Page 1

March1993

Form:

OM-160518

Effective

With

Serial

No.

KD398640

OWNERS

MANUAL

Read

and

follow

these

instructions

and

all

Give

this

manualtothe

operator.

safety

blocks

carefully.

Have

only

trained

and

qualified

persons

install,

operate,

or

service

this

unit.

Call

your

distributor

if

you

do

not

understand

the

directions.

For

help,

call

your

distributor

or:

MILLER

ELECTRIC

Mfg.

Co.,

P.O.

Box

1079,

Appleton,

WI

54912

414-734-9821

Millerfi

~.

r.~1~Ic4...1

-

~_

~

I

1

~.w

Gold

SealTM

Model

3000

CC/DC

Welding

Generator

For

SMAW

Welding

90

Amperes,

25

VoltsDCAt

60%

Duty

Cycle

1.2

kVA/kW

DC

Auxiliary

Power

With

Overload

Protection

Kohler

CH5+

Air-Cooled,

Four-Cycle,

Gasoline

Engine

Optional

Low

Oil

Pressure

Shutdown

Switch

coven

5/92ASt-161

477

PRINTEDIN~SA

Page 2

Page 3

s

a

MILLERS

TRUE

BLUETM

LIMITED

WARRANTY

Effective

January

1,

1992

(Equipment

with

a

serial

number

preface

of

KC

or

newer)

This

limited

warranty

supersedes

all

previous

MILLER

warranties

endisexclusive

withnoother

guerantees

or

warranties

eapressed

or

Implied.

u

LIMITED

WARRANTY

Subject

to

the

terms

end

conditions

below,

MILLER

Electric

MIg.

Co.,

Appleton.

Wisconsin,

wsrrsnts

to

its

originsl

retell

purchsser

that

new

MILLER

equipment

sold

sfter

the

effective

dateofthis

limited

warranty

is

tree

of

de

tects

in

material

end

workmanship

at

the

timeitis

shipped

by

MILLER.

THIS

WAR

RANT?

IS

EXPRESSLY

IN

LIEU

OF

ALL

OTHER

WARRANTIES.

EXPRESS

OR

IMPLIED,

INCLUDING

THE

WARRANTIES

OF

MERCHANTABILITY

AND

FIT

NESS.

Within

the

warranty

periods

listed

below,

MILLER

will

repair

or

replace

any

war

ranted

pans

or

components

that

tall

duetosuch

detectsinmaterial

or

workmanship.

MILLER

must

be

notified

in

writing

within

thiny

(30)

days

of

such

defect

or

failure,

at

which

lime

MILLER

will

provide

instructions

on

the

warranty

claim

procadurea

to

be

followed.

MILLER

shall

honor

warranty

claimsonwarranted

equipment

listed

below

in

the

event

of

suchafailure

within

the

warranty

time

periods.

All

warranty

lime

periods

start

on

the

date

that

the

equipment

was

delivered

to

the

original

retail

purchaser,

and

are

as

follows:

1.

5

Yearn

Pans3

Years

Labor

*

Original

main

power

rectifiers

2.

3

Yearn

Pans

and

Labor

*

Transformer/Rectifier

Power

Sources

Plasma

Arc

Cutting

Power

Sources

Semi-Automatic

and

Automatic

Wire

Feeders

*

Robots

3.

2

YearsPans

and

Labor

Engine

Driven

Welding

Generators

(NOTE:

Engines

are

warranted

separately

by

the

angina

manufacturer.)

4.

I

Year

Pans

and

Labor

*

Motor

Driven

Guns

*

Process

Controllers

*

Water

Coolant

Systems

HF

Units

*

Grids

Spot

Welders

*

Load

Banks

SDX

Transformers

Running

Gear/Trailers

*

Fietd

Options

(NOTE:

Field

options

are

covered

under

True

BIuenM

for

the

remaining

warranty

period

ol

the

product

they

are

installed

in,

or

for

a

minimum

of

one

yaar

whichever

is

greater.)

5.

6

Months

Batteries

6.

90

Days

Pans

and

Labor

*

MIS

Guns/TIG

Torches

*

Plasma

Cutting

Torches

*

Remote

Controls

*

Accessory

Kits

*

Replacement

Pans

MILLERS

True

BiuanM

Limited

Warranty

shall

not

apply

to:

1.

Items

furnished

by

MILLER,

but

manufactured

by

others,

such

as

anginea

or

trade

accessories.

These

items

are

coveredbythe

manufacturers

warranty,

it

any.

2.

Consumabla

components;

such

as

contact

tips,

cutting

nozzles,

conlaclorn

and

relays.

3.

Equipment

that

has

bean

modilied

by

any

party

other

than

MILLER.

or

equip

ment

that

has

been

improperly

installed,

improperly

operated

or

misused

based

upon

industry

standards,

or

aquipmenl

which

has

not

had

reasonable

and

necessary

maintenance,

or

equipment

which

han

bean

used

for

operation

outside

of

the

spacifications

br

the

equipment.

MILLER

PRODUCTS

ARE

INTENDED

FOR

PURCHASE

AND

USE

BY

COMMER

CIALJINDUSTRIAL

USERS

AND

PERSONS

TRAINED

AND

EXPERIENCED

IN

THE USE

AND

MAINTENANCE

OF

WELDING

EOUIPMENT

In

the

avant

01

a

warranty

claim

covaradbythis

warranty,

the

eacluniva

remedies

shall

ba,

at

MILLERS

option:

(1)

repair;or(2)

replacement;

or,

where

authorized

in

writing

by

MILLER

in

appropriate

cases.

(3)

the

reasonabia

cost

of

repairorreplace

ment

alan

authorized

MILLER

service

station;

or

(4)

payment

oforcredit

for

the

pur

chase

price

(lass

reasonable

depracialion

based

upon

actual

usa)

upon

return

of

the

goods

at

customers

risk

and

expense.

MILLERS

optionofrepair

or

replacement

will

ba

FOB.,

Factory

atAppleton,

Wisconsin,

or

P.0.6.

at

a

MILLER

authorized

ser

vice

facility

as

determinedbyMILLER.

Therefore

no

compensation

or

raimburse

went

for

transportation

costs

of

any

kind

will

be

allowed.

TO

THE

EXTENT

PERMITTED

BY

LAW,

THE

REMEDIES

PROVIDED

HEREIN

ARE

THE

SOLE

AND

EXCLUSIVE

REMEDIES.INNO

EVENT

SHALL

MILLER

BE

LIABLE

FOR

DIRECT,

INDIRECT,

SPECIAL.

INCIDENTAL

OR

CONSEOUENTIAL

DAMAGES

(INCLUDING

LOSS

OF

PROFIT).

WHETHER

BASED

ON

CON

TRACT,

TORT

OR

ANY

OTHER

LEGAL

THEORY.

ANY

EXPRESS

WARRANTY

NOT

PROVIDED

HEREIN

AND

ANY

IMPLIED

WAR

RANTY,

GUARANTY

OR

REPRESENTATION

AS

TO

PERFORMANCE,

AND

ANY

REMEDY

FOR

BREACH

OF

CONTRACT

TORT

DR

ANY

OTHER

LEGAL

THEORY

WHICH.

BUT

FOR

THIS

PROVISION,

MIGHT

ARISE

BY

IMPLICATION,

OPERATION

OF

LAW.

CUSTOM

OF

TRADE

OR

COURSE

OF

DEALING.

IN

CLUDING

ANY

IMPLIED

WARRANTY

OF

MERCHANTABILITY

OR

FITNESS

FOR

PARTICULAR

PURPOSE.

WITH

RESPECT

TO

ANY

AND

ALL

EOUIPMENT

FURNISHED

BY

MILLER

IS

EXCLUDED

AND

DISCLAIMED

BY

MILLER.

Some

slates

in

the

U.S.A.

do

not

allow

limitations

of

how

long

an

implied

warranty

lasts,

or

the

esciusion

of

incidental,

indirect,

special

or

consequential

damages,

ao

the

above

liwitatlon

or

exclusion

may

not

apply

to

you.

This

warranty

provides

spa

citic

legal

rights,

and

other

rights

may

be

available,

but

may

vary

from

stale

to

stale.

In

Canada,

legislation

in

some

provinces

provides

br

certain

additional

warranties

or

remedies

other

thanasstaled

herein,

and

to

the

astant

that

they

may

not

ba

waived.

Ihe

limitations

and

exclusions

set

out

above

may

not

apply.

This

Limited

Warranty

provides

specific

legal

rights,

and

other

rights

may

be

available,

but

may

vary

Irom

province

to

province.

I

r

_____________________________

I

RECEIVING-HANDLING

Before

unpacking

equ(pment,

check

carton

for

any

damage

that

may

have

occurred

during

Shipment.

File

any

claims

for

loss

or

damage

with

the

delivering

carrier.

Assistance

for

filing

or

settling

claims

may

be

obtained

from

distributor

and/or

equipment

manufacturers

Transportation

Department.

When

requesting

infDrmation

about

this

equipment,

always

provide

Mode)

Designation

and

Serial

or

Sty(e

Number.

USe

the

following

spaces

to

record

Model

Designation

and

Serial

or

Style

Number

of

your

unit.

The

information

is

located

on

the

rating

label

or

namep(ate.

Model

__________

Serial

or

Style

No.

DateofPurchase

miller

5192

Page 4

Page 5

March

1

993

Form:

OM-160

518

Effective

With

Serial

No.

KD398640

OWNERS

MANUAL

U

Read

and

follow

these

instructions

and

all

U

Give

this

manualtothe

operator.

U

U

safety

blocks

carefully.

Have

only

trained

and

qualified

persons

install,

operate,

or

service

this

unit.

Callyourdistributorifyoudonotunderstand

the

directions.

rt~i

U

U

For

help,

call

your

distributor

or:

MILLER

ELECTRIC

Mfg.

1079,

Appleton,

WI

54912

Co.,

P.O.

Box

414-734-9821

1~oIsfi

(jJOJ1

cI~j\r~J~

PAW

100

CC/DC

Welding

Generator

For

SMAW

Welding

U

90

Amperes,

25

VoltsDCAt

60%

Duty Cycle

U

1.2

kVAJkW

DC

Auxiliary

Power

With

Overload

Protection

Kohler

CH5+

Air-Cooled,

Four-Cycle,

Gasoline

Engine

Optional

Low

Oil

Pressure

Shutdown

Switch

cover

8/92

ST-161

477

PRINTED

IN

~SA

Page 6

Page 7

ARC

WELDING

SAFETY

PRECAUTIONS

5.

