The Arrow Series Fluid Head Operator’s Manual

#1020 Arrow 30 with Euro camera platform

#1012 Arrow with Euro camera platform

#1014 Arrow HD with Euro camera platform

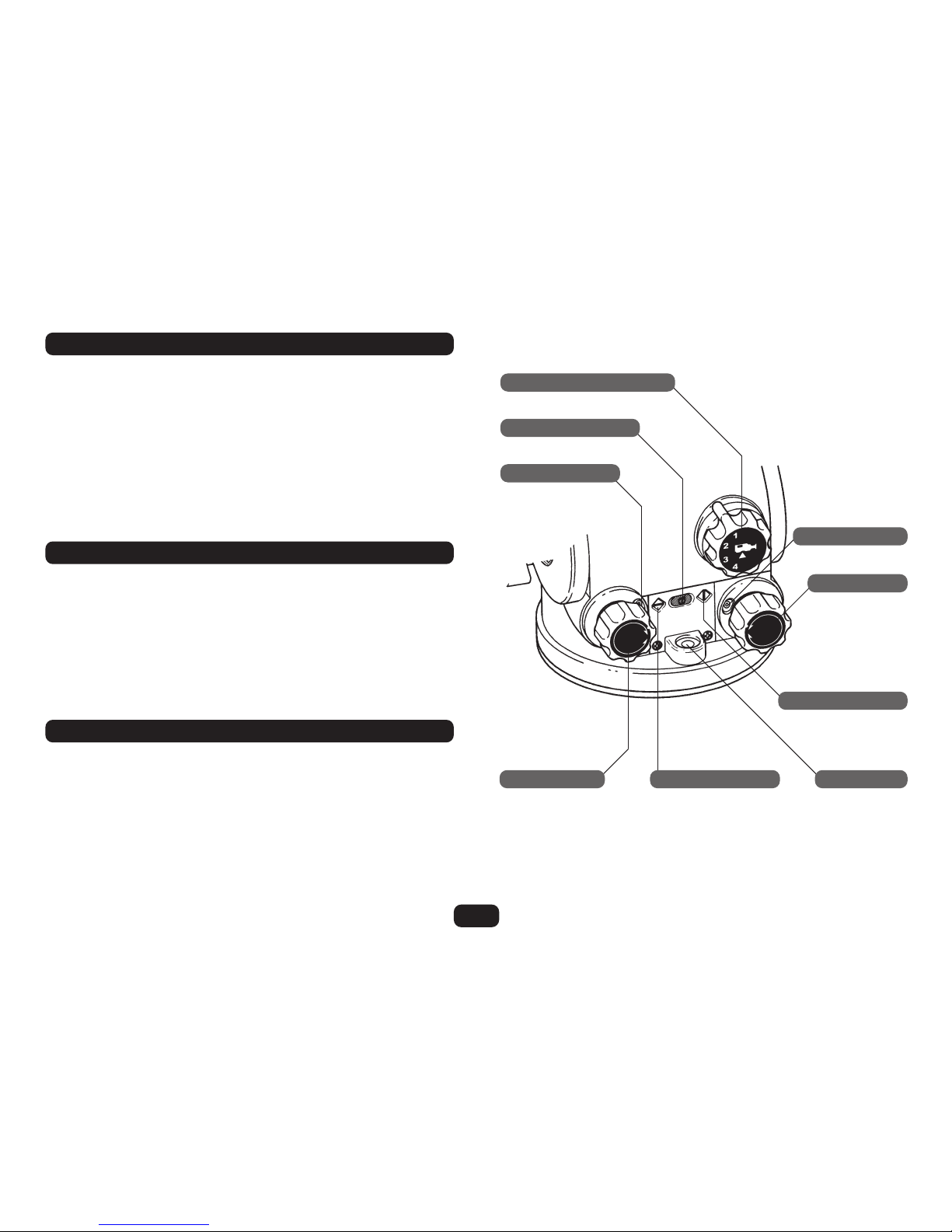

SLIDING PLATFORM

Arrow 30 and Arrow - 70mm range

Arrow HD - 100mm range

Arrow 30 only

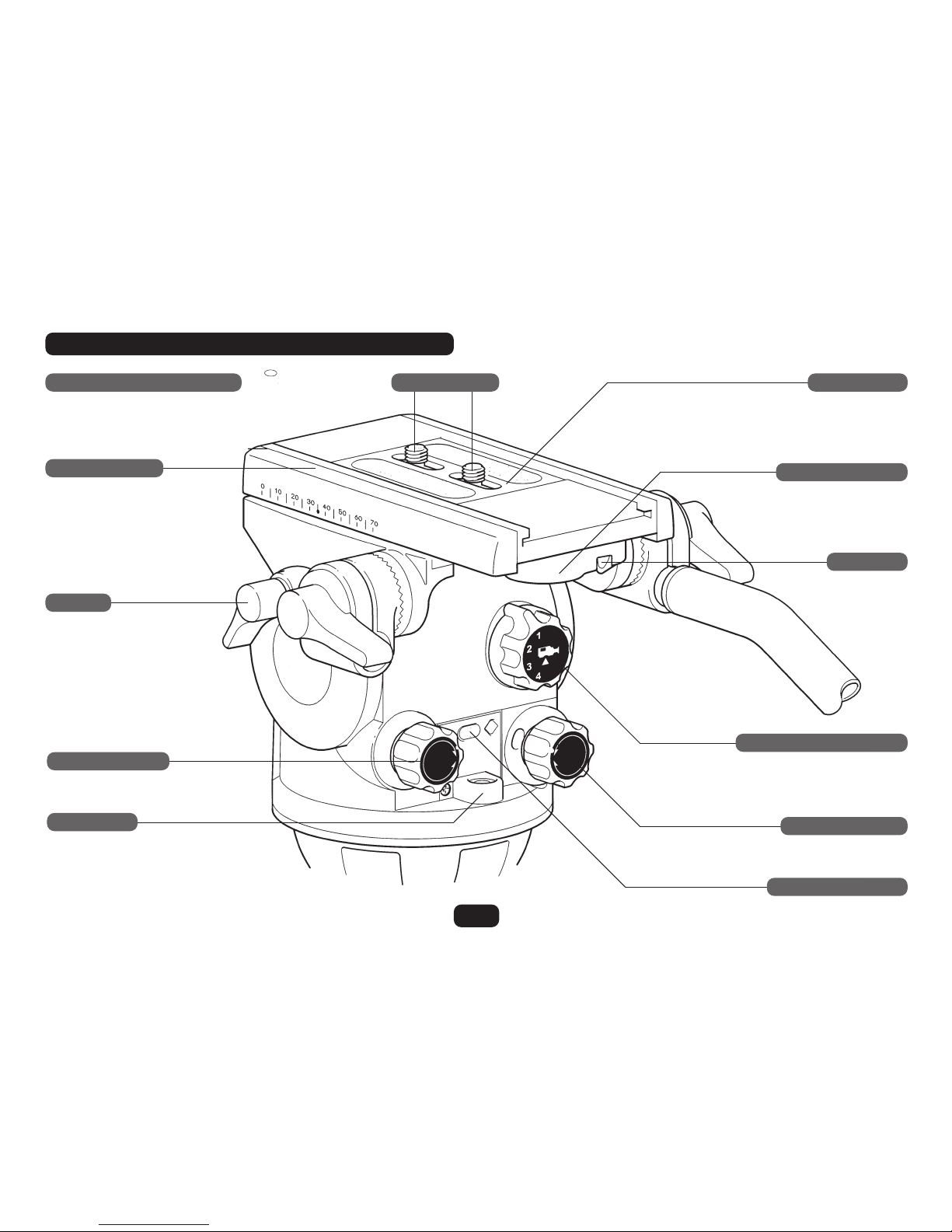

CAMERA SCREWS1/4” AND PIN ADAPTOR CARRIAGE CAMERA PLATE

QUICK RELEASE LEVER

