Miller

The

Power

fBlue.

OM-2217

April

1997

En.

w/SeriaI

Number

KH384382

Processes

TIG

(GTAW)

Welding

Stick

(SMAW)

Welding

0

Description

Arc

Welding

Power

Source

~

fllli~Gk~1

7J~

TM

Visit

our

website

at

www.m~e~weIds.com

OWNERS

MANUAL

Thank

you

and

congratulationsonchoosing

Miller.

Now

you

can

get

the

job

done

and

get

it

done

right.

We

know

you

dont

have

time

to

do

it

any

other

way.

Thats

why

when

Neils

Miller

first

started

building

arc

welders

in

1929,

he

made

sure

his

products

offered

long-lasting

value

and

superior

quality.

Like

you,

his

customers

couldnt

afford

anything

less.

Miller

products

had

to

be

more

than

the

best

they

could

be.

They

had

to

be

the

best

you

could

buy.

Today,

the

people

that

build

and

sell

Miller

products

continue

the

tradition.

Theyre

just

as

conmiitted

to

providing

equipment

and

service

that

meets

the

high

standards

of

quality

and

value

establishedin1929.

This

Owners

Manual

is

designed

to

help

you

get

the

most

out

of

your

Miller

products.

Please

take

timetoread

the

Safety

precautions.

They

will

help

you

protect

yourself

against

potential

hazards

on

the

worksite.

Weve

made

installation

and

operation

quick

and

easy.

With

Miller

you

can

count

on

years

of

reliable

service

with

proper

maintenance.

And

if

for

______________

some

reason

the

unit

needs

repair,

theres

a

Troubleshooting

section

that

will

help

you

figure

out

what

the

problem

is.

The

parts

list

will

then

help

you

to

decide

which

exact

part

you

may

need

to

fix

the

problem.

Warranty

and

service

information

for

your

particular

model

are

also

provided.

Miller

Electric

manufactures

a

full

line

of

welders

and

welding

related

equipment.

For

information

on

other

quality

Miller

products,

contact

your

local

Miller

distributor

to

receive

the

latest

full

line

catalog

or

individual

catalog

sheets.Tolocate

your

nearest

distributor

call

1-800-4-A-Miller.

From

to

You

11~iIJIIIII

Ir

REGISTERED

QUALITY

SYSTEM

Miller

is

the

first

weldiNg

equipment

manufacturer

in

the

U.S.A.

to

be

registered

to

the

ISO

9001

Quality

System

Standard.

~?ft~JR~ft1ll1?

Working

as

hard

as

you

do

every

power

source

from

MillerIsbackedbythe

most

hassle-free

warranty

in

the

business.

f//A

MHIer

The

Power

?fBlue.

TM

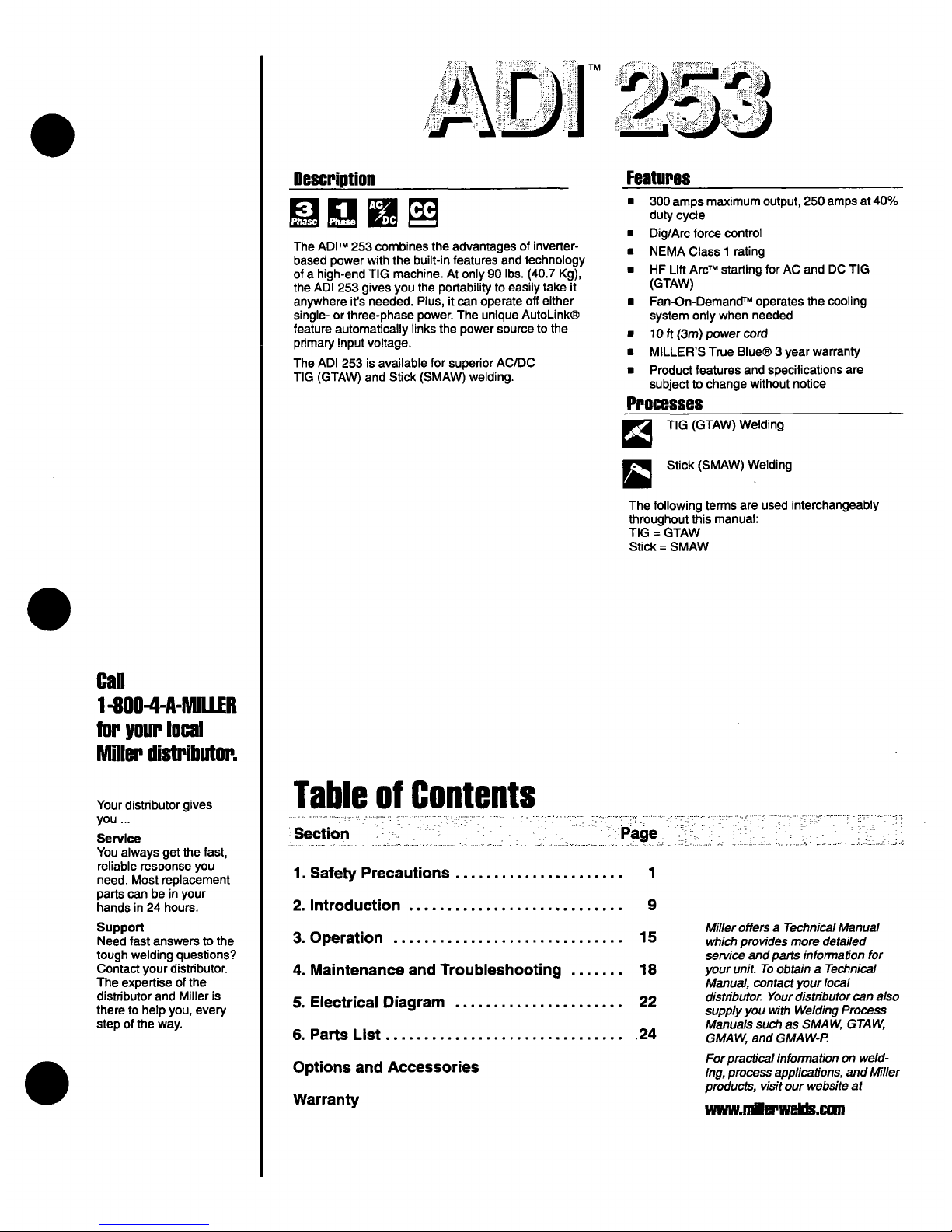

Description

The

ADl~

253

combines

the

advantages

of

inverter

based

power

with

the

built-in

features

and

technology

of

a

high-end

TIG

machine.