Properly

install

and

ground

this

equipment

according

to

its

Owners

Manual

and

national,

state,

and

local

codes.

6.

When

making

input

connections,

attach

proper

grounding

conductor

first.

7.

Turn

off

all

equipment

when

not

in

use.

8.

Do

not

use

worn,

damaged,

undersized,

or

poorly

spliced

cables.

9.

Do

not

wrap

cables

around

your

body.

10.

Ground

the

workpiece

to

a

good

electrical

(earth)

ground.

11.Donot

touch

electrode

if

in

contact

with

the

work

or

ground.

12.

Use

only

well-maintained

equipment.

Repair

or

replace

damaged

parts

at

once.

13.

Wear

a

safety

harness

if

working

above

floor

level.

14.

Keep

all

panels

and

covers

securelyinplace.

ARC

RAYS

can

burn

eyes

and

skin;

NOISE

can

damage

hearing.

Arc

rays

from

the

welding

process

produce

intense

heat

and

strong

ultraviolet

rays

that

can

burn

eyes

and

skin.

Noise

from

some

processes

can

damage

hearing.

ARC

RAYS

2.

Wear

a

welding

helmet

fitted

with

a

proper

shadeoffilter

(see

ANSI

Z49.

1

listed

in

Safety

Standards)

to

protect

your

face

and

eyes

when

welding

or

watching.

3.

Wear

approved

safety

glasses.

Side

shields

recommended.

4.

Use

protective

screens

or

barriers

to

protect

others

from

flash

and

glare;

warn

others

not

to

watch

the

arc.

5.

Wear

protective

clothing

made

from

durable,

flame-resistant

material

(wool

and

leather)

and

foot

protection.

FUMES

AND

GASES

can

be

hazardous

to

your

health.

Welding

produces

fumes

and

gases.

Breathing

these

fumes

and

gases

can

be

hazardous

to

your

health.

Keep

your

head

out

of

the

fumes.

Do

not

breathe

the

fumes.

If

inside,

ventilate

the

area

and/or

use

exhaust

at

the

arc

to

remove

welding

fumes

and

gases.

If

ventilation

is

poor,

use

an

approved

air-supplied

respirator.

Read

the

Material

Safety

Data

Sheets

(MSDS5)

and

the

manufacturers

instruction

for

metals,

consumables,

coatings,

and

cleaners.

5.

Work

in

a

confined

space

only

if

itiswell

ventilated,

or

while

wearing

an

air-supplied

respirator.

Shielding

gases

used

for

welding

can

displace

air

causing

injury

or

death.

Be

sure

the

breathing

air

is

safe.

6.

Do

not

weldinlocations

near

degreasing,

cleaning,

or

spraying

operations.

The

heat

and

rays

of

the

arc

can

react

with

vapors

to

form

highly

toxic

and

irritating

gases.

7.

Do

not

weld

on

coated

metals,

such

as

galvanized,

lead,

or

cadmium

plated

steel,

unless

the

coating

is

removed

from

the

weld

area,

the

area

is

well

ventilated,

and

if

necessary,

while

wearing

an

air-supplied

respirator.

The

coatings

and

any

metals

containing

these

elements

can

give

off

toxic

fumes

if

welded.

WELDING

can

cause

fire

or

explosion.

Sparks

and

spatter

fly

off

from

the

welding

arc.

The

flying

sparks

and

hot

metal,

weld

spatter,

hot

workpiece,

and

hot

equipment

can

cause

fires

and

burns.

Accidental

contactofelectrode

orwelding

wire

to

metal

objects

can

cause

sparks,

overheating,

or

fire.

Protect

yourself

and

others

from

flying

sparks

and

hot

metal.

Do

not

weld

where

flying

sparks

can

strike

flammable

material.

Remove

all

flammables

within

35

ft

(10.7

m)

of

the

welding

arc.

If

this

is

not

possible,

tightly

cover

them

with

approved

covers.

Be

alert

that

welding

sparks

and

hot

materials

from

welding

can

through

small

cracks

and

openings

to

adjacent

areas

FLYING

SPARKS

AND

HOT

METAL

can

cause

injury.

Chipping

and

grinding

cause

flying

metal.

As

welds

cool,

they

can

throw

off

slag.

Watch

for

fire,

and

keep

a

fire

extinguisher

nearby.

Be

aware

that

welding

on

a

ceiling,

floor,

bulkhead,

or

partition

can

cause

fire

on

the

hidden

side.

Do

not

weld

on

closed

containers

suchastanks

or

drums.

Connect

work

cable

to

the

workasclosetothe

welding

area

as

practical

to

prevent

welding

current

from

traveling

long,

possibly

unknown

paths

and

causing

electric

shock

and

fire

hazards.

Do

not

use

welder

to

thaw

frozen

pipes.

Remove

stick

electrode

from

holder

or

cut

off

welding

wire

at

contact

tip

when

not

in

use.

11.

Wear

oil-free

protective

garments

such

as

leather

gloves,

heavy

shirt,

cuffless

trousers,

high

shoes,

and

a

cap.

1.

Wear

approved

face

shield

or

safety

goggles.

Side

shields

recommended.

2.

Wear

proper

body

protection

to

protect

skin.

a

WARNING

ARC

WELDING

can

be

hazardous.

PROTECT

YOURSELF

AND

OTHERS

FROM

POSSIBLE

SERIOUS

INJURY

OR

DEATH.

KEEP

CHILDREN

AWAY.

PACEMAKER

WEARERS

KEEP

AWAY

UNTIL

CONSULTING

YOUR

DOCTOR.

In

welding,

as

in

most

jobs,

exposure

to

certain

hazards

occurs.

Welding

is

safe

when

precautions

are

taken.

The

safety

information

given

below

is

only

a

summary

of

the

more

complete

safety

information

that

will

be

found

in

the

Safety

Standards

listed

on

the

next

page.

Read

and

follow

all

Safety

Standards.

HAVE

ALL

INSTALLATION,

OPERATION,

MAINTENANCE,

AND

REPAIR

WORK

PERFORMED

ONLY

BY

QUALIFIED

PEOPLE.

ELECTRIC

SHOCK

can

kill.

Touching

live

electrical

parts

can

cause

fatal

shocks

or

severe

burns.

The

electrode

and

work

circuit

is

electrically

live

whenever

the

output

is

on.

The

input

power

circuit

and

machine

internal

circuits

are

also

live

when

power

is

on.

In

semiautomatic

or

automatic

wire

welding,

the

wire,

wire

reel,

drive

roll

housing,

and

all

metal

parts

touching

the

welding

wire

are

electrically

live.

Incorrectly

installed

or

improperly

grounded

equipment

is

a

hazard.

1.

Do

not

touch

live

electrical

parts.

2.

Wear

dry,

hole-free

insulating

gloves

and

body

protection.

3.

Insulate

yourself

from

work

and

ground

using

dry

insulating

mats

or

covers.

4.

Disconnect

input

power

or

stop

engine

before

installing

or

servicing

this

equipment.

1.

Use

approved

ear

plugs

or

ear

muffsifnoise

level

is

high.

1.

2.

3.

4.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

srI

9/92

Page 8

Page 9

MOVING

PARTS

can

cause

injury.

Moving

parts,

such

as

fans,

rotors,

and

belts

can

cut

fingers

and

hands

and

catch loose

clothing.

1.

Keep

all

doors,

panels,

covers,

and

guards

closed

and

securely

in

place.

2.

Stop

en

me

before

installingorconnecting

unit.

SafetyinWelding

and

Cutting,

ANSI

Standard

Z49.1,

from

American

Welding

Society,

550

N.W.

LeJeune

Rd,

MiamiFL33126

Safety

and

Health

Standards,

OSHA

29

CFR

1910,

from

Superinten

dent

of

Documents,

U.S.

Government

Printing

Office,

Washington,

D.C.

20402.

Recommended

Safe

Practices

for

the

Preparation

for

Welding

and

Cutting

of

Containers

That

Have

Held

Hazardous

Substances,

Ameri

can

Welding

Society

Standard

AWS

F4.i

from

American

Welding

So

ciety,

550

N.W.

LeJeune

Rd,

Miami,

FL

33126

National

Electrical

Code,

NFPA

Standard

70,

from

National

Fire

Pro

tection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

ENGINES

can

be

hazardous.

1.

Use

equipment

outside

in

open,

well-ventilated

areas.

2.

If

used

in

a

closed

area,

vent

engine

exhaust

outside

and

away

from

any

building

air

intakes.

1.

Stop

engine

before

checking

or

adding

fuel.

2.

Do

not

add

fuel

while

smoking

or

if

unit

is

near

any

sparks

or

open

flames.

3.

Allow

engine

to

cool

before

fueling.

If

possible,

check

and add

fuel

to

cold

engine

before

beginning

job.

4.

Do

not

overfill

tankallow

room

for

fuel

to

expand.

5.

Do

not

spill

fuel.Iffuel

is

spilled,

clean

up

before

starting

engine.

3.

Have

only

qualified

people

remove

guards

or

covers

for

maintenance

and

troubleshooting

as

necessary.

4.

To

prevent

accidental

starting

during

servicing,

disconnect

negative

()

battery

cable

from

battery.

5.

Keep

hands,

hair,

loose

clothing,

and

tools

away

from

moving

parts.

6.

Reinstall

panels

or

guards

and

close

doors

when

servicing

is

finished

and

before

starting

engine.

Safe

Handling

of

Compressed

Gases

in

Cylinders,

CGA

Pamphlet

P-i,

from

Compressed

Gas

Association,

1235

Jefferson

Davis

High

way,

Suite

501,

Arlington,

VA

22202.

Code

for

Safety

in

Welding

and

Cutting,

CSA

Standard

Wi

17.2,

from

Canadian

Standards

Association,

Standards

Sales,

178

Rexdale

Bou

levard,

Rexdale,

Ontario,

Canada

M9W

1R3.

Safe

Practices

ForOccupationAnd

Educational

Eye

And

Face

Protec

tion,

ANSI

Standard

Z87.1,

from

American

National

Standards

Institute,

1430

Broadway.

