Page 1

MiOØrfi~

~i4

#~41uI14Ft~4S4IV1

-

~a

p

~

I

I

~.w

April

1993

Form:

OM-157

745

Effective

With

Serial

No.

KD398640

OWNERS

MANUAL

Gold

SealTM

Model

5000

Read

and

follow

these

instructions

and

all

safety

blocks

carefully.

Have

only

trained

and

qualified

persons

install,

operate,

or

service

this

unit.

Call

your

distributor

if

you

do

not

understand

the

directions.

CV/DC

Welding

Power

Source/Wire

Feeder

For

FCAW

Welding

Or

GMAW

Welding

With

Optional

Gas

Valve

Rated

Output

Of

70

Amperes

At16Volts

DC,

20%

Duty

Cycle

Uses

115

VAC

Single-Phase

Input

Power

Motor

Overload

Protection

Basic

Model

Includes

Gun,

Standard

Model

Adds

Gas

Valve,

Deluxe

Model

Adds

Gas

Regulator/Flowmeter

U

Give

this

manual

to

the

operator.

For

help,

call

your

distributor

or:

MILLER

ELECTRIC

Mfg.

Co.,

P.O.

Box

1079,

Appleton,

WI

54912

414-734-9821

cover

8/92

ST.161

158

PRINTEDINUSA

Page 2

Page 3

J

U

MILLERS

TRUE

BLUETM

LIMITED

WARRANTY

EffectIve

January

1,

1992

(Equipment

withaserial

number

preface

of

KC

or

newer)

This

limited

werrenty

supersedes

sit

previous

MILLER

warrentlas

end

is

eaclunive

withnoother

gusrentees

or

warrenflea

espreseed

or

Implied.

al-

LIMITED

WARRANTYSubject

to

the

terms

end

conditions

below,

MILLER

Electric

Mlg.

Co.,

Appleton,

Wioconain,

werrents

to

its

original

retell

purcheser

thet

new

MILLER

equipment

sold

elfer

the

effective

dete

of

this

limited

werrenty

is

free

of

de

tects

in

meteriel

end

workmanship

et

the

timeitis

shipped

by

MILLER.

THIS

WAR

RANTY

IS

EXPRESSLY

IN

LIEU

OF

ALL

OTHER

WARRANTIES,

EXPRESS

OR

IMPLIED,

INCLUDING

THE

WARRANTIES

OF

MERCHANTABILITY

AND

FIT

NESS.

Within

the

werrenty

periods

listed

below,

MILLER

will

repeir

or

replece

eny

wer

rented

perle

or

components

thet

tell

due

to

such

defectsinmeteriel

or

workmanship.

MILLER

must

be

notified

in

writing

within

thirty

(30)

deys

of

such

detect

or

teiture,

et

which

time

MILLER

will

provide

instructions

on

the

werrenty

cleim

procedures

to

be

followed.

MILLER

shell

honor

werrenty

ctelme

on

werrented

equipment

listed

belowinthe

event

of

such

e

teilure

within

the

werrenty

time

periods.

All

werrenty

time

periods

stert

on

the

dete

thet

the

equipment

wee

deliveredtothe

originel

retell

purcheser,

end

ere

es

follows:

t.

S

Yeers

Perts

3

Yeers

Lebor

Originel

mein

power

rectifiers

2.

3

Yeers

Perts

end

Lebor

Treneformer/Rectilier

Power

Sources

*

Plesme

Arc

Cutting

Power

Sources

Semi-Autometic

end

Autometic

Wire

Feeders

Robots

3.

2

Yeers

Perte

end

Lebor

Engine

Driven

Welding

Generet

ore

)NOTE:

Engines

em

werrented

eeperetely

by

the

engine

menufecturer.)

4.

1

Yeer

Perte

end

Lebor

*

Motor

Driven

Guns

Process

Controllers

Water

Coolent

Systems

HF

Unite

*

Grids

Spot

Welders

*

Loed

Benko

SDX

Trenetormern

*

Running

Geer/Treilere

*

Field

Options

(NOTE:

Field

options

ere

covered

under

True

BIaenM

for

the

remeining

werrenty

period

of

the

product

they

ere

inatelled

in,

or

foreminimum

of

one

yeer

whichever

in

greeter.)

S.

6

Months

Bell

eries

6.

90

Deye

Perle

end

Lebor

MIG

Gune/TIG

Torches

*

Pleeme

Culling

Torches

*

Remote

Controls

4>

*

Acceeeory

Kite

*

Replecement

Perle

MILLERS

True

BtuenM

Limited

Werrenty

shell

not

epply

to:

1.

Iteme

furnished

by

MILLER,

but

menufectured

by

others,

such

es

engines

or

trede

ecceeeoriee.

These

items

ere

covered

by

the

menufeclurers

werrenty,

If

eny.

2.

Coneumeble

components;

euch

en

contect

tips,

culling

nozzles,

contectore

end

releye.

3.

Equipment

thet

hen

been

modified

by

eny

perty

other

then

MILLER.

or

equip

ment

thet

hee

been

improperly

inetelled,

improperly

opereted

or

mIsused

based

upon

induetry

etenderde,

or

equipment

which

hee

not

hed

reeeonebte

end

neceeeery

meintenence,

or

equipment

which

hoe

been

used

for

operetlon

outside

of

the

epeciticetione

for

the

equipment.

MILLER

PRODUCTS

ARE

INTENDED

FOR

PURCHASE

AND

USEBYCOMMER

CIAtJINDUSTRIAL

USERS

AND

PERSONS

TRAINED

AND

EXPERIENCED

IN

THE

USE

AND

MAINTENANCE

OF

WELDING

EOUIPMENT.

In

the

event

of

e

werrenty

claim

coveredbythis

werrenty.

the

eecluslve

remedies

shell

be,

et

MILLERS

option:

II)

repeir;or12)

replecement;

or,

where

euthorlzed

In

writing

by

MILLER

in

eppropriete

ceees,

)3)

the

reesoneble

cost

of

repelr

or

replece

ment

at

en

euthorized

MILLER

service

stetlon;

or

(4)

peyment

of

orcredlt

for

the

pur

chase

price

(less

reesonebte

deprecietion

besed

upon

ectuel

use)

upon

return

of

the

goode

et

customers

risk

end

espenee.

MILLERS

option

of

repeir

or

reptecement

will

be

FOB.,

Fectory

at

Appleton,

Wisconsin,

or

FOB.

et

e

MILLER

euthorlzed

ser

vice

facility

es

determined

by

MILLER.

Therefore

no

compensetion

or

reImburse

ment

for

transportation

costs

of

eny

kind

wilt

be

ellowed.

TO

THE

EXTENT

PERMITTED

BY

LAW,

THE

REMEDIES

PROVIDED

HEREIN

ARE

THE

SOLE

AND

EXCLUSIVE

REMEDIES.

IN

NO

EVENT

SHALL

MILLER

BE

LIABLE

FOR

DIRECT,

INDIRECt

SPECIAL,

INCIDENTALORCONSEOUENTIAL

DAMAGES

(INCLUDING

LOSS

OF

PROFIT).

WHETHER

BASED

ON

CON

TRACT,

TORT

OR

ANY

OTHER

LEGAL

THEORY.

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

AND

ANY

IMPLIED

WAR

RANTY,

GUARANTY

OR

REPRESENTATION

AS

TO

PERFORMANCE,

AND

ANY

REMEDY

FOR

BREACH

OF

CONTRACT

TORT

OR

ANY

OTHER

LEGAL

THEORY

WHICH,

BUT

FOR

THIS

PROVISION,

MIGHT

ARISE

BY

IMPLICATION,

OPERATION

OF

LAW,

CUSTOM

OF

TRADE

OR

COURSE

OF

DEALING,

IN

CLUDING

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

PARTICULAR

PURPOSE,

WITH

RESPECT

TO

ANY

AND

ALL

EOUIPMENT

FURNISHED

BY

MILLER

IS

EXCLUDED

AND

DISCLAIMED

BY

MtLLER.