SAFETY TAB

COUNTERBALANCE SELECTOR

PAN DRAG CONTROL

ILLUMINATION BUTTON

TILT LOCK

TILT DRAG CONTROL

BUBBLE LEVEL

FEATURES AND CONTROLS

2

FIG 1

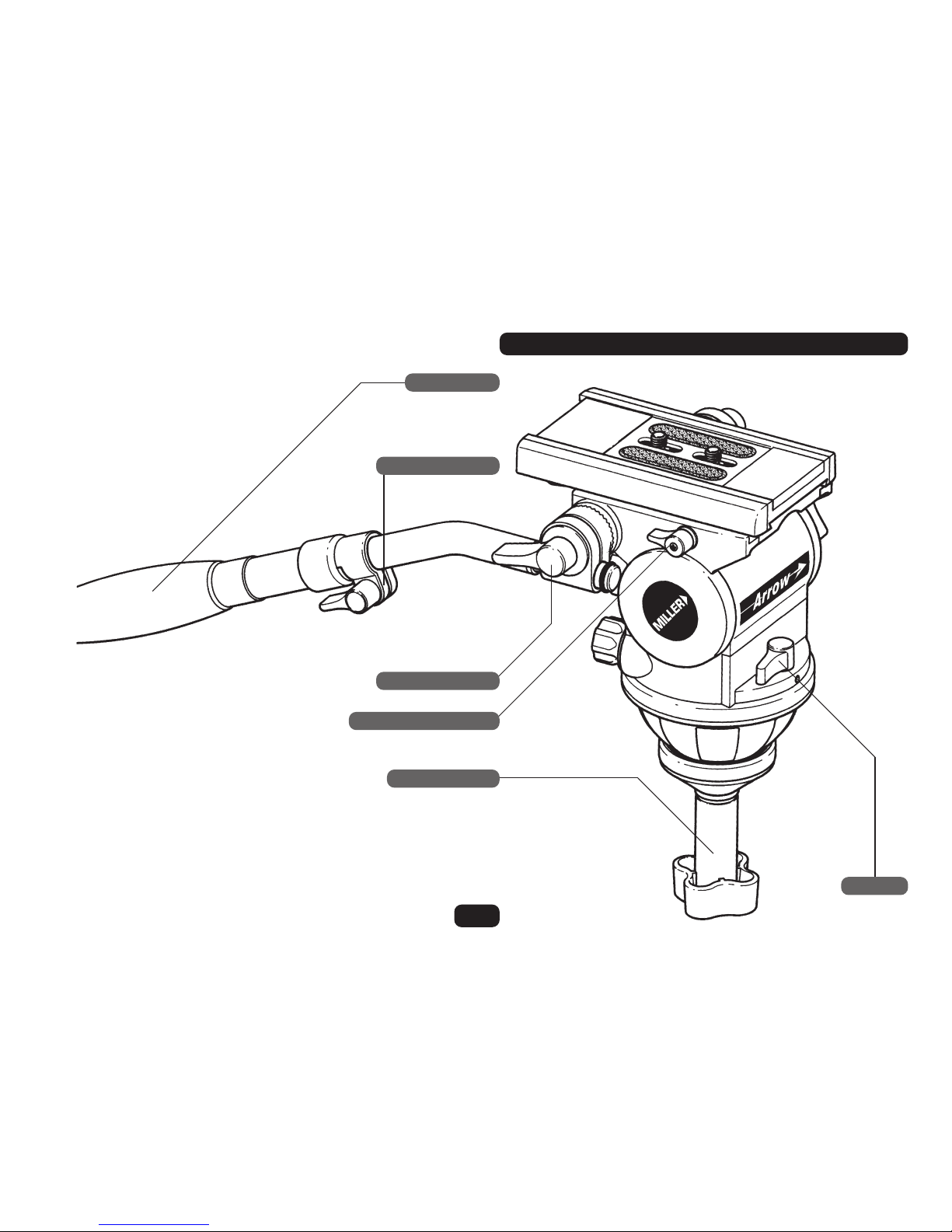

FEATURES AND CONTROLS

3

FIG 2

PAN HANDLE

TELESCOPIC CLAMP

PAN HANDLE CLAMP

SLIDING PLATFORM LOCK

BOWL CLAMP NUT

PAN LOCK

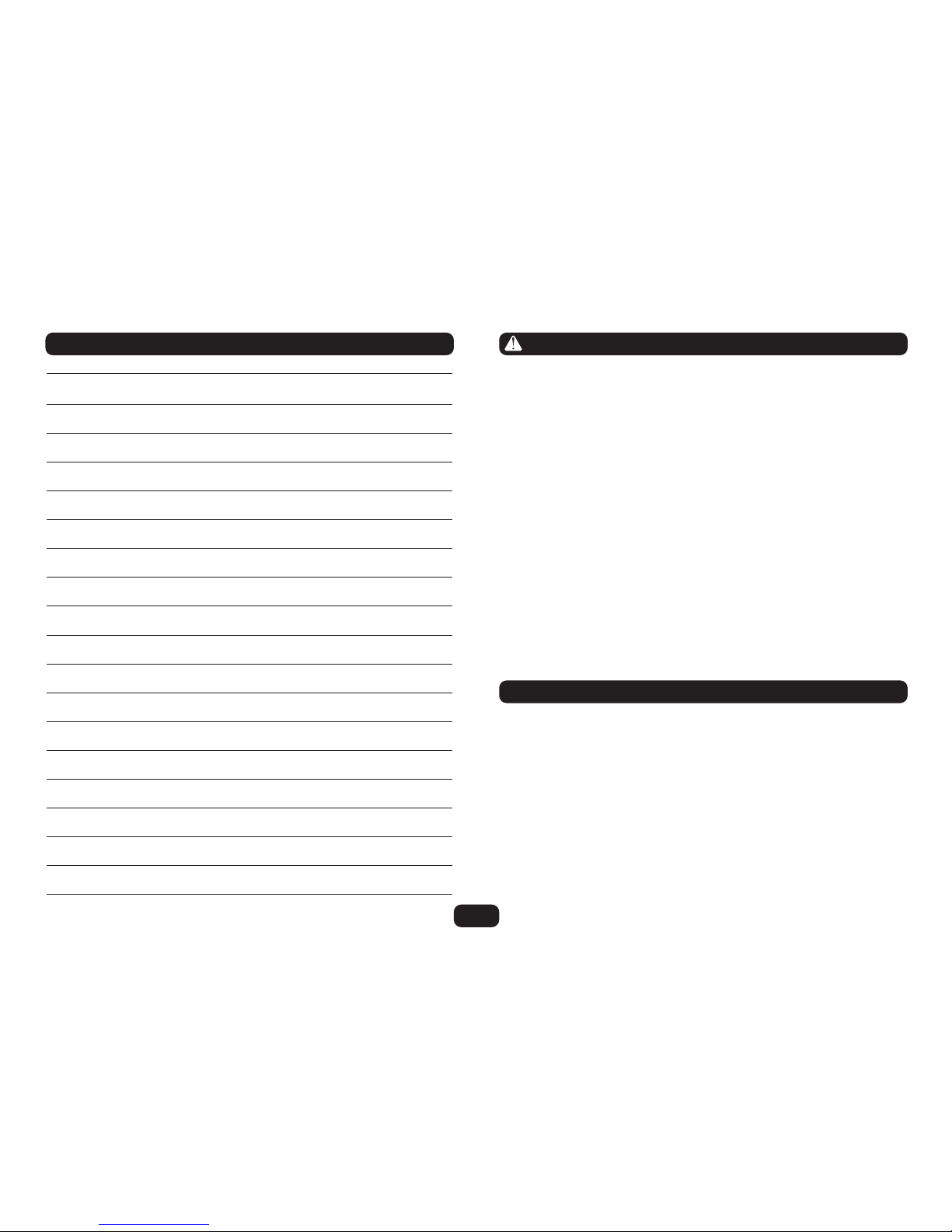

SAFETY INSTRUCTIONSCONTENTS

4

FEATURES AND CONTROLS 2 and 3

SAFETY INSTRUCTIONS 4

INTRODUCTION 4

TECHNICAL DATA 5

OPERATING INSTRUCTIONS 6

1. Install and level the Head 6

2. Mount Your Camera 7

3. Centre Your Camera on the Head 8

4. Counterbalance Your Camera 9

5. Drag Control 10

6. Illumination 10

MAINTENANCE 10

7. Battery Replacement 11

CLEANING 11

STORAGE Back Cover

SPARE PARTS AND ACCESSORIES Back Cover

WARRANTY Back Cover

SERVICE Back Cover

Before operation read the Operating Instructions (pp6-12).

Arrow fluid heads have been designed to accommodate film

and television cameras, and to be operated by qualified

camera operators.

Hold camera securely during all fitting or removal operations.

Do not adjust the counterbalance or drag settings without

securing (holding) pan handle.

To prevent accidental or sudden movement do not release the

TILT LOCK without holding the PAN HANDLE.