At

only

90

lbs.

(40.7

Kg),

the

ADI

253

gives

you

the

portability

to

easily

take

it

anywhere

its

needed.

Plus,

it

can

operate

oft

either

single-

or

three-phase

power.

The

unique

AutoLirikfi

feature

automatically

links

the

power

source

to

the

primary

input

voltage.

The

AOl

253

is

available

for

superior

AC/DC

TIG

(GTAW)

and

Stick

(SMAW)

welding.

300

amps

maximum

output,

250

amps

at

40%

duty

cycle

Dig/Arc

force

control

NEMA

Class

1

rating

HF

Lift

ArcTM

starting

forACand

DC

TIG

(GTAW)

Fan-On-Demand~

operates

the

cooling

system

only

when

needed

lOft(3m)powercord

MILLERS

True

Bluefi

3

year

warranty

Product

features

and

specifications

are

subjecttochange

without

notice

Processes

TIG

(GTAW)

Welding

Call

1

-800-4-A-MILLER

for

your

local

Miller

distributor.

Your

distributor

gives

you

Service

You

always

get

the

fast,

reliable

response

you

need.

Most

replacement

parts

can

be

in

your

hands

in

24

hours.

Support

Need

fast

answers

to

the

tough

welding

questions?

Contact

your

distributor.

The

expertise

of

the

distributor

and

Miller

is

there

to

help

you,

every

step

of

the

way.

Stick

(SMAW)

Welding

The

following

terms

are

used

interchangeably

throughout

this

manual:

TIG

=

GTAW

Stick=SMAW

Miller

offersaTechnical

Manual

15

which

provides

more

detailed

se,vice

and

parts

information

for

your

unit.Toobtain

a

Technical

Manual,

contact

your

local

distributo,

Your

distributor

can

also

supply

you

~wTh

Welding

Process

Manuals

such

as

SMAW,

GTAW,

GMAW,

and

GMAW-P

For

practical

information

on

weld

ing,

process

applications,

and

Miller

products,

visit

our

website

at

Features

1

Table

of

Contents

Section

.

:

:

Page

1.

Safety

Precautions

2.

Introduction

9

3.

Operation

4.

Maintenance

and

Troubleshooting

18

5.

Electrical

Diagram

22

6.

Parts

List

.24

Options

and

Accessories

Warranty

www.n~erwe~Is.com

1.

Safety

Precautions

Read

Before

Using

111

SymbOl

Usage

4A

Means

Warning!

Watch

Out!

There

are

possible

hazards

with

this

procedure!

The

possible

hazards

are

showninthe

adjoining

symbols.

A

Marks

a

special

safety

message.

~

Means

Note;

not

safety

related.

1

2

Arc

Welding

Hazards

A

The

symbols

shown

below

are

used

throughout

this

manual

to

call

attentiontoand

identify

possible

hazards.

When

you

see

the

symbol,

watch

out,

and

follow

the

related

instructions

to

avoid

the

hazard.

The

safety

information

given

below

is

only

a

summary

of

the

more

complete

safety

information

foundinthe

Safety

Standards

listed

in

Section

1.4.

Read

and

follow

all

Safety

Standards.

A

Only

qualified

persons

should

install,

operate,

maintain,

and

repair

this

unit.

A

During

operation,

keep

everybody,

especially

children,

away.

Touching

live

electrical

parts

can

cause

fatal

shocks

or

severe

bums.

The

electrode

and

work

circuit

is

electrically

live

whenever

the

output

is

on.

The

input

power

circuit

and

machine

internal

circuits

are

also

live

when

power

is

on.

In

semiautomatic

or

automatic

wire

welding,

the

wire,

wire

reel,

drive

roll

housing,

and

all

metal

parts

touching

the

welding

wire

are

electrically

live.

Incorrectly

installed

or

improperly

grounded

equipment

is

a

hazard.

Do

not

touch

live

electrical

parts.

Wear

dry,

hole-free

insulating

gloves

and

body

protection.

Insulate

yourself

from

work

and

ground

using

dry

insulating

mats

or

covers

big

enough

to

prevent

any

physical

contact

with

the

work

or

ground.

Do

not

use

AC

output

in

damp

areas,

if

movement

is

confined,

or

if

there

is

a

danger

of

falling.

Use

AC

output

ONLY

if

required

for

the

welding

process.

If

AC

output

is

required,

use

remote

output

control

if

present

on

unit.

Disconnect

input

power

or

stop

engine

before

installing

or

servicing

this

equipment.

Lockout/tagout

input

power

according

to

OSFIA

29

CFR

191

0.147

(see

Safety

Standards).

Properly

install

and

ground

this

equipment

according

to

its

Owners

Manual

and

national,

state,

and

local

codes.

Always

verify

the

supply

ground

check

and

be

sure

that

input

power

cord

ground

wire

is

properly

connected

to

ground

terminal

in

disconnect

box

or

that

cord

plug

is

connected

to

a

properiy

grounded

receptacle

outlet.

When

making

input

connections,

attach

proper

grounding

conductor

first

double-check

connections.

Frequently

inspect

input

power

cord

for

damage

or

bare

wiring

replace

cord

immediately

if

damaged

bare

wiring

can

kill.

Turn

oft

all

equipment

when

not

in

use.

Do

not

use

worn,

damaged,

undersized,

or

pooriy

spliced

cables.

This

group

of

symbols

means

Warning!

Watch

Out!

possible

ELECTRIC

SHOCK,

MOVING

PARTS,

and

HOT

PARTS

hazards.

Consult

symbols

and

related

instructions

below

for

necessary

actions

to

avoid

the

hazards.

Do

not

drape

cables

over

your

body.

If

earth

grounding

of

the

workpiece

is

required,

grounditdirectly

with

a

separate

cabledo

not

use

work

clamp

or

work

cable.

Do

not

touch

electrode

if

you

are

in

contact

with

the

work,

ground,

or

another

electrode

from

a

difterent

machine.

Use

only

well-maintained

equipment.

Repairor

replace

damaged

parts

at

once.

Maintain

unit

according

to

manual.