Some

otetee

in

the

U.S.A.

do

not

allow

Ilmitetions

of

how

long

en

implIed

werrenty

lesto,

or

the

eaclusion

of

incidentel.

indirect.

opeciel

or

consequentlel

demeges,

so

the

ebove

limitationoreaciusion

may

not

apply

to

you.

This

werrenty

provides

spe

cific

legal

rights,

end

other

rights

may

be

available,

but

may

vary

from

statetostate.

In

Canada,

legislation

in

some

provinces

provides

for

certain

additional

warranties

or

remedies

other

than

as

staled

herein.

andtothe

entent

that

they

may

not

be

waived,

the

limitations

and

eaclusione

eat

out

abova

may

not

apply.

ThIs

Limited

Warranty

provides

specific

legal

rights,

and

other

rights

may

be

available,

but

may

vary

1mm

provincetoprovince.

F

-

RECEIVING-HANDLING

Before

unpack)ng

equipment,

ChBCk

carton

for

any

damage

that

may

haVB

occurred

dUr)ng

shipment.

File

any

C)aimS

for

)oss

or

damage

with

the

delivering

carrier,

Assistance

for

filing

or

setthng

c)aims

may

be

obta)ned

from

distributor

and/or

equipment

manufacturers

Transportation

Department.

When

requesting

information

about

this

equipment,

always

provide

Mode)

Designation

and

Serial

or

Style

Number.

Use

the

following

spaces

to

record

Model

Designation

and

Serial

or

Style

Number

of

your

unit.

The

information

is

located

on

the

rating

label

or

nameplate.

Model

_________

Serial

or

Style

No.

DateofPurchase

miller

5/92

Page 4

Page 5

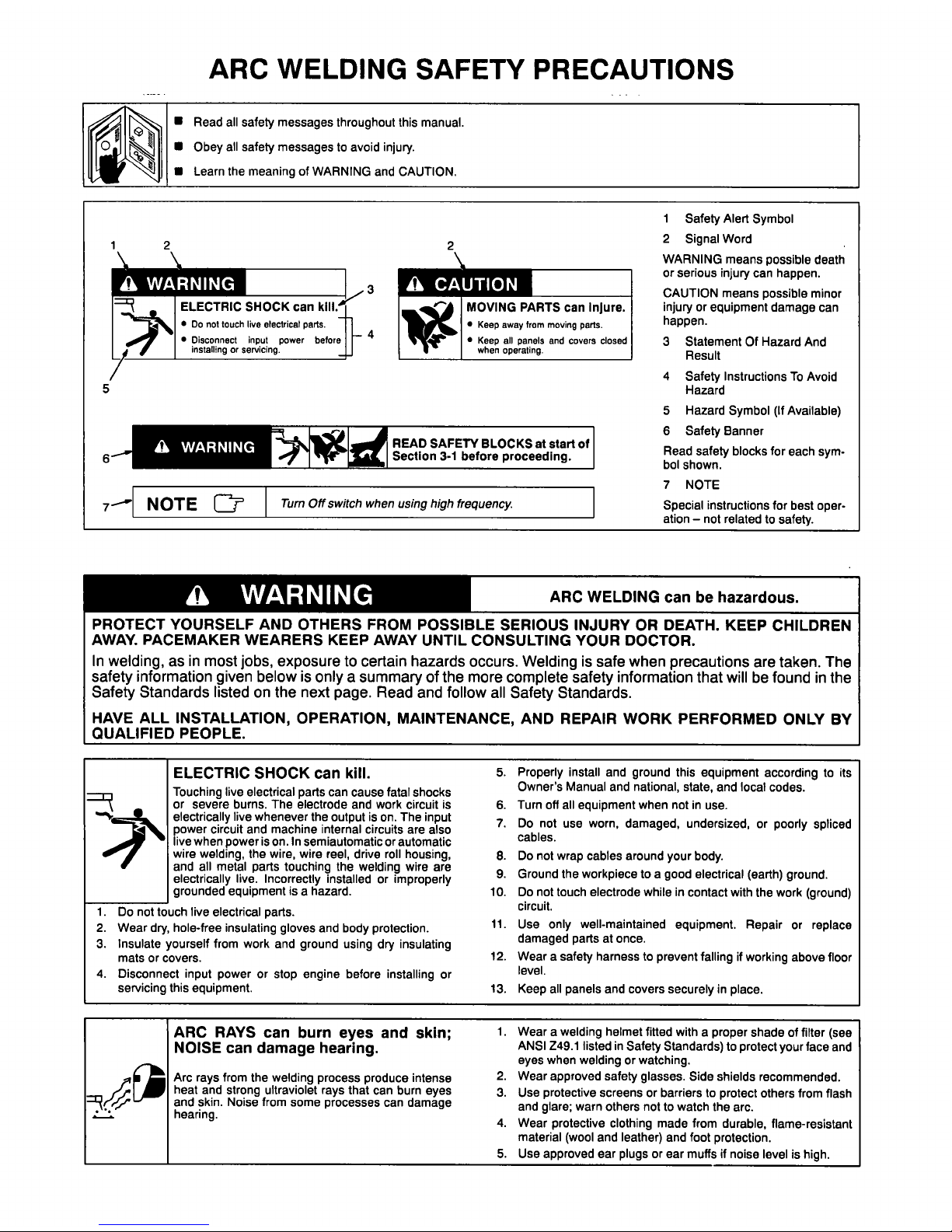

ARC

WELDING

SAFETY

PRECAUTIONS

Read

all

safety

messages

throughout

this

manual.

Obey

all

safety

messages

to

avoid

injury.

Learn

the

meaning

of

WARNING

and

CAUTION.

A~

WARNING

ARC

WELDING

can

be

hazardous.

PROTECT

YOURSELF

AND

OTHERS

FROM

POSSIBLE

SERIOUS

INJURY

OR

DEATH.

KEEP

CHILDREN

AWAY.

PACEMAKER

WEARERS

KEEP

AWAY

UNTIL

CONSULTING

YOUR

DOCTOR.

In

welding,

as

in

most

jobs,

exposure

to

certain

hazards

occurs.

Welding

is

safe

when

precautions

are

taken.

The

safety

information

given

below

is

only

a

summary

of

the

more

complete

safety

information

that

will

be

found

in

the

Safety

Standards

listedonthe

next

page.

Read

and

follow

all

Safety

Standards.

HAVE

ALL

INSTALLATION,

OPERATION,

MAINTENANCE,

AND

REPAIR

WORK

PERFORMED

ONLY

BY

QUALIFIED

PEOPLE.

ELECTRIC

SHOCK

can

kill.

Touching

live

electrical

parts

can

cause

fatal

shocks

or

severe

burns.

The

electrode

and

work

circuit

is

electrically

live

whenever

the

output

is

on.

The

input

power

circuit

and

machine

internal

circuits

are

also

live

when

power

is

on.

In

semiautomatic

or

automatic

wire

welding,

the

wire,

wire

reel,

drive

roll

housing,

and

all

metal

parts

touching

the

welding

wire

are

electrically

live.

Incorrectly

installed

or

improperly

grounded

equipment

is

a

hazard.

1.

Do

not

touch

live

electrical

parts.

2.

Wear

dry,

hole-free

insulating

gloves

and

body

protection.

3.

Insulate

yourself

from

work

and

ground

using

dry

insulating

mats

or

covers.

4.

Disconnect

input

power

or

stop

engine

before

installing

or

servicing

this

equipment.

5.

Properly

install

and

ground

this

equipment

according

to

its

Owners

Manual

and

national,

state,

and

local

codes.

6.

Turn

oft

all

equipment

when

not

in

use.

7.

Do

not

use

worn,

damaged,

undersized,

or

poorly

spliced

cables.

8.

Do

not

wrap

cables

around

your

body.

9.

Ground

the

workpiece

to

a

good

electrical

(earth)

ground.

10.

Do

not

touch

electrode

while

in

contact

with

the

work

(ground)

circuit.

