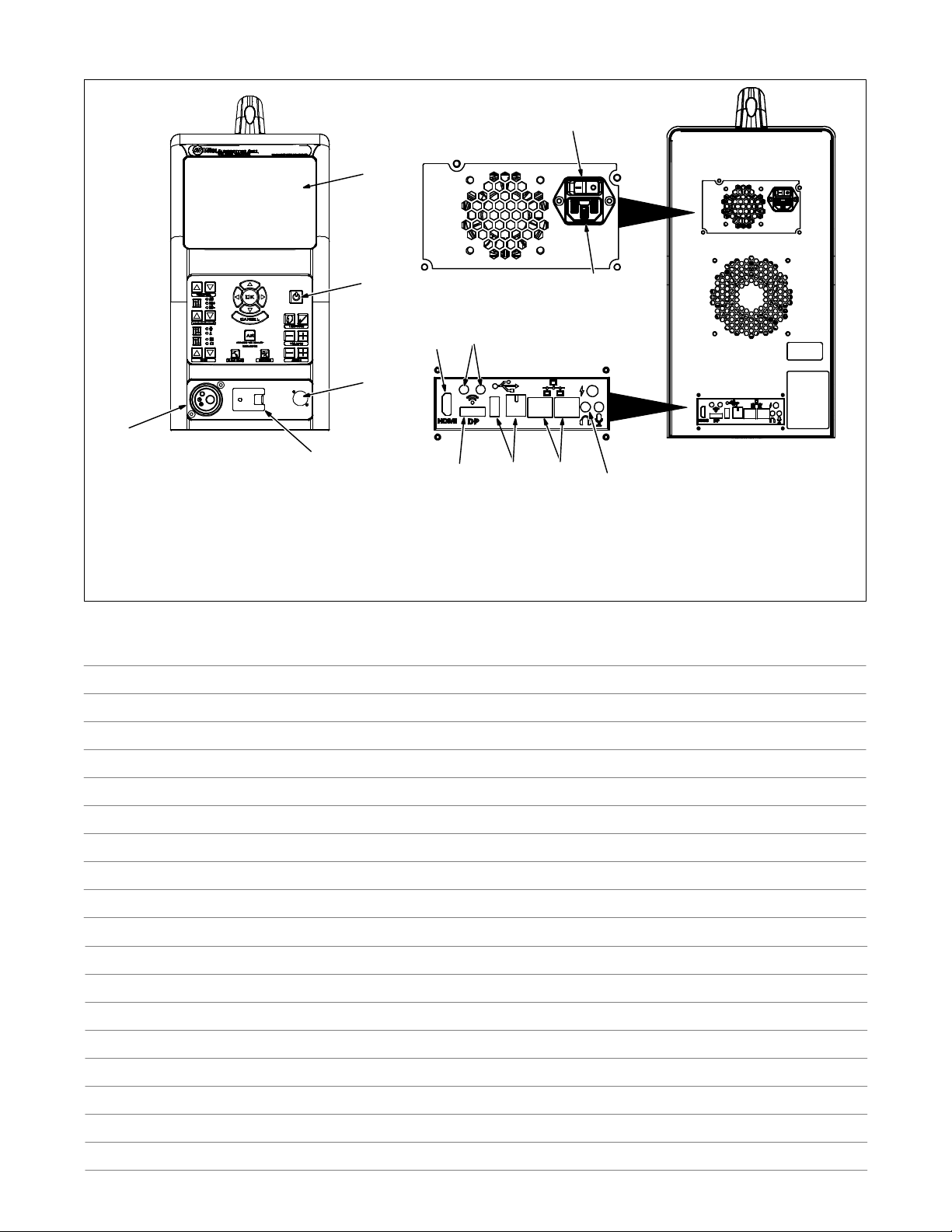

5-2. Simulator Components

6

1

5

1 Display Screen

2 Control Panel (See Section 6-1)

3 Stick Cable And TIG Foot Pedal

Receptacle

4 AR Helmet Cable (Cable Not Shown)

Notes

2

10

8

3

4

13

5 MIG/FCAW And TIG Cable Receptacle

6 Simulator Input Power Switch

7 120 Volt AC Input Receptacle

8 HDMI Receptacle

9 Audio Output Receptacle

11

12

7

9

10 WiFi Antenna Receptacles

11 USB Receptacle

12 Internet/Ethernet Receptacle

13 DisplayPort Receptacle

276 687-A

OM-278680 Page 7

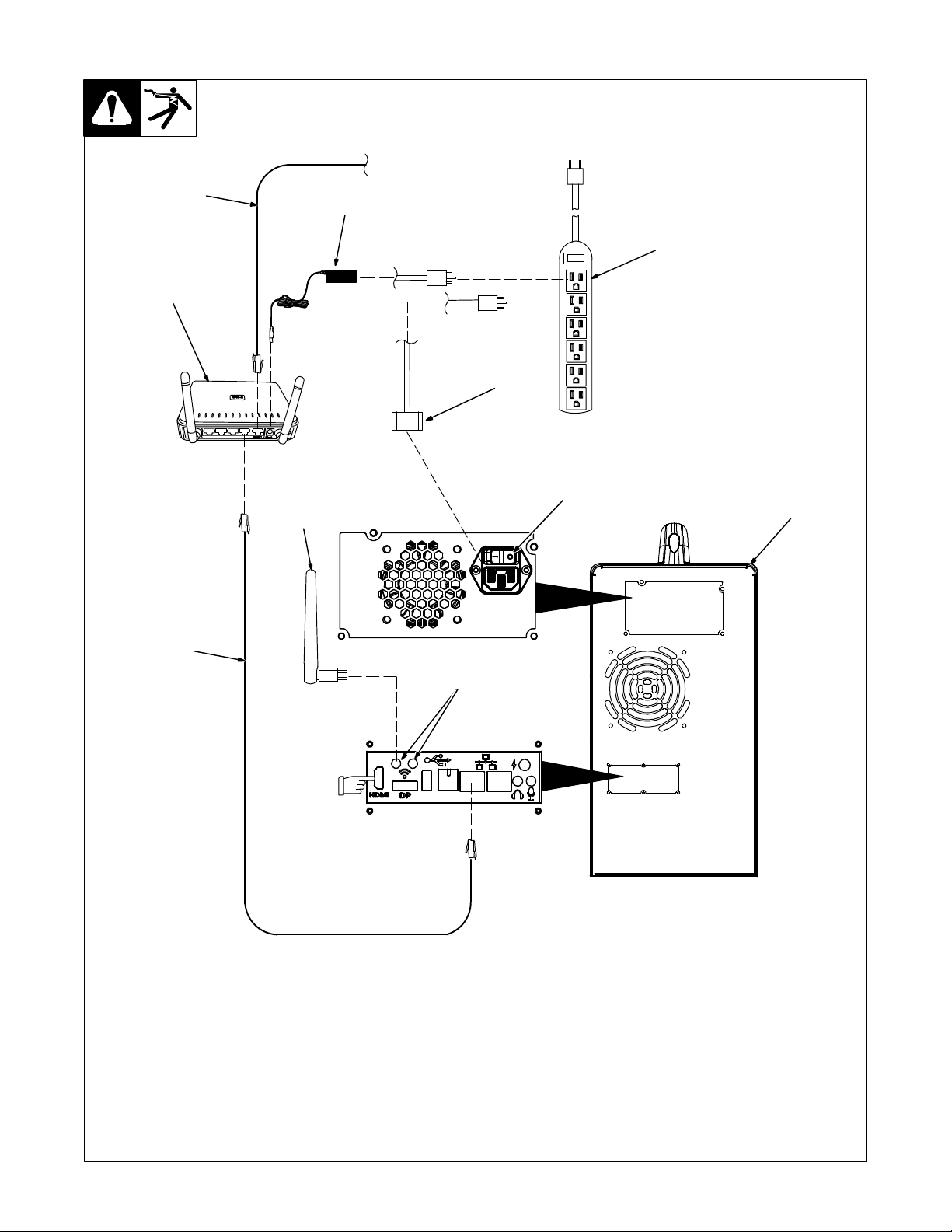

5-3. Installing The Training System − Standalone Configuration

120 V, 15A AC

IP Network

7

2

1

8

9

5

3

4

7

See Section 5-5

to connect an

external monitor

to the HDMI

receptacle.

Use standalone configuration when

system is not set up with optional controller.

1 Standalone Router

2 Router Power Cable

3 120 Volt 15 Amp AC Receptacle Or

Power Strip

Use of a surge-protected power strip is

recommended.

For best results, locate router within 39