New

York,

NY

10018.

Cutting

And

Welding

Processes,

NFPA

Standard

51

B,

from

National

Fire

Protection

Association,

Batterymarch

Park,

Quincy,

MA

02269.

IL~c

CYLINDERS

can

explode

if

damaged.

Shielding

gas

cylinders

contain

gas

under

high

pressure.

If

damaged,

a

cylinder

can

explode.

Since

gas

cylinders

are

normally

part

of

the

welding

process,

be

sure

to

treat

them

carefully.

Protect

compressed

gas

cylinders

from

excessive

heat,

mechanical

shocks,

and

arcs.

2.

Install

and

secure

cylinders

in

an

upright

position

by

chaining

them

to

a

stationary

support

or

equipment

cylinder

rack

to

prevent

fallingortipping.

3.

Keep

cylinders

away

from

any

welding

or

other

electrical

circuits.

4.

Never

allow

a

welding

electrode

to

touch

any

cylinder.

5.

Use

only

correct

shielding

gas

cylinders,

regulators,

hoses,

and

fittings

designed

for

the

specific

application;

maintain

them

and

associated

parts

in

good

condition.

6.

Turn

face

away

from

valve

outlet

when

opening

cylinder

valve.

7.

Keep

protective

cap

in

place

over

valve

except

when

cylinder

is

in

use

or

connected

for

use.

8.

Read

and

follow

instructions

on

compressed

gas

cylinders.

associated

equipment,

and

CGA

publication

P-i

listed

in

Safety

Standards.

a

WARNING

ENGINE

EXHAUST

GASES

can

kill.

Engines

produce

harmful

exhaust

gases.

ENGINE

FUEL

can

cause

fire

or

explosion.

Engine

fuel

is

highly

flammable.

SPARKS

can

cause

BATTERY

GASES

1.

Always

wear

a

face

shield

when

working

on

a

battery.

TO

EXPLODE;

BATTERY

ACID

can

2.

Stop

engine

before

disconnecting

or

connecting

battery

burn

eyes

and

skin,

cables.

Batteries

contain

acid

and

generate

explosive

gases.

3.

4.

5.

Do

not

allow

tools

to

cause

sparks

when

working

on

a

battery.

Do

not

use

welder

to

charge

batteries

or

iump

start

vehicles.

Observe

correct

polarity

(+

and

)

on

batteries.

4

~

.

(.~

~

~

STEAM

AND

COOLANT

can

skin.

The

coolant

in

the

under

pressure.

PRESSURIZED

burn

face,

eyes,

radiator

can

be

very

h

HOT

and

ot

and

1.

2.

3.

Do

not

remove

radiator

cap

when

engine

is

hot.

Allow

engine

to

cool.

Wear

gloves

and

put

a

rag

over

cap

area

when

removing

cap.

Allow

pressure

to

escape

before

completely

removing

cap.

PRINCIPAL

SAFETY

STANDARDS

Sri

9/92

Page 10

Page 11

TABLE

OF

CONTENTS

SECTION

1

-

SAFETY

SIGNAL

WORDS

.

SECTION

2

SPECIFICATIONS

2-1.

Volt-Ampere

Curves

2-2.

Duty

Cycle

2-3.

Fuel

Consumption

2-4.

DC

Auxiliary

Power

Curve

SECTION

3INSTALLATION

3-1.

Selecting

A

Location

And

Moving

Welding

Generator

3-2.

Engine

Prestart

Checks

3-3.

Grounding

The

Generator

Auxiliary

Power

System

3-4.

Connecting

To

Weld

Output

Terminals

SECTION

4OPERATING

THE

WELDING

GENERATOR

SECTION

5

OPERATING

AUXILIARY

EOUIPMENT

5-1.

Auxiliary

Power

DC

Receptacle

5-2.

Auxiliary

Equipment

Operation

1

11

12

13

13

14

14

15

16

22334566

7

10

10

SECTION

6

MAINTENANCE

&

TROUBLESHOOTING

6-1.

Routine

Maintenance

6-2.

Changing

Engine

Oil

6-3.

Adjusting

Engine

Speed

6-4.

Air

Cleaner

Service

6-5.

Clean

Air

Intake

And

Cooling

Areas

6-6.

Drive

Belt

Adjustment

And

Replacement

6-7.

Overload

Protection

6-8.

Troubleshooting

SECTION

7

ELECTRICAL

DIAGRAMS

SECTION

8-

WELDING

METHODS

&

TROUBLESHOOTING

8-1.

Shielded

Metal

Arc

Welding

(SMAW)

8-2.

Welding

Troubleshooting

SECTION

9

PARTS

LIST

Figure

9-1.

Main

Assembly

Figure

9-2.

Panel,

Front

w/Components

Figure

9-3.

Panel,

Control

w/Components

18

20

25

28

31

32

OM.160

518

3)93

Page 12

Page 13

SECTION

1

SAFETY

SIGNAL

WORDS

Read

all

safety

messages

throughout

this

manual.

Obey

all

safety

messages

to

avoid

injury.

Learn

the

meaning

of

WARNING

and

CAUTION.

Figure

1-1.

Safety

Information

SECTION

2

SPECIFICATIONS

Table

2-1.

Welding

Generator

rnodl.1

2/93

1

2

2

\

a

CAUTION

/

;

3

_______________

______________

ELECTRIC

SHOCK

can

kill

MOVING

PARTS

can

injure.

L~

I

Disconnect

input

power

betore~

~

Keep

all

panels

and

covers

closed

I

I

Do

not

touch

live

electrical

parts.

Keep

away

from

moving

parts,

I

installingorservicing.

when

operating.

I

5

READ

SAFETY

BLOCKS

at

start

of

6

Section

3-1

before

proceeding

7H

NOTE

~

1

Safety

Alert

Symbol

2

Signal

Word

WARNING

means

possible

death

or

serious

injury

can

happen.

CAUTION

means

possible

minor

injury

or

equipment

damage

can

happen.

3

Statement

Of

Hazard

And

Result

4

Safety

Instructions

To

Avoid

Hazard

5

Hazard

Symbol

(If

Available)

6

Safety

Banner

Read

safety

blocks

for

each

sym

bol

shown.

7

NOTE

Special

instructions

for

best

oper

ation

not

related

to

safety.

Turn

Off

switch

when

using

high

frequency.

Specification

TypeOfOutput

Rated

Weld

Output

Amperage

Range

Maximum

Open-Circuit

Voltage

Welding

Process

Description

Auxiliary

Power

Rating

Engine

Engine

Speed

(No

Load)

Fuel

Tank

Capacity

Engine

Oil

Capacity

Drive

Belt

Size

Overall

Dimensions

Weight

Options

Constant

Current/Direct

Current

(CC/DC)

90

Amperes,

25

Volts

DC

At

60%

Duty

Cycle

(See

Section

2-2)

40

To

100

A

75

Volts

DC

(See

Section

2-1)

Shielded

Metal

Arc

Welding

(SMAW);

Flux

Cored

Arc

Welding

(FCAW)

And

Gas

Tungsten

Arc

Welding

(GTAW)

Possible

With

Appropriate

Process

Options

1.2

kW,

120

Volts

DC,

10

Amperes

Kohler

CH5+

Air-Cooled,

One-Cylinder,

Four-Cycle

Gasoline

Engine

1800

rpm

Idle

Speed;

4150

rpm

Weld

And

Power

Speed

2.3

U.S.

gal

(8.7L)

22.4

oz

(0.66L)

1/2

x

.343x32.3

Cogged

See

Figure

3-2

Net:

101

lb

(46

kg);

Ship:

113

lb

(51

kg)

See

Rear

Cover

OM-160

518

Page

1

Page 14

Page 15

2-1.

Volt-Ampere

Curves

Figure

2-1.

Volt-Ampere

Curves

2-2.

Duty

Cycle

a

CAUTION

300

-

250

-

200

U)

150

w

a

<

100

.

75

.

Figure

2-2.

Duty

Cycle

Chart

Cl)

0

>

0

100

90

80

70

60

50

40

30

20

10

0

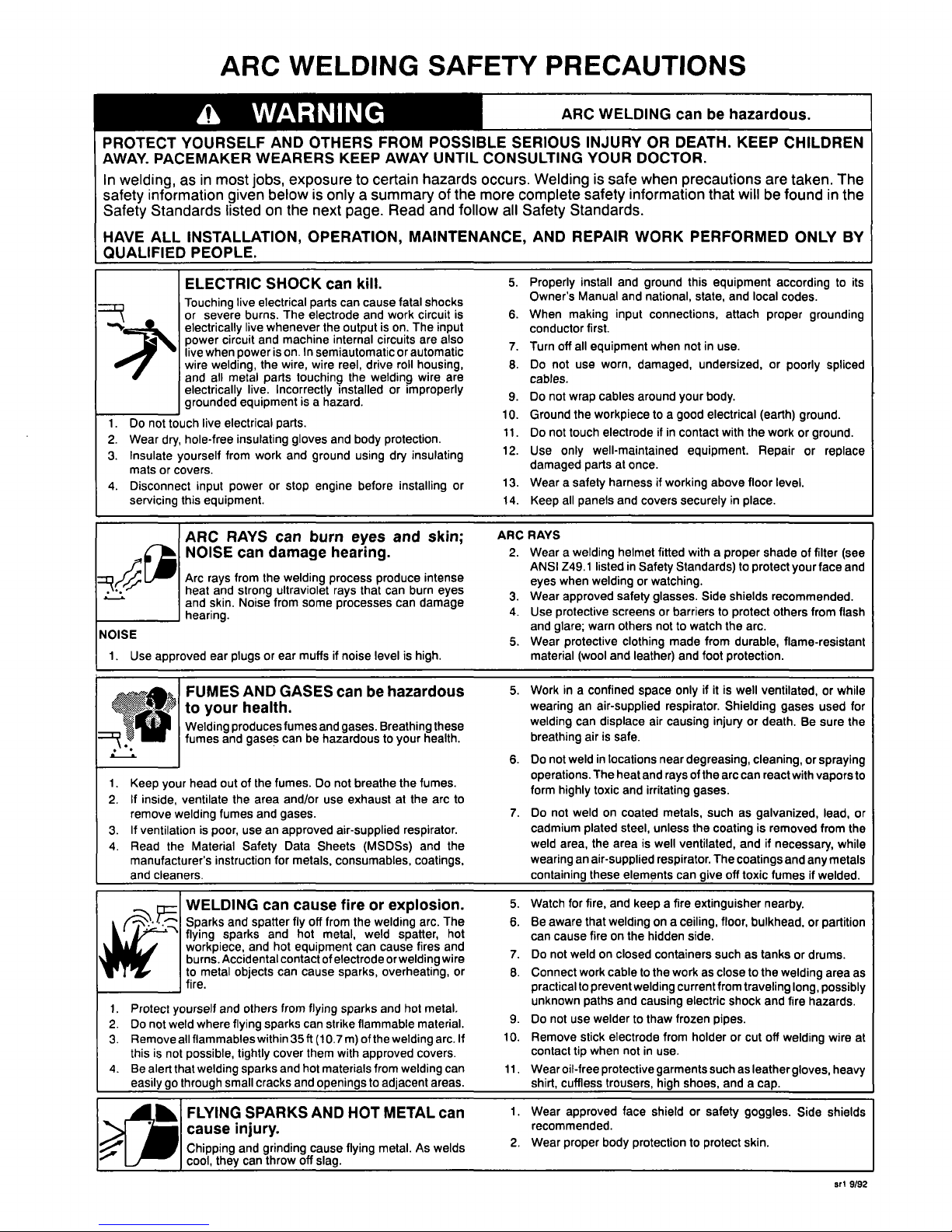

The

volt-ampere

curves

show

the

minimum

and

maximum

voltage

and

amperage

output

capabilities

of

the

welding

generator.