11.

Use

only

well-maintained

equipment.

Repair

or

replace

damaged

parts

at

once.

12.

Wear

a

safety

harness

to

prevent

falling

if

working

above

floor

level.

13.

Keep

all

panels

and

covers

securelyinplace.

/~p~

~2

-

ARC

RAYS

can

burn

eyes

and

skin;

NOISE

can

damage

hearing.

Arc

rays

from

the

welding

process

produce

intense

heat

and

strong

ultraviolet

rays

that

can

burn

eyes

and

skin.

Noise

from

some

processes

can

damage

hearing.

1.

2.

3.

4.

5.

Wear

a

welding

helmet

fitted

with

a

proper

shadeoffilter

(see

ANSI

Z49.1

listed

in

Safety

Standards)

to

protect

your

face

and

eyes

when

weldingorwatching.

Wear

approved

safety

glasses.

Side

shields

recommended.

Use

protective

screens

or

barriers

to

protect

others

from

flash

and

glare;

warn

others

nottowatch

the

arc.

Wear

protective

clothing

made

from

durable,

flame-resistant

material

(wool

and

leather)

and

foot

protection.

Use

approved

ear

plugs

or

ear

muffs

if

noise

level

is

high.

1

2

\

A~

WARNING

2

a

CAUTION

/

1

Safety

Alert

Symbol

______________

3

I

~

ELECTRIC

SHOCK

can

kill

MOVING

PARTS

can

Injure.

I

Do

not

touch

live

electrical

parts.

h

1…~I.

Keep

away

tram

moving

parts.

Disconnect

input

power

before

installingorservicing.

J~j

~

Keep

all

panels

and

covers

closed

I

when

operating.

5

2

SignalWord

WARNING

means

possible

death

or

serious

injury

can

happen.

CAUTION

means

possible

minor

injuryorequipment

damage

can

happen.

V

6

3

Statement

Of

Hazard

And

Result

NOTE

~

READ

SAFETY

BLOCKS

at

start

of

I

_____

Section

3-1

before

proceeding.

4

Safety

InstructionsToAvoid

Hazard

Turn

Off

switch

when

using

high

frequency.

5

Hazard

Symbol

(If

Available)

6

Safety

Banner

Read

safety

blocks

for

each

sym.

bol

shown.

7

NOTE

Special

instructions

for

best

oper

ation

not

related

to

safety.

Page 6

Page 7

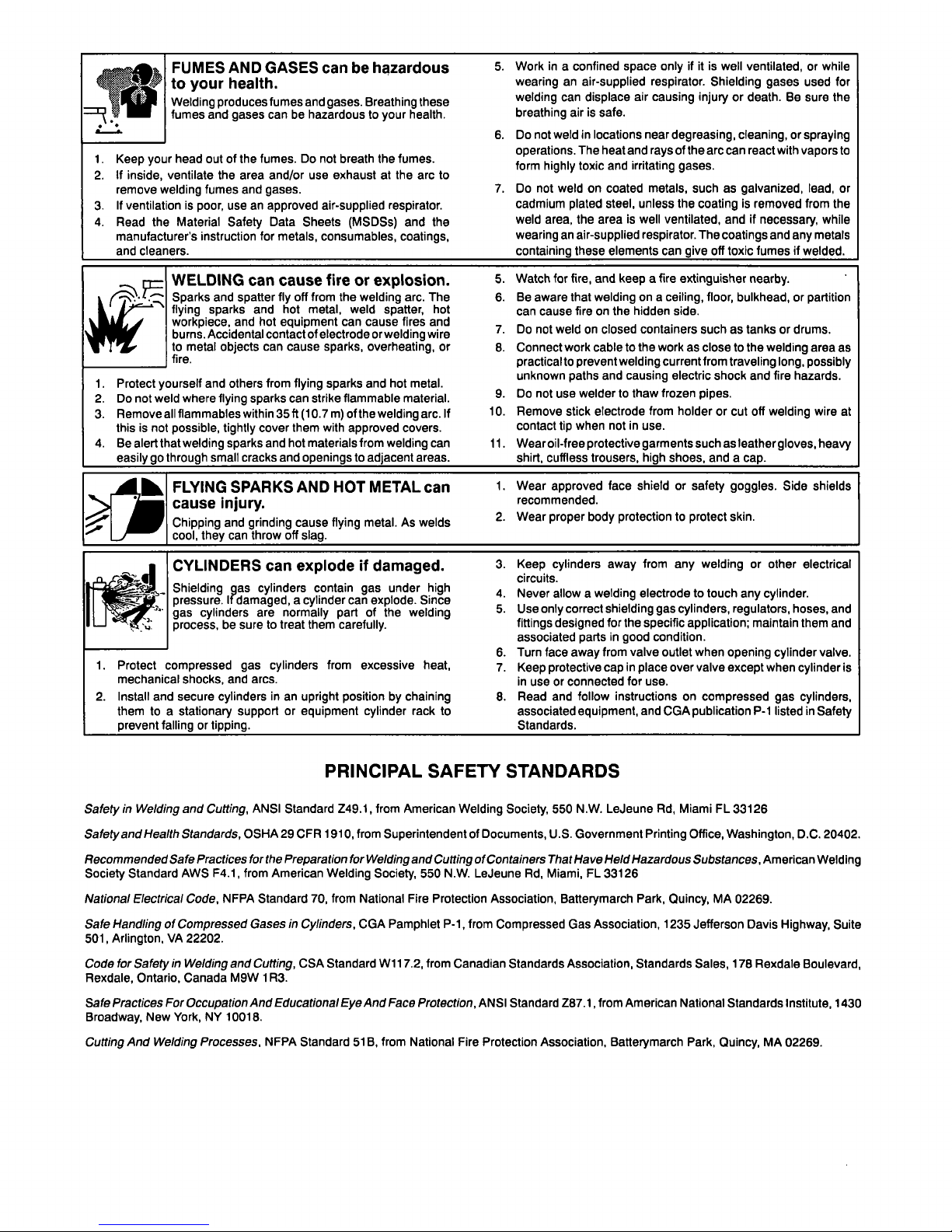

FUMES

AND

GASES

can

be

hazardous

to

your

health.

Welding

produces

fumes

and

gases.

Breathing

these

fumes

and

gases

can

be

hazardous

to

your

health.

Keep

your

head

out

of

the

fumes.

Do

not

breath

the

fumes.

If

inside,

ventilate

the

area

and/or

use

exhaustatthe

arc

to

remove

welding

fumes

and

gases.

3.

If

ventilation

is

poor,

use

an

approved

air-supplied

respirator.

4.

Read

the

Material

Safety

Data

Sheets

(MSDSs)

and

the

manufacturers

instruction

for

metals,

consumables,

coatings,

and

cleaners.

5.

Work

in

a

confined

space

only

if

it

is

well

ventilated,

or

while

wearing

an

air-supplied

respirator.

Shielding

gases

used

for

welding

can

displace

air

causing

injury

or

death.

Be

sure

the

breathing

air

is

safe.

6.

Do

not

weldinlocations

near

degreasing,

cleaning,orspraying

operations.

The

heat

and

rays

of

the

arc

can

react

with

vapors

to

form

highly

toxic

and

irritating

gases.

7.

Do

not

weldoncoated

metals,

such

as

galvanized,

lead,

or

cadmium

plated

steel,

unless

the

coating

is

removed

from

the

weld

area,

the

area

is

well

ventilated,

and

if

necessary,

while

wearinganair-supplied

respirator.

The

coatings

and

any

metals

containing

these

elements

can

give

off

toxic

fumes

if

welded.

Chipping

and

grinding

cause

flying

metal.Aswelds

cool,

they

can

throw

off

slag.

PRINCIPAL

SAFETY

STANDARDS

Safety

in

Welding

and

Cutting,

ANSI

Standard

Z49.1,

from

American

Welding

Society,

550

N.W.

LeJeune

Rd,

Miami

FL

33126

Safetyand

Health

Standards,

OSHA

29

CFR

1910,

from

Superintendent

of

Documents,

U.S.

