Page 1

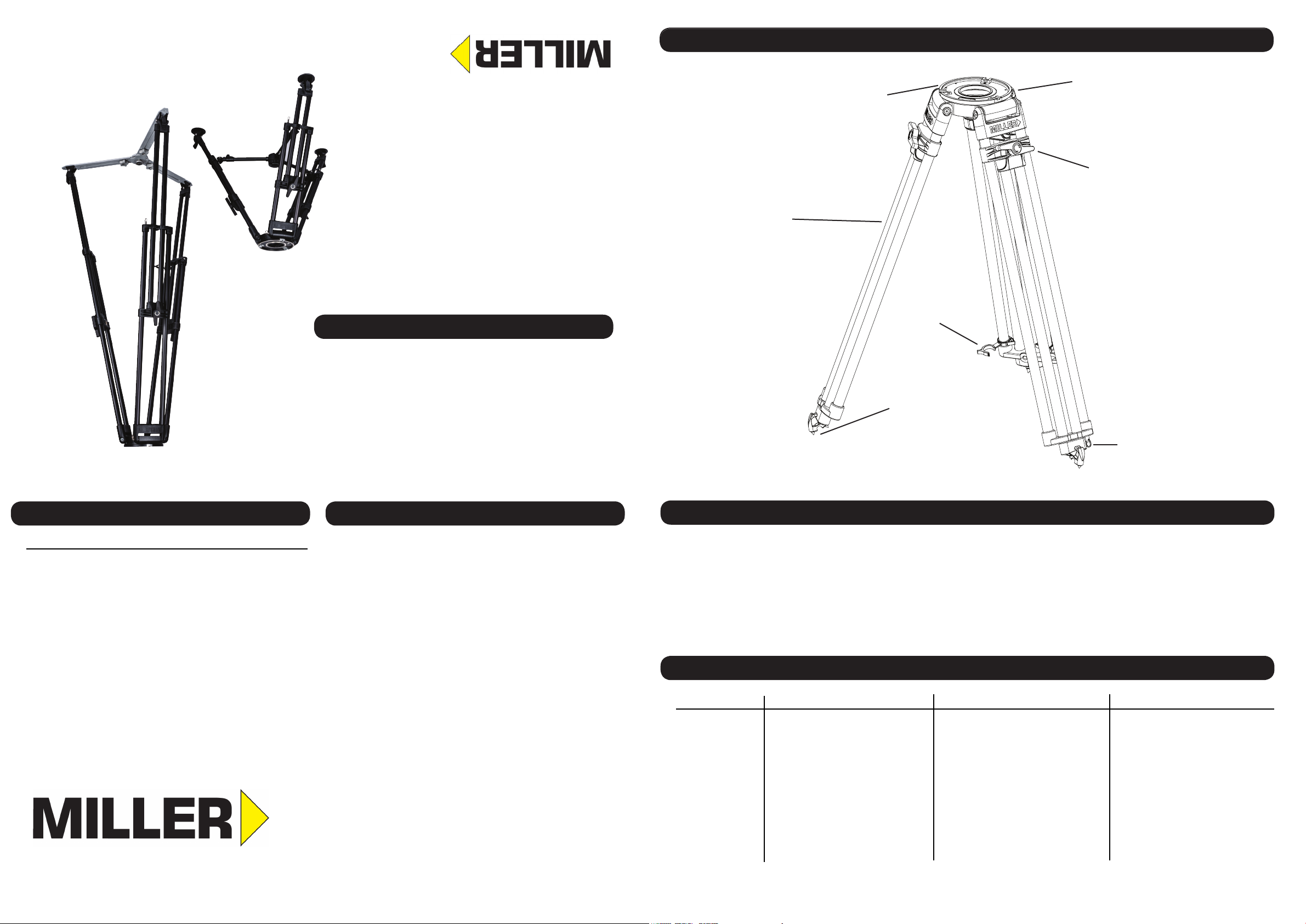

FEATURES AND CONTROLS

Mitchell base

Bubble Level (only on MB model)