Wear

a

safety

harness

if

working

above

floor

level.

Keep

all

panels

and

covers

securely

in

place.

Clamp

work

cable

with

good

metal-to-metal

contact

to

workpiece

or

worktable

as near

the

weld

as

practical.

Insulate

work

clamp

when

not

connected

to

workpiece

to

prevent

contact

with

any

metal

object.

SIGNIFICANT

DC

VOLTAGE

exists

after

removal

of

input

power

on

inverters.

Turn

Off

inverter,

disconnect

input

power,

and

discharge

input

capacitors

according

to

instructionsinMaintenance

Section

before

touching

any

parts.

FUMES

ANDGASES

can

be

hazardous.

Welding

produces

fumes

and

gases.

Breathing

these

fumes

and

gases

can

be

hazardous

to

your

health.

Keep

your

head

out

of

the

fumes.

Do

not

breathe

the

fumes.

If

inside,

ventilate

the

area

and/or

use

exhaust

at

the

arc

to

remove

welding

fumes

and

gases.

If

ventilation

is

poor,

use

an

approved

air-supplied

respirator.

Read

the

Material

Safety

Data

Sheets

(MSDSs)

and

the

manufacturers

instructions

for

metals,

consumables,

coatings,

cleaners,

and

degreasers.

Work

in

a

confined

space

only

if

it

is

well

ventilated,

or

while

wearing

an

air-supplied

respirator.

Always

have

a

trained

watch-

person

nearby.

Welding

fumes

and

gases

can

displace

air

and

lower

the

oxygen

level

causing

injury

or

death.

Be

sure

the

breathing

air

is

safe.

Do

not

weld

in

locations

near

degreasing,

cleaning,

or

spraying

operations.

The

heat

and

rays

of

the

arc

cart

react

with

vapors

to

form

highly

toxic

and

irritating

gases.

Do

not

weld

on

coated

metals,

such

as

galvanized,

lead,

or

cadmium

plated

steel,

unless

the

coating

is

removed

from

the

weld

area,

the

area

is

well

ventilated,

and

if

necessary,

while

wearing

an

air-supplied

respirator.

The

coatings

and

any

metals

containing

these

elements

can

give

oft

toxic

fumes

if

welded.

OM-2217

-

Date,

safety_corn

4197

ELECTRIC

SHOCK

can

kill.

OM-221

7

1

ARC

RAYS

can

burn

eyes

and

skin

Arc

rays

from

the

welding

process

produce

intense

visible

and

invisible

(ultraviolet

and

infrared)

rays

that

can

bum

eyes

and

skin.

Sparks

fly

oft

from

the

weld.

Wear

a

welding

helmet

fitted

with

a

proper

shade

of

filter

to

protect

your

face

and

eyes

when

welding

or

watching

(see

ANSI

Z49.1

and

Z87.1

listed

in

Safety

Standards).

Wear

approved

safety

glasses

with

side

shields

under

your

helmet.

Use

protective

screens

or

barriers

to

protect

others

from

flash

and

glare;

wam

others

not

to

watch

the

arc.

Wear

protective

clothing

made

from

durable,

flame-resistant

matenal

(leather

and

wool)

and

foot

protection.

WELDING

can

causefireorexplosion.

Welding

on

closed

containers,

such

as

tanks,

drums,

or

pipes,

can

cause

themtoblow

up.

Sparks

can

fly

off

from

the

welding

arc.

The

flying

sparks,

hot

workpiece,

and

hot

equipment

can

cause

fires

and

burns.

Accidental

contact

of

electrode

to

metal

objects

can

cause

sparks,

explosion,

overheating,

or

fire.

Check

and

be

sure

the

area

is

safe

before

doing

any

welding.

Protect

yourself

and

others

from

flying

sparks

and

hot

metal.

Do

not

weld

where

flying

sparks

can

strike

flammable

material.

Remove

all

flammables

within35ft

(10.7

m)

of

the

welding

arc.

If

this

is

not

possible,

tightly

cover

them

with

approved

covers.

Be

alert

that

welding

sparks

and

hot

materials

from

welding

can

easilygothrough

small

cracks

and

openingstoadjacent

areas.

Watch

for

fire,

and

keep

a

fire

extinguisher

nearby.

Be

aware

that

welding

on

a

ceiling,

floor,

bulkhead,

or

partition

can

cause

fireonthe

hidden

side.

Do

not

weldonclosed

containers

such

as

tanks,

drums,

or

pipes,

unless

they

are

properly

prepared

according

to

AWS

F4.i

(see

Safety

Standards).

Connect

work

cable

to

the

work

as

close

to

the

welding

area

as

practical

to

prevent

welding

current

from

traveling

long,

possibly

unknown

paths

and

causing

electric

shock

and

fire

hazards.

Do

not

use

weldertothaw

frozen

pipes.

Remove

stick

electrode

from

holder

or

cut

off

welding

wire

at

contact

tip

when

not

in

use.

Wear

oil-free

protective

garments

such

as

leather

gloves,

heavy

shirt,

cuffless

trousers,

high

shoes,

and

a

cap.

Remove

any

combustibles,

such

as

a

butane

lighter

or

matches,

from

your

person

before

doing

any

welding.

FLYING

METALcan

injure

eyes.

Welding,

chipping,

wire

brushing,

and

grinding

cause

sparks

and

flying

metal.

As

welds

cool,

they

can

throw

oft

slag.

Wear

approved

safety

glasses

with

side

shields

even

under

your

welding

helmet.

BUILDUP

OF

GAS

can

injure

or

kill

Shut

off

shielding

gas

supply

when

not

in

use.

Always

ventilate

confined

spaces

or

use

approved

air-supplied

respirator.

HOT

PARTS

can

causesevere

burns..

Do

not

touch

hot

parts

bare

handed.

Allow

cooling

period

before

working

on

gun

or

torch.

MAGNETIC

FIELDS

can

affect

pacemakers..

Pacemaker

wearers

keep

away.

Wearers

should

consult

their

doctor

before

going

near

arc

welding,

gouging,

or

spot

welding

operations.

NOISE

can

damage

hearing.

Noise

from

some

processes

or

equipment

can

damage

hearing.

Wear

approved

ear

protection

if

noise

level

is

high.

CYLINDERS

can

explode

if

damaged.

Shielding

gas

cylinders

contain

gas

under

high

pressure.