6

in. (1 m) of simulator.

4 Simulator

5 WiFi Antenna (One Shown)

6 WiFi Receptacles

Connect both WiFi antennas to WiFi receptacles on simulator.

7 Network (Ethernet) Cables (Optional)

Connect IP network cable to Internet receptacle on back of router (either receptacle

can be used). Connect additional network

276 687 / 161-94

cable from router receptacle LAN1 to Ethernet receptacle on back of simulator.

8 Simulator Power Cable

Connect one end of simulator power cable

to simulator. Connect other end of power

cord to 120 volt AC receptacle.

9 Input Power Switch

Place Power switch in On position.

Information on using the Teacher Soft-

ware program is provided in Section 9).

OM-278680 Page 8

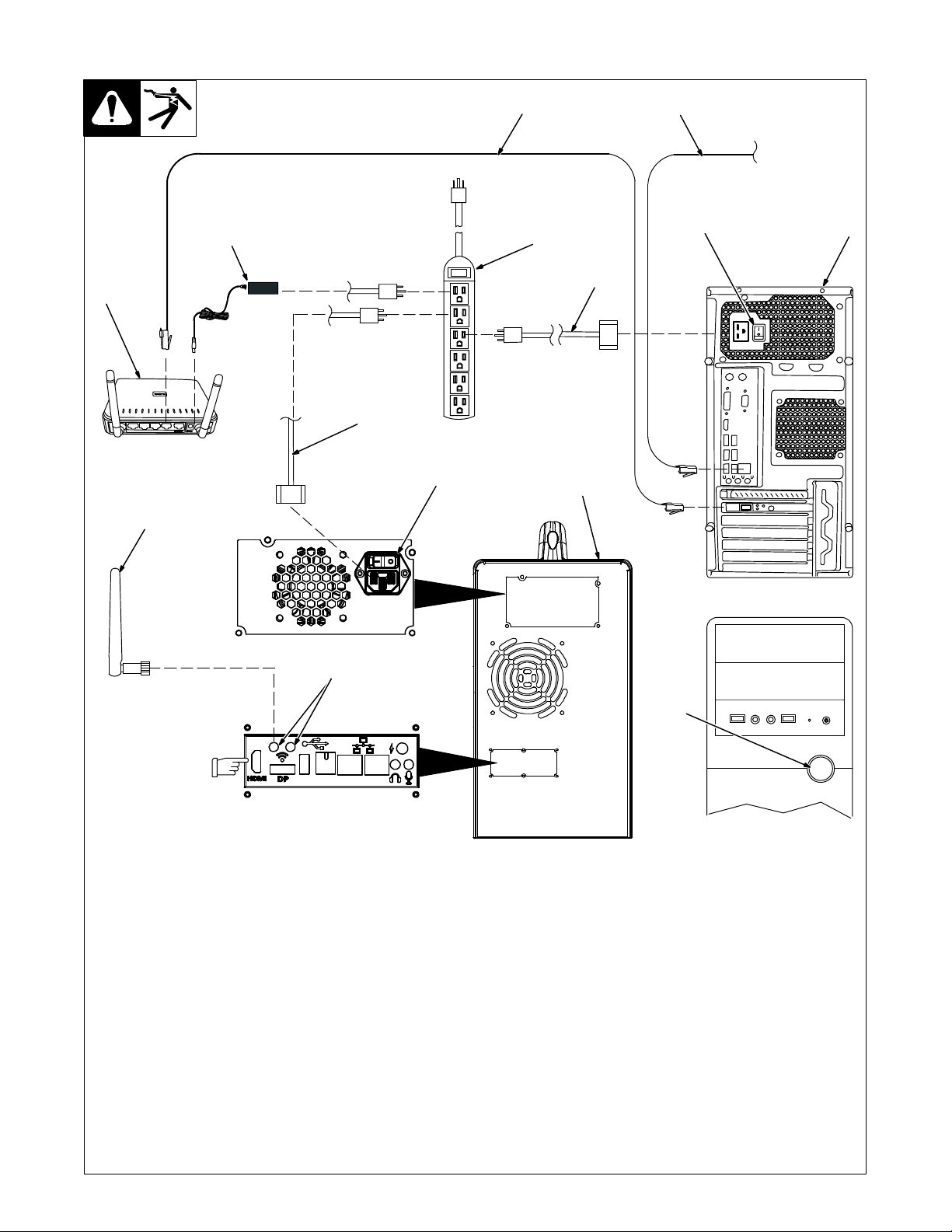

5-4. Installing The Training System − Classroom Configuration

5

Local AugmentedArc Network

120 V, 15A AC

2

1

13

14

11

3

7

10

4

IP Network

(Internet)

8

Controller

Back

6

See Section 5-5 to

connect an external

monitor to the HDMI

receptacle.