Government

Printing

Office,

Washington,

D.C.

20402.

Recommended

Safe

Practices

for

the

Preparation

for

Welding

and

Cutting

of

Containers

That

Have

Held

Hazardous

Substances,

American

Welding

Society

Standard

AWS

F4.1,

from

American

Welding

Society,

550

N.W.

LeJeune

Rd,

Miami,

FL

33126

National

Electrical

Code,

NFPA

Standard

70,

from

National

Fire

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

Safe

Handling

of

Compressed

Gases

in

Cylinders,

CGA

Pamphlet

P-i,

from

Compressed

Gas

Association,

1235

Jefferson

Davis

Highway,

Suite

501,

Arlington,

VA

22202.

Code

for

SafetyinWelding

and

Cutting,

CSA

Standard

Wi

17.2,

from

Canadian

Standards

Association,

Standards

Sales,

178

Rexdale

Boulevard,

Rexdale,

Ontario,

Canada

M9W1R3.

Safe

Practices

For

Occupation

And

Educational

Eye

And

Face

Protection,

ANSI

Standard

Z87.

1

,from

American

National

Standards

Institute,

1430

Broadway,

New

York,

NY

10018.

1.

2.

WELDING

can

cause

fire

or

explosion.

5.

Watch

for

fire,

and

keep

a

fire

extinguisher

nearby.

Sparks

and

spatter

fly

off

from

the

welding

arc.

The

flying

sparks

and

hot

metal,

weld

spatter,

hot

workpiece,

and

hot

equipment

can

cause

fires

and

burns.

Accidental

contact

of

electrode

orwelding

wire

6.

7.

Be

aware

that

welding

on

a

ceiling,

floor,

bulkhead,

or

partition

can

cause

fire

on

the

hidden

side.

.

Do

not

weld

on

closed

containers

such

as

tanks

or

drums.

to

metal

objects

can

cause

sparks,

overheating,

or

fire,

8.

Connect

work

cabletothe

workasclose

to

the

welding

area as

practical

to

prevent

welding

currentfrom

traveling

long,

possibly

.

1.

Protect

yourself

and

others

from

flying

sparks

and

hot

metal.

2.

Do

not

weld

where

flying

sparks

can

strike

flammable

material.

9.

unknown

paths

and

causing

electric

shock

and

fire

hazards.

Do

not

use

welder

to

thaw

frozen

pipes.

3.

Remove

all

flammables

within

35

ft

(10.7

m)

of

the

welding

arc.

If

this

is

not

possible,

tightly

cover

them

with

approved

covers,

10.

Remove

stick

electrode

from

holder

or

cut

off

welding

wire

at

contact

tip

when

not

in

use.

4.

Be

alert

that

welding

sparks

and

hot

materials

from

welding

can

11.

Wearoil-free

protective

garments

such

as

leather

gloves,

heavy

easilygothrough

small

cracks

and

openingstoadjacent

areas,

shirt,

cuffless

trousers,

high

shoes,

and

a

cap.

FLYING

SPARKS

AND

HOT

METAL

can

cause

injury,

1.

2.

Wear

approved

face

shield

or

safety

goggles.

Side

shields

recommended.

Wear

proper

body

protection

to

protect

skin.

CYLINDERS

can

explodeifdamaged.

3.

Keep

cylinders

away

from

any

welding

or

other

electrical

circuits.

1.

Shielding

gas

cylinders

contain

gas

under

high

pressure.

If

damaged,acylinder

can

explode.

Since

gas

cylinders

are

normally

part

of

the

welding

process,

be

sure

to

treat

them

carefully.

Protect

compressed

gas

cylinders

from

excessive

heat,

mechanical

shocks,

and

arcs.

4.

5.

6.

7.

Never

allow

a

welding

electrode

to

touch

any

cylinder.

Use

only

correct

shielding

gas

cylinders,

regulators,

hoses,

and

fittings

designed

for

the

specific

application;

maintain

them

and

associated

parts

in

good

condition.

Turn

face

away

from

valve

outlet

when

opening

cylinder

valve.

Keep

protective

cap

in

place

over

valve

except

when

cylinder

is

in

use

or

connected

for

use.

2.

Install

and

secure

cylinders

in

an

upright

position

by

chaining

8.

Read

and

follow

instructions

on

compressed

gas

cylinders,

them

to

a

stationary

support

or

equipment

cylinder

rack

to

associated

equipment,

and

CGA

publication

P-i

listed

in

Safety

prevent

falling

or

tipping.

Standards.

Cutting

And

Welding

Processes,

NFPA

Standard

51

B,

from

National

Fire

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

Page 8

Page 9

TABLE

OF

CONTENTS

SECTION

1

SPECIFICATIONS

1-1.

Volt-Ampere

Curve

And

Duty

Cycle

Chart

1

SECTION

2INSTALLATION

2-1.

Installing

Work

Clamp

2

2-2.

Gun

Polarity

For

Wire

Type

2

2-3.

Installing

Welding

Gun

3

2-4.

Connecting

Input

Power

3

2-5.

Threading

And

Feeding

Welding

Wire

.

3

2-6.

Installing

Gas

Supply

5

SECTION

3OPERATION

6

SECTION

4-

MAINTENANCE

&

TROUBLESHOOTING

4-1.

Overload

Protection

7

4-2.

Drive

Assembly

Maintenance

8

4-3.

Gun

Maintenance

9

4-4.

Troubleshooting

10

SECTION

5

ELECTRICAL

DIAGRAMS

11

SECTION

6

PARTS

LIST

Figure

6-1.

Main

Assembly

13

Figure

6-2.

Drive

Assembly,

Wire

15

Figure

6-3.

GA-i

6C1

Gun

16

OM.1

57

745

4/93

Page 10

Page 11

Page 12

Page 13

SECTION

1

SPECIFICATIONS

Table

1-1.

Welding

Power

Source

a

CAUTION

30

25

20

15

g

5

0

I0

Specifications

Description

Type

Of

Output

Constant

Voltage/Direct

Current

(CV/DC)

Rated

Weld

Output

70

Amperes,

16

Volts

DC,

20%

Duty Cycle

Type

Of

Input

Power

Single-Phase;

60

Hz;

At

115

Volts

AC

Input

Amperes

At

Rated

Output

15

A

KVA/KW

UsedAtRated

Output

2.2

kVN2

kW

Max.

Open-Circuit

Voltage

29

Volts

DC

Control

Circuit

Voltage

At

Gun

24

Volts

DC

Welding

Processes

Flux

Cored

Arc

(FCAW)

And

Gas

Metal

Arc

Welding

(GMAW)

Speed

Range

AtNoLoad

22

To

286

ipm

(0.6

To

7.3

mpm)

Wire

Diameter

Range

.023

To

.035

in

(0.58

To

0.89

mm)

Overall

Dimensions

Length:

16-1/2

in

(419

mm);

Width:

9-1/2

in

(241

mm);

Height:

17

in

(432

mm)

Weight

Net:

53

lb

(24

kg);

Ship:

65

lb

(29

kg)

Welding

Gun

Rated

Output

(Air

Cooled)

160

Amperes

At

60%

Duty Cycle

Using

CO2

Shielding

Gas

Cable

Length

10

ft

(3

m)