If

damaged,acylinder

can

explode.

Since

gas

cylinders

are

normally

part

of

the

welding

process,

be

sure

to

treat

them

carefully.

Protect

compressed

gas

cylinders

from

excessive

heat,

mechanical

shocks,

slag,

open

flames,

sparks,

and

arcs.

Install

cylinders

in

an

upright

position

by

securing

to

a

stationary

support

or

cylinder

rack

to

prevent

falling

or

tipping.

Keep

cylinders

away

from

any

welding

or

other

electrical

circuits.

Never

drape

a

welding

torch

over

a

gas

cylinder.

Never

allow

a

welding

electrodetotouch

any

cylinder.

Never

weld

on a

pressurized

cylinderexplosion

will

result.

Use

only

correct

shielding

gas

cylinders,

regulators,

hoses,

and

fittings

designed

for

the

specific

application;

maintain

them

and

associated

parts

in

good

condition.

Turn

face

away

from

valve

outlet

when

opening

cylinder

valve.

Keep

protective

cap

in

place

overvalve

except

when

cylinder

is

in

use

or

connected

for

use.

Read

and

follow

instructions

on

compressed

gas

cylinders,

associated

equipment,

and

CGA

publication

P-i

listed

in

Safety

Standards.

2

OM-22i

7

-

FIRE

OR

EXPLOSION

hazard.

Do

not

install

or

place

unit

on,

over,

or

near

A

combustible

surfaces.

Do

not

install

unit

near

flammables.

Do

not

overload

building

winng

be

sure

power

supply

system

is

properly

sized,

rated,

and

protected

to

handle

this

unit.

FALLING

UNIT

can

cause

injury

Use

lifting

eye

to

lift

unit

only,

NOT

running

gear,

gas

cylinders,

or

any

other

accessories.

Use

equipmentofadequate

capacity

to

lift

and

support

unit.

If

using

lift

forks

to

move

unit,

be

sure

forks

are

long

enough

to

extend

beyond

opposite

side

of

unit.

OVERUSE

can

cause

OVERHEATING

Allow

cooling

period;

follow

rated

duty

cycle.

Reduce

current

or

reduce

duty

cycle

before

starting

to

weld

again.

Do

not

block

or

filter

airflow

to

unit.

STATIC

(ESD~

can

damage

PC

boards.

Put

on

grounded

wrist

strap

BEFORE

handling

boards

or

parts.

Use

proper

static-proof

bags

and

boxes

to

store,

move,

or

ship

PC

boards.

MOVING

PARTS

can

cause

injury.

Keep

away

from

moving

parts.

Keep

away

from

pinch

points

such

as

drive

rolls.

WELDING

WIRE

Can

cause

injury.

Do

not

press

gun

trigger

until

instructed

to

do

so.

Do

not

point

gun

toward

any

part

of

the

body,

other

people,

or

any

metal

when

threading

welding

wire.

:1.4

Principal

Safety

Standards

Safety

in

Welding

and

Cutting,

ANSI

Standard

Z49.1

from

American

Welding

Society,

550

N.W.

LeJeune

Rd,

Miami

FL

33126

Safety

and

Health

Standards,

OSHA

29

CFR

1910,

from

Superinten

dent

of

Documents,

U.S.

Government

Printing

Office,

Washington,

D.C.

20402.

Recommended

Safe

Practices

for

the

Preparation

for

Welding

and

Cutting

of

Containers

That

Have

Held

Hazardous

Substances,

American

Welding

Society

Standard

AWS

F4.1

from

American

Welding

Society,

550

N.W.

LeJeune

Rd,

Miami,

FL

33126

National

Electrical

Code,

NFPA

Standard

70,

from

National

Fire

Protection

Association,

Batteryrnarci,

Park,

Quincy,

MA

02269.

MOVING

PARTS

can

cause

injury.

Keep

away

from

moving

parts

such

as

fans.

Keep

all

doors,

panels,

covers,

and

guards

closed

and

securely

in

place.

H.F.

RADIATION

can

cause

interference.

High-frequency

(H.F.)

can

interfere

with

radio

navigation,

safety

services,

computers,

and

communications

equipment.

Have

only

qualified

persons

familiar

with

electronic

equipment

perform

this

installation.

The

user

is

responsible

for

having

a

qualified

electrician

promptly

correct

any

interference

problem

resulting

from

the

installation.

If

notified

by

the

FCC

about

interference,

stop

using

the

equipment

at

once.

Have

the

installation

regularly

checked

and

maintained.

Keep

high-frequency

source

doors

and

panels

tightly

shut,

keep

spark

gaps

at

correct

setting,

and

use

grounding

and

shielding

to

minimize

the

possibility

of

interference.

ARC

WELDING

can

cause

interference.

Electromagnetic

energy

can

interfere

with

sensitive

electronic

equipment

such

as

computers

and

computer-driven

equipment

such

as

robots.

Be

sure

all

equipment

in

the

welding

area

is

electromagnetically

compatible.

To

reduce

possible

interference,

keep

weld

cablesasshort

as

possible,

close

together,

and

down

low,

such

as

on

the

floor.

Locate

welding

operation

100

meters

from

any

sensitive

elec

tronic

equipment.

Be

sure

this

welding

machine

is

installed

and

grounded

according

to

this

manual.

If

interference

still

occurs,

the

user

must

take

extra

measures

such

as

moving

the

welding

machine,

using

shielded

cables,

using

line

filters,

or

shielding

the

work

area.

Safe

Handling

of

Compressed

Gases

in

Cylinders,

CGA

Pamphlet

P-i,

from

Compressed

Gas

Association,

1235

Jefferson

Davis

Highway,

Suite

501,

Arlington,

VA

22202.

Code

for

Safety

in

Welding

and

Cutting,

CSA

Standard

Wi

17.2,

from

Canadian

Standards

Association,

Standards

Sales,

178

Rexdale

Boulevard,

Rexdale,

Ontario,

Canada

M9W

1

R3.

Safe

Practices

For

Occupation

And

Educational

Eye

And

Face

Protection,

ANSI

Standard

Z87.1

,

from

American

National

Standards

Institute,

1430

Broadway,

New

York,

NY

10018.