Curves

of

other

settings

fall

between

the

curves

shown.

rsDl.1

10/91

SB-152

541

0

25

50

75

100

125

150

DC

AMPERES

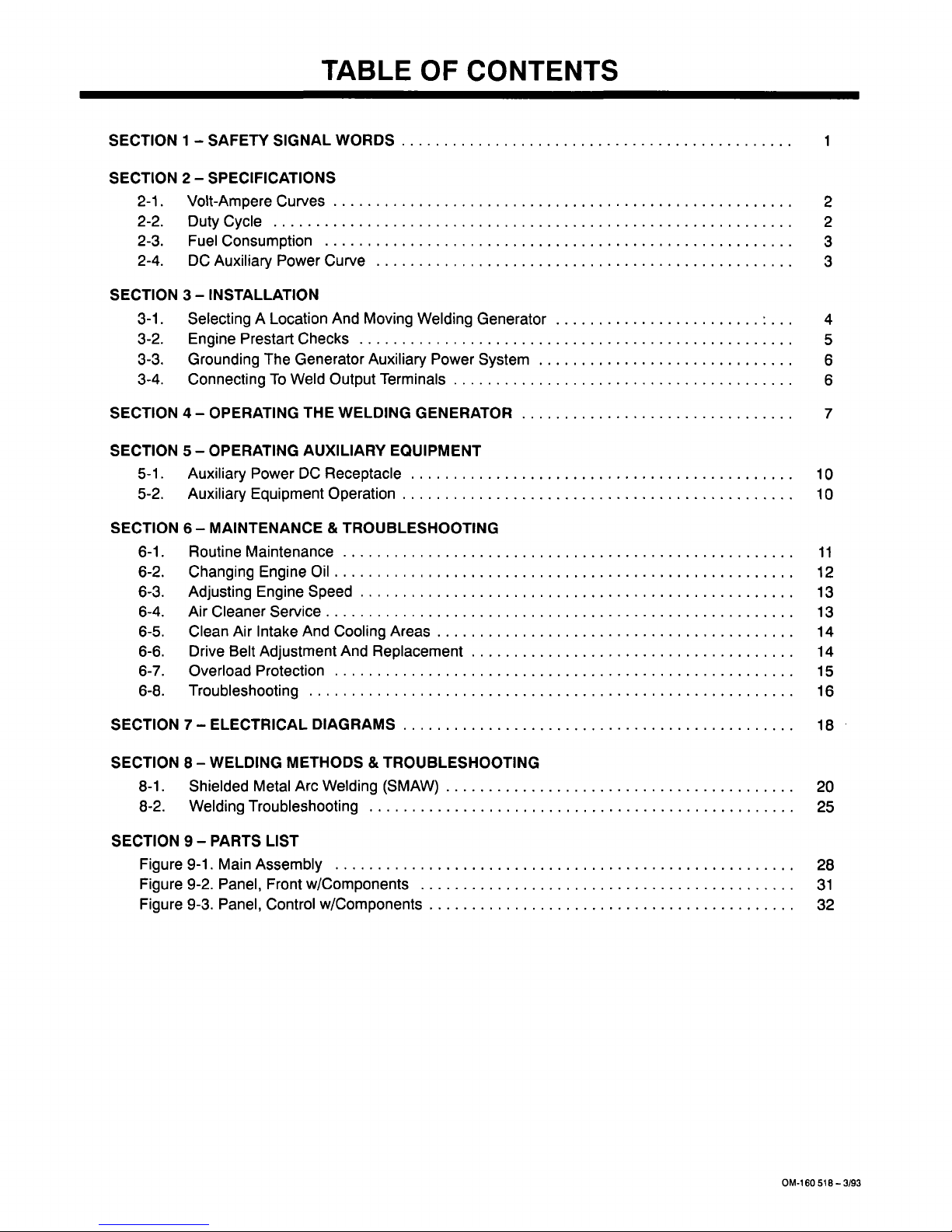

EXCEEDING

DUTY

CYCLE

RATINGS

will

damage

unit.

Do

not

exceed

indicated

duty

cycles.

warn7.1

2/92

This

unit

is

rated

at

60%

duty

cycle

allowing

welding

6

minutes

out

of

every

10

minutes.

RATED

OUTPUT

~......,

50-

---

--

10

15

20

25

30

40

50

60

7080

100

Duty

cycle

is

how

long

the

unit

can

operate

within

a

ten

minute

period

without

causing

overheating

or

damage.

%

DUTY

CYCLE

sbl.2

10/91

SB-152

540

OM-160

518

Page

2

Page 16

Page 17

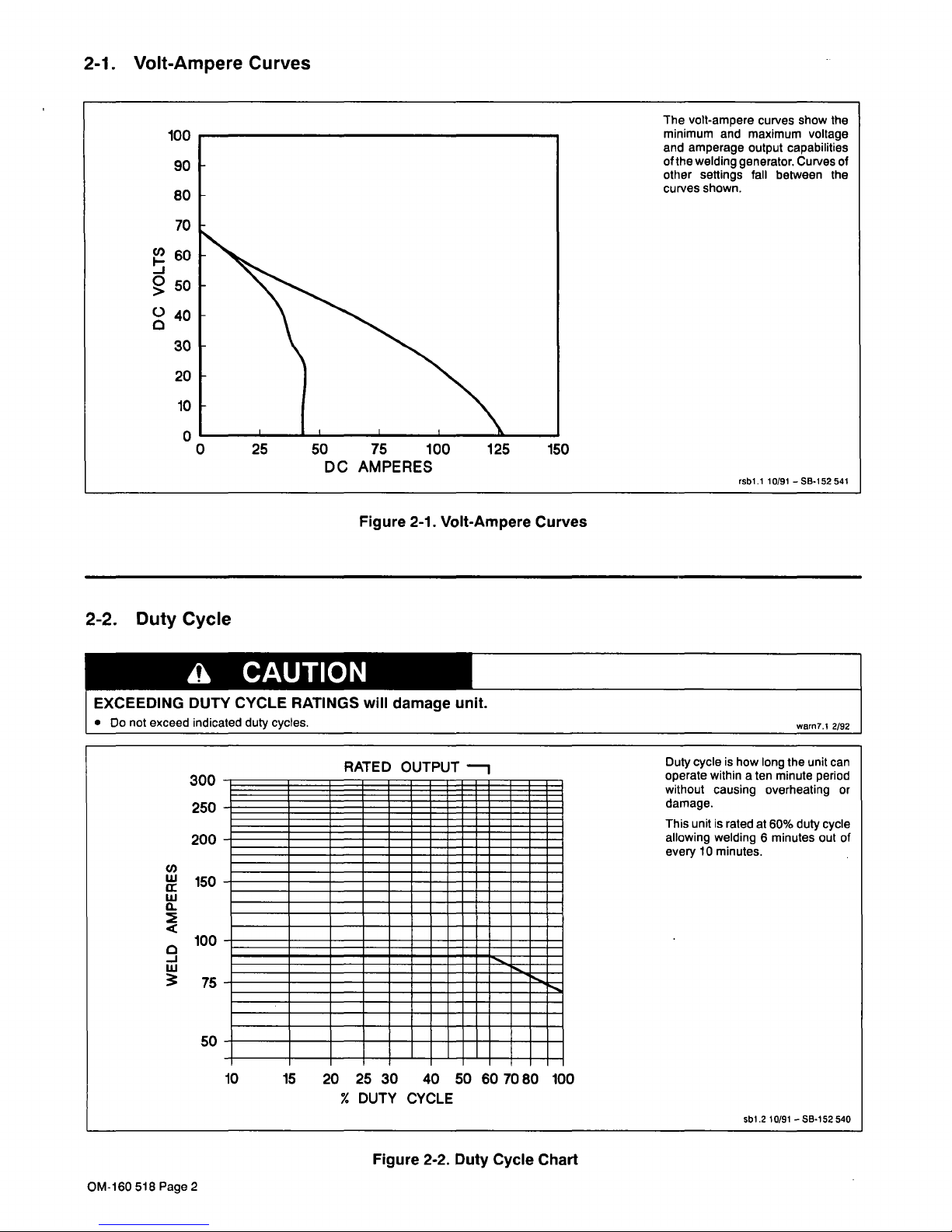

2-3.

Fuel

Consumption

The

fuel

consumption

curve

shows

typical

fuel

use

under

weld

or

pow

er

loads.

~

-J

_j

ci,

w

I-

Q~

ci

1.89

0.42

0.50

1

.66

0.37

0.44

~

1.42

0.31

0.38

1

.18

0.26

0.31

DC

AUX

POWER

0.95

0.21

0.25

0.71

0.16

0.19

0.47

0.10

0.12

-IDLE

0.23

0.05

0.06

0

0

15

30

45

60

75

90

DC

WELD

AMPERES

(25

VOLTS)

0.2

0.4

0.6

0.8

1.0

1.2

DC

POWER

KW

rsb2.I

10/91SB-153

250

Figure

2-3.