#2116/G HDC 150 TALL

#2115/G HDC 150

#2114/G HDC 150 SHORT

150mm Bowl Models

#2122/G HDC 100 TALL

#2121/G HDC 100

#2120/G HDC 100 SHORT

100mm Bowl Models

#2111/G HDC MB TALL

#2110/G HDC MB

#2109/G HDC MB SHORT

Mitchell Base Models

Single stage alloy tubing

Available in:

- Short

- Standard

- Tall

Also available in

- 100mm bowl

- 150mm bowl

Leg lock lever

ACCESSORIES & COMPONENTS SERVICE, SALES & SUPPORT

Cat # Description

#2130 HDC Ground Spreader

#2132 HDC Ground Spreader Short

#478 HD Rubber Feet (set of 3)

#993 Mid Level Spreader

#3222 HD Dolly

Miller Authorised Service Agents must carry out all service and repair work.

Failure to observe this requirement may void warranty. It is advisable to

notify Miller or a MIller Authorised Service Agent if a change of perform-

ance is observed as a result of dropping or rough usage. For information

regarding sales and service of Miller products, or for your nearest Miller

representative please contact us via our website or at the following:

MILLER CAMERA SUPPORT EQUIPMENT

30 Hotham Parade

Sydney, NSW, 2064, Australia

Tel: +61 2 9439 6377

Fax: +61 2 9438 2819

Email: sales@miller.com.au

MILLER FLUID HEADS (Europe) LTD.

12A Shepperaton Business Park

Govett Avenue, Shepparton

Middlesex TW17 8BA, United Kingdom

Tel: +44 (0)1243 555 255

Fax:+44 (0)1243 555 001

Email: sales@millertripods-europe.com

MILLER CAMERA SUPPORT LLC (USA)

216 Little Falls Road (unit 15 & 16)

Cedar Grove, New Jersey, 07009, USA

Tel: (973) 857 8300

Fax: (973) 857 8188

Email: sales@millertripods.us

D9631-1 02/19

O P E R A T O R ’ S M A N U A L

HDC

INTRODUCTION

Thank you for purchasing the HDC Tripod.

The HDC tripod range is specifically built for cinematographers and outside broadcasters who demand the highest levels of stability, low torsional distortion,

even at maximum drag. The HDC range is differentiated by the mounting base, the height and the spreader type, the quick action rotary screw type leg locks

allow for maximum lock off performance without need for maintenance.

No matter where your work takes you, the HDC tripod series performs in extreme environments and terrains every time.

TECHNICAL DATA

Cat# 2109/G 2110/G 2111/G 2114/G 2115/G 2116/G 2120/G 2121/G

Base MB MB MB 150mm

Height Short Standard Tall Short Standard Tall Short Standard

Material Alloy Alloy Alloy Alloy Alloy Alloy Alloy Alloy

Maximum Load kg (lb) 95 (210) 95 (210) 95 (210) 95 (210) 95 (210) 95 (210) 95 (210) 95 (210)

Weight kg (lb) 4.8 (10.6) 5.9 (13.2) 6.4 (14.1) 5.6 (12.4) 6.2 (13.7) 4.3 (9.5) 5.4 (11.9) 6.0 (13.2)

Max Height mm (in) 900 (35.4) 1549 (61.0) 1764 (69.5) 1539 (60.6) 1754 (69.1) 900 (35.4) 1539 (60.6) 1690 (66.5)

Min Height mm (in) 415 (16.4) 737 (29.0) 886 (34.9) 727 (28.2) 876 (34.5) 370 (14.6) 710 (28.0) 845 (33.3)

Transport Length mm (in)

610 (24.0) 916 (36.1) 1010 (39.8)

Transport clip

Steel spikes

Adapts to:

#478 HD Feet (non “G” model)

#475 Feet (non “G” model)

#2130 Spreader (“G” model)

#2132 Spreader (“G” model)

150mm

4.5 (9.9)

890 (35.0)

405 (16.0)

600 (23.6)

906 (35.7) 1000 (39.4) 600 (23.6)

Split ring for transport strap (opt.)