Cutting

And

Welding

Processes,

NFPA

Standard

51

B,

from

National

Fire

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

1

3

Additional

Symbols

for

Installation,

Operation,

and

Maintenance

OM-221

7

3

1

5

EMF

Information

Considerations

About

Welding

And

The

Effects

Of

Low

Frequency

Electric

And

Magnetic

Fields

The

following

is

a

quotation

from

the

General

Conclusions

Section

of

the

U.S.

Congress,

Office

of

Technology

Assessment,

Biological

Effects

of

Power

Frequency

Electric

&

Magnetic

Fields

Background

Pape,

OTA-BP-E-53

(Washington,

DC:

U.S.

Government

Printing

Office,

May

1989):.

.

.

there

is

now

a

very

large

volume

of

scientific

findings

based

on

experiments

at

the

cellular

level

and

from

studies

with

animals

and

people

which

clearly

establish

that

low

frequency

magnetic

fields

can

interact

with,

and

produce

changes

in,

biological

systems.

While

most

of

this

work

is

of

very

high

quality,

the

results

are

complex.

Current

scientific

understanding

does

not

yet

allow

us

to

in

terpret

the

evidence

in

a

single

coherent

framework.

Even

more

frustrating,

it

does

not

yet

allow

us

to

draw

definite

conclusions

about

questions

of

possible

risk

or

to

offer

clear

science-based

advice

on

strategies

to

minimize

or

avoid

potential

risks.

To

reduce

magnetic

fieldsinthe

workplace,

use

the

following

procedures:

1.

Keep

cables

close

togetherbytwistingortaping

them.

2.

Arrange

cables

to

one

side

and

away

from

the

operator.

3.

Do

not

coil

or

drape

cables

around

the

body.

4.

Keep

welding

power

source

and

cables

as

far

away

from

opera

tor

as

practical.

5.

Connect

work

clamptoworkpiece

as

closetothe

weld

as

possible.

About

Pacemakers:

The

above

procedures

are

also

recommended

for

pacemaker

wearers.

Consult

your

doctor

for

complete

information.

4

OM-2217

1.

Consignes

do

sØcuritØ

lire

avant

utilisatioN

:1.1

Signification

des:symbOles

a

Signifie

Mise

en

garde!

Soyez

vigilant!

Cette

procedure

prØsente

des

risquesdedanger!

Ceux-ci

sont

identifies

par

des

symboles

adjacents

aux

directives.

A

Identifie

un

message

de

sØcuritØ

particulier.

~

Signifie

NOTA

nestpas

relatif

aIasØcuritO.

12

Dangersrelatifsau

Soudage

a

Iarc

A

Lea

symboles

prØsentØs

ci-aprŁs

sont

utilisØs

tout

au

long

du

present

manuel

pour

attirer

votre

attention

et

identifier

les

risquesdedanger.

Lorsque

vous

voyez

un

symbole,

soyez

vigilant

et

suivez

les

directives

mentionnØes

atm

dØviter

tout

danger.

Les

consignes

de

sØcuritØ

prØsentees

ci-aprŁs

ne

font

que

rØsumer

linformation

contenue

dans

lea

normes

de

sØcuritØ

ØnumØrØes

aIasection

1-5.

Veuillez

lire

et

respecter

toutes

ces

normes

de

sØcuritØ.

A

Linstallation,

lutilisation,

lentretienetles

reparations

ne

doi

vent

Œtre

confiØs

qua

des

personnes

qualifiØes.

A

Au

cours

de

lutilisation,

tenirtoute

personne

a

lØcart

et

plus

par

ticuliŁrement

les

enfants.

UNCHOC

ELECTRIQUE

peut

tuer.

Un

simple

contact

avec

des

piŁces

Łlectrtques

peut

provoquer

une

electrocution

ou

des

blessures

graves.

LØlectrodeetle

circuit

de

soudage

sont

sous

tension

des

que

lappareil

est

sur

ON.

Le

circuit

dentrØe

et

les

circuits

intemes

de

Iappareil

sont

egalement

sous

tension

ace

moment-l.

En

soudage

semi-automatique

ou

automatique,

le

fil,

le

dØvidoir,

le

logement

des

galets

dentraInement

et

es

piŁces

metalliques

en

contact

avec

le

fil

de

soudage

sont

sous

tension.

Des

matØnels

mal

installØs

ou

ma!

mis

a

Ia

terre

presentent

un

danger.

Ne

jamais

toucher

es

piŁces

electnques

sous

tension.

Porter

des

gants

et

des

vØtements

de

protection

secs

ne

comportant

pas

de

trous.

Sisoler

de

Ia

piŁce

et

de

Ia

terre

au

moyen

de

tapis

ou

dautres

moyens

isolants

suffisamment

grands

pour

empecher

le

contact

phy

sique

Øventuel

avec

a

piŁce

ou

Ia

terre.

Ne

passe

servir

do

source

electrique

courant

electnque

dans

les

zones

humides,

dans

les

endroits

confines

ou

l

oU

on

risque

de

tomber.

Se

servir

dune

source

Ølectrique

courant

Ølectnque

UNIQUEMENT

si

le

procØdØdosoudage

le

demande.

Si

Iutilisation

dune

source

electrique

courant

electnque

savŁre

neces

saire,

se

servir

de

Ia

fonctiondetelØcommande

Si

Iappareil

en

est

equipe.

Couperlalimentation

ou

arrØter

!e

moteuravant

de

procedera

instal

lation,

a

Ia

reparation

ou

a

lentretien

de

lappareil.

DŁverrouiller

lalimentation

selon

Ia

norme

OSHA29CFR

191

0.147

(voir

norrnes

de

sØcunte).

Installeret

mettre

a

laterre

correctement

cot

apparel!

conformØment

a

son

manuel

dutilisation

et

aux

codes

nationaux,

provinciaux

et

municipaux.

Toujours

verifier

Ia

terre

du

cordon

dalimentationVerifier

et

sassu

rer

que

le

fil

de

terre

du

cordon

dalimentation

est

bien

raccordØaIa

borne

de

terre

du

sectionneurou

que

Ia

fiche

du

cordon

esi

raccordØe

a

une

pnse

correctement

miseaIa

terre.

En

effectuant

les

raccordements

dentrØe

fixer

dabord

le

conducteur

de

miseaIa

terre

approprie

et

contre-vØrifier

les

connexions.

Verifier

frequemment

le

cordon

dalimentation

pour

voir

sil

nest

pas

endommage

ou

dØnudØ

remplacer

le

cordon

immØdiatement

si!

est

endommagŁ

un

cable

dØnudØ

pout

provoquer

une

electrocution.