Fuel

Consumption

Curve

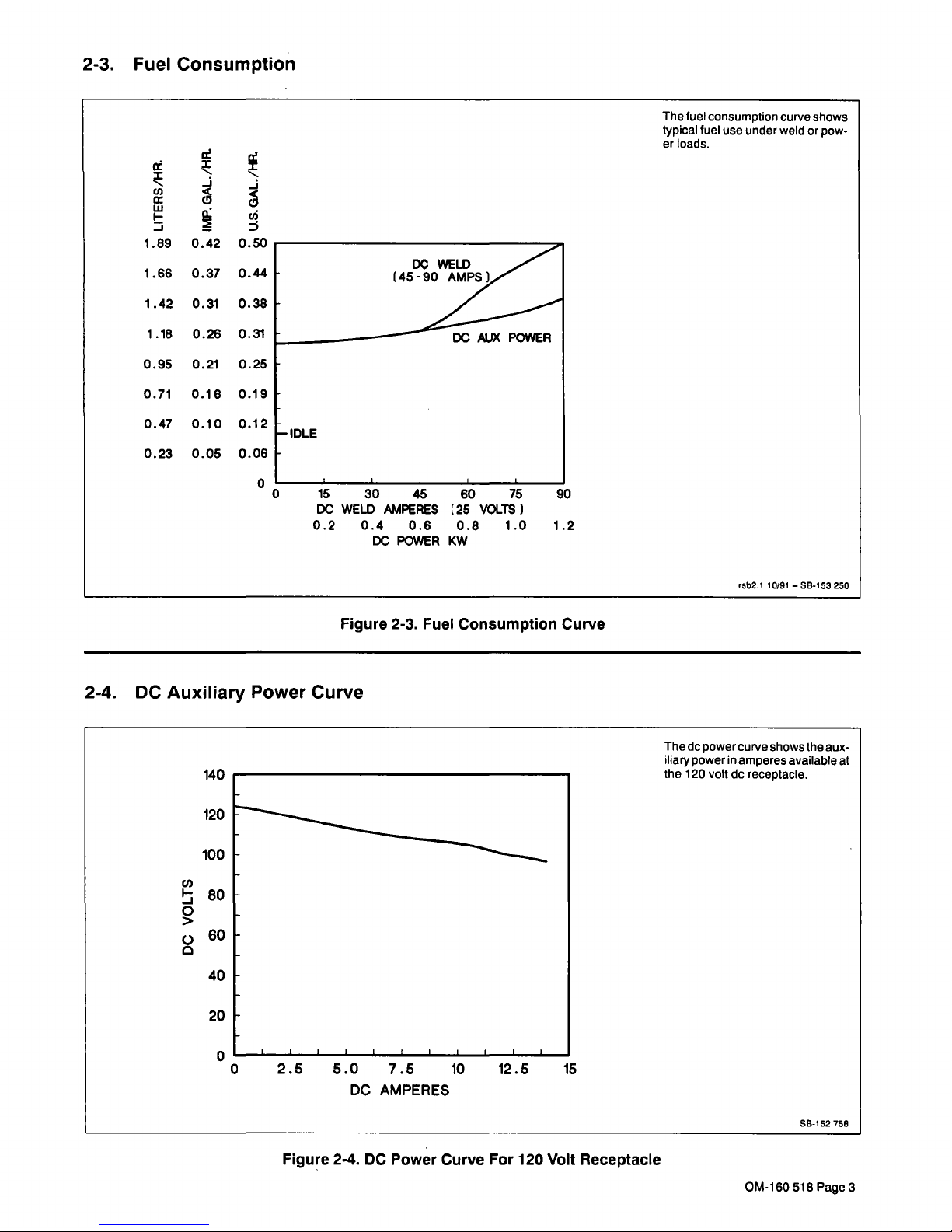

2-4.

DC

Auxiliary

Power

Curve

The

dc

power

curve

shows

the

aux

iliary

power

in

amperes

available

at

140

the

120

volt

dc

receptacle.

~80

0

>

Q60

40

20

0

0

2.5

5.0

7.5

10

12.5

15

DC

AMPERES

SB.152

758

Figure

2-4.

DC

Power

Curve

For

120

Volt

Receptacle

OM-160

518

Page

3

Page 18

Page 19

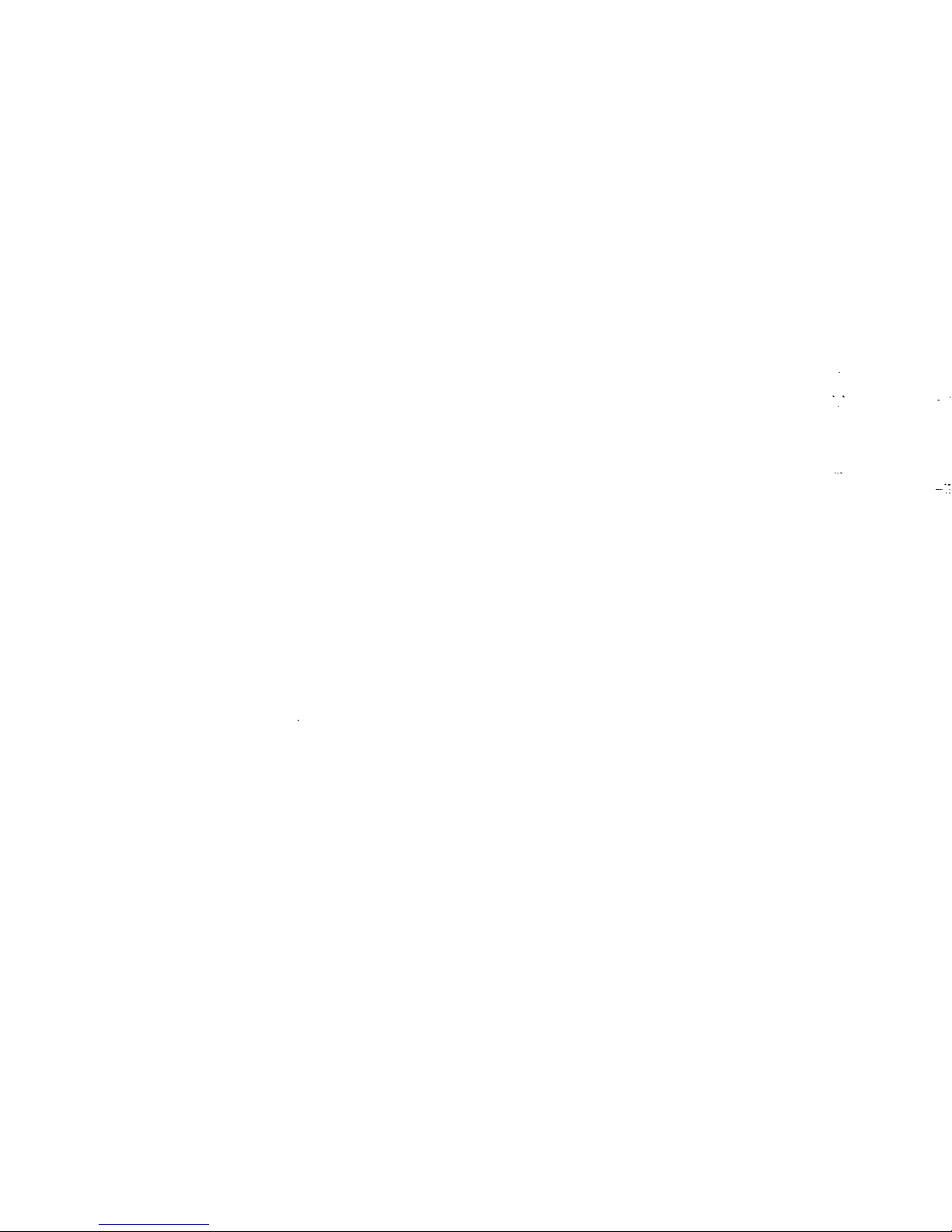

SECTION

3INSTALLATION

3-1.

Selecting

A

Location

And

Moving

Welding

Generator

a

WARNING

ENGINE

EXHAUST

GASES

can

kill.

Do

not

breathe

exhaust

fumes.

Use

in

open,

well-ventilated

areas,

or

vent

exhaust

outside

and

away

from

building

air

intakes.

ENGINE

EXHAUST

SPARKS

can

cause

fire.

Use

only

U.S.

Forestry

Department

approved

spark

arrestor

and

comply

with

all

local,

state,

and

federal

laws.

A

spark

arrestor

is

mandatory

in

all

National

Forests

and

in

grass,

brush,

or

forest

covered

lands

in

California,

Oregon,

and

Washington.

Check

with

state

and

local

authorities

in

other

areas.

Properly

maintain

the

spark

arrestor.

Stop

engine

and

allow

exhaust

system

to

cool

down

before

servicing

spark

arrestor.

Service

spark

arrestor

away

from

flammables.

HOT

ENGINE

EXHAUST

AND

EXHAUST

PIPE

can

cause

fires.

Keep

exhaust

and

pipe

away

from

flammables.

FALLING

EQUIPMENT

can

cause

serious

personal

injury

and

equipment

damage.

Lift

Unit

at

handlesonends

of

base.

Have

two

persons

of

adequate

strength

lift

unit.

Move

unit

with

hand

cart

or

similar

device

of

adequate

capacity.

It

using

a

fork

lift

vehicle,

secure

unit

on

a

proper

skid

before

transporting.

rwarnl.1

12/91

Keep

unit

level

tilting

can

cause

fuel

and

oil

leaks

and

possible

fire

or

engine

damage.

2

2

1

18

in

(457

mm)

Open

Space

On

All

Sides

2

Lifting

Handles

Lift

unit

with

hands

positioned

in

centerof

handles.

Obtain

help

to

lift

and

transport

unit.

3

Exhaust

Outlet

Keep

flammables

away

from

ex

haust

outlet.

Figure

3-1.

Location

And

Movement

Of

The

Welding

Generator

5T-161

4771

ST-151

556/

Ref.

5T.161

478

~<

Inches

Millimeters

A

B

C

19

14-5/8

28-3/4

483

371

730

C

>.-.~<

Figure

3-2.