1 Classroom Router

It is very important that only the Class-

room Router is used and that all Standalone Routers are not powered on.

2 Router Power Cable

3 120 Volt 15 Amp AC Receptacle Or

Power Strip

Use of a surge-protected power strip is

recommended.

For best results, locate router within 39 in.

(1 m) of simulator.

Connect one end of router power cable to receptacle on back of router. Connect other end

of cable to 120 volt AC receptacle.

Wait about 90 seconds until the WiFi signal

icon on the router is illuminated.

4 IP Network (Ethernet) Cable

5 Local AugmentedArc Network

(Ethernet) Cable

12

6 Controller

The controller must have the same ver-

sion of the software as the simulator (see

Section 8-3).

Connect one end of network cable to receptacle LAN1 on back of router. Connect other end

of cable to Network receptacle on controller.

Connect IP network cable to internet receptacle on back of controller.

7 Controller Power Cable

Connect one end of controller power cable to

120 AC receptacle on back of controller. Connect other end of cable to 120 volt AC power

supply.

8 Controller Input Power Switch

Place Power switch in On position.

9 Controller Power On/Off Switch

Press and release the On/Off switch and wait

90 seconds for controller to boot up completely.

Controller Front

9

10 Simulator

11 WiFi Antenna (One Shown)

12 WiFi Receptacles

Connect both WiFi antennas to WiFi recepta-

cles on simulator.

13 Simulator Power Cable

Connect one end of power cable to simulator.

Connect other end of power cord to 120 volt

AC receptacle.

14 Simulator Input Power Switch

Place Input Power switch in On position.

Press the On/Off button on the front panel and

allow 90 seconds for simulator to boot up

completely. Change system mode to Classroom (see Section 8-2D).

To use the teacher software in either the

classroom or standalone configuration, connect a laptop or PC to the network provided by

the router.

Information

ware program is provided in Section 9.

276 687 / 161-94 / 161-102

on using the Teacher Soft-

OM-278680 Page 9

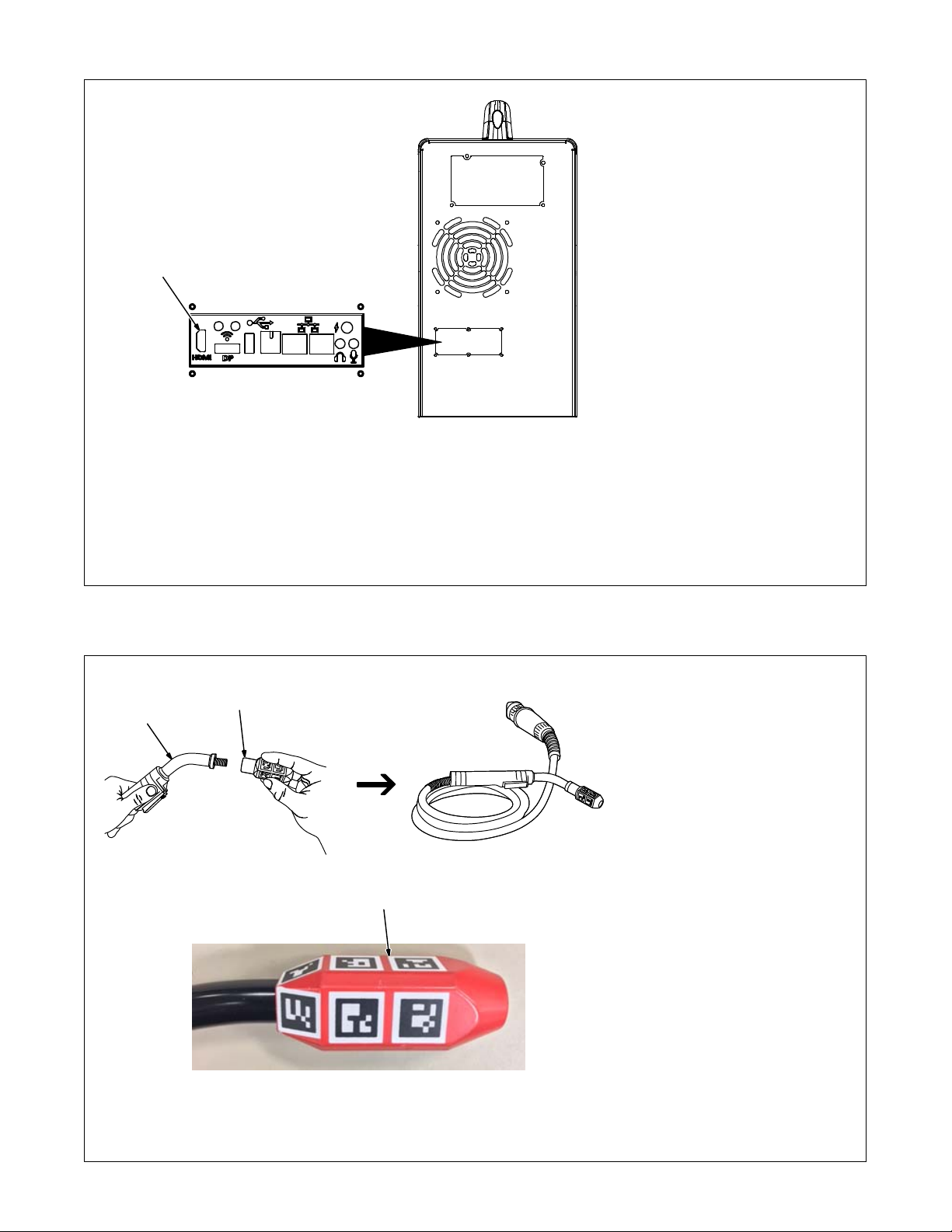

5-5. Connecting Simulator To An External Monitor

1

1 HDMI Receptacle

Use the HDMI receptacle to connect

the simulator to an external monitor.

(HDMI cable is not supplied.)

The external monitor must be connected to the simulator at start-up for

the HDMI output to be enabled. If the

simulator is already turned on, connect the external monitor via HDMI

and then restart the simulator

Due to resolution compatibility issues,

some external monitors will show the

initial start-up screens but not any

subsequent screens. To resolve this

problem, after the simulator starts up,

disconnect the HDMI cable from the

simulator and then reconnect it.

5-6. Assembling AR MIG Gun

2

1

1 AR MIG Welding Gun

2 MIG Gun AR Nozzle

Locate gun AR nozzle supplied with

system.

Screw AR nozzle on gun (clockwise).