Mettre

lappareil

hors

tension

quand

on

ne

lutilise

pas.

Ne

pas

utiliser

des

cables

uses,

endommagØs,

de

grosseur

insuffi

sante

ou

mal

ØpissØs.

Ne

pas

enrouler

les

cables

autour

du

corps.

Si

Ia

piŁce

soudØe

doit

Øtre

mise

a

laterre,

le

faire

directementavec

un

cable

distinct

ne

pas

utiliser

le

connecteur

cie

piŁce

ou

le

cable

de

retour.

Ne

pas

toucher

lØ!ectrode

quand

on

est

en

contact

avec

Ia

piŁce,

Ia

terre

ou

une

electrode

provenant

dune

autre

machine.

ri~~d

Ce

groupe

de

symboles

signifie

Mise

en

garde!

Soyez

vigilant

Ill

y

a

des

risques

de

danger

relies

aux

CHOCS

ELECTRIQUES,

aux

PIECES

EN

MOUVEMENTetaux

PIECES

CHAUDES.

Reportez-vousauxsymboles

et

aux

directives

ci-dessous

afin

de

connaltre

es

mesures

a

prendre

pour

Øviter

tout

danger.

Nutiliser

quun

materiel

en

bon

Øtat.

Reparer

ou

remplacer

sur-le

champ

les

piŁces

endommagees.

Entretenir

lappareil

conforniØment

ace

manuel.

Porter

un

hamais

de

sŁcuntŁ

quand

on

travaille

en

hauteur.

Maintenir

solidement

en

place

tous

les

panneaux

et

capots.

Fixerlecable

de

retour

de

faon

a

obtenir

un

bon

contact

mŁtal-mŁtal

avec

Ia

piŁce

a

souderou

latable

do

travail,

le

plus

prŁs

possible

de

Ia

soudure.

Rangeret

isolercorrectement

Ia

pince

de

masse

aprŁs

utilisation

pour

Łviter

le

contact

avec

des

objets

relies

a

Ia

masse.

Ily

a

DU

COURANT

CONTINU

IMPORTANT

dans

les

convertisseurs

aprŁs

Ia

suppression

de

Ialimenta

tion

electrique.

ArrØter

les

convertisseurs,

debrancher

le

courant

Ølectnque,

et

dØ

charger

es

condensateurs

dalimentation

selon

es

instructions

indiquees

dans

Ia

partie

entretien

avant

do

toucher

les

piŁces.

LES

FUMEES

El

LES

GAZpeuvent~~

ºtre

dangereux~

:

:.:..

Le

soudage

genere

des

fumŁes

et

des

gaz.

Leur

inhalation

pout

Øtre

dangereux

pour

votre

sante.

Eloigner

voire

tŒte

des

fumØes.

Ne

pas

respirer

les

fumØes.

A

IintØneur,

ventiler

Ia

zone

etlou

utiliser

un

Łchappemenl

au

ni

veau

de

arc

pour

lŁvacuation

des

fumŁes

et

des

gaz

de

soudage.

SiIaventilation

est

insuffisante,

utiliser

un

respirateur

a

alimenta

tion

dair

homologue.

Lire

es

specifications

de

sØcuntØ

des

matØnaux

(MSDS5)

et

los

ins

tructions

du

fabncant

concemant

los

mØtaux,

les

consommables,

les

revØtements,

les

nettoyants

et

les

degraisseurs.

Travailler

dans

un

espace

ferrnØ

seulement

siI

est

bien

ventilØ

ou

en

portant

un

respirateur

alimentation

dair.

Demandertoujours

a

un

surveillant

dQment

formŁ

dose

tenir

a

prvximitØ.

Des

fumØes

et

des

gaz

de

soudage

peuvent

dep!acer

lair

et

abaisser

le

niveau

doxygene

provoquant

des

blessures

ou

des

accidents

mortels.

Sassurer

que

lair

de

respiration

no

presente

aucun

danger.

Ne

pas

souder

dans

des

endroits

situŁs

a

proximite

doperations

de

degraissage,

de

nettoyage

ou

de

pu!vŁnsation.

La

chaleur

et

les

rayons

do

Iarc

peuvent

rØagir

en

presence

de

vapeurs

et

former

des

gaz

hautement

toxiques

et

irritants.

Ne

pas

souder

des

mØtaux

munis

dun

revØtement,

tels

quo

lacier

gatvanise,

plaqueenp10mb

ou au

cadmium

a

moms

quo

le

revØte

meni

nait

ete

enlevØ

dans

Ia

zone

de

soudure,

que

lendroit

soit

bien

ventilØ,

et

si

nŁcessaire,

en

portant

un

respirateur

a

a!imenta

tion

dair.

Las

revØtements

et

tous

les

mØtaux

renfermant

ces

Øle

ments

peuvent

degager

des

fumØes

toxiques

en

cas

do

soudage.

5

OM-221

7

LES

RAVONS

DE

LARC

peuvent

pro

I:

voquer

des

brUlures

dans

lea

yeux

et

sur

Ia

peau

Le

rayonnement

de

larc

du

procØdØ

de

soudage

gØnŁre

des

rayons

visibles

et

invisibles

intenses

(ultraviolets

et

infrarouges)

susceptibles

de

provoquer

des

brUlures

dans

les

yeux

et

sur

Ia

peau.

Des

etincelles

sont

projetees

pendant

le

soudage.

Porter

un

casque

de

soudage

muni

dun

ecran

de

filtre

appropriO

pour

proteger

votre

visage

et

vos

yeux

pendant

le

soudage

ou

pour

regar

der

(voirANSi

Z49.1

et

Z87.1

Ønumere

dans

les

nornies

de

securite).

Porter

des

protections

approuves

pour

es

oreilles

si

le

niveau

sondre

est

trop

Øleve.

Utiliser

des

ecrans

ou

des

barriŁres

pour

proteger

des

tiers

de

leclair

et

de

leblouissement;

demander

aux

autres

personnes

de

ne

pas

re

garder

arc.

Porter

des

vØtements

de

protection

constitue

dans

une

matiere

dura

ble,

resistant

au

feu

(cuir

ou

lame)

et

une

protection

des

pieds.

m

5~5J

LE

SOUDAGE

peut

prvoquer

~

incendie

ou

une

explosion.