Overall

Dimensions

OM-160

518

Page

4

Page 20

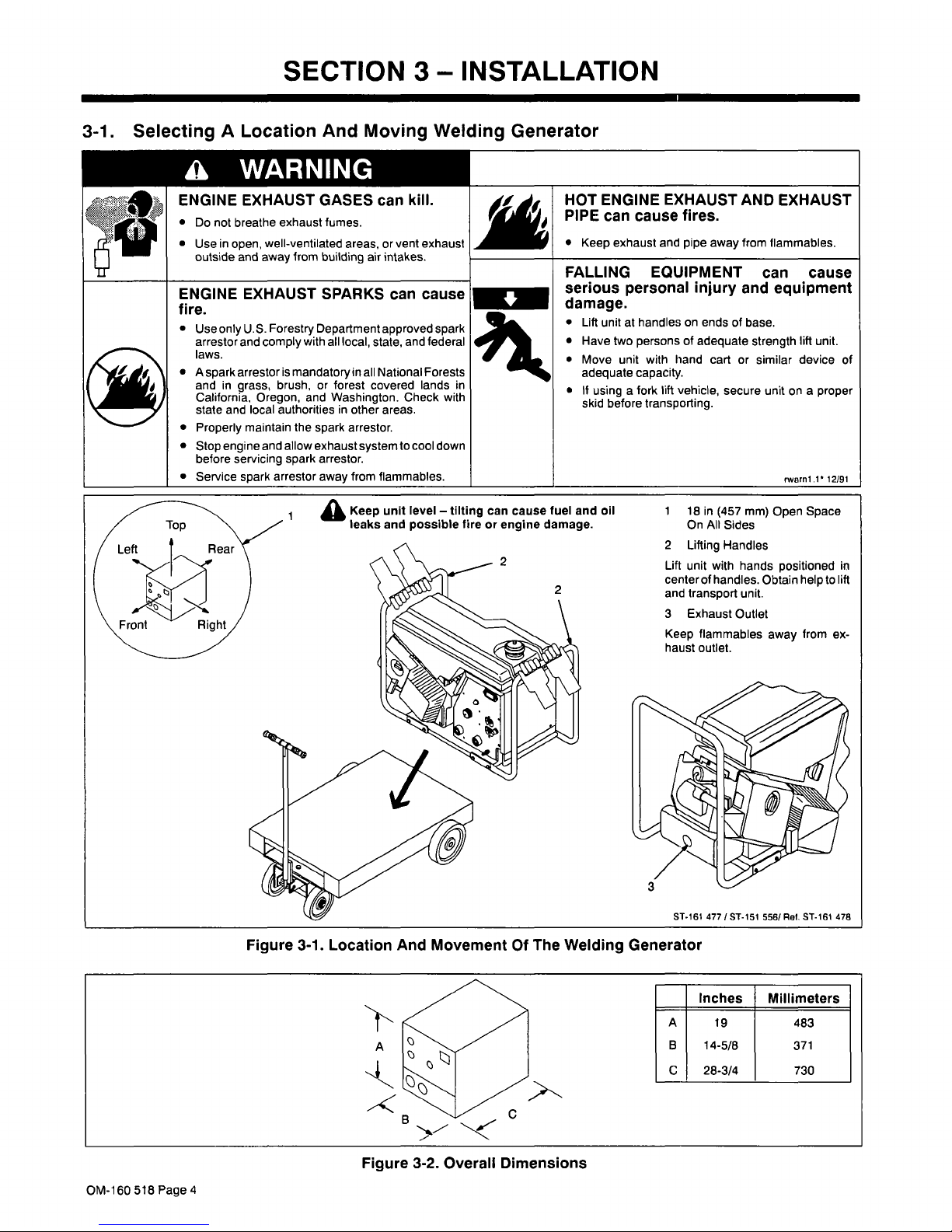

Page 21

200

200

Maximum

tilting

angles

for

proper

lubrication.

Keep

fuel

cap

at

highest

point

when

tilted.

Do

not

let

fuel

leak

from

cap

during

tilting.

S-0702

Do

not

overfill

fuel

room

for

expansion

a

tank

leave

nd

tilting

with

out

causing

leaks.

Figure

3-3.

Maximum

Welding

Generator

Tilt

Angles

3-2.

Engine

Prestart

Checks

a

WARNING

.~

ENGINE

FUEL

can

cause

fire

or

explosion.

Stop

engine

before

fueling.

Do

not

fuel

while

smoking

or

near

sparks

or

flames.

Do

not

overfill

tank;

clean

up

any

spilled

fuel.

REMOVE

FUEL

CAP

SLOWLY;

FUEL

SPRAY

may

cause

injury;

FUEL

may

be

under

pressure.

Rotate

fuel

cap

slowly

and

wait

until

hissing

stops

before

removing

cap.

rwarn3

1

9191

Check

all

fluids

daily.

Engine

must

be

cold

and

on

a

level

surface.

Add

fresh

fuel

before

starting

engine

the

first

time

(see

Figure

6-1).

I

Fuel

Cap

Fill

fuel

tanktowithin

1

in

(25

mm)

of

bottomoffiller

neck

to

provide

space

for

expansion.

2

Oil

Fill

Cap/Dipstick

3

Oil

Fill

Tube

Remove

dipstick

and

wipe

off

oil.

Reinsert

dipstick

in

tube

so

oil

fill

cap

rests

on

tube

collar.

Do

not

thread

cap

onto

tube.

Remove

dip

stick

and

check

oil

level.

If

oil

is

not

up

to

full

mark,

add

oil

(see

Figure

6-1).

Add

4

oz

(0.12

L)

oil

to

raise

oil

level

on

dipstick

from

L

to

F.

rsb4,1

11/92ST-16l

479

Figure

3-4.

Checking

Fluid

Levels

OM-160

518

Page

5

Page 22

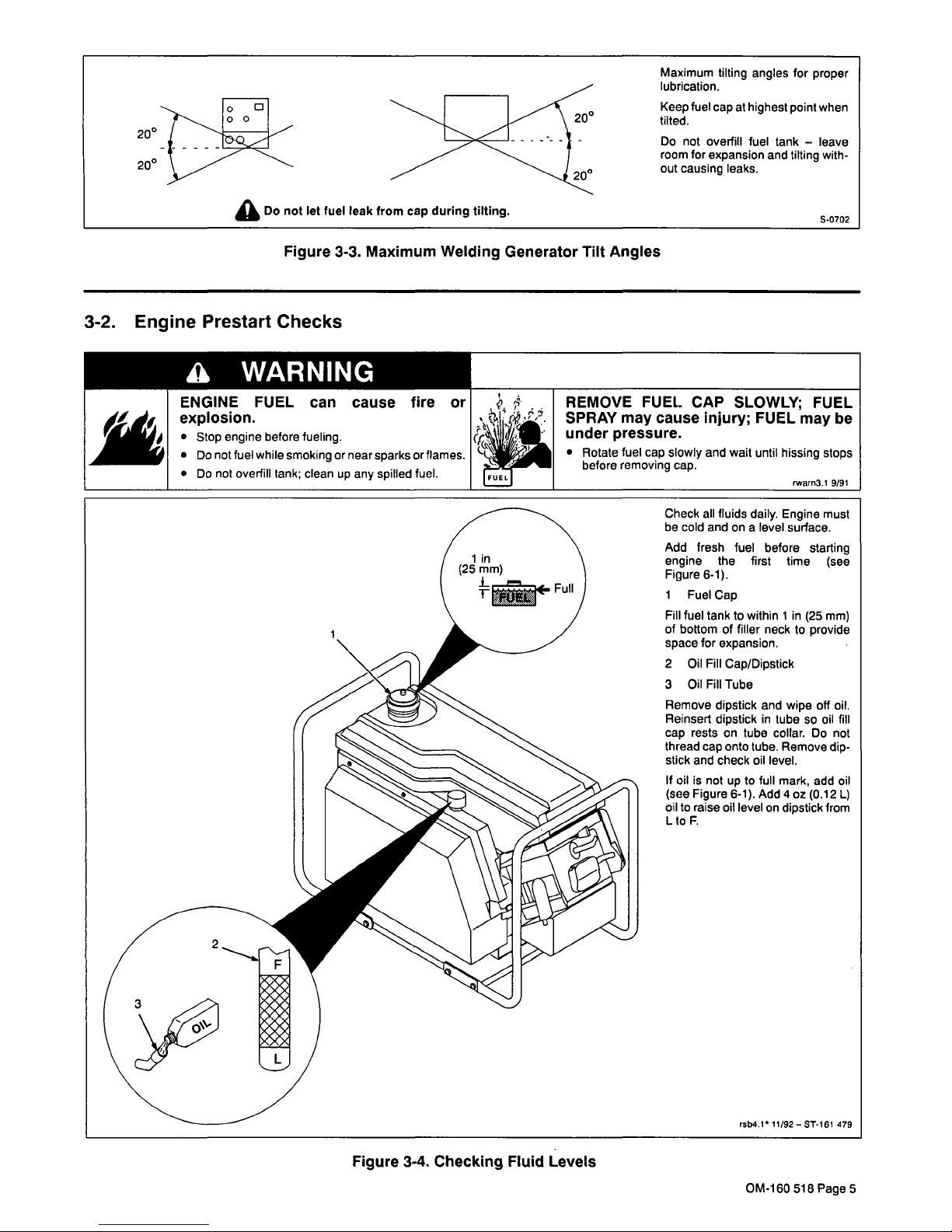

Page 23

3-3.

Grounding

The

Generator

Auxiliary

Power

System

3-4.

Connecting

To

Weld

Output

Terminals

a

WARNING

~-

1

Equipment

Grounding

Terminal

The

generator

auxiliary

power

neutralisconnected

to

the

machine

frame.

Tools

Needed:

-.~

rsb5.1

1/93

Ret.

ST-i

~7

863-A/Ret.

ST-I

81

479

Figure

3-5.