2

OM-278680 Page 10

161-111

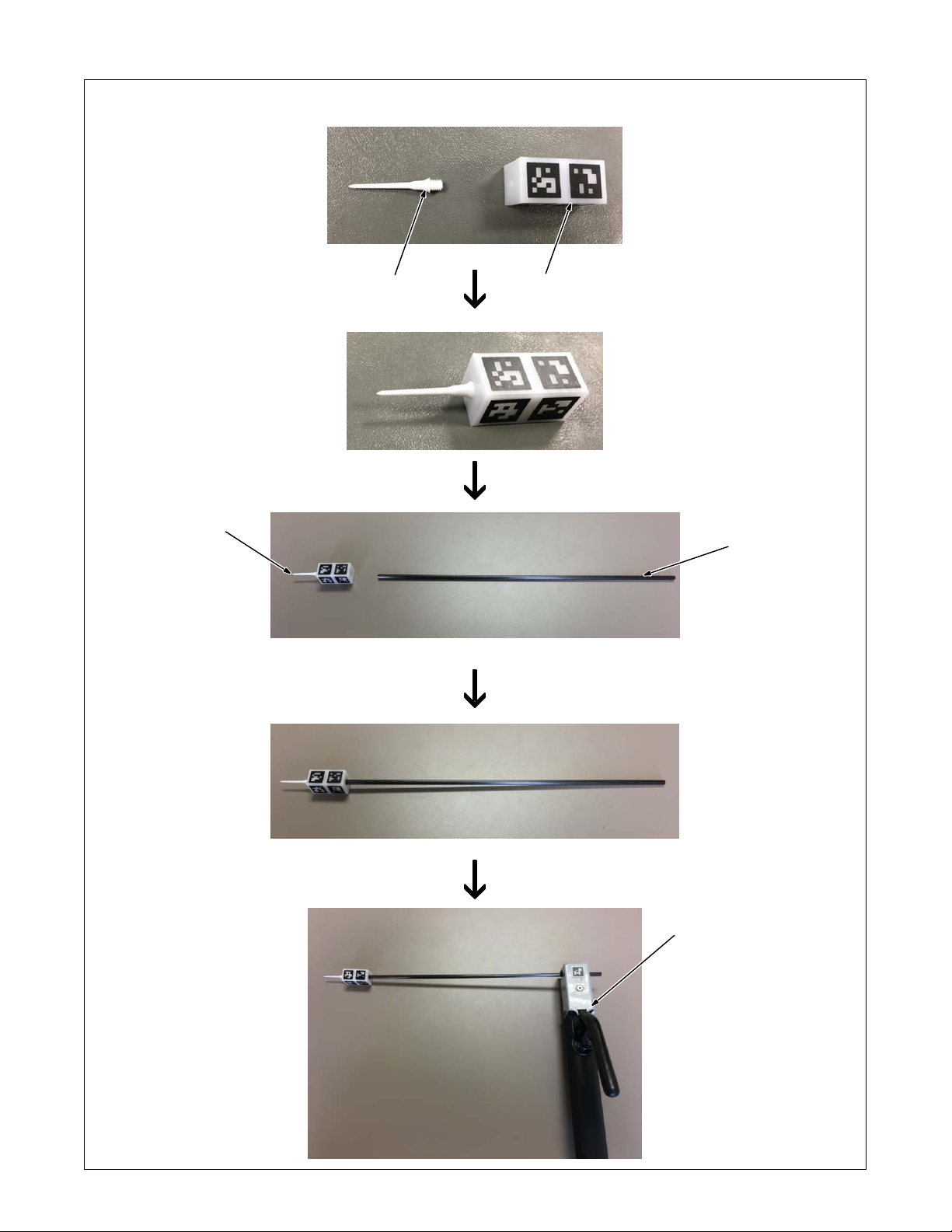

5-7. Assembling AR TIG Torch

2

9

8

1 AR TIG Torch

2 Backcap

1

7

6

4

3

5

10

3 Cup

4 Collet Body

5 Tungsten Electrode

6 Collet

7 Heat Shield

Remove backcap (counterclockwise).

The original backcap is not used

in the AR TIG torch assembly

and can be discarded.

Unscrew cup and collet body (counterclockwise).

Remove tungsten electrode and

collet.

Remove heat shield.

8 TIG Torch AR Nozzle

9 TIG Torch AR Tip

10 TIG Torch AR Backcap

Locate TIG torch AR nozzle, tip, and

backcap supplied with system.

Insert the head of the torch into the

opening of the AR nozzle. Insert the

AR backcap through the opening in

the rear of the AR nozzle and screw

into the TIG torch head (clockwise).

Screw the TIG torch AR tip into the

TIG torch AR nozzle (clockwise).

OM-278680 Page 11

5-8. Assembling AR Stick Electrode

1

1 Marker Tip

2 Marker Block

Screw the marker tip into the

marker block.

3 Marker Assembly

4 Electrode

Press fit the marker assembly

over the tip of the electrode.

This assembly will also be

used as the TIG filler rod.

2

5 Electrode Holder

Place the stick electrode in the

electrode holder as shown. With

the handle facing up, the electrode

should face left.