Le

soudage

effectue

sur

des

conteneurs

fermes

tels

que

des

reservoirs,

tambours

ou

des

conduites

peut

provoquerleureclatement.

Des

Otincelles

peuvent

ºtre

projetees

de

larc

de

soudure.

La

projection

detincel

les,

des

piŁces

chaudesetdes

Øquipements

chauds

peut

provoquerdes

incendiesetdes

brUlures.

Le

contact

accidentel

de

electrode

avec

des

objets

mØtalliques

peut

provoquer

des

etincelles,

une

explosion,

un

surchauffement

ou

un

incendie.

Avant

de

commencer

le

soudage,

verifier

et

sassurer

que

lendroit

ne

presente

pas

de

danger.

Se

protØger

et

dautres

personnes

de

Ia

projection

detincelles

et

de

metal

chaud.

Ne

pas

souder

dansunendroit

l

o

des

Øtincelles

peuvent

tomber

sur

des

substances

inflammables.

DOplacertoutes

les

substances

inflammables

a

une

distance

de

10,7

m

de

lam

de

soudage.

En

cas

dimpossibilite

les

recouvrirsoigneuse

ment

avec

des

protections

homologues.

Des

etincellesetdes

materlaux

chauds

du

soudage

peuvent

facile

ment

passer

dans

dautres

zones en

traversant

de

petites

fissures

et

des

ouvertures.

Surveillertout

declenchement

dincendie

et

tenirun

extincteura

proxi

mite.

Le

soudage

effectue

sur

un

plafond,

plancher,

paroi

ou

separation

peut

declencher

un

incendiedelautre

cOte.

Ne

pas

effectuer

le

soudage

sur

des

conteneurs

fermes

tels

que

des

reservoirs,

tambours,ouconduites,

a

moms

quils

naient

ete

prepa

rØs

correctement

conformementaAWS

F4.1

(voir

les

normes

de

securite).

Brancherlecable

sur

Ia

piŁce

le

plus

pres

possible

de

Ia

zone

de

sou

dage

pour

eviter

le

transport

du

courant

sur

une

longue

distance

par

des

chemins

inconnus

eventuels

en

provoquant

des

flsques

dØlec

trocution

et

dincendie.

Ne

pas

utiliser

le

poste

de

soudage

pour

dØgeler

des

conduites

ge

lees.

En

casdenon

utilisation,

enlever

Ia

baguette

dØlectrode

du

porte-

electrode

ou

couper

le

fil

a

Ia

pointe

de

contact.

Porter

des vetements

de

protection

depourvus

dhuile

tels

que

des

gants

en

cuir,

une

chemise

en

materiau

lourd,

des

pantalons

sans

re

vers,

des

chaussures

hautes

et

un

couvre

chef.

Avant

de

souder,

retirertoute

substance

combustible

de

vos

poches

telles

quun

allumeur

au

butane

ou

des

allumetfes.

Le

soudage,

lecaillement,

le

passage

de

Ia

piece

a

Ia

brosse

en

fil

de

fer,

et

le

meulage

generent

des

Øtincelles

et

des

particules

metalliques

volan

tes.

Pendant

Ia

periode

de

ref

roidissement

des

soudures,

elles

risquent

de

projeter

du

laitier.

Porter

des

lunettes

de

securite

avec

ecrans

lateraux

ou

un

ecran

facial.

iiai

LES

ACCUMULATIONS

DE

GAZ

ris

~4

quent

de

provoquer

des

blessures

ou

mØme

lamort.:

:

:.:

1,

L.J

.

Fermer

Ialimentation

du

gaz

protecteur

en

cas

de

non

utilisation.

Veillertoujours

a

bien

aerer

es

espaces

confines

ou

se

servir

dun

respi

rafeur

dadduction

dair

homologue.

DESI

PI¨CES

CHAUDES

peuieæt

pro

vquer

des

brOlures

graves.

Ne

pas

toucher

des

parties

chaudes

a

mains

nues

Prevoir

une

pOriode

de

refroidissement

avant

dutiliser

le

pistolet

ou

Ia

torche.

LES

CHAMPS

MAGNETIQUES

peuvent

affecter

les

stimulateurs

cardiaques.

Porteurs

de

stimulateurcardiaque,

restez

a

distance.

Les

porteurs

dun

stimulateur

cardiaque

doivent

dabord

consulter

leur

medecin

avant

de

sapprocher

des

operations

de

soudage

a

Iarc,

de

gougeage

ou

de

soudage

par

points.

LE BRUIT

peut

affecter

IouIe.

Le

bruit

des

processus

et

des

equmpements

peuf

affecter

louie.

Porter

des

protections

approuves

pour

les

oreilles

si

le

niveau

sondre

est

trop

eleve.

Si

des

BOUTE1LLES

sont

endomma

gSa,

elles

pourront

exploser.

Des

bouteilles

de

gaz

profecteur

contiennent

du

gaz

sous

haute

pression.

Si

une

bouteille

est

endomma

gee,

elle

peutexploser.

Du

faitque

les

bouteilles

de

gaz

font

normalement

partie

du

procØdØ

de

soudage,

les

manipuler

avec

precaution.

ProtØger

les

bouteilles

de

gaz

comprimØ

dune

chaleur

excessive,

des

chocs

mecaniques,

du

laitier,

des

flammes

ouvertes,

des

etin

celles

et

des

arcs.

Placer

les

bouteilles

debout

en

les

fixant

dans

un

support

station

naireoudans

un

porte-bouteilles

pour

les

empecher

de

tomber

ou

de

se

renverser.

Tenir

les

bouteilles

eloignees

des

circuits

de

soudage

ou

autres

cir

cuits

electriques.

Ne

jamais

placer

une

torche

de

soudage

sur

une

bouteille

a

gaz.

Une

electrode

de

soudage

ne

doit

jamais

entrer

en

contact

avec

une

bouteille.

Ne

jamais

souder

une

bouteille

pressuriseerisque

dexplosion.

Ufiliser

seulement

des

bouteilles

de

gaz

pittecteur,

rØgulateurs,

tuyaux

et

raccords

convenables

pour

cette

application

specifique;

les

mamntenir

ainsi

que

les

elements

associesenbon

etat.