Do not release the clamp nut without holding either the head

or attached camera.

Do not exceed the maximum total payload (see Technical

Specifications).

The operator is responsible for the safe operation of this piece

of equipment.

Welcome to the Operating Manual for the Arrow 30, Arrow and

Arrow HD fluid head. Arrow is a versatile fluid pan/tilt head

designed for a wide variety of cameras and configurations.

Developed using the latest 3D modelling software and

manufactured with computer-controlled precision, Arrow is

designed to reliably and stably support portable film and video

cameras shooting in the world’s most challenging conditions.

From lightweight ENG camcorders to heavier EFP dockable

cameras, Arrow heads offer optimum lightweight, robust

performance with the smoothest fluid motion - from the

company that invented and patented the fluid head.

INTRODUCTION

DATA Arrow 30 Arrow Arrow HD

5

WEIGHT 3.2kg 3.2kg 3.3kg

MAX REC. LOAD 15kg (see graph on Page 9) 20kg (see graph on Page 9) 25kg (see graph on Page 9)

BALL LEVELLING BASE 100mm 100mm 100mm

PAN MECHANISM Stepped Fluid Drag Stepped Fluid Drag Stepped Fluid Drag

Adjustment 7 selectable positions + zero 7 selectable positions + zero 7 selectable positions + zero

Rotation 360º 360º 360º

Lock Calliper disc brake system Calliper disc brake system Calliper disc brake system

TILT MECHANISM Stepped Fluid Drag Stepped Fluid Drag Stepped Fluid Drag

Adjustment 7 selectable positions + zero 7 selectable positions + zero 7 selectable positions + zero

Tilt Angle

+

_ 90º

+

_ 90º

+

_ 90º

Lock Calliper disc brake system Calliper disc brake system Calliper disc brake system

COUNTERBALANCE 4 selectable positions 4 selectable positions 4 selectable positions

CAMERA PLATFORM Euro quick release camera plate in Euro quick release camera plate in Euro quick release camera plate in

sliding camera balance platform sliding camera balance platform sliding camera balance platform

Camera Attachment

3/8”+ 1/4” screws + 1/4” pin carriage 3/8”+ 1/4” screws 3/8”+ 1/4” screws

Sliding Range 70mm (+/-35mm) 70mm (+/-35mm) 100mm (+/-50mm)

LEVELLING

Illuminated bubble level: 10 sec auto-off Illuminated bubble level: 10 sec auto-off Illuminated bubble level: 10 sec auto-off

PAN HANDLE Telescopic (220mm extension range) Telescopic (220mm extension range) Telescopic (220mm extension range)

ILLUMINATED CONTROLS

Bubble level, pan/tilt number Bubble level, pan/tilt number Bubble level, pan/tilt number

TEMP. RANGE –40ºC to +65ºC – 40ºC to +65ºC – 40ºC to +65ºC

OPERATING INSTRUCTIONS

6

The Operating Instructions for Arrow series fluid heads are

described in six (6) steps. Please read and understand these

instructions before using this equipment. Do not omit any

step.

1.1 Unscrew the CLAMP NUT from its threaded stud.

1.2 Place the head in your 100mm tripod bowl and re-fit the

CLAMP NUT. Do not tighten CLAMP NUT.

1.3 Level the fluid head by centering the bubble in the

BUBBLE LEVEL. Then tighten the CLAMP NUT.

1.4 In low light conditions the BUBBLE LEVEL can be

illuminated by pressing the ILLUMINATION BUTTON.

1.5 Note: If adjusting the level with your camera mounted,

first ensure the camera is securely held before loosening

CLAMP NUT.

1 INSTALL AND LEVEL THE HEAD

ILLUMINATION BUTTON

BUBBLE LEVEL

TRIPOD BOWL

THREADED STUD

CLAMP NUT

FIG 3

2 MOUNT YOUR CAMERA

7

Arrow is equipped with a sliding platform for balance fine

tuning, plus a quick-release camera plate and standard camera

mounting screws (Arrow and Arrow 30 have 70mm sliding

range, Arrow HD has 100mm sliding range). Please note that

best camera control can be achieved by balancing the camera

centre of gravity (C of G) over the centre axis of the head.

2.1 Lock the PAN and TILT LOCKS (rotate both levers clockwise

until firm).