2122/G

150mm

Specs based on ‘G’ variant - ‘non-G’ variant will have lower Min Height

100mm

100mm

906 (35.7)

100mm

Tall

Alloy

95 (210)

1000 (39.4)

Page 2

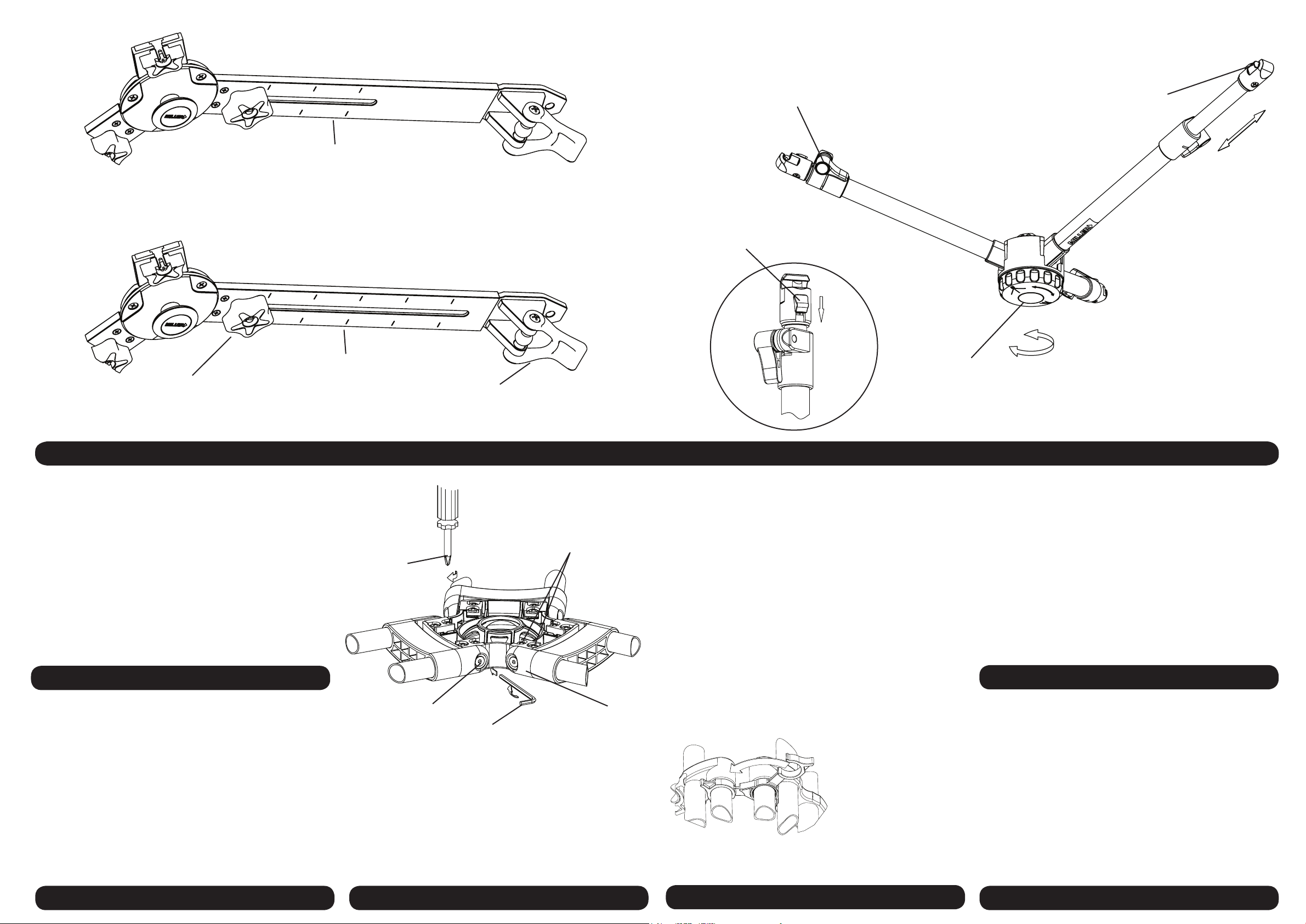

866-1146mm

Spreader arm length

Telescopic clamp

Quick release latch

Spreader adjusting knob

the camera and fluid head is attached.