3

5

4

OM-278680 Page 12

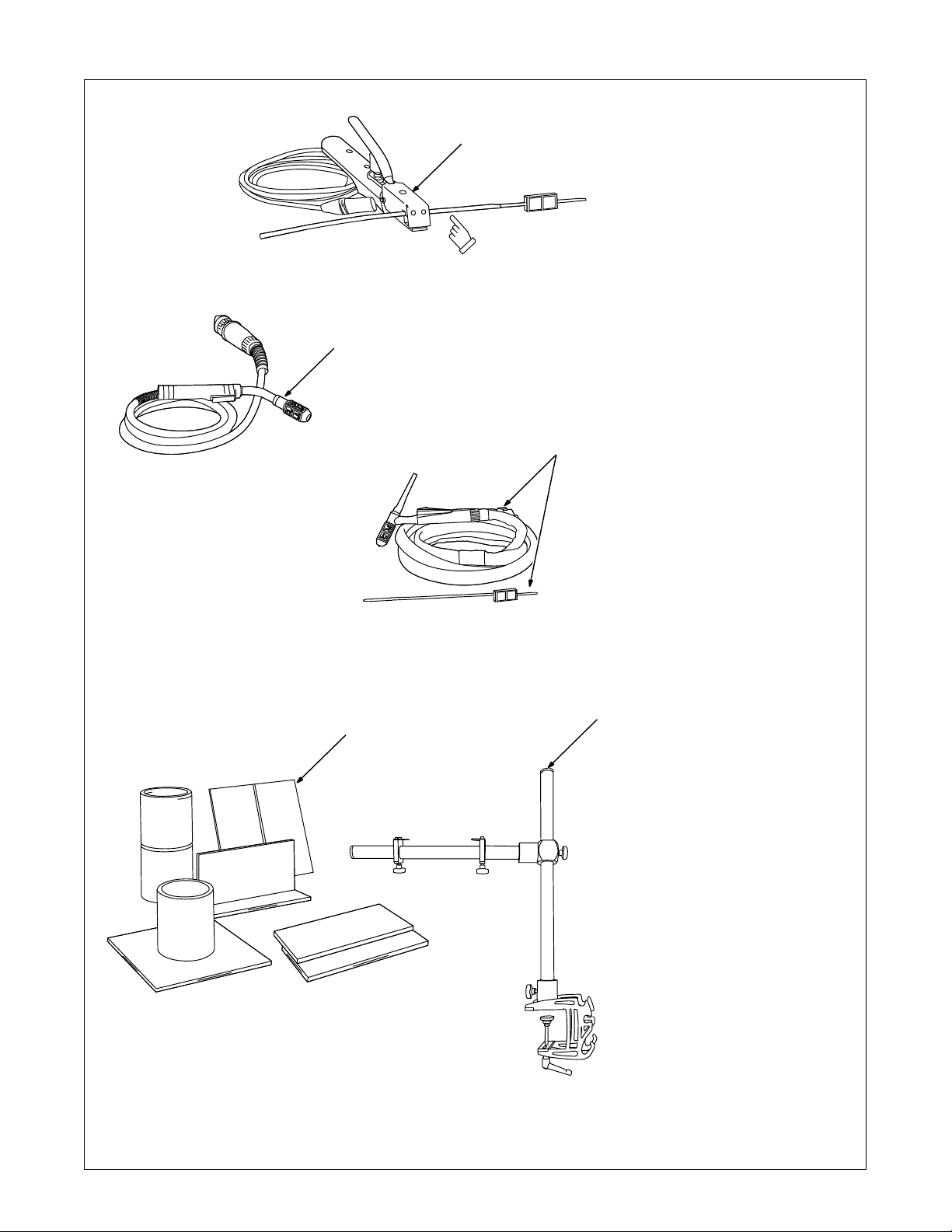

5-9. AR Stick Electrode, MIG Gun, TIG Torch, And Workpieces

1

Install Stick electrode in

holder exactly as shown.

2

3

5

4

1 AR Stick Electrode And Holder

Markers on the stick electrode allow it

to work with the AR system. The electrode is similar in shape, weight, and

size to a real electrode. It is placed

within the holder, which is connected to

the simulator. The holder retracts the

electrode during welding to simulate

the electrode consumption in real

welding.

2 AR MIG/FCAW Welding Gun

Markers on the AR MIG/FCAW welding gun allow it to work with the AR system. The gun is connected to a real

welding connector in the simulator.

MIG/FCAW welding is a semiautomatic process that uses a continuous wire

feed as an electrode and an inert (MIG)

gas mixture to protect the weld from

contamination.

(GMAW) or cored (FCAW). The stu-

dent begins by selecting the shielding

gas, wire type, and diameter. After the

exercise has begun, the student adjusts

the wire feed speed on the simulator.

3 AR TIG Torch And Filler Rod

Markers on the TIG (GTAW) torch and

AR filler rod allow it to work with the AR

system. The torch is connected to a real welding connector in the simulator.

The filler material is added to the weld

joint by a AR filler rod that is tracked using the AR marker accessory. The student adds filler by dipping the rod into

the weld joint, just as in real welding.

The AR filler rod is similar in shape,

size, and weight to a real filler rod and

helps the student become familiar with

using this equipment.

4 AR Workpieces

The AR workpieces are in standard

joint configurations (Bead On Plate,

T-Joint, Butt Joint, Lap Joint,

Pipe-Plate, Pipe-Pipe) and are designed to work with the AR system.

5 Workpiece Stand

Use to hold workpieces in position for

simulated flat, horizontal, vertical, or

overhead welding.

The wire can be solid

161-97

OM-278680 Page 13

5-10. AR Welding Helmet

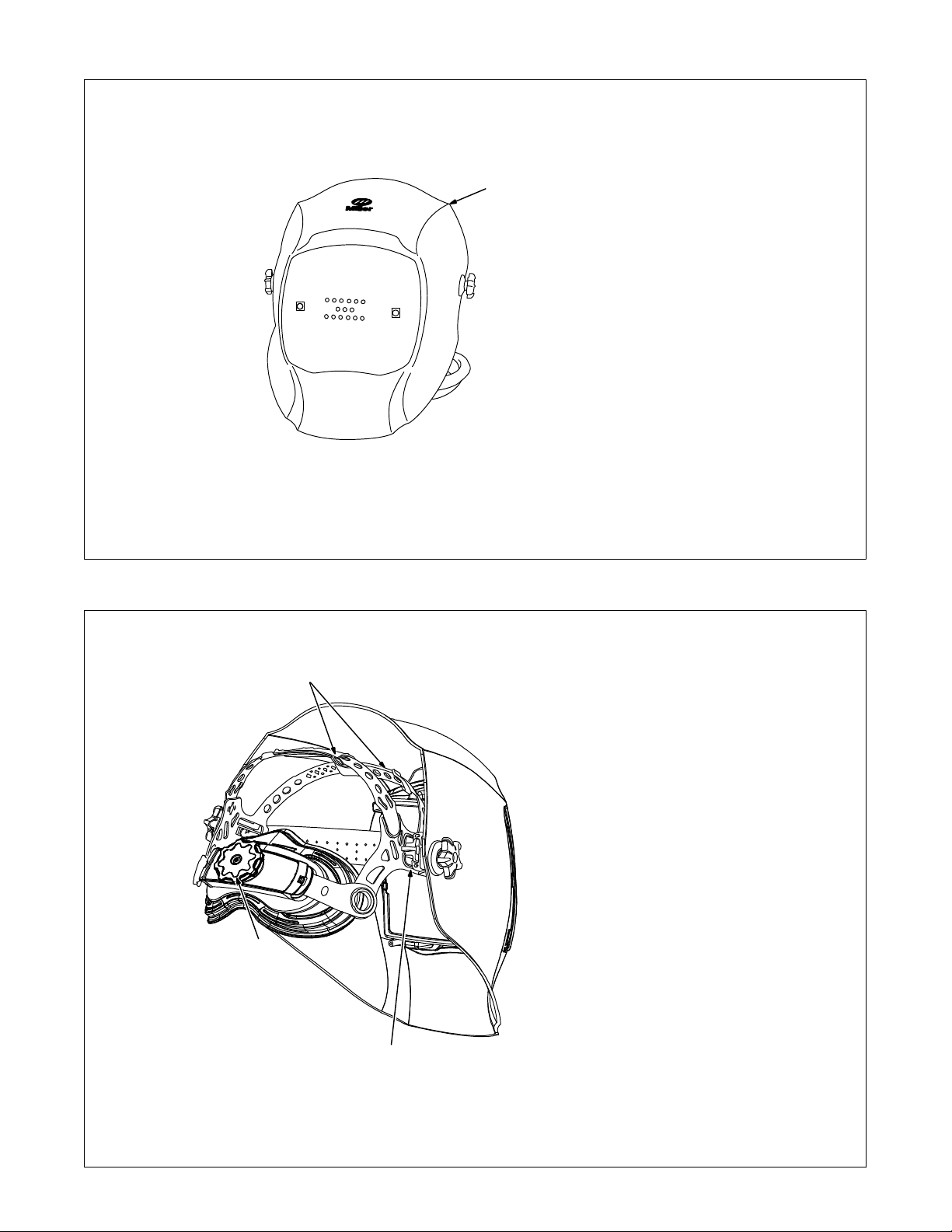

1 AR Welding Helmet

The AR welding helmet has two high

resolution micro-cameras and a 4.8 in.