Equipment

Grounding

Connection

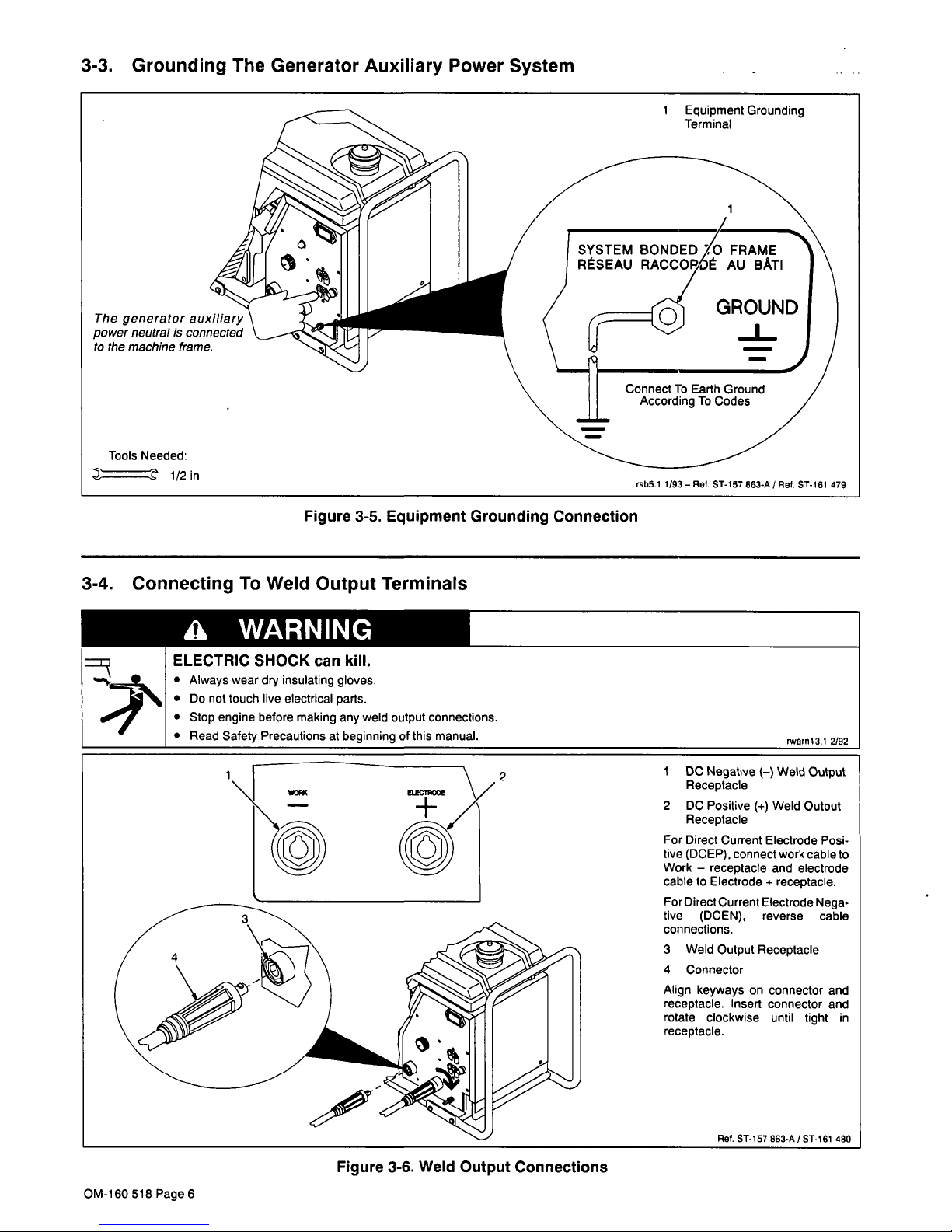

.

.~

ELECTRIC

SHOCK

can

kill.

Always

wear

dry

insulating

gloves.

Do

not

touch

live

electrical

parts.

Stop

engine

before

making

any

weld

output

connections.

Read

Safety

Precautions

at

beginning

of

this

manual.

rwarnl3,l

2/92

1

~

~

2

~

I

DC

Negative

()

Weld

Output

Receptacle

2

DC

Positive

(+)

Weld

Output

Receptacle

For

Direct

Current

Electrode

Posi

tive

(DCEP).

connect

work

cable

to

Work

receptacle

and

electrode

cable

to

Electrode

+

receptacle.

For

Direct

Current

Electrode

Nega

tive

(DCEN),

reverse

cable

connections.

3

Weld

Output

Receptacle

4

Connector

Align

keyways

on

connector

and

receptacle.

Insert

connector

and

rotate

clockwise

until

tight

in

receptacle.

Figure

3-6.

Weld

Output

Connections

Ret.

ST-I57863-A/ST-161

480

OM-160

518

Page

6

Page 24

Page 25

SECTION

4-

OPERATING

THE

WELDING

GENERATOR

a

WARNING

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Always

wear

dry

insulating

gloves.

Insulate

yourself

from

work

and

ground.

Stop

engine

before

installingorservicing.

Keep

all

panels

and

covers

securely

in

place

WELDING

can

cause

fire

or

explosion.

Do

not

weld

near

flammable

material.

Watch

for

fire;

keep

extinguisher

nearby.

Do

not

locate

unit

over

combustible

surfaces.

Do

not

weldonclosed

containers.

Allow

work

and

equipment

to

cool

before

handling.

ARC

RAYS

can

burn

eyes

and

skin;

NOISE

can

damage

hearing.

Wear

welding

helmet

with

correct

shade

of

filter.

Wear

correct

eye,

ear,

and

body

protection

FUMES

AND

GASES

can

be

hazardous.

Keep

your

head

out

of

the

fumes.

Ventilate

area,

or

use

breathing

device.

Read

Material

Safety

Data

Sheets

(MSDS5)

and

manufacturers

instructions

for

material

used.

Figure

4-2.

Safety

Equipment

E

NGINE

EXHAUST

GASES

can

kill.

Do

not

breathe

exhaust

fumes.

Use

in

open,

well-ventilated

areas,

or

vent

exhaust

outside

and

away

from

any

building

air

intakes.

ENGINE

FUEL

can

cause

fire

or

explo

sion.

!

Stop

engine

before

fueling.

Do

not

fuel

while

smoking

or

near

sparks

or

flames.

Do

not

overfill

tank;

clean

up

any

spilled

fuel.

=~!t?

,~

~

MOVING

PARTS

can

cause

injury.

Keep

away

from

moving

parts

such

as

fans,

belts.

and

rotors.

Keep

all

doors,

panels,

covers,

and

guards

closed

and

securely

in

place.

I

\

~_.

MAGNETIC

FIELDS

FROM

HIGH

CUR

RENTS

can

affect

pacemaker

operation.

Pacemaker

wearers

keep

away.

Wearers

should

consult

their

doctor

before

going

near

any

welding

operations.

See

Safety

Precautions

at

beginning

of

manual

for

ba

sic

welding

safety

information.

~

110/91

4

1

Amperage

Control

2

Engine

Hour

Meter

(Optional)

3

Low

Oil

Level

Light

(Optional)

4

Throttle

Control

Lever

6

5

Choke

Control

6

Fuel

Shutoff

Valve

ST-161

477/Rel.ST-161

479

Figure

4-1.

Controls

2

3

4

1

Insulating

Gloves

2

Safety

Glasses

With

Side

_______

Shields

3

Welding

Helmet

~LE~1

U

welding

helmet

or

hand

shield

with

_______

______

4

Hand

Shield

Wear

dry

insulating

gloves,

safety

glasses

with

side

shields,

and

a

a

correct

shadeoffilter

(see

ANSI

Z49.1).

sb3.110/91

OM-160

518

Page

7

Page 26

Page 27

1

Work

Clamp

Tools

Needed:

Connect

work

clamp

to

a

clean,

paint-free

location

on

workpiece,

as

close

to

weld

area as

possible.

Use

wire

brush

or

sandpaper

to

clean

metal

at

weld

joint

area.

Use

chipping

hammer

to

remove

slag

after

welding.

sb4.1

2/93

Figure

4-3.

Work

Clamp

1

Amperage

Control

Use

control

to

select

weld

amper

age.

Engine

must

be

running

at

weld/power

speed

to

attain

full

weld

output.

Control

may

be

ad

justed

while

welding.

1

2

Electrode

Scale

Scale

shows

recommended

elec

trode

diameter

for

weld

amperage.

3

Amperage

Scale

Numbers

in

scale

are

welding

amperes.

2

3

Ret.

ST-157

883-A

Figure

4-4.

Amperage

Control

1

Fuel

Shutoff

Valve

Open

valve

before

starting

engine.

Close

valve

when

unit

is

not

in

use

or

during

transport.

2

Throttle

Control

Lever

Use

lever

to

start

and

stop

engine

and

select

engine

speed.

To

start

engine,

move

levertoRun.

3

Choke

Control

Lever

Use

lever

to

regulate

carburetor

air/fuel

mixture.

Move

choke

lever

to

right

(choke

on)

if

starting

a

cold

engine.Ifstarting

a

warm

engine,

move

choke

levertoleft

(choke

off).

4

Starter

Handle

Pull

starter

handle

with

quick,

smooth

motion.

After

engine

warms,

move

choke

levertoleft.

Keep

throttle

lever

in

Run

for

weld/

auxiliary

power.

Move

lever

to

Idle

for

idle

speed.

Stop

unit

by

moving

lever

to

Stop.

S-0690

/

Ret.

ST-161

478

Figure

4-5.

Engine

Controls

OM-160

518

Page

8

Page 28

Page 29

1

Engine

Hour

Meter

Use

meter

to

check

total

operating

6

hours

(see

Section

6).

This

meter

op

erates

only

when

engine

is

running.

rsb6.1

2/92

Figure

4-6.

Engine

Hour

Meter

(Optional)

I

Low

Oil

Level

Light

Q~

1

Light

flickers

when

starter

handle

is

pulled

if

engine

has

stopped

due

to

automatic

low

oil

level

shutdown.

LOW

OIL

Engine

does

not

start

until

sufficient

oil

is

added

to

engine.

Fill

engine

with

oil

to

F

mark

on

dip

stick

(see

Figure

3-4).

Ref.

ST-157

863

Figure

4-7.

Automatic

Low

Oil

Shutdown

(Optional)

Install

&

Connect

)

EquIpment~)

Electrode

Personal

Safety

I

I

Set

ControI~~)

Start

Eng~~Uia~)__..)

Select

Put

On

________________

________________

Equipment

~~JJ

________________

_____

_____

_____ _____

_____

~g~pmen~,~

~-

)

Insert

Begin

Weldin~

Electrode

Into_Holder

_________________

Figure

4-8.