5. Do not remove the Mid Level Spreader or Ground Spreader whilst

Head.

4. Do not move the Tripod whilst the camera is attached to the Fluid

the Fluid Head.

3. Do not adjust the tripod Leg locks whilst the camera is attached to

2. Do not leave the camera unattended on the Fluid Head.

1. Do not exceed the maximum payload capacity of the Tripod.

The operator is responsible for the safe operation of this equipment.

that the bowl is approximately horizontal when attaching the camera.

and damage, also please ensure that the tripod is steady, secure and

Ensure that all equipment is operating correctly and free from defects

866-1346mm

Spreader arm length

Screw Driver

#2 Pozi Head

Rubber stirrup

HDC GROUND SPREADER SHORT - Designed for short HDC tripods (“G” versions)

.

Fig 8

Quick release latch knob

Spreader adjusting knob

HDC GROUND SPREADER - Designed for standard and tall HDC tripods (“G” versions)

Fig 6.

Screws

Bracket Mounting

Fig 7.

MID LEVEL SPREADER - Designed for non “G” HDC tripods

SPREADER

Attach both Transport Clips.7.

Tighten Leg Lock Levers.6.

While feet are on floor allow base/bowl to fall to stops.

5.

While holding the top of the tripod, release the Leg Lock Levers.

4.

Hold and lift off the ground by two legs, then bring the legs inwards.3.

Retract the spreader arms fully.

2.

Remove the camera from the Fluid Head.1.

SAFETY

tripod in a dry place, away from direct sunlight.

Transport and store the tripod in Miller case wherever possible. Store the

sives or wire brushes.

Do not clean with solvents, cleaning fluids, lubricants, polishes, abra-

brush. Wipe off all sand, dust and salt spray.

behind levers. Regularly clean the tripod with a clean damp rag or soft

Keep grit and dirt away from the locking pads as much as possible, including

rim, spreader mounting points, carry handle and feet.

damage, leg lock adjustment, leg top adjustment, condition of the bowl

Regularly inspect the tripod, paying particular attention to any tube

Leg Pivot Screw

4mm Allen Key

MAINTENANCE

Leg Top Bracket

Fig 3

all legs.

using a 4mm allen key until a smooth resistance is maintained. Check

Tighten the Leg Pivot Screws on each side of the Leg Top Bracket

Leg pivot or ‘swing’ adjustment to ensure firm, smooth resistance. 2.

Check all legs.

both sides of the Leg Top Bracket are tight. Retighten if necessary.

Using a cross head screwdriver, ensure Bracket Mounting Screws on

Leg to Bowl Adjustment to eliminate lateral, or free play movement: 1.

following procedure must be observed. (Fig 6.)

ment is usually not required, however, should it become necessary, the

play movement and should swing with a firm, smooth resistance. AdjustThe leg to bowl pivot joint on the HDC tripod should have no lateral or free

.

LEG TO BOWL ADJUSTMENT

transporting the tripod.

securely attached before

The Transport Clips must be

legs for transporting tripod.

snapped back on to the

for set up, and just as easily

are easily gripped and detached

legs together during transport. Their spring-loaded design means they

The 2 Transport Clips (Fig.3) are designed to hold the HDC tripod’s three

TRANSPORT CLIPS

TRIPOD PULL DOWN

7.

Check that the tripod is secure. Place fluid head on tripod base/bowl.

6.

Re-adjust the legs individually if required.

approximately level to the ground (use the bubble level on MB versions).

5.

Spread the Tripod Legs apart, check that the Tripod Bowl is

Levers (do not over tighten).

4. Lift the top of the tripod to a desired height and then tighten Leg Lock

rotary Leg Lock Levers.

3. Place the Tripod Feet on level surface (if possible) and release the

2. Remove tripod from the Softcase and unclip the Transport Clips.

spreader should be attached.

1. Before setting-up the tripod, the Mid Level Spreader or HDC Ground

TRIPOD SET-UP

Loading...

Loading...