(122 mm) display screen that enhances the augmented reality experience. The AugmentedArc acces-

1

sories (workpieces, guns, torches,

electrode, filler rod) and the real environment are displayed on the helmet

screen and these elements interact to

create a real-time augmented reality

for a realistic welding experience.

The AR welding helmet also includes

LED lights (controlled at the simulator)

to maintain the stable light environment necessary for the artificial vision

technology to work properly.

The AR welding helmet is also

equipped with speakers to recreate the

sounds emitted during the welding

process to make the training more authentic.

See Section 10 for information on

installing the optional magnifying

lens.

5-11. Making Helmet Adjustments

1

2

161-97

Helmet image is intended only for

reference in locating helmet adjustments.

There are four headgear adjust-

ments: headgear top, tightness,

angle, and distance.

1 Headgear Top

Adjusts headgear for proper depth on

the head to ensure correct balance and

stability.

2 Headgear Tightness

To adjust, turn the adjusting knob located on the back of the headgear left

or right to desired tightness.

3 Angle Adjustment (Not Shown)

Seven slots on the right side of the

headband provide adjustment for the

forward tilt of the helmet. To adjust, lift

and reposition the control arm to the

desired position.

4 Distance Adjustment

Adjusts the distance between the face

and the lens. To adjust, press black

tabs on the top and bottom of the pivot

4

point and use other hand to slide

headgear forward or backward. Release tabs. (Both sides must be equally positioned for proper vision.)

OM-278680 Page 14

Numbers on the adjustment slides

indicate set position so both sides

can be adjusted equally.

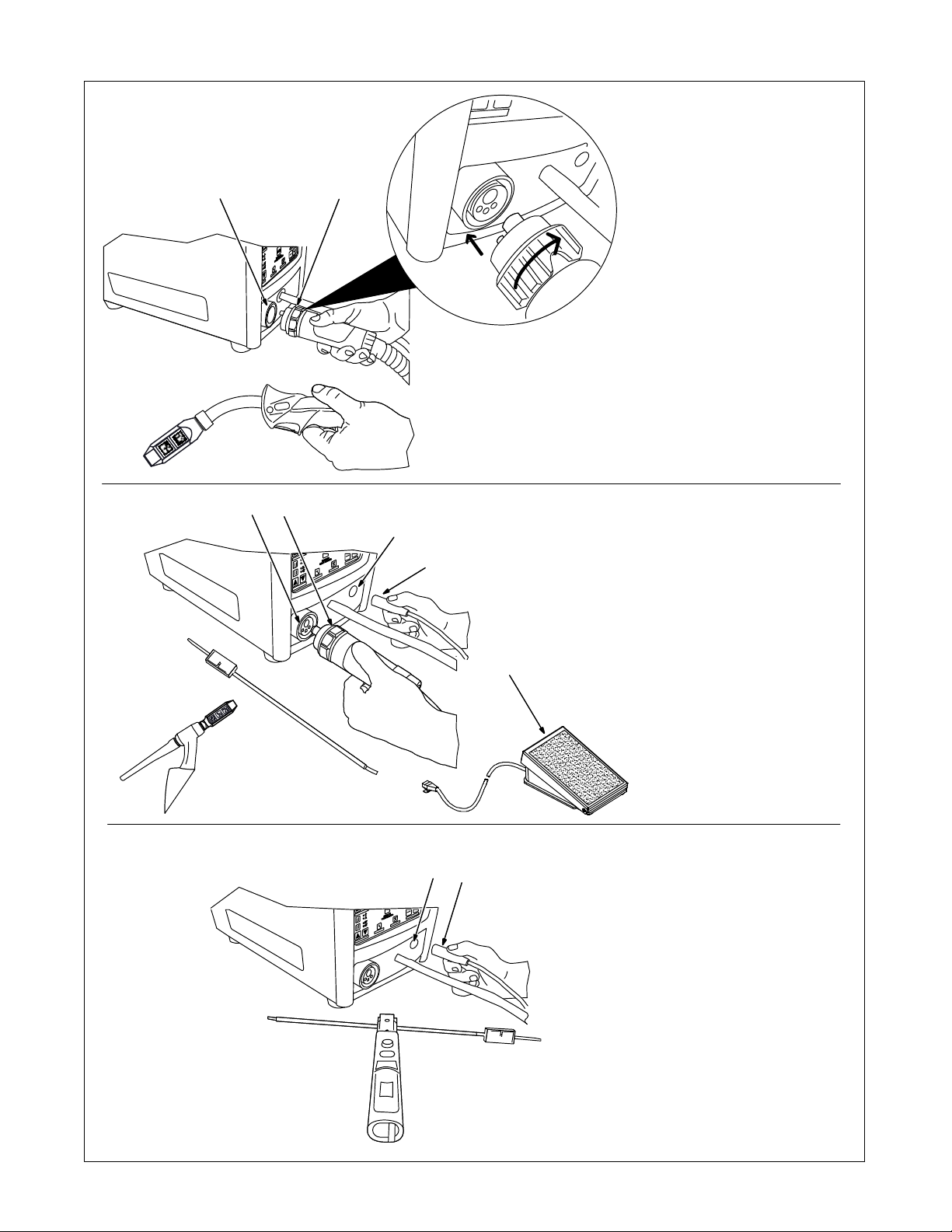

5-12. Connecting Weld Cables

2

1

MIG/FCAW Connections

1 MIG/FCAW Cable Connector

2 MIG/FCAW Receptacle

Align pins in connector with holes in receptacle. Insert connector in receptacle and tighten collar clockwise.

34

7

6

TIG Connections

3 TIG Cable Connector

4 TIG Cable Receptacle

Align pins in connector with holes in receptacle. Insert connector in receptacle

and tighten collar clockwise.