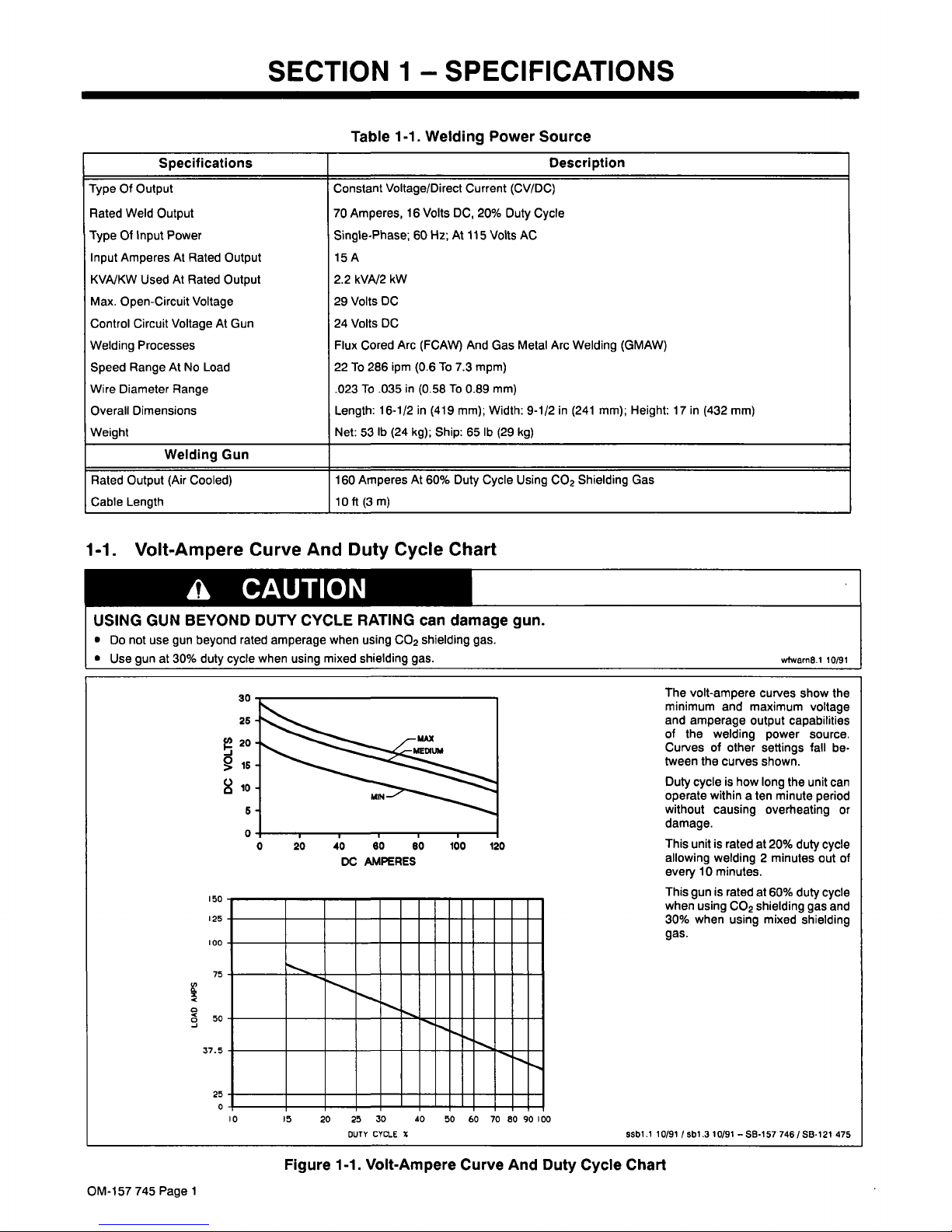

1-1.

Volt-Ampere

Curve

And

Duty

Cycle

Chart

U

SING

GUN

BEYOND

DUTY

CYCLE

RATING

can

damage

gun.

Do

not

use

gun

beyond

rated

amperage

when

using

CO2

shiel

ding

gas.

Use

gun

at

30%

duty

cycle

when

using

mixed

shielding

gas.

~arn8.1

10/91

The

volt-ampere

curves

show

the

minimum

and

maximum

voltage

and

amperage

output

capabilities

of

the

welding

power

source.

Curves

of

other

settings

fall

be

tween

the

curves

shown.

Duty

cycle

is

how

long

the

unit

can

operate

within

a

ten

minute

period

without

causing

overheating

or

damage.

This

unit

is

rated

at

20%

duty

cycle

DC

AMPERES

allowing

welding

2

minutes

out

of

every

10

minutes.

This

gun

is

rated

at

60%

duty

cycle

when

using

CO2

shielding

gas

and

30%

when

using

mixed

shielding

gas.

5

20

25

30

40

50 60

70

80 90

00

DUTY

CYCt.E

~

ssbl.1

10/91

/sbl.3

10/91

SB-157

146/SB.121

475

Figure

1-1.

Volt-Ampere

Curve

And

Duty

Cycle

Chart

OM-157

745

Page

1

Page 14

Page 15

2-1.

Installing

Work

Clamp

Figure

2-1.

Installing

Work

Clamp

2-2.

Gun

Polarity

For

Wire

Type

a

WARNING

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Turn

Oft

welding

power

source,

and

disconnect

input

power

before

inspectingorinstalling.

SwOrnl.1

2/93

1

Polarity

Changeover

Label

1

2

Polarity

Jumper

Links

STRAIGHTIREVERSE

For

Flux

~

POLARITY POLARITY

For

Solid

L

Always

read

and

follow

welding

~

~{~

I

Steel

Or

wire

manufacturers

recom

(FCAW

~

Wires

mended

polarity.

Cored

Wires

J

Aluminum

IGMAWI

Processi

L

S.~.P

Processi

Close

door.

DCEN

OCEP

GUN

POLARITY

CHANGEOVER

S-116

599-Cl

SECTION

2

INSTALLATION

1

Insulator

2

Bolt

3

Smaller

Hole

4

Work

Clamp

Tabs

Bend

tabs

around

work

cable.

5

Work

Cable

From

Unit

6

Nut

Tools

Needed:

~

3/8,

7/16

in

Ret.

ST-025

190-C

2

Tools

Needed:

C~~~JzztC

3/8

in

C

)1

_______

I

~)

I 1

1

1

1

I

1

-

Ref.

ST-159

619-A

Figure

2-2.

Gun

Polarity

Connections

OM-157

745

Page

2

Page 16

Page 17

2-3.

Installing

Welding

Gun

2-4.

Connecting

Input

Power

Connect

unitto

a

properly

grounded

115

VAC

receptacle

of

a

20

ampere

individual

branch

circuit

protected

bytime-delay

fusesorcircuit

breakers.

Selectanextension

cord

of

12

AWG

for

up

to

75

ft

(23

m)

or

10

AWG

for

up

to

140

ft

(46 m).

2-5.

Threading

And

Feeding

Welding

Wire

a

WARNING

ELECTRIC

SHOCK

can

kill.

S

Do

not

touch

live

electrical

parts.

The

welding

wire,

drive

rolls,

drive

assembly,

and

all

metal

parts

touching

the

welding

wire

are

electrically

live

when

weldingorfeeding

wire

using

gun

trigger.

1

Gun

Securing

Nut

2

Drive

Assembly

3

Gun

End

Loosen

securing

nut.

Insert

end

through

front

panel

opening

until

it

bottoms

against

drive

assembly.

Tighten

nut.

4

Gun

Trigger

Leads

Insert

leads,

oneata

time,

through

grommet

on

front

panel.

Connect

leads

to

matching

leadsinunit.

Close

door.

Ref.

ST.159

619-A/

Ret.

ST-159

216

Tools

Needed:

~

5/l6in

Figure

2-3.

Gun

Connections

S

HOT

SURFACES

can

burn

skin.

Allow

gun

to

cool

before

touching.

WELDING

WIRE

can

cause

puncture

wounds.

Do

not

press

gun

trigger

until

instructedtodo

so.

Donotpointguntowardanypartofthebody,other

people,

or

any

metal

when

threading

welding

wire.

.~_

~

-

~

C

YLINDERS

can

explode

if

damaged.

Keep

cylinders

away

from

welding

and

other

electrical

circuits.

Always

secure

cylinder

to

running

gear,

wall,

or

Never

touch

cylinder

with

welding

electrode.

other

stationary

support.

swarn5.1

10/91

/

swarn2.1

9/91

OM-157

745

Page

3

Page 18

Page 19

2

3

6

(150

mm)

Pull

and

hold

wire;

cut

off

end.