Ne

pas

tenir

Ia

fŒteenface

de

Ia

sortie

en

ouvranf

Ia

soupape

de

Ia

bouteille.

Maintenir

le

chapeaudeprotection

sur

Ia

soupape,

sauf

en

cas

dutilisationoude

branchement

de

Ia

bouteille.

Lireetsuivreesinstructions

concemant

les

bouteilles

de

gai

com

prime,

les

equipements

associes

et

les

publications

P-i

CGA

enu

mØrees

dans

les

normes

de

securite.

DES

PARTICULES

VOLANTES

_____

peuventblesser

les

yeux.

6

OM-2217

et

la

maintenance

Risque

DINCENDIE

OU

D!EXPLOSION.

Ne

pas

placer

lappareil

sur,

au-dessus

ou

a

proximite

de

surfaces

infilammables.

Ne

pas

installer

lappareil

a

proximitØ

de

produits

inflammables

Ne

pas

surcharger

installation

Ølectrique

sassurer

que

lalimen

tation

est

correctement

dimensionnØ

et

protØgØ

avantdemettre

lappareil

en

service.

LA

CHUTE

DE

LAPPAREIL

peut

blesser.

Utiliserlanneau

de

levage

uniquementpoursou

lever

lappareil,

NON

PAS

les

chariot,

les

bouteil

es

de

gaz

ou

tout

autre

accessoire.

Utiliser

un

engin

dune

capacitØ

appropriee

pour

soulever

lappareil.

En

utilisant

des

fourches

de

levage

pour

dØplacer

lunttØ,

sassurer

que

les

fourches

sont

suffisamment

longues

pourdØpasserdu

ctØ

opposedeIappareil.

LEMPLOI

EXCESSIF

peut

SURCHAUFFER

LEQUIPEMENt

PrØvoir

une

pØnode

de

refroidissement,

respec

ter

le

cycle operatoire

nominal.

RØduirelecourantoulecycleopŁratoireavantde

recommancer

le

soudage.

Ne

pas

obstruer

les

passages

dair

du

poste.

LES

CHARGES

ELECTROSTATIQUES

peuvent

endommager

les

circuits

im

primes.

Etablir

Ia

connexion

avec a

barrette

de

terre

avant

de

manipuler

des

cartes

ou

des

piŁces.

Utiliser

des

pochettes

et

des

boTtes

antistatiques

pour

stocker,

deplacerouexpØdier

des

cartes

de

circuits

impnmes.

I.

DES

ORGANES

MOBILES

~

Pr9V~qUe!

desbiessures.

Ne

pas

sapprocher

des

organos

mobiles.

Ne

pas

sapprocher

des

points

de

coincement

tels

que

des

rouleaux

de

commande.

LES

F1LS

DE

SOUDAGE

peuvent

pro

voquer

des

blessures.

Ne

pas

appuyer

sur

Ia

gachette

avant

den

avoir

recu

instruction.

Ne

pas

dinger

le

pistolet

vers

soi,

dautres

per

sonnes

ou

toute

piŁce

mecanique

en

engageant

le

fil

de

soudage.

DES

ORGANES

MOBILES

peuvent

provoquer

des

blessures.

ResteralŁcart

des

organes

mobiles

comme

le

ventilateur.

MaintenirfermŁs

et

fixement

en

place

les

portes,

panneaux,

recouvrements

et

dispositifs

do

protection.

LE

RAVONNEMENT

HAUTE

FRE

QUENCE

(H.F.)

risque

de

provoquer

des

interferences.

Le

rayonnement

haute

frequence

peut

provoquer

des

interferences

avec

les

equipements

de

ra

dionavigationet

de

communication,

los

services

de

sØcuntØetles

ordinateurs.

Demander

seulement

a

des

personnes

qualifiees

familiansØes

avec

des

equipements

Łlectroniques

de

faire

fonctionner

linstalla

tion.

Lutilisateur

est

tenu

de

faire

corriger

rapidemont

par

un

electncien

qualifie

les

interferences

resultantdolinstallation.

SileFCC

signale

des

interferences,

arrºterimmØdiatement

lappa

roil.

Effectuer

rŁgulierement

le

contrleetlentretiendeinstallation.

Maintenir

soigneusement

fermes

les

portes

et

les

panneaux

des

sources

do

haute

frOquence,

maintenir

les

Øclateurs

a

une

distance

correcte

et

utiliser

uno

terre

et et

un

blindage

pour

rØduire

los

inter

fØrences

Øventuelles.

LE

SOUDAGE

A

LARC

risque

de

provoquer

des

interferences.

LŁnergie

ØlectromagnØtique

risque

do

provoquer

des

interferences

pour

lŁquipement

electronique

sensible

tel

que

les

ordinateurs

et

lequipement

commandØ

par

ordinateur

tel

que

les

robots.

Veiller

ace

que

tout

lequipement

de

Ia

zone

de

soudage

soit

com

patible

electromagnetiquement.

Pour

rØduire

Ia

possibilitŁ

dinterfØrence,

maintenir

los

cables

do

soudage

aussi

courts

quo

possible,

les

grouper,

et

es

poser

aussi

bas

quo

possible

(ox.

par

terre).

Veiller

a

souder

a

une

distance

de

100

metres

do

tout

equipement

electronique

sensible.

Veiller

a

ce

quo

ce

poste

de

soudage

soft

pose

et

misaIa

terre

contomiØment

a

ce

mode

demploi.

En

cas

dinterfØrences

aprŁs

avoir

pns

los

mesures

prØcOdentes,

il

incombealutilisateur

do

prendre

des

mesures

supplØmentaires

telles

que

le

deplacement

du

poste,

lutilisationdocables

blindØs,

lutilisation

de

filtres

de

ligne

ou

Ia

pose

do

protecteurs

dans

Ia

zone

do

travail.

LES

CHAMPS

MAGNETIQUES

peuv~nt

affecter

les

stimulateurs

cardiaques.

Porteurs

do

stimulateur

cardiaque,

restez

a

dis

tance.

Las

porteurs

dun

stimulateur

cardiaque

doivent

dabord

consutter

leur

mØdecin

avant

do

sappro

cher

des

operations

do

soudage

a

Iarc,

de

gou

geage

ou

de

soudage

par

points.

1.3

Dangers

supplØmentaires

en

relation

avec

linstallation,

le

fonctionnement

OM-2217

7

Loading...

Loading...