Optional Foot Pedal Kit Connections

TIG foot pedal and adapter cable are

included in optional TIG Foot Pedal

5

9

8

Kit.

5 TIG Foot Pedal

6 Adapter Cable

7 TIG Foot Pedal Receptacle

Insert foot pedal connector (RJ-45) into

adapter cable receptacle. Insert adapter

cable connector into TIG foot pedal receptacle on simulator.

Stick Connections

8 Stick Cable Connector

9 Stick Cable Receptacle

Align pins in connector with holes in

receptacle. Insert connector in receptacle.

161-103 / 104 / 105 / 106

OM-278680 Page 15

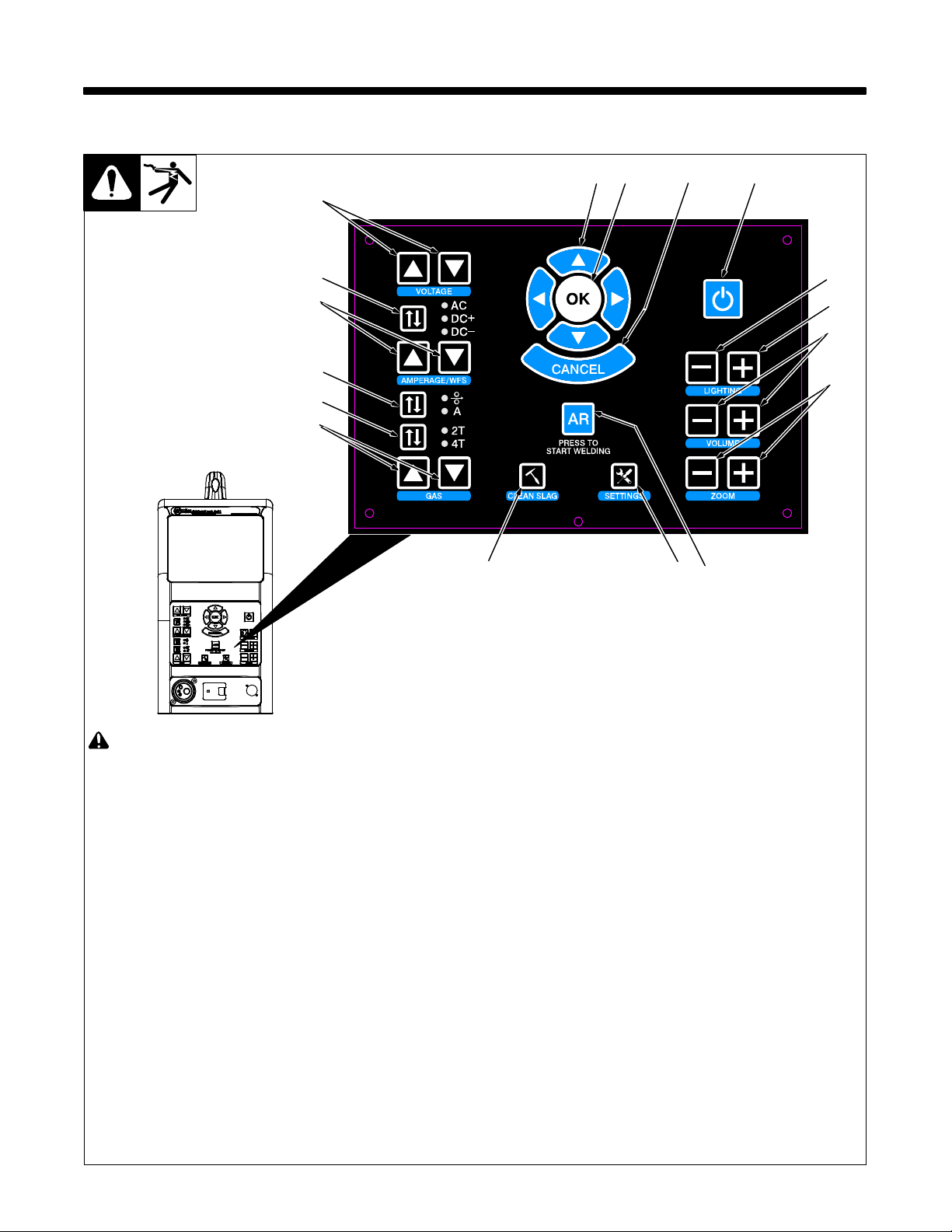

SECTION 6 − SYSTEM CONTROLS AND COMPONENTS

6-1. Simulator Controls

14

13

12

11

10

15

16 17

9

678

1

2

3

4

5

! Do not use the welding simulator if

you are light sensitive or affected by

video, flashing lights, or other visual

stimuli. Stop using simulator and

consult your physician if you experience vision problems, nausea,

headaches,

other conditions.

dizziness, vertigo, or

For best performance, keep helmet,

guns, torches, and workpieces free of

dust and debris. Clean components

with a damp cloth. (Do not use chemicals, solvents, or abrasives to clean

markers.)

1 Power On/Off Button

Use button to turn system on and off.

2 Helmet Light Intensity Decrease

Button

Use button to decrease intensity of helmet

light.

3 Helmet Light Intensity Increase Button

Use button to increase intensity of helmet

light.

4 Volume Adjustment Buttons

Use buttons to increase or decrease volume of helmet speakers

5 Display (Zoom) Adjustment Buttons

Use buttons to magnify images on display

screens.

6 Augmented Reality (AR) Button

Use button to turn augmented reality feature

on and off.

7 System Settings Button

Use button to access system settings

menu. Use the settings menu to change language, units of measure (standard or metric), camera settings and other parameters.

After starting an exercise, use the System

Settings button to adjust video device settings and optimize AR tracking for the room

lighting conditions (see Section 8-7).

Some settings can only be changed by

the system administrator.

8 Clean Slag Button

Use button to remove slag from augmented

reality workpiece when Stick and FCAW

welding. Slag must be cleaned for test results to be displayed.

9 Shielding Gas Flow Adjustment

Buttons

Use buttons to increase or decrease the

shielding gas flow for the GMAW, FCAW,

and GTAW weld processes.

Ref. 276687-A

10 Gun Trigger Selection Button

Use button to select either two-step or

four-step trigger operation.

11 Amperage/Wire Feed Speed

Selection Button

Use button to select the weld parameter

(amperage or wire feed speed) to be adjusted (see Item 12).

12 Amperage/Wire Feed Speed

Adjustment Buttons

Use buttons to increase or decrease amperage or wire feed speed (see item 11).

13 AC/Polarity Selection Button

Use button to select AC weld output or

DCEP or DCEN weld polarity.

14 Voltage Adjustment Buttons

Use buttons to increase or decrease weld

voltage.