Tools

Needed:

~

9/l6in

1

Wire

Spool

2

Hub

Tension

Nut

Grasp

spool.

Turn

while

using

wrench

to

adjust

nut.

When

a

slight

force

is

needed

to

turn

spool,

ten

sion

is

set.

3

Welding

Wire

4

Inlet

Wire

Guide

5

Pressure

Adjustment

Knob

6

Drive

Roll

7

Outlet

Wire

Guide

8

Gun

Conduit

Cable

Lay

gun

cable

out

straight.

Close

and

tighten

pressure

assembly,

and

let

go

of

wire.

ON

POWER

00FF

Set

switch.

-*=~

Remove

gun

nozzle

and

contact

tube.

Press

gun

trigger

until

wire

comes

out

of

gun.

Reinstall

contact

tube

and

nozzle.

Feed

wiretocheck

drive

roll

pressure.

lighten

knob

enough

to

prevent

slipping.

Cut

off

wire.

Close

and

latch

door.

Figure

2-4.

Feeding

Welding

Wire

Ref.

ST-161

157/

Ret.

ST-159

615-Al

Ret.

ST.159

216

/

S-0627-A

Hold

wire

tightly

to

keep

it

from

unraveling.

Open

pressure

assembly.

4

in~

(102

mm)

Push

wire

thru

guides

into

gun;

continuetohold

wire.

1111

II

-~

~~r~J/

OM-157

745

Page

4

Page 20

Page 21

2-6.

Installing

Gas

Supply

£~

WARNING

CYLINDERS

can

explode

if

damaged.

Keep

cylinders

away

from

welding

and

other

electrical

circuits.

Never

touch

cylinder

with

welding

electrode.

Always

secure

cylindertorunning

gear,

wall,

or

other

stationary

support.

3

Tools

Needed:

1-1/8,5/8

in

BUILDUP

OF

SHIELDING

GAS

can

harm

health

or

kill.

Shut

off

shielding

gas

supply

when

not

in

use.

warn4.1

9/91

Obtain

gas

cylinder

and

chain

to

running

gear,

wall,

or

other

station

ary

support

so

cylinder

cannot

fall

and

break

off

valve.

1

Cap

2

Cylinder

Valve

Remove

cap,

standtoside

of

valve,

and

open

valve

slightly.

Gas

flow

blows

dust

and

dirt

from

valve.

Close

valve.

3

CO2

Cylinder

4

0-Ring

5

Regulator/Flowmeter

If

not

supplied,

obtain

proper

regu

lator/flowmeter

for

use

with

CO2

gas.

Install

onto

gas

cylinder

so

that

face

is

vertical.

Flow

rate

for

supplied

regulator/

flowmeter

is

set

to

20

cfh

(cubic

feet

per

hour).

6

Gas

Rose

Connection

Obtain

and

install

gas

hose.

ssb31*

12/92

ST-154

583

/

ST-154

823

Figure

2-5.

InstallationOfDeluxe

Model

Regulator/Flowmeter

6

OM-157

745

PageS

Page 22

Page 23

SECTION

3

OPERATION

a

WARNING

1

Power

Switch

Use

switch

to

turn

unitOnand

Off.

=~

READ

SAFETY

BLOCKS

at

beginning

of

manual

before

proceeding.

MOVING

PARTS

can

cause

injury.

ARCING

can

damage

switch.

Keep

away

from

pinch

points

suchasdrive

rolls.

Keep

all

doors,

panels,

covers,

and

guards

closed

and

securely

in

place

Do

not

change

ThicknessNoltage

switch

position

while

welding.

Arcing

inside

switch

can

damage

contacts,

causing

switch

to

fail.

1

2

3

/

~S8

Figure

3-1.

Safety

Equipment

1

Insulating

Gloves

2

Safety

Glasses

With

Side

Shields

3

Welding

Helmet

Wear

dry

insulating

gloves,

safety

glasses

with

side

shields,

and

a

welding

helmet

with

a

correct

shadeoffilter

(see

ANSI

Z49.1).

sb3.1

10/91

2

Wire

Speed

Control

Use

controltoselectawire

feed

speed.

As

Voltage

switch

setting

increases,

wire

speed

range

also

increases.

The

numbers

around

the

control

are

not

a

wire

feed

speed

(see

rear

cover).

3

ThicknessNoltage

Switch

Use

switchtoselect

an

arc

voltage.

Use

Low

to

weld

thin

materialand

High

to

weld

thicker

material

(see

rear

cover).

Use

wire

brush

or

sandpaper

to

clean

metalatweld

joint

area.

Use

chipping

hammer

to

remove

slag

after

welding.

Connect

work

clamp

to

clean,

paint-free

location

on

workpiece,

as

close

as

possible

to

weld

area.

Figure

3-2.

Controls

5T-159

017IRet.

ST-157

049

OM-157

745

Page

6

Page 24

Page 25

SECTION

4-

MAINTENANCE&

TROUBLESHOOTING

-

A~

WARNING

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Turn

Oft

welding

power

source,

and

disconnect

input

power

before

inspecting,

maintaining,

or

servicing.

HOT

PARTS

can

cause

severe

burns.

Allow

cooling

period

before

maintaining

or

servicing.

4f

M

OVING

PARTS

can

cause

injury.

Keep

away

from

moving

parts.

Keep

away

from

pinch

points

suchasdrive

rolls.

Maintenance

and

troubleshooting

to

be

performed

only

by

qualified

persons.

swarnS

2

2/93

Table

4-1.

Maintenance

Schedule

Time

Maintenance

Before

each

use.

Tighten

all

connections.

Check

gun

and

clean

nozzle.

After

each

spool

of

wire.

Blow

out

gun

liner.

Clean

and

check

wire

drive

parts;

replace

as

necessary.

Every

3

months.

Tapeorreplace

cracked

cables:

clean

and

tighten

connections.

Replace

unreadable

labels.

Every

6

months.

Blow

out

or

vacuum

insideofunit.

4-1.

Overload

Protection

READ

Sectio

SAFETY

BLOCKS

at

start

of

n

4

before

proceeding.

Thermostat

TP1

protects

the

unit

from

damage

due

to

overheating.

If

main

transformer

Ti

gets

too

hot,

TPi

opens

and

weld

output

stops.

The

fan

keeps

running

to

cool

the

transformer.

Wait

several

minutes

before

trying

to

weld.

A.

Overheating

B.

Motor

Fuse

Fl

Turn

Off

and

unplug

unit.

Unlatch

door,

remove

handle,

and

remove

door/wrapper.

1

Fuse

Fl

(See

Parts

List

For

Rating)

If

this

fuse

opens,

the

wire

drive

motor

does

not

run.

Push

on

fuseholder

and

twist

to

open.

Replace

fuse.

Reinstall

wrapper

and

handle,

and

latch

door.

1T~~1ZJfl

1/4,3/Bin

ST-159

618/Ret.

ST-I

52

031

Tools

Needed:

Figure

4-1.

Fuse

Fl

Location

OM-157

745

Page

7

Page 26

Page 27

4-2.

Drive

Assembly

Maintenance

I~4s.

READ

SAFETY

BLOCKS

at

start

of

7

______

Section

4

before

proceeding.

Turn

Off

and

unplug

unit.

1

Wire

Spool

Cut

welding

wire

off

at

contact

tube.

Retract

wire

onto

spool

and

secure.

2

Pressure

Roll

Arm

3

Cotter

Pin

4

Pin

5

Screw

6

Bearing

Remove

bearing

as

shown.

Install

new

bearing

and

secure

with

screw.

Reinstall

arm

onto

pin

and

secure

with

cotter

pin.

7

Setscrew

8

Smooth

Groove

For

Hard

Wire

9

Drive

Roll

Remove

drive

roll

as

shown.

Useawire

brushtoclean

drive

roll.

Push

drive

roll

onto

shaft

with

de

sired

groove

in.

Turn

drive

roll

so

one

setscrew

faces

flat

side

of

shaft,

and

tighten

both

setscrews.