2.2 Remove the CAMERA PLATE by pulling downwards on the

SAFETY TAB while rotating the QUICK RELEASE to the left

until it reaches the automatic stop position (the CAMERA

PLATE will pop up).

2.3 With accessories and battery fitted, determine your

camera’s C of G by the best method available (Eg: balance

the camera on a rod or similar to find balance point).

2.4 Attach the CAMERA PLATE over the C of G by fastening

the 3/8” + 1/4” CAMERA SCREWS into your camera’s base

or ‘tripod adaptor plate’. These screws should be

tightened evenly and as far apart as possible to prevent

any movement between your camera and the fluid head.

N.B. Arrow 30 is also supplied with a 1/4” screw & pin

carriage (Cat#493) for direct attachment to MiniDV

camcorders which do not require a tripod adaptor plate.

When attaching the camera carriage to a camcorder,

ensure the carriage’s locating pin fits comfortably into the

camcorder socket, then screw the 1/4” screw clockwise

until the camera plate is attached firmly to the camcorder.

Warning: If the carriage pin does not easily fit into the

camcorder socket, DO NOT force it. Contact Miller or your

nearest authorised dealer for specific advice relating to

your camcorder model.

FIG 4

CAMERA PLATE

SLIDING PLATFORM

CENTRE AXIS

2 MOUNT YOUR CAMERA Continued

8

2.5 Attach your camera to the fluid head by holding your

camera slightly ‘lens down’ and place the attached

CAMERA PLATE under the front lip on the top of the

SLIDING PLATFORM. Lower the back of the camera until

the QUICK RELEASE snaps automatically to the locked

position. Ensure the QUICK RELEASE knob is firmly seated.

2.6 To ensure a successful mount, grip the PAN HANDLE firmly

and then disengage the PAN and TILT LOCKS. Your camera

should be firmly attached with no obvious free movement.