Sequence

Of

Shielded

Metal

Arc

Welding

(SMAW)

rSbO.1

9/92

OM-160

518

Page

9

Page 30

Page 31

SECTION

5-

OPERATING

AUXILIARY

EQUIPMENT

a

WARNING

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Stop

engine

before

making

internal

inspection

or

reconnection.

Ground

generator

according

to

all

applicable

national,

state,

and

local

codes.

Connect

equipment

grounding

terminal

to

a

proper

earth

ground.

Do

not

connect

to

any

electrical

distribution

system

normally

supplied

by

utility

power.

ELECTRIC

SPARKS

can

cause

fire.

If

using

auxiliary

power

only

and

not

welding,

disconnect

both

welding

cables

to

prevent

live

electrode

from

causing

electric

shock

and

fire

hazards.

Watch

for

fire.

Keep

a

fire

extinguisher

nearby,

and

know

how

to

use

it.

The

weld

output

terminals

are

electrically

energized

when

the

engine

is

running.

DC

AUXILIARY

POWER

electrical

equipment

incorrect

operation.

Use

DC

output

only

for

incandescent

lights

and

tools

rated

for

DC.

Do

not

use

DC

to

power

AC

motors,

transformer

equipment,

or

induction

motors.

Essentially

all

hand

tools

are

powered

by

universal

motors.

However,

the

switches

on

inexpensive/light

duty

tools

may

be

damaged

by

DC

power,

and

variable

speed

tools

will

run

only

at

full

speed

on

DC.

This

unit

provides

1200

watts

of

direct

current

(DC)

auxiliary

power.

DC

power

is

suitable

for

incandescent

lights

and

portable

power

tools

with

115or120

volt

AC/DC

or

DC

ratings.

This

power

must

not

be

used

to

power

any

AC-only

rated

equipment.

rwarn8.1

10/92

Figure

5-1.

Auxiliary

Power

DC

Receptacle

And

Circuit

Protection

5-2.

Auxiliary

Equipment

Operation

)

)

lnstat&Co~n~ct~)

)Turn

OnA

liarY))

Begin

Ope~on

Figure

5-2.

SequenceOfAuxiliary

Equipment

Operation

,~-.

~

X

~

MOVING

PARTS

can

cause

serious

injury.

Keep

away

from

moving

parts

such

as

fans,

belts,

and

rotors.

Keep

all

doors,

panels,

covers,

and

guards

closed

and

securely

in

place.

can

damage

and

cause

cii

0

5-1.

Auxiliary

Power

DC

Receptacle

1

120V

1OA

DC

Receptacle

Maximum

output

at

RUN

speed

is

1.2

kW.

Full

auxiliary

power

is

avail

able

only

when

not

welding.

DC

power

is

suitable

for

incandes

cent

lights

and

portable

power

tools

with

115

or

120

volt

AC/DC

or

DC

ratings.

The

switchesoninex

pensive/light

duty

tools

may

be

2

damaged

by

DC

power,

and

vari

able

speed

tools

will

run

only

at

full

speed

on

DC.

Use

DC

output

only

for

incandes

cent

lights

and

tools

rated

for

DC.

Do

not

use

DC

power

to

run

any

AC-only

rated

equipment,

AC

mo

tors,

transformer

equipment,

or

in

duction

motors.

2

lOAFuseFi

Fl

protects

generator

from

over

load

or

short

circuits

on

dc

recep

tacle.IfFl

opens,

the

generator

continues

to

run

but

there

is

no

out

put

at

the

receptacle.

Weld

output

is

still

available.

See

Section

6-7

for

fuse

replacement.

Ret.

ST.157

863-A

OM-160

518

Page

10

Page 32

Page 33

SECTION

6

MAINTENANCE

&

TROUBLESHOOTING

ELECTRIC

SHOCK

can

kill.

Do

not

touch

live

electrical

parts.

Always

wear

dry

insulating

gloves.

Insulate

yourself

from

work

and

ground.

Stop

engine

before

installing

or

servicing.

Keep

all

panels

and

covers

securely

in

place.

ENGINE

EXHAUST

GASES

can

kill.

Do

not

breathe

exhaust

fumes.

Use

in

open,

well-ventilated

areas,

or

vent

exhaust

outside

and

away

from

any

building

air

intakes.

ENGINE

FUEL

can

cause

fire

or

explo

sion.

Stop

engine

before

fueling.

Do

not

fuel

while

smoking

or

near

sparks

or

flames.

Do

not

overfill

tank;

clean

up

any

spilled

fuel

MOVING

PARTS

can

cause

injury.

Keep

hands,

loose

clothing,

and

tools

away

from

moving

parts

such

as

pulleys,

fans,

belts,

and

ro

tors.

Keep

all

doors,

panels,

covers,

and

guards

closed

and

securelyinplace.

HOT

PARTS

can

cause

severe

burns.

Allow

cooling

period

before

servicing.

Wear

protective

gloves

and

clothing

when

working

on

a

hot

engine.

Maintenancetobe

performed

onlybyqualified

per

sons.

rwarn9.I

10/91

6-1.

Routine

Maintenance

The

maintenance

label

is

located

on

the

fuel

tank

above

the

throttle

control

lever

(see

Figure

6-3).

Recommended

Oil-API

Service

Classification

SF-SG/CC-CD

Below

32F

(0C)

SAE

5W-20,

SAE

5W-30

Above

32F

(0C)

SAE

1OW-30,

SAE

1OW-40

Check

oil

daily

(4

oz.

Add

to

Full

on

dipstick)

Oil

Capacity

22.4

oz.

(0.66L)

Oil

Change

Normal

conditions

100

hours

Drive

Belt

Inspection

100

hours

See

Manual

Drive

Belt

Miller

150412

4

Spark

plug

gap

Resistor

&

Std

.030

in.

(.76

mm)

Spark

Plug

Champion

RCI2YC*

*Resistor

Spark

Plug

Mandatory

in

Canada

Air

filter

element

.

Kohler

1506306

~

Air

Filter

Service

100

hours

or

less-See

Manual

.2

Miller

067101

Fuel

grade

Regular

or

Unleaded

Fuel

Capacity

2.3

U.S.

Gal

(8.7L)

Vented

cap

at

least

87

octane

(RON

+

MON)

2

~5

Engine

RPM

... .

IDLE

-

1800

RUN

(Weld&Power)

-

4150

If

equipped

with

spark

arrestor,

inspect

and

service

per

Manual

or

supplied

instructions.

KOHLER

CH5+

ENGiNE

STOP

~

~

R~J

L$~

SPEED

CONTROL

S.146

281-A

Figure

6-1.

Maintenance

Label

a

WARNING

OM-160

518

Page

11

Page 34

Page 35

Stop

engine

before

maintaining.

Do

not

throw

away

engine

fluids

take

to

area

recycling

~-

center.

~JJ

25

Hours

ED

500

Hours

~y~

Clean

Air

Cleaner

Foam

Element

6-4~J

Check

engInes

Clearance

Valve

manual

Every200

hours

havealferna

for

brushes,

slip

rings,

bear

ings

and

optional/ow

oil

shut

down

checked

by

FactoryAu

thorized

Service

Station.

6-2.

Changing

Engine

Oil

Figure

6-2.

Maintenance

Schedule

Stop

engine.

Change

engine

oil

at

interval

listed

in

Figure

6-1.

Change

oil

while

en

gine

is

still

warm.

1

Support

Block

Use

blocks

large

enough

to

provide

room

for

oil

pan.

2

Oil

Fill

Cap/Dipstick

Remove

oil

fill

cap/dipstick

before

draining

oil.

3

Oil

Drain

Plug

Remove

plug.

Allow

enough

time

for

oiltodrain

completely.

Reinstall

plug.

4

Maintenance

Label

Fill

crankcase

with

new

oil

to

F

mark

on

dipstick.

Use

correct

type

and

grade

of

oil.

See

Figure

6-1

for

specifications.

Reinstall

oil

fill

cap/dipstick.

ST-I

61

481

Tools

Needed:

3/8

in

Figure

6-3.

Changing

Engine

Oil

OM-160

518

Page

12

Page 36

Page 37

6-3.

Adjusting

Engine

Speed

Start

and

run

engine

at

no

load.

1

Throttle

Control

Lever

Move

levertoRun.

2

Speed

Adjustment

Plate

3

Securing

Screw

Loosen

securing

screws

and

move

adjustment

plate

right

or

left

until

engine

runs

at

4150

rpm.

Tighten

screws.

4

Belt

Guard

If

engine

does

not

reach

4150rpm,

stop

engine

and

remove

belt

guard

(see

Section

6-6).

5

Speed

Adjustment

Screw

Turn

screw

out

(counterclockwise)

two

full

turns.

Reinstall

belt

guard

and

start

engine.

Move

throttle

control

lever

and

speed

adjustment

plate

left

or

right

to

adjust

engine

speed

(see

items

2

and

3).

Tighten

securing

screws

and

stop

engine.

6-4.

Air

Cleaner

Service

Figure

6-4.

Engine

Speed

Adjustment

Stop

engine.

1

Air

Cleaner

Cover

2

Retaining

Screw

Loosen

retaining

screw

and

re

move

air

cleaner

cover.

3

Wing

Nut

Remove

as

shown.

4

Foam

Element

(Precleaner)

Wash

element

in

warm

water

with

detergent.

Rinse

all

detergent

from

element

and

allow

to

air-dry.

Saturate

element

with

clean

en

gine

oil.

Squeeze

out

excess

oil.

Reinstall

element

on

paper

element.

5

Paper

Element

Replace

dirty

or

damaged

element

with

a

new

element.

Do

not

wash

dirty

element

or

clean

with

com

pressed

air.

Reinstall

air

cleaner

cover.

5T-151

839

READ

SAFETY

BLOCKS

at

start

of

Section

6

before

proceeding.

Moving

Parts

Hazard.

Have

belt

guard

in

place

before

running

engine.

Tools

Needed:

~

3/8,

9/32

in

Ref.

ST-161

482

READ

SAFETY

BLOCKS

at

start

of

Section6before

proceeding.

4

2

3

Figure

6-5.

Air

Cleaner

Maintenance

OM-160

518

Page

13

Page 38

Page 39

6-5.

Clean

Air

Intake

And

Cooling