10

Knurled

Groove

For

Flux-

Cored

Wire

11

Wire

Inlet

Guide

Remove

guide

by

pressing

on

barbed

area

or

cutting

oft

one

end

near

housing

and

pulling

it

out

of

hole.

Push

new

guide

into

hole

from

rear

until

it

snaps

in

place.

Thread

welding

wire

(see

Section

2-5).

Close

door.

Tools

Needed:

5/6~1

Ret.

ST-159

615-A

/

ST-154

199

Figure

4-2.

Drive

Assembly

Maintenance

OM-157

745

Page

8

Page 28

Page 29

4-3.

Gun

Maintenance

3/8,

5/16

in

Figure

4-3.

Gun

Maintenance

swarrilOl

10/91

Turn

Off

and

unplug

unit.

1

Wire

Spool

Cut

welding

wire

off

at

contact

tube.

Retract

wire

onto

spool

and

secure.

2

Gun

Securing

Nut

Disconnect

trigger

leads.

Loosen

nut

and

remove

gun

and

trigger

leads.

3

Nozzle

4

Contact

Tube

5

Head

Tube

6

Liner

Collet

Disassemble

gun

as

shown.

7

Liner

Pull

liner

from

this

end.

Blow

gun

casing

out

with

compressed

air.

Insert

new

liner

into

gun

casing

until

even

with

end

of

head

tube.

Install

collet

onto

liner.

Install

contact

tube

and

nozzle.

Insert

gun

into

feeder

and

mark

where

liner

touches

drive

roll.

Re

move

gun

and

cut

liner

off.

Reinstall

gun

so

that

liner

is

as

close

as

possible

to

drive

rolls

without

touching.

Thread

welding

wire

(see

Section

2-5).

Close

door.

READ

SAFETY

BLOCKS

at

start

of

1

Section4before

proceeding.

FLYING

METAL

CHIPS

AND

DIRT

can

cause

injury

and

damage

equipment.

Point

gun

away

from

people

and

in

a

safe

direction

when

blowing

out

with

compressed

air.

2

3

4

5

7

Tools

Needed:

Rot.

57-159

619-A

/

Rot.

ST-155

509

OM-157

745

Page

9

Page 30

Page 31

4-4.

Troubleshooting

READ

SAFETY

BLOCKS

at

start

of

Section4before

proceeding.

Table

4-2.

Welding

Trouble

Table

4-3.

Wire

Drive/Gun

Trouble

Welding

Trouble

No

weld

output;

wire

does

not

fee~

-,

Remedy

Secure

power

cord

plug

in

receptacle.

Motor

fuse

Fl

open,

replace

fuse.

Replace

building

line

fuse

or

reset

circuit

breaker

if

open.

Secure

gun

trigger

leads

or

repair

leads,

or

replace

trigger

switch.

No

weld

output;

wire

does

not

feed;

fan

--

motor

continues

to

run,

and

pilot light

turns

off.

Section

-~

2-4

-~

~

--

--

-a

2-3

No

weld

output;

wire

feeds.

Thermostat

TP1

open

(overheating).

Allow

fan

to

run;

the

thermo

stat

will

close

when

the

unit

has

cooled.

---p.

4-lA

Low

weld

output.

Replace

contact

tube.

Connect

work

clamp

to

get

good

metal-to-metal

contact.

H

Figure

3-2

4-3

-ru-~

Connect

unit

to

proper

input

voltage

or

check

for

low

line

voltage.

--L

2-4

Wire

Drive/Gun

Trouble

Remedy

Section

Electrode

wire

feeding

stops

during

-~

-~

4-3

welding.

2-5

2-5

-~

4-3

-~

4-2,4-3

4.2

2-3

-~

4-lB

4-2,4-3

---~

--

Straighten

gun

cable

and/or

replace

damaged

parts.

Adjust

drive

roll

pressure.

Readjust

hub

tension.

Replace

contact

tubeifblocked.

Clean

or

replace

wire

inlet

guide

or

liner

if

dirty

or

plugged.

Replace

drive

roll

or

pressure

bearing

if

worn

or

slipping.

Secure

gun

trigger

leads

or

repair

leads,

or

replace

trigger

switch.

Check

and

replace

Fl.

Check

and

clear

any

restrictions

at

drive

assembly

and

liner.

Have

nearest

Factory

Authorized

Service

Station

check

drive

motor.

OM-157

745

Page

10

Page 32

Page 33

SECTION

5-

ELECTRICAL

DIAGRAMS

Figure

5-1.

Circuit

Diagram

For

Welding

Power

Source

2

CR

I

I

L

PLC

I

69N.

z

ST-157

378

OM-157

745

Page

11

Page 34

Page 35

SI

S2

8A(FM-2~V.)

~~1

--j

P2

WORK

SPLIcE

GND

POWER

CORD

SC-157

379-A

Figure

5-2.

Wiring

Diagram

For

Welding

Power

Source

Page 36

Page 37

SECTION

6

PARTS

LIST

>

E

a,

U,

U,

4

(a

a)

L.

IL.

C0

c~:J

C,,

CD

Lf)~

LI~

OM-157

745

Page

13

Page 38

Page 39

Item

Dia.

Part

No.

Mkgs.

No

-~

Description

1

010909..

2

010910..

3

073355..

4

111998..

5

111929..

6....

CR1

120706..

7

120675..

8....

FM

111931..

9

005656..

10

053297..

11

Fl

*012663..

12....

VR1

087156..

13

R2

117116..

14

Ci

109039..

15

161439..

16

108105..

17

134834..

18

149322..

29....

GS1

116996..

120077..

20

157190..

21

Ri

119653..

22

605227..

23

157187..

24

089899..

25

157376..

26

134464..

27

+157188..

28

PLG1

113494..

29

111644..

30

019663..

31

....

TP1

120638..

32

Ti

157389..

33

157447..

34

Z

118457..

35

010368..

36

111443..

37

S2

157305..

38

39

.40

41

42

.43

Si

44

..45....SR2....

46

..47....TE1....

48

49

50

51

52

53

Figure

6-1.

Main

Assembly

Quantity

NUT,

SB

slflkg

hex

.375-16

1

WASHER,

flatstl

SAE

.375

2

SPRING,

cprsn

.625

OD

x

.093

wire

x

1

.000

1

PIN,

cotter

hair

.l2Odia

x

2.375

Ig

x

.500

shaft

HUB,

spool

1

RELAY,

end

24VAC

DPDT

1

BRACKET,

mtg

motor

fan

1

MOTOR,

fan

115V

50/60Hz

2600RPM

.i8i8dia

shaft

BLADE,

fan

6

in

4wg

3odeg

.175

bore

CW

1

HOLDER,

fuse

crtg

in-line

1

FUSE,

mintr

gI

slo-blo

3A

1

VARISTOR,

10

joule

68VDC

1

RESISTOR,

WWfxd

20W

50

ohm

1

CAPACITOR,

elctlt

46000uf

35VDC

1

STRIP,

comb

rmr

.012

x

1.500x9.000

CLAMP,

capacitor

2.500dia

1

HOSE,

SAE

.187

ID

x

.410

OD

(order

by

ft)

3ft

CLAMP,

hose

.405-.485clp

dia

slfttng

2

VALVE,

115VAC

2

way

custom

port

1/8

orf

(std

&

deluxe

model)

BLANK,

snap-in

nyl

sq

1.250

(basic

model

only)

1

CASE

SECTION,

front/base/rear

1

RHEOSTAT,

WW

25W

25

ohm

1

NUT,

nyl

hex

jam

.75ONPST

(std

&

deluxe

model)

PANEL,

side

1

LATCH,

slide

1

HANDLE,

lifting

1

LABEL,

warning

general

precautionary

WRAPPER

1

CORD

SET,

125V

5-15P

l4ga

3/c

7ft

1

BUSHING,

strain

relief

.370/430

ID

x

.875mtg

hole

MOUNT,

nprn

15/16

OD

4

THERMOSTAT,

NC

1

TRANSFORMER,

pwr

main

115

(consisting

of)

1

COIL,

pwr

main

1

STABILIZER

1~

CLAMP,

grd

200A

1

BUSHING,

strain

relief

.240/.510

ID

x

.875mtg

hole

1

SWITCH,

rocker

DPDT

15A

125VAC

600

325..