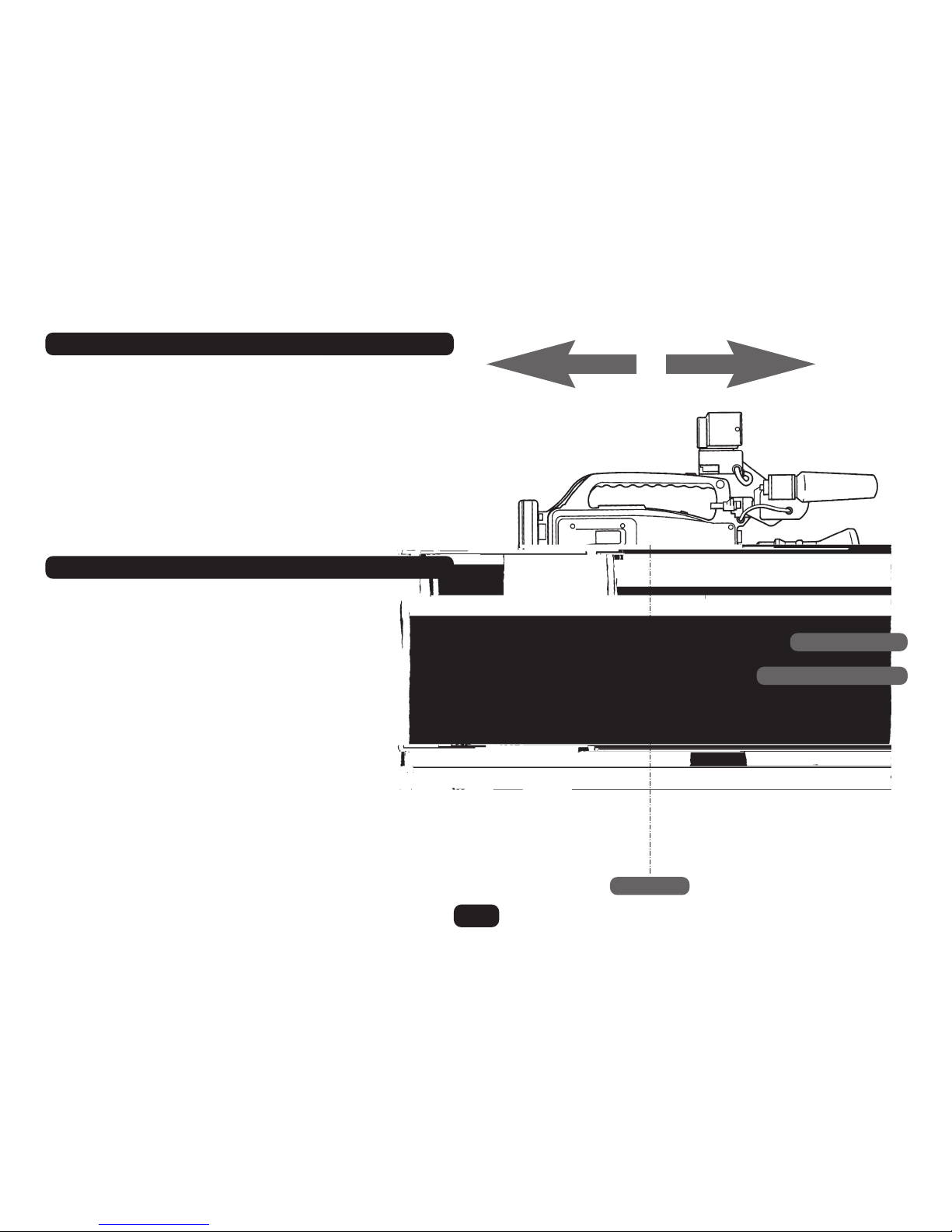

SLIDING PLATFORM

SLIDING PLATFORM LOCK

CENTRE AXIS

FIG 5

3 CENTRE YOUR CAMERA ON THE HEAD

3.1 With your camera attached to the fluid head, hold the PAN

HANDLE and release the TILT LOCK.

3.2 Turn the TILT DRAG CONTROL knob to position ‘0’. Turn

the COUNTERBALANCE SELECTOR knob to position ‘1’.

3.3 Release the SLIDE LOCK lever and slide your camera

forward or backward until balanced over the centre axis of

fluid head. If necessary, be prepared to stop your

camera sliding suddenly. Your camera will remain

static when balanced.

3.4 Re-engage the SLIDE LOCK and TILT LOCK by

turning clockwise until firm.

4 COUNTERBALANCE YOUR CAMERA

9

The Arrow 30, Arrow and Arrow HD include a variable

counterbalance system that provides fingertip control through

its tilt range and allows the camera to be set at any angle

within that range. The counterbalance control can be set in

one of four (4) positions depending on your camera payload.

4.1 Hold the PAN HANDLE and release the TILT LOCK.

4.2 Rotate the counterbalance control knob to setting ‘1’ or ‘2’

for light payloads, ‘3’ or ‘4’ for heavy or off-set payloads.

4.3 Tilt the camera through its tilt range. Loosen hold on the

PAN HANDLE to check that your camera remains static in a

tilted position. If the camera moves from its tilted position,

return the camera to the horizontal position and turn the

COUNTERBALANCE SELECTOR knob to a higher or lower

setting. Tilt through the range again and repeat this test

until the camera remains static in both tilted forward and

tilted backward positions.

Note: If accessories are added or removed, re-balance can be

achieved by adjusting the COUNTERBALANCE SELECTOR,

and/or adjusting the SLIDING PLATFORM position, or by repositioning the CAMERA PLATE on your camera’s base or

‘tripod base plate’.

250

200

150

100

50

0

Centre of Gravity (mm)

Camera Payload (kg)

024 6 8101214161820222426024 6 81012141618202224024 6 81012141618

Counterbalance data;

Arrow 30 Arrow Arrow HD

COUNTERBALANCE SELECTOR

ILLUMINATION BUTTON

TILT DRAG SETTING

FIG 6

5 DRAG CONTROL

6 ILLUMINATION

MAINTENANCE

10

5.1 Arrow heads provide seven (7) incremental settings for tilt

and pan drag control as well as a zero (0) freewheeling

position. There are no half stops. When changing drag

settings, pan and tilt movements must be stopped. There

is an endstop between Position 7 and Zero. This eliminates

the risk of moving the control clockwise from ‘7’ to ‘0’ and

the potential risk of the payload falling forward.

5.2 To achieve smooth diagonal movement, ensure that tilt

and pan drag controls are on similar settings.