15 System Navigation Buttons

Use buttons to navigate AR system pro-

grams and select menu items.

16 OK (System Selection) Button

Use button to activate selected menu items.

17 System Cancel Button

Use button to stop the AR program or activi-

ty in use, or return to the previous screen.

OM-278680 Page 16

SECTION 7 − OPERATION

Do not use the welding simulator if you are light sensitive or affected by video, flashing lights, or other visual stimuli. Stop using simulator and consult your physician if you experience vision problems, nausea, headaches, dizziness, vertigo, or other conditions.

A MIG/FCAW welding simulation is shown in these examples. Setup and adjustments are similar for other welding processes.

7-1. Equipment Setup

• Assemble AugmentedArc training system. Install system in proper location and near 120 volt AC power source (see Section 5-1).

• Connect desired gun or torch to simulator (see Sections 5-9 and 5-12).

• Connect simulator and router power cords to 120 volt AC receptacles.

• Place simulator Input Power switch in On position (on back of simulator). Press router Power switch. Press and hold On-Off switch on front of

simulator until simulator turns on. For Classroom applications, also place controller Input Power switch (on back panel) in On position (see Section

5-4). Press and hold controller Power On/Off switch (on front panel) until unit turns on.

7-2. Getting Started

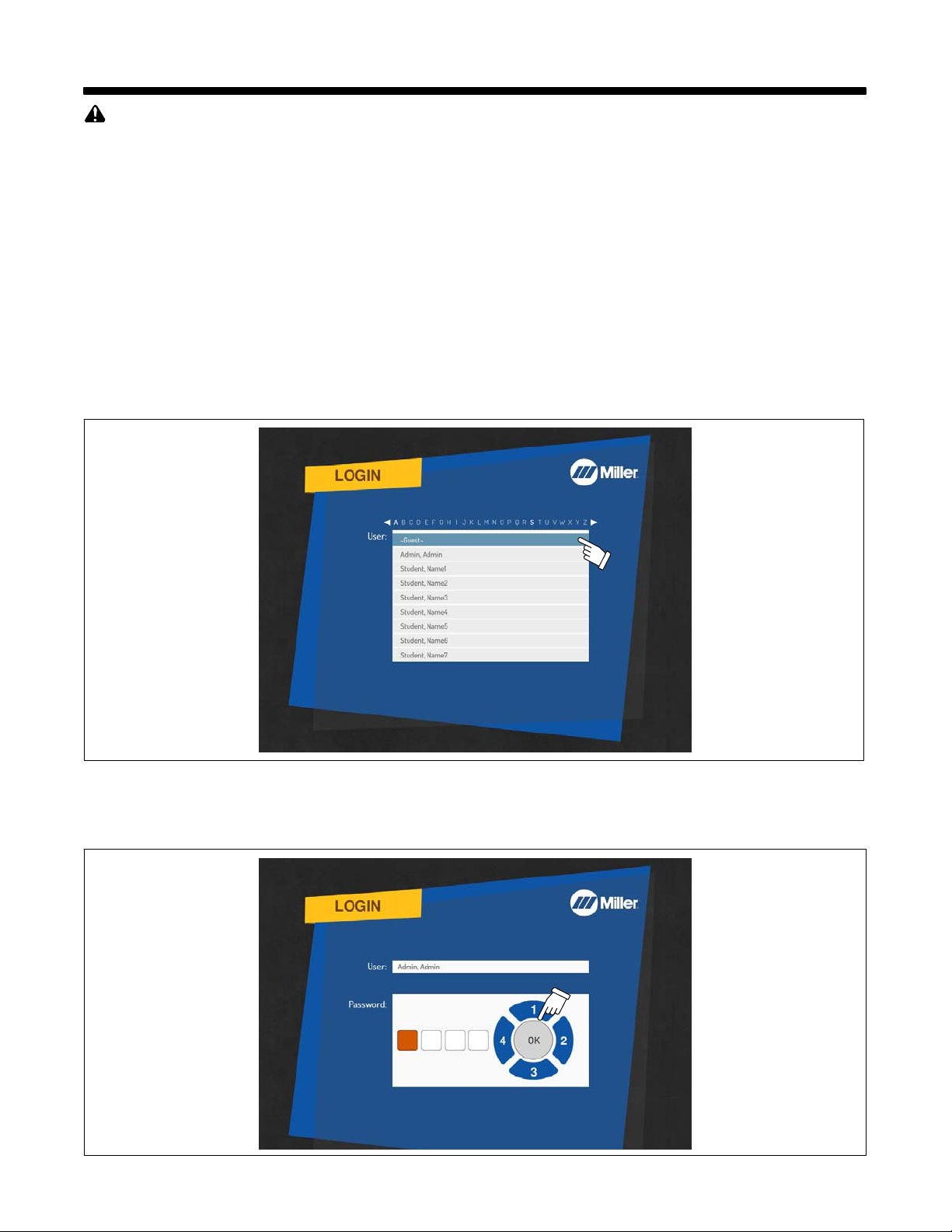

A. Login Screens

Use System Navigation buttons to select guest or user name from Login menu. Press OK.

To create a new user, see Section 9, Using The Teacher Software.

Figure 7-1. User Selection Screen

Use System Navigation buttons to enter User password. Each button represents a specific numeral (1 − 4) as shown in Figure 7-2. (The default

Admin user password is 1111.) Press OK.

Passwords are established by the instructor. Guest users do not need a password.

The default Admin user

password is 1111.

Figure 7-2. Password Screen

OM-278680 Page 17

B. Course Selection

Use System Navigation buttons to select desired course (Figure 7-3). Press OK.

Course selection will vary for each user.

Press the Cancel button at any time to stop the program and return to the previous screen.

Figure 7-3. Course Selection Screen

Use Navigation buttons to select (Start) a new exercise session or review previous sessions (under the History tab). See Figure 7-4. Press OK.

The History feature is not available to Guest users.

OM-278680 Page 18

Figure 7-4. Activity Selection Screen

Use Navigation buttons to select or acknowledge the difficulty level (Beginner, Intermediate, Advanced), joint type, position, material

type/thickness, weld process, electrode type/diameter, gas composition, and other parameters as applicable (Figure 7-5).

Figure 7-5. Welding Parameters Screen

C. Lighting Calibration

Depending on the selected Lighting Calibration option for the system (see Section 8-2F), the user may be prompted to perform a lighting

calibration procedure before starting the exercise. The lighting calibration will adjust the video device settings (temperature, intensity) based on

the room lighting conditions.

Ensure helmet illumination is turned on (see Section 6-1).

Press the AR button to begin the process.

Figure 7-6. Lighting Calibration Screen

OM-278680 Page 19

Loading...

Loading...