CABLE,

weld

cop

strd

No.

6

(orderbyft)

1

5ft

026

843..

INSULATOR,

vinyl

blk

2

119

697..

GA-l6Ci

GUN,

(Fig

6-3)

1

025

338..

BUSHING,

nyl

univ

23/32

hd

dia

.625mtg

hole

1

097

922..

KNOB,

pointer

1

153

698..

SWITCH,

rocker

SPST

16A

125VAC

NAMEPLATE,

(order

by

model

and

serial

number)

1

119

264..

RECTIFIER,

si

iph

100A

200PIV

1

010

047..

TUBING,

stl

.625

OD

x

1

2ga

wall

x

1.000

1

122

385..

TERMINAL

ASSEMBLY,

chgov

(consisting

of)

1

601

835....

NUT,

brs

hex

10-32

8

038

887....

STUD,

pri

bd

brs

10-32

x

1.375

4

.116620....

TERMINALBOARD,chgov

1

038618....

LINK,

jumper

term

bd

pri

2

157

191

..

BAFFLE,air

1

131

336..

DRIVE

ASSEMBLY,

wire

(Fig

6-2)

1

059

712..

CLIP,

component

.437dia

mtg

adh

back

1

153

714..

REGULATOR/FLOWMETER,

dual

scale

(deluxe

model

only)

602

958..

FITTING,

brs

barbed

M

1/4tbg

x

1/4NPT

(deluxe

model

only)

1

*Recommended

Spare

Parts.

+When

ordering

a

component

originally

displaying

a

precautionary

label,

the

label

should

also

be

ordered.

BE

SURE

TO

PROVIDE

MODEL

AND

SERIAL

NUMBER

WHEN

ORDERING

REPLACEMENT

PARTS.

OM-157

745

Page

14

Page 40

Page 41

Item

Dia.

Part

No.

Mkgs.

No.

Description

..1..MOT..

..2

.5

..6

.7

..8

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

119

021

604 657

602

213

010

910

128

189

602

211

604

538

129

893

126

838

090

416

124

817

151

828

112 031

090 443

114

415

010

224

058

549

085

242

085

244

090 415

092

237

602

204

604 537

605

853

119

028

602

169

601

862

602

203

604

673

Figure

6-2.

Drive

Assembly,

Wire

1

1

1

1

1

3

1

3

1

2

1

1

1

BE

SURE

TO

PROVIDE

MODEL

AND

SERIAL

NUMBER

WHEN

ORDERING

REPLACEMENT

PARTS.

OM-157

745

Page

15

131

336

Figure

6-2.

Drive

Assembly,

Wire

(Fig

6-1

Item

53)

Quantity

1

MOTOR,

gear

12VDC

80RPM

SCREW,

.375-16x1.250

hexhd

sti

WASHER,

lock

stl

split

.375

WASHER,fIatstlSAE.375

SCREW,

.312-18

x

1.750

hexhd

sti

WASHER,

lock

stl

split

.312

WASHER,flatstlSAE.312

INSULATOR,

housing

drive

WIRE

DRIVE,

(consisting

of)

PIN,

hinge

HOUSING,

wire

drive

PIN,

cotter

hair

.042

x

.750

LEVER,

pressure

roll

BEARING,

ball

rdl

sgl

row

.315

x

.866

x

.447

SCREW,

10-24

x

.625

flathd-phl

stl

PIN,

spring

CS

.187

x

1.000

GUIDE,

wire

inlet

1/16

FASTENER,

pinned

WASHER,

cupped

stl

.328

ID

x

.812

OD

x

.125

SPRING,

cprsn

.720

OD

x

.072

wire

x

1.250

KNOB,

adj

tension

WASHER,

lock

stl

ext

tooth

No.

10

NUT,

stl

hex

full

.312-18

SCREW,

10-32

x

.750

rndhd-slt

stl

ROLL,

drive

V

groove

combination

SCREW,

set

8-32

x

.187

cup

pt

sch

stl

NUT,

stl

hex

10-32

WASHER,

lock

sti

split

No.

10

SCREW,

10-32

x

.625

flathd-slt

sti

2.

5

7

8

18-

12

16

28

27

22

13

14

26 25

15

24

7

SC.121

448.C

Page 42

Page 43

Part

No.

Description

119

697

Figure

6-3.

GA-16C1

Gun

(Fig

6-1

Item

40)

BE

SURE

TO

PROVIDE

MODEL

AND

SERIAL

NUMBER

WHEN

ORDERING

REPLACEMENT

PARTS.

Quantity

Itern

No.

1

110793..

HANDLE

ASSEMBLY

2

110

795

..

TUBE,

head

(consisting

of)

3

110780....

NUT,

MiOxi

4

110

779

....

JACKET,

head

tube

5

110

781

....

STOP,

nozzle

6

....

128

878

....

ADAPTER,

head

tube/nozzle

7

110

782

....

SPRING,

nozzle

8

110786

10..

11

..12..

.13..

.14..

15..

16..

.17..

.18..

9

2

.110789..

.110794..

080565..

...110797..

120714..

120715..

079974..

...110796..

047994..

...110792..

TUBE

contact

030

wire

(quantity

of

1

included

with

gun)

3

NOZZLE,

slip

type

1/2

orE

1

TRIGGER

SWITCH

ASSEMBLY

1

TERMINAL,

frict

fern

.110x.016

22-18

wire

2

SLEEVE,

rbr

1

LINER,

rnonocoil

.030-.035

wire

w/collet

lOft

(consisting

of)

1

COLLET,

liner

.035

wire

1

0-RING,

.500

ID

x

.1O3CS

rbr

2

CONNECTOR,

gun/feeder

1

TERMINAL,

frict

fern

.250

x

.032

22-18

wire

2

CABLE/CONDUIT,

lOft

1

Ref.

SC-lb

832-0

10

11

12

18

17

Figure

6-3.

GA-16C1

Gun

OM-157

745

Page

16

Page 44

Page 45

SUGGESTED

PARAMETERS

FOR

WELDING

MILD

STEEL

PROCESS

WIRE

SIZE

AND

TYPE

WELDING

POLARITY

SETTINGS

STICK

OUT

SHIELDING

GAS

Material

Thickness

CONTROL

SETTINGS

Thinner

Than

20

ga

0.0359

in

(0.91

mm)

20-18

ga

0.0359-0.0478

in

(0.91

-1.21

mm)

17-15

ga

0.0538-0.0673

in

(1.36-1.71

mm)

14-13

ga

0.0747-0.0897

in

(1.89-2.28

mm)

12

ga

and

thicker

0.1046

in

+

(2.65

mm)

FCAW

0.030

in

(0.76

mm)

Flux

Cored

E-71T-GS

DCEN

1/2

in

(12.7

mm)

NA

Voltage

Adjustment

LOW

LOW

MEDIUM

MEDIUM

HIGH

Wire

Feed

Adjustment

Control

30

60

40

50

90

FCAW

0.035

in

(0.889

mm)

Flux

Cored

E-71T-GS

DCEN

1/2

in

(12.7

mm)

NA

Voltage

Adjustment

LOW

LOW

MEDIUM

MEDIUM

HIGH

Wire

Feed

Adjustment

Control

25

50

30

40

60

GMAW

0.023-0.025

in

(0.58-0.64

mm)

Solid

Steel

DCEP

1/4

in

(6.35

mm)

CO

2

Voltage

Adjustment

LOW

LOW

MEDIUM

MEDIUM/HIGH

Not

Recommended

Wire

Feed

Adjustment

Control

55

60

95

100

Not

Recommended

0

0

-.4

01

-4

Ref.

S-157

696

Page 46

Page 47

Page 48

Loading...

Loading...