For low light conditions, Arrow heads provide illumination of

the bubble level, the pan and tilt drag settings and pan and

tilt knob indicators.

6.1 Press the ILLUMINATION BUTTON to illuminate these

features. You do not need to hold it down. All the above

features will remain illuminated for 10 seconds, then will

switch OFF automatically.

With the exception of external surface cleaning and battery

replacement, Arrow heads do not require additional

maintenance.

Miller Authorised Service Agents must carry out all service and

repair work. Failure to observe this requirement may void

warranty.

PAN DRAG SETTING

PAN DRAG KNOB

PAN KNOB INDICATOR

BUBBLE LEVELTILT KNOB INDICATORTILT DRAG KNOB

7 BATTERY REPLACEMENT

CLEANING

11

The Arrow illumination feature uses a standard long–life

alkaline 12v battery. Under most operating conditions the

battery will provide two years of operation.

Miller approves use of the following batteries: Duracell MN21,

Eveready A23, Vinnic L 1028. Other GP23A batteries also fit.

To change the BATTERY:

7.1 Unscrew the two battery door RETAINING SCREWS and

remove the BATTERY DOOR.

7.2 Remove the BATTERY.

7.3 Insert a new battery, negative end (-) first

7.4 Replace BATTERY DOOR and RETAINING SCREWS.

7.5 Press the ILLUMINATION BUTTON to test operation.

WARNING: Do not immerse in any liquid.

WARNING: Do not use stiff brushes, abrasives, or solvents.

Arrow heads feature protective coatings, dust and moisture

seals and anti-corrosive fittings to ensure long and trouble free

operation, even in harsh environments. To ensure optimum

performance through the life of the head Miller recommends

basic routine maintenance.

When Arrow heads have been used in harsh environments

(such as sand, mud or salt water spray), wipe over with a soft

damp cloth as soon as possible. Use a soft brush to clean

crevices. Remove and clean CAMERA PLATE.

FIG 7

ILLUMINATION BUTTON

BATTERY

BATTERY DOOR RETAINING SCREW

SERVICE, SALES AND SUPPORT

WEB SITE www.millertripods.com

STORAGE

SPARE PARTS AND ACCESSORIES

WARRANTY

When storing your Arrow for extended periods: remove

BATTERY, clean fluid head, and place in a safe, dry place, away

from direct sunlight. Arrow heads can be stored horizontally or

upright. However, it is not advisable to store the head for

extended periods with the tilt locked in an extreme position,

either forward or backward.

ITEM ITEM NO.

Battery P3798

Euro camera plate 79 x 64.5mm (3/8” + 1/4” screws) #860

Camera screw 3/8”W P0037

Camera screw 1/4”W P0036

1/4” + pin camera carriage #493

Telescopic Pan Handle with clamp #694

Telescopic Pan Handle #692

Pan handle - Telescopic with handle clamp #684

Clamp nut P3836

Flat Base adaptor #360

Miller Authorised Service Agents must carry out all service and

repair work. Failure to observe this requirement may void

warranty. It is advisable to notify Miller or a Miller Authorised

Service Agent if a change of performance is observed as a

result of dropping or rough usage. For information regarding

sales and service of Miller products, or for your nearest Miller

representative please contact us via our website or at the

following:

MILLER CAMERA SUPPORT EQUIPMENT

30 Hotham Parade, Artarmon, Sydney,

NSW 2064 Australia

Tel: +61 2 9439 6377

Fax: +61 2 9438 2819

Email: sales@miller.com.au

MILLER FLUID HEADS (EUROPE) LTD.

Unit A2, Ford Lane Industrial Estate

Ford Lane, Ford

West Sussex BN18 0DF, United Kingdom

Tel: +44 (0)1243 555255 Fax: +44 (0)1243 555 001

Email: sales@millertripods-europe.com

MILLER Camera Support (LLC) USA

216 Little Falls Road, Cedar Grove,

New Jersey 07009-1231 USA

Tel: (973) 857 8300

Fax: (973) 857 8188

Email: sales@millertripods.us

MILLER TRIPODS Canada

1055 Granville Street

Vancouver BC V6Z1L4, Canada

Tel: (604) 685 4654

Fax: (604) 685 5648

Email: sales@millercanada.com

Please refer to warranty card for complete details.

3994-5 05/06

Loading...

Loading...